Patents

Literature

134results about How to "Reduce burrs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

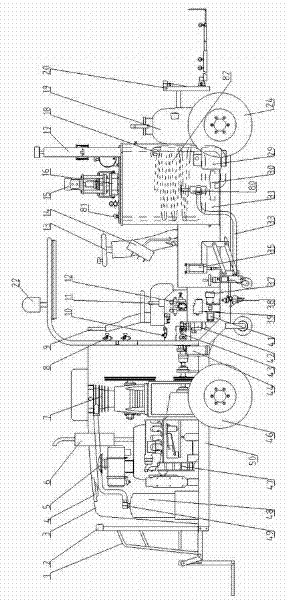

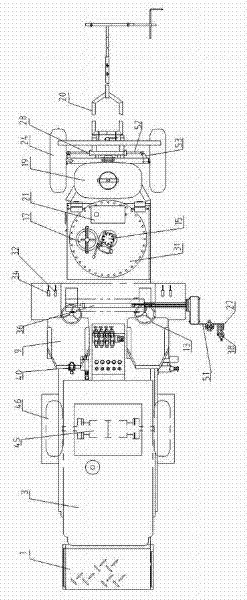

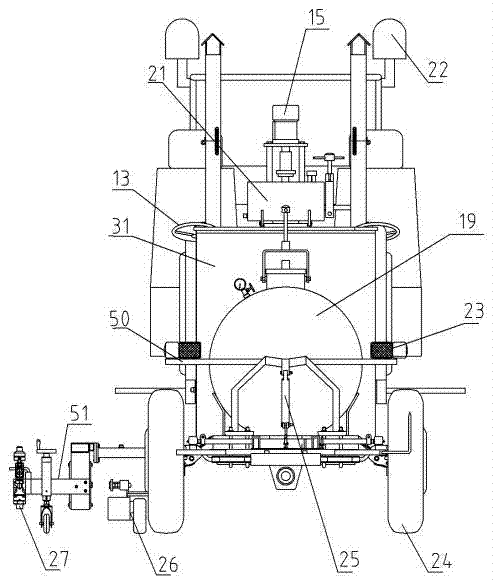

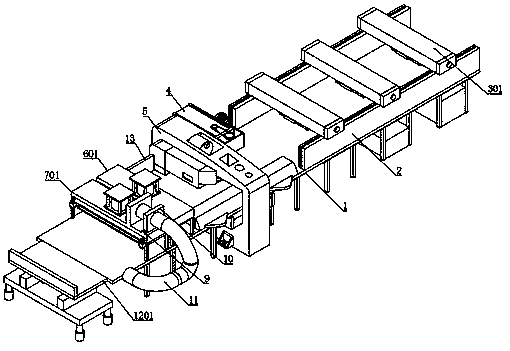

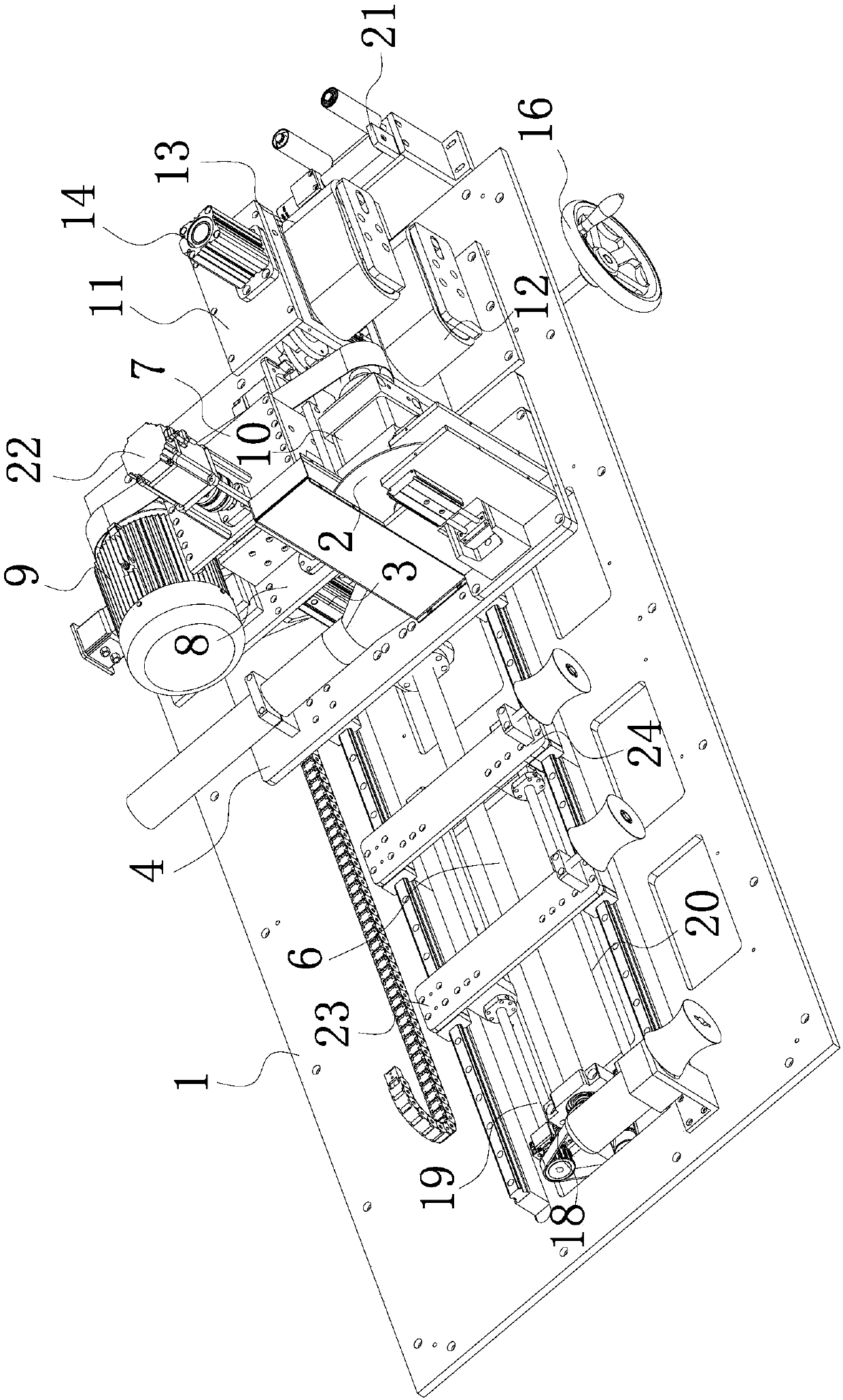

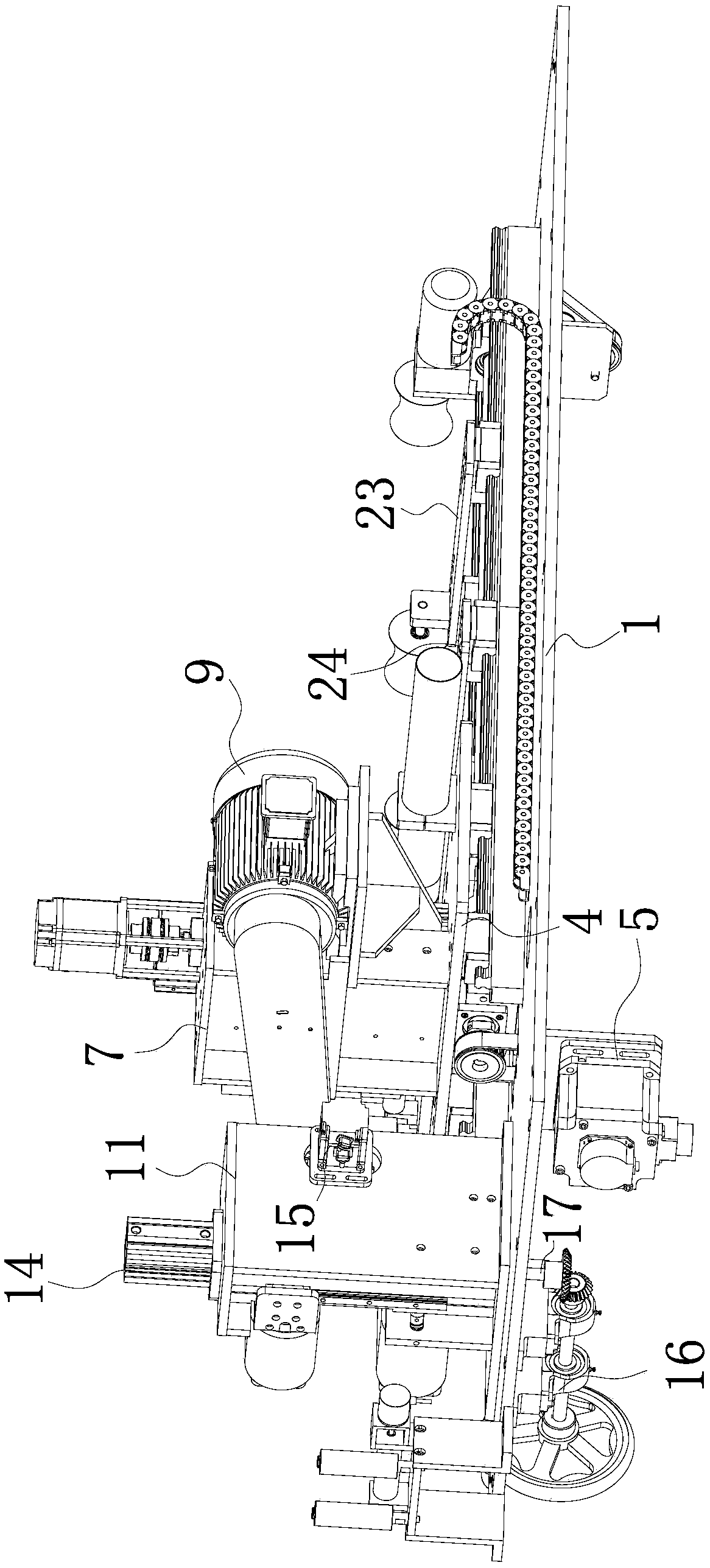

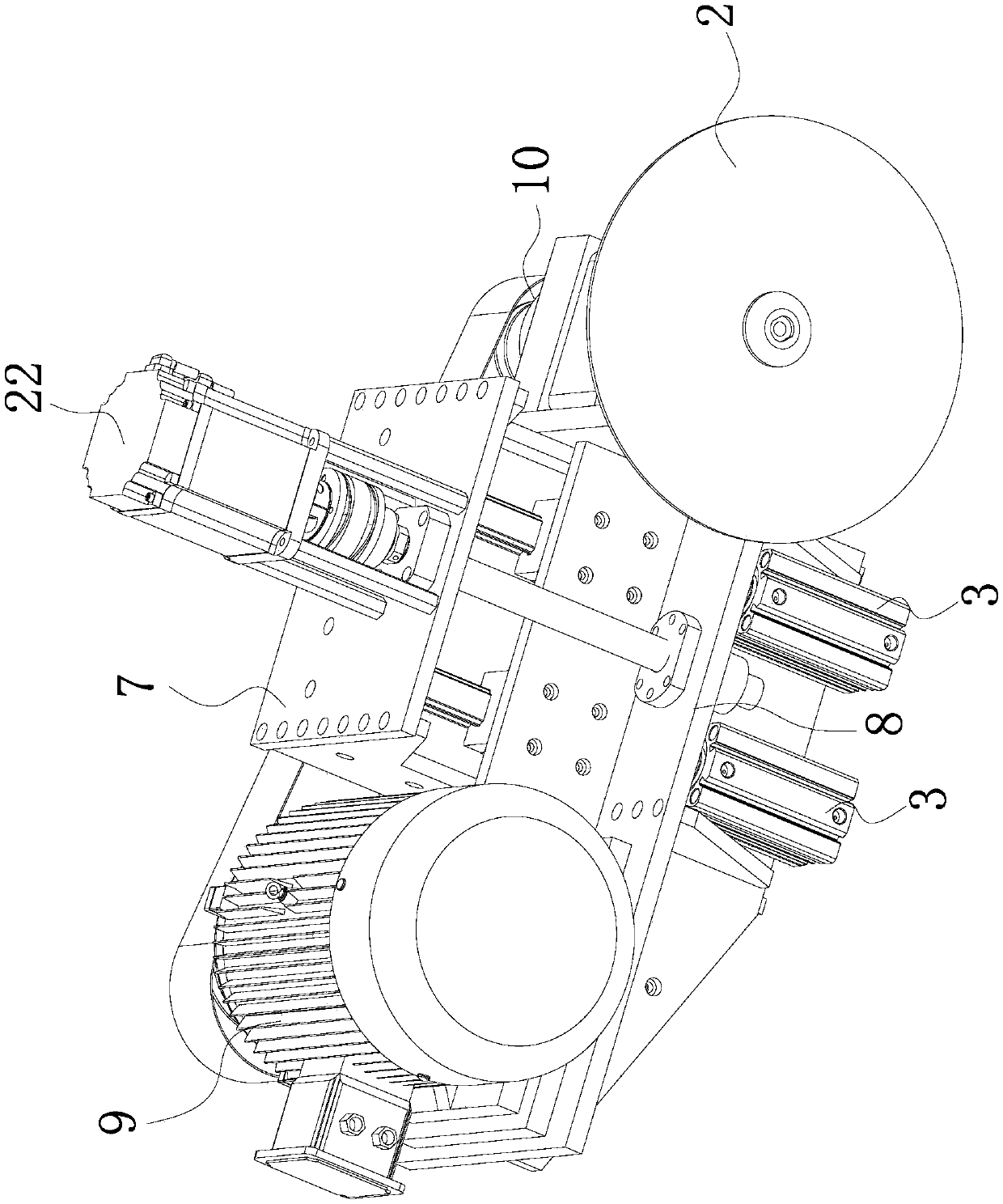

Ride-on Hot Melt Spray Marking Machine

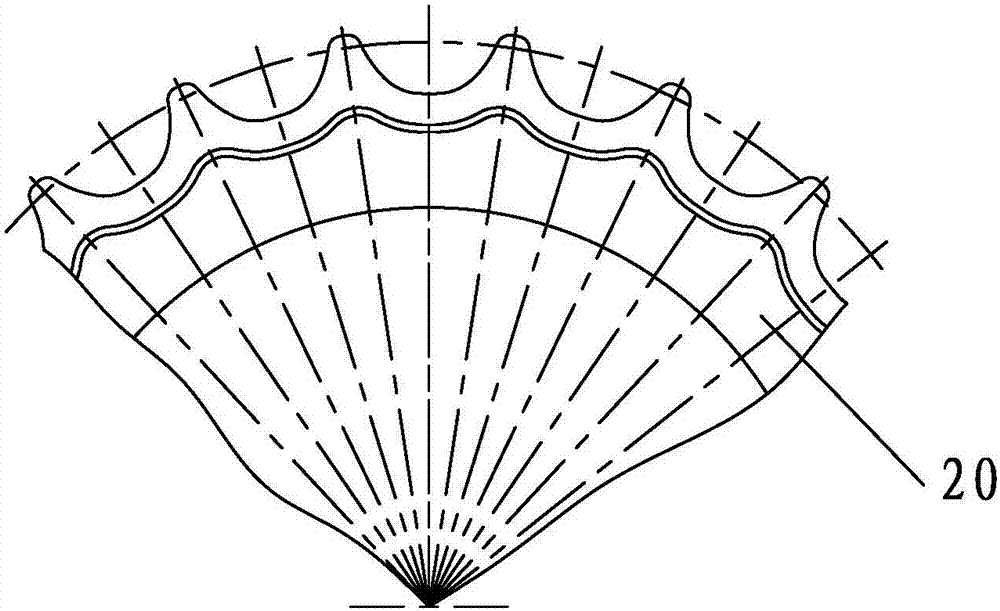

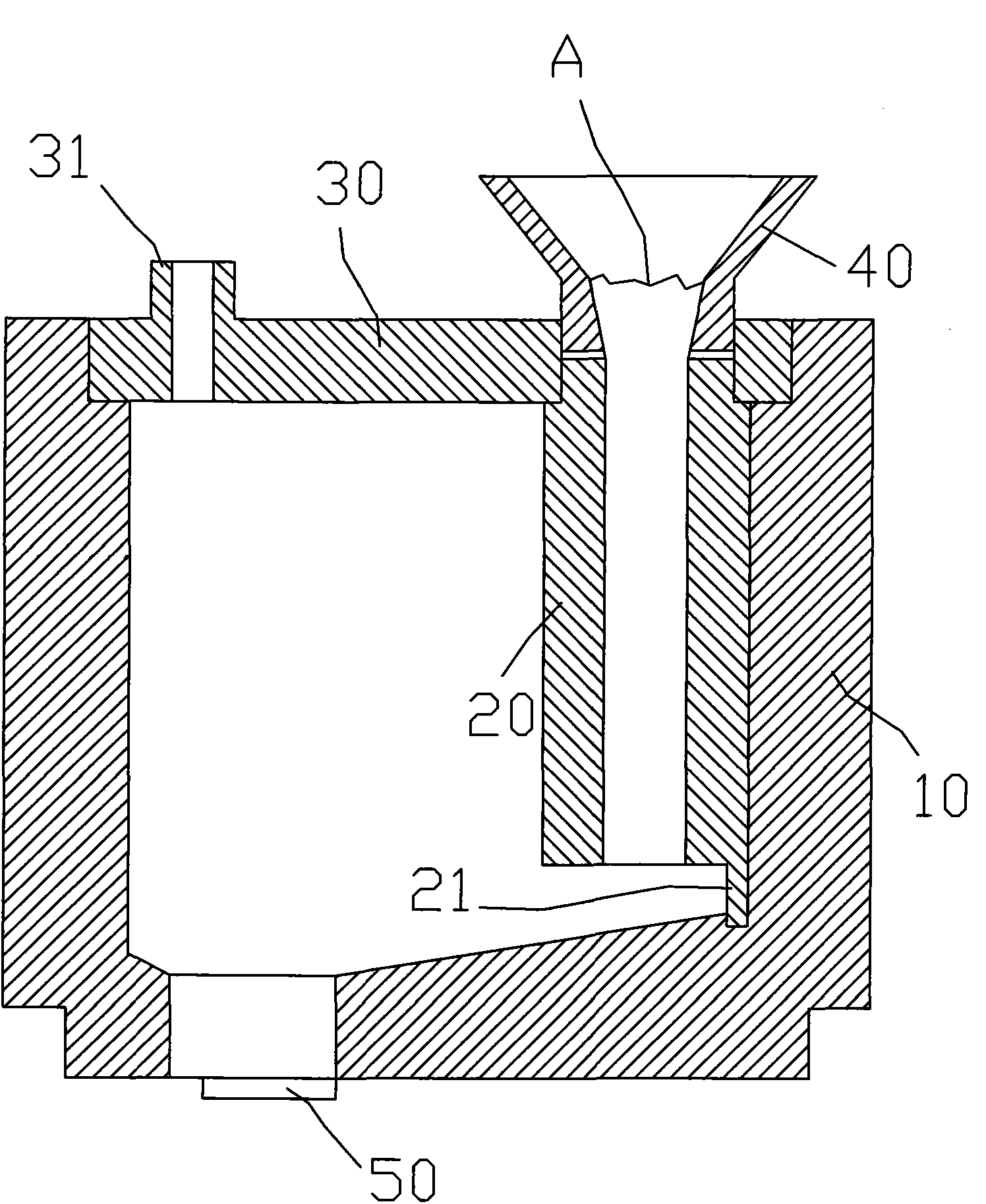

ActiveCN102268855AImprove atomization effectReduce burrsRoads maintainenceHeating systemHeating efficiency

The invention discloses a drive type hot-melt spraying marking machine, which comprises a rack, and the rack is provided with a power-driven system, a heating system, a marking system, a travel system, a hydraulic control system, a pneumatic control system and a steering system, wherein the power-driven system is in drive connection with the travel system, the hydraulic control system and the pneumatic control system respectively; the hydraulic control system is in drive connection with the steering system; and the marking system is in drive connection with the hydraulic control system and the pneumatic control system respectively. In the invention, a hot-melt spraying coating is heated to be a molten condition through an infrared heating system and a heat-conduction-oil heat preservationcyclic system, and then is sprayed to specified positions through a hot-melt gun, and the like. The drive type hot-melt spraying marking machine has the advantages of high marking efficiency, no needof removing existing lines for redintegration, adjustable width and thickness of marking lines, high heating efficiency, sufficiency for combustion and flexible control of flames.

Owner:天途路业集团有限公司

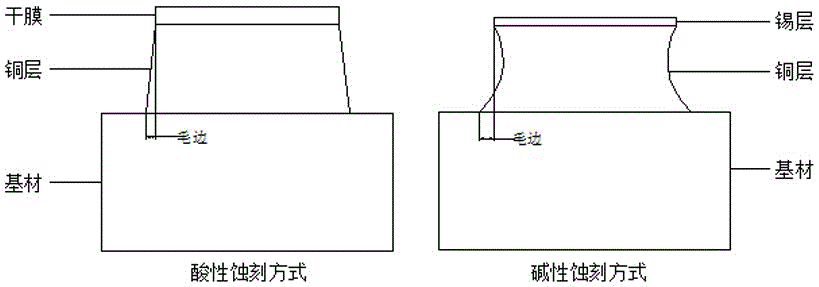

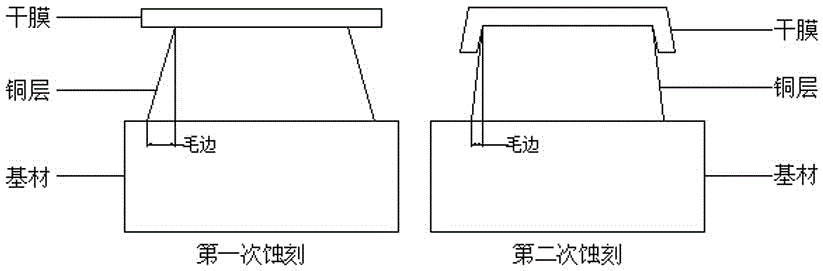

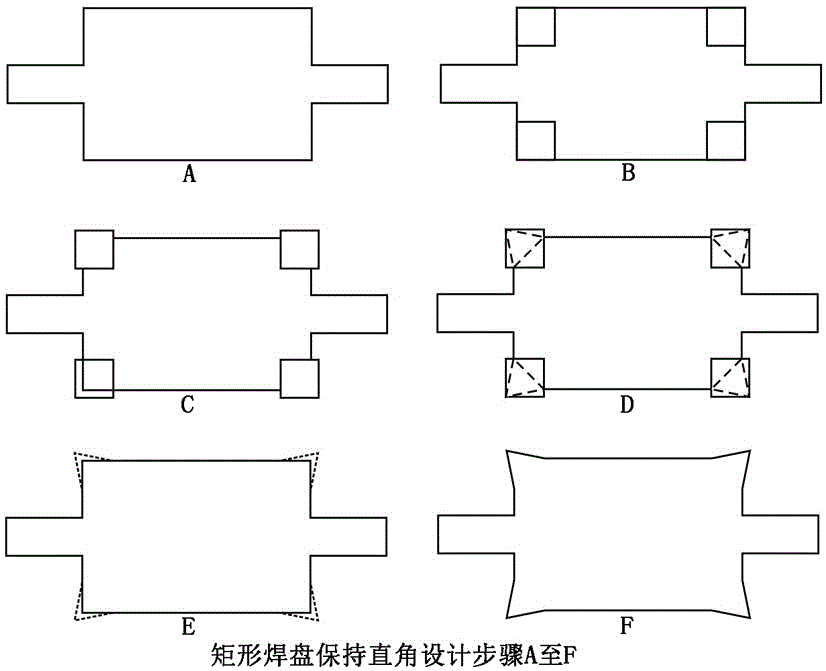

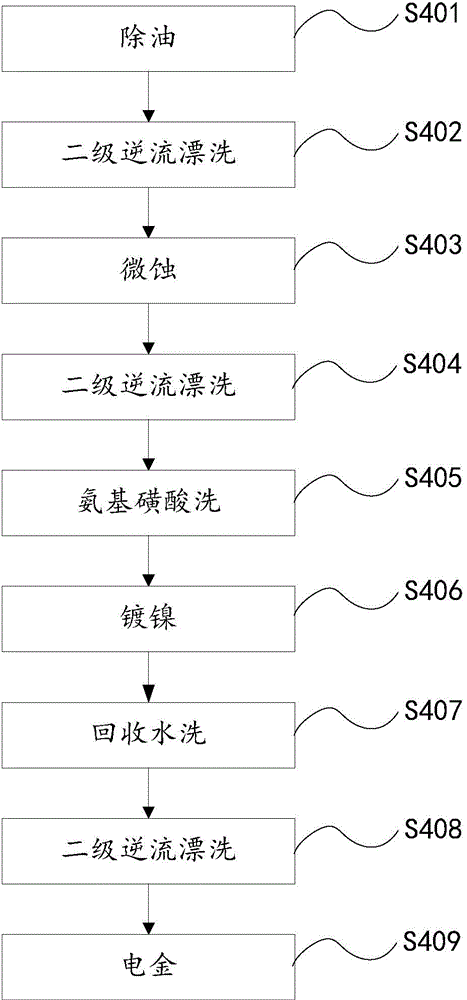

Manufacturing method of 77Ghz high-precision radio radar printed circuit board

ActiveCN106455325AReduce burrsReduce widthComputer designed circuitsConductive material chemical/electrolytical removalAcid etchingRadar

The invention discloses a manufacturing method of a 77Ghz high-precision radio radar printed circuit board. The method mainly comprises the steps of line double compensation design, acid etching way selection, optimization design of keeping a rectangular bonding pad and copper-free zone corner in a right angle and optimization design of a sheet electroplating frame. The others are manufactured by adopting a conventional process. The manufacturing method of the 77Ghz high-precision radio radar printed circuit board has the advantages of high pattern-etching precision, small line burrs, high processing efficiency, high yield and the like; the rectangular bonding pad and copper-free zone corner is kept in the right angle; and the cost is effectively reduced.

Owner:HUIZHOU KING BROTHER CIRCUIT TECH +2

Acetate plasticizer for improving smoking property of cigarette and method for preparing same

InactiveCN1994164AQuality improvementHigh fullnessTobacco smoke filtersVegetal fibresFlavorPlasticizer

Owner:YUNNAN REASCEND TOBACCO TECH GRP +1

Polydextrose cigarette humectant and using method thereof

InactiveCN102742928AIncrease moistureMaintain tobacco moisture contentTobacco preparationTobacco treatmentPolydextroseChemistry

Owner:HONGYUN HONGHE TOBACCO (GRP) CO LTD

Polyarylene sulfide having reduced outgassing and preparation method thereof

This disclosure relates to polyarylene sulfide that may exhibit excellent processability at low temperature, decrease outgassing and flash or burr generation, and thus may satisfactorily mold a product requiring high molding accuracy, and a method for preparing the same. Specifically, the polyarylene sulfide includes an arylene sulfide repeat unit and an arylene disulfide repeat unit, wherein the weight ratio of the arylene sulfide repeat unit:arylene disulfide repeat unit is 1:0.0001 to 1:0.05.

Owner:SK CHEM CO LTD

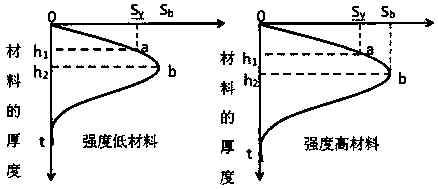

Copper alloy sheet and QFN package

ActiveCN101525702AReduce burrsReduced blade wearSemiconductor/solid-state device detailsSolid-state devicesHardnessCopper alloy

The invention relates to a QFN package which is provided with a lead frame formed by processing a copper alloy sheet containing 0.01 to 0.50% by mass Fe, 0.01 to 0.20% by mass P, and Cu and inevitable impurities as other components, having a micro Vickers hardness of 150 or above, a uniform elongation of 5% or below and a local elongation of 10% or below, or a copper alloy sheet containing 0.05 to 2% by mass Ni, 0.001 to 0.3% by mass P, 0.005 to 5% by mass Zn, and Cu and inevitable impurities as other components, having a micro Vickers hardness of 150 or above, a uniform elongation of 5% or below and a local elongation of 10% or below. Lead burrs formed during the dicing of the QFN package are short, and a dicing blade used for dicing the QFN package is abraded at a low wear-out rate.

Owner:KOBE STEEL LTD

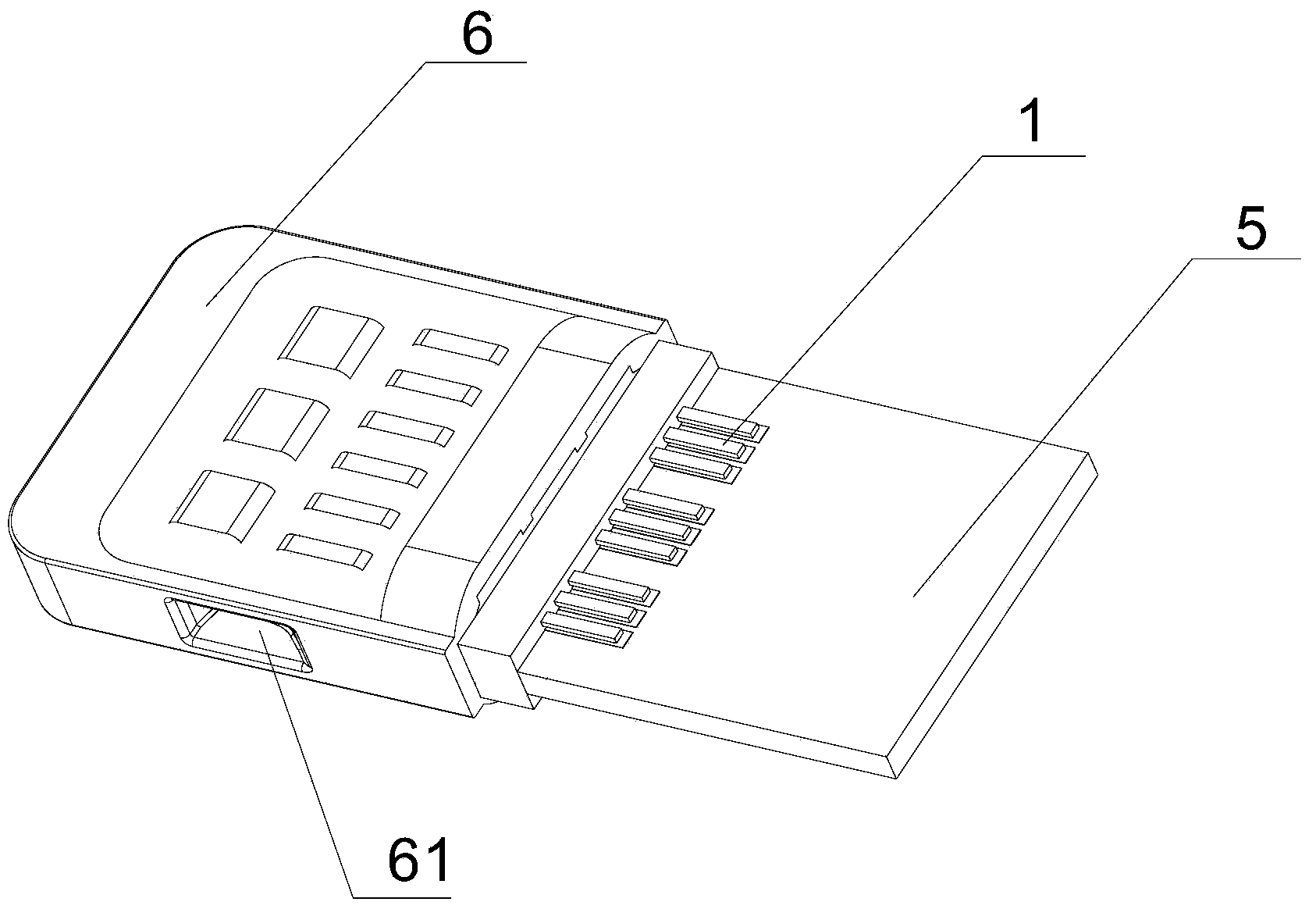

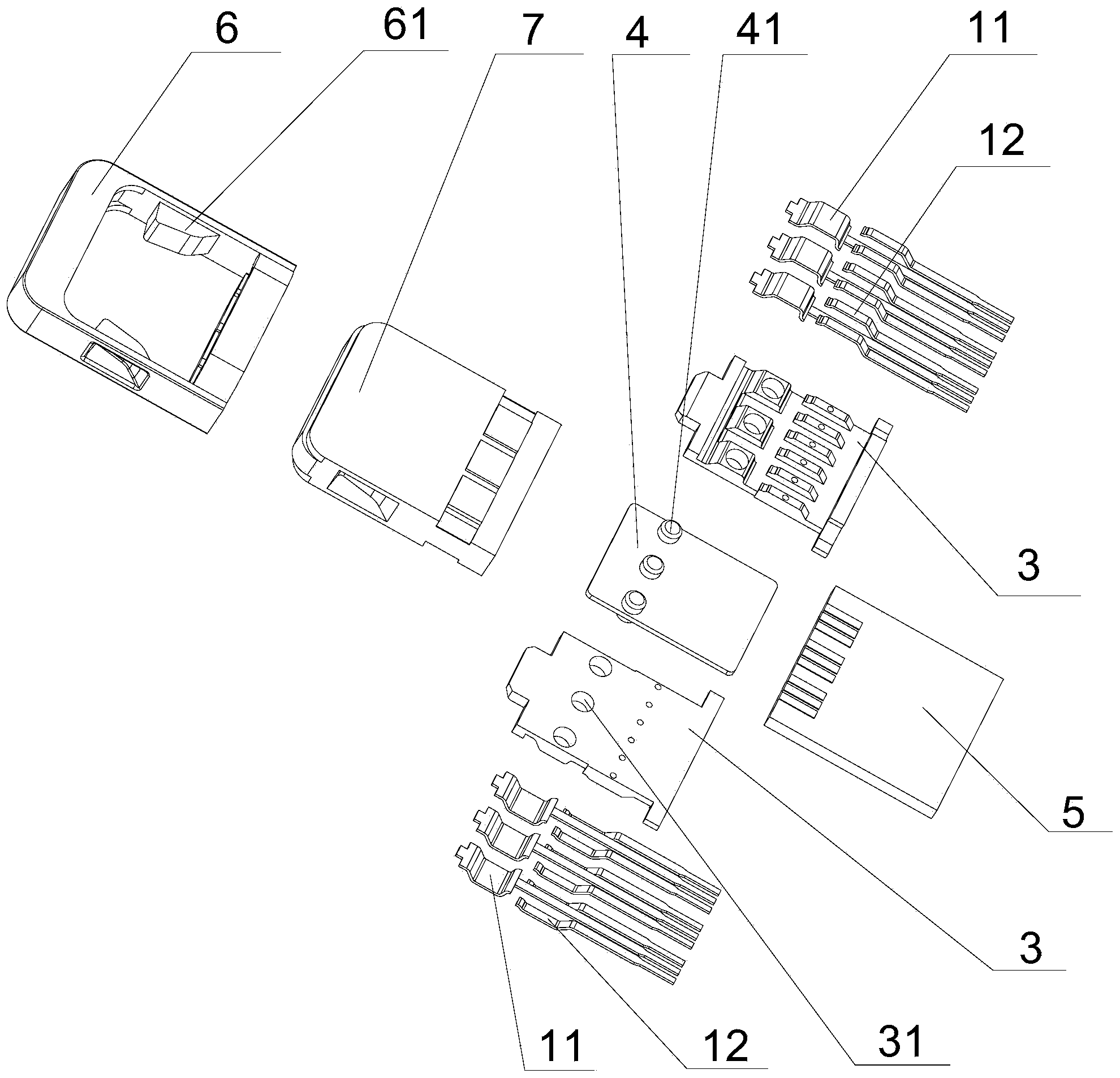

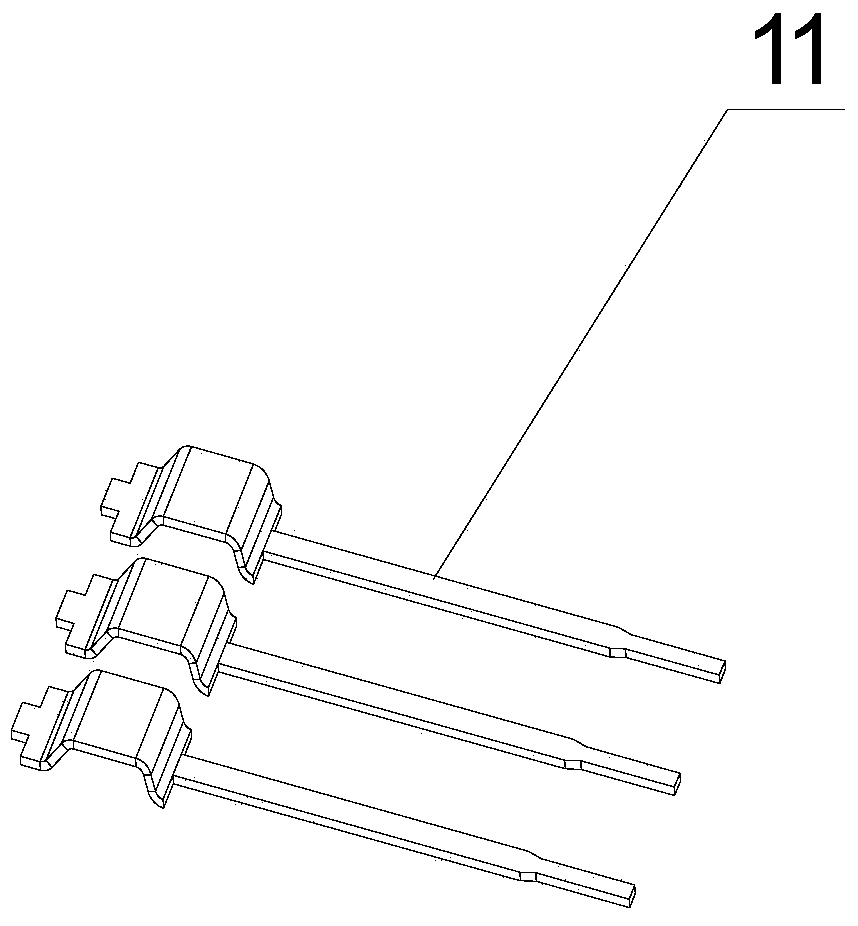

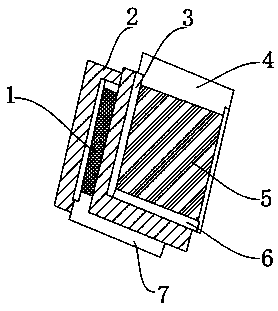

Two-sided plug-in connector and manufacturing method thereof

ActiveCN104377481ASolve the problem that the height tolerance is difficult to controlReduce poor contactContact member assembly/disassemblyCouplings bases/casesWork in processMechanical engineering

The invention provides a two-sided plug-in connector. The two-sided plug-in connector comprises an electric connecting piece, a shell, terminal sets, a terminal fixing layer and an elastic piece. The terminal sets are fixed to the terminal fixing layer, so that first injection parts are formed. The elastic piece is fixed between the two injection parts. The tail ends of the terminal sets are fixed to the electric connecting piece. The elastic piece, the first injection parts and the electric connecting piece are fixed together to form a semi-finished product. In this way, the two-sided plug-in connector can reduce the production cost, poor contact between the terminals can be reduced, and the quality of the connector is improved.

Owner:GOERTEK INC

Magnesium-lithium alloy foil and preparation method and application thereof

ActiveCN111004951AShort preparation processImprove efficiencyTemperature control deviceMetal rolling arrangementsIngotAluminum foil

The invention belongs to the technical field of magnesium-lithium alloy materials, and particularly relates to a magnesium-lithium alloy foil and a preparation method and application thereof. A magnesium-lithium alloy cast ingot is coiled into an alloy coiled tape with the thickness of 1.5-3.5 mm through large-deformation hot extrusion cogging, then, multi-pass coiling type cooling rolling is conducted through a four-roller aluminum foil rolling mill provided with a tension roller set and a coiling machine, and thus the magnesium-lithium alloy foil is obtained, wherein the minimum thickness ofthe magnesium-lithium alloy foil can be rolled to 0.014 mm. The foil is short in preparation process, high in efficiency, small in residual stress, fine in grain, smooth, free of burrs and high in yield, and the yield can reach 80% or above. The magnesium-lithium alloy foil is used for preparing a vibrating diaphragm or a vibrating diaphragm dome base material, and has good shock absorption performance and high fidelity.

Owner:郑州轻研合金科技有限公司

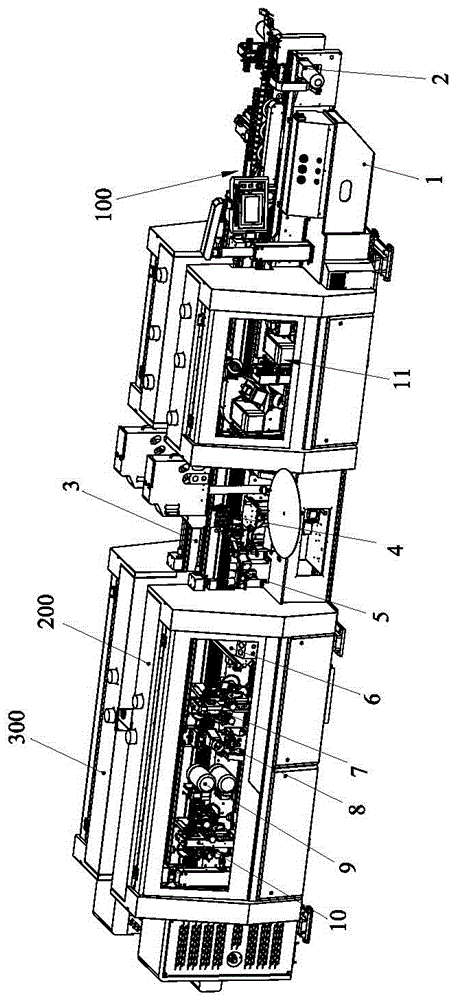

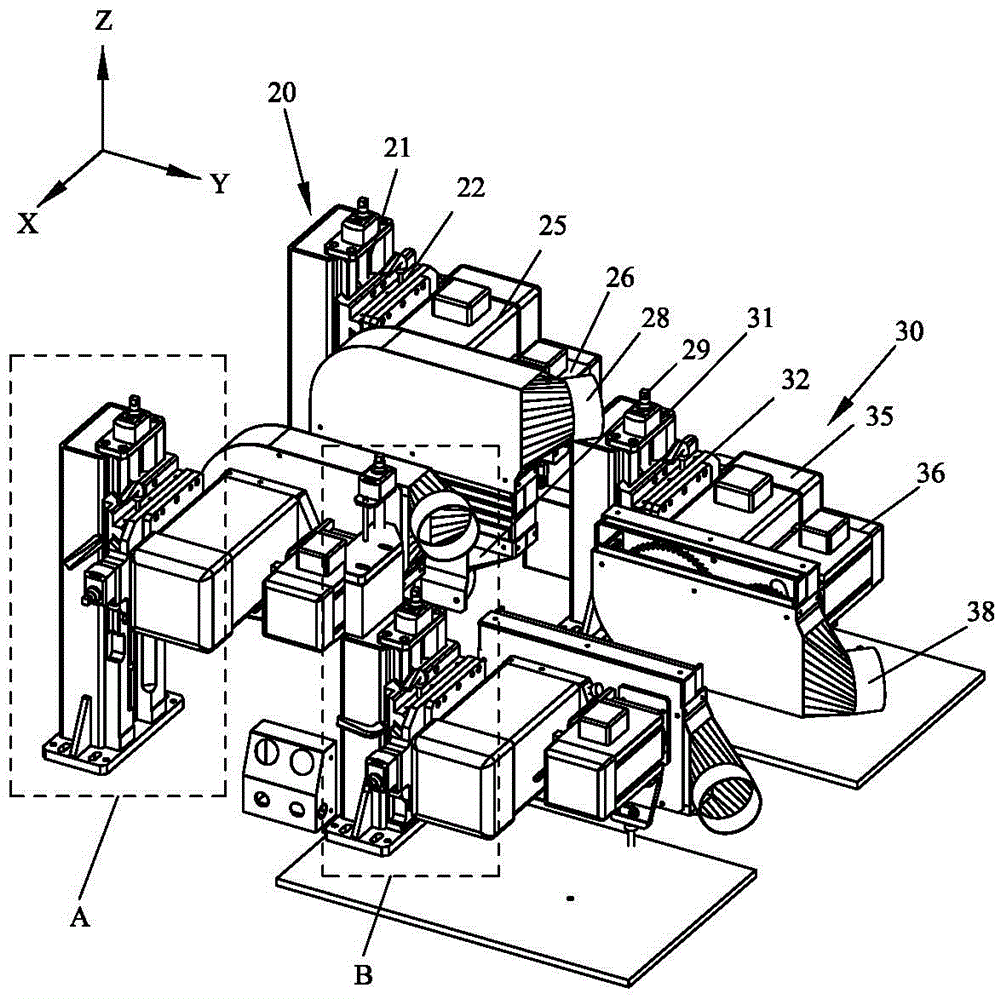

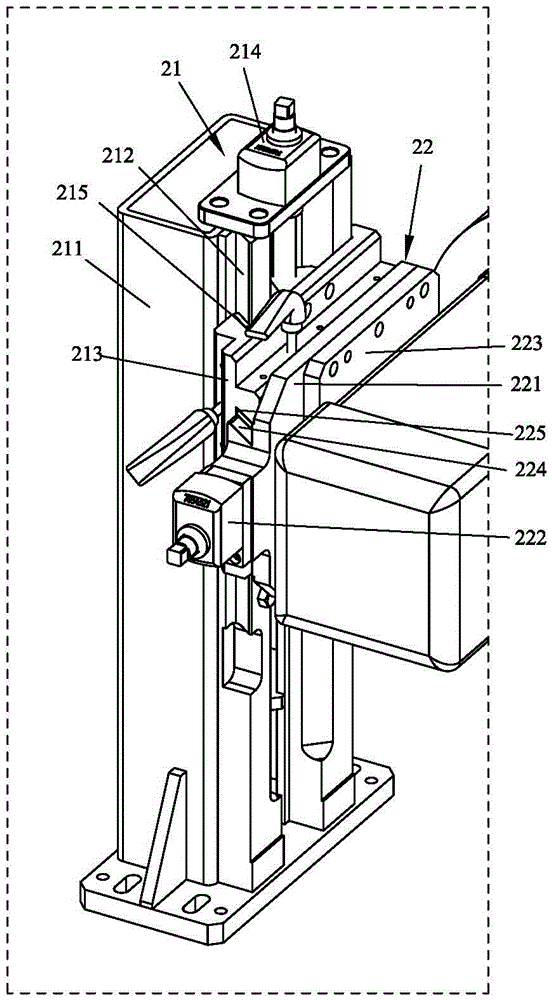

Automatic edge sealing machine provided with double saws

ActiveCN105643764ALow costRaise the price-to-earnings ratioMulti-purpose machinesWood mortising machinesMechanical engineeringEngineering

The invention discloses an automatic edge sealing machine provided with double saws. On the basis of gluing, pressing, tape cutting, rough trimming, fine trimming, scraping and polishing in general universal edge sealing operation, a double-saw device is additionally arranged at the two sides; the double-saw device is integrated with the edge sealing machine, so the user cost is lowered, the installation factory area of the user is also reduced, the edge sawing, milling and sealing time is shortened as well, and the price-to-earning ratio of the user is increased; particularly, the double-saw device comprises an upper saw component and a lower saw component, wherein the upper saw component and the lower saw component are each provided with a cutting saw blade and a slotting saw blade; the slotting saw blade has a positive and negative tilt angle function, so burrs and fracture generated after slotting and sawing can be reduced.

Owner:NANXING MACHINERY CO LTD

Quick-charging and safe low-temperature lithium ion battery and manufacturing method thereof

InactiveCN111370752AIncrease contact areaEliminate the "partition wall effect"Final product manufactureSecondary cellsInternal resistanceFast charging

The invention discloses a quick-charging and safe low-temperature lithium ion battery and a manufacturing method thereof. The battery is prepared by putting a dry battery cell into a shell, injectingelectrolyte, forming, sealing and grading capacity, and the dry battery cell is formed by winding a positive plate, a ceramic diaphragm, a negative plate and a ceramic diaphragm. The positive / negativeelectrode active substance is secondary micron particles formed by primary nanoparticles, and the nanoscale particles can effectively shorten the migration distance of lithium ions and improve the migration speed of the lithium ions in the charging and discharging process of the battery. Meanwhile, the multiple tabs led out from the positive and negative plates of the dry battery cell are gathered and then are welded with the planar metal sheet current collector to form a full tab. The internal resistance and the temperature rise of the battery in the charging process are effectively reduced,the problem of high-rate quick charging of the battery is solved, the high-current charging and discharging performance of the battery is improved, and the safety stability and the low-temperature electrochemical performance of the battery are also improved.

Owner:LONG POWER SYST NANTONG CO LTD

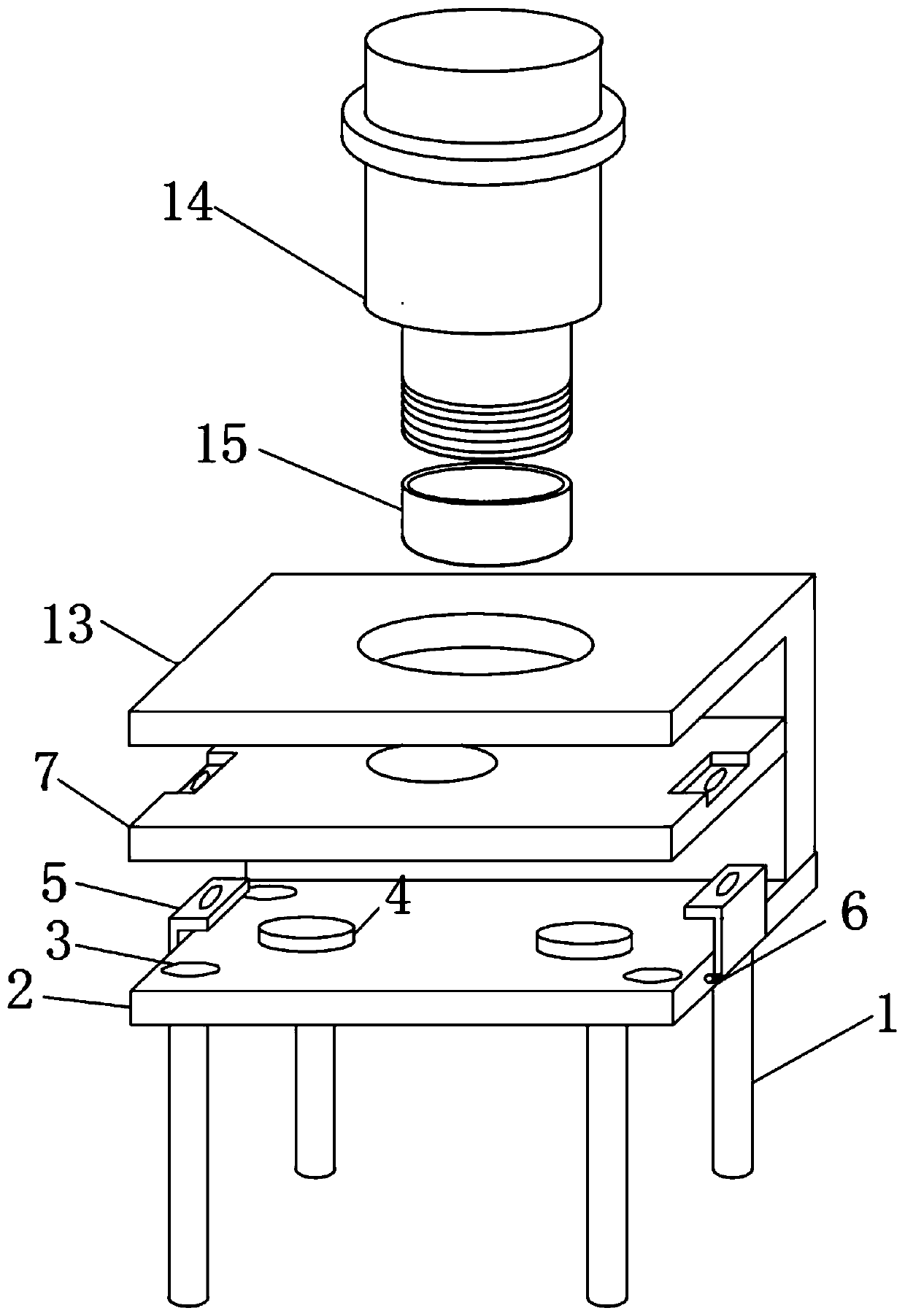

Automatic punching mechanism for aluminum plate punching

The invention discloses an automatic punching mechanism for aluminum plate punching. The mechanism comprises a punching machine bracket, a support plate and a movable punching rod; the upper end of the punching machine bracket is fixedly connected with the support plate; a first limiting groove and a first limiting column are arranged on the support plate; the side surface of the support plate ismovably connected with a fixed plate; through arrangement of a punching device, when aluminum plates are punched, surrounding annular blades firstly cut the aluminum plates, so that the cracking condition can be reduced during punching; an elastic circular plate is arranged in a template hole, and is compressed to a template groove during punching to eject onto a template; after punching, the elastic circular plate returns the punched aluminum plates; and through cooperative arrangement of a punching head and the template, and arrangement of a cutting device on the punching head, punched holescan be punched more smoothly, and the burr phenomenon of the aluminum plates is reduced.

Owner:盐城紫环工业机械有限公司

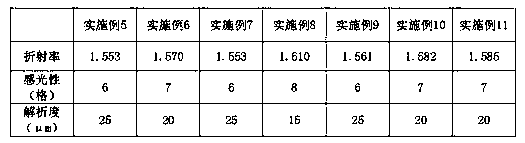

High-refractive-index alkaline water soluble resin and preparation method thereof, and high-refractive-index photoresist

ActiveCN111100237AHigh refractive indexHigh light transmittancePhotosensitive materials for photomechanical apparatusAlkaline waterPolymer science

The invention relates to high-refractive-index alkaline water soluble resin. The alkaline water soluble resin is characterized by being obtained by copolymerization of a monofunctional monomer with high refractive index and acrylic acid or methacrylic acid or / and an acrylate monomer, the weight-average molecular weight of the alkaline water soluble resin with the high refractive index is 20,000-150,000, the acid value is 500mgKOH / g-100mgKOH / g, and the refractive index is greater than or equal to 1.50. The invention also relates to a preparation method of the high-refractive-index alkaline water soluble resin and a high-refractive-index photoresist containing the high-refractive-index alkaline water soluble resin. The high-refractive-index alkaline water soluble resin and the preparation method thereof, and the high-refractive-index photoresist have the advantages that the alkaline water soluble resin with high refractive index and the photoresist with high refractive index have higherrefractive index and light transmittance.

Owner:WUXI DERBELL PHTO ELECTRONICS MATERIAL

Automatic sheet metal part loading, processing and forming device

ActiveCN111113050AEasy to useEasy to measureEdge grinding machinesMetal-working feeding devicesStructural engineeringSheet metal stamping

The invention discloses an automatic sheet metal part loading, processing and forming device. A sheet metal punch is mounted in the middle of the outer surface of a loading rack, a sheet metal cuttingmachine is mounted in a position, located on one side of the sheet metal punch, of the outer surface of the loading rack, and a measuring mechanism is mounted in a position, located on one side of the sheet metal cutting machine, of the outer surface of the loading rack. The measuring mechanism comprises a measuring rack, a main air cylinder, a movable L-shaped plate, a driven manual telescopic rod, a connecting rod, a round hole and a laser lamp. The measuring rack is mounted in a position, located on one side of the sheet metal cutting machine, of the outer surface of the loading rack. It is convenient to measure the edge of a cut sheet metal part by means of the measuring rack, the main air cylinder, the movable L-shaped plate, the driven manual telescopic rod, the connecting rod, theround hole and the laser lamp, so that the flatness of the edge of the cut sheet metal part is guaranteed. Meanwhile, a phenomenon that the edge of the cut sheet metal part deviates is prevented, so that the sheet metal part is cut more flatly.

Owner:晋江荣达机械有限公司

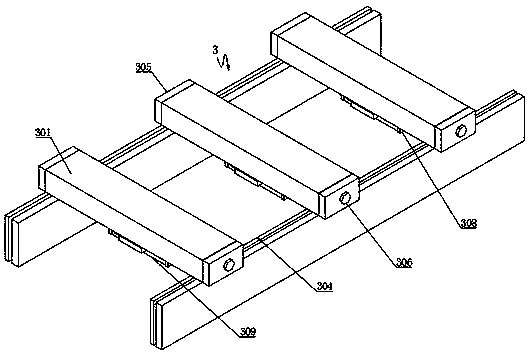

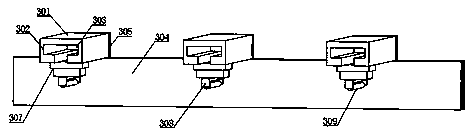

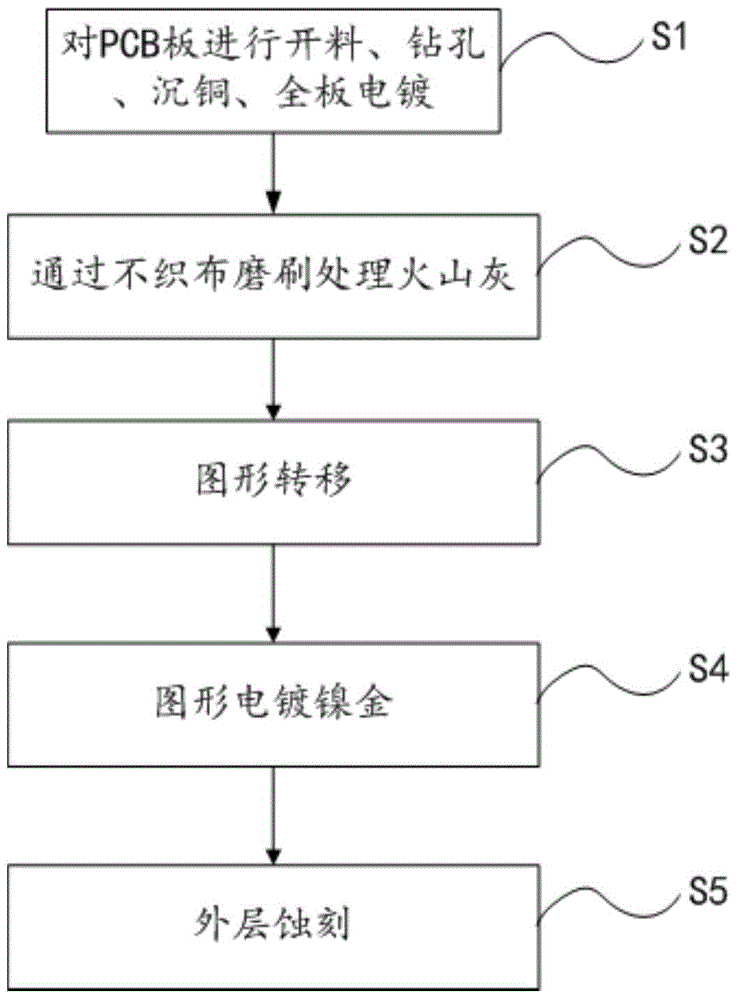

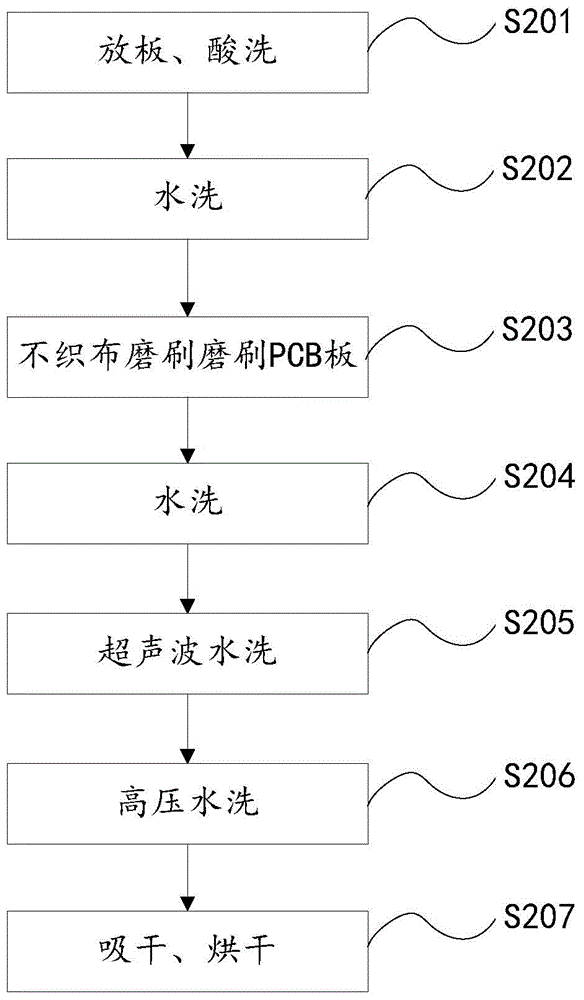

Printed circuit board (PCB) manufacturing method

ActiveCN104619123AReduce burrsReduce side erosionInsulating substrate metal adhesion improvementConductive material chemical/electrolytical removalCopper platingEtching

The invention relates to a PCB manufacturing method. The method comprises the steps of S1, performing cutting, drilling, electroless copper plating and full-board electroplating; S2, brushing and processing cinerite through non-woven fabrics; S3, pattern transfer; S4, pattern nickel gold electroplating; S5, outer layer etching. By the aid of the method, the PCB bonding tension value can reach 9N, compared with the prior art, the bonding tension value is improved greatly, the problems of bonding de-soldering, bonding deviation, poor bonding recognition and the like are solved effectively, and accordingly, the PCB quality is improved greatly.

Owner:HUIZHOU XINGZHIGUANG TECH

Machining method for aero-engine inclusive casing

ActiveCN104439934AGuarantee processing qualityReduce processing costsAircraft componentsFiberTechnical standard

The invention discloses a machining method for an aero-engine inclusive casing. When the aero-engine inclusive casing is machined, the margin of turning is determined firstly, tools for turning and drilling and machining parameters are determined respectively, the machined casing is treated through pliers to meet the subsequence surface treatment requirements, and the whole machining process of the inclusive casing is finished. In addition, the inclusive casing is cooled in an air cooling mode after being machined. In order to prevent fibers from absorbing water and causing expansion and deformation of materials in the machining process of the inclusive casing, cooling liquid is not used, and a compared air cooling method is used for in the machining process to realize dry cutting. The machining method can effectively guarantee the machining quality of parts, guarantee that the defects of layering, cracking and the like among layers are avoided, completely meet the related technical standards of parts, reduce the machining cost of parts, and reduce machining technical difficulty.

Owner:AECC AVIATION POWER CO LTD

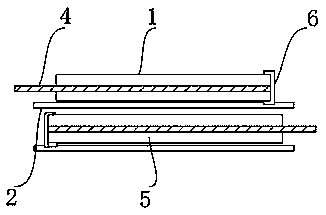

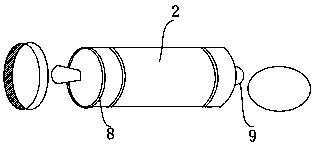

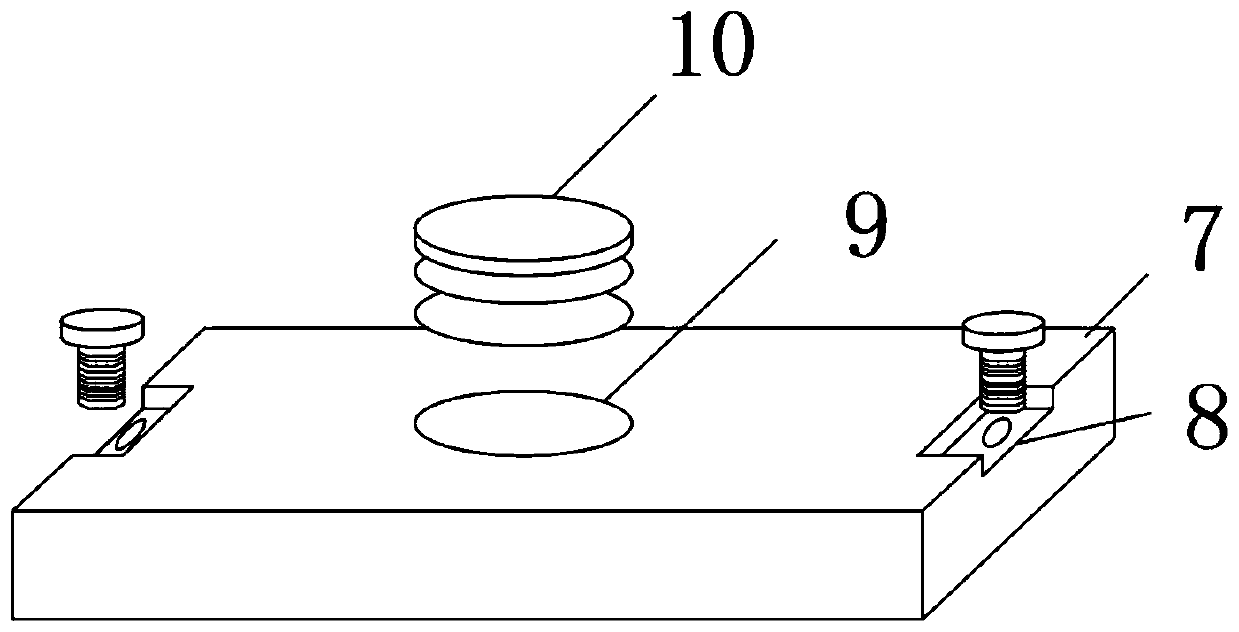

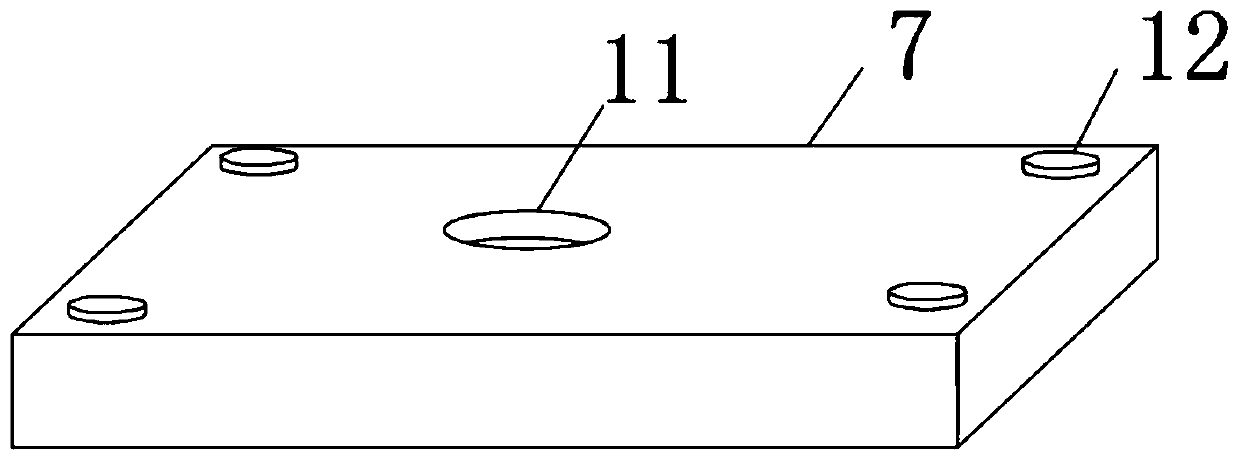

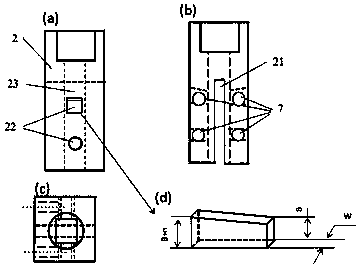

Shearing clamp and method for measuring material shearing performance and deformation using same

PendingCN109238837AAvoid slackEasy to take outMaterial strength using steady shearing forcesBiomedical engineering

A shearing clamp, consisting of two parts, that are an outer clamp (9) and an inner clamp (3). The outer clamp (9) is mainly composed of a base part (1) and a function part (2). The upper part of thefunction part (2) is provided with the base part (1) which forms a fixed connection relationship with it. The inner clamp (3) is provided with inner clamp through holes (32) adaptive to through holes(22) in the shape and the size and is coaxial with the through holes (22) after assembly. An experiment sample piece (8) to be sheared is placed inside hole cavities formed by communicating the through holes (22) and the inner clamp through holes (32). The invention further provides a method for measuring material shearing performance and deformation using the shearing clamp. In conclusion, the invention provides a shearing clamp with high operability, and provides a method for measuring material shearing performance and deformation using the same. The technical scheme is standard and reasonable; the technical effects are excellent, and it has the expected huge economic value and social value.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

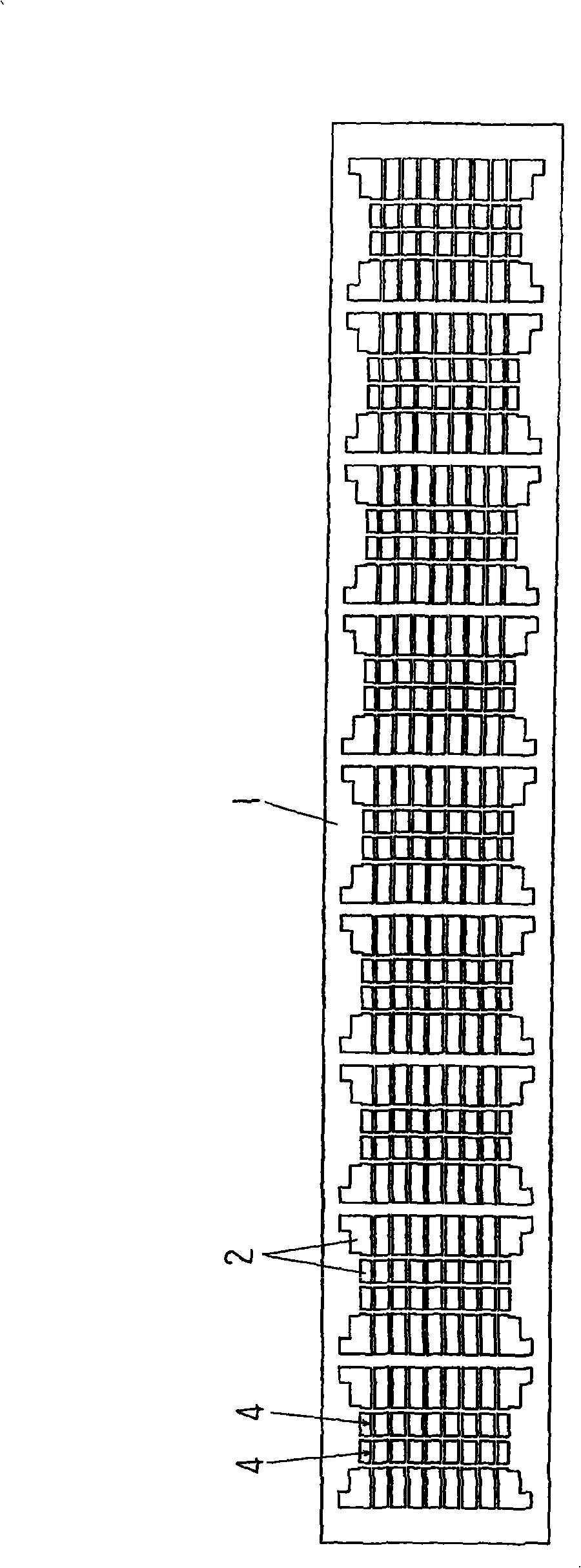

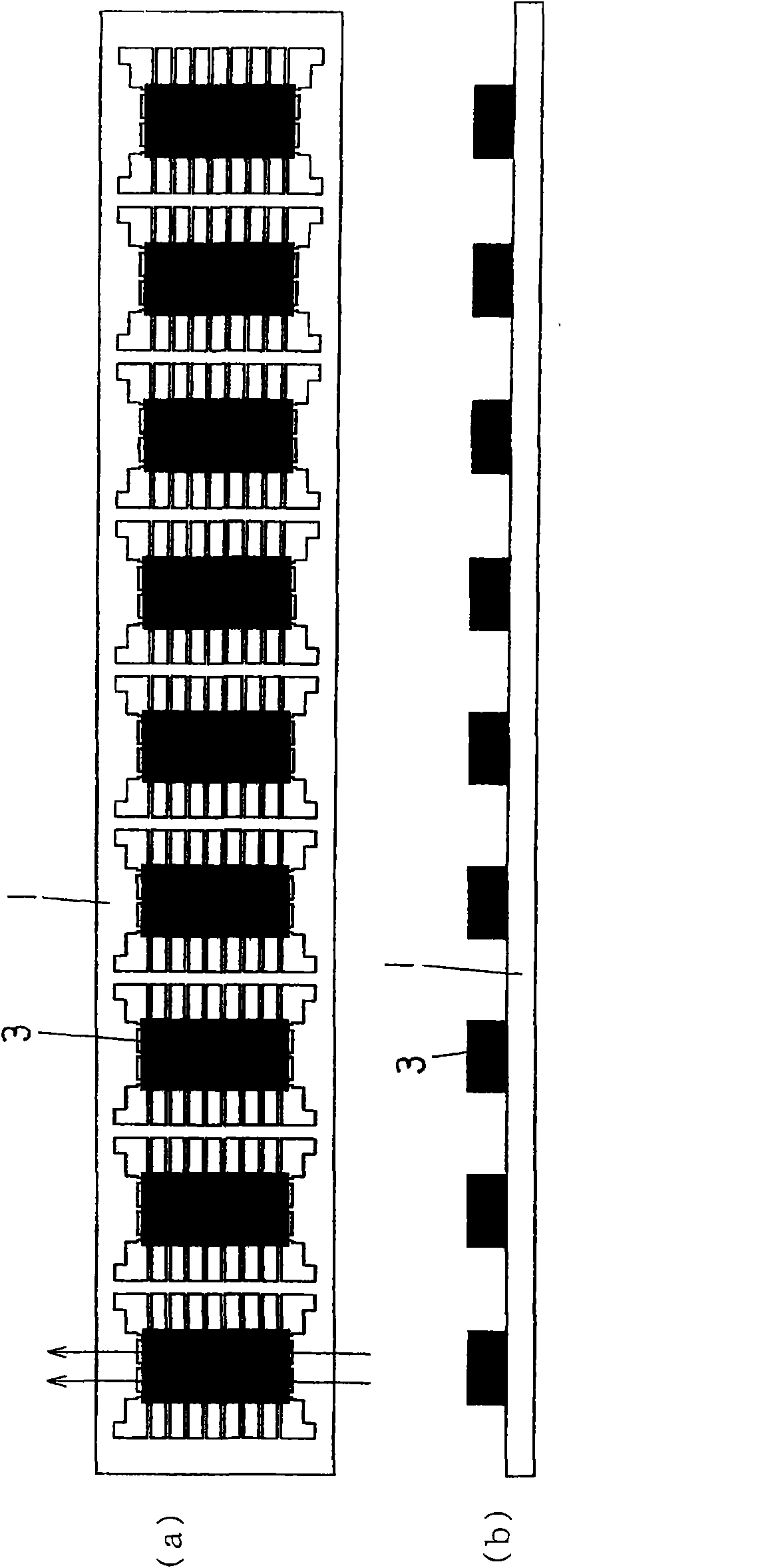

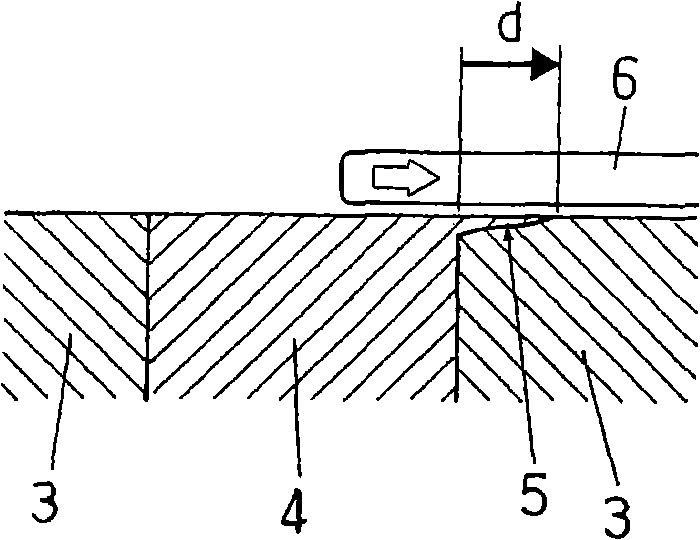

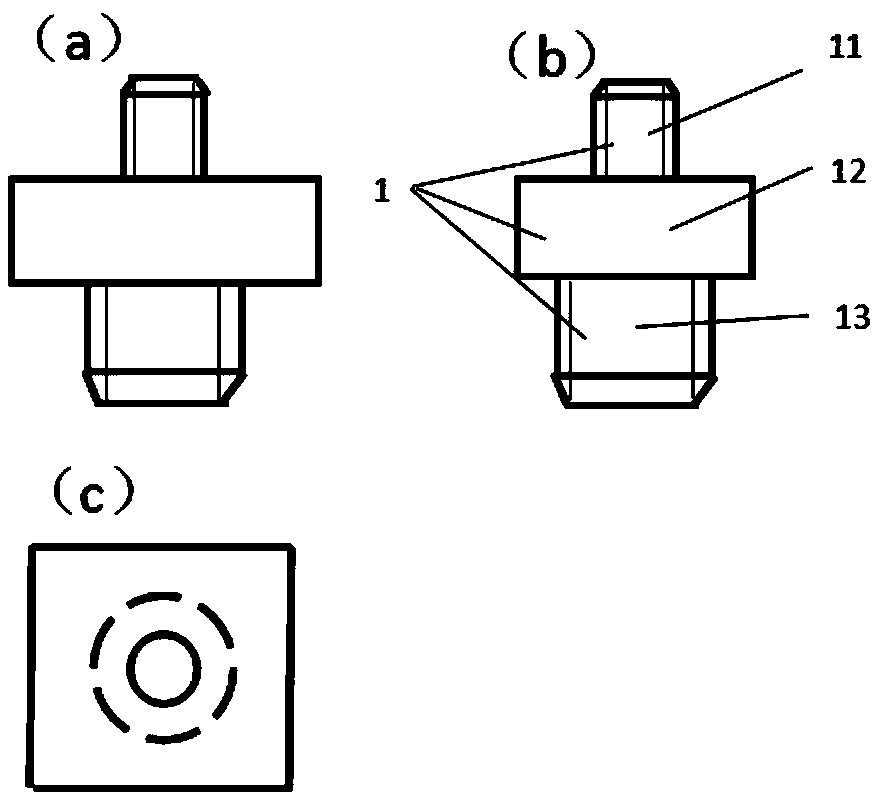

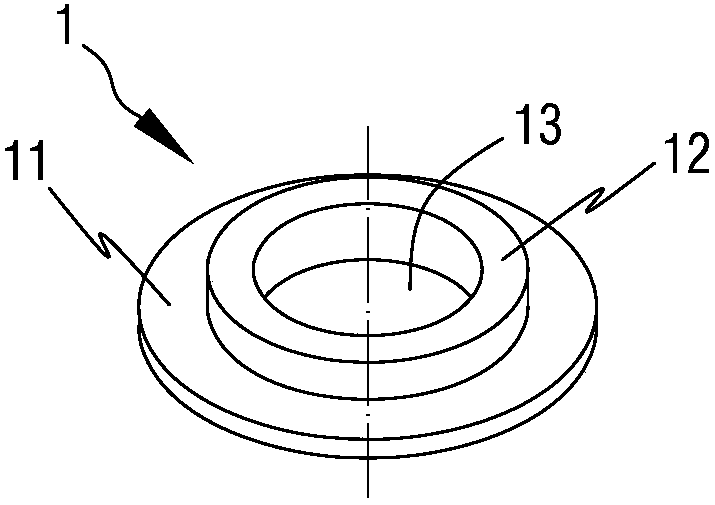

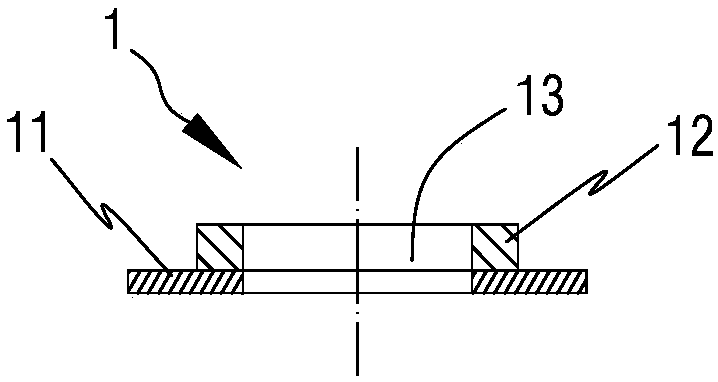

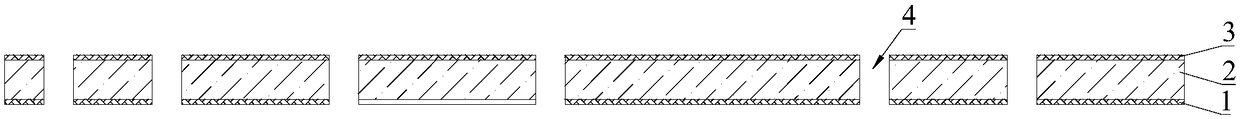

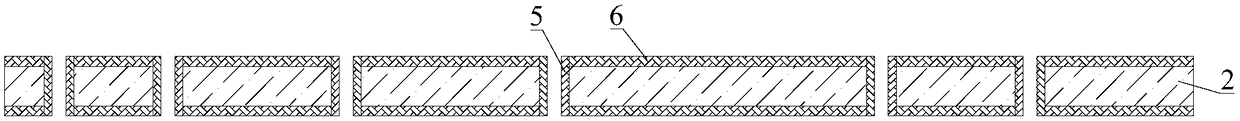

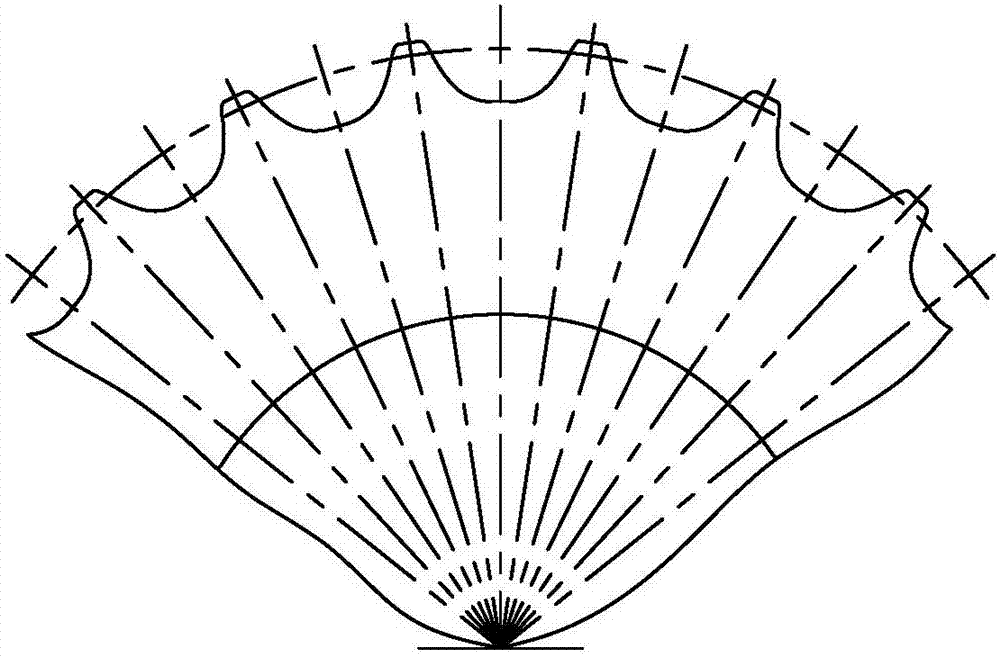

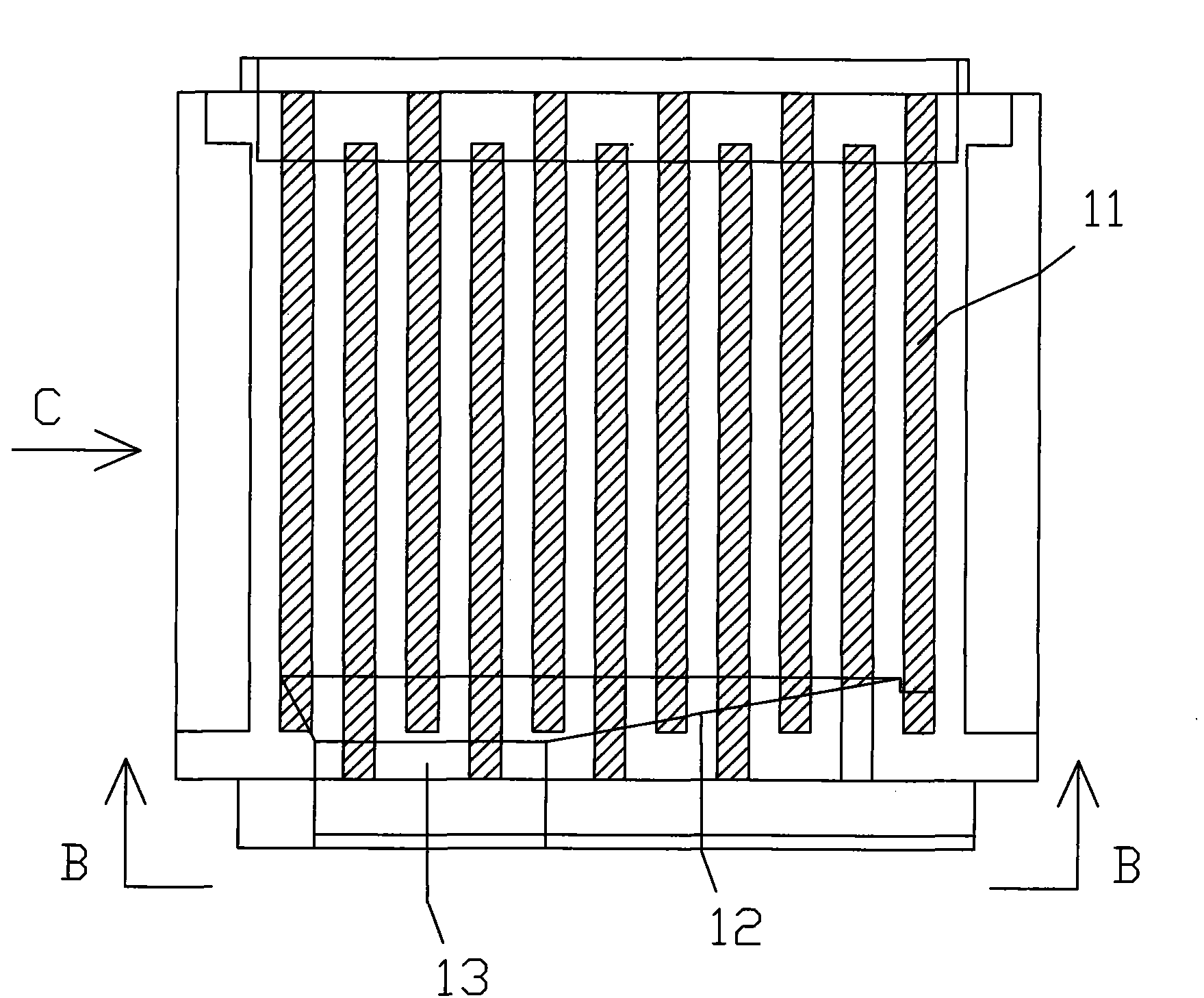

Wire frame and the manufacture of resin sealed semiconductor unit with the wire frame

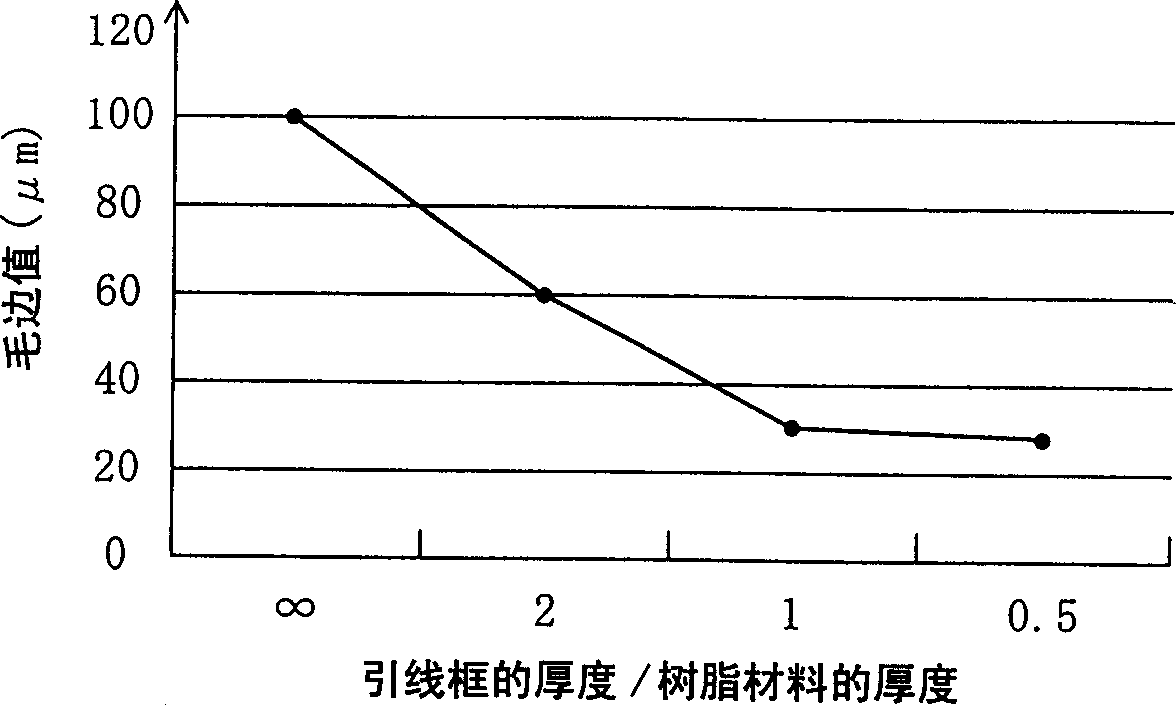

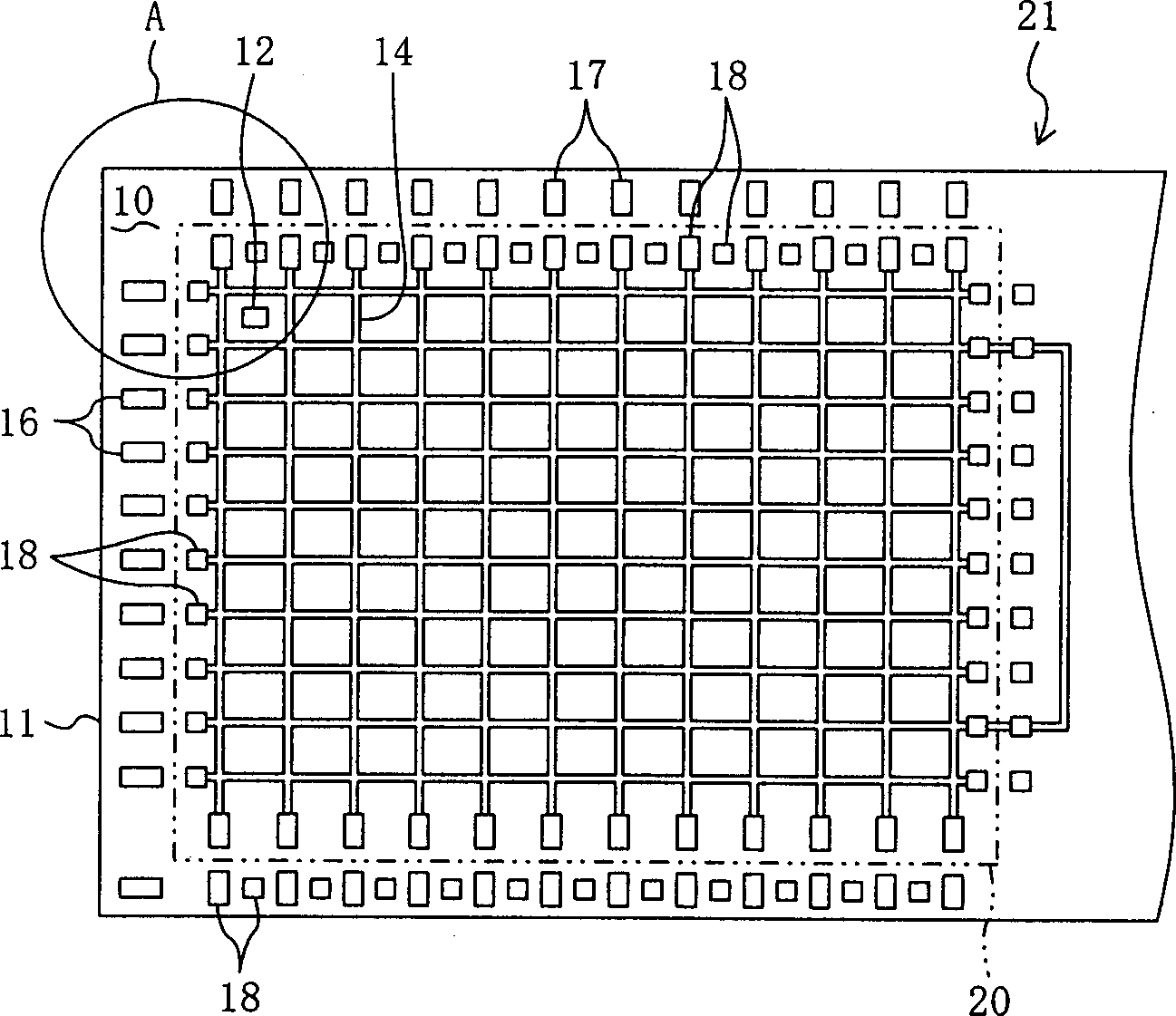

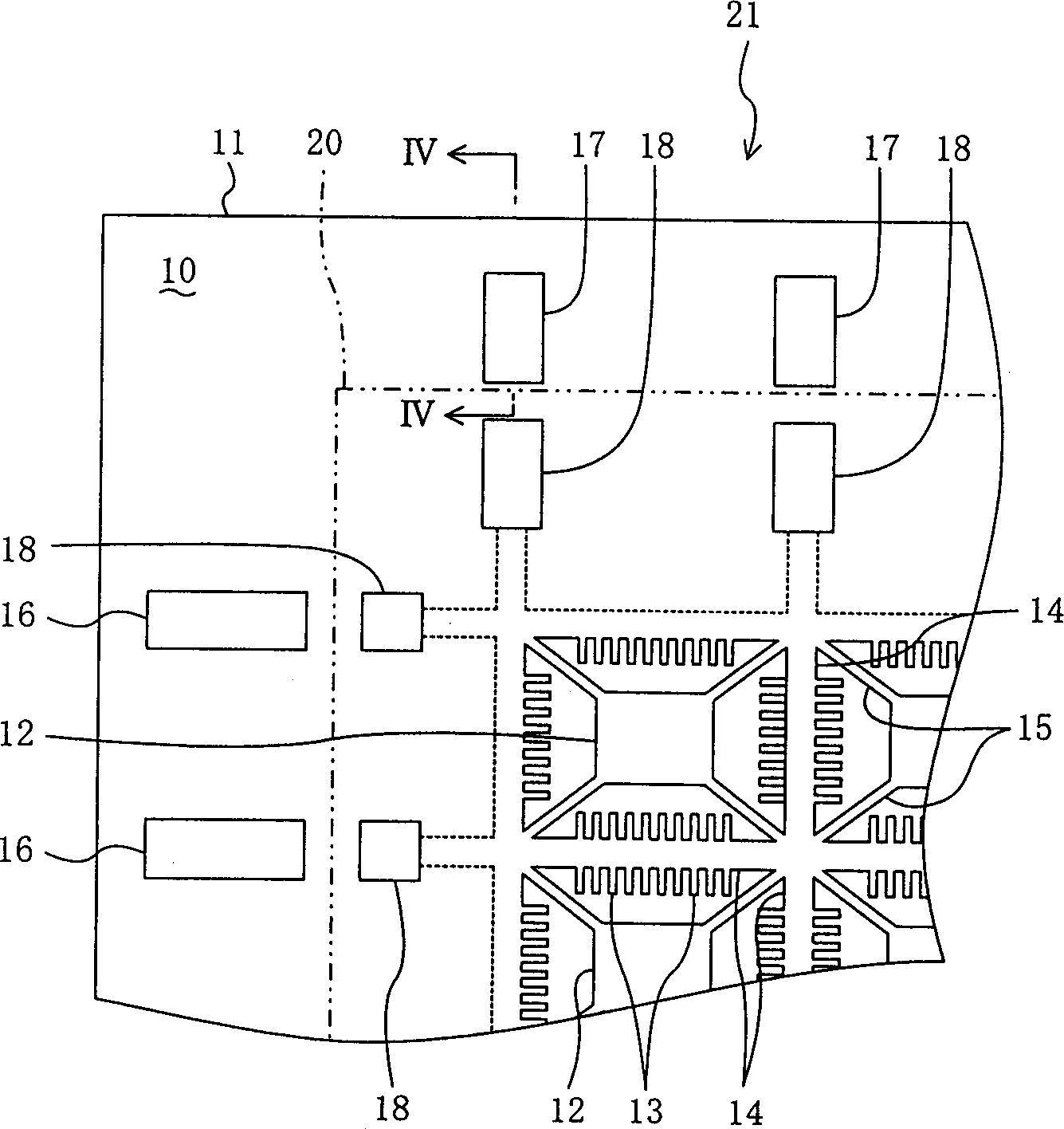

InactiveCN1371127AQuality improvementReduce the amount of cuttingSemiconductor/solid-state device detailsSolid-state devicesSemiconductor chipLead frame

A lead frame 10 includes: a plurality of chip loading parts 12 supported by the outer frame part 11 and respectively loading a plurality of semiconductor chips; inner lead parts 13 arranged around each chip loading part 12; The connecting portion 14 between the lead portion 13 and the outer frame portion 11 . The plurality of chip mounting portions 12 are surrounded by a sealing region 20 that is entirely sealed with a sealing resin. Outside the sealing area 20 of the outer frame portion 11 of the lead frame 10 and in the area on the extension line of the connecting portion 14, a first opening portion 16 having a width larger than that of the dicing blade is provided. To improve the quality of a resin-sealed semiconductor device by reducing burrs generated on the cut surface of a lead frame, while prolonging the life of a dicing blade and improving production efficiency.

Owner:TESSERA ADVANCED TECH

Mobile phone, mobile phone panel and manufacturing method thereof

InactiveCN101340467ASimple processEasy to operateTelephone set constructionsAgricultural engineeringEngineering

The invention discloses a mobile phone and a mobile phone panel thereof, the mobile phone panel of the mobile phone comprises a panel sheet which is made of transparent materials and a pattern color layer, the panel sheet comprises a shell body region and a visual window region, and the pattern color layer is covered on the shell body region of the panel sheet. The invention simultaneously discloses a manufacturing method of the mobile phone panel, and the method comprises the following steps: A. the color and the pattern of the shell body region are printed on the panel sheet, and the visual window region is maintained to be transparent; B. the panel sheet is cut into sizes which are applicable to the shaping of the panel; C. the shaping of the panel is realized by a high-temperature and high-pressure mode. The manufacturing method of the mobile phone panel of the invention is simple and practical, the shaping mode thereof is conductive to the improvement of the product yield, thereby effectively saving raw materials and saving cost of a mold and a machine.

Owner:BYD CO LTD

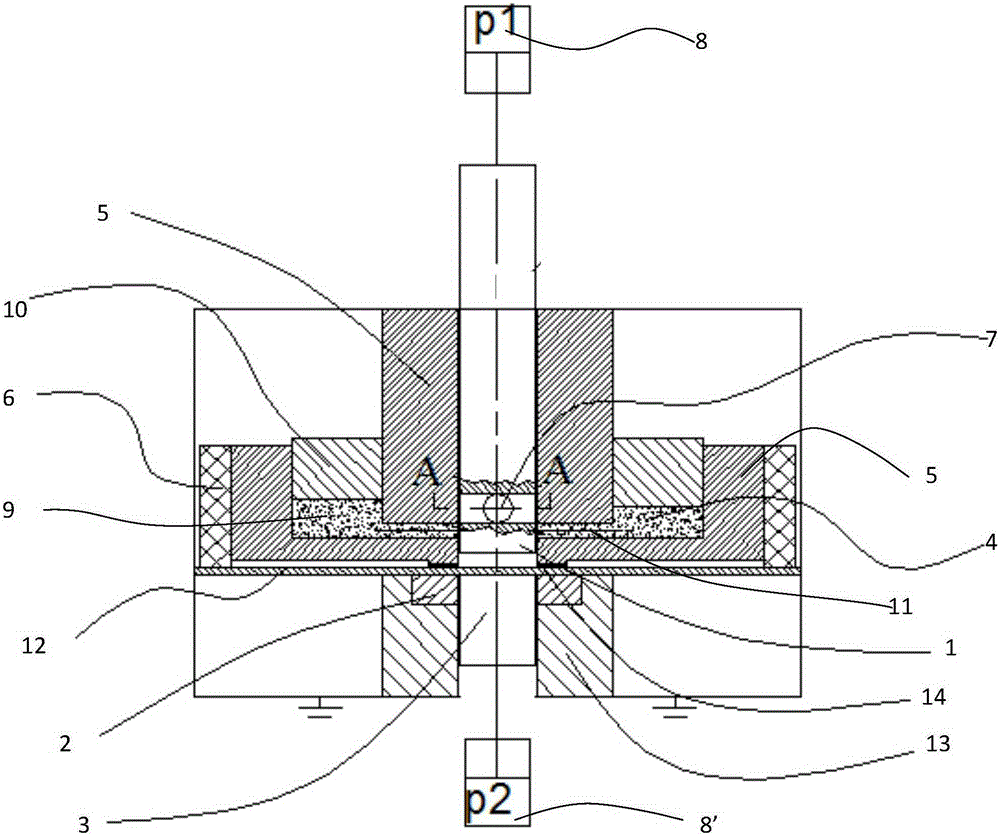

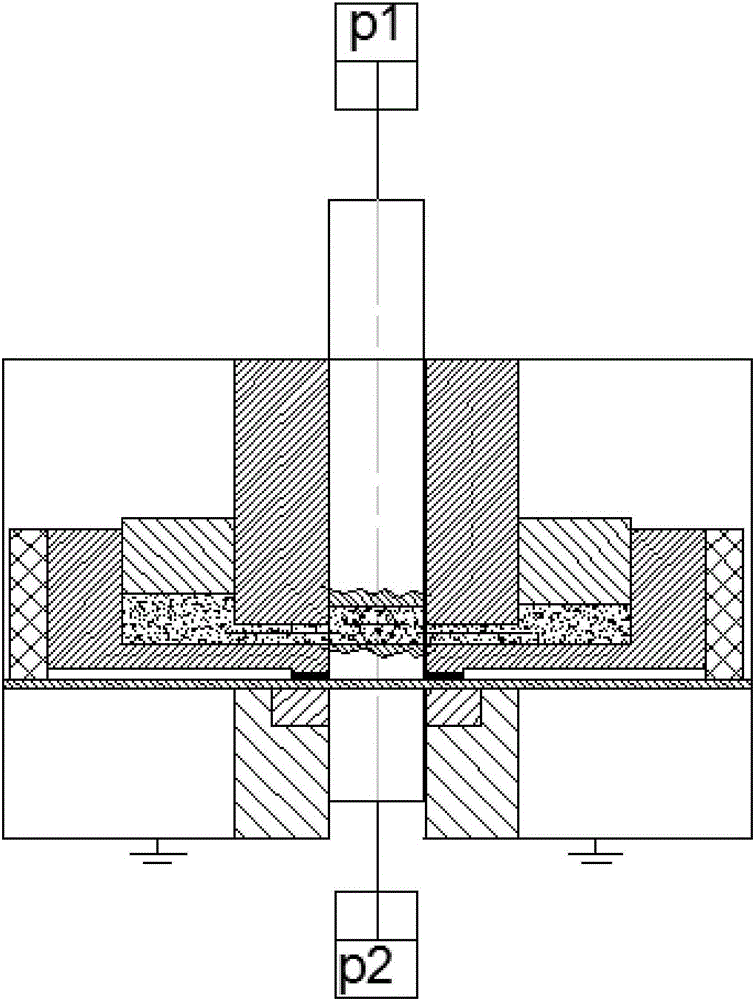

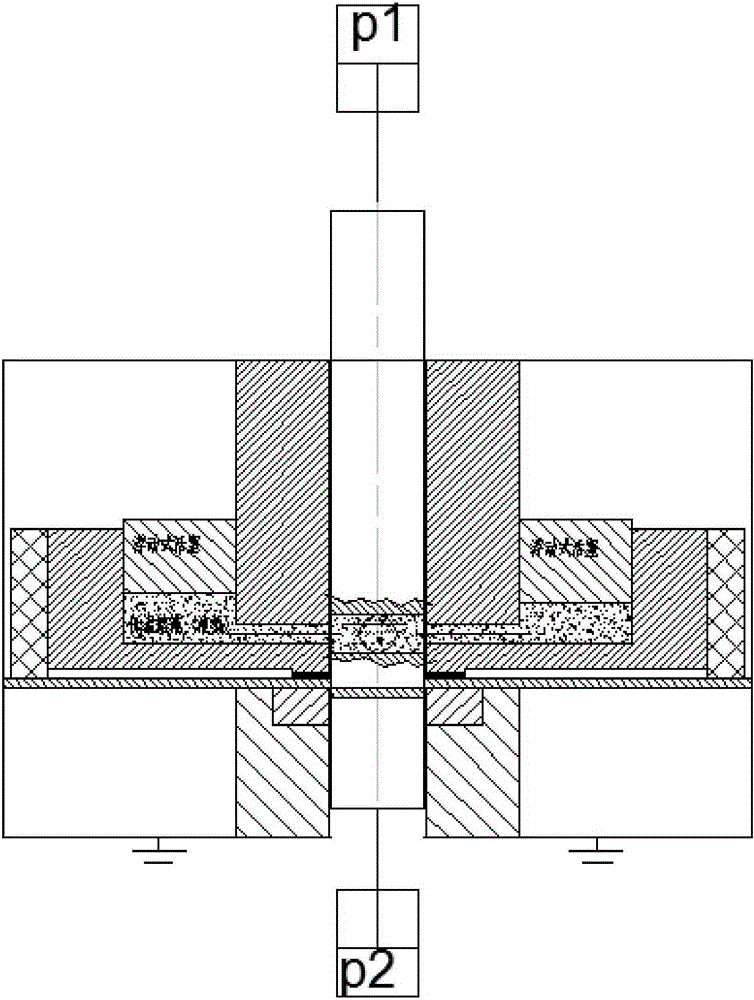

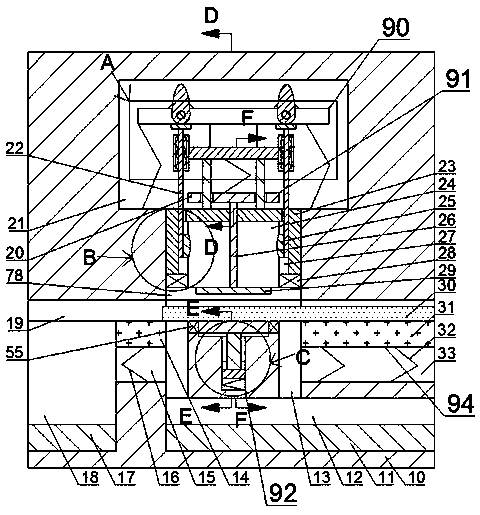

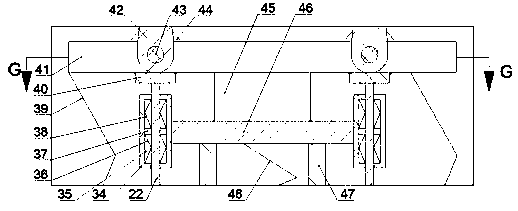

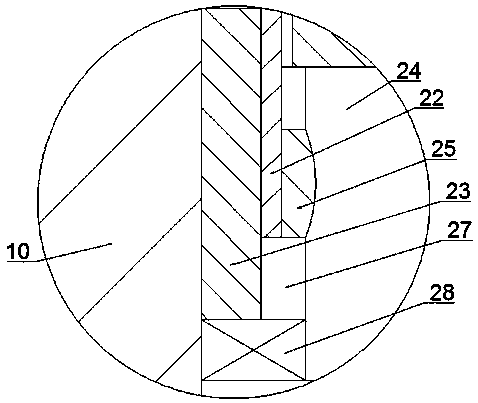

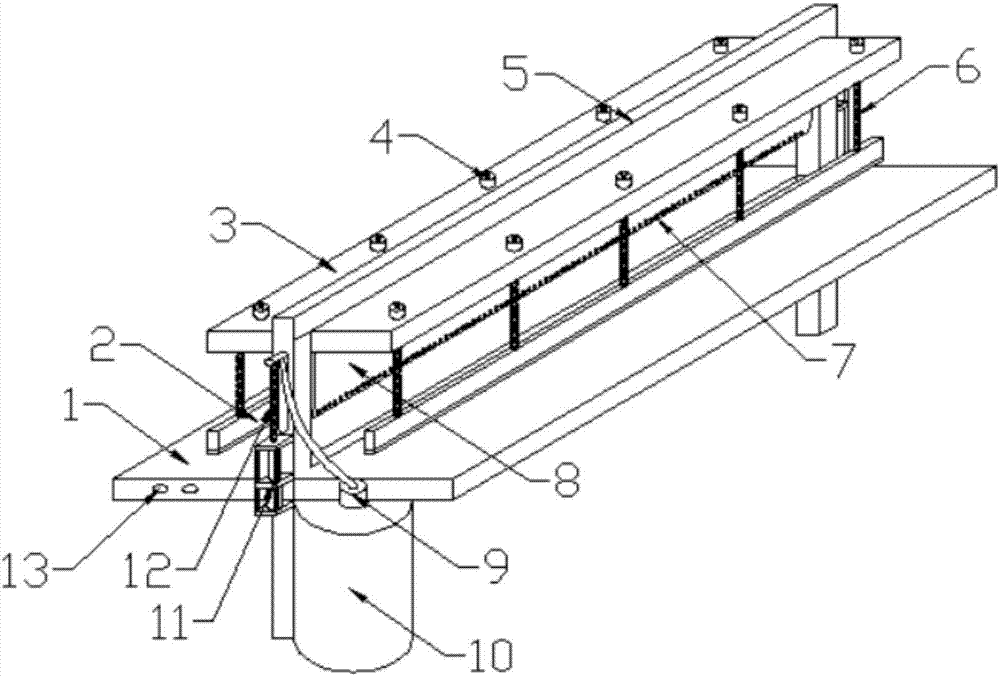

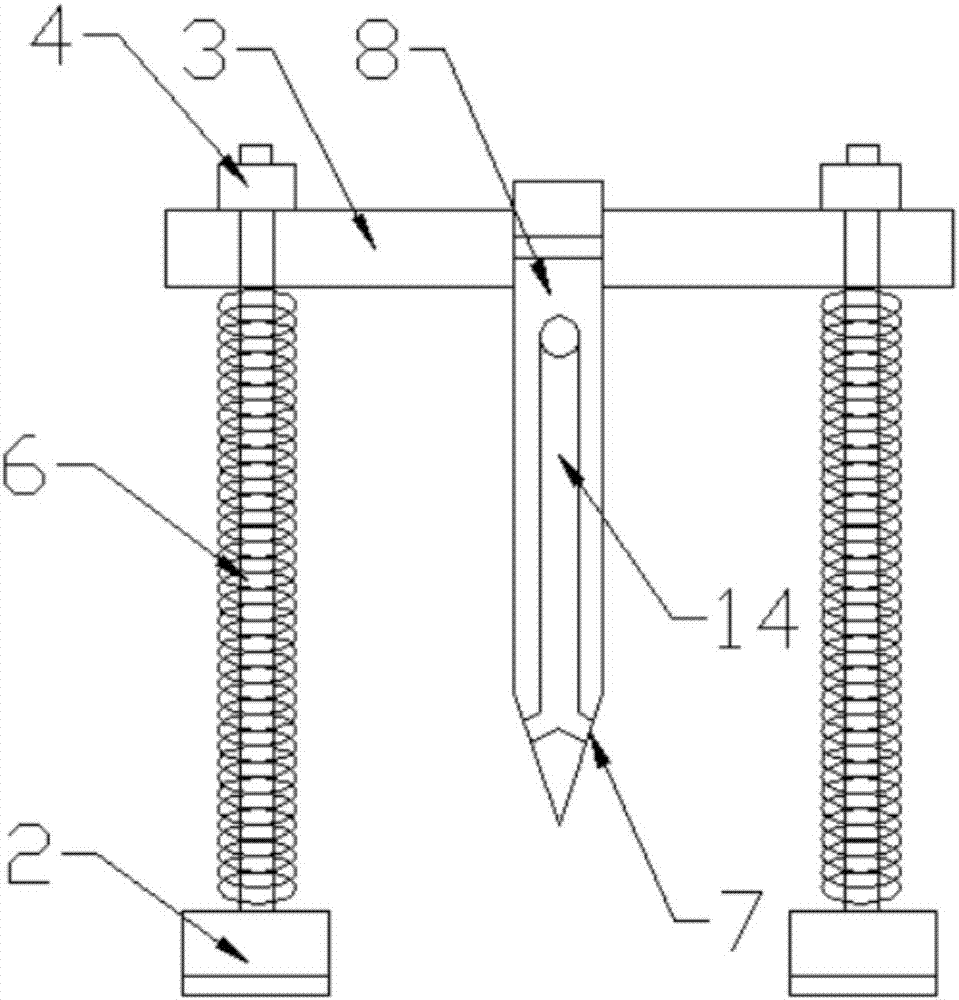

Cryogenic stamping, shearing and forming device with terrace die for micro workpieces and forming method using cryogenic stamping, shearing and forming device

InactiveCN105328003APrevent downward flowAchieve precision machiningShaping toolsHydraulic cylinderPiston

The invention relates to a cryogenic stamping, shearing and forming device with a terrace die for micro workpieces and a forming method using the cryogenic stamping, shearing and forming device, and belongs to the field of mechanical engineering. The cryogenic stamping, shearing and forming device comprises the terrace die, a hollowing block, an ejector rod, a low-temperature solution, a blank holder, a heat insulating material and a terrace die supporting base, wherein the side wall of the terrace die is locally provided with a through hole; a hydraulic cylinder drives the terrace die to move in the blank holder; the hollowing block is fixed in a hollowing block supporting base; the hydraulic cylinder drives the ejector rod to move in the hollowing block; a storage slot capable of accommodating the low-temperature solution is formed in the blank holder; the top of the storage slot is provided with a floating type piston; and the inner side wall of the blank holder is provided with a side wall hole capable of allowing the low-temperature solution to flow. The forming method based on the device comprises the five steps of clamping plates, cooling, stamping and shearing, drawing the plates out of the die and carrying out shape inspection. According to the cryogenic stamping, shearing and forming device with the terrace die for micro workpieces and the forming method using the cryogenic stamping, shearing and forming device, the advantages are that precision processing for micro workpieces is realized, deckle edges and burrs are reduced in a facilitated mode, section is flattened, section forming precision and forming precision for forming the workpieces are improved, and batched production is realized.

Owner:JILIN UNIV

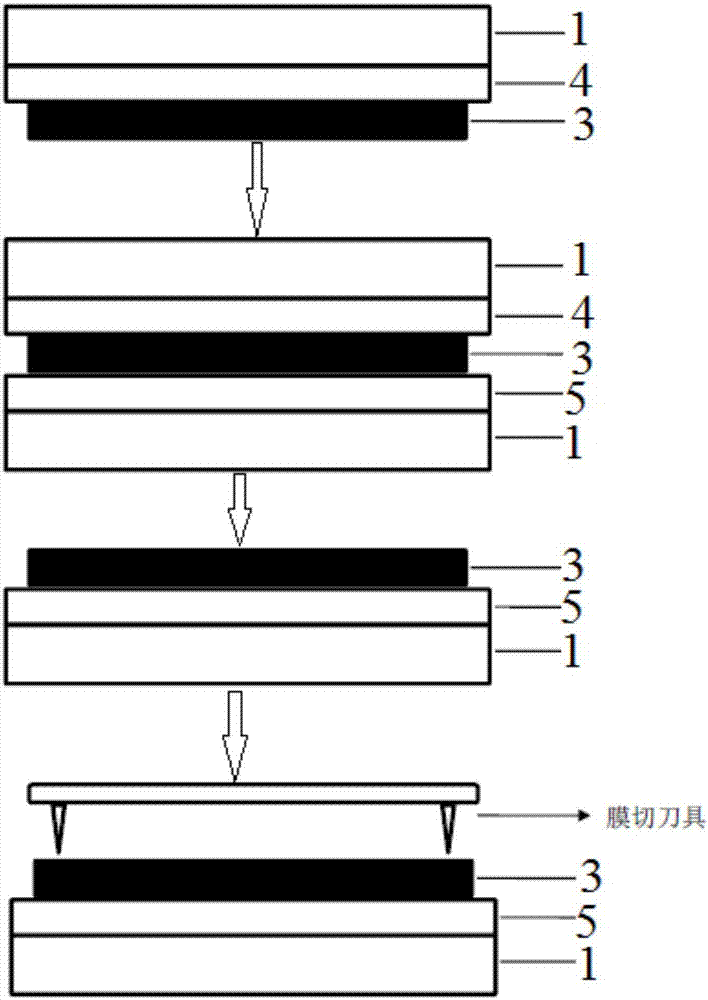

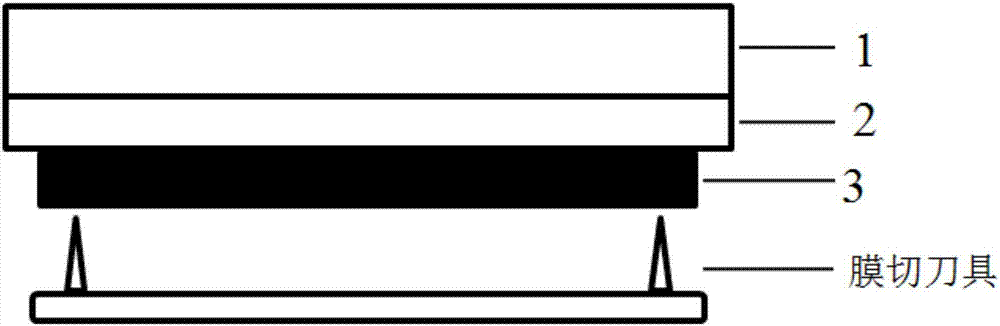

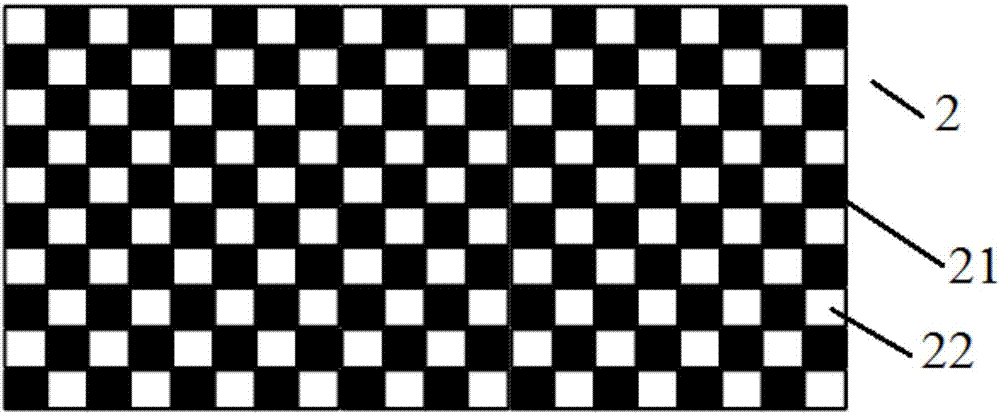

Heat conduction graphite composite film and preparation method thereof

InactiveCN107011854AEasy to adjust peel forceReduce productionNon-macromolecular adhesive additivesSynthetic resin layered productsComposite filmAdhesive

The invention discloses a heat conduction graphite composite film and a preparation method thereof. The heat conduction graphite composite film comprises a substrate, a coating layer and a heat conduction graphite film, wherein the coating layer is arranged at the surface of one side of the substrate; the viscosity of the coating layer is smaller than the viscosity of an adhesive, and the release force of the coating layer in unit area is greater than the release force of a release agent in the unit area; the heat conduction graphite film is pressed at the surface of one side, back to the substrate, of the coating layer. The preparation method comprises the following steps of coating the coating layer with required thickness onto the surface of one side of the substrate; calendering the heat conduction graphite film onto the surface of one side, back to the substrate, of the coating layer. The heat conduction graphite composite film has the advantage that the coating layer has the releasing and adhering functions, one coating layer can replace the release agent layer in the existing release film and the adhesive layer in the existing protective film, a layer of substrate can replace the substrates in the existing release film and the existing protective film, the composite film can be formed by one step of film coating technology, and the next step of film cutting technology can be directly entered, so that the preparation process of the composite film is shortened, one layer of auxiliary material is not needed, and the preparation cost is reduced.

Owner:世星科技股份有限公司

Simulation four-needle six-line double-stitching overlaying sewing method

InactiveCN109097918APrevent deviationConcave-convex smoothWork-feeding meansEngineeringSewing machine

The invention discloses a simulation four-needle six-line double-stitching overlaying sewing method. The simulation four-needle six-line double-stitching overlaying sewing method includes steps of A,placing two pieces of cloth side by side, integrally sewing the two pieces of cloth by a stitching machine by the aid of two-line processes and forming first sewn lines; B, leveling the insides of thefirst sewn lines; C, placing the cloth in the stitching machine again, and sewing second sewn lines on the first sewn lines by the stitching machine by the aid of four-line processes; D, turning overthe cloth, placing the cloth in the stitching machine again and sewing sewn lines on the reverse sides of the cloth by the stitching machine by the aid of the two-line processes according to sewn line tracks. Compared with the prior art, the simulation four-needle six-line double-stitching overlaying sewing method has the advantages that the sewn lines with similar four-needle six-line effects can be sewn by the common stitching machine, sewing effects are superior to four-needle six-line effects, and the problems of severe idleness of four-needle six-line sewing machines and incapability ofstitching complicated sewn lines by the common stitching machine can be solved by the aid of the simulation four-needle six-line double-stitching overlaying sewing method.

Owner:NINGBO SHENZHOU KNITTING

Metal stamping part polishing device

ActiveCN110773620AReduce the number of mold setsIncrease productivityEdge grinding machinesMetal-working feeding devicesPolishingMachining

The invention discloses a metal stamping part polishing device which comprises a shell, wherein a machining cavity is formed in the shell, a pressing mechanism is arranged in the machining cavity, a polishing mechanism is arranged in the upper end wall of the machining cavity, a transmission mechanism is arranged on the lower side of the machining cavity, and a driving mechanism is arranged on therear side of the machining cavity. In the pressing process of a metal stamping part, the metal stamping part is pressed through the pressing mechanism and then pressed and lifted through the transmission mechanism in the pressing process, the metal stamping part is trimmed and shaped through the polishing mechanism, and therefore the two steps of processes are sequentially completed in the same procedure. The number of die sets is reduced, the production efficiency is improved, and meanwhile the rough edges generated by workpiece movement caused by die misalignment and the machining cost arereduced.

Owner:广东辽原五金电器有限公司

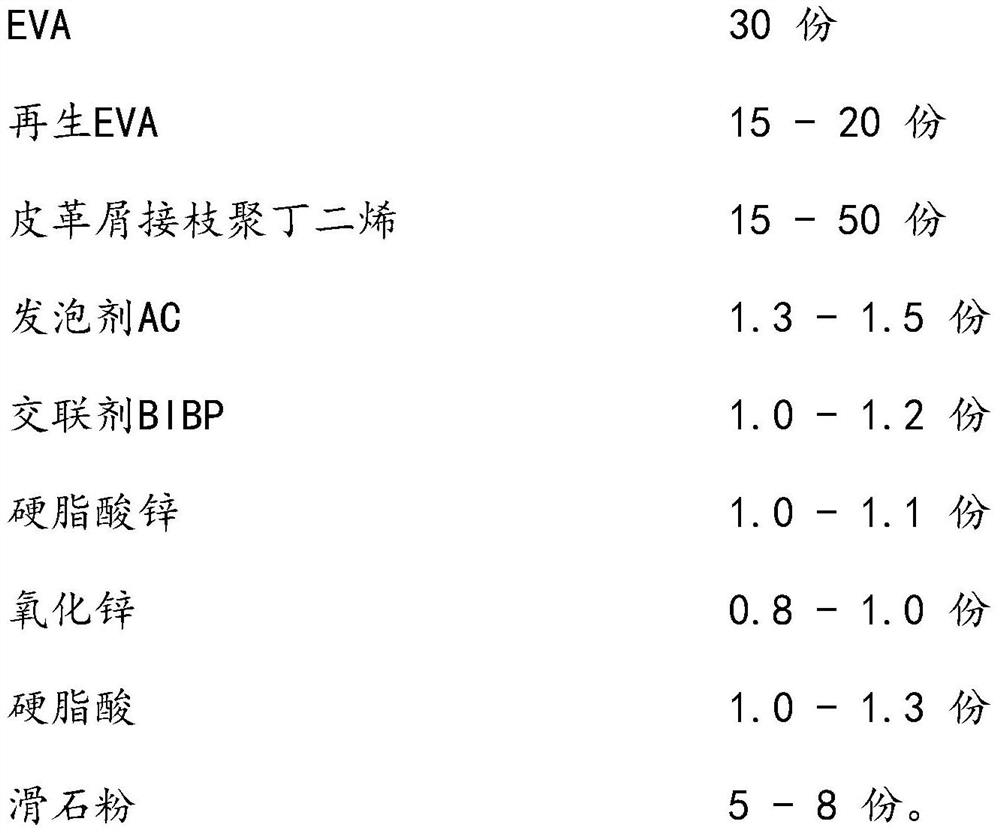

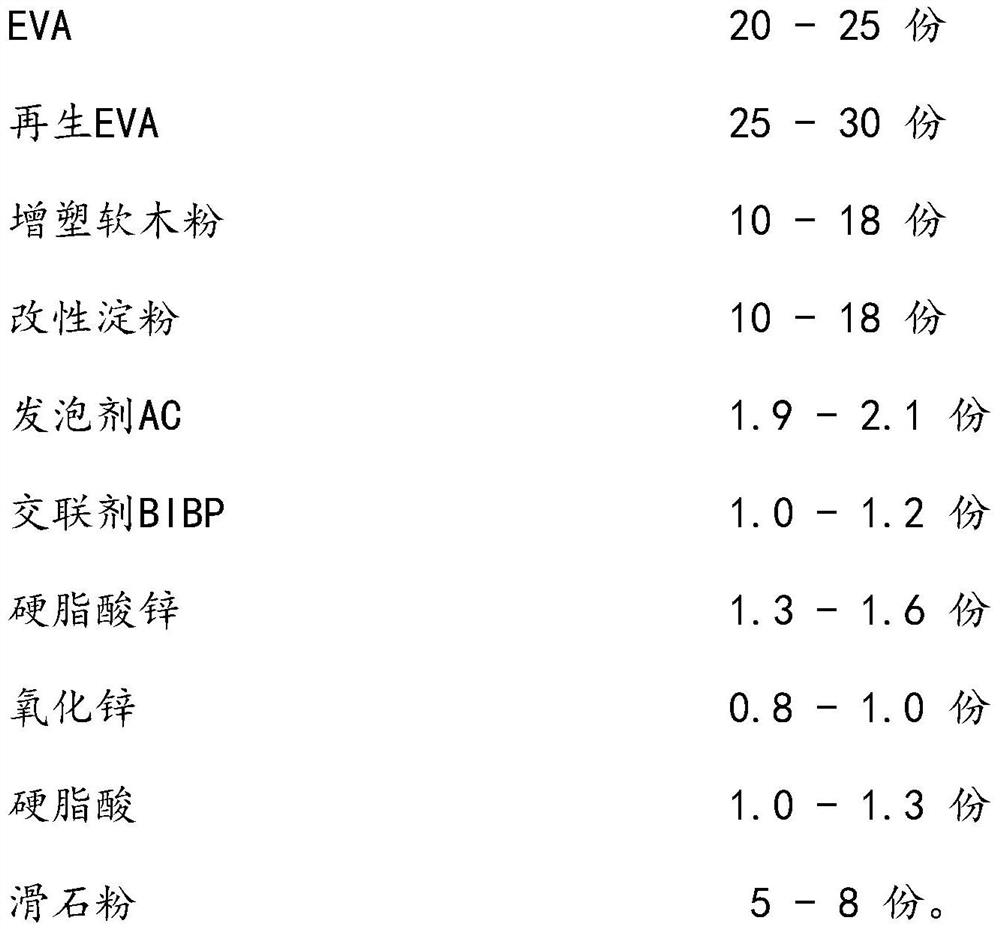

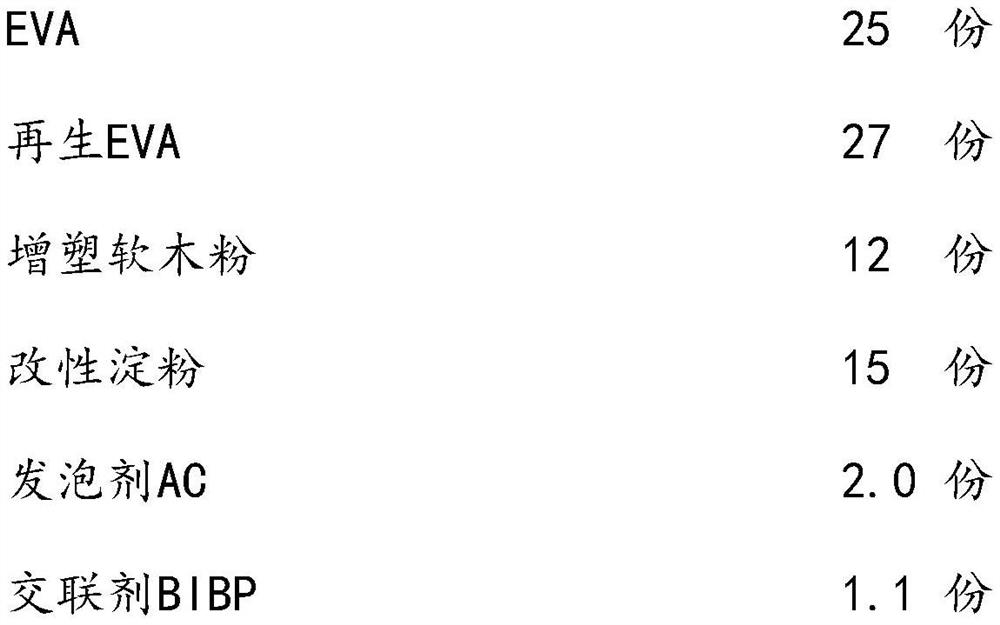

Leather scrap modified foamed shoe insole and preparation method thereof

The leather scrap modified foamed shoe insole comprises, by weight, 30 parts of EVA, 15-20 parts of regenerated EVA, 15-50 parts of leather scrap grafted polybutadiene, 1.3-1.5 parts of a foaming agent AC, 1.0-1.2 parts of a cross-linking agent BIBP, 1.0-1.1 parts of zinc stearate, 0.8-1.0 part of zinc oxide, 1.0-1.3 parts of stearic acid and 5-8 parts of talcum powder. According to the invention,carboxyl groups in maleic anhydride grafted polybutadiene and amido groups of leather scraps are subjected to amidation crosslinking by utilizing a melt grafting modification technology, so that thecompatibility of leather wastes and EVA shoe materials is improved; a macromolecular protein is introduced into EVA, so that the problem of environmental pollution caused by difficult biodegradation of EVA can be solved; and through amidation crosslinking, the environment-friendly performance of the EVA shoe materials is improved, the crosslinking degree between molecular chains can be increased,the leather scrap modified foaming material with excellent performance is obtained, high-value utilization of leather waste is achieved, resource recycling is achieved, environmental pollution is reduced, and the production cost of shoe materials is reduced.

Owner:MAOTAI FUJIAN SOLES CO LTD

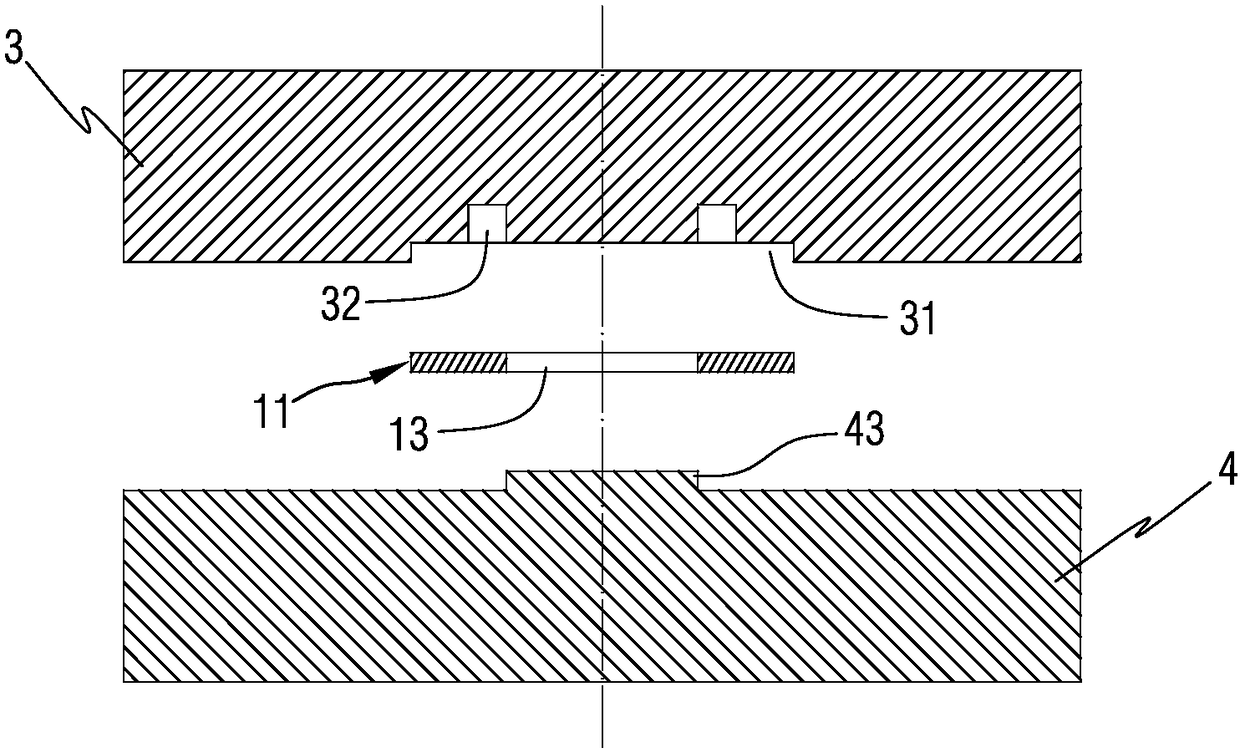

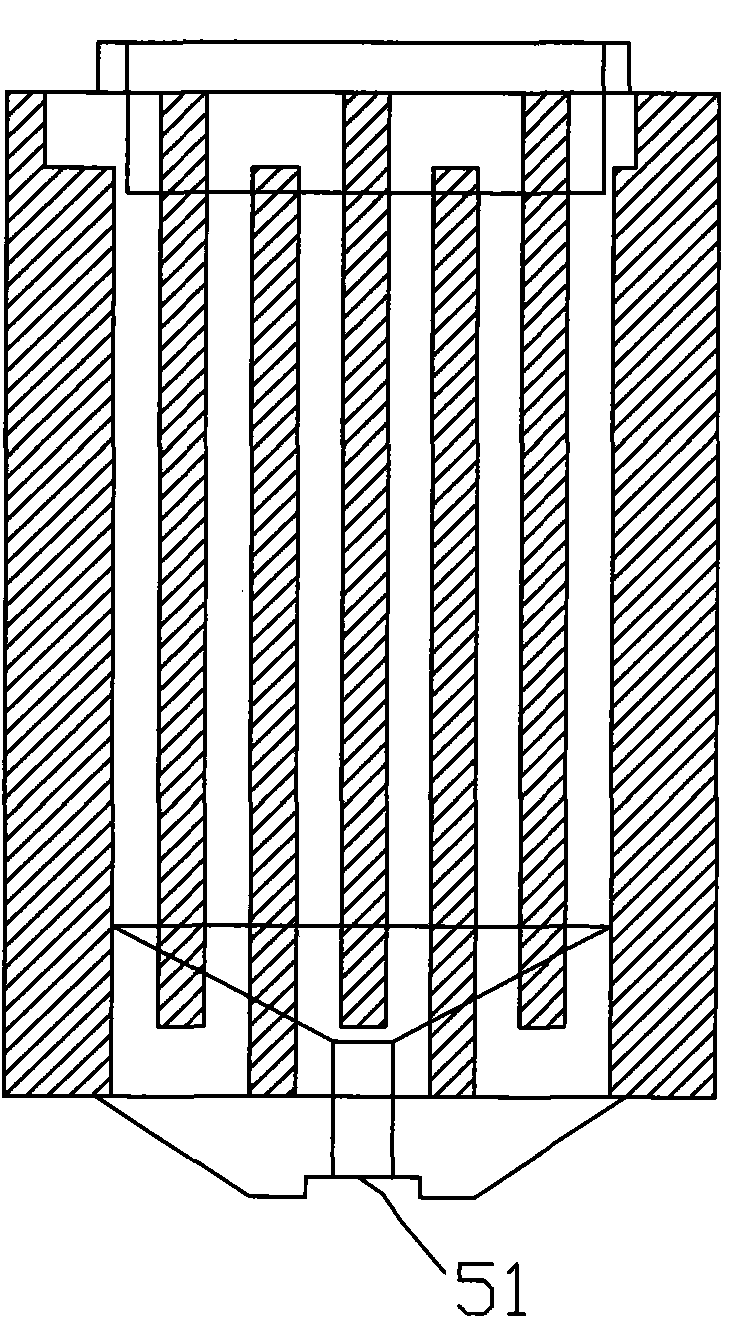

Rubber injection method containing metal insert and mold

The invention relates to a rubber injection mold containing a metal insert. The rubber injection mold is used for carrying out injection molding on a rubber injection molded part which is composed ofthe annular metal insert and the annular rubber part; the mold comprises an upper mold and a lower mold, the upper mold is provided with an upper mold concave part for containing the metal insert andan upper mold rubber groove for forming a rubber part, the lower mold is provided with a lower mold boss penetrating into the central hole of the metal insert, the lower mold is arranged in the uppermold concave part, and a first rubber overflow groove and a second rubber overflow groove are formed in the inner side and the outer side of the upper mold rubber groove respectively. The invention further provides a method for carrying out injection molding by utilizing the mold. The first rubber overflow groove and the second rubber overflow groove are arranged, so that sealing rings can be formed around the inner side and the outer side of the upper mold rubber groove through the rubber overflow phenomenon, overflow waste materials are used for sealing and automatic size adjustment, waste and burrs are reduced, and important parts in the overflow protection mold can also be used, such as a sliding block, a guide column and the like, and the waste materials can be prevented from enteringa precise part to cause the damage of the mold.

Owner:NOLATO MOBILE COMMUNICATION POLYMERS (BEIJING) CO LTD

Automobile sealing strip follow-up sawing machine

PendingCN109623915AGuaranteed sizeMake sure the size meets the requirementsMetal working apparatusEngineeringMechanical engineering

The invention belongs to the field of automobile part processing devices, and provides an automobile sealing strip follow-up sawing machine. The automobile sealing strip follow-up sawing machine comprises a machine table, a feeding assembly, a cutting assembly, a retarding assembly and a discharging assembly, wherein the feeding assembly is movably arranged on the machine table, the feeding assembly can clamp and drive a sealing strip to move; the cutting assembly is movably arranged on the machine table, the cutting assembly is electrically connected with the feeding assembly and can transversely move at the same speed as the sealing strip, the cutting assembly is rotationally connected with a saw blade, and the cutting assembly can drive the saw blade to move up and down; the retarding assembly is arranged in the cutting assembly, and the descent speed of the saw blade can be reduced by the retarding assembly; and the discharging assembly is located on the side of the cutting assembly and is connected with the machine table, and the discharging assembly is provided with two bearing plates with different movement speeds. Compared with the prior art, the automobile sealing strip follow-up sawing machine has the advantages that the size of the cut sealing strip meets the requirement, the cutting edge of the sealing strip is prevented from being damaged, burrs generated by cutting of the sealing strip are reduced, and the manual processing steps are reduced.

Owner:宁波齐盛智能设备有限公司

Preparation method of secondary mold pressing foaming sole

ActiveCN112157861ASolve the cooling effectResolution timeDomestic articlesPolymer scienceMolding machine

The invention discloses a preparation method of a secondary mold pressing foaming sole. The preparation method comprises the following steps: a) preparing EVA (Ethylene Vinyl Acetate) foam granules; b) conducting mold pressing foaming on the EVA foam granules obtained in the step a), wherein the first foaming ratio is 140%-185%, the foaming temperature is 172 DEG C-182 DEG C, conducting automaticmold opening after foaming is completed, and obtaining a foaming primary blank with the surface temperature not lower than 130 DEG C; an c) putting the foaming primary blank with the surface temperature not lower than 130 DEG C into an oil pressure mold, closing the mold, pushing the mold into a heating station of a secondary foaming forming machine, and conducting pressurizing and heating, wherein the ratio of the oil pressure mold is 135%-180%, the temperature is 170 DEG C-180 DEG C, and the time is 20 seconds-100 seconds; and then transferring the oil pressure mold to a cooling station, conducting pressurizing, spraying water to cool the mold, setting the mold for 150 seconds-400 seconds, pulling out the mold, taking out a finished product, and obtaining the foaming sole, wherein the first foaming ratio is greater than the foaming ratio of the oil pressure mold. According to the preparation method, after primary foaming, the product is immediately transferred to the oil pressure mold, the oil pressure heating foaming time is shortened, the energy consumption is reduced, and embossing is easy.

Owner:MAOTAI FUJIAN SOLES CO LTD

Cloth shearing machine with fracture gluing function

InactiveCN107574653AImprove flatnessReduce burrsTextile selvedgesSevering textilesFixed framePulp and paper industry

The invention discloses a cloth shearing machine with a fracture gluing function. The cloth shearing machine comprises a worktable, a fixing frame and a glue barrel. The fixing frame is arranged in the middle of the worktable, cylinders are arranged at two ends of the fixing frame, output ends of the two cylinders are fixedly connected with the middles of two ends of a fixing plate by L-shaped connecting rods, a cutter is fixedly arranged in the middle of the fixing plate, a glue flowing pipeline is arranged inside the cutter, an end of the glue flowing pipeline is connected with a glue outletof a glue delivery pump by a hose, a glue inlet of the glue delivery pump is connected with a glue outlet of the glue barrel by a pipeline, and a plurality of gluing openings are uniformly formed inthe bottoms of two sides of the cutter. The cloth shearing machine has the advantages that shorn locations are fixed by the aid of cloth pressure rods before cloth is shorn, accordingly, the flatnessof notches can be improved, and rough selvedges due to dislocation of the notches can be reduced; the notches are glued while the cloth is shorn, accordingly, the problem of deterioration of the compactness of existing cloth due to ripping of the existing cloth at existing notches can be solved, the quality of the cloth can be guaranteed, and the cloth shearing machine is convenient to operate andhigh in automation degree.

Owner:湖州里白整木家居科技有限公司

A manufacturing method of a flexible circuit board

InactiveCN109152229AGuaranteed amount of microetchingImprove adhesionLithography/patterningConductive material chemical/electrolytical removalEtchingCopper plating

The invention discloses a manufacturing method of a flexible circuit board. The substrate used for manufacturing the flexible circuit board is drilled so as to form a through hole on the substrate. Carrying out blackening treatment on the drilled substrate so that a toner layer is attached to the hole wall of the through hole; Performing copper plating on the blackened base material to form a first copper layer on the hole wall of the through hole, forming a second copper layer on the surface of the base material, wherein the thickness value of the first copper layer is greater than 8 mum andthe thickness value of the second copper layer is less than 10 mum; The substrate after electroplating copper is subjected to super-coarsening treatment, so that the micro-etching amount of the secondcopper layer is 0.5-1.5 mum; The substrate after the supercoarsening treatment is sequentially subjected to film pasting, exposure, development, vacuum etching and film stripping to obtain the flexible circuit board, and the thickness of the dry film used in the film pasting is 14 to 16 mum. The precision circuit with line width and line distance of 20 [mu] m / 20 [mu] m can be fabricated, and thequality of the circuit is stable, which is suitable for batch production.

Owner:台山市精诚达电路有限公司

Chain wheel or tooth ring production process

The invention provides a chain wheel or tooth ring production process. The chain wheel or tooth ring production process comprises such steps as shape cutting, inner hole cutting, forging formation and trimming treatment; and a steel plate is formed by forging after tooth-shaped cutting, so that the forging resistance is relatively lower, burrs are relatively fewer, the side surfaces of arc teeth of chain wheels or tooth rings are not liable to break, the product reject ratio is relatively lower, the mold life is relatively longer, the tonnage of a needed forging machine is relatively lower, and the production cost is relatively lower.

Owner:福建泉海工贸投资集团有限公司

Pressure spray bag for use in pressured making of amorphous strip and amorphous strip making method

The invention relates to strip making equipment for an amorphous strip, in particular to a pressure spray bag for use in pressured making of the amorphous strip and an amorphous strip making method. The pressure spray bag comprises a spray bag shell and a conveying mechanism for conveying molten steel into the spray bag, wherein a prism-shaped liquid guide cavity which is larger on the upper portion and smaller on the lower portion is formed in the bottom in the spray bag shell; the liquid guide cavity is communicated with a jet cavity below; the bottom of the jet cavity is connected with a nozzle. Molten steel enters the pressure spray bag from a liquid guide hopper through a flow guide pipe, nitrogen is added into the pressure spray bag through an air inlet nozzle, and the molten steel flows towards the nozzle under the actions of own dead weight and the pressure of nitrogen, meets a hollow structure and a copper roller into which cooling water is introduced continuously after flowing out of the nozzle, is condensed into solid momentarily, and is molded into the amorphous strip. By adopting the pressure spray bag and the amorphous strip making method, the flowing degree of molten steel is increased, molten steel flowing into the spray bag can be sprayed completely at one time, high density, uniform thickness and a small quantity of rough edges are realized, and the quality of the amorphous strip is improved.

Owner:安徽众恒复合材料科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com