A kind of asphalt mixture for test track and asphalt concrete pavement of test track

A technology of asphalt concrete and asphalt mixture, which is applied to cohesive pavement paved on site, roads, roads, etc. It can solve the problems of poor vertical compaction effect of traction roller on road surface, influence of asphalt pavement shear performance, asphalt pavement material and There are very few structural studies and other issues to achieve the effect of preventing downward flow, reliable test site, and uniform layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] An asphalt mixture for a test track, which comprises the following components by weight: 60.7% of gravel, 28.7% of sand material and 10.6% of mineral powder.

[0028] Mineral powder is a mixture of limestone mineral powder and cement, the weight ratio of limestone mineral powder and cement is 9:1, and all the mineral powder passes through a 0.075mm square hole sieve; the sand material is a mixture of river sand machine and sand making machine, river sand and mechanism The weight ratio of sand is 1:1, and all sand materials pass through a 1.18mm square hole sieve; the gravel is a mixture of basalt and diabase that all pass through a 16mm square hole sieve after mechanical crushing.

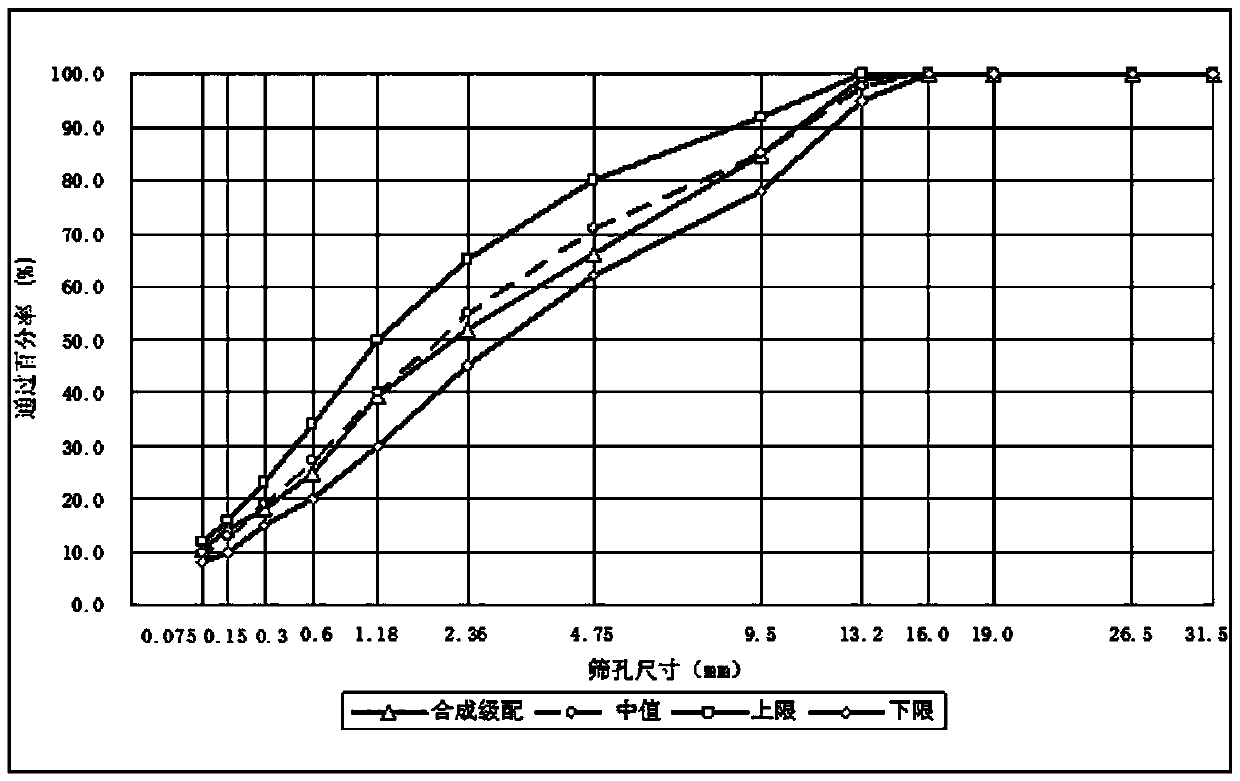

[0029] The synthesis gradation of the asphalt mixture in this embodiment is: the sieve size of the square hole sieve is 16mm, 13.2mm, 9.5mm, 4.75mm, 2.36mm, 1.18mm, 0.6mm, 0.3mm, 0.15mm, 0.075mm When the pass rate corresponding to each square hole sieve is 100%, 99%, 84.7%, 66.1%, 51.7%, 39....

Embodiment 2

[0031] An asphalt mixture for a test track, which comprises the following components by weight: 61.1% of gravel, 28.6% of sand material and 10.3% of mineral powder.

[0032] Mineral powder is a mixture of limestone mineral powder, slaked lime and cement. The weight ratio of limestone mineral powder, slaked lime and cement is 8:1:1. All the mineral powder passes through a 0.075mm square hole sieve; the sand material is a mixture of river sand and machine-made sand , The weight ratio of river sand to machine-made sand is 1.2:1, and all sand materials pass through a 1.18mm square hole sieve; gravel is a mixture of limestone and granite that passes through a 19mm square hole sieve after mechanical crushing.

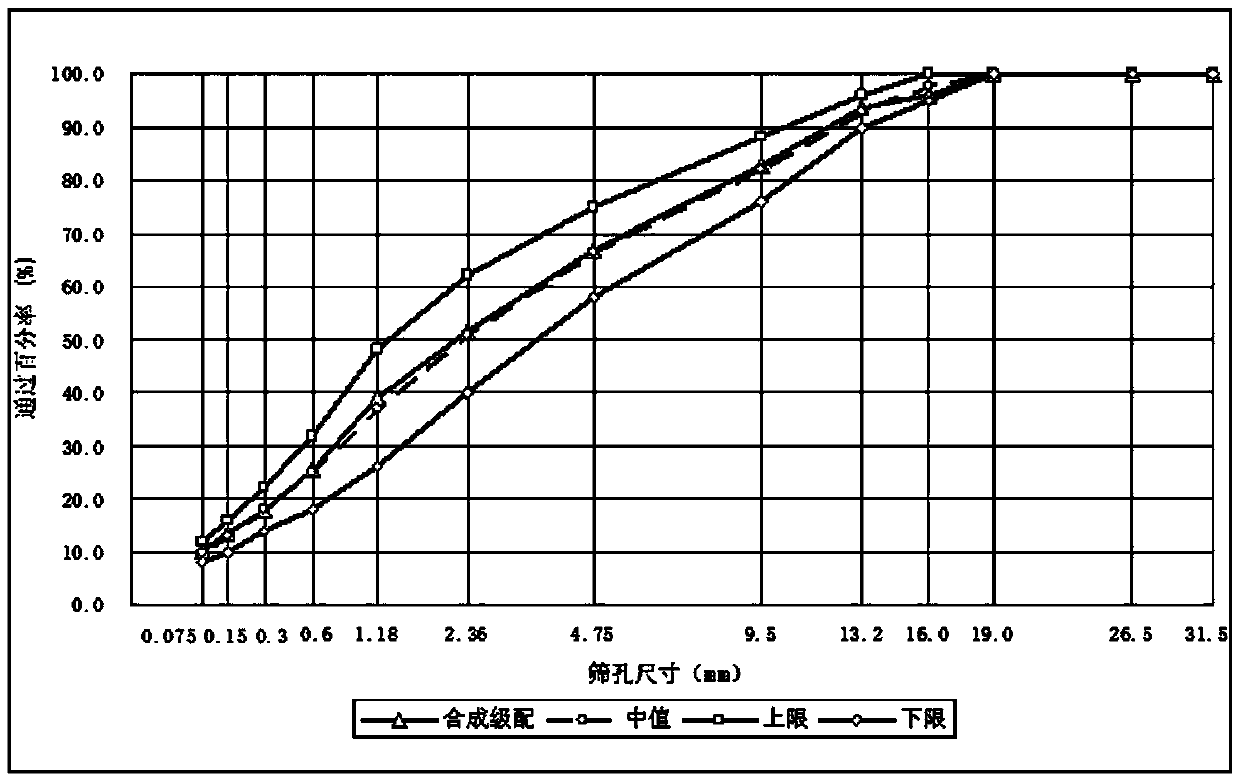

[0033] The synthesis gradation of the asphalt mixture in this embodiment is: the sieve size of the square hole sieve is 19mm, 16mm, 13.2mm, 9.5mm, 4.75mm, 2.36mm, 1.18mm, 0.6mm, 0.3mm, 0.15mm, When the thickness is 0.075mm, the passing rate corresponding to each square hole s...

Embodiment 3

[0035] An asphalt mixture for a test track, which comprises the following components by weight: 60.4% of gravel, 29.1% of sand material and 10.5% of mineral powder.

[0036]Mineral powder is slaked lime, all of which pass through a 0.075mm square hole sieve; the sand material is a mixture of river sand and machine-made sand, the weight ratio of river sand and machine-made sand is 1.5:1, and all sand materials pass through a 1.18mm square hole sieve; the crushed stone is Basalt that has passed through a 26.5mm square hole sieve after mechanical crushing.

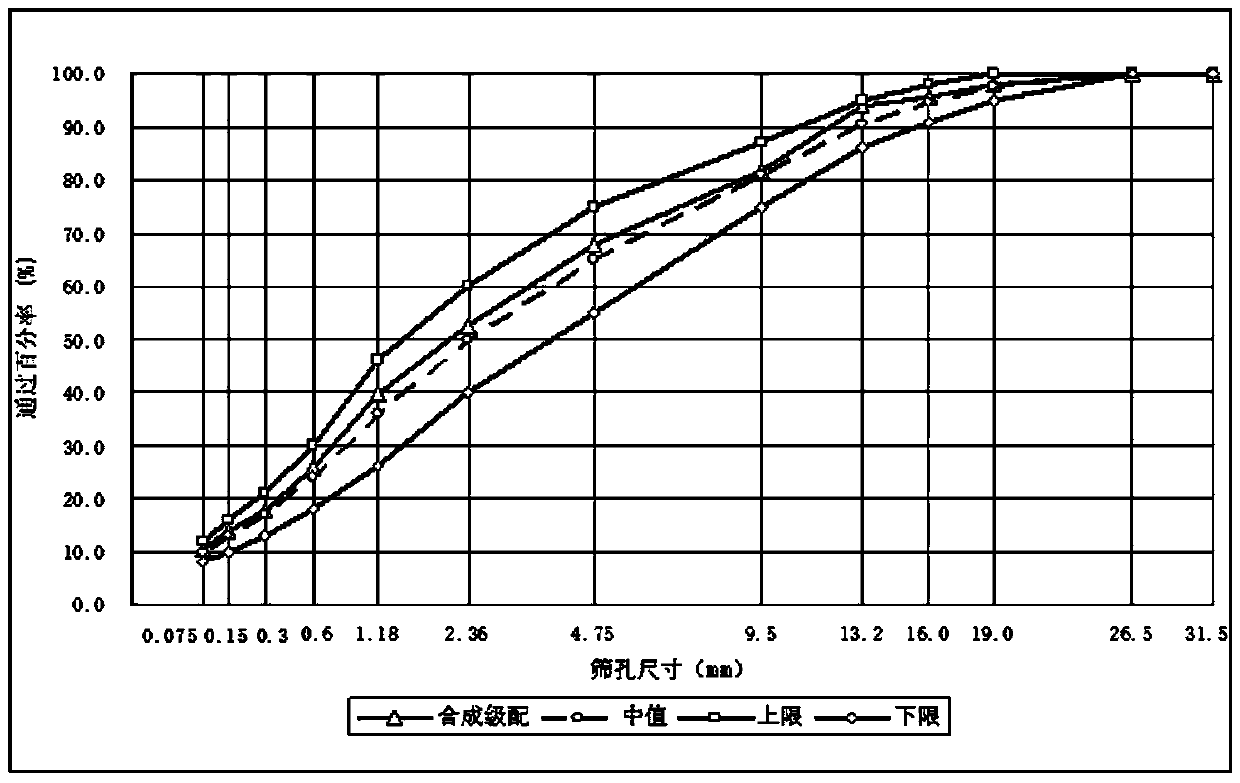

[0037] The synthesis gradation of the asphalt mixture in this embodiment is: the sieve size of the square hole sieve is 26.5mm, 19mm, 16mm, 13.2mm, 9.5mm, 4.75mm, 2.36mm, 1.18mm, 0.6mm, 0.3mm, When 0.15mm and 0.075mm, the passing rate corresponding to each square hole sieve is 100%, 98.1%, 95.7%, 93.9%, 81.6%, 67.7%, 52.4%, 39.6%, 25.2%, 17.7%, 13.8% , 10.5%, its ore grading curve is shown in image 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com