Patents

Literature

1261results about How to "Meet the requirements of green environmental protection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

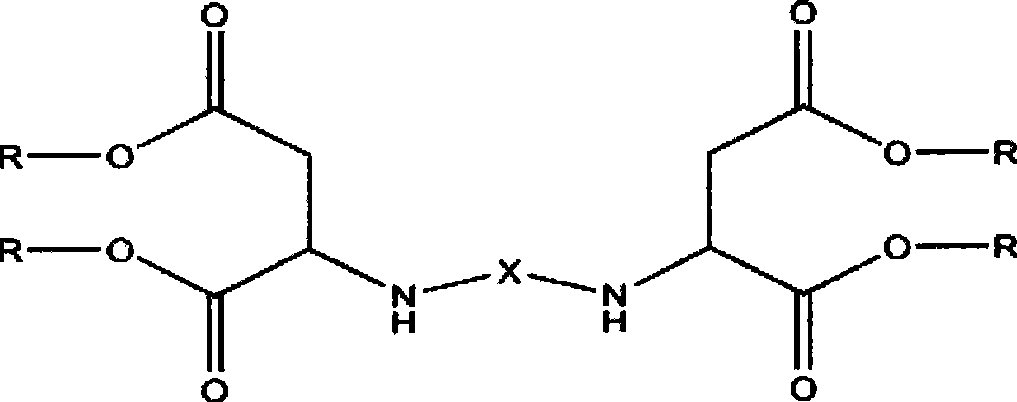

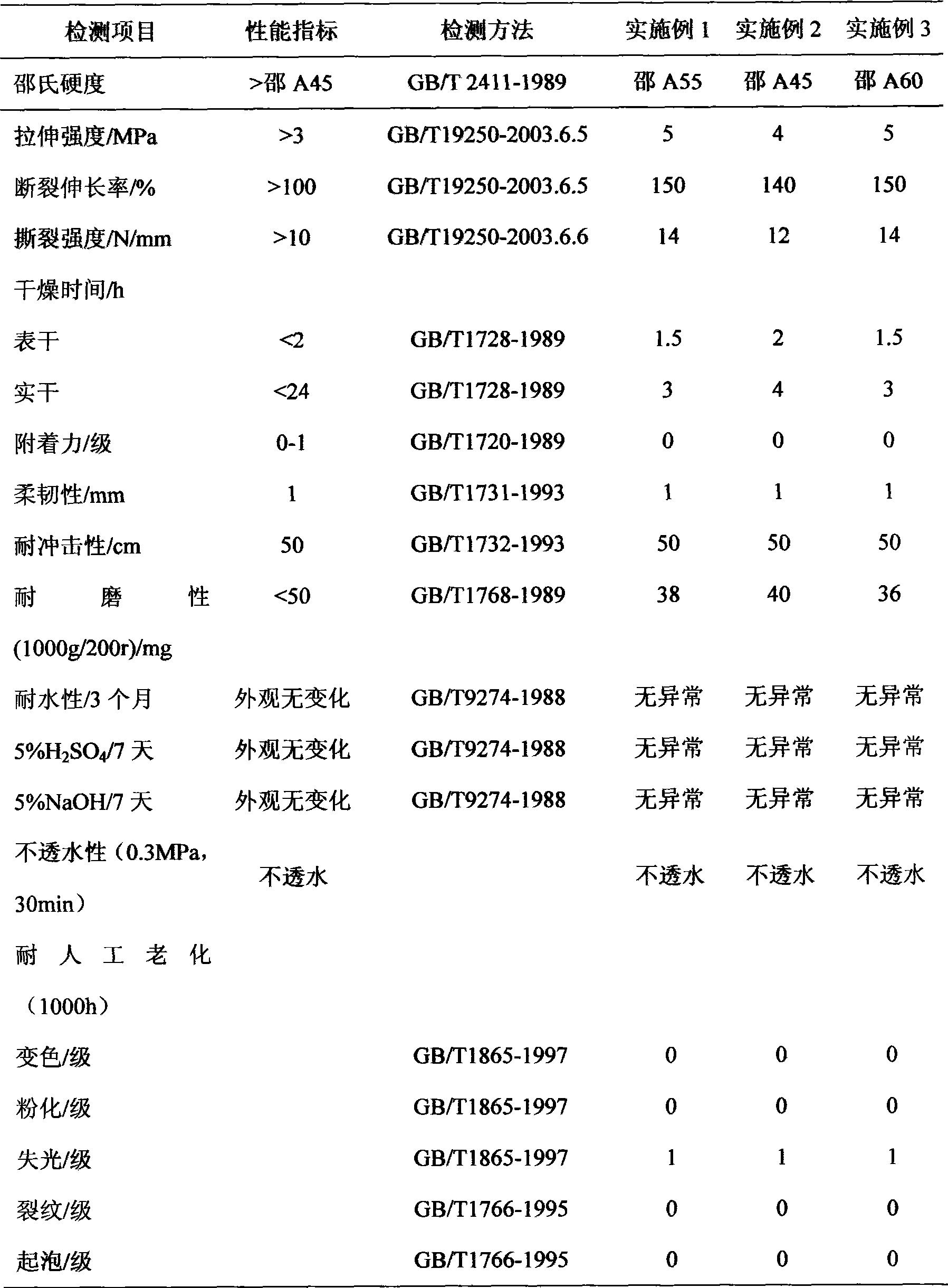

Preparation of polyaspartate polyurea waterproof coating material

InactiveCN101469246AStrong adhesionImprove toughnessAntifouling/underwater paintsPaints with biocidesAdhesion forceSpray coating

The invention discloses a method for preparing a polyaspartate polyurea waterproof coating, which is characterized in that the coating is based on polyaspartate polyurea and takes polyisocyanates as a curing agent. The coating material maintains the excellent performance of the prior polyurea coating, and also overcomes the disadvantages that the prior polyurea has overquick gelation time and needs special equipment for construction at the same time. The coating has the advantages of strong adhesion force, good toughness and wear resistance, good weather performance and so on, does not contain a solvent, is green and environment-friendly, and can reach the needed thickness through spray coating at one time.

Owner:SHANGHAI HUAYI FINE CHEM CO LTD

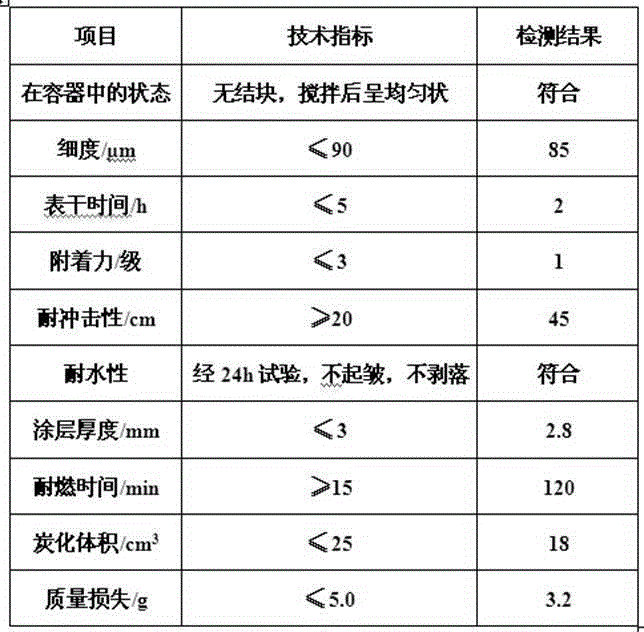

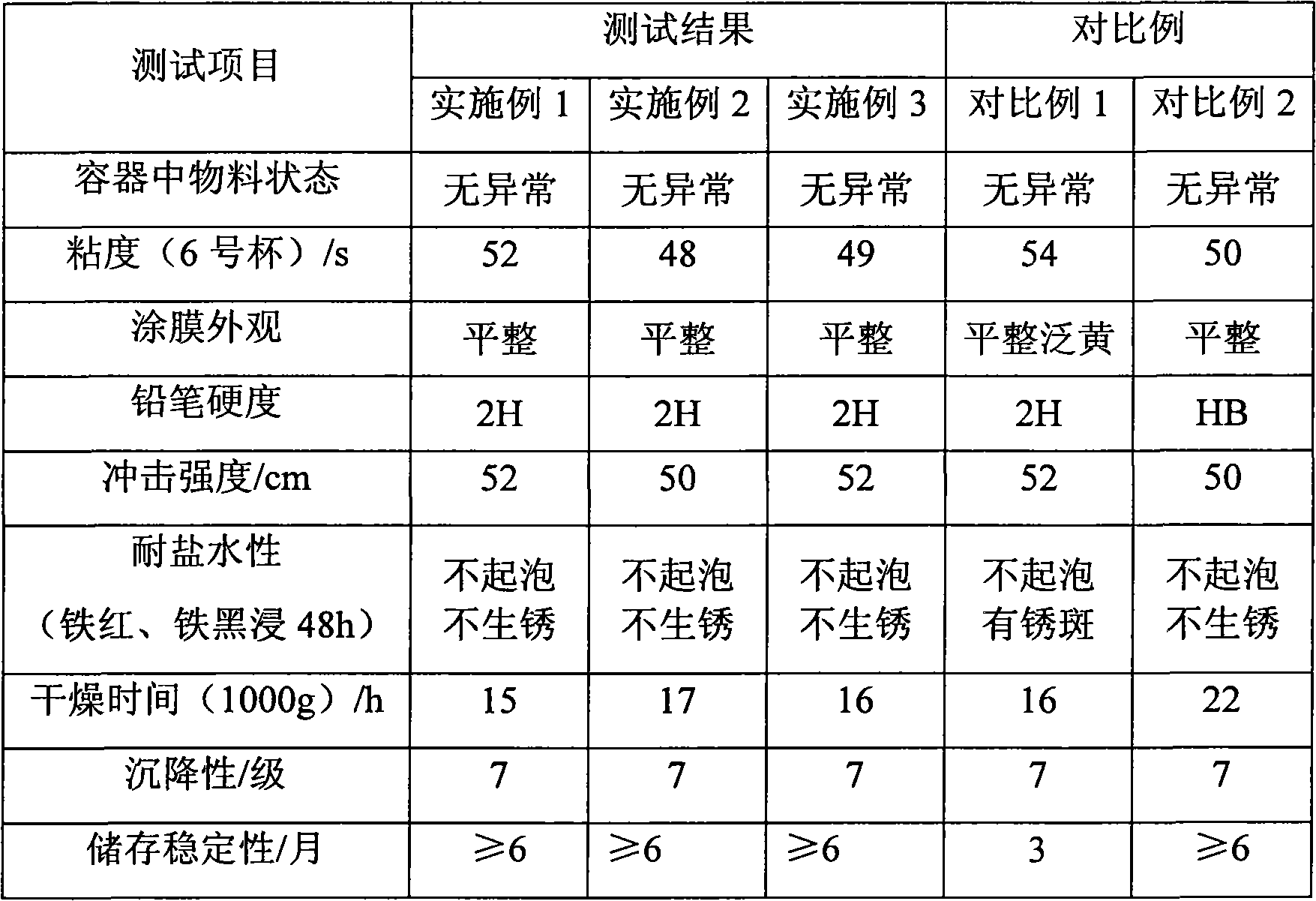

Aqueous ultrathin expansion-type fireproof coating for steel structure and preparation method thereof

ActiveCN104130671AImprove corrosion resistanceStrong adhesionFireproof paintsEpoxy resin coatingsPolymer sciencePentaerythritol

The invention discloses an aqueous ultrathin expansion-type fireproof coating for a steel structure and a preparation method thereof, and belongs to the technical field of fireproof coatings. The aqueous ultrathin expansion-type fireproof coating comprises, by mass, 10-35 parts of a modified aqueous epoxy emulsion, 1-8 parts of a curing agent, 5-15 parts of a styrene-acrylic emulsion or a silicone-acrylic emulsion, 10-20 parts of ammonium polyphosphate, 6-12 parts of melamine, 8-16 parts of pentaerythritol, 5-15 parts of a fire retardant, 5-15 parts of a pigment and a filling material, 2-8 parts of an assistant and 15-35 parts of water. The aqueous ultrathin expansion-type fireproof coating has the characteristics of low raw material cost, simple preparation process and environmental friendliness.

Owner:沈阳泰丰化工有限公司

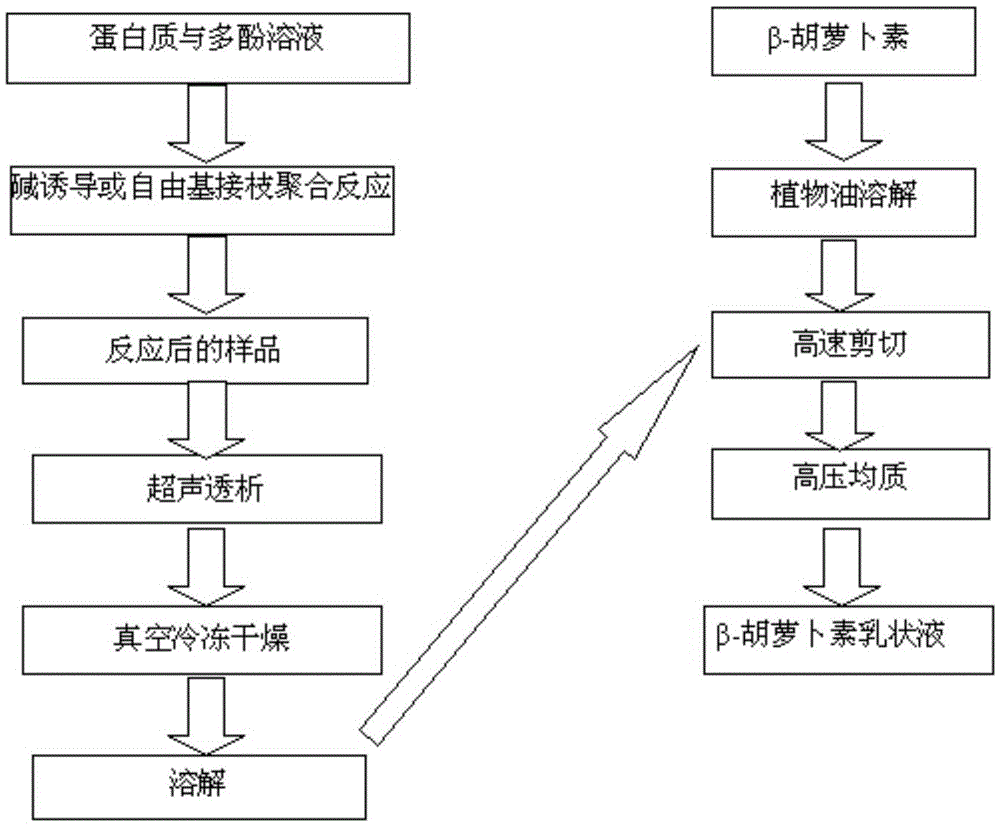

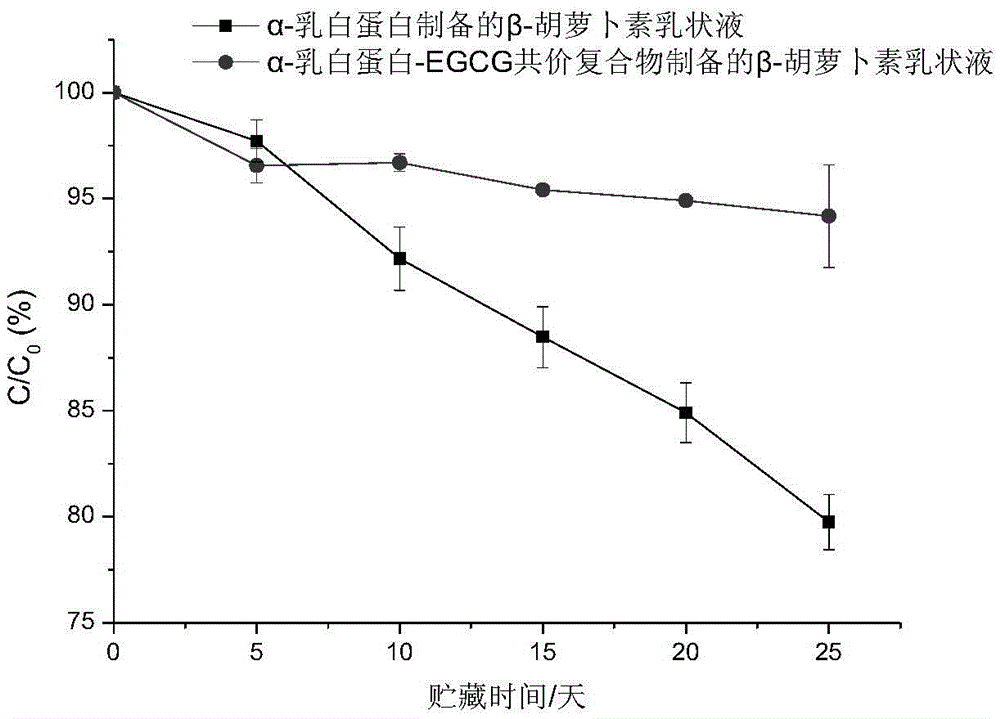

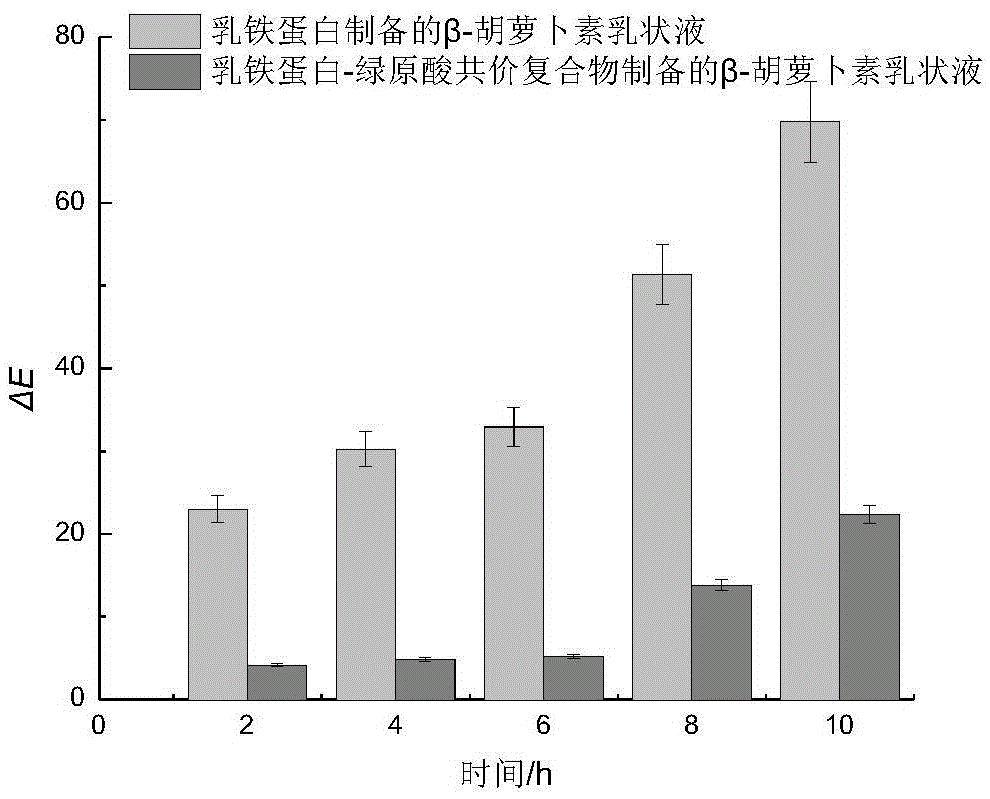

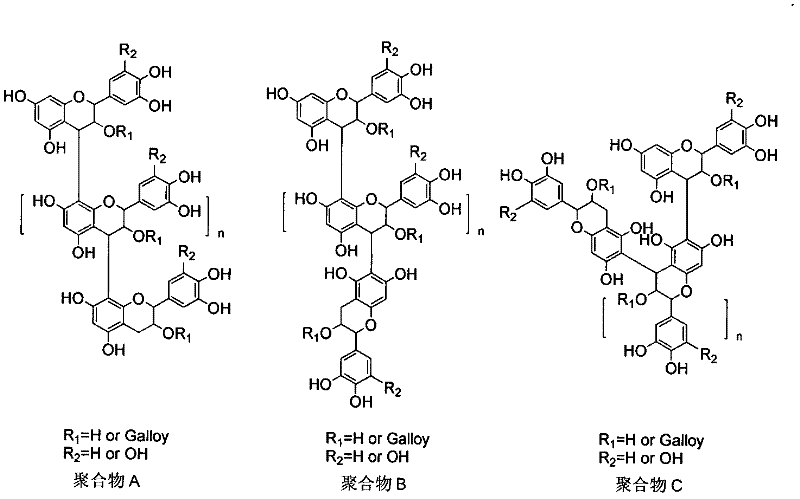

Protein-polyphenol covalent compound and preparation method and application thereof

InactiveCN105601701AEasy to prepareImprove stabilityOrganic active ingredientsPeptide preparation methodsFood additiveBeta-Carotene

The invention belongs to the technical field of food science and food additives and discloses a protein-polyphenol covalent compound and a preparation method and application thereof. The preparation method includes that the protein-polyphenol covalent compound is prepared by free radical grafting copolymerization or base-induced reaction of protein and polyphenol. The preparation method is simple and avoids toxic chemical reagents and high-temperature high-pressure conditions, all processes are carried out in aqueous phase, and the requirement on environment friendliness is met. Beta-carotene emulsion prepared by taking the protein-polyphenol covalent compound as an emulsifying agent is high in safety, physical and chemical stability and bioavailability and is widely applicable to the technical fields of food industry, biomedicine, hygiene and the like.

Owner:CHINA AGRI UNIV

Metal cutting solution of green semi-synthesis double-base oil and preparation method thereof

InactiveCN101531946ASuitable for cuttingSuitable for grindingBase-materialsFoaming agentActive agent

The invention relates to a metal cutting solution of green semi-synthesis double-base oil, which comprises the following components in percentage by weight: 0 to 30 percent of mineral oil, 0 to 30 percent of synthetic ester, 5 to 10 percent of anionic surfactant, 5 to 10 percent of non-ionic surfactant, 5 to 15 percent of anti-rust agent, 0 to 15 percent of extreme pressure agent, 1 to 3 percent of de-foaming agent and 0 to 2 percent of bactericide, and the balance being water. A preparation method for the metal cutting solution comprises the following steps: firstly, heating the mineral oil to about 50 DEG C, adding the synthetic ester into the mineral oil, and stirring the mixture evenly to form a double-base oil system; and then adding the anti-rust agent, the extreme pressure agent, the de-foaming agent and the bactericide into the water respectively, and using the anionic surfactant and the non-ionic surfactant to regulate the system to balance so as to form the metal cutting solution of the green semi-synthesis double-base oil. Because the synthetic ester is added in the preparation process to form the double-base oil system, the biodegradability, oxidative stability and flash point are improved; and the method meets the requirement of environmental protection, and is applicable to cutting, grinding and processing various mechanical parts.

Owner:SHANGHAI INST OF TECH

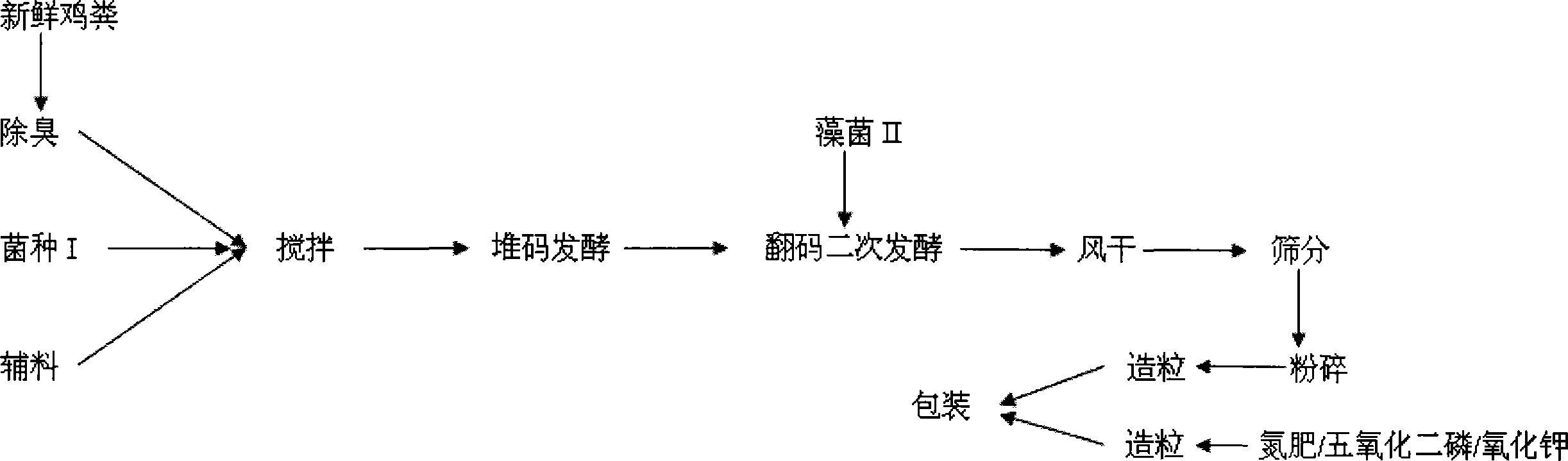

Fowl dung fermentation fertilizer and preparation method thereof

InactiveCN101186530AImprove breathabilityReduce and eliminate compactionBio-organic fraction processingClimate change adaptationEcological environmentPollution

The invention discloses a fowl manure fermentation fertilizer. The fertilizer is produced by materials of fresh fowl manure, rice bran powder, maize meal, wheat flour, brown sugar, lime powder, dinoflagellate, microzyme, lactobacillus, thermophilic actinomycetes, etc. The invention improves culture environment of henhouses, and heavy metal in the fowl manure is degraded and changed into treasure, becoming an ecological organic fertilizer which is comprehensively and abundantly nutrient. Nitrate and secondary salt formed in the soil by fertilizer residual can be degraded by the fowl manure fermentation fertilizer, and therefore functions of disease resistant, lodging resistant, crop yields improvement can be realized; ventilation property of the soil is improved, soil hardening and virus can be reduced and banished, meanwhile, dosage of the chemical fertilizer and pesticide is reduced; production cost is reduced, pollution is reduced and soil environment is optimized, and microeubiosis of the soil is achieved; therefore the crops can be ripen in advance, grade of the crops is improved, hazardous and noxious substance contents remained in the crops are lowered and banished, and the green environmental requirements of heavy metal residual of the crops can be achieved.

Owner:重庆拓阳科技有限公司

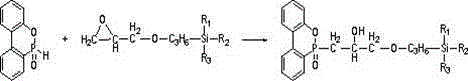

Water-borne epoxy ester modified alkyd resin emulsion and preparation method thereof

InactiveCN101942063AStrong adhesionImprove performanceDyeing processCoatingsEnvironmental resistanceEpoxy

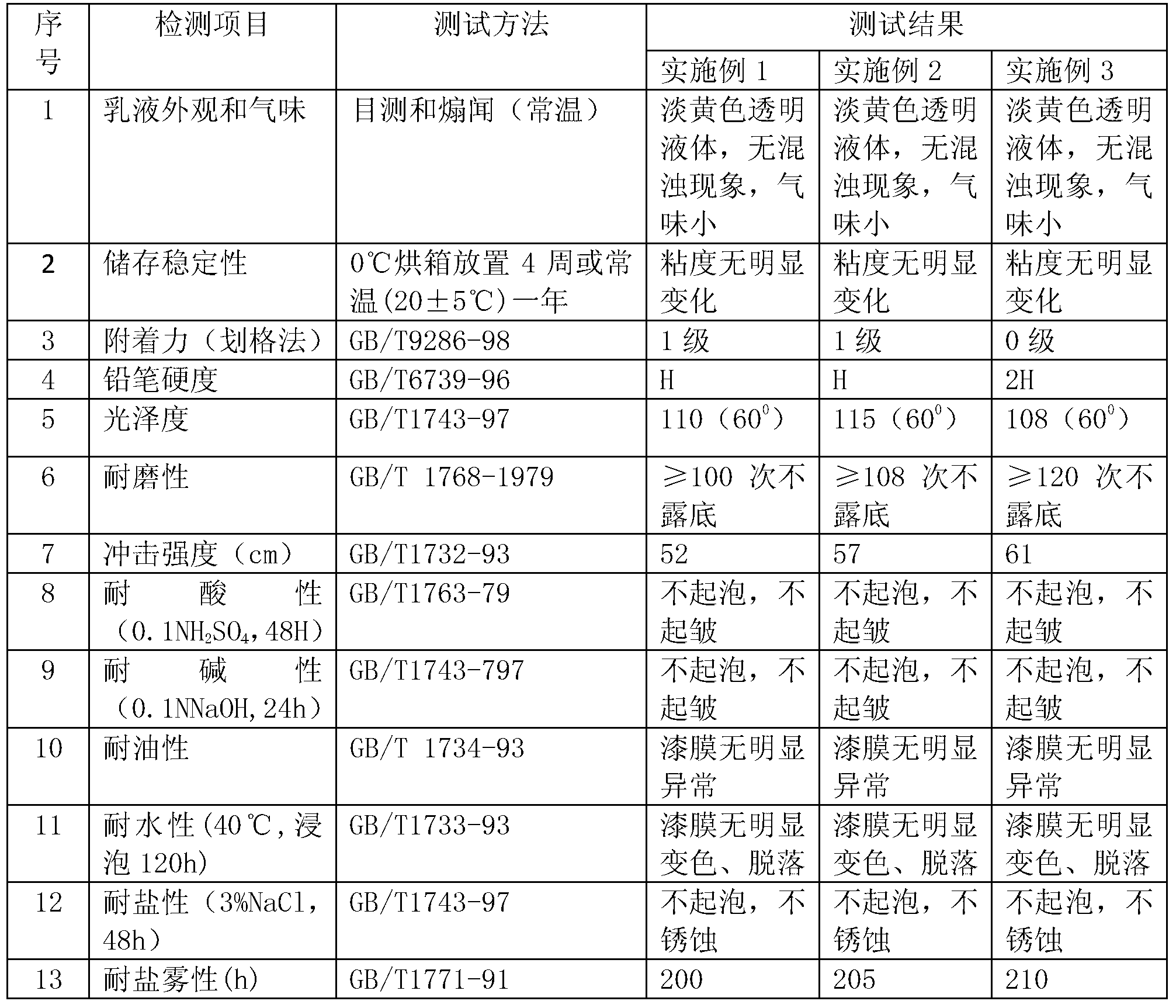

The invention provides water-borne epoxy ester modified alkyd resin emulsion and a preparation method thereof. The method comprises the following steps: allowing unsaturated fatty oil, polyalcohol, epoxy resin and the like to carry out alcoholysis reaction by using triphenylphosphine and an alcoholysis catalyst; adding polyacid for esterification; dropwise adding crylic acid monomers such as methacrylic acid, phenylethylene, butyl acrylate and the like and a silane coupling agent for copolymerization under initiation of benzoyl peroxide; adding amine to the obtained copolymer for neutralizing to form salt; and dispersing with water to obtain the high-performance water-borne epoxy ester modified alkyd resin emulsion. The emulsion maintains self-drying property, flexibility and other excellent properties of alkyd resin, has excellent adhesive property of the epoxy resin as well as excellent adhesion force, excellent physical and mechanical properties and strong water resistance, strong salt fog resistance, strong acid and alkali resistance and other properties; and the emulsion has the advantages of possessing good stability and being nontoxic and harmless, thus meeting the environmental friendly requirement.

Owner:SOUTH CHINA UNIV OF TECH

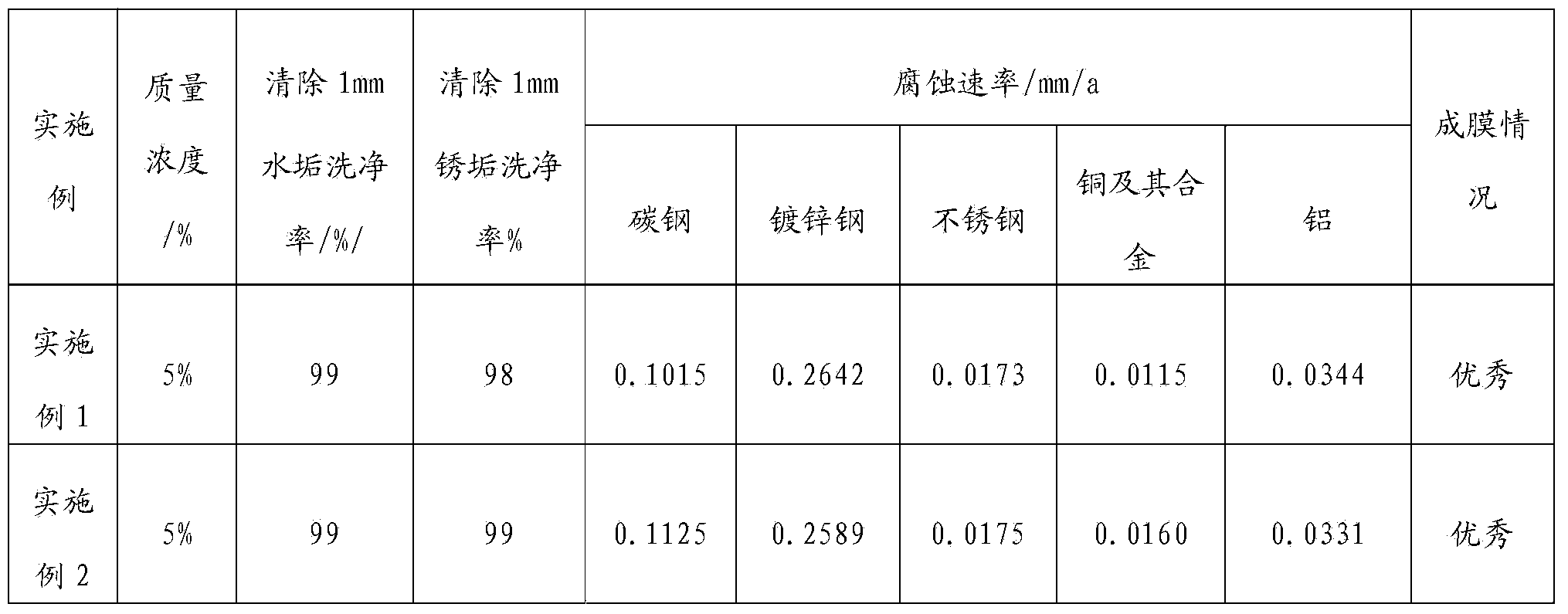

Composition for cleanser, cleanser and application thereof

ActiveCN103409763AChemically stableMeet the requirements of green environmental protectionChemistryAluminium

The invention belongs to the technical field of fine chemical engineering, particularly relates to a composition for a cleanser and application thereof in cleaning water scales and rusty scales on various commercial unit surfaces, and discloses a composition for a cleanser and application thereof. The composition for a cleanser contains the following components in parts by weight: 1 part of organic phosphonate, 0.15-1.5 parts of dispersant, 0.02-0.75 part of reducer, 0.02-0.75 part of wetting agent and 0.002-0.075 part of corrosion inhibitor. The composition disclosed by the invention satisfies the requirements for environmental protection, and is suitable for cleaning water scales and rusty scales on various metal surfaces, such as carbon steel, stainless steel, brass, red copper, aluminum and the like. The composition has the advantages of thorough scale removal and favorable corrosion inhibition property, does not need special passivating treatment after cleaning, and can be directly put into normal operation, so that the whole cleaning process is simpler and easy for popularization.

Owner:深圳市爱康泉水处理服务有限公司

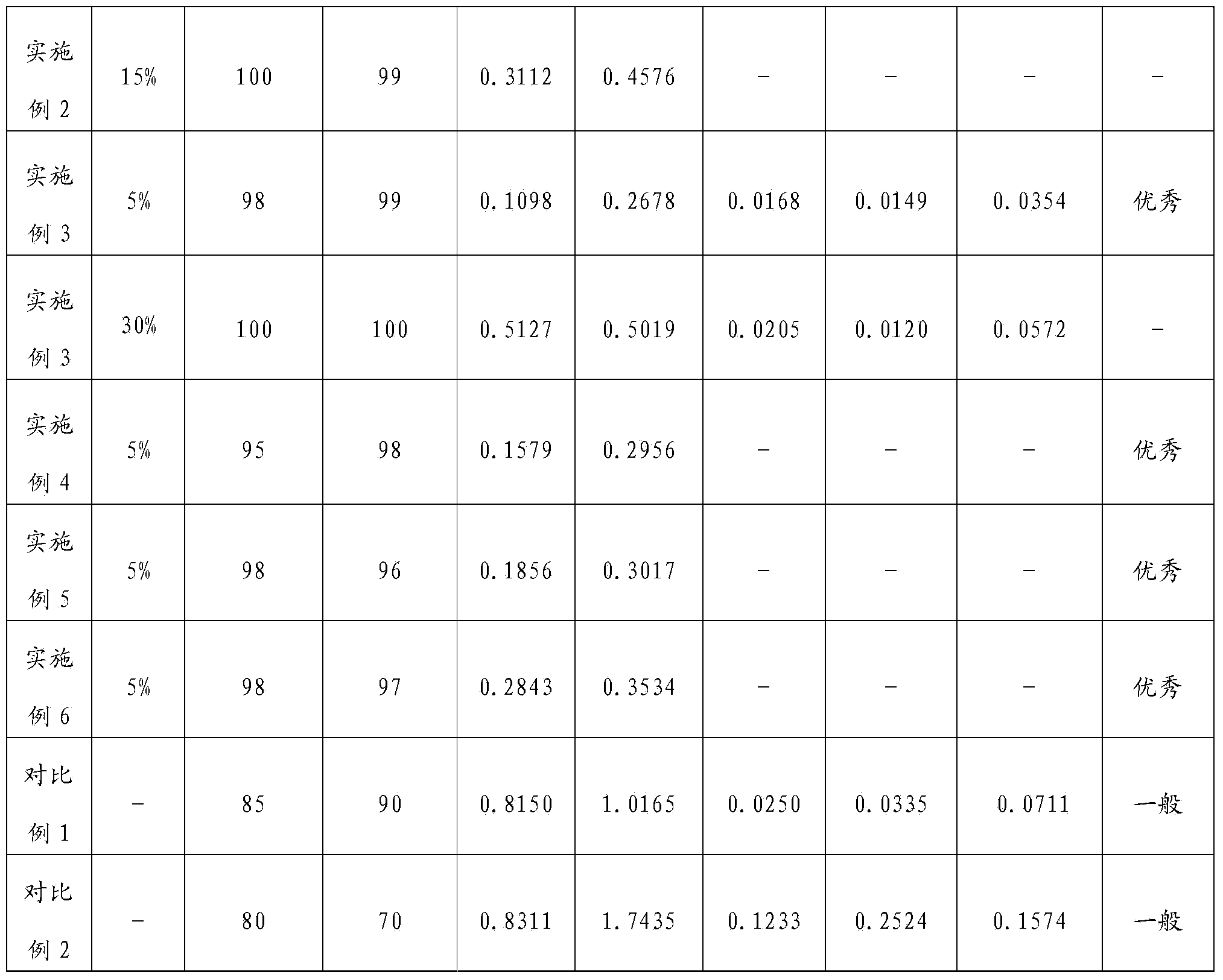

Starch-filled PLA/PBAT full-biodegradable composite material and preparation method thereof

The invention provides a starch-filled PLA / PBAT full-biodegradable composite material and a preparation method thereof, and belongs to the field of high polymer materials. A purpose of the invention is to solve the problems of poor toughness, brittleness and easy breaking of polylactic acid and the technical problems of difficult processing of starch, poor compatibility with PLA / PBAT resins and the like. The starch-filled PLA / PBAT full-biodegradable composite material comprises, by weight, 5-90 parts of polylactic acid, 10-90 parts of polyadipic acid / butylene terephthalate, 10-50 parts of starch, 2-15 parts of a plasticizer, 0.1-5 parts of a coupling agent, 0.1-0.5 part of a dispersing agent, 0.1-1 part of a compatibilizer and 0.1-0.5 part of an antioxidant. According to the invention, thepreparation method can be applied to preparation of starch-filled PLA / PBAT full-biodegradable composite materials.

Owner:QINGDAO RICH PLASTIC NEW MATERIAL

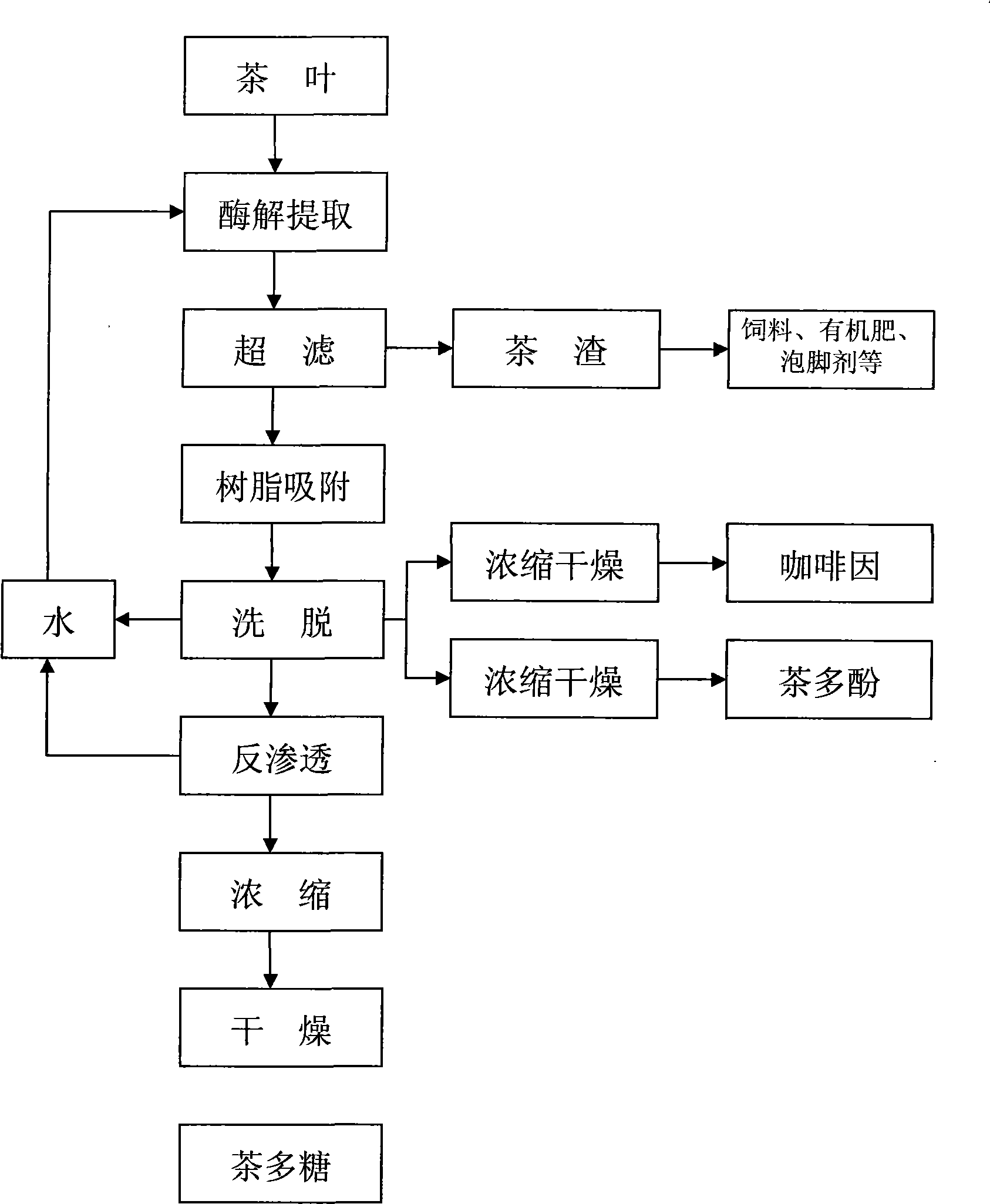

Novel methods for simultaneously extracting tea polyphenol, tea polysaccharide and caffeinum from tea

InactiveCN101508690AReduce water consumptionSave energyOrganic chemistryFermentationOrganic solventReverse osmosis

The invention provides a new method for simultaneously extracting tea polyphenol, tea polysaccharide and caffeine from tea leaves. The method comprises the following steps: extracting by enzymolysis, ultrafiltering, adsorbing the tea polyphenol and the caffeine with resin, obtaining the caffeine and the tea polyphenol by elution, and obtaining the tea polysaccharide by reverse osmosis. The method organically combines a new concept of enzymolysis extraction, membrane separation and resin adsorption, does not use any organic solvent (including ethanol), only uses water for precipitation and elution, and has the advantages of pollution-free, safe and reliable production, low cost, high product purity and high yield.

Owner:林峰 +2

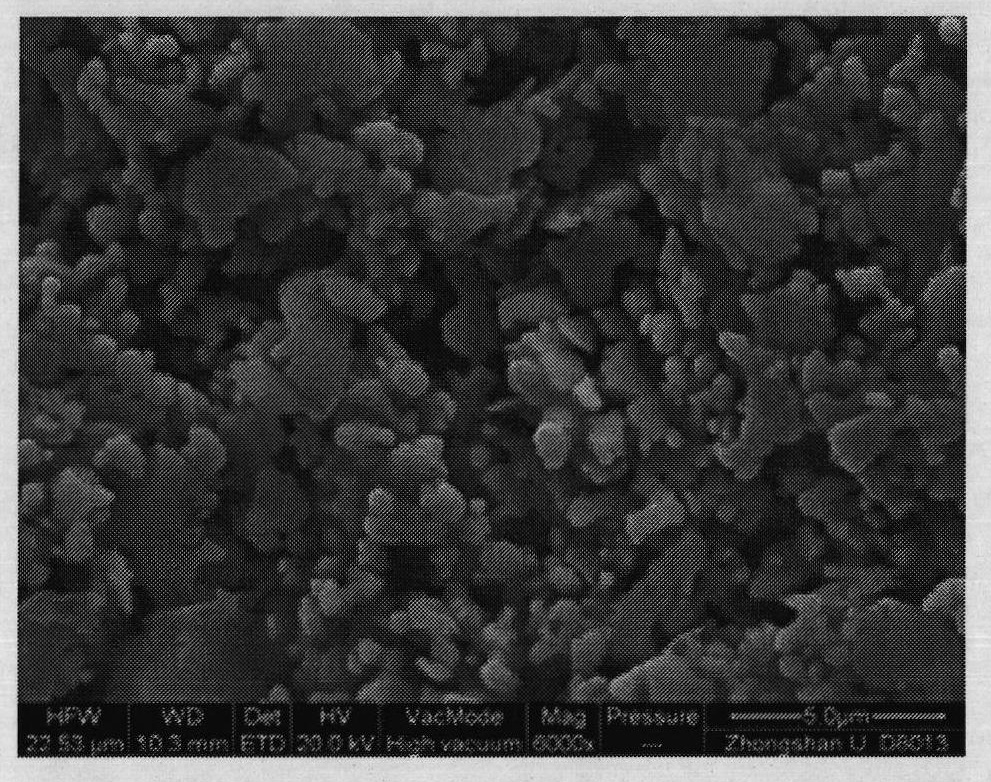

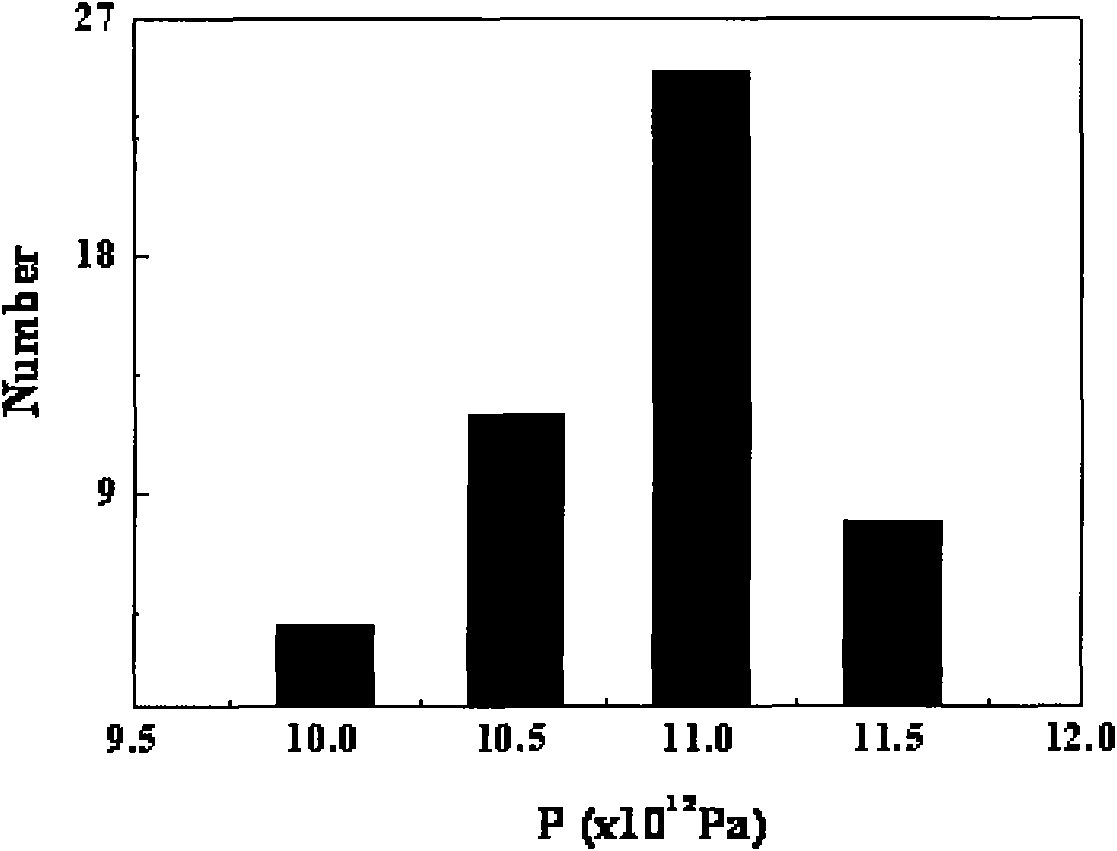

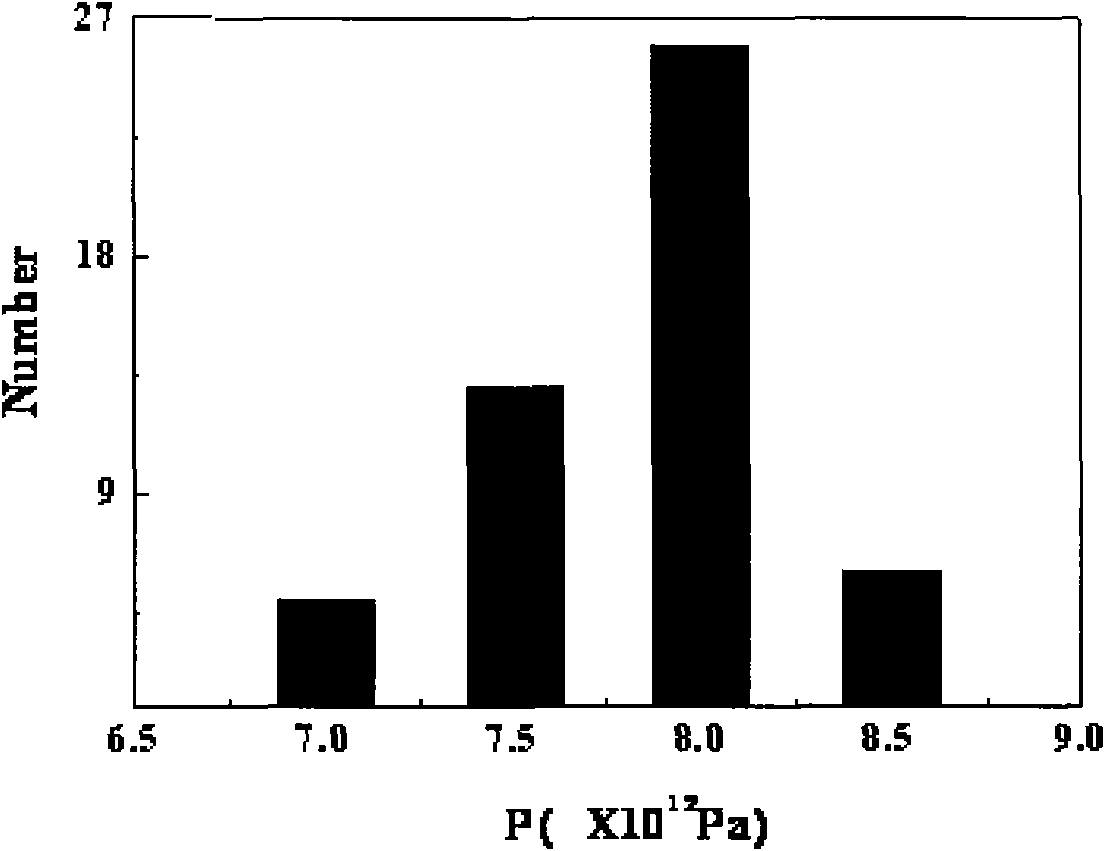

Method for synthesizing fine grain MCM-22 molecular sieve

InactiveCN1699170ALower synthesis costNot corrosiveCrystalline aluminosilicate zeolitesPolyethylene glycolSurface-active agents

Disclosed is a method for synthesizing fine grain MCM22 molecular sieve, wherein the templating agent employs the product yield of hexanolactam hydrogenation, and mainly comprises hexamethyleneimine, water, a small amount of byproduct and hexanolactam (reacted unconcompletely), the method comprises using silicon source, aluminium source, alkali source, templating agent and deionized water as reaction raw material, crystallizing for a finite period of time at 135-185 deg. C, untill completion of the reaction, obtaiting the needed molecular screen through hydrothermal synthesis, the invention is characterized in that organic additives can be charged into the reaction raw material, the organic additive can be sodium dodecylbenzene sulfonate, polyethylene glycol type surface active agent, or their mixture, the molecule ratio of the charged additive and the silicon dioxide in the reaction raw material is 0.01-2.5.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Environment-friendly heat conduction insulating glue used by high-power LEDs and preparation method

ActiveCN101812280AImprove cooling effectImprove work efficiencyNon-macromolecular adhesive additivesEpoxynovolac adhesivesEpoxyWorking temperature

The invention relates to an environment-friendly heat conduction insulating glue used by high-power LEDs, which is characterized by being prepared from the following raw materials in percentage by weight: 50-68 percent of micro-grade high-thermal conductive powder, 18-30 percent of epoxy resin, 4-10 percent of curing agent, 7-15 percent of solvent, 0.6-1.5 percent of accelerator and 1-2 percent of additive; and the micro-grade high-thermal conductive powder is selected from a mixture formed by one or more of micro-grade aluminum powder, palladium powder, platinum powder, gold powder, C powder, AlN powder and SiC powder. The invention also relates to a preparation method of the heat conduction insulating glue. The environment-friendly heat conduction insulating glue used by high-power LEDsis obtained by optimizing the matching ratio and the modification of the raw materials and improving and simplifying the preparation process. Besides high resistivity, the heat conduction insulating glue also has high thermal conductivity, higher working temperature, strong viscosity, high cutting strength and fine performance index.

Owner:连云港市昭华光电科技有限公司

Single-component room-temperature multiple-self-crosslinking aqueous epoxy acrylate resin emulsion and preparation method thereof

ActiveCN103319665AImprove corrosion resistanceImprove insulation performanceAnti-corrosive paintsFunctional monomerNitrogen gas

The invention discloses a single-component room-temperature multiple-self-crosslinking aqueous epoxy acrylate resin emulsion and a preparation method thereof. The method comprises the steps of: firstly, in parts by mass, preparing 40-50 parts of bisphenol A type epoxy resin and 50-60 parts of unsaturated fatty acid, introducing nitrogen gas to protect under the action of a catalyst, and carrying out esterification reaction so as to synthesize unsaturated fatty acid-modified epoxy ester resin; then, adding a cosolvent to room-temperature self-crosslinking epoxy ester resin, dropwise adding an initiator, monomers with hydrophilic groups, self-crosslinking functional monomers and a chain transfer agent to the room-temperature self-crosslinking epoxy ester resin in 1-3 h at the temperature of 100-110 DEG C, and then, carrying out free radical grafting and copolymerizing reaction so as to obtain single-component room-temperature multiple-self-crosslinking aqueous epoxy acrylate resin; and adding an amine neutralizer to neutralize, and then, adding deionized water to disperse, thereby obtaining a single-component dual-self-crosslinking aqueous epoxy acrylate resin emulsion. The emulsion has the advantages of fast paint film drying, strong adhesive power, high mechanical strength and excellent corrosion resistance.

Owner:天达科技股份有限公司

Manufacture process of imitation stainless steel metal drawbench film

InactiveCN102642439AIncrease the dyne coefficientHigh fastnessLamination ancillary operationsSynthetic resin layered productsPolyesterAcrylic coating

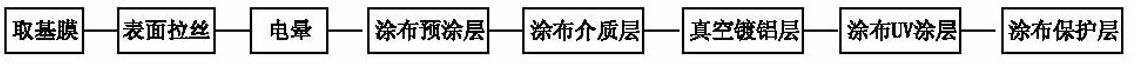

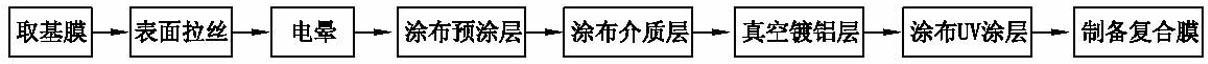

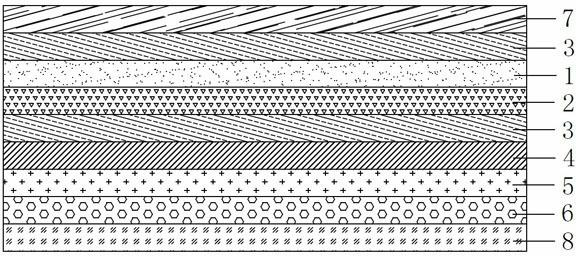

The invention discloses a manufacture process of an imitation stainless steel metal drawbench film, which comprises the following steps: 1 taking a base film which is a polyester (PET) film; 2 conducting surface drawbench and surface polishing one surface of the base film; 3 conducting surface corona and conducting corona processing on two surfaces of the base film, 4 conducting precoat coating and conducting network roller coating on the surface of the base film receiving surface drawbench and corona processing through methyl methacrylate coating, 5 conducting media layer coating and conducting network roller coating on a precoat through acrylic coating, 6 conducting vacuum aluminizing on the media layer, 7 conducting ultraviolet (UV) coating coating and conducting network roller coating on one face of the base film without surface drawbench through colored translucent UV coating, and 8 conducting protection layer coating and preventing an aluminizing layer from being oxidized. The manufacture process improves product structure firmness, and ensures optimum using effects of products. The products can show different gloss effects from dumb light to high light, thereby meeting requirements for environment protection.

Owner:DONGGUAN GUODING OPTICAL MEMBRANE TECH

Preparation method of starch and fatty acid compound

The invention belongs to the technical field of natural polymer modification and discloses a preparation method of a starch and fatty acid compound. The method comprises the following steps: adding de-ionized water into starch and balancing moisture in a closed container; carrying out heat treatment to obtain the starch subjected to wet and hot treatment; then adding a buffering solution to prepare a starch solution; after pre-heating, adding 2 to 5u / g pullulanase liquid to react for 4 to 5 hours; after carrying out enzyme deactivation, centrifuging and separating to obtain enzyme treatment modified starch; then stirring and gelatinizing the starch in a boiled water bath for 25 to 45 minutes and cooling to 60 to 90 DEG C to obtain gelatinized starch; then transferring the gelatinized starch into a homogenizing machine and adding fatty acid to carry out homogenization and mixing; and keeping the heat of the water bath to synthesize for 30 to 40 minutes to obtain the starch and fatty acid compound. According to the preparation method, a greener and more environment-friendly new way is provided for synthesizing the starch and fatty acid compound through wet and hot treatment and controlled enzymolysis treatment by adopting a gelatinizing method.

Owner:SOUTH CHINA UNIV OF TECH

High-performance conductive silver paste and preparation method thereof

ActiveCN101805575AEvenly dispersedUniform size distributionNon-macromolecular adhesive additivesEpoxynovolac adhesivesEpoxyWorking temperature

The invention relates to a high-performance conductive silver paste, which is characterized by comprising the following raw materials in percentage by weight: 65-80% of micron-sized metal silver powder, 10-20% of epoxy resin, 1.4-3.5% of curing agent, 6-9% of solvent, 0.5-1.2% of accelerator, 0.05-0.1% of flexibilizer and 1-2% of additive. The invention also discloses a preparation method of the high-performance conductive silver paste. The conductive silver paste of the invention has high conductivity, very high thermal conductivity, high working temperature, strong viscosity and very high shear strength, and the performance indexes are apparently higher than the working performance of the conductive silver paste in the prior art, thereby solving the technical problems of poor shear performance, low working temperature, poorer thermal conductivity, long curing time, high curing temperature, poor viscosity, easy pollution of environment and the like in the field of the conductive silver paste in the prior art.

Owner:连云港市昭华光电科技有限公司

Low-temperature dyeing and finishing technology of cottonette

InactiveCN105002730AProcess temperature changeLow processing temperatureBiochemical fibre treatmentHeating/cooling textile fabricsInorganic saltsDiastase

The invention discloses a low-temperature dyeing and finishing technology of cottonette. The technology comprises the following steps: pretreatment; preshaping; modification treatment; dyeing; mordant removing; soaping; color fixing; post-treatment; drying; shaping; calendaring; rolling. According to the technology, pretreatment is carried out through the adoption of helicase and alpha-amylase, and modification treatment is carried out before dyeing, so that the property of the cottonette is fundamentally modified, and the dye-uptake of the fabric is increased; during the dyeing procedure, large quantities of alkaline substances and inorganic salt are not used, and a levelling agent, a low-temperature dyeing accelerant, a migration inhibitor and a dispersing agent are added, so that the dye uniformity is improved; during the whole dyeing process, the temperature is lower than 80 DEG C, and the dyeing process belongs to low-temperature dyeing, so that energy consumption is reduced; self-cleaning treatment is added in post-treatment, so that the self-cleaning capacity, wrinkle resistance and water washable firmness of the fabric are improved; post-treatment is carried out through the adoption of silk fibroin and sericin, so that the pilling resistance and antistatic property of the cottonette are improved; the whole technology is environment-friendly and free of pollution.

Owner:TAICANG TIANLONG CHEM FIBER

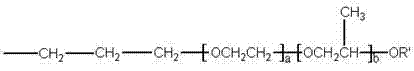

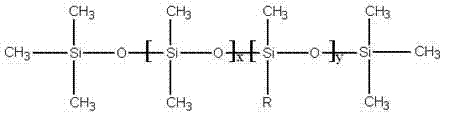

Preparation method of polyurethane foam stabilizer

The invention discloses a preparation method of a polyurethane foam stabilizer. The method comprises the following steps: (1) reacting allyl alcohol with oxirane and epoxypropane with an effect of a basic catalyst under conditions of a temperature of 90 to 130 DEG C and a pressure of not more than 0.5 MPa to obtain allyl-terminated copolyether; (2) reacting octamethylcyclotetrasiloxane with hexamethyldisiloxane and high hydrogenous silicone oil with a hydrogen content of 1.2% to 5% in the presence of an acidic ion exchanger under the condition of the temperature of 30 to 80 DEG C to obtain low hydrogenous silicone oil with the hydrogen content of 0.1% to 1%; and (3) adding the allyl-terminated copolyether obtained in step (1), the low hydrogenous silicone oil obtained in step (2), the catalyst and 1 to 5 wt% of amine ether to a reaction kettle under the conditions of the reaction temperature of 80 to 120 DEG C and the reaction pressure of 0.5 to 2 atm to obtain the polyurethane foam stabilizer. Compared with the prior art, the method of the present invention has the advantages of less pollution and cost reduction.

Owner:苏州思德新材料科技有限公司

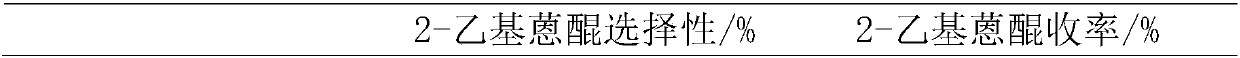

Technology for preparing 2-ethylanthraquinone

InactiveCN107746372AReduce the difficulty of productionLow costMolecular sieve catalystQuinone preparation by oxidationMolecular sieveAnthracene

The invention discloses a technology for preparing 2-ethylanthraquinone from anthracene and ethylene. The technology comprises the following steps: alkylating anthracene and ethylene by using a transition metal oxide supported MWW type molecular sieve catalyst to prepare 2-ethylanthracence; and oxidizing the 2-ethylanthracence by using a molybdena supported Y type molecular sieve catalyst to prepare the 2-ethylanthraquinone. The technology has the advantages of facilitation of the proceeding of the reactions, low cost and high yield.

Owner:QINZHOU UNIV

Low-cost high-strength prepainted steel sheet and manufacture method thereof

InactiveCN101880832AHigh strengthGood stamping performanceHot-dipping/immersion processesMetal rolling arrangementsCorrosion preventionHigh intensity

The invention discloses a low-cost high-strength prepainted steel sheet and a manufacture method thereof. The low-cost high-strength prepainted steel sheet comprises the following base materials containing chemical components in percent by weight: 0.06-0.10 percent of C, not more than 0.05 percent of Si, 0.30-0.70 percent of Mn, 0.01-0.03 percent of P, not more than 0.02 percent of S, 0.01-0.07 percent of solAl, not more than 0.005 percent of N, not more than 0.08 percent of Cr, not more than 0.11 percent of Cu, not more than 0.06 percent of Ni and the balance of Fe and unavoidable impurities. The preparation method comprises the steps of: steel-making through molten iron, continuously casting, hot-rolling, acid-washing, hot dipping, alloying, finishing and prepainting. The prepainted steel sheet has the advantages of good stamping property, excellent corrosion prevention property, low production cost and better economic and social benefits, and can be widely applied to the outdoor large building industry.

Owner:WUHAN IRON & STEEL (GROUP) CORP

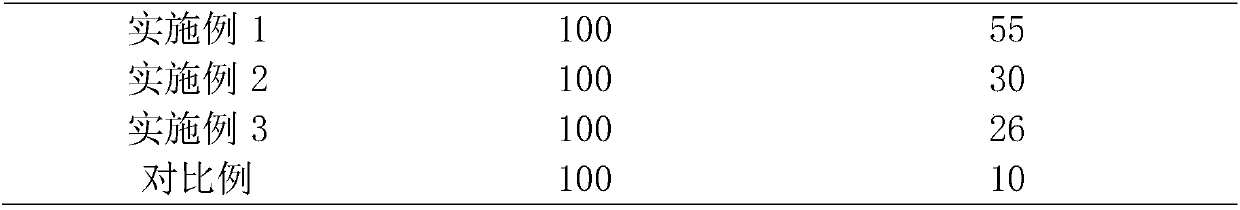

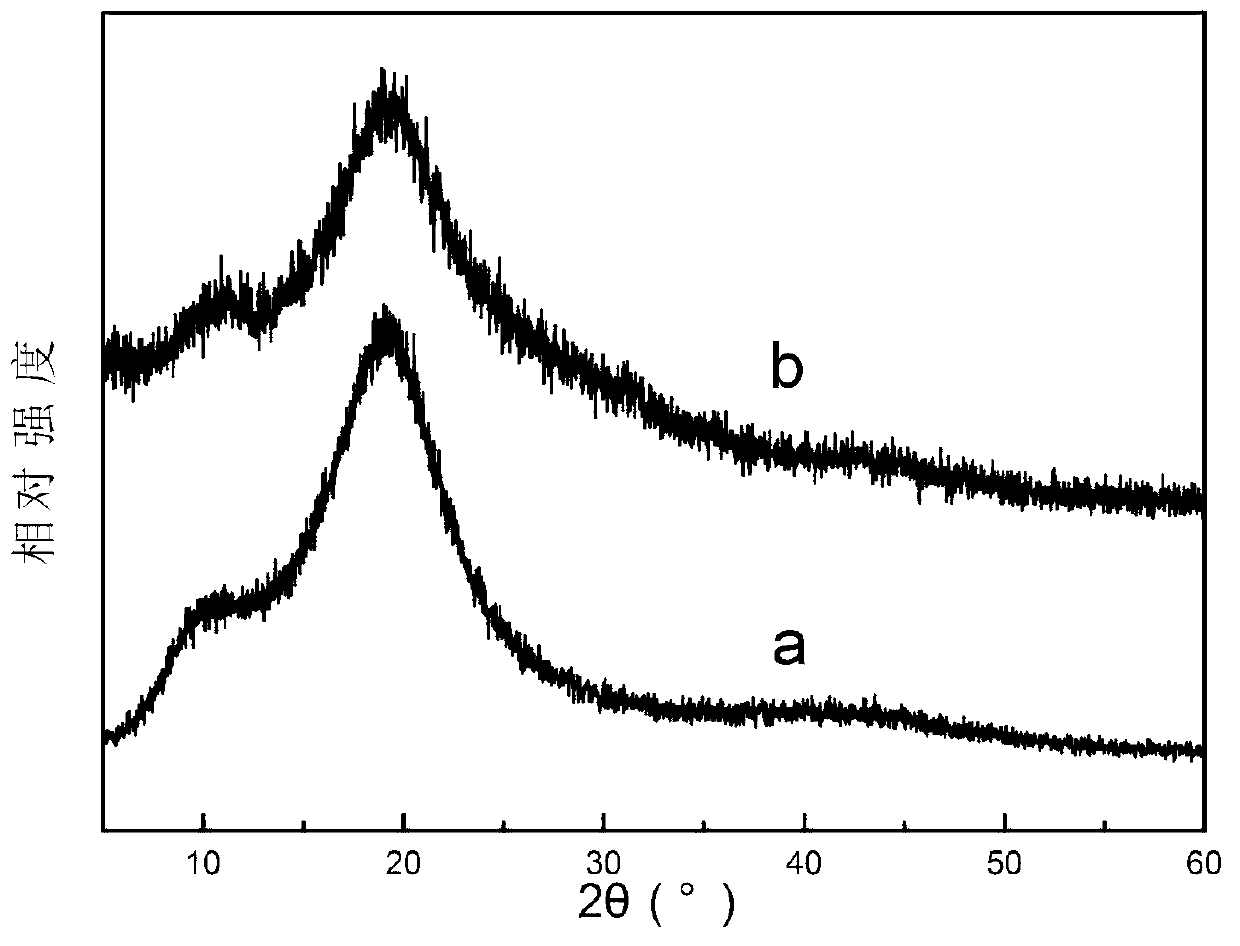

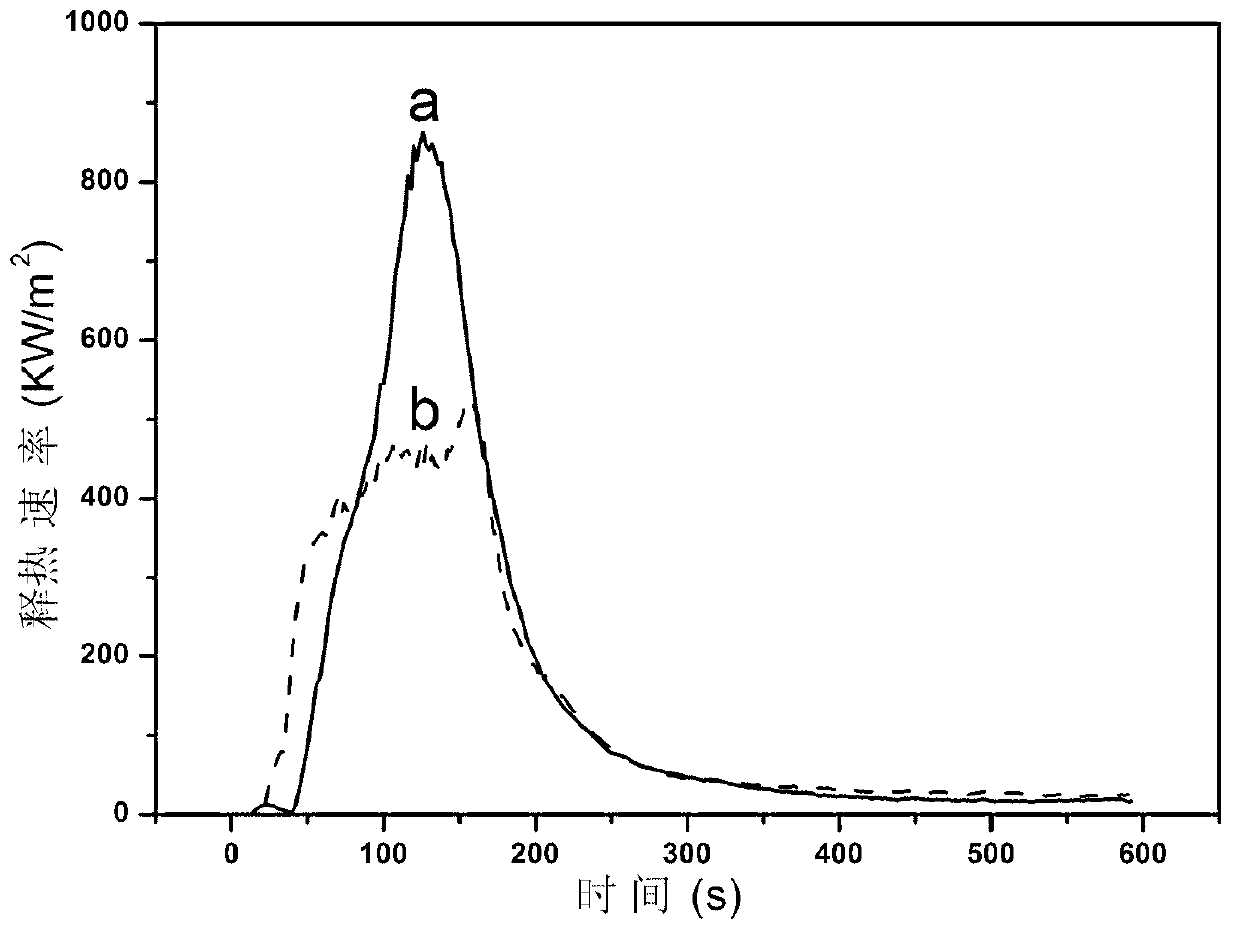

Graphene/layered double hydroxide composite flame retardant and preparation method of polystyrene nanometer flame-retardant composite material

InactiveCN103275408AReduce Secondary HazardsMeet the requirements of green environmental protectionNano compositesCarbon nanotube

The invention relates to a graphene / layered double hydroxide composite flame retardant and a preparation method of a polystyrene nanometer flame-retardant composite material. The preparation method comprises the following steps of: dissolving a carbon nanotube into graphene oxide colloid; stirring and performing ultrasonic dispersion until the materials are dispersed uniformly; adding M<2+> salt and Al<3+> salt; adding urea; performing a reflux reaction to obtain a graphene / carbon nanotube / layered double hydroxide composite assembling body; mixing the composite assembling body and polystyrene resin; and performing melt extrusion to obtain the polystyrene nanometer flame-retardant composite material. The graphene / carbon nanotube / layered double hydroxide composite assembling body is prepared by dispersing carbon nanotubes by a graphene oxide nanosheet, controlling the pH value of the solution by the urea and reducing the graphene oxide into the graphene. The polystyrene nanometer flame-retardant composite material prepared by the melt extrusion method has excellent flame resistance and mechanical properties.

Owner:HOHAI UNIV

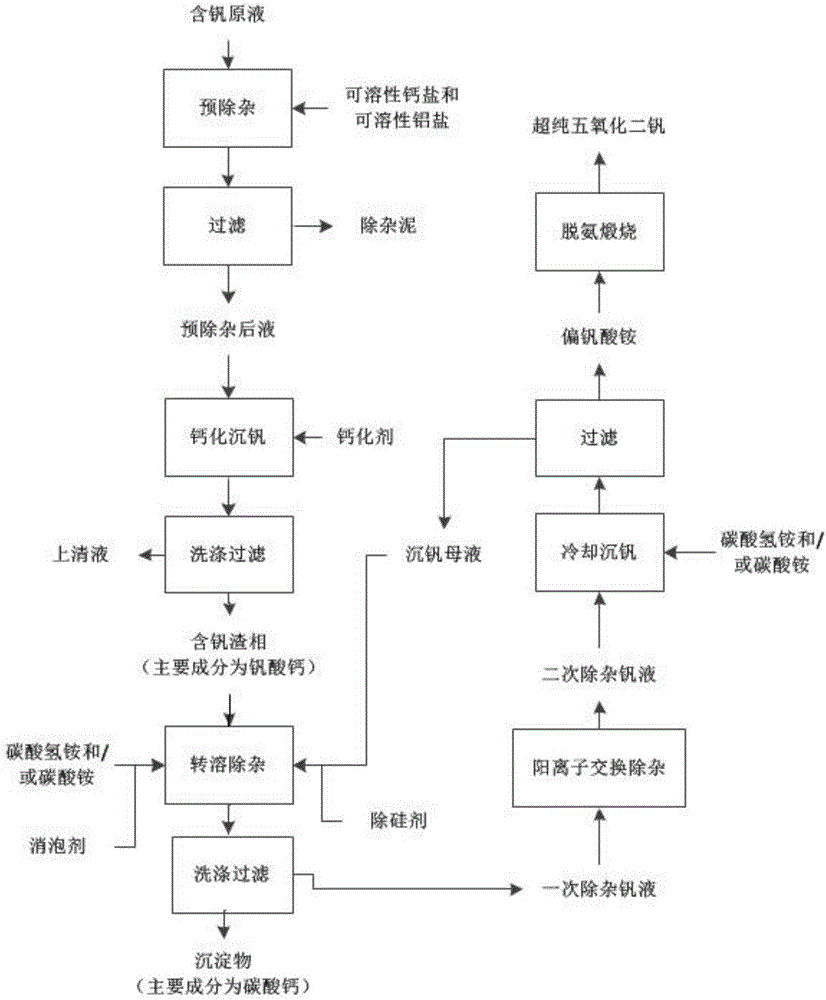

Preparation method of ultra-pure vanadium pentoxide

The invention discloses a preparation method of ultra-pure vanadium pentoxide. The preparation method comprises the following steps of: removing impurities in advance; transferring phosphorus and silicon in a vanadium-containing solution into a solid phase for removal; performing calcification and vanadium precipitation; transferring vanadium in a liquid phase into a calcium vanadate phase; leaving the impurities such as chromium, manganese, potassium and sodium in the liquid phase for removal; performing solubilization reaction of vanadium in the calcium vanadate into the liquid phase through ammonium bicarbonate and / or ammonium carbonate; leaving the calcium, phosphorus, silicon, iron and magnesium in the solid phase for removal; replacing residual trace cations of the liquid phase with ammonium ions by an ammonium type cation exchange system to realize deep purification; and performing cooling vanadium precipitation and deamination calcination to obtain vanadium pentoxide. In the invention, the process route is simple, the drug consumption is low, the vanadium pentoxide with purity of over 99.95% can be stably obtained, and the content of main impurities such as iron, chromium, manganese, silicon, phosphorus, calcium, sodium, magnesium, potassium and aluminum is all lower than 0.002%.

Owner:HEBEI IRON AND STEEL

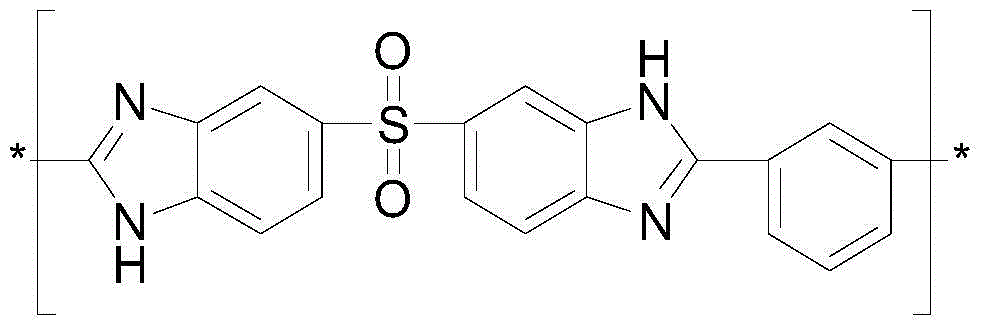

Flame retardant fiber and preparation method thereof

ActiveCN104018243AImprove flame retardant performanceLess smokeFlame-proof filament manufactureConjugated cellulose/protein artificial filamentsCelluloseHigh concentration

The invention relates to a flame retardant fiber and a preparation method thereof. The preparation method comprises the following steps: mixing cellulose or polyacrylonitrile and a flame retardant high polymer according to a ratio, dissolving at high temperature to prepare a high concentration spinning solution, filtering, cooling, pressurizing for extruding, uniformly mixing two components in the spinning solution through a shearing effect generated by pressure, and performing multiple stretching, thereby forming the blended fiber of polyacrylonitrile or cellulose with the phase domain size of less than 50nm. The flame retardant fiber, namely the blended fiber, is prepared by directly spinning, the problem of mixing uniformity is solved, and the flame retardant fiber has the excellent characteristics of good flame retardant performance, high flame retardant durability, zero halogen and phosphorus, low toxicity, comfort and the like and has significance for developing flame retardant fibers which are not toxic, less in smoke and environmentally friendly.

Owner:TIANE CHEM FIBER GROUP CORP BAODING +1

Lobster feed capable of purifying water and improving immunity and preparation method of lobster feed

InactiveCN104489354AImprove survival rateNutritional balanceFood processingAnimal feeding stuffBiotechnologyDisease

The invention discloses a lobster feed capable of purifying water and improving immunity. The lobster feed is prepared from the following raw materials in parts by weight: 3-5 parts of garlic, 1-3 parts of calcium dihydrogen phoshate, 2-3 parts of tender leaves of fennel, 4-6 parts of banana skin, 2-4 parts of villous amomrum fruit, 3-5 parts of cluster mallow fruit, 3-4 parts of sargassum thunbergii, 4-6 parts of dehydrated spinach, 2-4 parts of cinnamon, 6-8 parts of cuttleflsh bone, 5-8 parts of wheat middling, 20-30 parts of rapeseed dregs, 15-20 parts of meat and bone meal, 4-6 parts of stevioside and 6-10 parts of an assistant. The lobster feed disclosed by the invention is balanced in nutrient; due to addition of the rapeseed dregs, the meat and bone meal and the like, most of basic nutrients required by the lobster can be supplemented; the added stevioside is high in sweetness, and long in duration, and can play a good attractant effect; due to addition of villous amomrum fruit, the cluster mallow fruit and the like, the disease resistance of the lobster is further enhanced; and the survival rate of the lobster is increased.

Owner:全椒县赤镇龙虾经济专业合作社

Natural dyestuff dyeing and finishing process of polyester fabric

The invention discloses a natural dyestuff dyeing and finishing process of polyester fabric. The natural dyestuff dyeing and finishing process of the polyester fabric comprises pretreatment, preshaping, modification treatment, dyeing, mordant removing, soaping, fixation, finishing, drying, shaping, calendering and winding. According to the natural dyestuff dyeing and finishing process of the polyester fabric, helicase and alhpa-amylase are adopted to conduct pretreatment, modification treatment is radically conducted on the performance of the polyester fabric through a acetic acid aqueous solution of chitosan, hydrogen peroxide and epoxy chloropropane, and the dyeing rate of the fabric is increased; in the dyeing process, a large amount of alkaline matter and inorganic salt are not used, a levelling agent and diffusant are added, the level-dyeing property is improved, natural dyestuff is used, therefore, environmental pollution is avoided, and requirements of green environmental protection are met; modification treatment and fire-retardant treatment are conducted on the fabric through montmorillonite, and the fire resistance of the fabric is high; anti-yellowing reagents are used in the preshaping and the shaping, and the final fabric is not prone to yellowing.

Owner:TAICANG CHENGLE CHEM FIBER

Surface treatment method of automobile covering parts

ActiveCN103088393ASimple processImprove technical effectElectrophoretic coatingsChromium freeEngineering

The invention provides a surface treatment method of automobile covering parts. The surface treatment method comprises the following steps of: 1) hanging and fixing automobile covering parts to be treated, then carrying out spraying pre-degreasing, dipping main degreasing and spraying degreasing sequentially, and washing with water; 2) carrying out surface conditioning by using a surface conditioning agent, then dipping and phosphatizing, and washing with water; 3) carrying out passivating treatment by using a chromium-free passivating agent, and then washing with water; and 4) carrying out electrophoretic painting, and then washing with water. A three-way degreasing technology of spraying, dipping and spraying is adopted by the scheme of the surface treatment method, so that grease is thoroughly cleaned. Due to a dip technology, the inner cavity of a complex workpiece is also cleaned. A reverse feeding method is adopted by the surface treatment method, and a degreasant of a degreasing work (the third tank) is always kept very fresh, so that the degreasing effect is the best, the utilization rate of the degreasant is also improved, and at the same time, the cost is saved. Due to the implementation of additional degreasing step, grease on the workpiece surface is removed completely, and the binding force of coatings is enhanced, so that the anti-corrosion effect is remarkably improved.

Owner:昆山田盛汽车配件有限公司

High-COD special non-phosphorus corrosion and scale inhibitor and preparation method thereof

ActiveCN104261575AGood anti-scaling effectGood corrosion inhibition effectSpecific water treatment objectivesTreatment using complexing/solubilising chemicalsTungstateWater quality

The invention provides a high-COD (Carbon Oxide Demand) special non-phosphorus corrosion and scale inhibitor and preparation method thereof. The corrosion and scale inhibitor mainly comprises cyclodextrin or cyclodextrin derivatives, a soluble metal salt, a copolymer containing a sulfonic acid group, a homopolymer containing carboxylic acid, an acrylic acid / ethyl acrylate / 2-acrylamide-2-methallylsulphonate copolymer, tetrahydroglyoxaline matters, sodium gluconate, and quaternary ammonium salt. The non-phosphorus corrosion and scale inhibitor is suitable for an open circulated cooling water system, and suitable for surface water high in COD and free of treatment, and the non-phosphorus corrosion and scale inhibitor is added into the circulated cooling water system by an automatic reagent feeding device. The non-phosphorus corrosion and scale inhibitor is environmentally-friendly, avoids using phosphorous compounds or non-renewable molybdate or tungstate, has the characteristic of being free from phosphorus and nitrogen, meets the requirement of environmental protection, reduces the environmental burden, has a sterilizing ingredient at the same time, and effectively reduces the problems of bacterial corrosion and algae growth in a circulated water system.

Owner:SHANDONG TIANQING TECH DEV

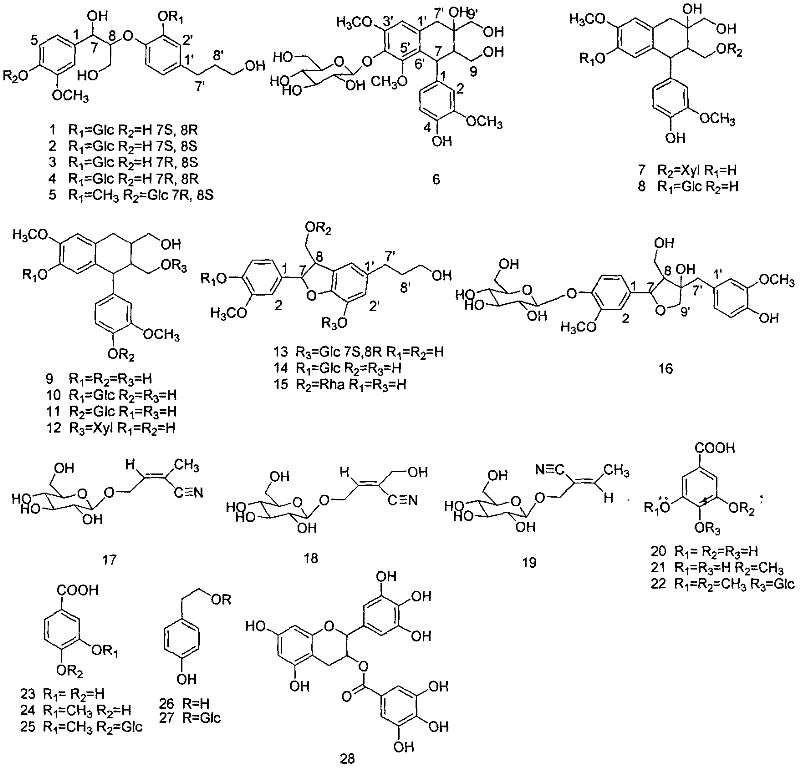

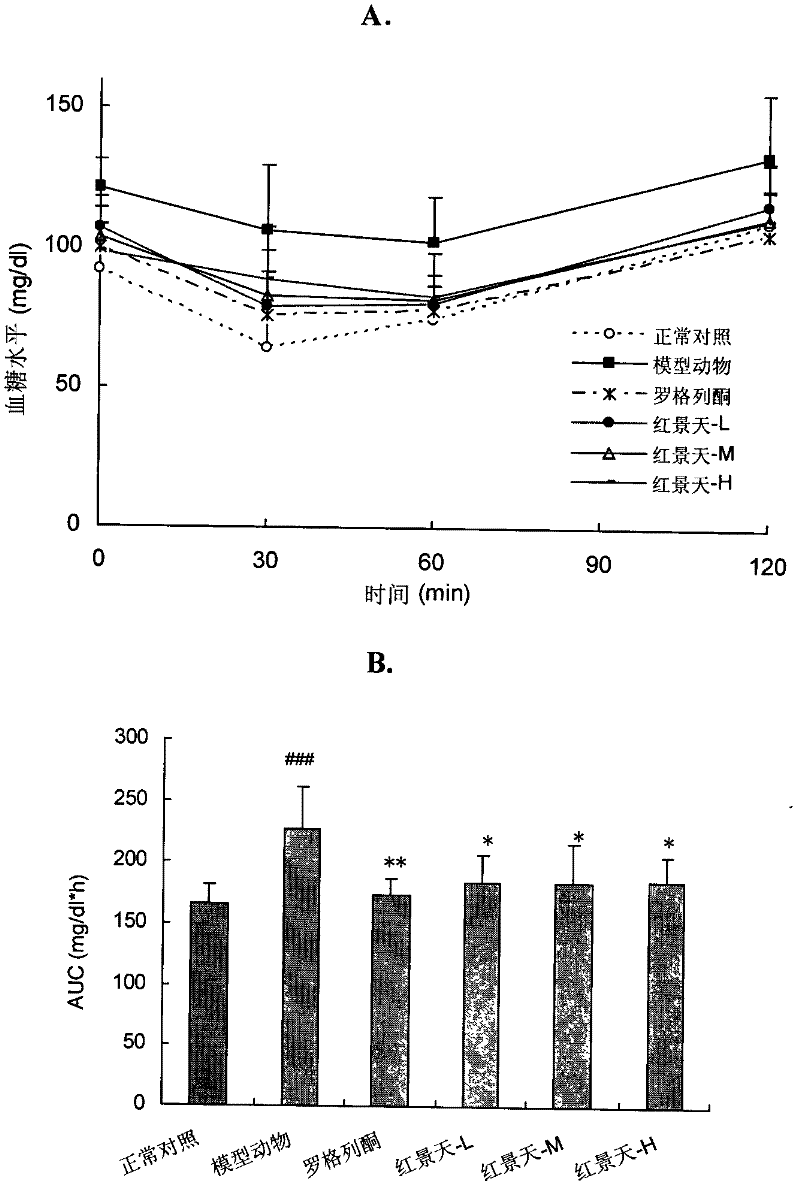

Rhodiola effective fractions, preparation method, drug composition and uses thereof

ActiveCN102526165ASmall doseObvious anti-metabolic syndrome effectMetabolism disorderEndocrine system disorderMedicineMetabolic syndrome

The present invention relates to effective fractions, a preparation method of the effective fractions, drug compositions of the effective fractions, and uses of the effective fractions in preparations of anti-metabolism syndrome drugs, wherein the effective fractions are prepared by carrying out extracting separation on a rhodiola plant.

Owner:INST OF MATERIA MEDICA CHINESE ACAD OF MEDICAL SCI

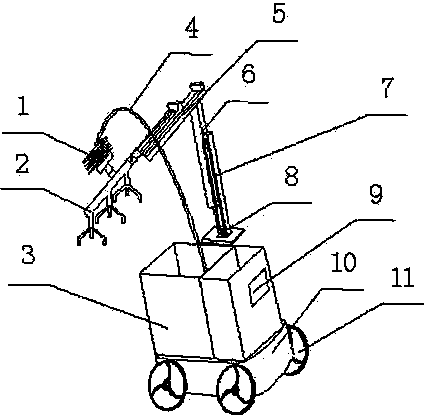

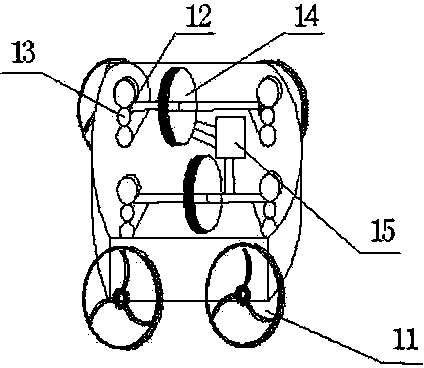

Full-automatic watering vehicle

InactiveCN105248256ALow energy consumptionReduce labor intensityWatering devicesCultivating equipmentsElectric machineryPiping

The invention discloses a full-automatic watering vehicle. The full-automatic watering vehicle is characterized in that a water storing tank and a storage cabinet are arranged over a lower vehicle body; a vertical telescopic assembly is arranged beside the water storage tank; a telescopic rod of the vertical telescopic assembly is provided with a chain; the chain is driven by a motor; a horizontal driving slide block of a horizontal telescopic assembly is engaged with a horizontal driving screw rod; the end part of the horizontal driving screw rod is provided with a pressing device; the pressing device is installed over a supporting water pipe; a water spraying head is installed under the supporting water pipe; the lower vehicle body is provided with a worm gear rod and a damping wheels; the worm gear rod is engaged with a turning gear via a driving motor; the turning gear is engaged with a wheel driving shaft; and the worm gear rod and the turning gear transmit power to damping wheels, so the damping wheels can rotate and drive the lower vehicle body to move forward, backward and steer. Watering load can be reduced for workers, so less labor and time can be achieved for flower planting workers; and the full-automatic watering vehicle benefits people.

Owner:QINGDAO LANNONGGU AGRI PROD RES & DEV

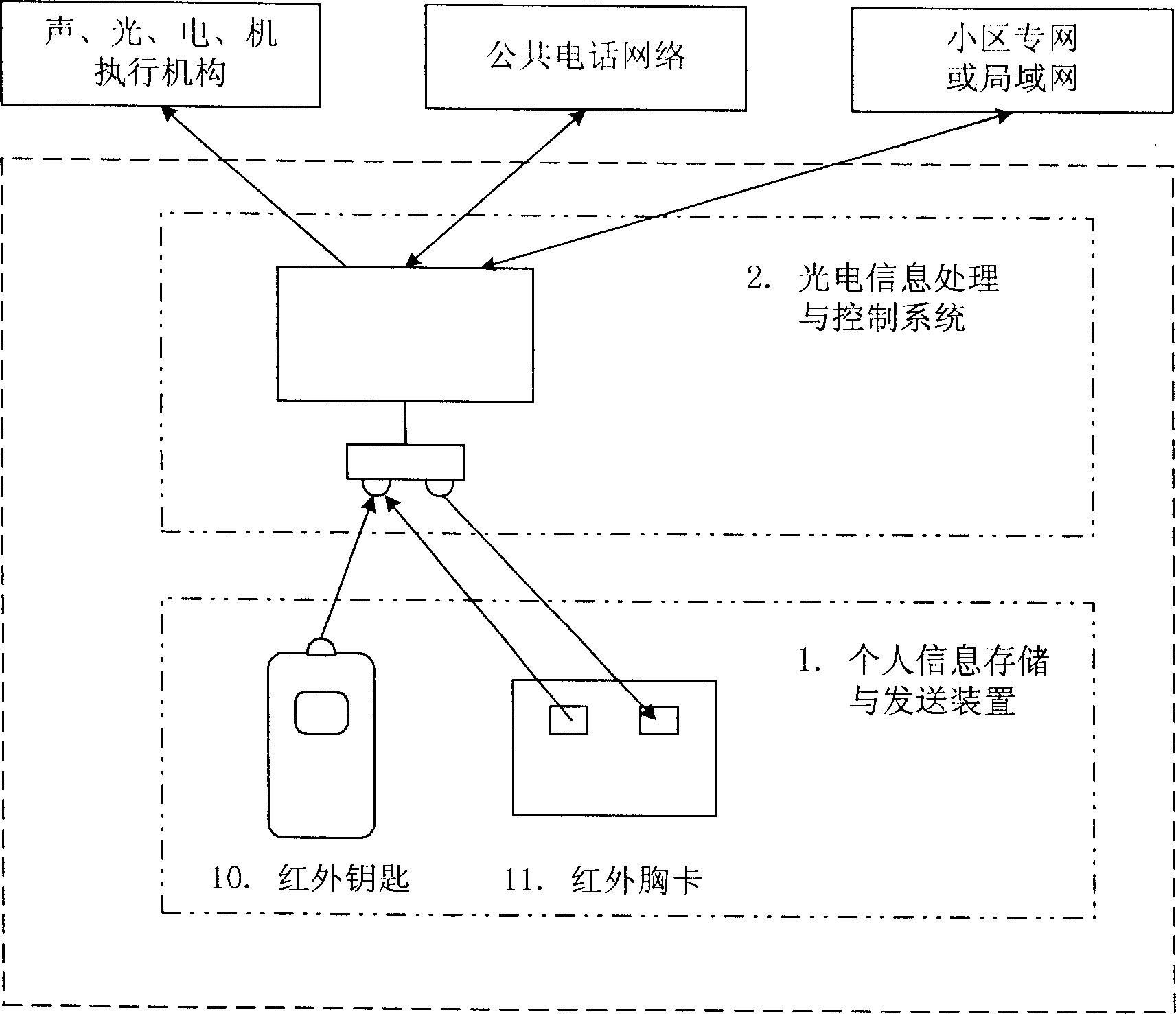

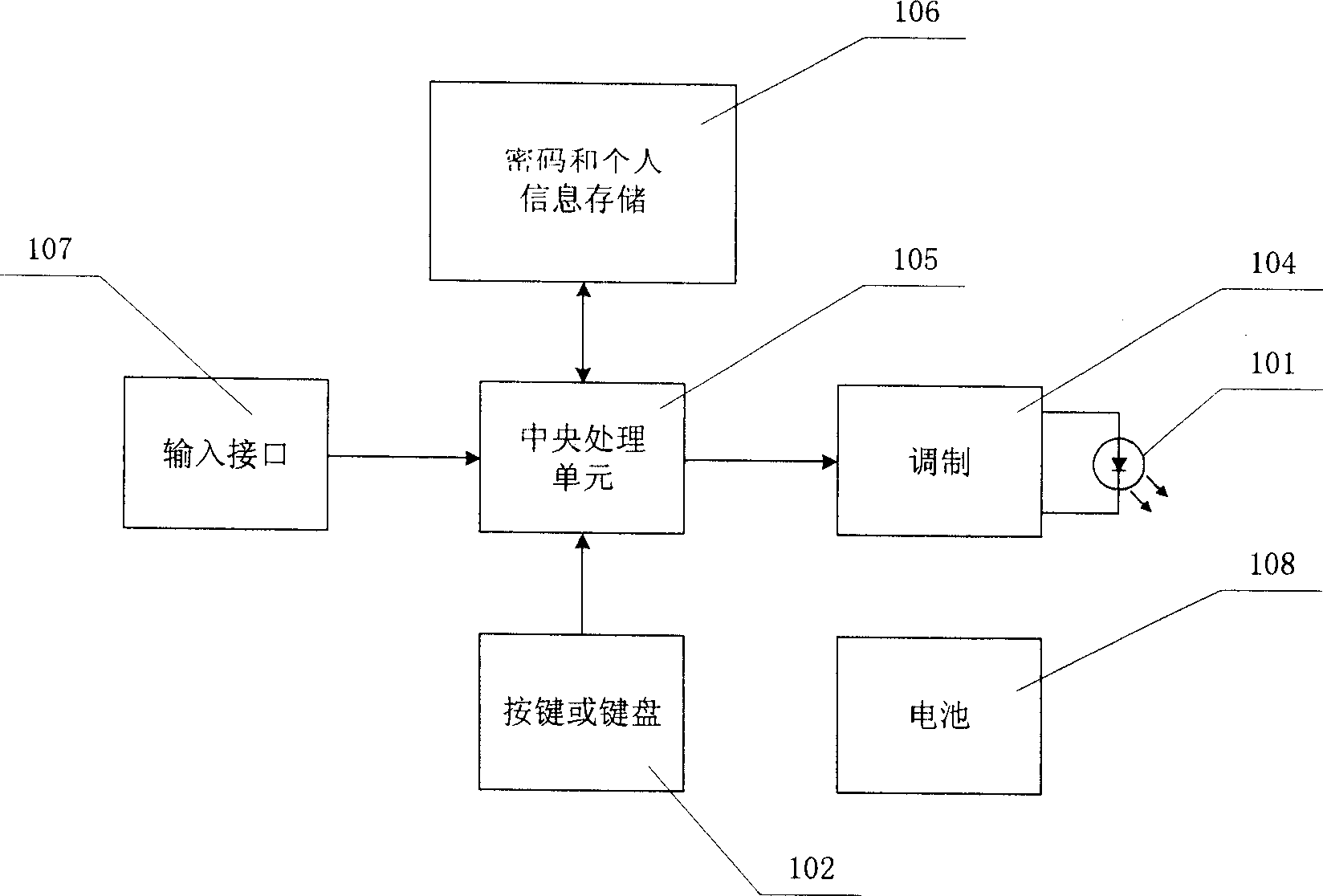

Photoelectric intelligent door safety system

InactiveCN1405426AMeet the requirements of green environmental protectionEasy to handleElectric permutation locksSecuring communicationOpto electronicElectricity

Photoelectric intelligence door-keeper system comprises private information storage, sending device and photoelectric information handling controlling device. The principal form of the private information storage, sending device is finifed card and infrared key. Private information storage, sending device has non-contact secret number and private information storage unit, the information is managed by operating controlling unit to conduct infrared send communication. The photoelectric information handling, controlling device receives and answers the information sent by private information storage and sending device. Through central controlling unit check and management, the controlling order is sent out and by wire or wireless net work, such as sound, light machine, electrical operation mechanism to carry out the order.

Owner:上海奥达光电子科技有限公司

Method for producing multilayer composite edible film through lamination technology

InactiveCN105196634AEasy to useHigh tensile strengthLaminationLamination apparatusCellulosePolymer science

The invention relates to a method for producing a multilayer composite edible film through a lamination technology. The method comprises the following steps: 1, producing a film I: adding raw materials comprising corn phosphate starch or carboxymethyl starch, corn straw cellulose, citric acid, glycerin and carboxymethyl cellulose to distilled water, stirring for fully dissolving, carrying out ultrasound-microwave combined modification treatment, carrying out vacuum degassing to obtain a film I mixed solution, and uniformly coating the film I mixed solution in an organic glass film formation device to produce the film I for later use; 2, producing a film II: preparing a film II mixed solution by using raw materials comprising zein, ethanol, carboxymethyl cellulose and glycerin, and uniformly coating the film II mixed solution in the organic glass film formation device to produce the film II for later use; and 3, tiling the film II on the surface of the film I, and carrying out ultrasonic wave-microwave assisted laminating compounding with a film I mixed solution wet base between the film I and the film II as an adhesive in order to obtain the multilayer composite edible film. The tensile strength, the elongation at break, the moisture barrier property and the gas barrier property of the multilayer composite edible film are obviously improved.

Owner:JILIN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com