Excellent heat-dissipating black resin composition, method for treating a zinc coated steel sheet using the same and steel sheet treated thereby

A technology of black resin and composition, applied in the direction of nanotechnology, carbon nanotubes, nanotechnology, etc. for materials and surface science, can solve the problems of corrosion-resistant surface conductivity limitation, high manufacturing cost, scratches, etc. Achieve the effect of excellent heat absorption/radiation properties and excellent physical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0064] Hereinafter, exemplary embodiments of the present invention will be described in detail with reference to the accompanying drawings. However, it should be considered that the descriptions presented herein are preferred embodiments for illustrative purposes only and are not intended to limit the scope of the invention.

Embodiment

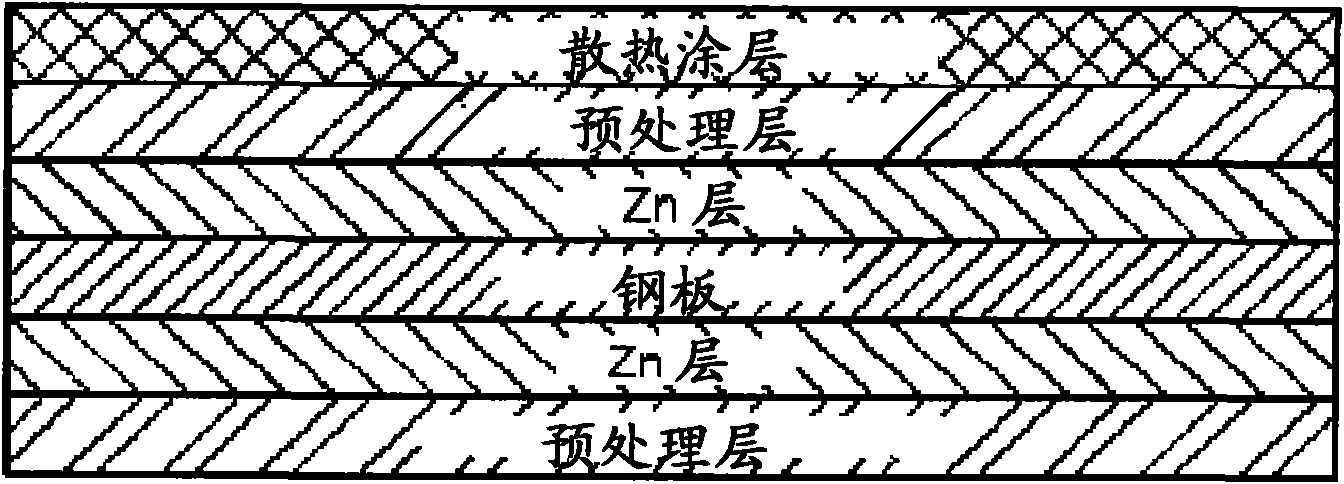

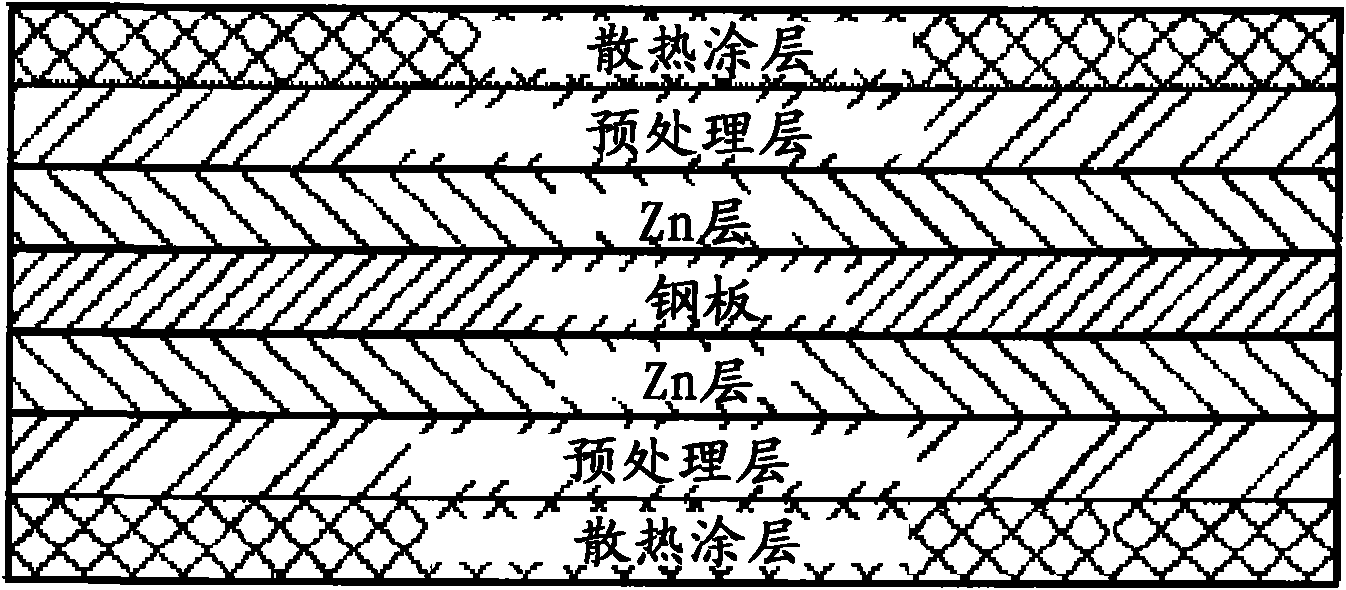

[0066] 1. The galvanized steel sheet used in this embodiment

[0067] The one used in this article is coated with 20g / m2 on both sides 2 (Amount of coating on one side) Electrogalvanized steel (EG, steel sheet thickness: 0.8mm) of zinc.

[0068] 2. Preparation of heat-dissipating black resin composition and test samples

[0069] The main resin and the melamine-based curing agent were mixed in a weight ratio of 10:4 to prepare a resin composition. Each of the obtained resin composition, carbon black, matting agent and titanate was mixed in the content range listed in Table 1 below, based on 100 parts by weight of the heat-dissipating composition. As other additives, 1 weight part of polyethylene wax, 2 weight parts of p-toluenesulfonic acid as curing catalyst, 0.5 weight part of BYK-170 TM Pigment anticoagulant (BYKchemie), 0.5 parts by weight of N-methylethanolamine defoamer, 0.5 parts by weight of zinc phosphate as a phosphate-based additive, and 1 part by weight of gamma-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com