Composite brazing filler metal, preparation method and application thereof, and weldment

A technology of composite brazing material and brazing filler metal, which is applied in the direction of welding equipment, welding medium, welding/cutting medium/material, etc., can solve the problems of low strength, tearing, etc., and achieve high strength, good formability, and easy storage and transportation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

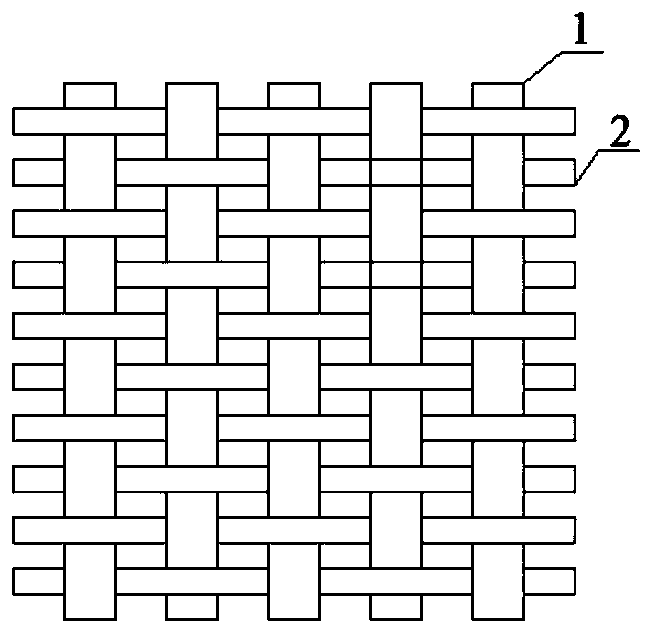

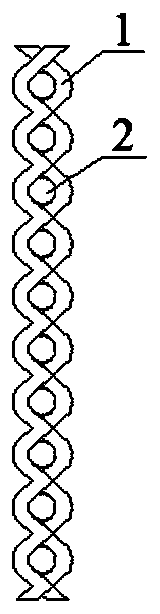

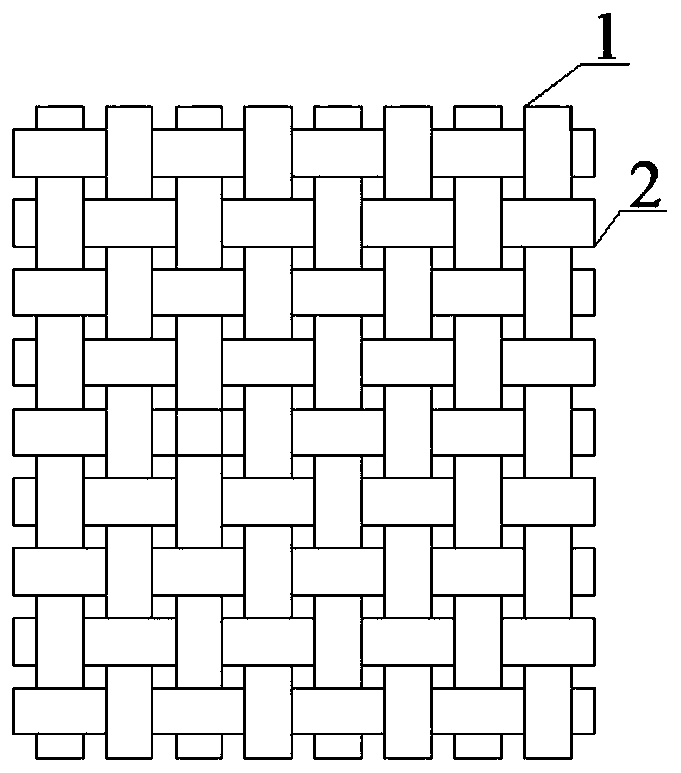

[0099] According to another aspect of the present invention, there is provided a method for preparing the above-mentioned composite solder, comprising: braiding a plurality of solder ribs and a plurality of stress buffer ribs to obtain the composite solder. The method has simple process, does not need to adopt multi-pass rolling process, has high production efficiency, and the obtained composite solder has high strength, and is not easy to be torn, desoldered and the like during use.

[0100] In a preferred embodiment, the solder bar is prepared by the following process: the raw material of the solder bar is sequentially smelted, cast, extruded, rolled, drawn or cut, optionally annealed and bent , to obtain brazing filler metal bars. After the raw material of the brazing filler metal is smelted, cast, extruded, rolled, drawn and bent in sequence, the brazing filler metal of the required size can be obtained, and after annealing between drawing and bending, the brazing filler m...

Embodiment 1

[0125] A composite solder, the preparation method comprising: (1) smelting, casting, extruding, rolling, and cutting the BCu58ZnMn solder alloy to a strip-shaped solder with a thickness of 0.2 mm and a width of 2 mm; (2) Anneal the brazing material strip under hydrogen protection conditions at 400°C to 500°C to a Vickers hardness of 95HV; (3) put the brazing material strip in a bending device and bend it to obtain a warp rib with a pit pitch of 0.5mm (4) Divide the warp ribs into odd parts and even parts, vertically link up and down to pull apart the warp ribs, the starting pits of the odd part warp ribs go upward, and the starting pits of the even part go upwards. Bottom; (5) The tensioned iron latitudinal ribs with a diameter of 0.1mm and a Vickers hardness of 125HV are fed into the pits of the warp ribs, and the ribs are staggered and clamped vertically to realize warp ribs. The ribs and the weft ribs are locked up and down; (6) feeding the weft ribs one by one and repeatin...

Embodiment 2

[0128] A composite solder, the preparation method of which comprises: (1) smelting, casting, extruding and drawing the BCu58ZnMn solder alloy to a diameter of 0.5mm; (3) put the solder wire into the bending device and bend it to obtain a warp rib with a pit pitch of 1mm; (4) divide the warp rib into an odd number For the part and the even part, the warp ribs are pulled up and down in a vertical direction and staggered, the starting pit of the odd part of the warp rib is upward, and the starting pit of the even part is downward; (5) The diameter is 0.1mm, Vickers hardness Feed the 125HV tensioned iron latitude ribs into the pits of the warp ribs, and vertically move up and down to clamp the ribs alternately, realizing the mutual locking of the warp ribs and the weft ribs up and down; (6) feeding the latitudinal ribs one by one and repeating the up-and-down linkage of the warp ribs to complete the preparation of high-performance composite solder.

[0129] Under the same brazing...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mesh | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com