Fowl dung fermentation fertilizer and preparation method thereof

A fertilizer and chicken manure technology, applied in the field of agricultural fertilizers, can solve problems such as water and soil environmental pollution, and achieve the effects of eliminating soil compaction, eliminating toxic and harmful substances, and eliminating viral diseases

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

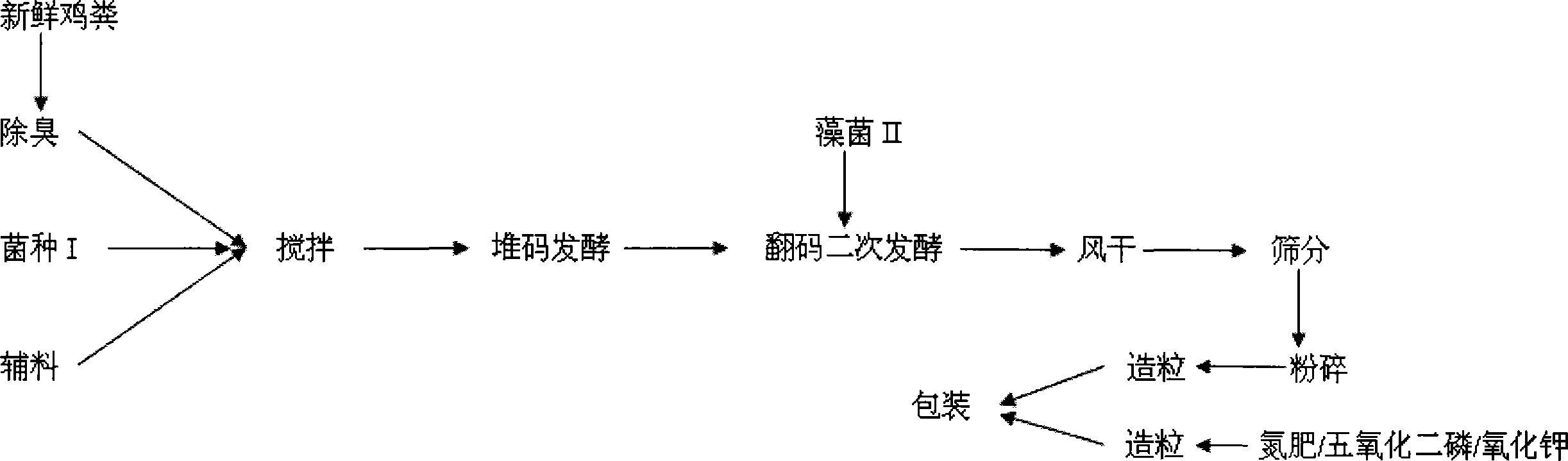

Method used

Image

Examples

Embodiment 1

[0036] 1. Prepare materials: 3 cubic meters of fresh chicken manure with a water content of 60% (dried about 600 kg), 200 kg of bran powder, 20 kg of corn flour, 15 kg of wheat flour, 3 kg of brown sugar, 8 kg of lime powder, 0.8 kg of A Algae, 1.6 kg of strain I and 2.3 kg of strain II; Among them, strain I is composed of 0.4 kg of yeast, 0.5 kg of lactic acid bacteria, 0.3 kg of high-temperature actinomycetes and 0.4 kg of bacillus; fermentation strain II is composed of 0.1 kg of photosynthetic bacteria, 0.3 kg of lactic acid bacteria, 0.6 kg of bacillus, 0.2 kg of yeast, 0.1 kg of actinomycetes and 1.0 kg of terrestrial cyanobacteria;

[0037] 2. Deodorize fresh chicken manure;

[0038] 3. After uniformly stirring the deodorized chicken manure, auxiliary materials and fermentation strain I, stacking for 25 days of anaerobic fermentation, the fermentation temperature is 45-60°C;

[0039] 4. Keep the temperature after the first fermentation at 50°C, add the fermentation stra...

Embodiment 2

[0055] 1. Prepare materials: 3 cubic meters of fresh chicken manure with a water content of 50% (dried about 700 kg), 250 kg of bran powder, 25 kg of corn flour, 17 kg of wheat flour, 5 kg of brown sugar, 10 kg of lime powder, 1 kg of Algae, 2 kg of strain I and 3 kg of strain II; Among them, strain I is composed of 0.5 kg of yeast, 0.6 kg of lactic acid bacteria, 0.4 kg of high-temperature actinomycetes and 0.5 kg of bacillus; fermentation strain II is composed of 0.2 kg of photosynthetic bacteria, 0.4 kg of lactic acid bacteria, 0.7 kg of bacillus, 0.3 kg of yeast, 0.2 kg of actinomycetes and 1.2 kg of terrestrial cyanobacteria;

[0056] 2. Deodorize fresh chicken manure;

[0057] 3. After uniformly stirring the deodorized chicken manure, auxiliary materials and fermentation strain I, stacking for 30 days of anaerobic fermentation, the fermentation temperature is 45-60°C;

[0058] 4. Keep the temperature after the first fermentation at 50°C, add fermentation strain II to th...

Embodiment 3

[0064] 1. Prepare materials: 3 cubic meters of fresh chicken manure with a water content of 55% (dried about 650 kg), 300 kg of bran powder, 30 kg of corn flour, 20 kg of wheat flour, 8 kg of brown sugar, 12 kg of lime powder, and 1.2 kg of A Algae, 2.4 kg of strain I and 3.6 kg of strain II; Among them, strain I is composed of 0.6 kg of yeast, 0.7 kg of lactic acid bacteria, 0.5 kg of high-temperature actinomycetes and 0.6 kg of bacillus; fermentation strain II is composed of 0.3 kg of photosynthetic bacteria, 0.5 kg of lactic acid bacteria, 0.8 kg of bacillus, 0.4 kg of saccharomyces, 0.3 kg of actinomycetes and 1.3 kg of terrestrial cyanobacteria;

[0065] 2. Deodorize fresh chicken manure;

[0066] 3. After the deodorized chicken manure, auxiliary materials and fermentation strain I are evenly stirred, they are stacked for 35 days of anaerobic fermentation, and the fermentation temperature is 45-60°C;

[0067] 4. Keep the temperature after the first fermentation at 50°C, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com