Patents

Literature

102results about How to "Good stamping performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

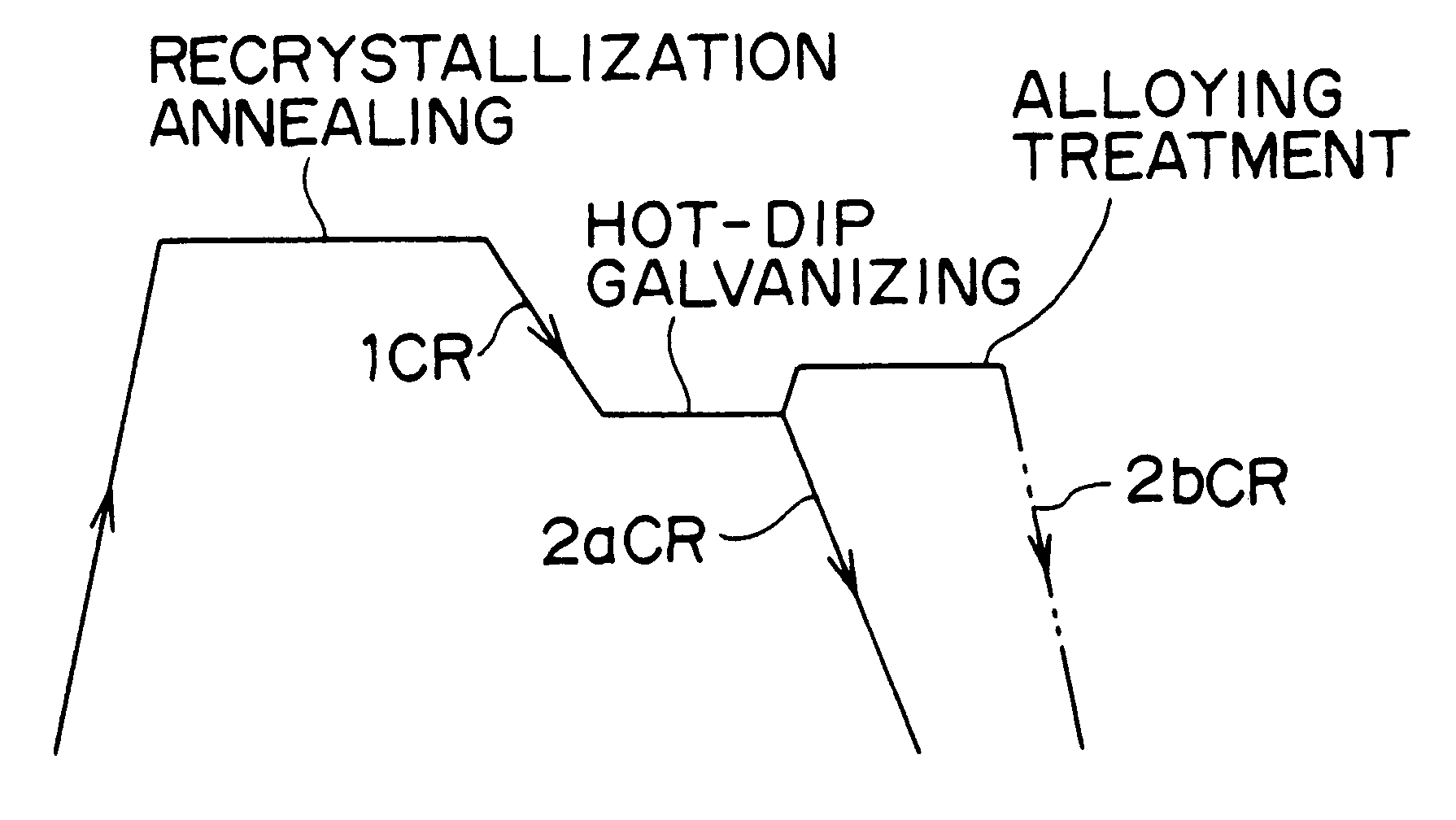

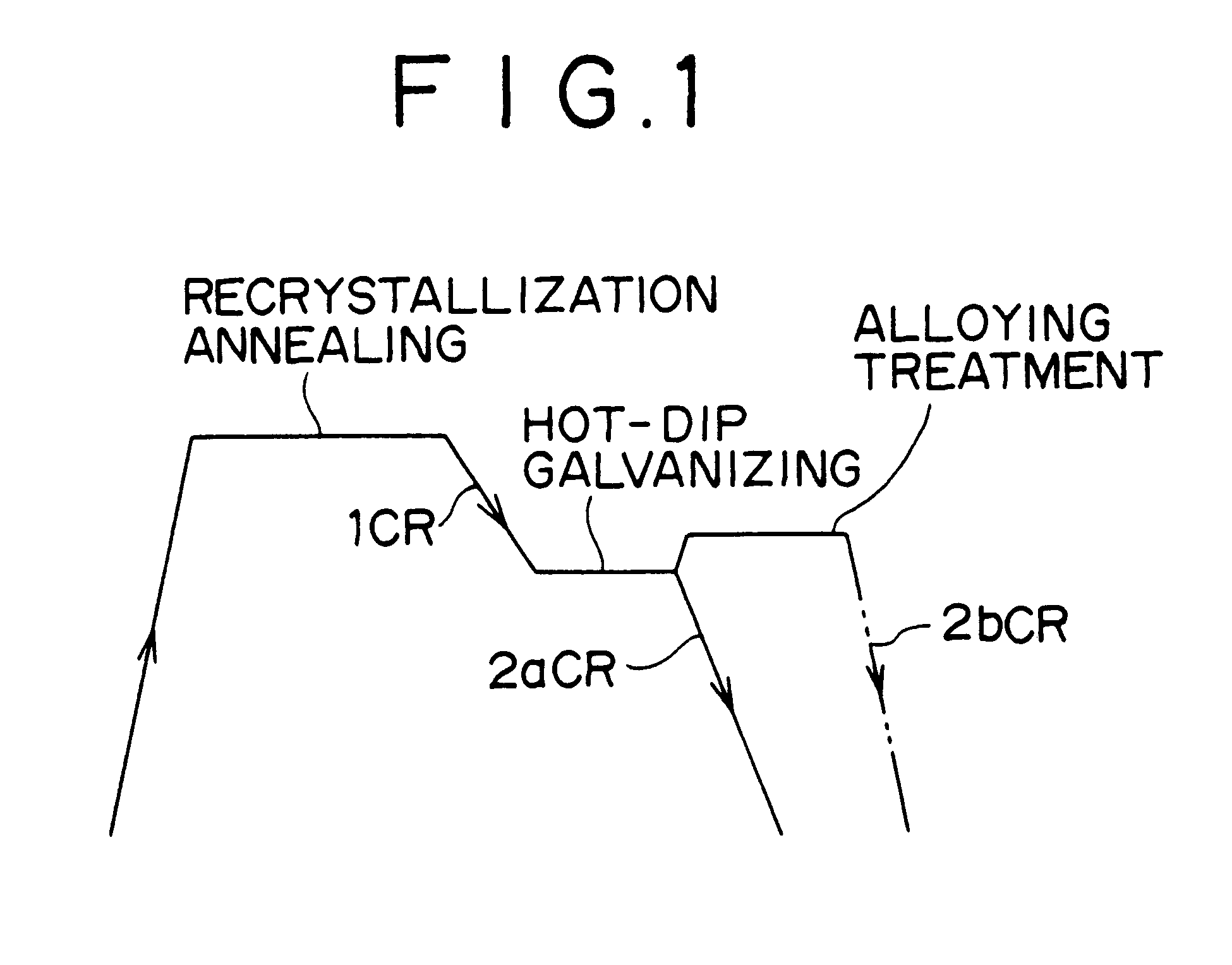

Hot-dip galvanized steel sheet and process for production thereof

InactiveUS6306527B1Ductility deterioratesImprove ductilityHot-dipping/immersion processesLiquid surface applicatorsHot-dip galvanizationDuctility

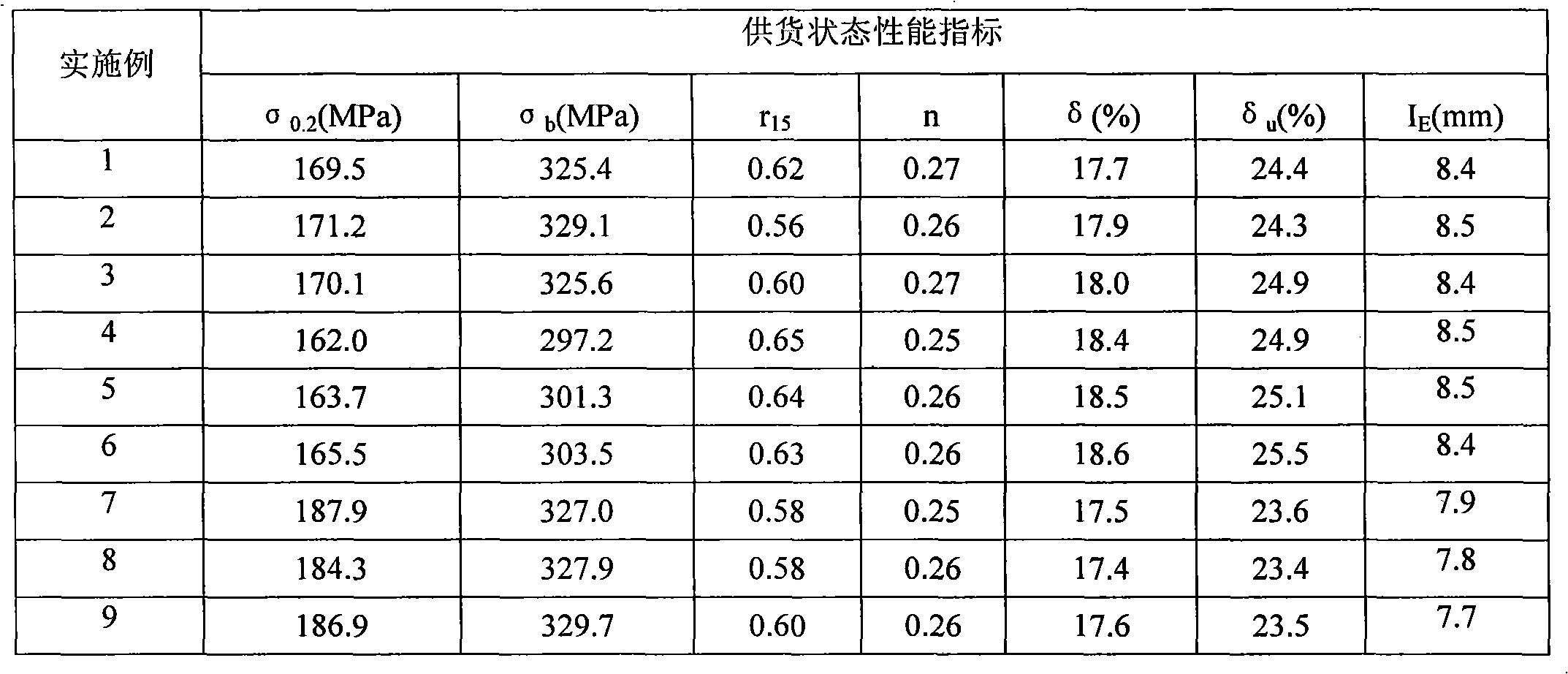

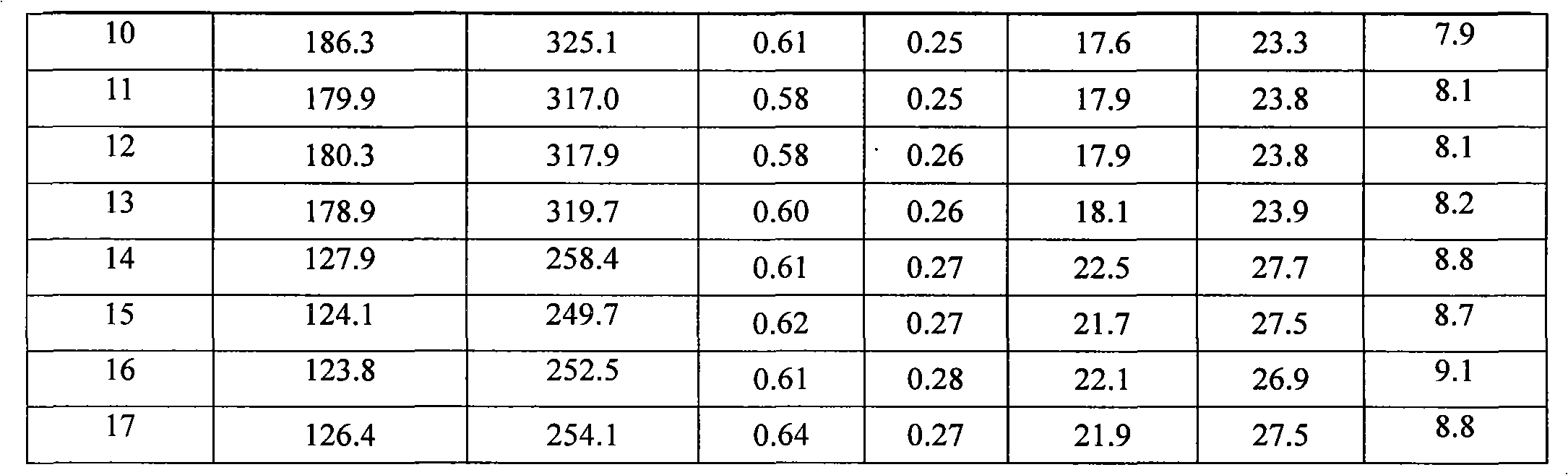

A hot-dip galvanized steel sheet which is produced from a cold-rolled steel sheet, as a base steel sheet, consisting essentially of C: 0.010-0.06 wt %, Si: no more than 0.5 wt %, Mn: no less than 0.5 wt % and less than 2.0 wt %, P: no more than 0.20 wt %, S: no more than 0.01 wt %, Al: 0.005-0.10 wt %, N: no more than 0.005 wt %, Cr: no more than 1.0 wt %, Mn+1.3Cr: 1.9-2.3 wt %, Fe: remainder, and having a structure composed of ferrite and a second phase containing martensite, said second phase in the structure accounting for no more than 20% in terms of area and martensite in the second phase accounting for no less than 50%, and which has a zinc-plated layer formed on the surface thereof by hot-dip galvanizing or hot-dip galvannealing. A process for production of said hot-dip galvanized steel sheet. This steel sheet has a composite structure containing martensite and yet it has a low strength (no higher than 500 MPa) and also has good strength-ductility balance.

Owner:KOBE STEEL LTD

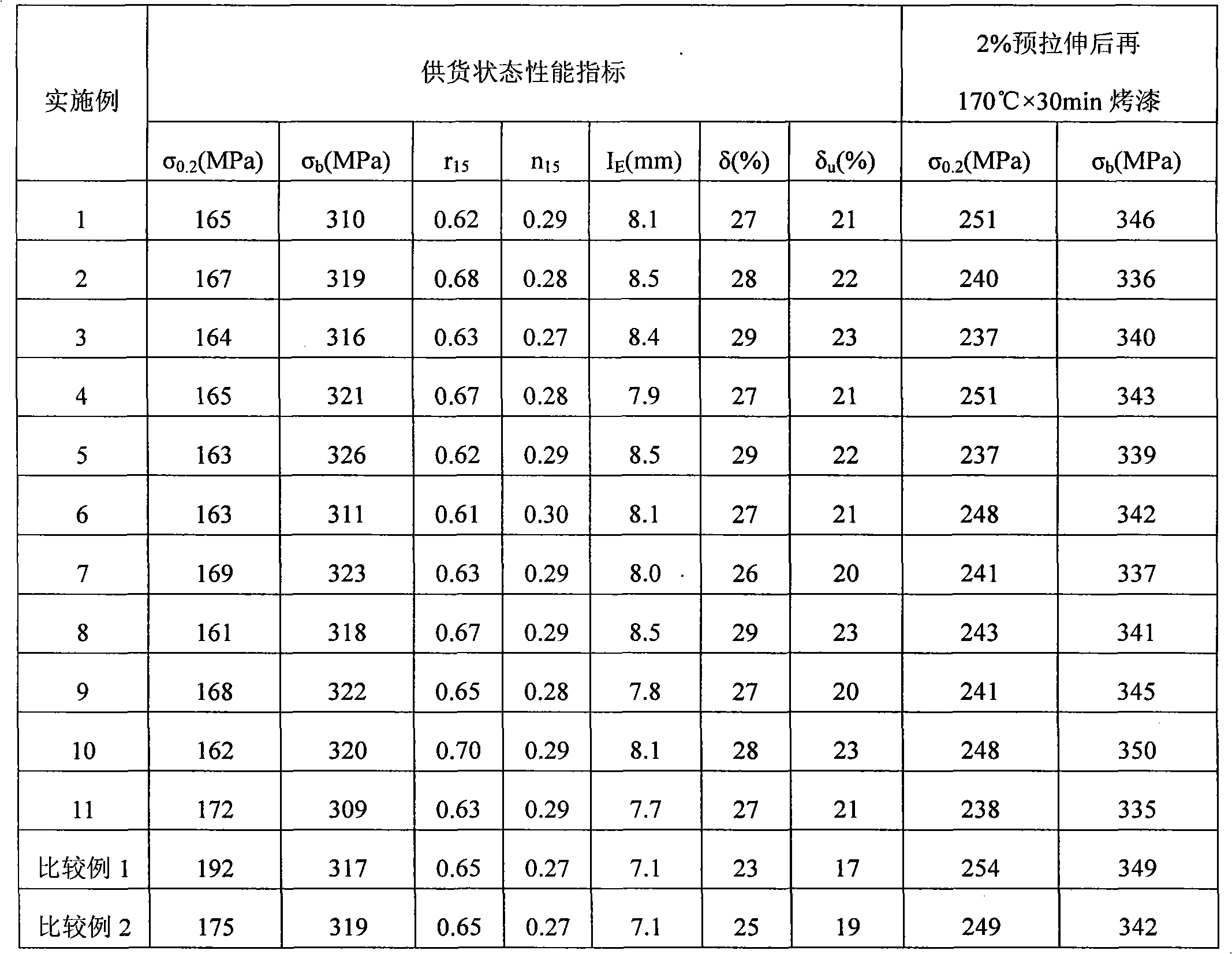

Aluminum alloy for automobile body of automobile and plate manufacturing method thereof

The invention relates to an aluminum alloy for an automobile body of an automobile and a plate manufacturing method thereof and belongs to the technical field of aluminum alloy. The alloy comprises the following components in percentage by weight: 0.6 to 1.33 percent of Mg, 0.6 to 1.33 percent of Si, 0.3 to 0.7 percent of Cu, less than or equal to 0.3 percent of Zn, less than or equal to 0.15 percent of Fe, 0.2 to 0.8 percent of Mn, 0.01 to 0.3 percent of Cr, 0.01 to 0.3 percent of Ti and the balance of Al, wherein the mass fraction ratio of Mg to Si is 1; the total content of the mass fractions of Mn, Cr and Ti alloy elements is more than or equal to 0.3 percent; and Cu content is more than or equal to 0.3 percent. The method for manufacturing the aluminum alloy for the automobile body of the automobile comprises the following steps of: (1) smelting the alloy; (2) shaping the alloy by casting; (3) performing pre-nucleation treatment; (4) performing homogenization treatment; (5) performing hot rolling; (6) performing intermediate annealing; (7) performing cold rolling; (8) performing solid solution water quenching treatment; (9) standing a product at room temperature; and (10) performing pre-ageing and standing the product at the room temperature for more than two weeks. The aluminum alloy and the method are characterized in that: an alloy casting process and a plate production process of the invention are simple and convenient to control; an alloy plate of the invention has high intensity and excellent stamping forming property; and the stamping yield of a covering part for the aluminum alloy automobile body can be effectively enhanced and stamping cost is lowered.

Owner:NORTHEASTERN UNIV

Hard tinned plate suitable for stamping processing and production process thereof

InactiveCN101603147AProduction control is less difficultLow costRoll force/gap control deviceTinningSteelmaking

The invention relates to a hard tinned plate which is suitable for stamping processing and is produced from low carbon Al-killed steel. The original plate comprises the chemical components by weight percentage: 0.08 to 0.13 percent of C, less than or equal to 0.025 percent of Si, less than or equal to 0.65 percent of Mn, less than or equal to 0.020 percent of P, less than or equal to 0.020 percent of S, 0.02 to 0.06 percent of solAl, less than or equal to 0.03 percent of Ti, less than or equal to 0.005 percent of N, and Fe and unavoidable impurities accounting for the margin. The production process adopts the steps of steelmaking with molten iron->continuous casting-hot rolling->push-pull mode pickling->HC rolling mill cold rolling->electrolytic degreasing->hydrogen bell furnace annealing(BA)->double-machine leveling->electrolytic tinning, and finally the hard tinned plate can be obtained. The hard tinned plate of the invention has the advantages of low cost, high hardness, favorable stamping processability, and the like, and can be widely used as packing materials for food, drinks, etc.

Owner:武钢集团有限公司

Low-cost high-strength prepainted steel sheet and manufacture method thereof

InactiveCN101880832AHigh strengthGood stamping performanceHot-dipping/immersion processesMetal rolling arrangementsCorrosion preventionHigh intensity

The invention discloses a low-cost high-strength prepainted steel sheet and a manufacture method thereof. The low-cost high-strength prepainted steel sheet comprises the following base materials containing chemical components in percent by weight: 0.06-0.10 percent of C, not more than 0.05 percent of Si, 0.30-0.70 percent of Mn, 0.01-0.03 percent of P, not more than 0.02 percent of S, 0.01-0.07 percent of solAl, not more than 0.005 percent of N, not more than 0.08 percent of Cr, not more than 0.11 percent of Cu, not more than 0.06 percent of Ni and the balance of Fe and unavoidable impurities. The preparation method comprises the steps of: steel-making through molten iron, continuously casting, hot-rolling, acid-washing, hot dipping, alloying, finishing and prepainting. The prepainted steel sheet has the advantages of good stamping property, excellent corrosion prevention property, low production cost and better economic and social benefits, and can be widely applied to the outdoor large building industry.

Owner:WUHAN IRON & STEEL (GROUP) CORP

Hot-rolled steel sheet, method for production thereof and molded article formed from hot-rolled steel sheet

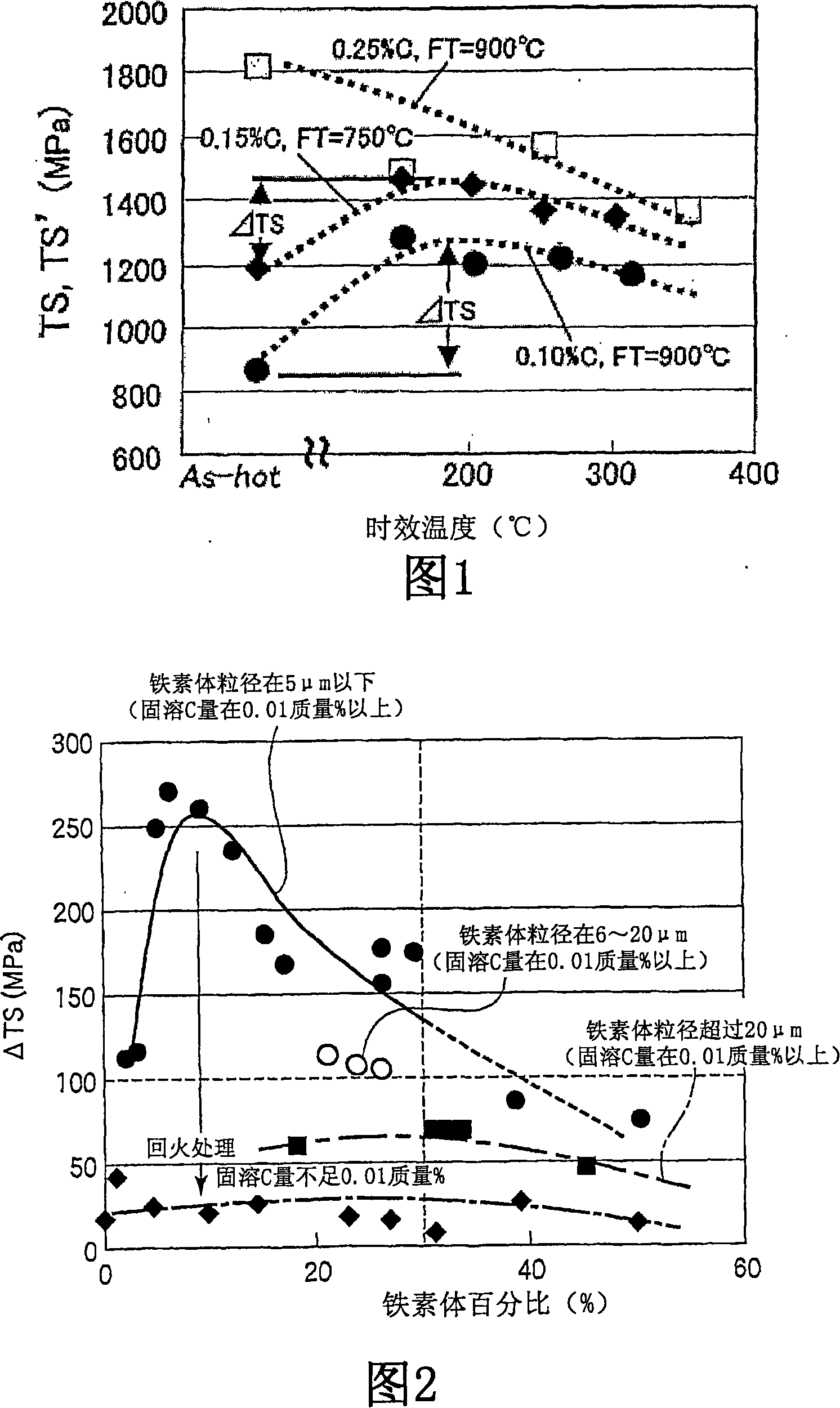

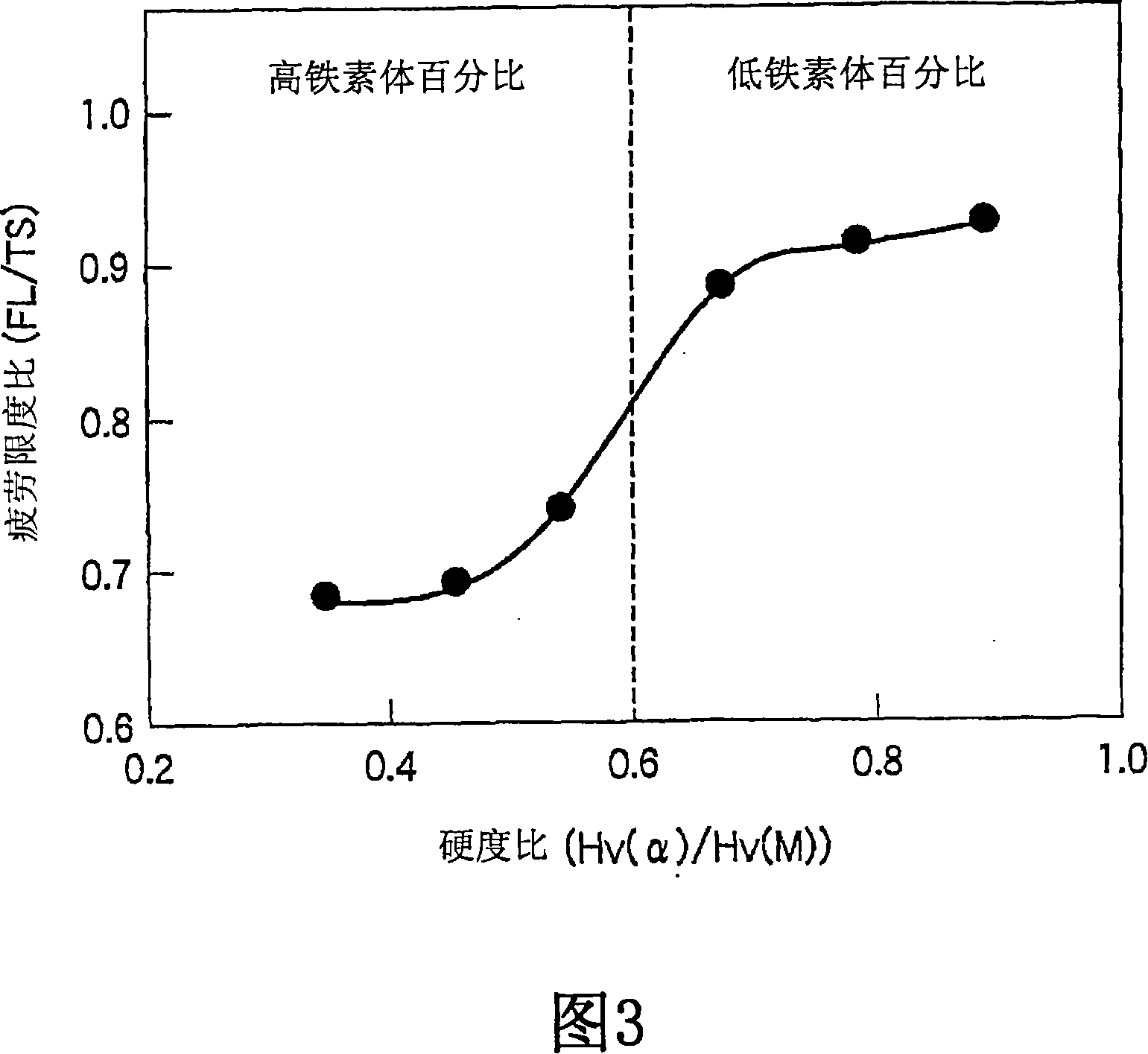

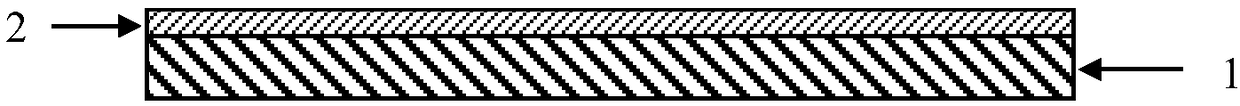

InactiveCN101151391AExcellent strain age hardening propertiesGood stamping performanceFurnace typesHeat treatment furnacesSheet steelSolid solution

A hot-rolled steel sheet which comprises 0.01 to 0.2% by mass of C, 2.0% by mass or less of Si and 3.0% by mass or less of Mn and has a martensite phase as the main phase and a ferrite phase as a second phase, the ferrite phase containing ferrite having a grain size of 20 [mu]m or less in such an amount that the area ratio of ferrite becomes 1 to 30% (inclusive) and also containing 0.01% by mass or more of solid solution carbon. The steel sheet has excellent press workability, and exhibits excellent strain ageing property, that is, can be markedly increased in its tensile strength by a heat treatment, after press forming, at a temperature around that for a conventional baking finish, and thus can be suitably used as a steel sheet for an automobile. Further, fatigue characteristics after the strain ageing treatment are improved by hardening the ferrite phase.

Owner:JFE STEEL CORP

Water-soluble lubricating oil

InactiveCN1575330AImprove machinabilityGood stamping performanceDischarging arrangementOther chemical processesOil and greaseMetalworking

The water-soluble lubricating oil composition of this invention contains animal fats and oils and / or plant fats and oils, and the nonionic surfactant of polyoxyethylene sorbitol fatty acid ester. The water-soluble lubricating oil composition of this invention is excellent in emulsion stability, and it can reduce environmental pollution. It is suitably as metal processing oils such as cutting oil and plastic working oils, and release agent such as asphalt mixture adhesion prevention agent and concrete release agent.

Owner:THE NISSHIN OILLIO GRP LTD

High-surface-quality aluminum-coated plate strip with easy stamping machining function and production method thereof

ActiveCN108796384AImprove plasticityImproved interfacial bonding propertiesFurnace typesMetal rolling arrangementsChemical compositionHigh surface

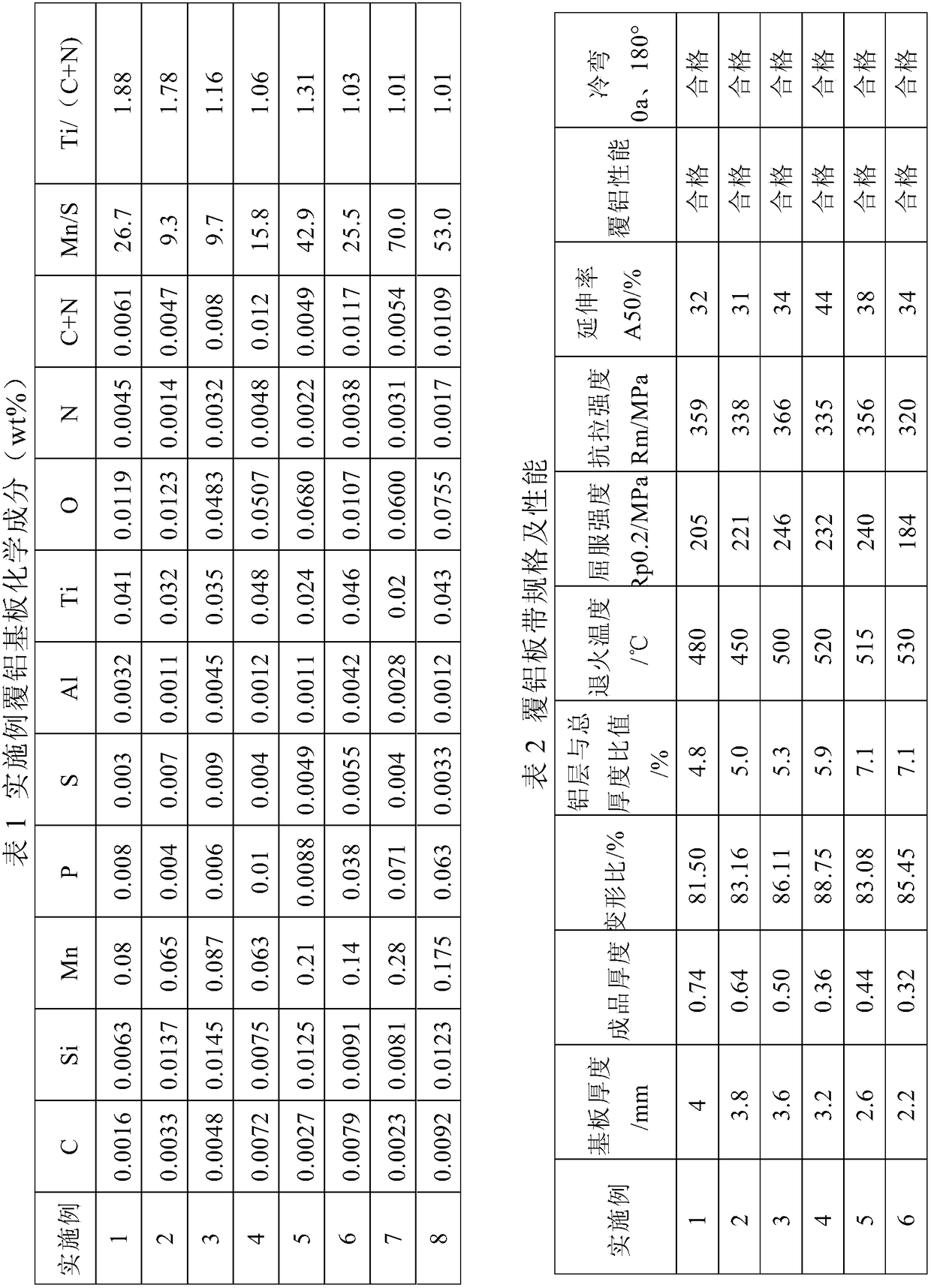

The invention provides a high-surface-quality aluminum-coated plate strip with an easy stamping machining function and a production method thereof. The aluminum-coated plate strip is composited of analuminum strip and a steel strip; the steel strip comprises the chemical compositions of, by weight, no more than 0.01% of C, 0.006-0.015% of Si, 0.05-0.3% of Mn, no more than 0.015% of P, no more than 0.01% of S, no more than 0.005% of Al, no more than 0.005% of N, 0-0.05% of Ti, 0.01-0.08% of O, and the balance Fe and unavoidable impurities; and the following formulas are met, specifically, C+N<=0.012%, Mn / S>=8, and Ti / (3.42N+4C)>=1. The aluminum-coated plate strip has good steel and aluminum bonding properties and adapts to single pass large deformation, and stamping machining performance and the high surface quality are achieved; and the aluminum-coated plate strip meets 300 MPa or above of tensile strength, the elongation exceeds 30%, and the aluminum-coated plate strip can replace analuminum-plated plate to be used for production of automobile engine sound-insulation covers, home appliance panels, food processing trays and the like.

Owner:BAOSHAN IRON & STEEL CO LTD

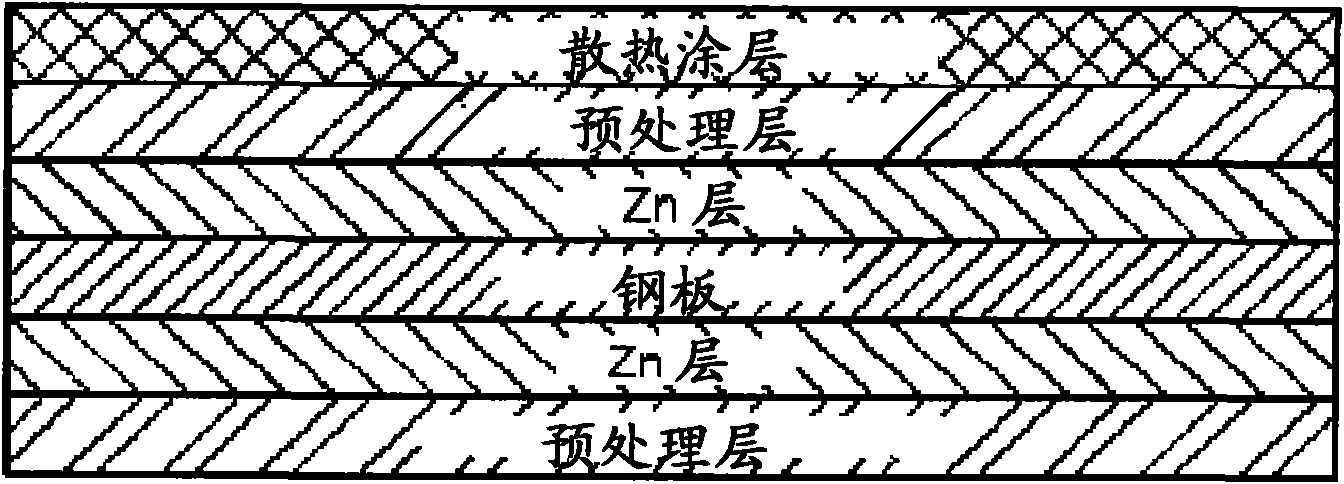

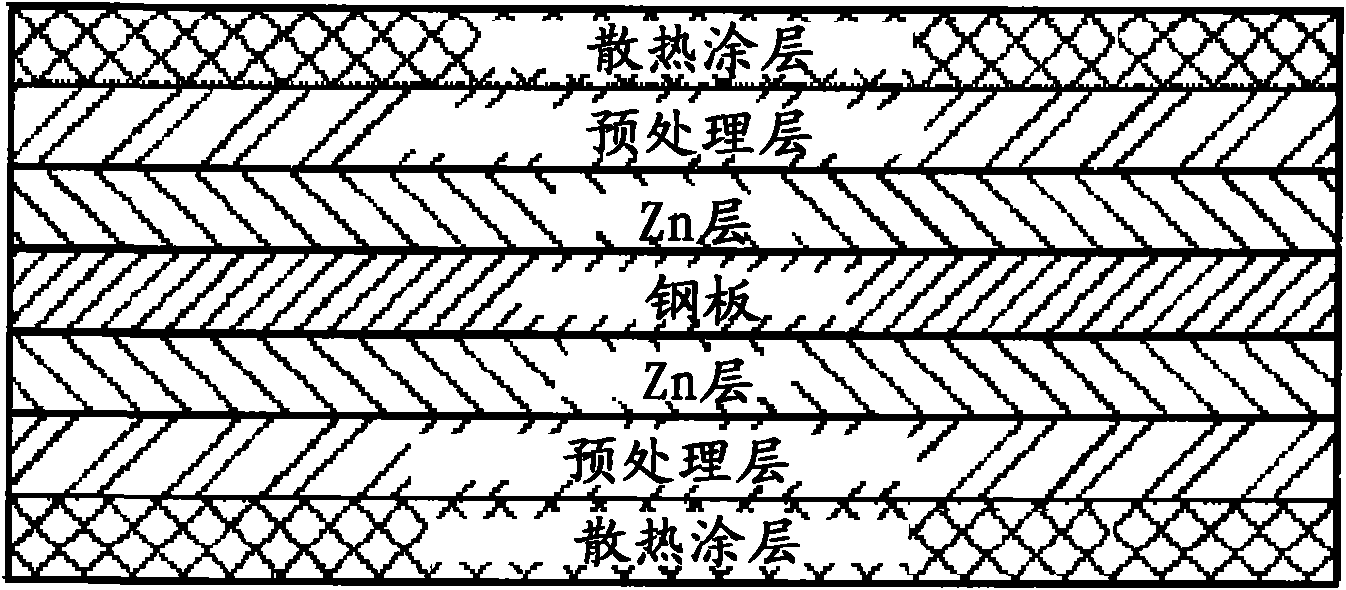

Excellent heat-dissipating black resin composition, method for treating a zinc coated steel sheet using the same and steel sheet treated thereby

InactiveCN101573403AExcellent heat absorption/radiation propertiesGood physical propertiesMaterial nanotechnologyCarbon nanotubesEpoxyPolyolefin

The present invention provides a heat-dissipating black resin composition having excellent physical properties such as heat-dissipating property, workability, corrosion resistance, solvent resistance, coating adherence and gloss and being free from chromium and used for surface treatment of a zinc coated steel sheet, a method for treating a zinc coated steel sheet, and a zinc coated steel sheet treated thereby. The heat-dissipating black resin composition includes, based on 100 parts by weight of the heat-dissipating black resin composition: 10 to 60 parts by weight of a resin composition which at least one main resin and a melamine-based curing agent are mixed in a weight ratio of 10:2-7, the main resin being selected from the group consisting of polyester resin, epoxy resin, polyolefin resin, polyurethane resin, fluorine resin, phenol resin, acryl resin and polycarbonate resin; 1 to 10 parts by weight of at least one pigment selected from the group consisting of carbon black and carbon nano tube; 1 to 10 parts by weight of a matting agent; and the balance of a solvent. Also, the method for treating a steel sheet with a heat-dissipating black resin composition includes: coating a steel sheet with the heat-dissipating black resin composition so that a thickness of a dry coating film is in a range of 3 to 30 micrometers; and drying the heat-dissipating black resin composition, and the steel sheet is treated according to the method. The resin-coated steel sheet includes a thin resin layer, shows excellent heat- absorbing / dissipating properties, has excellent physical properties such as corrosion resistance, press workability, surface electrical conductivity and solvent resistance, and is environmental- friendly since it is free from a chromium component.

Owner:POHANG IRON & STEEL CO LTD

Low-cost aging resistant household appliance color coated sheet and production method thereof

The invention discloses a low-cost aging resistant household appliance color coated sheet. The color coated sheet is made of, by weight, 0.010-0.030% of C, no more than 0.030% of Si, 0.015-0.35% of Mn, no more than 0.020% of P, no more than 0.020% of S, 0.020-0.060% of A1s, 0.005-0.020% of Ti, no more than 0.0040% of N, and the balance Fe and other unavoidable impurities. The invention further discloses a production method of the household appliance color coated sheet. The method comprises the steps of molten iron steelmaking, continuous casting, hot rolling, acid pickling, cold rolling, hot galvanizing, finishing, pulling correcting and color coating. In the hot galvanizing step, the continuous annealing temperature is 785-795 DEG C. The sum of the ductility of the finishing step and the ductility of the pulling connecting step is 1.0-1.2%. The low-cost aging resistant household appliance color coated sheet and the production method thereof are simple in technology, high in strength and rigidity, good in stamping property, aging resistant, low in cost, and capable of being widely used in the technical field of the iron and steel smelting technology.

Owner:武汉钢铁有限公司

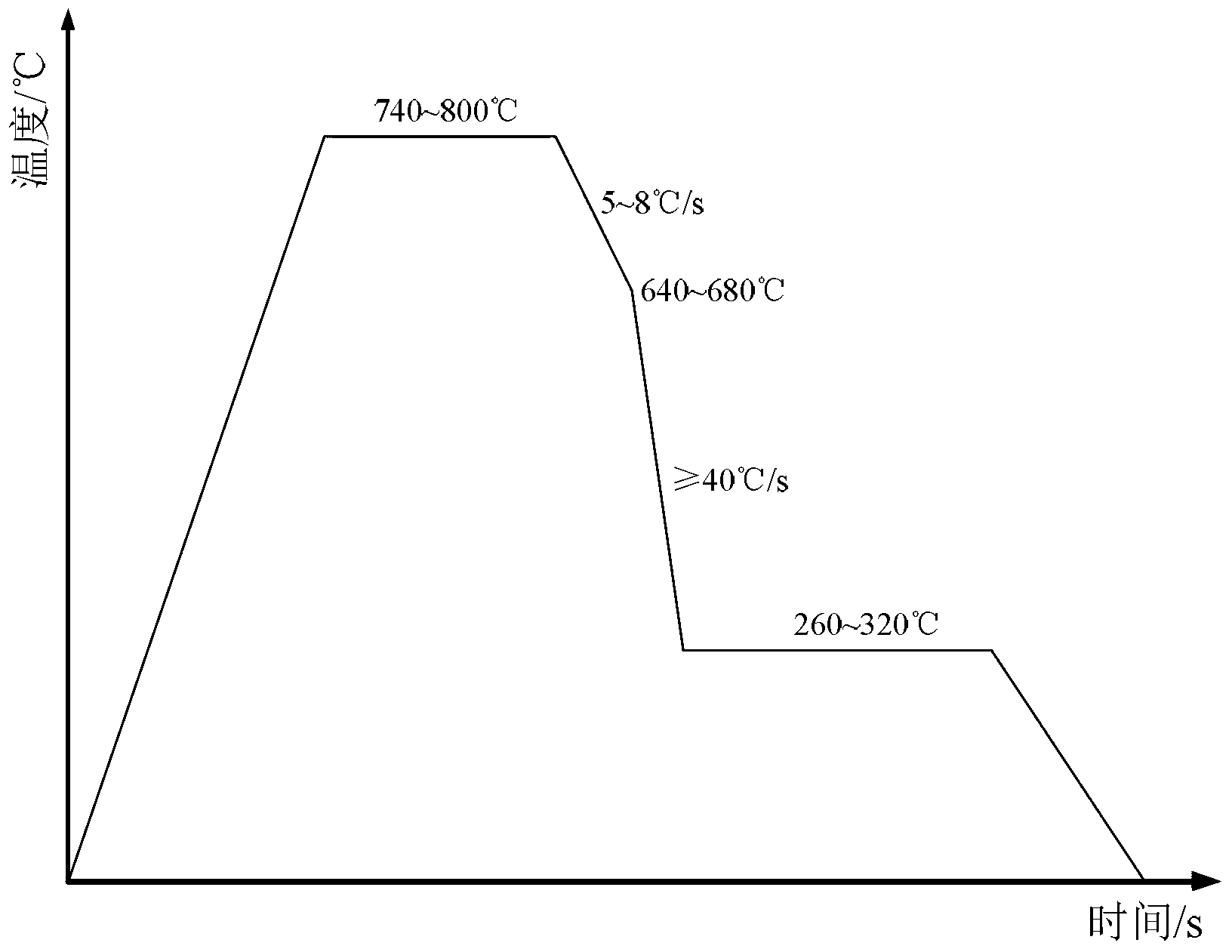

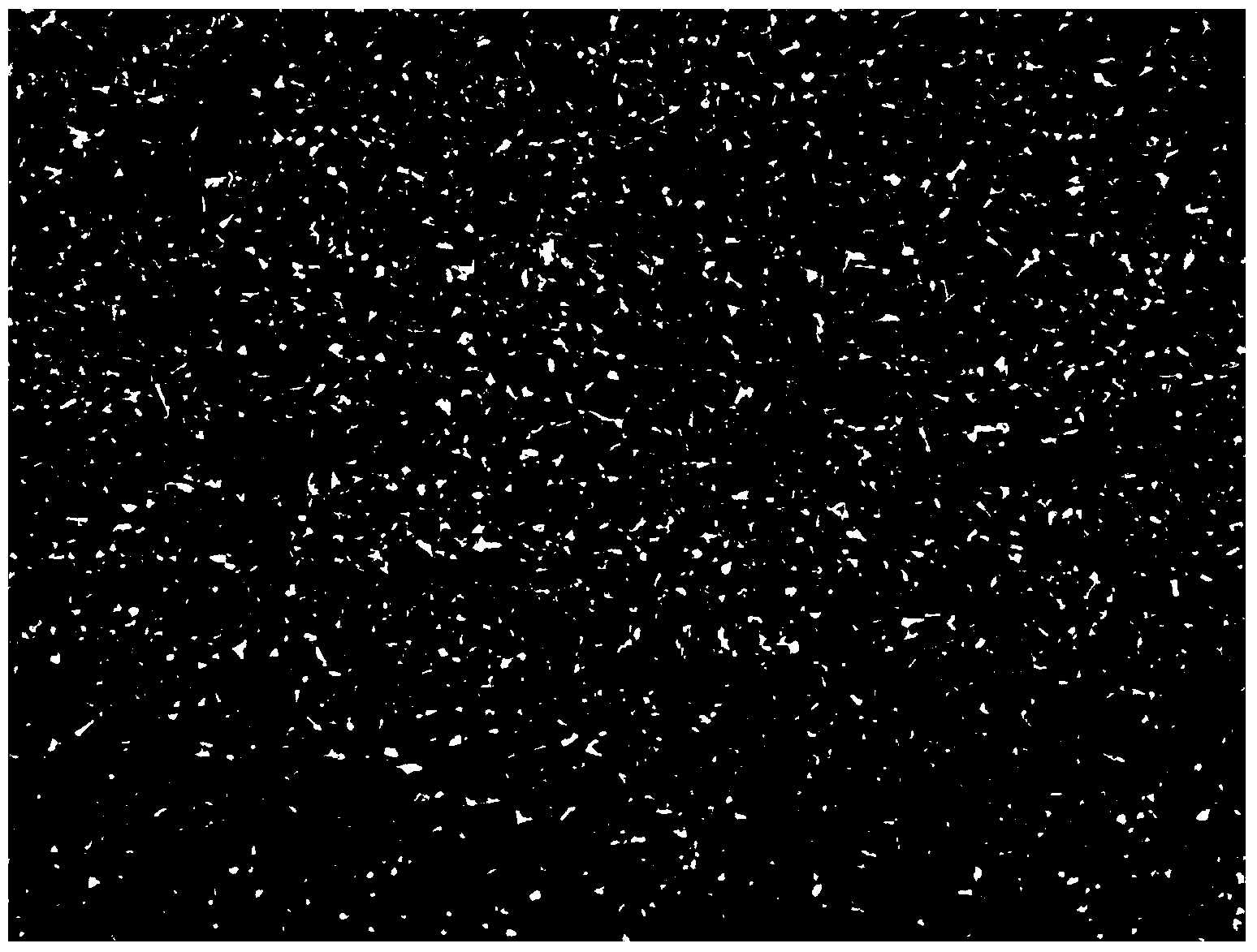

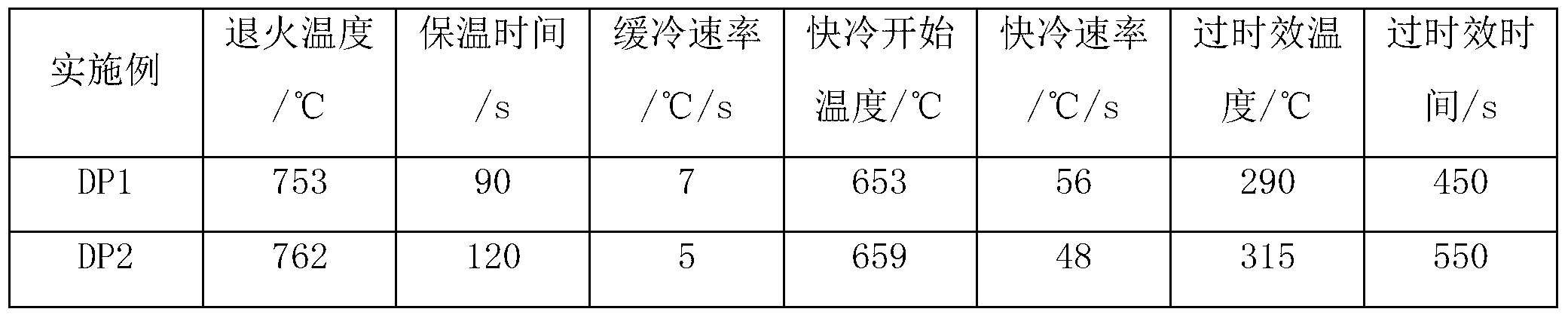

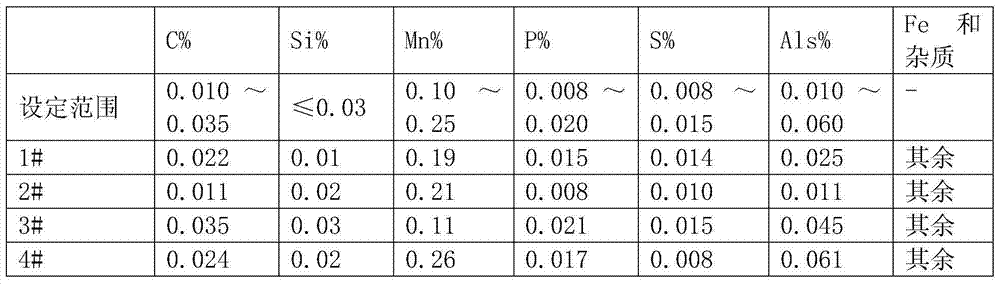

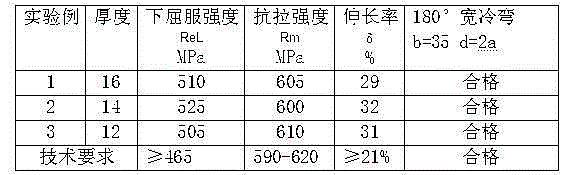

Cold-rolled dual-phase sheet steel with 400MPa-level tensile strength and preparation method thereof

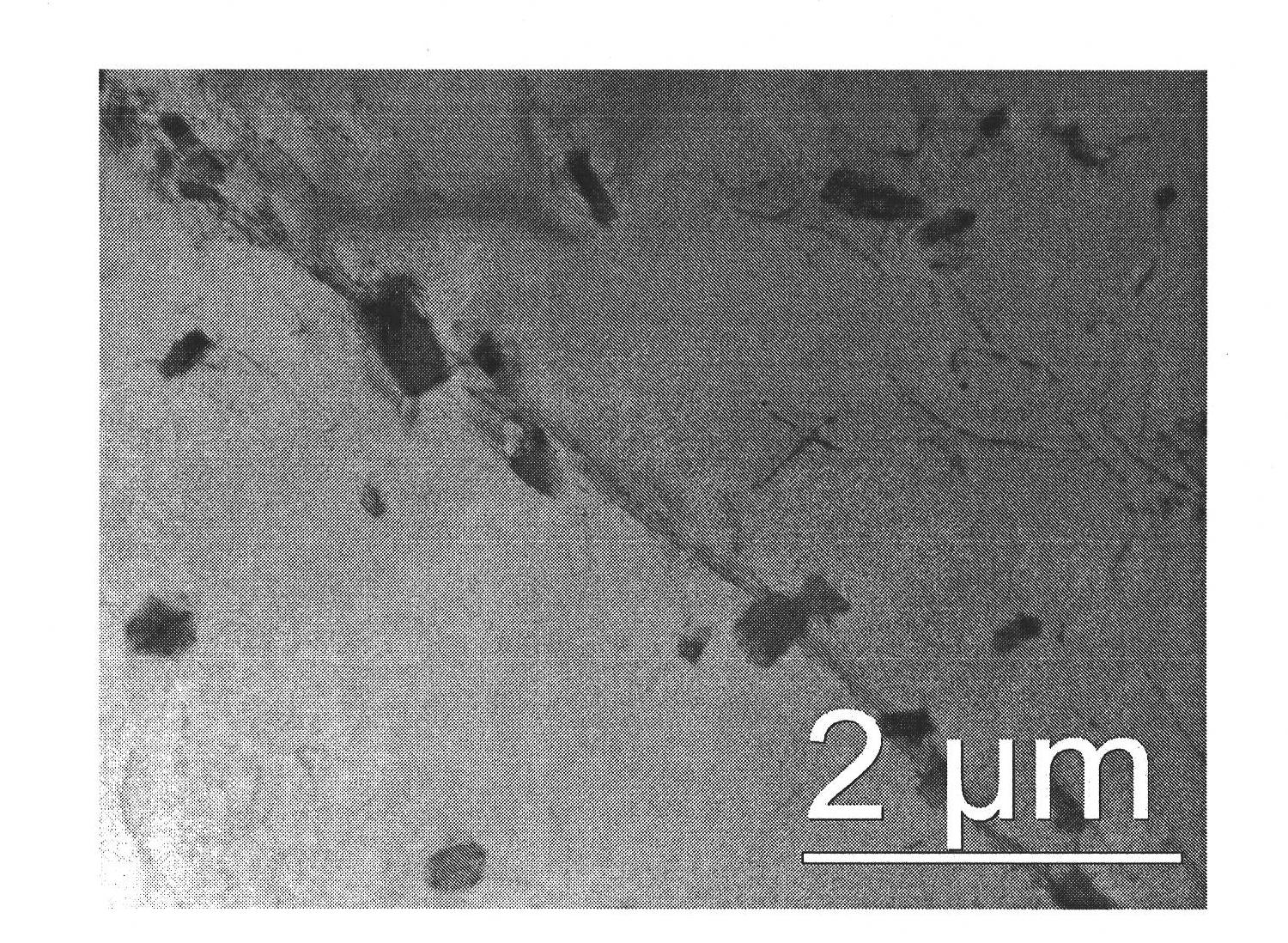

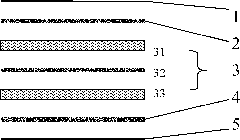

The invention discloses a cold-rolled high-strength dual-phase sheet steel with 400MPa-level tensile strength for a car and a preparation method thereof, and belongs to the field of steel materials. The double-phase sheet steel adopts a ferrite-martensite dual-phase structure serving as the main structure and contains 4 to 9% of martensite and comprises the following chemical components by mass percent: 0.01 to 0.05% of C, 0.1 to 0.4% of Si, 1.2 to 1.6% of Mn, 0.1 to 0.4% of Cr, 0.02 to 0.05% of Als, not greater than 0.005% of N, not greater than 0.02% of P, not greater than 0.01% of S, and the balance of Fe and inevitable residual impurity elements. The preparation method comprises the steps of hot rolling, acid pickling, cold rolling and heat treating. The produced cold-rolled double-phase sheet steel has the yield strength of 200 to 250MPa, tensile strength of 400 to 450MPa and percentage of elongation of 30 to 35%.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

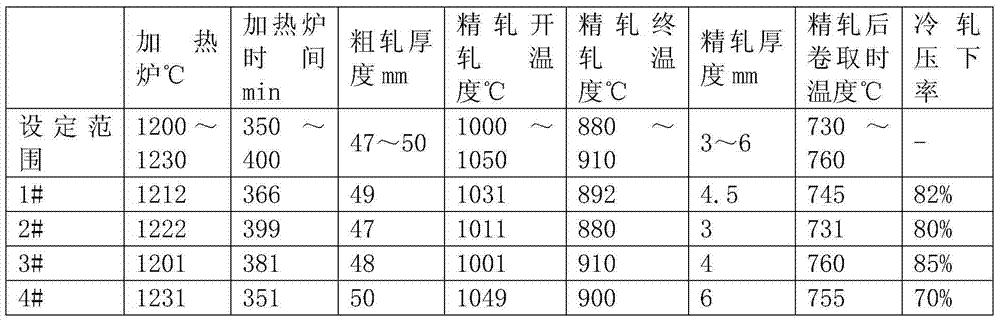

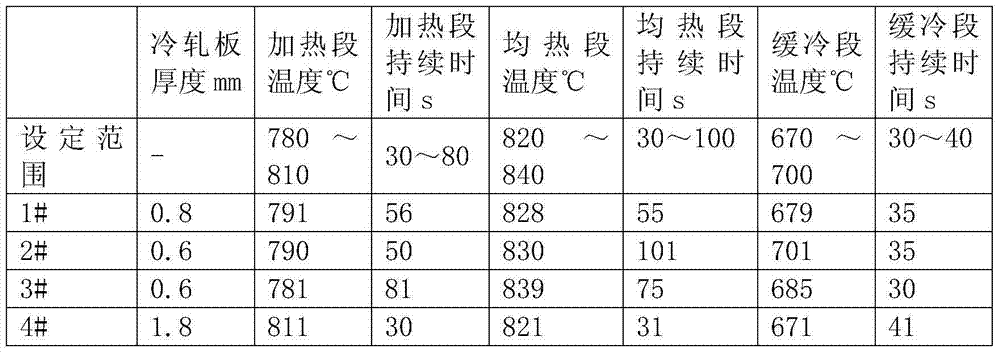

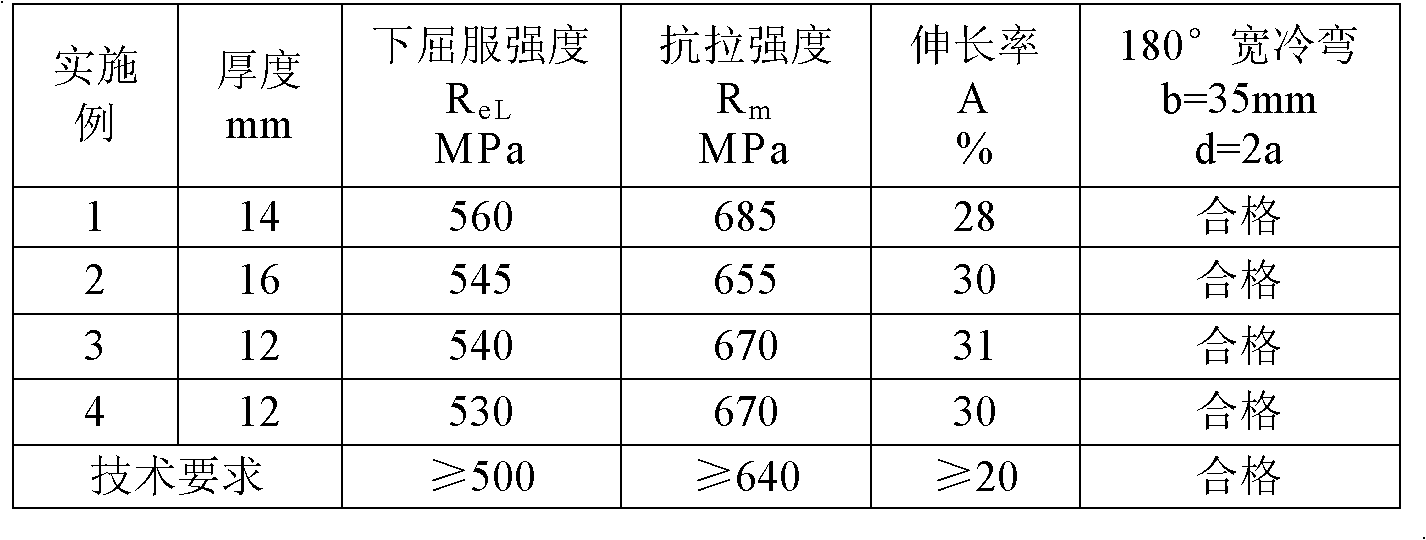

Low-cost cold-rolled steel plate production method

The invention relates to a low-cost cold-rolled steel plate production method, which comprises the following steps: controlling the compositions of molten steel; casting the molten steel into a steel billet; heating to 1200-1230DEG C; rough-rolling; refined rolling; reeling into a steel strip reel; cold rolling; continuously annealing, wherein a heating zone is at 780-810DEG C, a soaking zone is at 820-840DEG C, a retarded cooling zone is at 670-700DEG C, a rapid cooling zone is at 320-350DEG C, and an overaging zone is at 340-380DEG C; and cooling to room temperature. The production method is not required for adopting a deep decarbonization technology and adding alloy elements of Ti and the like, so that the production cost is lowered, the mechanical performance of the product achieves the yield strength of 140-170MPa, tensile strength of 280-320MPa, elongation rate of more than or equal to 45.0%, plastic strain ratio of more than or equal to 2.4 and strain hardening index of more than or equal to 0.22, to meet the market requirement, and has good impact molding processability and better material strength.

Owner:攀钢集团西昌钢钒有限公司 +1

Steel for 13-dwt vehicle axle housing and production method thereof

The invention relates to steel for 13-dwt vehicle axle housing and a production method thereof. The steel comprises the following chemical components by weight: 0.04%-0.08% of C, 0.10%-0.60% of Si, 1.3%-1.45% of Mn, not more than 0.025% of P, not more than 0.08% of S, 0.01%-0.06% of Al, 0.04%-0.06% of Nb, 0.03%-0.05% of Ti, and the balance of Fe and inevitable impurities; The preparation method comprises the following steps: converter smelting; vacuum treatment; continuous casting; casting blank heating; rough rolling; finish rolling by a 7 frame; cooling with laminar flow; coiling. Because of the low carbon content of the steel of the invention, the steel has excellent stamping performance and welding performance, has a stable dimension after cold forming, and completely meets the requirements for manufacturing and application of 13-dwt vehicle axle housing. Through bench tests of the manufactured 13-dwt vehicle axle housing assembly, the product has excellent vertical bending fatigue life, vertical bending rigidity, and vertical bending static strength, and completely meets the requirements of users.

Owner:武汉钢铁有限公司

Soft tin plate produced by using continuous annealing mode

InactiveCN101864534AUniform performanceEasy to shapeFurnace typesManufacturing convertersChemical compositionContinuous annealing

The invention provides a soft tin plate produced by using a continuous annealing mode. A raw material namely low-carbon aluminum killed steel of the tin plate comprises the following chemical components in percentage by weight: 0.01 to 0.03 percent of C, less than or equal to 0.025 percent of Si, 0.10 to 0.25 percent of Mn, less than or equal to 0.015 percent of P, less than or equal to 0.012 percent of S, 0.04 to 0.08 percent of Als, less than or equal to 0.004 percent of N, and the balance of Fe and inevitable impurities. The soft tin plate is produced by using the continuous annealing mode, and has the advantages of uniform performance, good plate shape and good surface quality. Simultaneously, the soft tin plate also has high stamping processability. Besides, the produced soft tin plate also has high corrosion resistance, has a very short production time and a shorter production cycle, saves production cost, has small production difficulties, and is easy to be implemented in large-scale production.

Owner:武钢集团有限公司

Duplex stainless steel plate having excellent press moldability

ActiveCN102356173AGood stamping performanceGood effectFurnace typesThin material handlingPhase fractionMaterials science

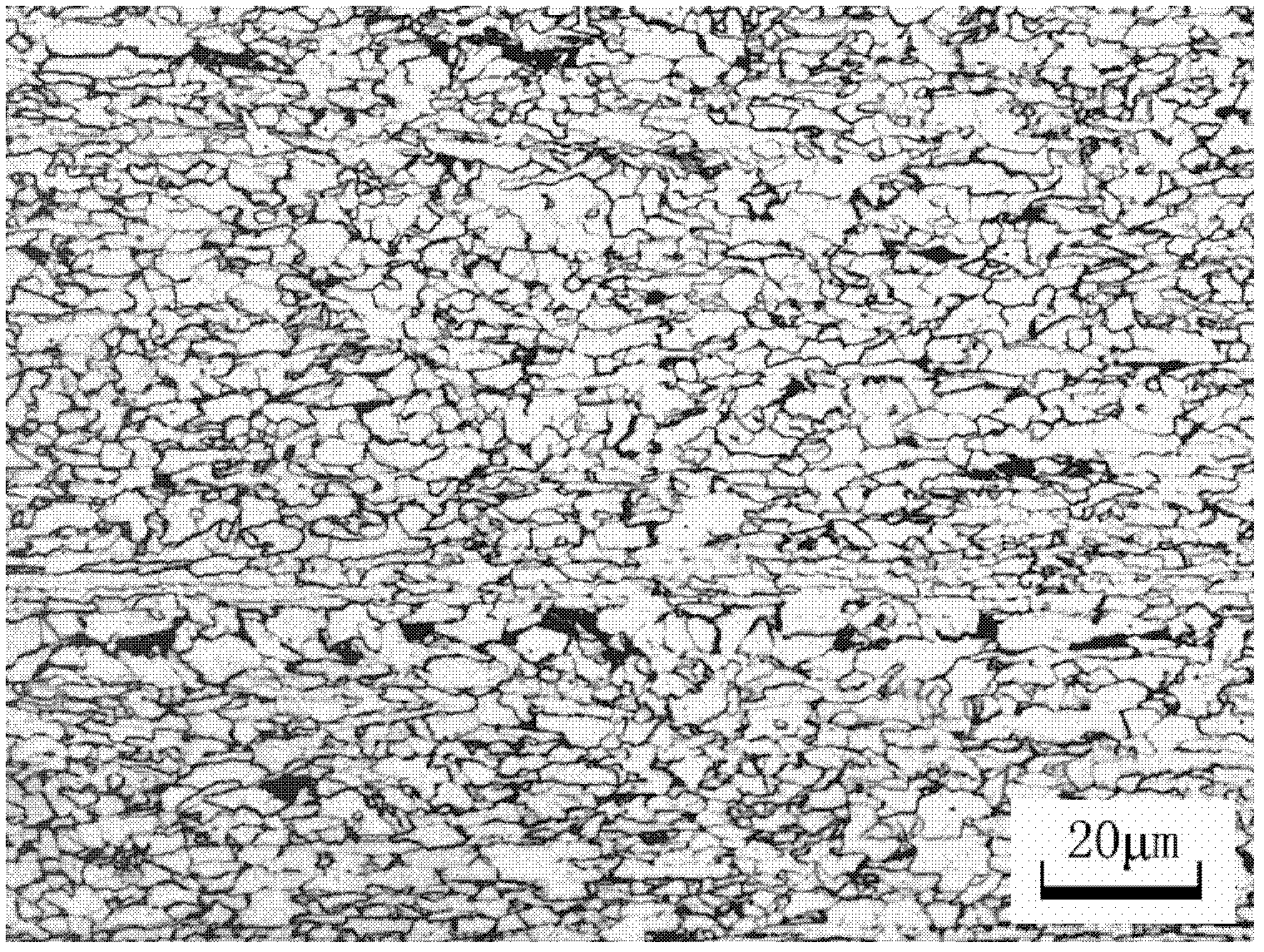

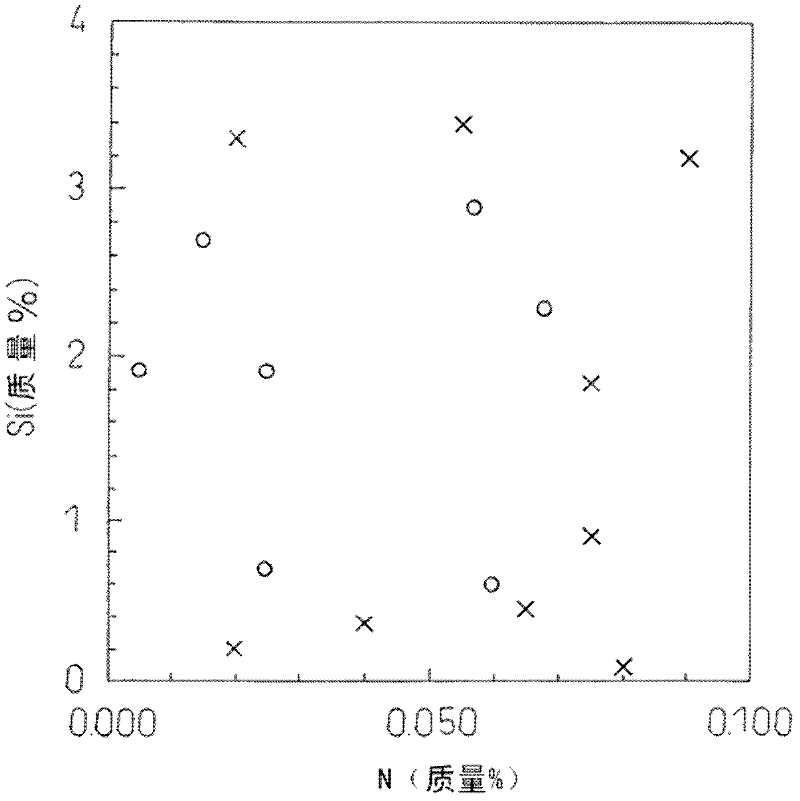

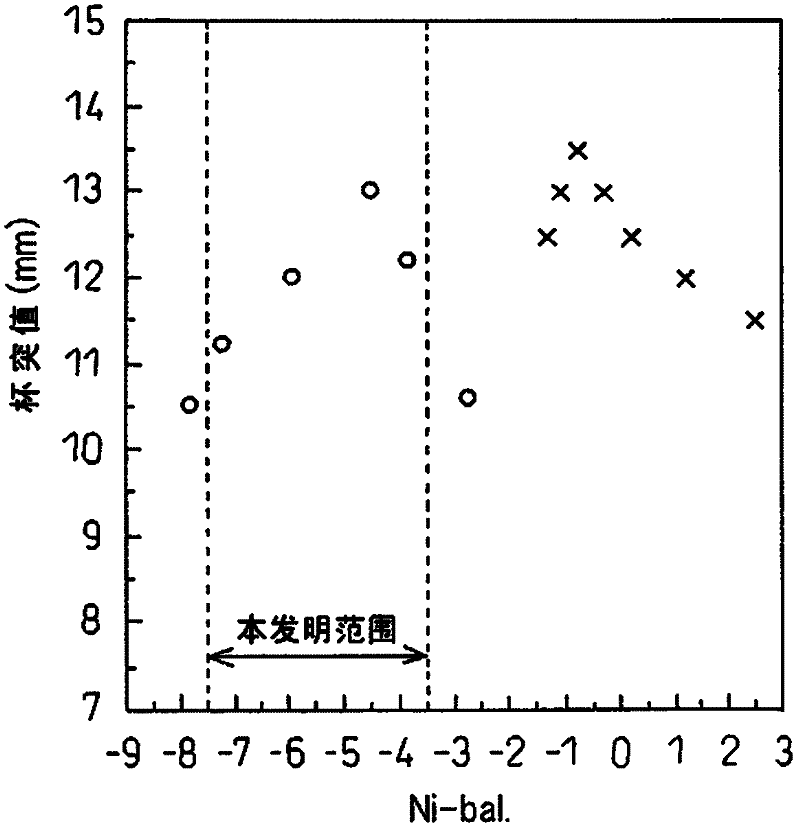

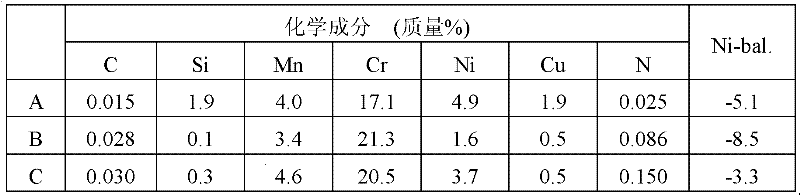

Disclosed is a duplex stainless steel plate having excellent press moldability, in which the balance between steel components and Ni and the austenite phase fraction are defined so as to show a 0.2% stress and an Erichsen value similar to those of austenitic stainless steels such as SUS 304. The duplex stainless steel plate contains 0.05 % by mass or less of C, 0.5 to 3% by mass of Si, 1 to 5% by mass of Mn, 16 to 21% by mass of Cr, 1 to 6% by mass of Ni, 0.5 to 3% by mass of Cu and 0.07% by mass or less of N, and has a Ni-bal. value determined in accordance with formula <1> shown below of -7.5 to -3.5 inclusive, with the remainder being Fe and unavoidable impurities. The duplex stainless steel plate has an austenite phase fraction of 50 to 95% inclusive, with the remainder being a ferrite phase. Ni-bal. = 30(C+N) + Ni + 0.5Mn + 0.3Cu - 1.1(Cr+1.5Si) + 8.2 <1>

Owner:NIPPON STEEL & SUMIKIN STAINLESS STEEL CORP

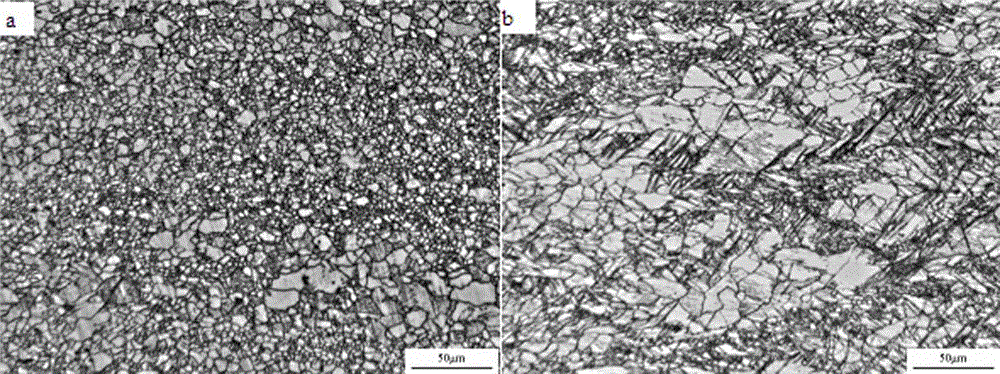

Processing method for increasing stamping formability of 6111 aluminium alloy automobile sheet

InactiveCN101885000ASolve bottlenecksImprove stamping yieldRoll mill control devicesMetal rolling arrangementsRoom temperatureIngot

The invention relates to a processing method for increasing the stamping formability of the 6111 aluminium alloy automobile sheet. The method comprises the following steps: 1. performing heat treatment to 6111 alloy ingot, which is prepared through semicontinuous casting, at 220-480 DEG C for 1-15h, heating to 550 DEG C with the furnace, keeping temperature for 24h to perform the conventional homogenizing treatment; 2. cropping the ingot and milling the face of the ingot, heating to 440-450 DEG C for hot rolling, wherein hot rolling adopts the mode of longitudinal and lateral alternation, thetotal rolling deformation is more than 85%, the finishing temperature is more than 300 DEG C and the final thickness of the hot rolled sheet is 6mm; 3. keeping the temperature of the hot-rolled sheetto 420-430 DEG C for 1h-2h, performing intermediate annealing, performing cold rolling to ensure the thickness of the sheet is 0.8 mm-1.0 mm, wherein the cold deformation is more than 75%; 4. keepingthe temperature of the cold-rolled sheet to 550 DEG C for 7min, performing solution treating and water quenching, standing at the room temperature for 1min-48h; 5. performing pre-aging treatment in adrying box at 150-220 DEG C for 4min-15min; and 6. standing at the room temperature for more than two weeks to obtain T4P temper. After the sheet is processed by the method of the invention, the stamping formability and after-painting strength are obviously improved, thus facilitating to increase the rate of stamping products and reduce the stamping cost.

Owner:NORTHEASTERN UNIV LIAONING

Copper-clad plate and processing method thereof

ActiveCN102189722AImprove technical performanceImprove heat resistanceLamination ancillary operationsLaminationGlass fiberSurface layer

The invention discloses a copper-clad plate which at leas comprises a copper foil layer, an upper surface layer and a lower surface layer of glass fiber cloth, and a core material located between the upper surface layer and the lower surface layer, wherein the core material formed by overlapping the glass fiber cloth prepreg and glass fiber non-woven cloth prepreg in any manner. The invention also discloses a processing method of the copper-clad plate, which at least comprises the steps of mixing a glue liquid, gluing, overlapping, pressing and the like. Due to the structure and processing method, the copper-clad plate disclosed by the invention has excellent comprehensive performance, which not only guarantees good heat resistance, electric performance and drug resistance, but also obtains good stamping performance, mechanical strength and size stability; and the production cost is lower. The copper-clad plate disclosed by the invention has stronger adaptability to the PCB (printed circuit board) processing process, causes less loss of the PCB processing equipment, and has lower processing cost; and moreover, the production energy consumption of raw materials is relatively low, and pollution is less.

Owner:SHANGHAI GUOJI ELECTRONICS MATERIALS CO LTD

Optical pressure-sensitive adhesive sheet

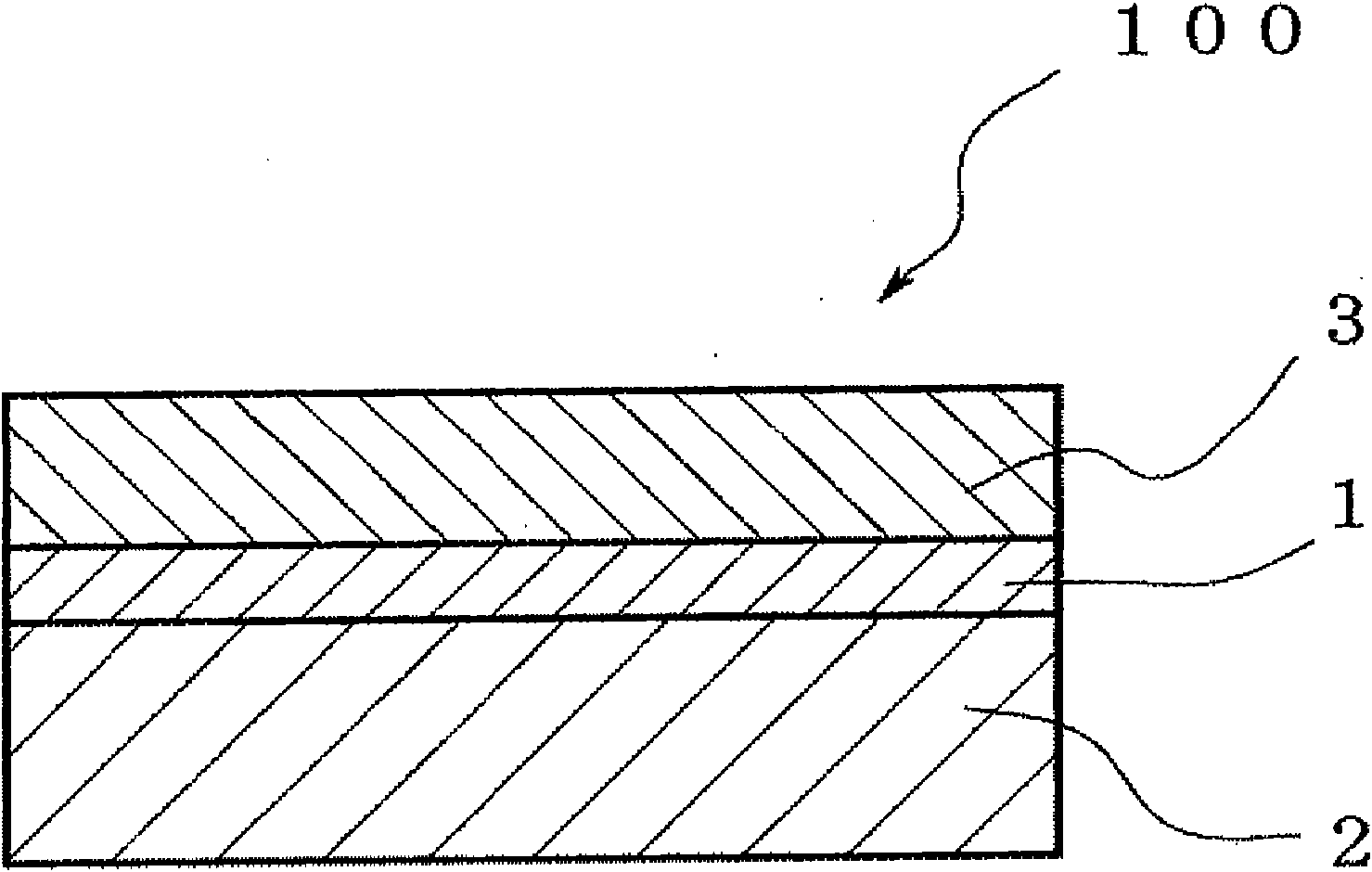

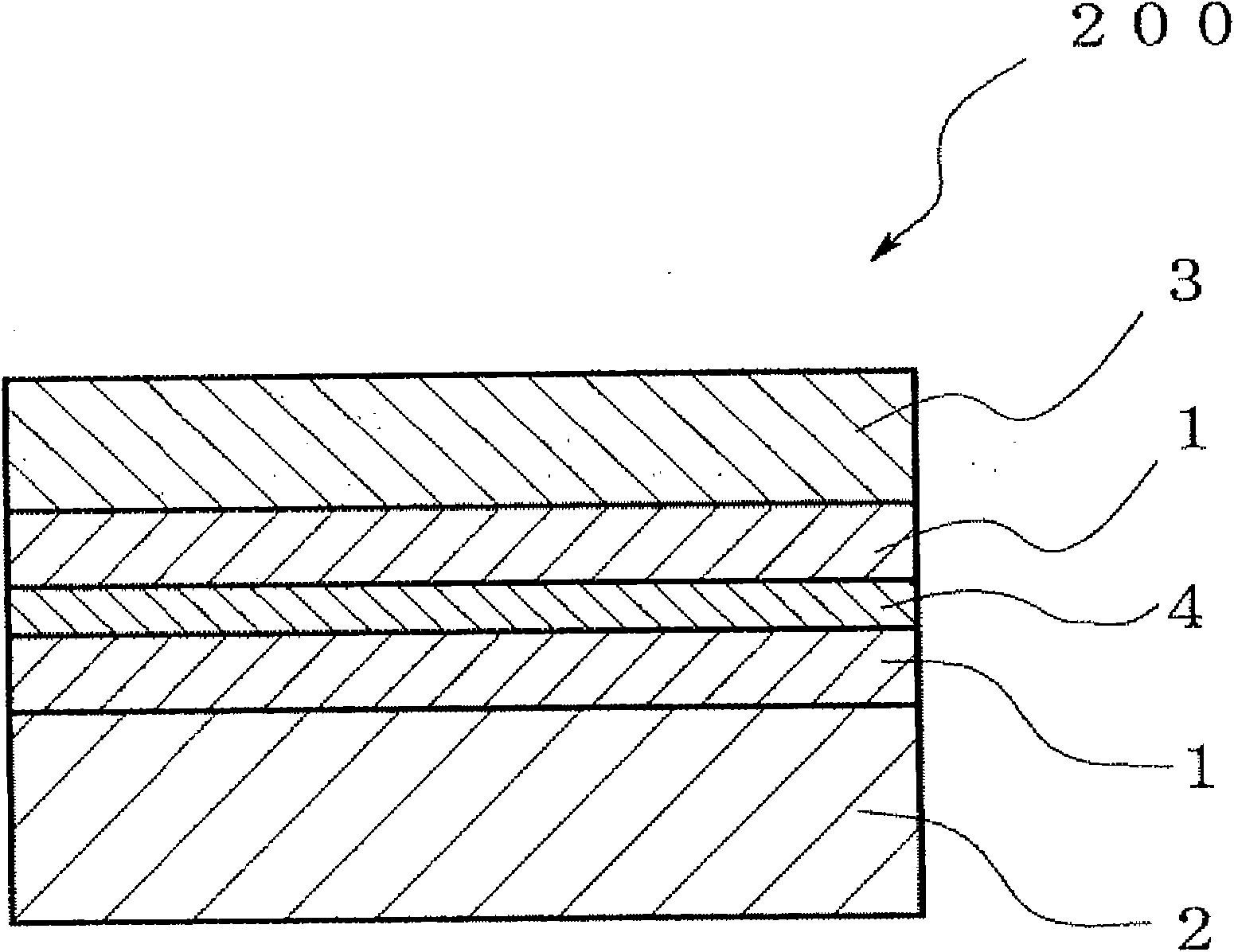

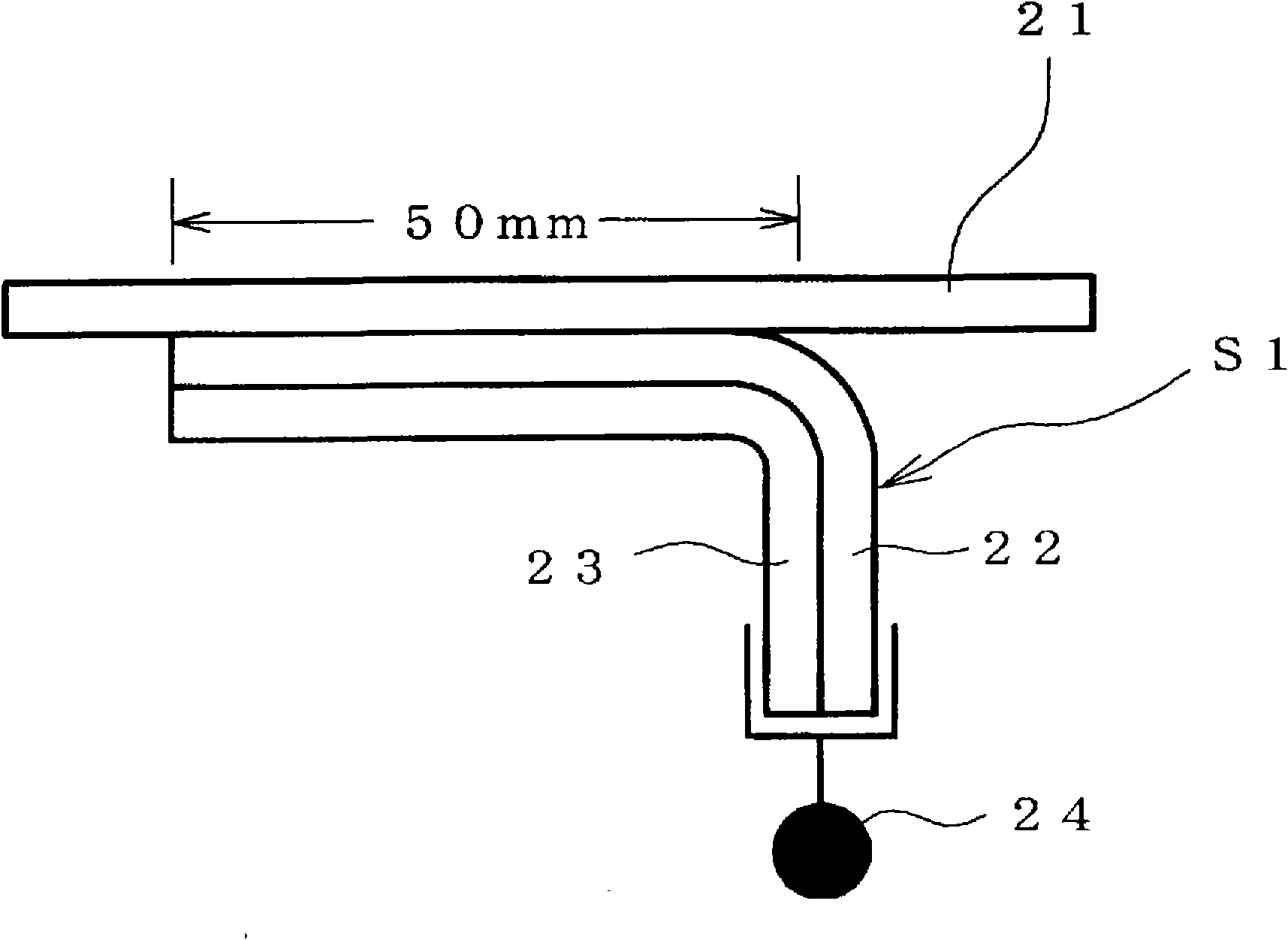

InactiveUS20120064275A1Good stamping performancePromote absorptionSynthetic resin layered productsEster polymer adhesivesBreaking strengthPunching

The present invention provides an optical pressure-sensitive adhesive sheet having excellent punching processability. The optical pressure-sensitive adhesive sheet includes: a pressure-sensitive adhesive body; and a separator on at least one side of the pressure-sensitive adhesive body, where the separator has a Young's modulus of 2 GPa or more in a machine direction and a transverse direction, a breaking strength of 400 MPa or less in a machine direction and a transverse direction, and a thickness of 70 μm or more and 250 μm or less, and a release force of the separator to the pressure-sensitive adhesive body in a 180° peel test at a tensile speed of 30 m / min is 0.8 N / 50 mm or more.

Owner:NITTO DENKO CORP

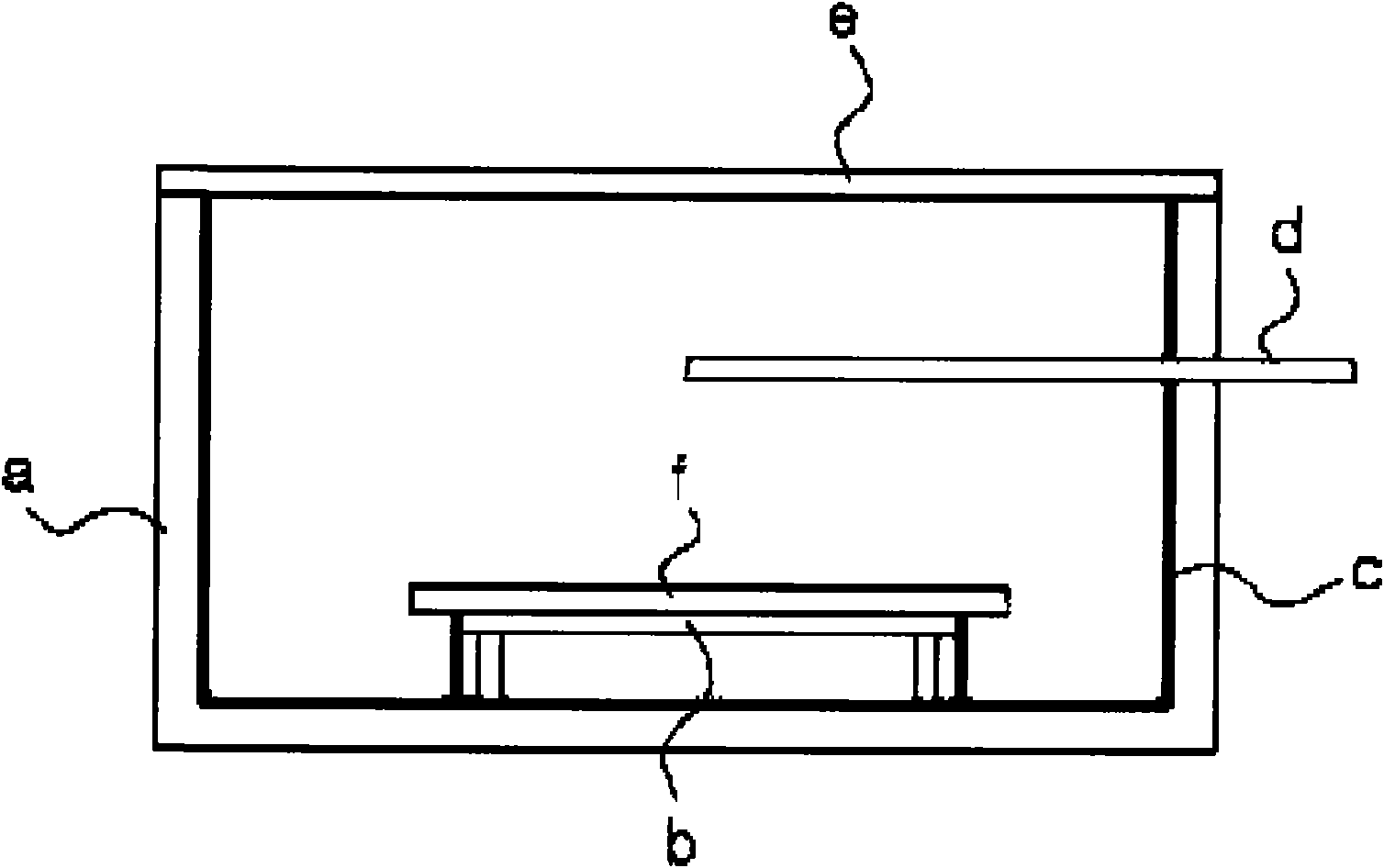

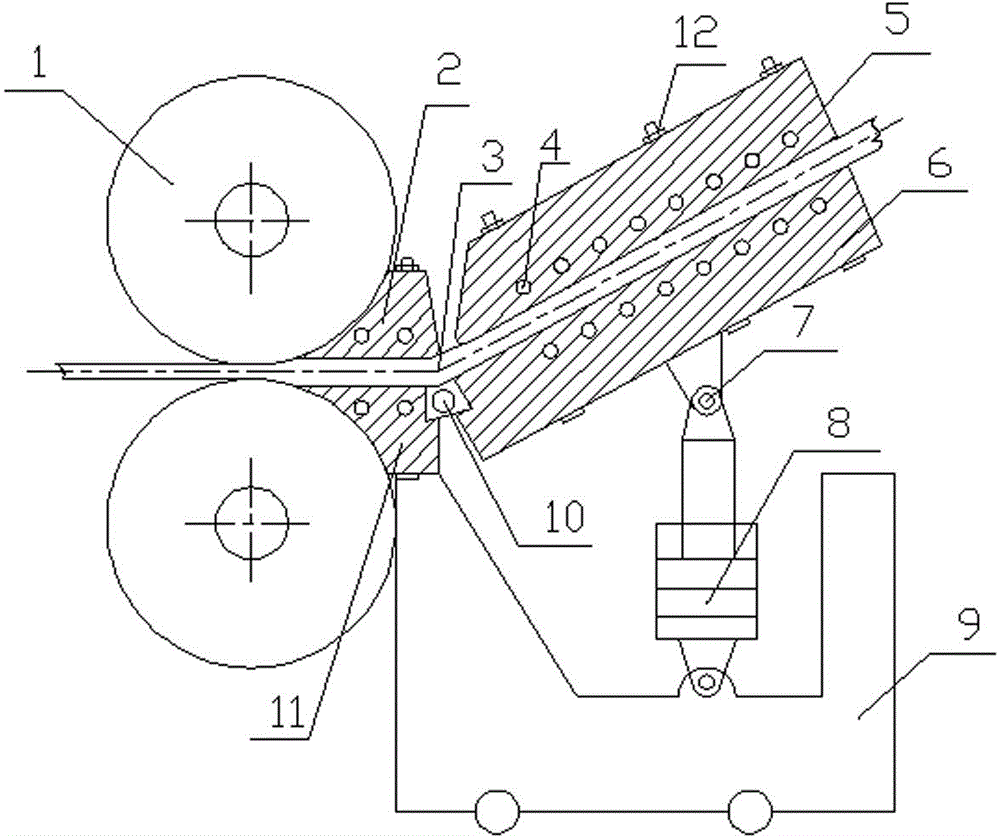

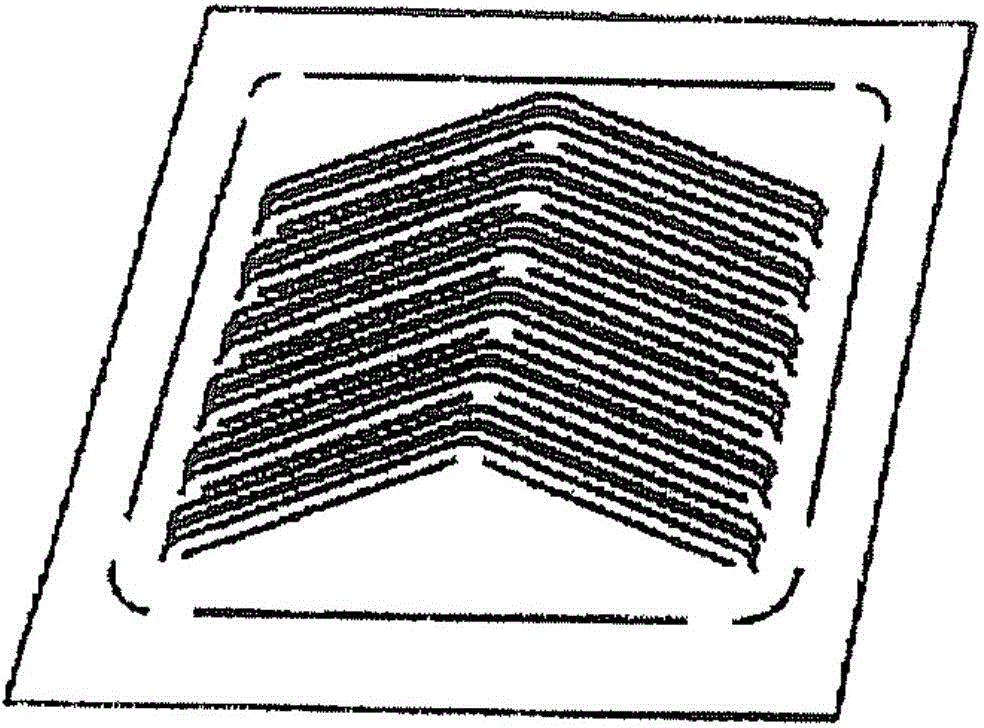

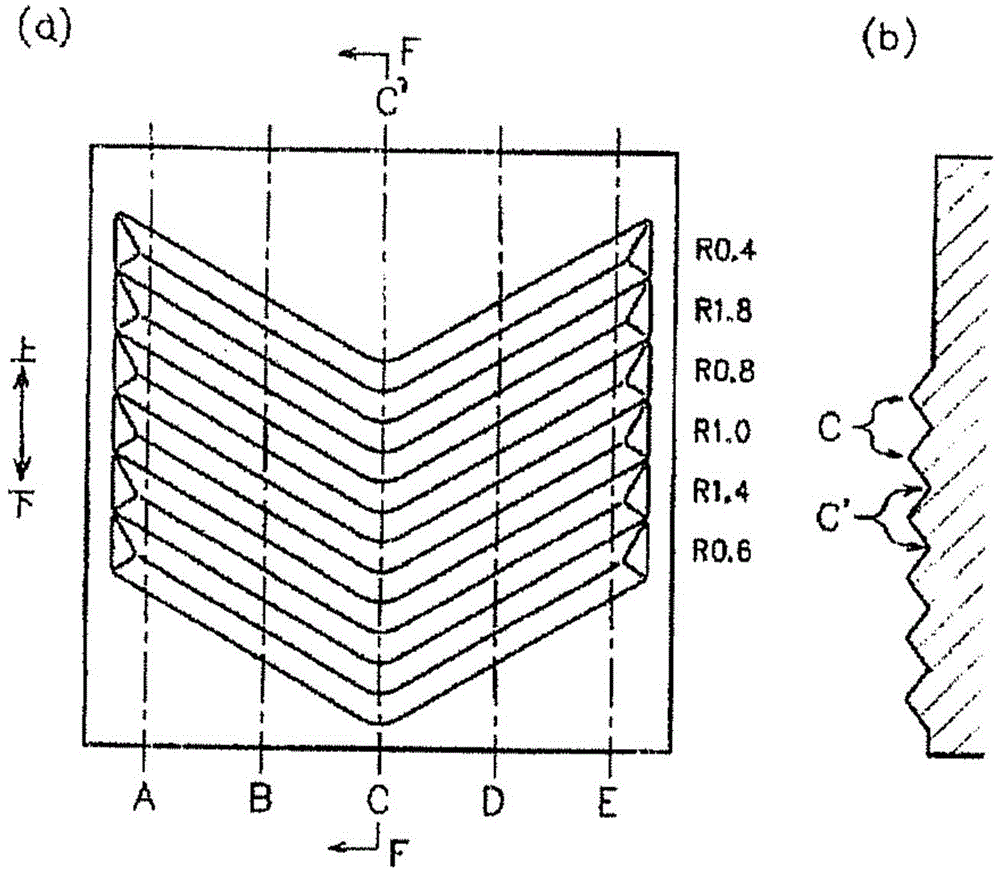

Strong-shear rolling forming method and device for metal plate

ActiveCN104646416AGrain refinementImprove microstructureForging/pressing devicesMetal rolling arrangementsRoll formingShearing deformation

The invention discloses a strong-shear rolling forming method and a strong-shear rolling forming device for a metal plate. Power is provided by friction force between the plate and rollers during rolling deformation, and the plate is subjected to the strong-shear deformation of dies, and then enters a part between the rollers for plate rolling deformation. The device comprises a double-roller rolling mill, a movable die upper template, a movable die lower template, a stand, a fixed die lower template and a fixed die upper template, wherein the fixed die lower template is fixedly arranged on the stand; the movable die lower template is hinged to the fixed die lower template, and is arranged on the stand through an oil cylinder; the fixed die upper template and the movable die upper template are arranged on the fixed die lower template and the movable die lower template through bolts respectively; the double-roller rolling mill is arranged at an outlet of a metal plate passage. The method and the device are flexible in die equal channel angular adjustment and low in cost; the rolling deformation and the shear deformation of the metal plate such as a magnesium plate and an aluminum plate can be effectively combined, crystal grains of the plate can be refined, the texture evolution of the plate can be controlled, and the mechanical performance and the forming performance of the plate can be improved.

Owner:HUNAN UNIV OF SCI & TECH

Economical aging-resistance household appliance colorful-coated substrate and production method thereof

InactiveCN109852894AReduce manufacturing costMeet the intensityHot-dipping/immersion processesPunchingChemical composition

The invention relates to an economical aging-resistance household appliance colorful-coated substrate. The substrate comprises the following chemical components in percentage by mass: 0.001-0.0160 ofC, Si not more than 0.025, 0.10-0.16 of Mn, P not more than 0.015, S not more than 0.012, 0.020-0.050 of Als, N not more than 0.004, and the balance of Fe and inevitable impurities. A production method of the substrate comprises the procedures of desulfurization of molten iron, converter smelting, RH vacuum treatment, continuous casting, inspection and cleaning of plate blanks, heating of the plate blanks, hot continuous rolling, laminar cooling, winding, acid washing, cold rolling, hot galvanization, polishing, finishing, oil coating and packing. The substrate can meet the strength and the hardness needed by household appliance plates, solves the aging, achieves excellent punching performances, facilitates production of deep-punched and deformation-complicated household appliance parts byusers, reduces such defects as cracking during punching, line slippage or edge formation on bent surfaces, and improves the yield of colored plates.

Owner:SD STEEL RIZHAO CO LTD

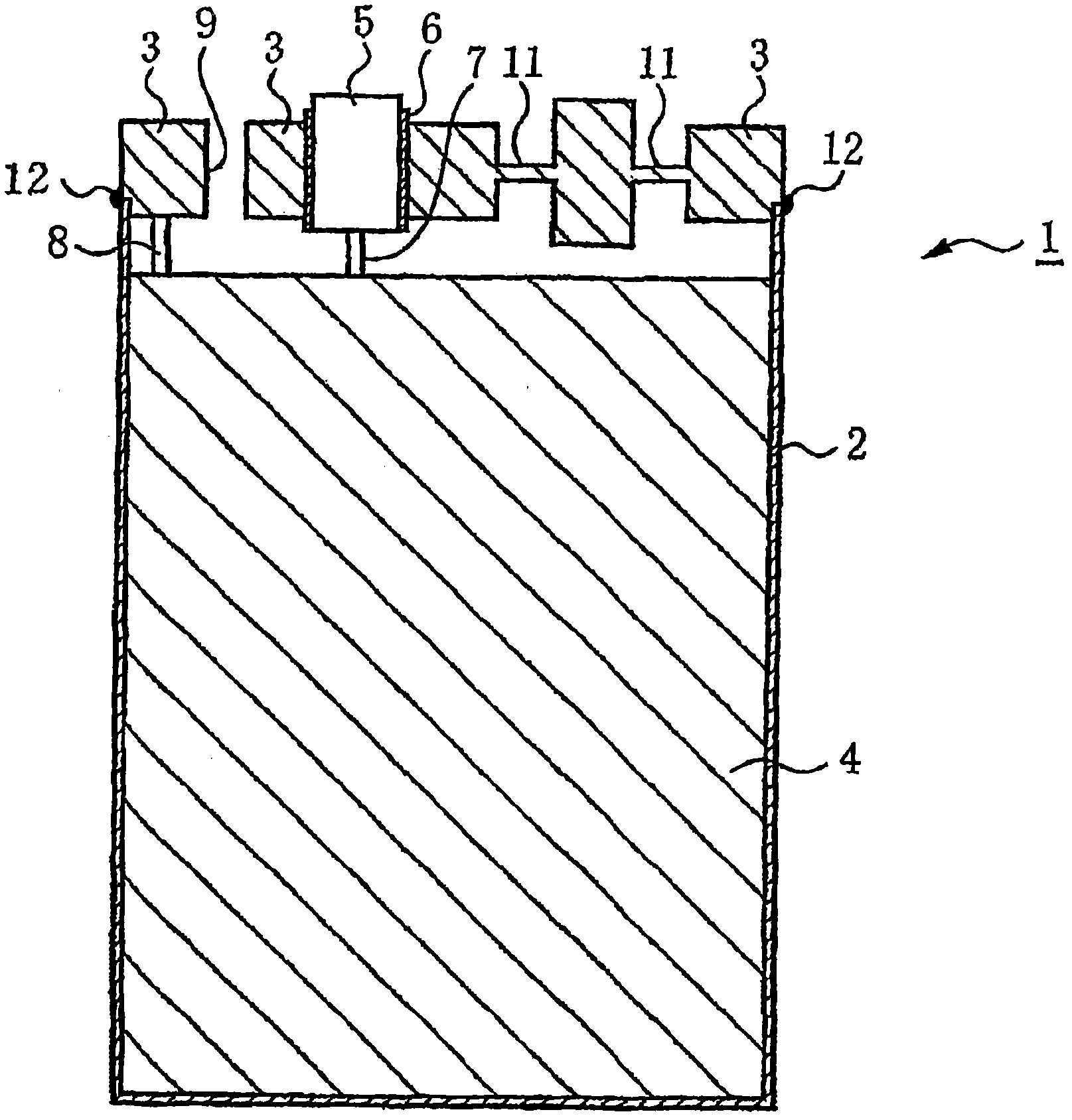

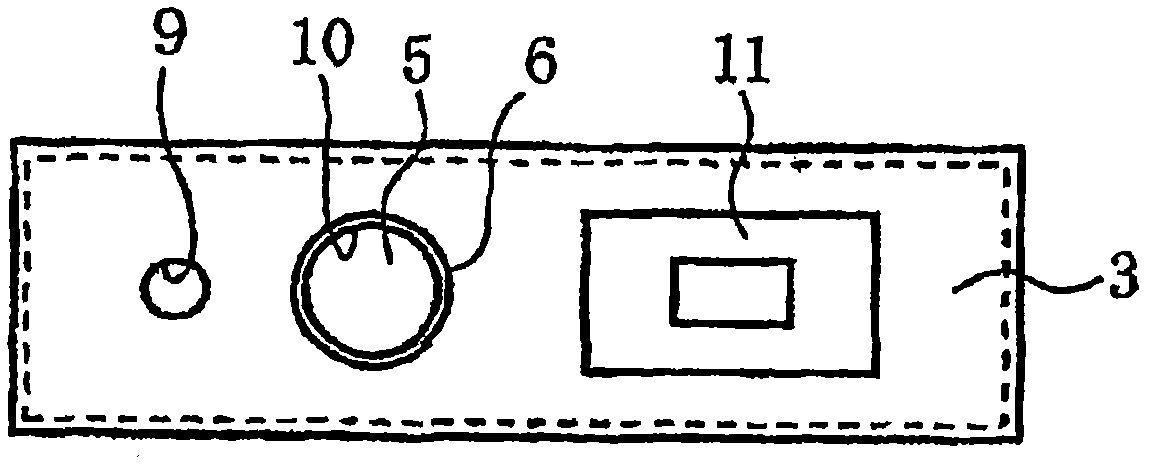

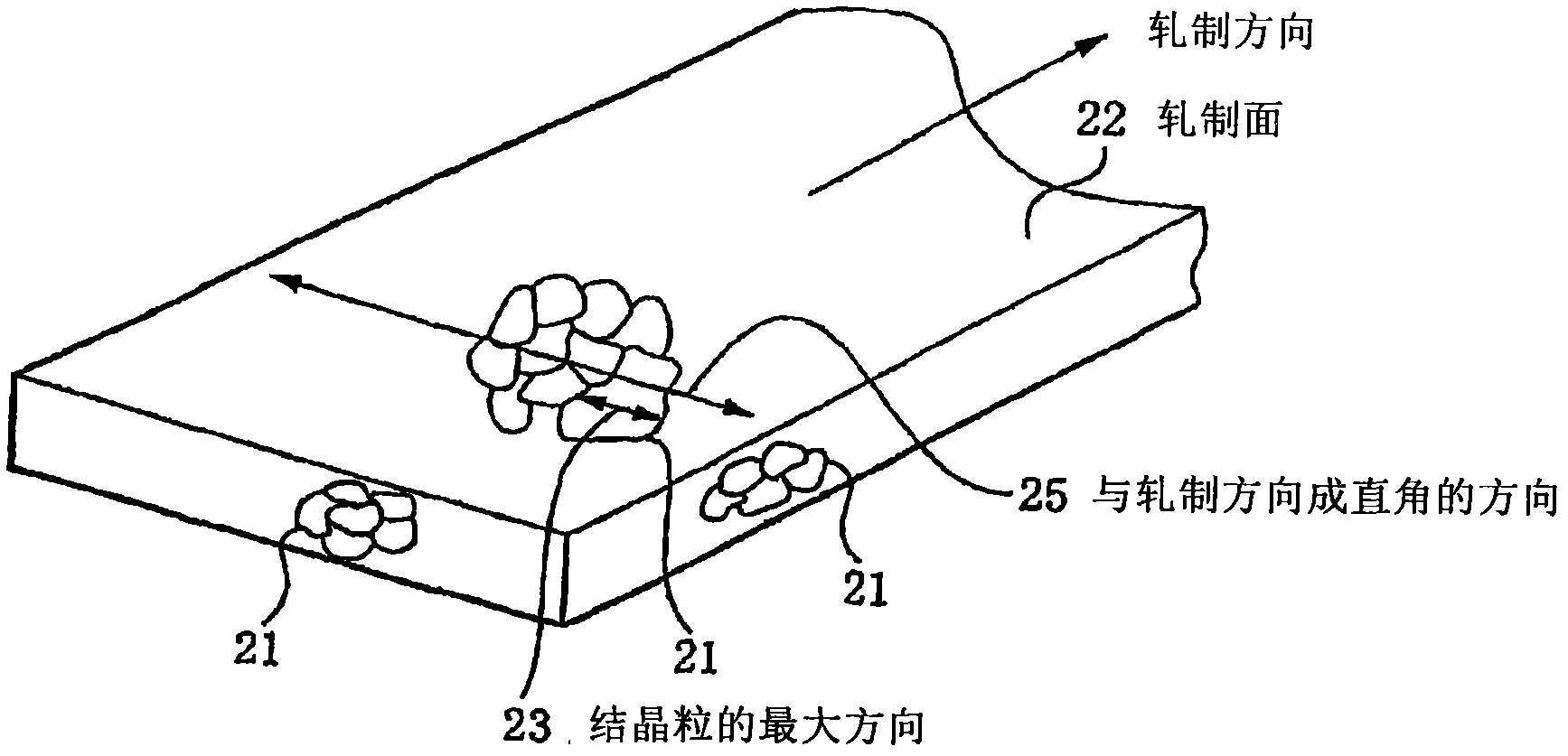

Aluminum alloy sheet for battery cover and its production method

ActiveCN102136554AGood precisionReduced compressive strength inconsistenciesCell lids/coversMetal rolling arrangementsInternal pressureImpurity

An aluminum alloy plate for a battery case and a manufacturing method thereof are provided to obtain desired internal pressure strength, reduce a deviation of internal pressure strength, and form a thin explosion-proof part accurately by forming the aluminum alloy plate with fine crystal grains. An aluminum alloy plate for a battery case(2) comprises Fe : 1.15 to 1.35 weight%, Mn : 0.40 to 0.60 weight%, the remainder Al, and unavoidable impurities. The aluminum alloy plate has a composition having, as the impurities, less than 0.05 weight% of Si, less than 0.05 weight% of Mg, and less than 0.05 weight% of Mg. The aluminum alloy plate has a structure in which a maximum width of a crystal grain is less than 100 microns and an average of a width of the crystal grain is less than 25 microns with regard to a direction perpendicular to the rolling direction. Ti : 0.005 to 0.15 weight% and B : 0.0005 to 0.05 weight% are contained.

Owner:NIPPON LIGHT METAL CO LTD

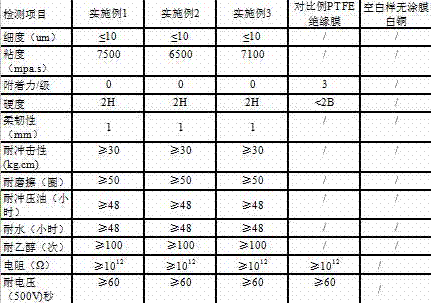

Single-component silk printing insulation ink for cupronickel

The invention provides silk printing insulation ink for substituting a PTFE insulation membrane by utilizing an electronic product cupronickel shielding cover. The single-component silk printing insulation ink is prepared from the following components by weight percent: 60 to 70 percent of epoxy modified polyester resin, 5 to 15 percent of amino resin, 5 to 10 percent of color concentrate, 1 to 3 percent of anti-settling agent, 5 to 15 percent of DBE environment-friendly solvent, 1 to 3 percent of adhesive agent, 1 to 2 percent of flatting agent, and 1 to 2 percent of defoaming agent. The silk printing insulation ink for substituting the PTFE insulation membrane by utilizing the electronic product cupronickel shielding cover is simple and convenient in use and high in insulation value which is equivalent to PTFE; and meanwhile, a coating film is resistant to scratch, good in flexibility, resistant to impact, capable of reaching 0T curvature, suitable for stamping processing after the silk printing, and suitable for a mobile phone, suitable for the mobile phone, and the insulation function of the electronic product cupronickel shielding cover is capable of substituting the original process of the laminated PTFE membrane, so that the purpose of achieving the high efficiency of mass production is realized.

Owner:HUIZHOU PERFECT CHEM IND CO LTD

Transparent pressure-sensitive adhesive sheet and flat panel display

InactiveCN101663695AEasy to peelExcellent peelabilityNon-macromolecular adhesive additivesFilm/foil adhesivesAdditive ingredientDisplay device

A transparent pressure-sensitive adhesive sheet for flat panel displays which has such excellent adhesive properties that after application to a display module (display panel) and a protective transparent plate, the adhesive sheet can be easily removed in the beginning and, despite this, comes to stick thereto at high peel force with the lapse of time. It is excellent especially in low-temperatureadhesion stability and excellent in punchability and the property of diminishing level differences. The transparent pressure-sensitive adhesive sheet is made mainly from a polyoxyalkylene polymer. Itis preferably one made of a material obtained by curing a composition which comprises a polyoxyalkylene polymer having at least one alkenyl group per molecule (ingredient A), a compound having two ormore hydrosilyl groups per molecule on the average (ingredient B), and a hydrosilylation catalyst (ingredient C).

Owner:NITTO DENKO CORP

Steel for 13-dwt vehicle axle housing and production method thereof

The invention relates to steel for 13-dwt vehicle axle housing and a production method thereof. The steel comprises the following chemical components by weight: 0.04%-0.08% of C, 0.10%-0.60% of Si, 1.3%-1.45% of Mn, not more than 0.025% of P, not more than 0.08% of S, 0.01%-0.06% of Al, 0.04%-0.06% of Nb, 0.03%-0.05% of Ti, and the balance of Fe and inevitable impurities; The preparation method comprises the following steps: converter smelting; vacuum treatment; continuous casting; casting blank heating; rough rolling; finish rolling by a 7 frame; cooling with laminar flow; coiling. Because of the low carbon content of the steel of the invention, the steel has excellent stamping performance and welding performance, has a stable dimension after cold forming, and completely meets the requirements for manufacturing and application of 13-dwt vehicle axle housing. Through bench tests of the manufactured 13-dwt vehicle axle housing assembly, the product has excellent vertical bending fatigue life, vertical bending rigidity, and vertical bending static strength, and completely meets the requirements of users.

Owner:武汉钢铁有限公司

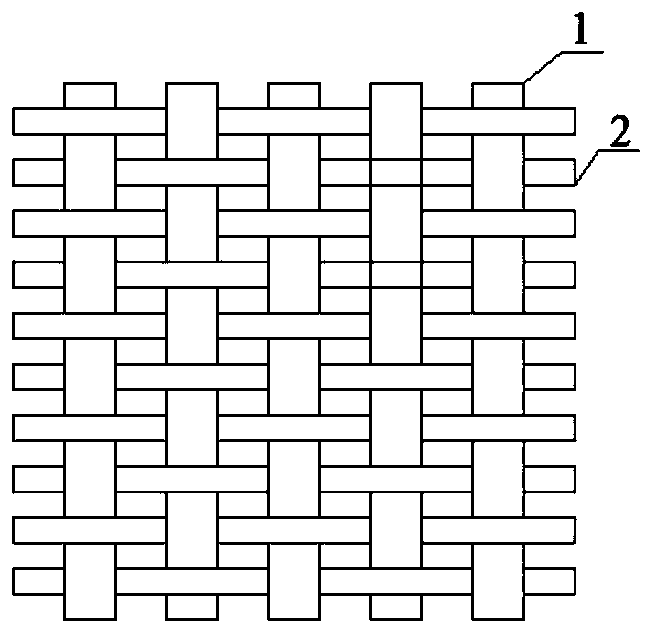

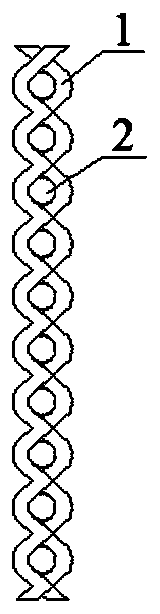

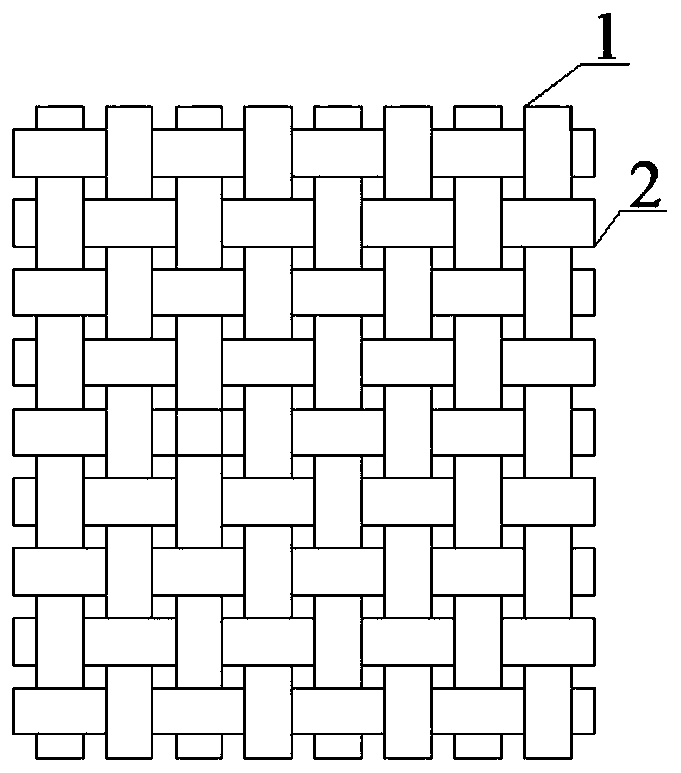

Composite brazing filler metal, preparation method and application thereof, and weldment

ActiveCN111055041ANovel structureSolve the tearing problemWelding/cutting media/materialsSoldering mediaWeld strengthMultiple stress

The invention relates to the field of welding, and particularly provides a composite brazing filler metal, a preparation method and application thereof, and a weldment. The composite brazing filler metal comprises a plurality of brazing filler metal ribs and a plurality of stress buffering ribs, and the multiple brazing filler metal ribs and the multiple stress buffering ribs are connected in a woven mode. The composite brazing filler metal is novel in structure, has a good effect of slowly releasing thermal stress, and is high in welding strength, and the problems of tearing, desoldering andthe like are not prone to occurring at a welding joint.

Owner:ZHENGZHOU RES INST OF MECHANICAL ENG CO LTD

Steel for axle housing and preparation method thereof

InactiveCN103805862BImprove mechanical propertiesGood stamping performanceTemperingChemical composition

The invention discloses a steel for an axle housing and a preparation method thereof, which has good stamping forming performance and welding performance, small springback after stamping and good shape retention. A steel for axle housing, the chemical composition and weight percentage are: C: 0.08%-0.12%, Si: 0.85%-1.0%, Mn: 0.62%-1.19%, P: ≤0.020%, S: ≤ 0.012%, Al: 0.025% to 0.07%, Ti: 0.041% to 0.06%, Nb: 0.05% to 0.062%, Mo: 0.12 to 2.1%, Ce: 0.48 to 0.62%, W: 4.8 to 5.2%, W: 4.8-5.2%, Cr: 1.68%-0.32%, the rest is Fe and unavoidable impurities. A method for preparing steel for axle housings, comprising the following steps: batching and smelting; performing vacuum treatment; performing continuous casting into blanks; heating the casting blanks; performing rough rolling; finishing rolling; and quenching and tempering heat treatment after forming.

Owner:SHANDONG TRANSPORT VOCATIONAL COLLEGE

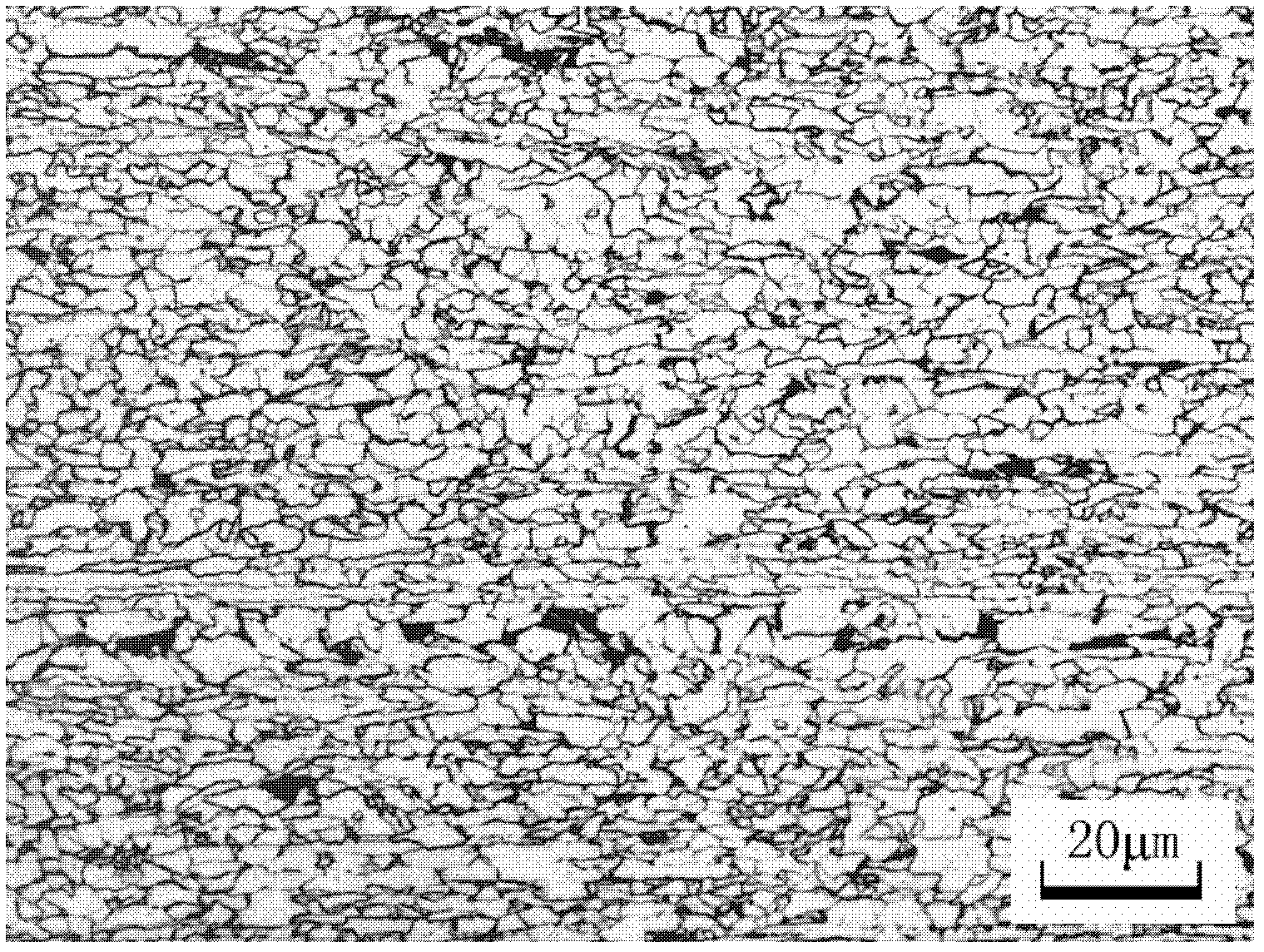

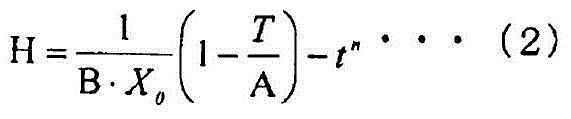

Pure titanium sheet having excellent balance between press formability and strength and excellent corrosion resistance, and process for manufacturing same

InactiveCN103562421AHigh tensile strengthGood stamping performanceLaminated elementsTitaniumUltimate tensile strength

This pure titanium sheet contains 0.02 to 0.10% of Fe and 0.04 to 0.20% of O, the balance consisting of titanium and unavoidable impurities and the Fe content and the O content satisfying relationship (1). In the pure titanium sheet, the area fraction of regions that exhibit Schmid factors of {11-22}<11-23> twin of 0.45 or more is at least 43%, each Schmid factor being determined with the axis set in the direction of rolling at a position corresponding to one-fourth of the sheet thickness. Further, the pure titanium sheet has a volume fraction of ß phase of 0.3% or less. [O content (mass%)] + 0.12×[Fe content (mass%)] = 0.050 ··· (1)

Owner:KOBE STEEL LTD

Low temperature curing transparent inner iron printing coating

ActiveCN106634480AGood yellowing resistanceImprove scratch resistancePolyester coatingsEnvironmental resistancePolyester

The invention discloses a low temperature curing transparent inner iron printing coating. The low temperature curing transparent inner iron printing coating contains raw material by weight part: 40-65 parts of saturated polyester, 5-10 parts of amino resin, 0.2-1 part of modified adhesion promoter, 0.5-1 part of wax powder, 0.1-0.3 part of catalyst and 18-25 parts of environment-friendly organic solvent, wherein the saturated polyester has Tu-4 cup viscosity of 60-80s, acid value of 2-4mgKOH / g, solid content of 55-60wt%, glass transition temperature of 40-50 DEG C, and average molecular weight between 4000Da and 6000Da. Compared with the prior art, by selecting the branched saturated polyester high in acid value and glass transition temperature, crosslinking the selected saturated polyester with partly methyl-etherified melamine formaldehyde resin and n-butyl-etherified melamine formaldehyde resin, which are good in hardness and high in reaction speed, and simultaneously using benzoguanamine resin and isocyanate for auxiliary crosslinking, the low temperature curing transparent inner iron printing coating has good adhesive force to base material, good yellowing resistance, good scratch resistance, strong resistance to corrosion, and good processing performance, and only needs to cure for 8-11min at low temperature of 125-135 DEG C, is environment friendly and safe, does contain materials such as bisphenol A and organic tin, and is a product which meets domestic and international innocuous and harmless test standards.

Owner:广东新威新材料技术有限公司

Quenchable steel sheet having high hot press workability and method of manufacturing the same

ActiveUS20110159314A1Improve corrosion resistanceMaximize economic benefitsHot-dipping/immersion processesThin material handlingAlloy elementHot press

The quenchable steel sheet has an alloy composition including carbon (C) in an amount of 0.15˜0.30 wt %, silicon (Si) in an amount of 0.05˜0.5 wt %, manganese (Mn) in an amount of 1.0˜2.0 wt %, boron (B) in an amount of 0.0005˜0.0040 wt %, sulfur (S) in an amount of 0.003 wt % or less, phosphorus (P) in an amount of 0.012 wt % or less, one or more selected from among calcium (Ca) in an amount of 0.0010˜0.0040 wt % and copper (Cu) in an amount of 0.05˜1.0 wt %, two or more selected from among cobalt (Co), zirconium (Zr) and antimony (Sb), and iron (Fe). Alloy elements are controlled to increasing hot ductility and enabling pressing at 600˜900° C. so that a tensile strength of 1400 MPa or more and an elongation of 8% or more are obtained after pressing.

Owner:HYUNDAE STEEL CO LTD

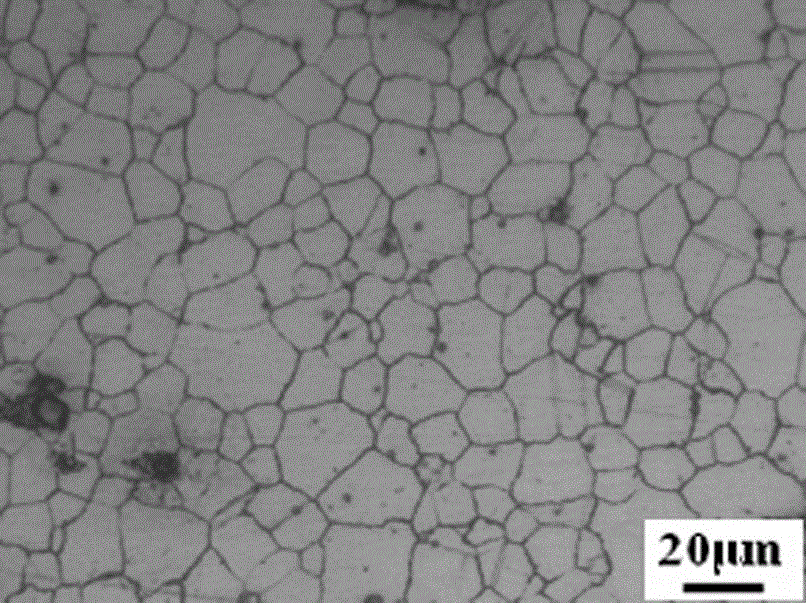

Stainless steel foil and method for manufacturing same

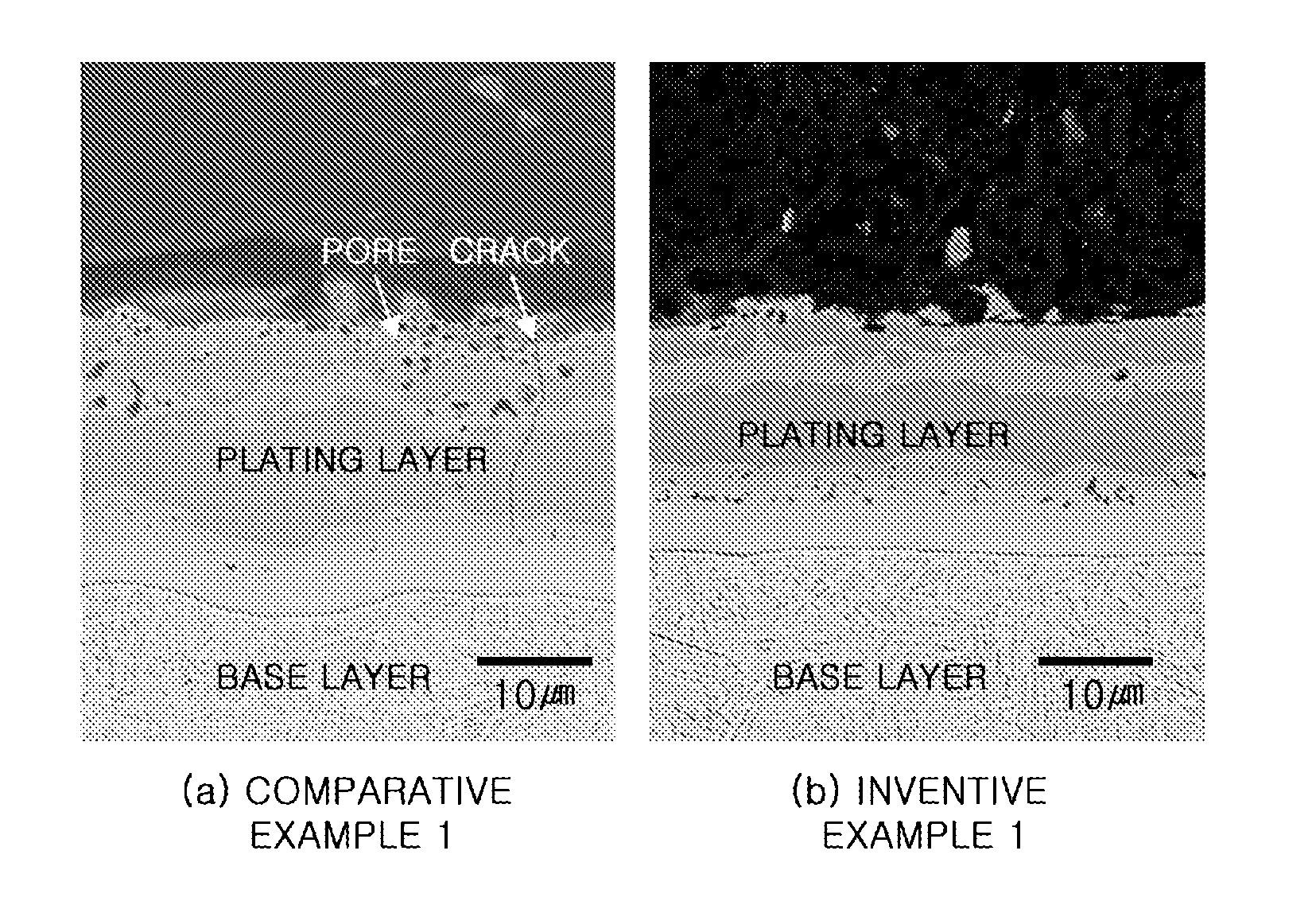

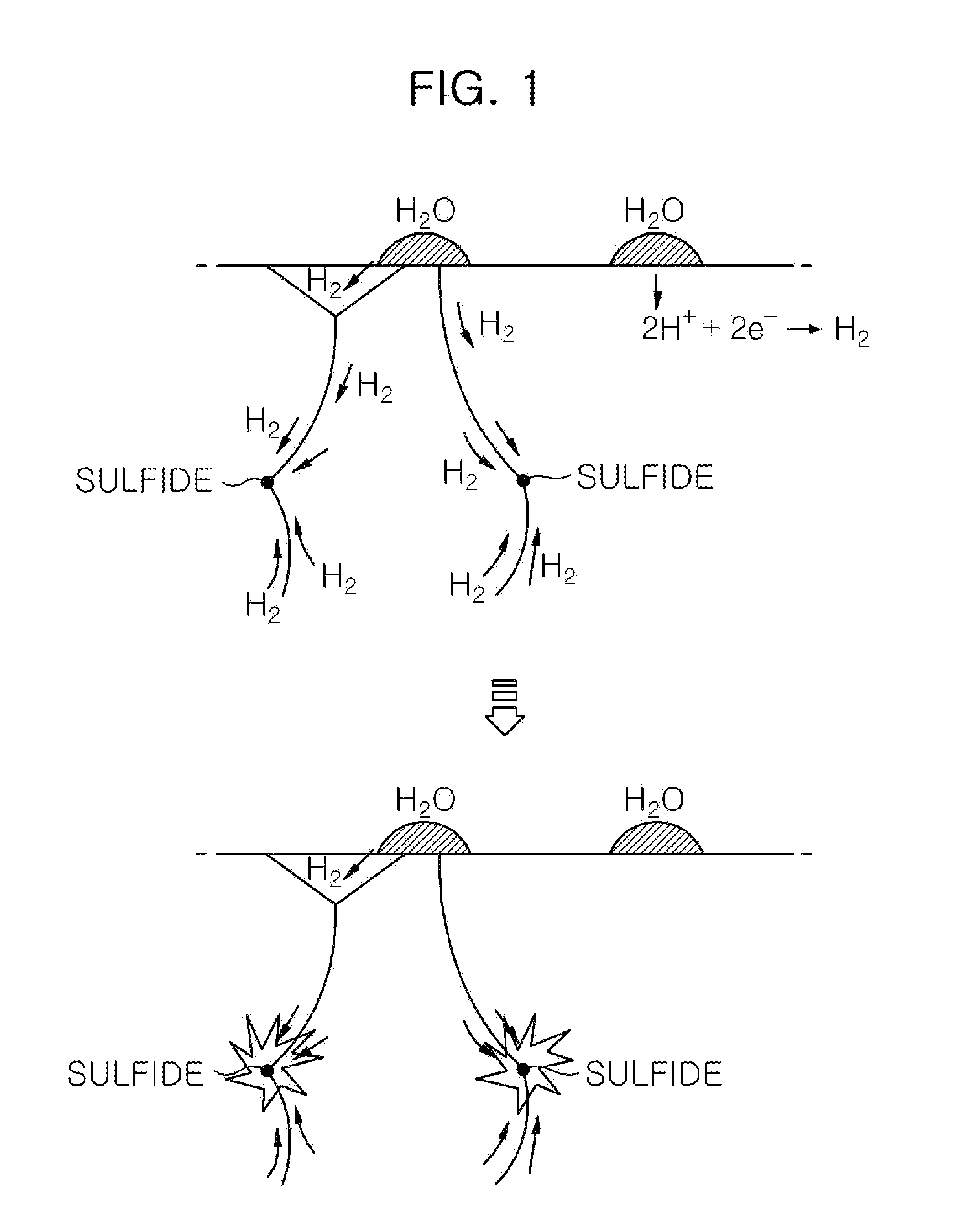

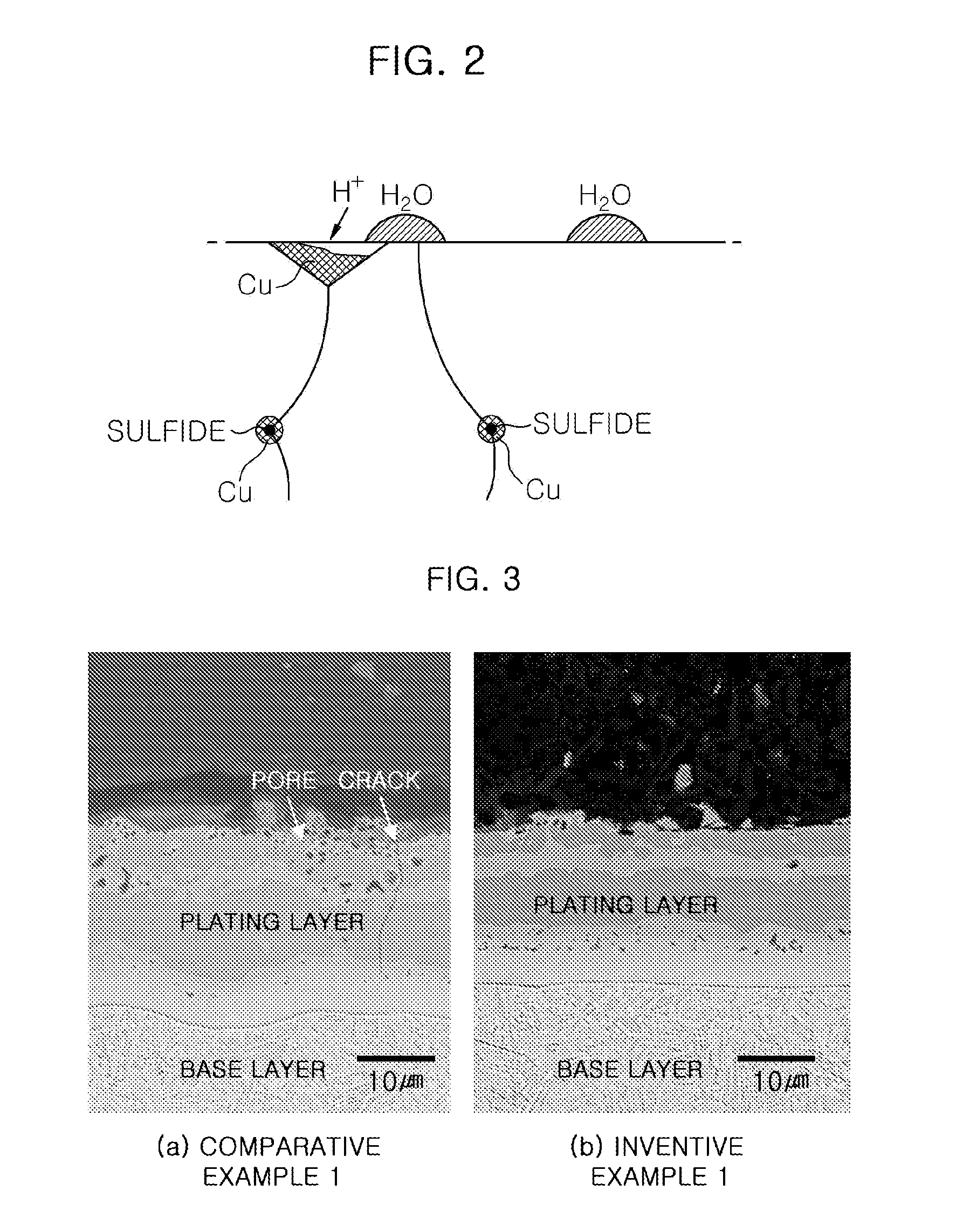

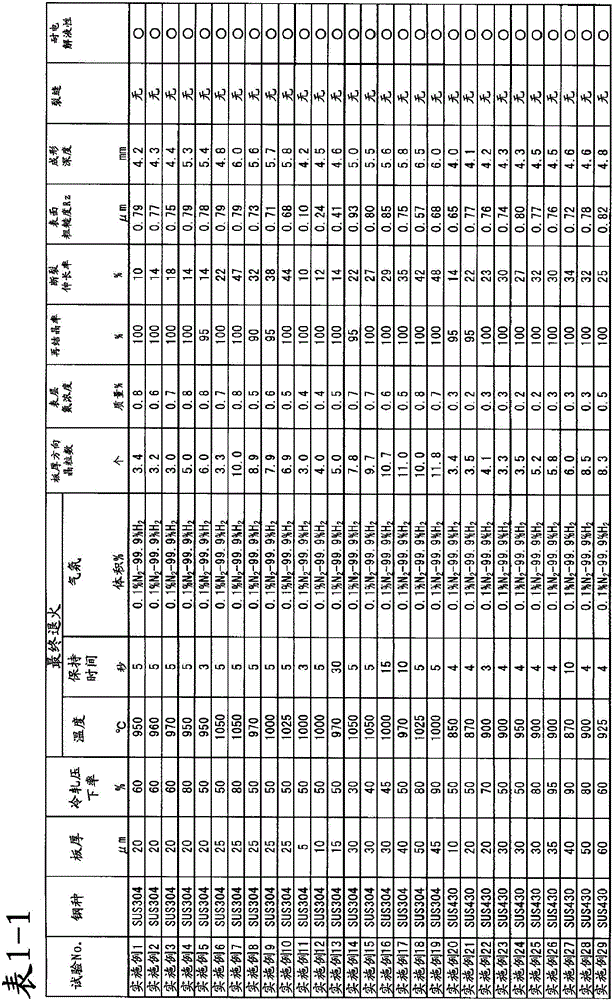

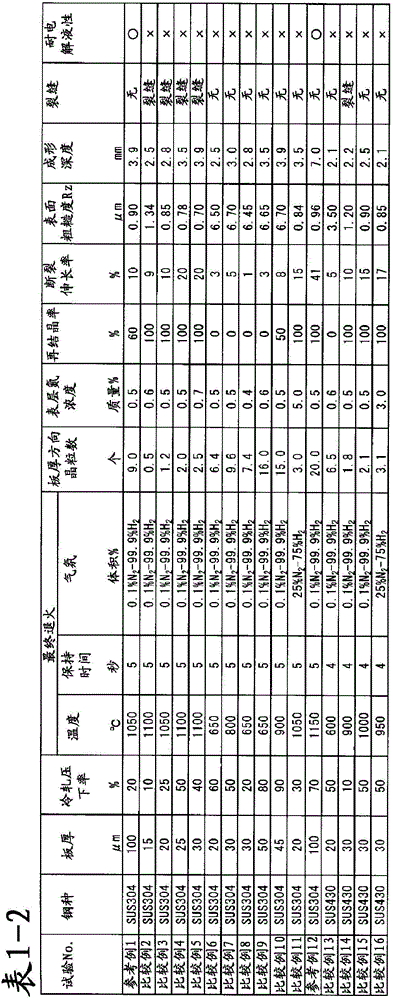

ActiveCN105829567AEnsure plastic deformation abilityGuaranteed elongation at breakFurnace typesCell component detailsMetallurgyAtmosphere

The present invention addresses the problem of securing high thickness accuracy even for ultra-thin stainless steel foil having a thickness of 60 mum or less while also securing plastic deformability and breaking elongation, that is, securing excellent press workability (deep drawability). The present invention solves the above problem by providing an ultra-thin stainless steel foil, which has 3 or more crystal grains in the thickness direction, and in which the recrystallization rate is between 90% and 100% inclusive, and the nitrogen concentration at the surface is 1.0 mass% or less. Thus, with this method for manufacturing an ultra-thin stainless steel foil having a thickness of 5 to 60 mum by rolling a stainless steel sheet and subsequently performing final annealing, it is possible to manufacture an ultra-thin stainless steel foil in which the rolling reduction from rolling immediately prior to the final annealing is 30% or more, the post-rolling final annealing temperature is 950 DEG C to 1050 DEG C in the case of austenitic stainless steel and 850 DEG C to 950 DEG C in the case of ferritic stainless steel, and the nitrogen content of the atmosphere gas during final annealing is 0.1 vol% or less.

Owner:NIPPON STEEL CHEMICALL &MATERIAL CO LTD

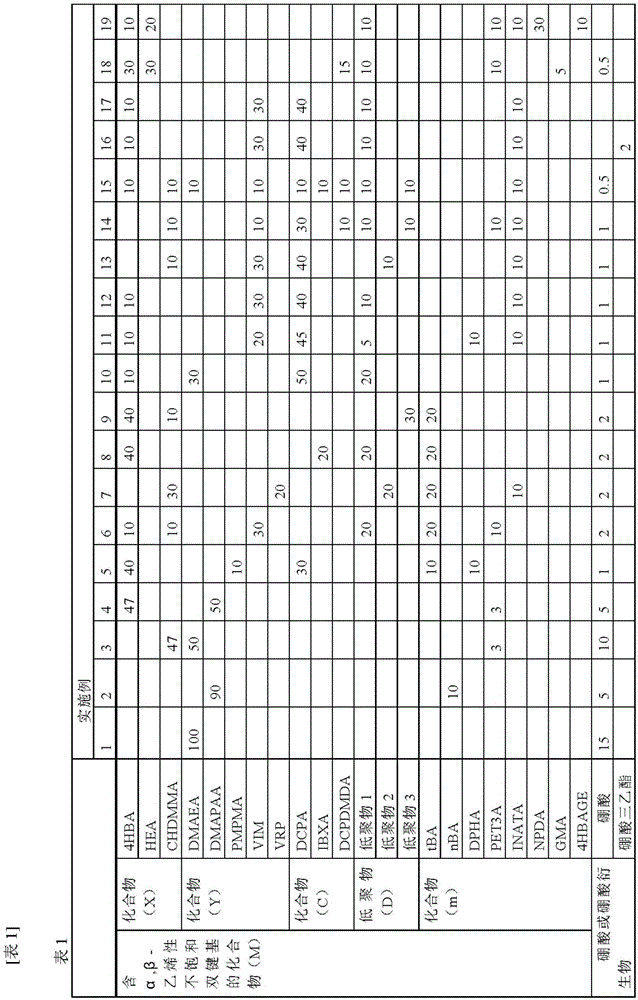

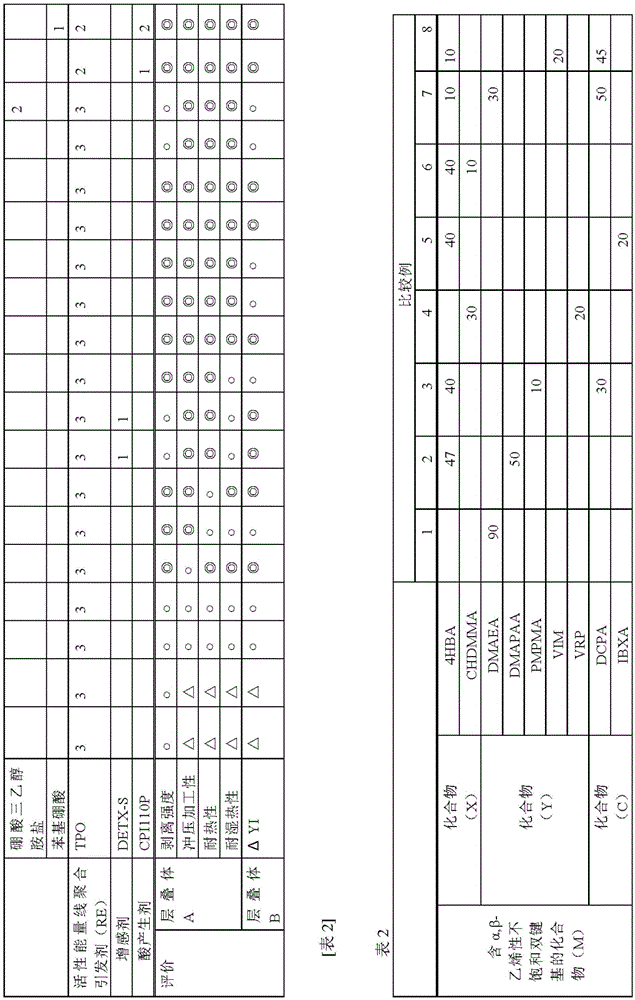

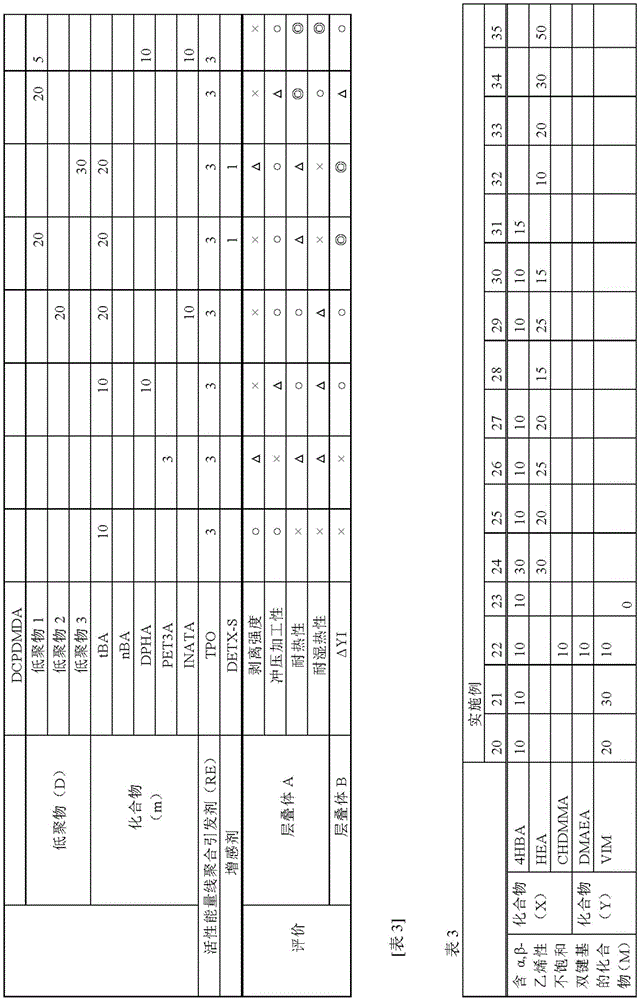

Active-energy-ray-polymerizable resin composition and laminate

ActiveCN105358584AGood stamping performanceIncreased durabilityNon-macromolecular adhesive additivesSynthetic resin layered productsCationic polymerizationDouble bond

The present invention provides a novel active-energy-ray-polymerizable resin composition having excellent adhesiveness, and a laminate using the same, the laminate being, in particular, a laminate for an optical device and having better punching workability and durability to heat and humidity than in the past. The present invention relates to: an active-energy-ray-polymerizable resin composition containing an [alpha], [belta]-ethylenic unsaturated double bond group-containing compound (M) and boric acid and / or a boric acid derivative; an active-energy-ray-polymerizable resin composition containing a cationic-polymerizable compound (K), boric acid and / or a boric acid derivative, and a cationic polymerization initiator (KE); and also an active-energy-ray-polymerizable resin composition using both the [alpha], [belta]-ethylenic unsaturated double bond group-containing compound (M) and the cationic-polymerizable compound (K), and containing boric acid and / or a boric acid derivative.

Owner:TOYO INK SC HOLD CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com