Copper-clad plate and processing method thereof

A processing method and technology of copper clad laminates, which are applied in the field of composite boards to achieve the effects of low processing costs, reduced production energy consumption, and excellent loss conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

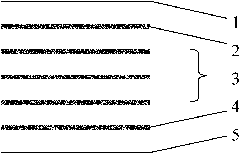

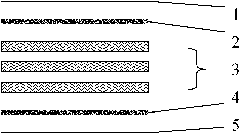

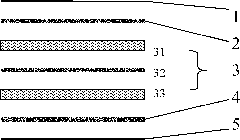

[0042] Such as image 3 As shown, a copper clad laminate of the present invention includes two copper foil layers 1 and 5, which are respectively located on the upper and lower outermost sides. The copper clad laminate also includes upper layers 2 and 4 made of glass fiber cloth, a lower layer, and a core material 3 between the upper layer 2 and the lower layer 4 .

[0043] The core material 3 is composed of glass fiber cloth prepreg and glass fiber non-woven prepreg. The stacking in this embodiment is the alternate stacking of glass fiber cloth prepregs and glass fiber non-woven prepregs. Specifically, in this embodiment, the core material 3 is composed of two glass fiber non-woven fabric prepregs 31 and 33, and a glass fiber cloth prepreg 32 sandwiched between them.

[0044]Specifically, the thickness of the copper foil layers 1 and 5 is between 3-150um.

[0045] In other embodiments, the copper clad laminate may only include one copper foil layer as required.

[0046] A...

Embodiment 2

[0056] The present invention also provides a processing method for any of the above-mentioned copper-clad laminates, which at least includes the following steps:

[0057] Step one, deploy glue. The components in the glue system are proportioned and matured in an industrial stirred tank according to the formula requirements.

[0058] Step two, gluing. The glass fiber cloth and the glass fiber non-woven fabric are respectively dipped in the glue solution, then taken out and baked, and then cooled to obtain the glass fiber cloth prepreg and the glass fiber non-woven prepreg respectively.

[0059] In different specific embodiments, the obtained glass fiber cloth prepreg and glass fiber non-woven fabric prepreg can also be cut according to the required size.

[0060] Among them, the baking temperature of the glass fiber cloth is 150°C-200°C, and the baking temperature of the glass fiber non-woven fabric is 170°C-210°C.

[0061] The gluing parameters are shown in the table below:...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com