Single-component room-temperature multiple-self-crosslinking aqueous epoxy acrylate resin emulsion and preparation method thereof

A technology of epoxy acrylic and resin emulsion, which is applied in the field of coatings, can solve the problems that water-based coatings cannot meet the application requirements, etc., achieve excellent gloss and outdoor aging resistance, improve corrosion resistance and wear resistance, and improve crosslinking effect of density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

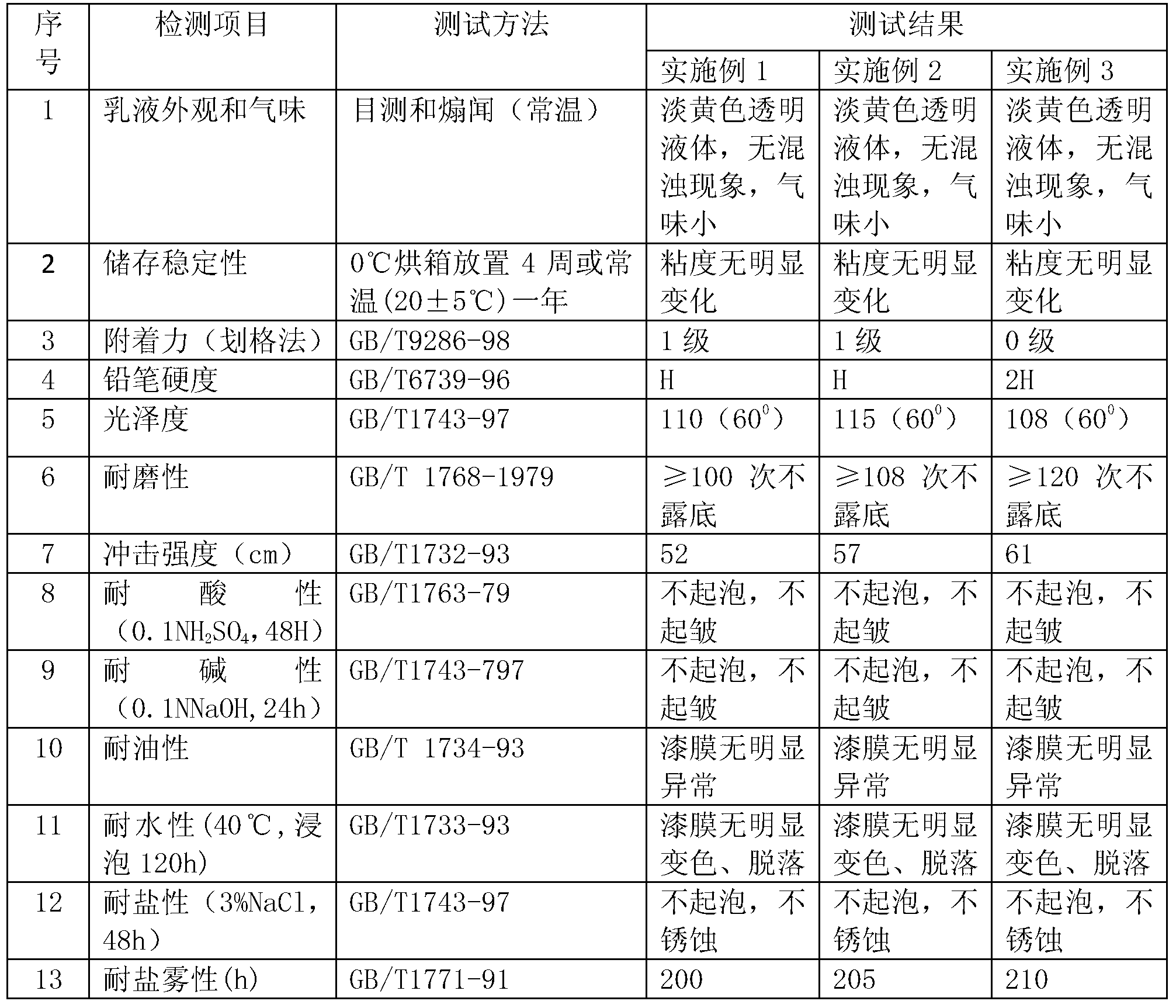

Examples

Embodiment 1

[0026] The preparation method of one-component room temperature multiple self-crosslinking waterborne epoxy acrylic resin emulsion comprises the following steps:

[0027] a. After adding 30g E-12 type epoxy resin and 20g E-20 type epoxy resin into the reaction kettle protected by nitrogen gas, heat up to 100°C and keep it warm for 0.5h to make the E-12 type epoxy resin in solid state completely After melting, start stirring, then add a mixture of 38g of linoleic acid and 15g of oleic acid, and add 0.5g of catalyst monobutyltin oxide, heat up to 140°C and keep it warm for 3 hours, at this time, the mass concentration of unsaturated fatty acids in the system decreases The acid value of the system is 2.8mgKOH / g, which is the end point of the reaction, and then the room temperature self-crosslinking epoxy ester resin modified by unsaturated fatty acid is obtained.

[0028]b. Add 60g of n-butanol to the above-mentioned reaction kettle equipped with 40g of self-crosslinking epoxy es...

Embodiment 2

[0032] The preparation method of one-component room temperature multiple self-crosslinking waterborne epoxy acrylic resin emulsion comprises the following steps:

[0033] a. Add 40g of E-12 epoxy resin to the reaction kettle protected by nitrogen gas, raise the temperature to 110°C, keep it warm for 0.5h to completely melt the E-12 epoxy resin in solid state, start stirring, and then add A mixture of 30g of dehydrated ricinoleic acid and 20g of oleic acid, and adding 2g of catalyst triphenylphosphine, heating up to 150°C and then keeping it warm for 3h. At this time, the mass concentration of unsaturated fatty acids in the system dropped to 70%, and then the temperature was raised to 200°C After holding the reaction at ℃ for 5 hours, the acid value of the system is 3.1 mgKOH / g, which is the end point of the reaction, and a room temperature self-crosslinking epoxy ester resin modified by unsaturated fatty acid is obtained.

[0034] b. In the reaction kettle equipped with 55g ro...

Embodiment 3

[0038] The preparation method of one-component room temperature multiple self-crosslinking waterborne epoxy acrylic resin emulsion comprises the following steps:

[0039] a. After adding 30g E-12 type epoxy resin and 10gE-20 type epoxy resin into the reaction kettle with nitrogen protection, raise the temperature to 100°C and keep it warm for 0.5h to make the E-12 type epoxy resin in solid state completely After melting, start stirring, then add 37g of linolenic acid, and add 1g of catalyst tetrabutylammonium bromide, heat up to 160°C and keep it warm for 2 hours, at this time, the mass concentration of unsaturated fatty acids in the system drops to 65%, and then After raising the temperature to 210°C and keeping it warm for 6 hours, the acid value of the system was 2.8 mgKOH / g, which was the end point of the reaction, and a room temperature self-crosslinking epoxy ester resin modified by unsaturated fatty acid was obtained.

[0040] b. In the reaction kettle equipped with the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com