Brine processing system having front heat exchanger and rear deduster and method thereof

A technology of a treatment system and a treatment method, applied in the field of waste water treatment, can solve the problems of low purity, ash agglomeration and recovery of crystal salt purity, and achieve the effects of reducing cost, good atomization effect, and avoiding secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

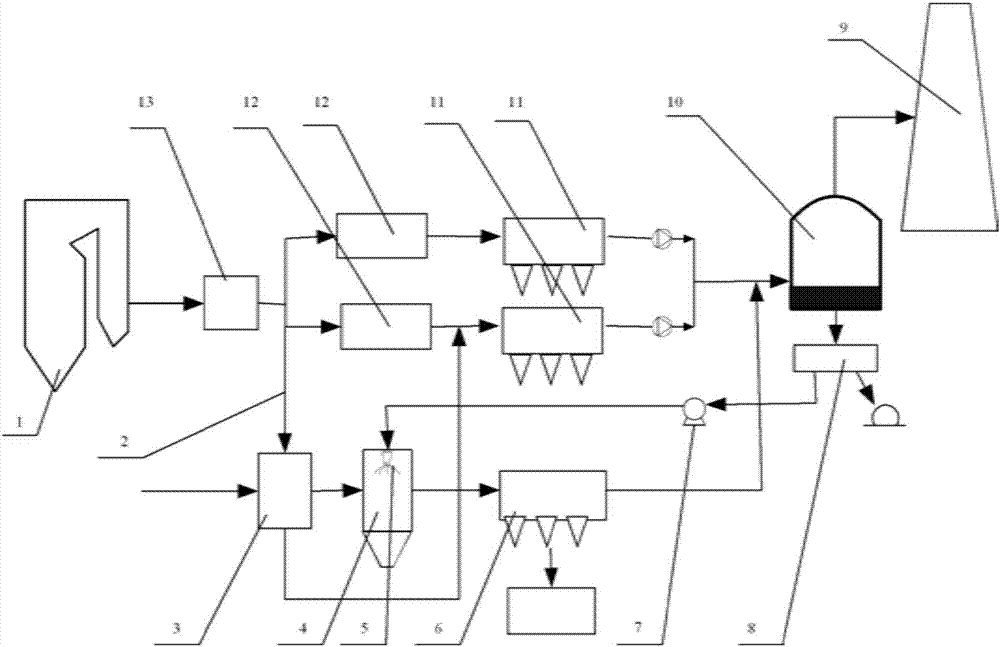

[0036] see figure 1 , the brine treatment system with a pre-heat exchanger and a rear-end dust collector includes a boiler 1, a denitrification device 13, an air preheater 12, an electric precipitator 11, a desulfurization tower 10, and a dehydration concentration device 8, which are connected in sequence through pipelines , water pump 7 and spray evaporation tower 4, also includes shell and tube heat exchanger 3, bag filter 6 and chimney 9. Wherein, there are two passages connected in parallel between the denitrification device 13 and the desulfurization tower 10 , and each passage is provided with an air preheater 12 and an electrostatic precipitator 11 .

[0037] Between the denitration device 13 and the air preheater 12, there is a bypass flue 2 as a heating medium lead-out channel. The raw flue gas inlet of the shell-and-tube heat exchanger 3 communicates with the end of the bypass flue 2. The raw flue gas outlet of the heater 3 communicates with the outlet of the air pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com