Ride-on Hot Melt Spray Marking Machine

A technology of hot melt spraying and marking machine, which is applied to roads, road repair, roads, etc., can solve problems such as affecting construction quality and progress, marking speed cannot be too fast, and temperature control is not timely, etc., to improve the atomization effect. , Improve the quality of the marking line and the effect of precise control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

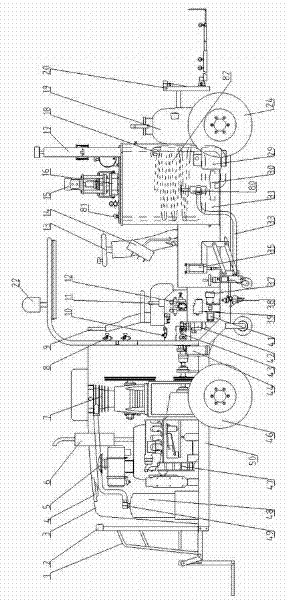

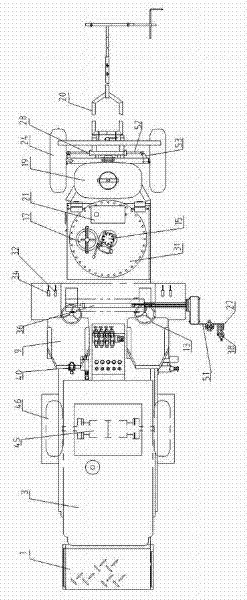

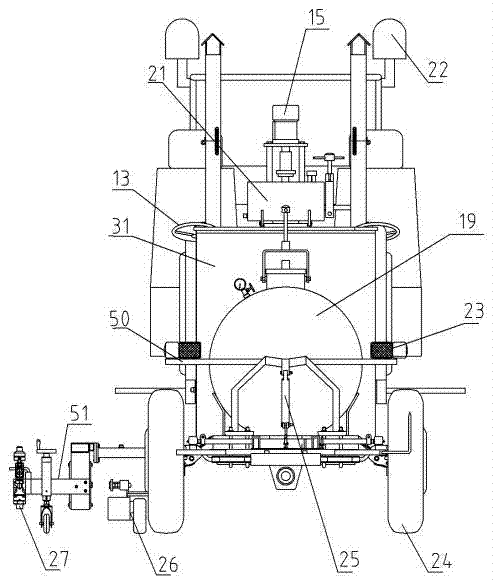

[0028] Such as Figure 1 to Figure 5 As shown, the ride-on type hot-melt spraying marking machine of the present invention includes a frame 50, and the frame 50 is provided with two driver's seats 9, a power drive system, a heating system, a marking system, and a microelectronic controller 14 , hydraulic control system, air pressure control system and steering system, the lower part of the frame 50 is equipped with a walking system, the power drive system is respectively connected with the walking system, hydraulic control system and air pressure control system, and the hydraulic control system is connected with the steering system. The system is respectively connected with the hydraulic control system and the air pressure control system; the walking system is provided with an encoder assembly 26, and the encoder assembly 26, the microelectronic controller 14, and the air pressure control system are connected by data lines, and the microelectronic controller 14 is provided wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com