Fabricated blocks, fabricated-block building system and construction method thereof

A prefabricated and block technology, applied in the direction of buildings, building components, building structures, etc., can solve the problems of poor seismic bearing capacity of masonry, low anti-seepage and anti-leakage performance, and many masonry procedures, and achieves a reduction in technology. Level dependence, improving anti-seepage and leak-proof performance, saving energy and raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

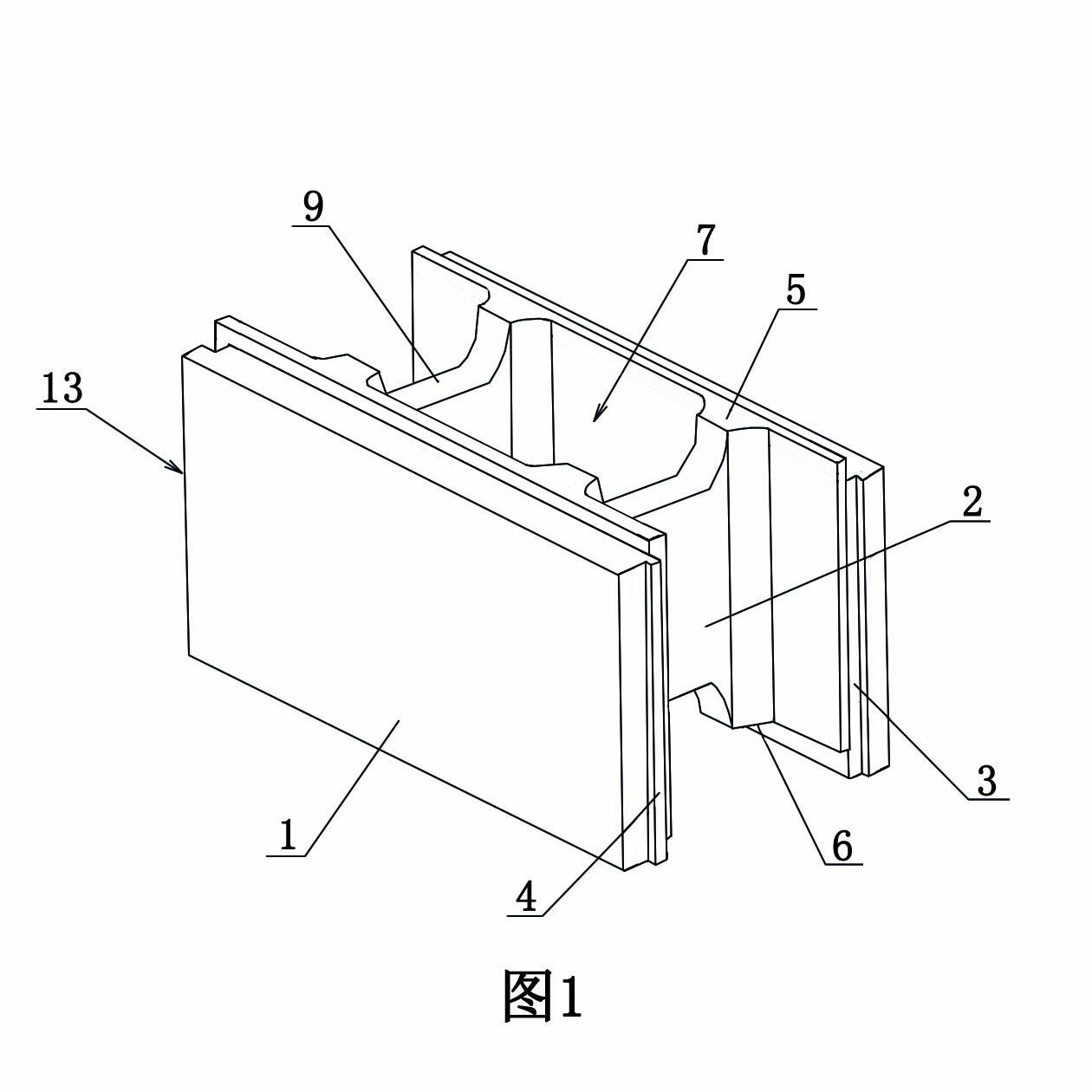

[0050] Examples see Figure 1~3 As shown, this assembled block includes a main block 13 and an auxiliary block, and the auxiliary block includes a 1 / 2 block 14, a T-shaped node block 15, a corner block 16 and an end block 19.

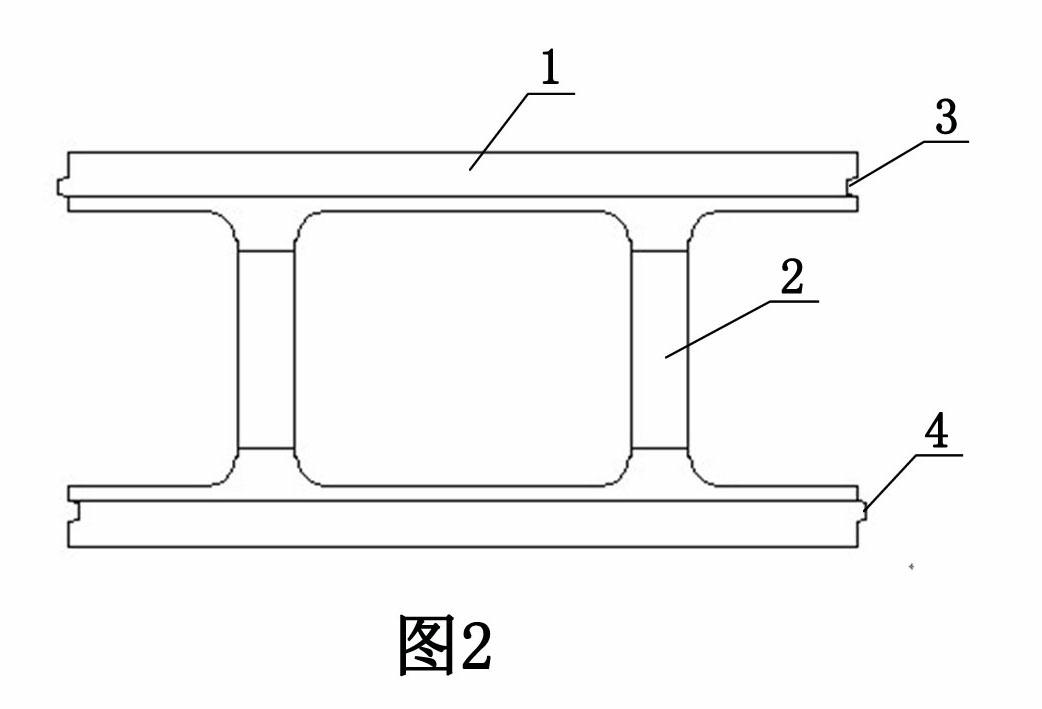

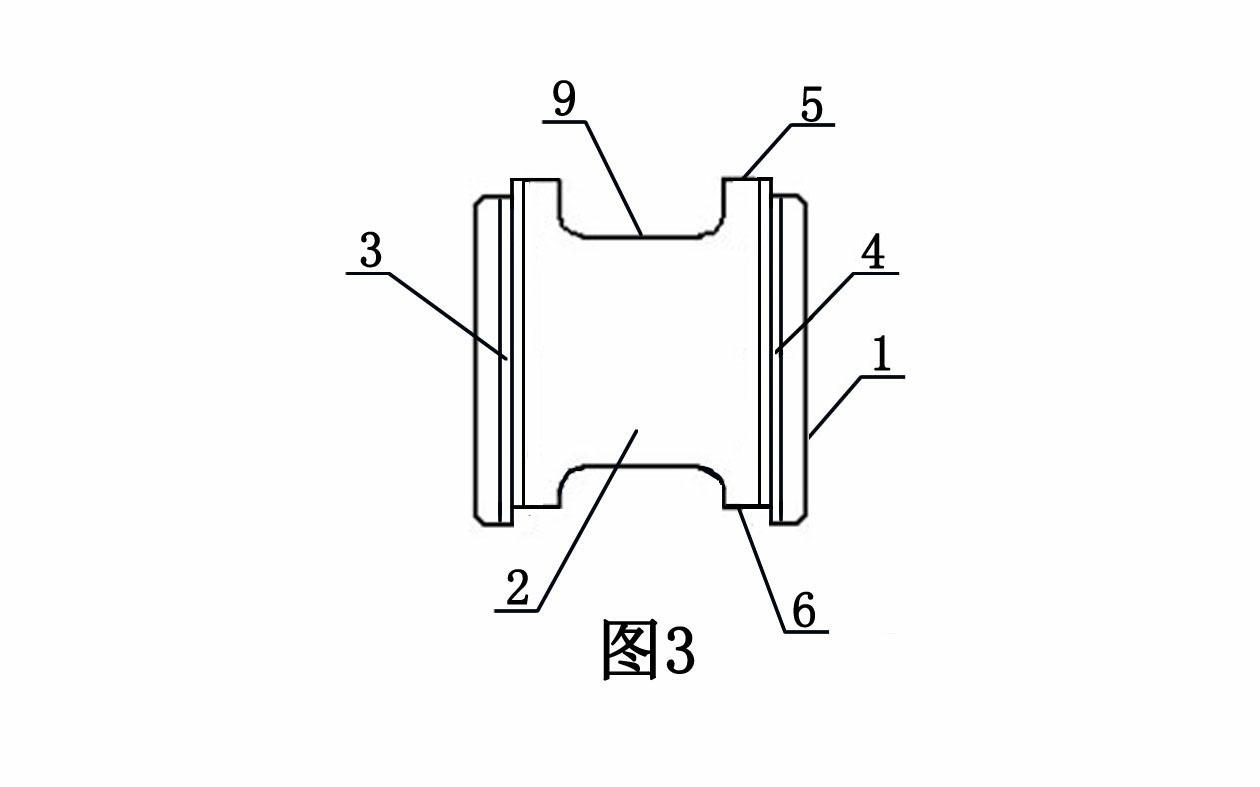

[0051] The main block 13 is composed of two long transverse ribs 1 arranged in parallel and at least two short longitudinal ribs 2 vertically connected between the two long transverse ribs 1. Both ends of the main block are H-shaped open structures, and the length The left and right ends of the transverse rib 1 are provided with mortise 4 and tongue and groove 3 respectively, and the main block 13 is connected with the horizontally adjacent blocks by tenon and tongue and groove mortise and tenon, and at the same time forms a joint between the horizontally adjacent blocks. Vertical through hole 7; the top surface and the inner edge of the bottom surface of the long transverse rib 1 are respectively provided with a convex edge and a concave edge, while th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com