High-surface-quality aluminum-coated plate strip with easy stamping machining function and production method thereof

A technology of stamping processing and production method, which is applied in the field of high surface quality aluminum-clad sheet and strip and its production, can solve the problem of incompatibility with single-pass large deformation, high surface quality and stamping processing requirements, poor steel-aluminum bonding performance, and difficult stamping processing. and other problems, to achieve good interface bonding characteristics, good stamping processing, and ensure the effect of stamping performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

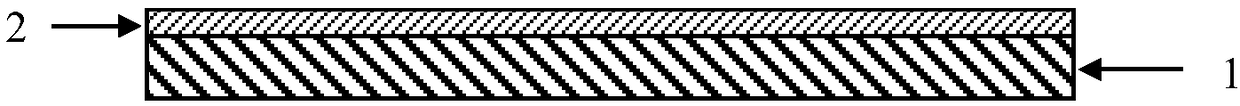

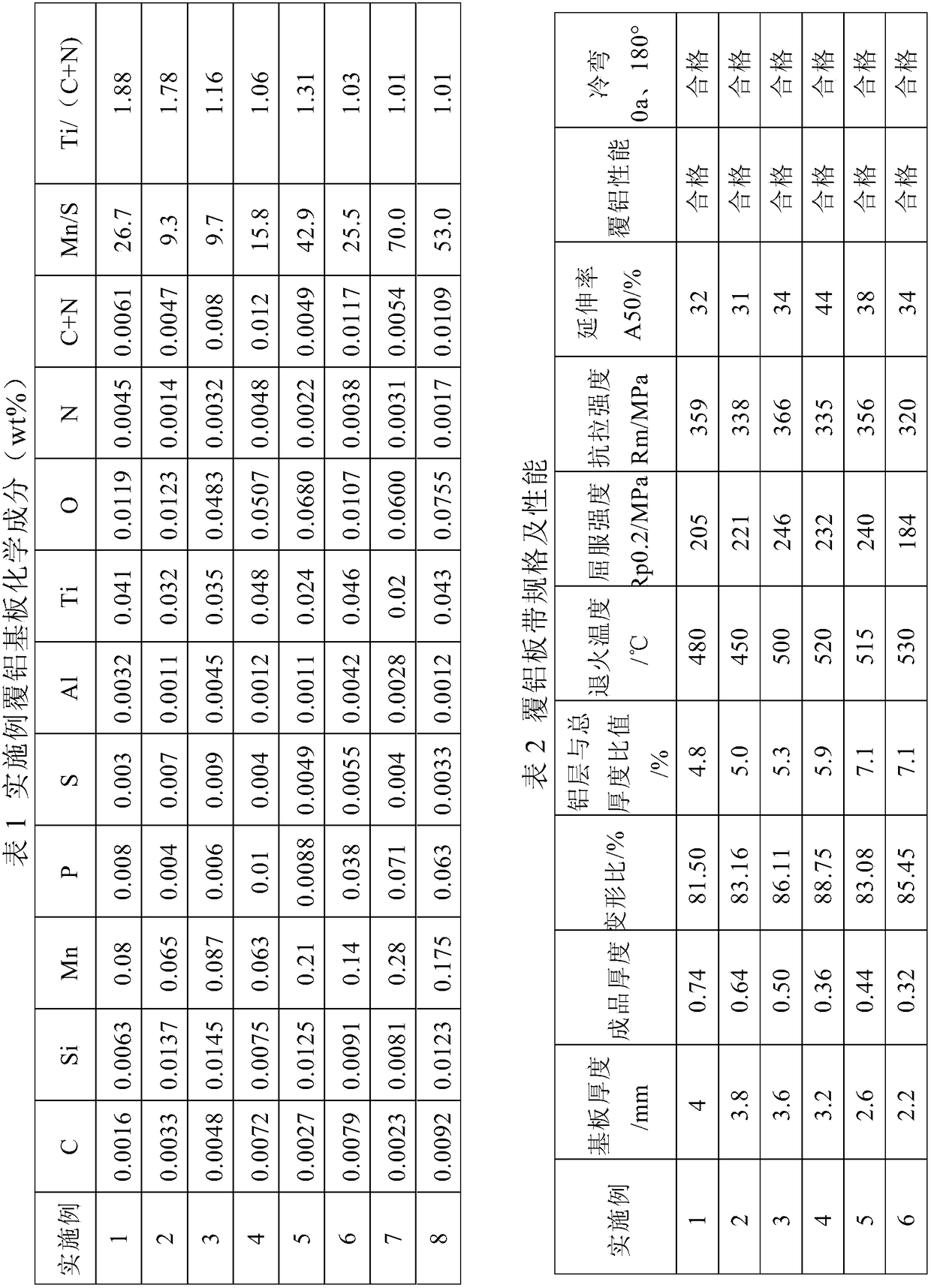

[0054] According to the chemical composition requirements of the aluminum-clad substrate involved in the present invention, steel strips 1 and 0.2mm aluminum strips 2 of different specifications are selected for single-layer compounding, such as figure 1 As shown, after surface cleaning and grinding, room temperature rolling is carried out. The chemical composition of the aluminum-clad substrate is shown in Table 1. The aluminum-clad strip is bell-type annealed. The thickness of the finished product is 0.3-8mm. The properties of the finished product are shown in Table 2.

[0055] In this embodiment, the aluminum-clad strip adopts a substrate of 2.2-4mm and an aluminum film of 0.2mm and is rolled in one pass to form a composite strip of 0.3-0.8mm aluminum+steel+aluminum structure or a composite strip of steel+aluminum structure.

Embodiment 2

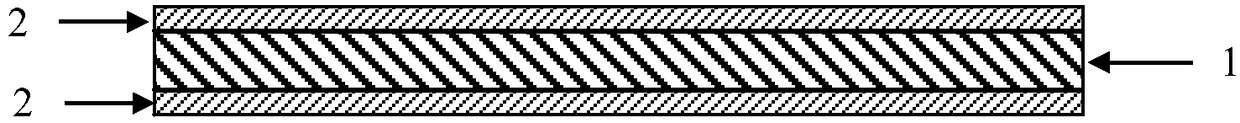

[0057] According to the chemical composition requirements of aluminum-clad substrates in Table 1, steel strips 1 and 0.2mm aluminum strips 2 of different specifications are selected for double-layer compounding, such as figure 2 As shown, after surface cleaning and grinding, room temperature rolling is carried out. The thickness of the finished product is 0.3-0.8mm, and the performance of the finished product is shown in Table 3.

[0058] According to the design scope of the steel grade composition of the present invention and the rolling process control technology, the examples obtained by the aluminum-clad steel strip have a tensile strength of more than 300 MPa, an elongation of more than 30%, excellent bonding performance of the steel-aluminum interface, and good stamping performance, especially Is the surface quality is excellent. It can be applied to the production of components such as home appliance panels, food processing trays, and engine sound insulation covers th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com