Cryogenic stamping, shearing and forming device with terrace die for micro workpieces and forming method using cryogenic stamping, shearing and forming device

A micro-miniature punch technology, applied in the field of mechanical engineering, can solve the problems of low forming section accuracy, poor section topography, uneven surface, etc., achieve novel structure, reduce burrs and burrs, and improve section forming accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

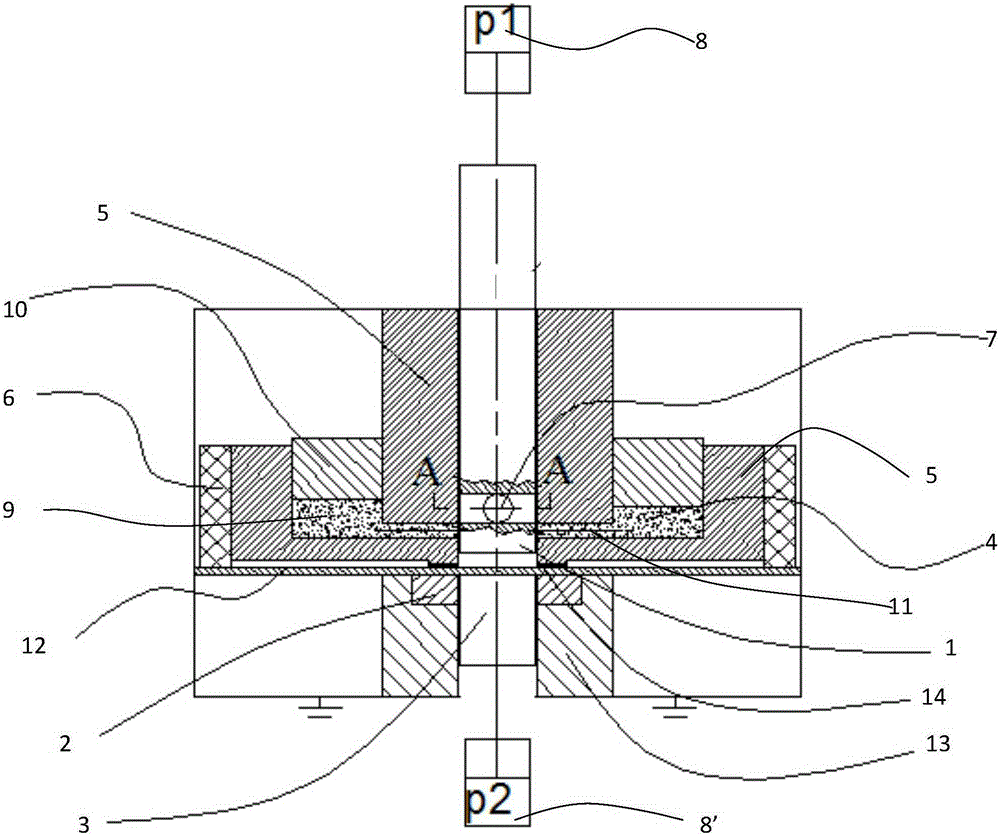

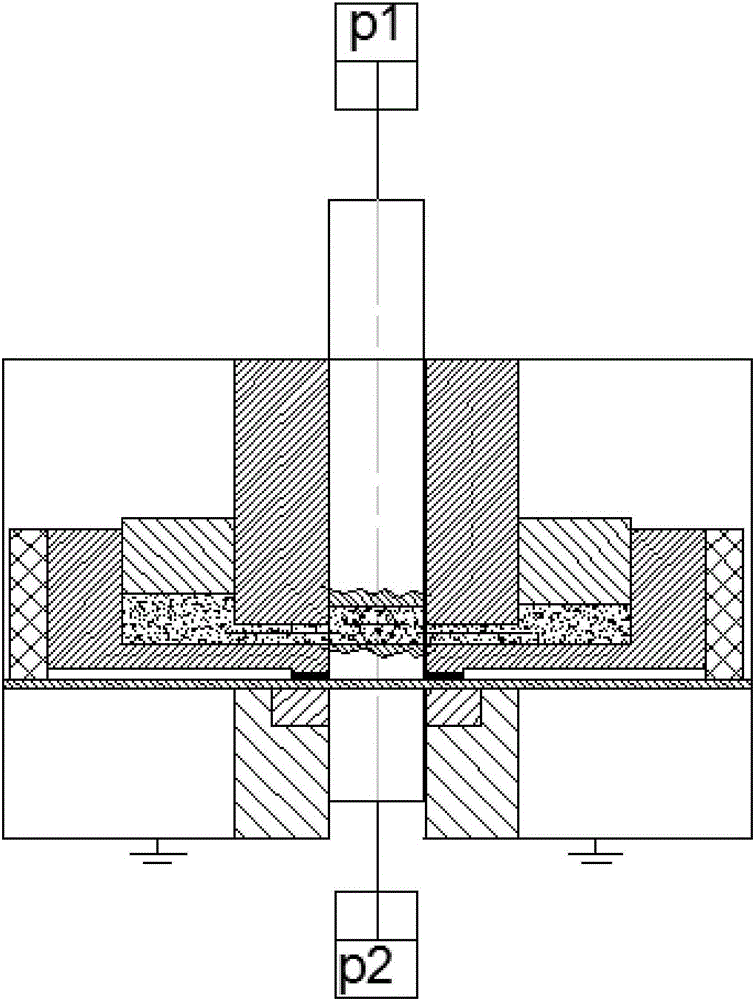

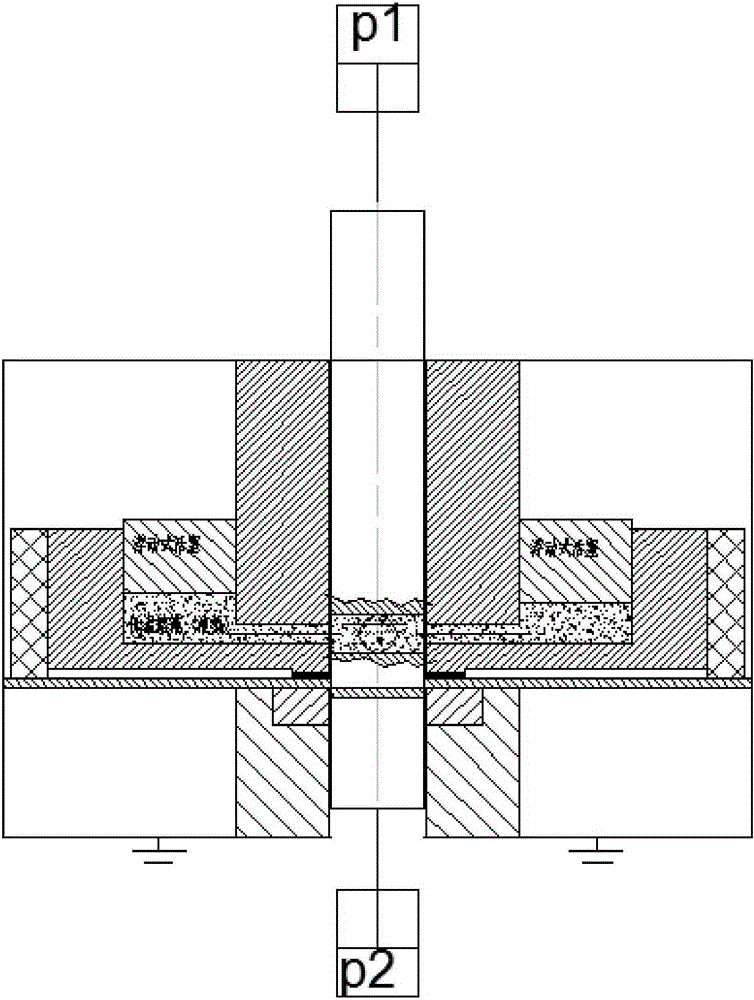

[0035] The punch 1 has a through hole 7 on its side wall, the punch 1 driven by the hydraulic cylinder P18 moves in the blank holder 5, the die 2 is placed in the die support 13 and fixed, and is driven by the hydraulic cylinder P28' The driven ejector rod 3 moves in the die 2, and a storage tank 9 that can accommodate the low-temperature solution 4 is opened in the blank holder, and a floating piston 10 is installed on the top of the storage tank 9. The side wall hole 11 for the low-temperature solution 4 to flow, the blank holder 5 can press the plate 12 against the edge of the die 2 under the action of force, and the surrounding of the blank holder 5 is covered with heat insulating material -6, heat insulating material -14 is pressed on the boundary between the blank holder 5 and the sheet material 12 .

[0036] The side wall through hole 7 of the punch 1 communicates with the side wall hole 11 of the blank holder 5 during operation.

[0037] The low-temperature solution 4...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com