Aluminum alloy sheet for battery cover and its production method

A technology of aluminum alloy plate and manufacturing method, which is applied in the direction of battery cover/end cover, metal rolling, battery pack parts, etc., can solve the problems of increased manufacturing process and deteriorated operability, and achieves excellent stamping formability, shrinkage and durability The effect of non-uniform compressive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0064] Next, specific examples will be described.

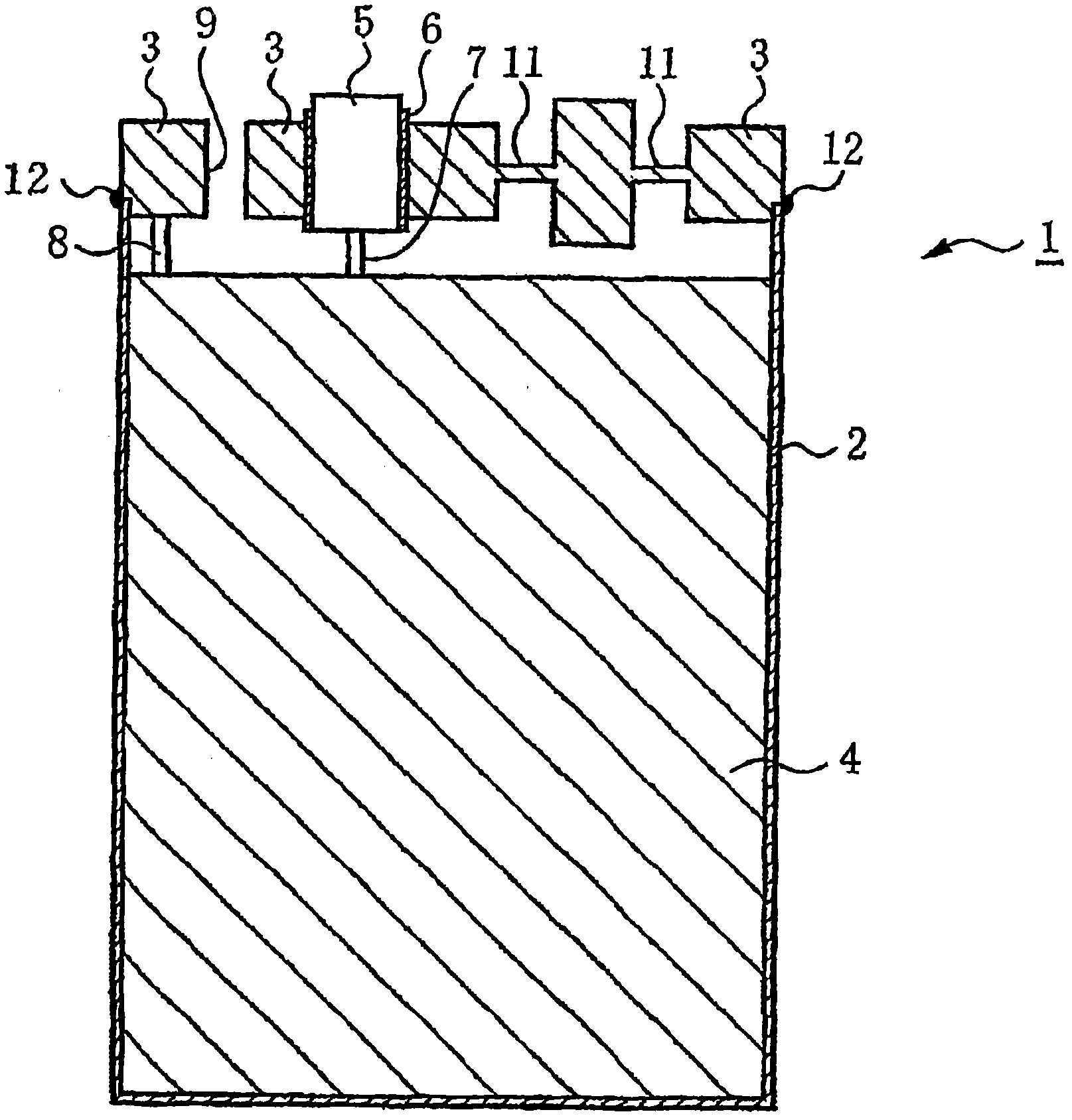

[0065] smelting as figure 1 An aluminum alloy molten metal having the composition shown above was cast into an ingot by a semi-continuous casting method with a thickness of 530 mm, a width of 1100 mm, cooling water from a mold of 3.0 liters / cm min, and an ingot withdrawal speed of 50 mm / min.

[0066] Next, after end-cutting the ingot, it was subjected to a homogenization treatment at 600°C for 2 hours, and hot rolling was started after holding, and it became a hot-rolled sheet with a thickness of 6 mm at a finishing temperature of 400°C. Next, cold-rolled 4-pass (pass) becomes a 1.4-mm-thick cold-rolled sheet.

[0067] Thereafter, the cold-rolled sheets of alloy No. 1, 2, 3, and 5 were heated to 500°C at an average speed of 200°C / sec, and after being kept at this temperature for 10 seconds, they were heated at an average speed of 200°C / sec. The rate of rapid cooling to 200 ° C for annealing. Next, the above-mentioned annea...

Embodiment 2

[0083] The aluminum alloy having the composition of No. 2 in the above Table 1 was used as a test material, and as shown in Table 3, various changes were made to the homogenization treatment, the cold rolling ratio before the final annealing, and the final annealing conditions to obtain Annealed plate with a thickness of 1mm.

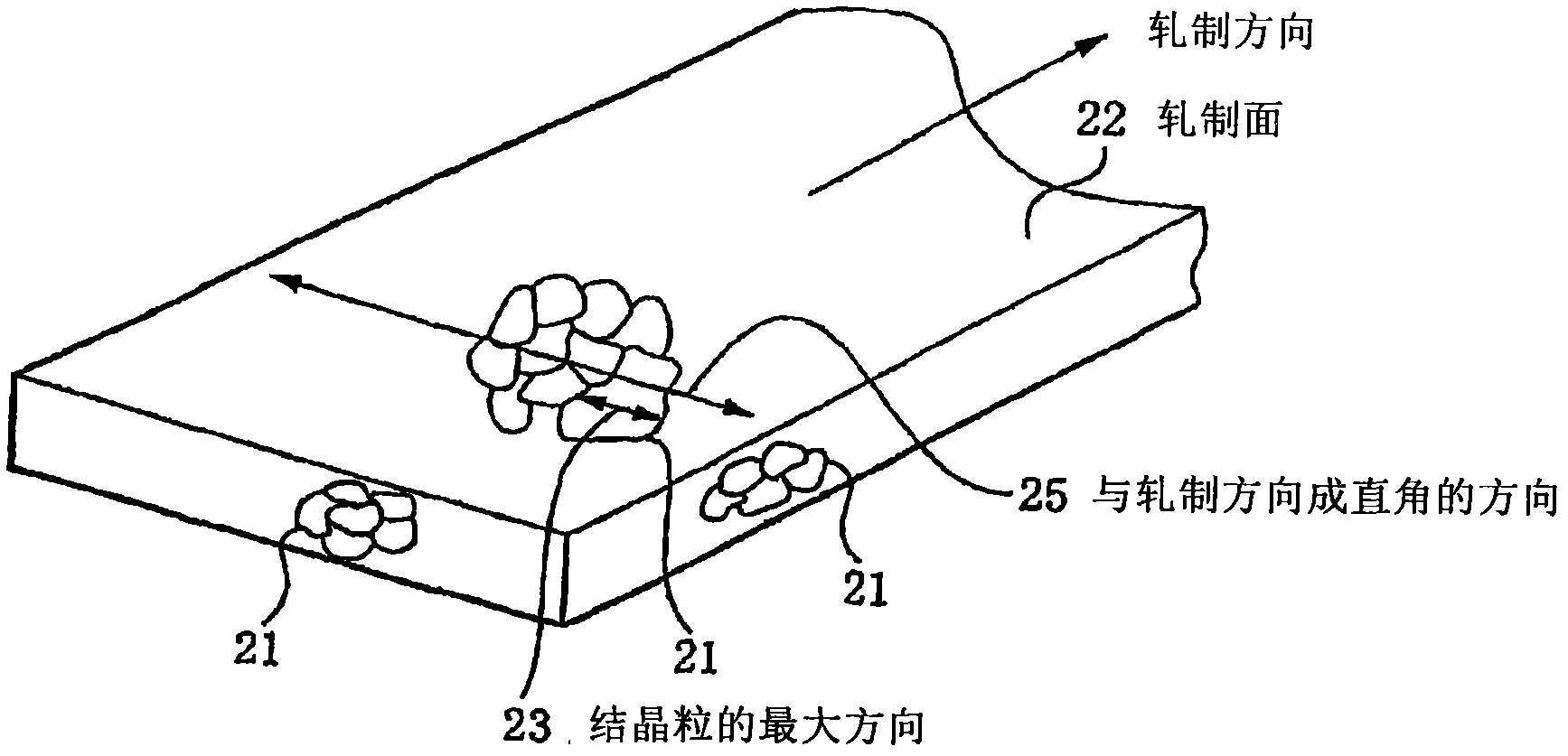

[0084] For each of the obtained annealed sheets, as in Example 1, the crystal grain width of the rolling surface was measured by the cross-section method, and at the same time, the compressive strength was measured by press forming to a thickness of 20 μm (the n number was 10). The measurement area was set to 2 mm×3 mm.

[0085] The results are shown in Table 4.

[0086] table 3

[0087] manufacturing conditions

[0088]

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com