Patents

Literature

67results about How to "Achieve precision machining" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

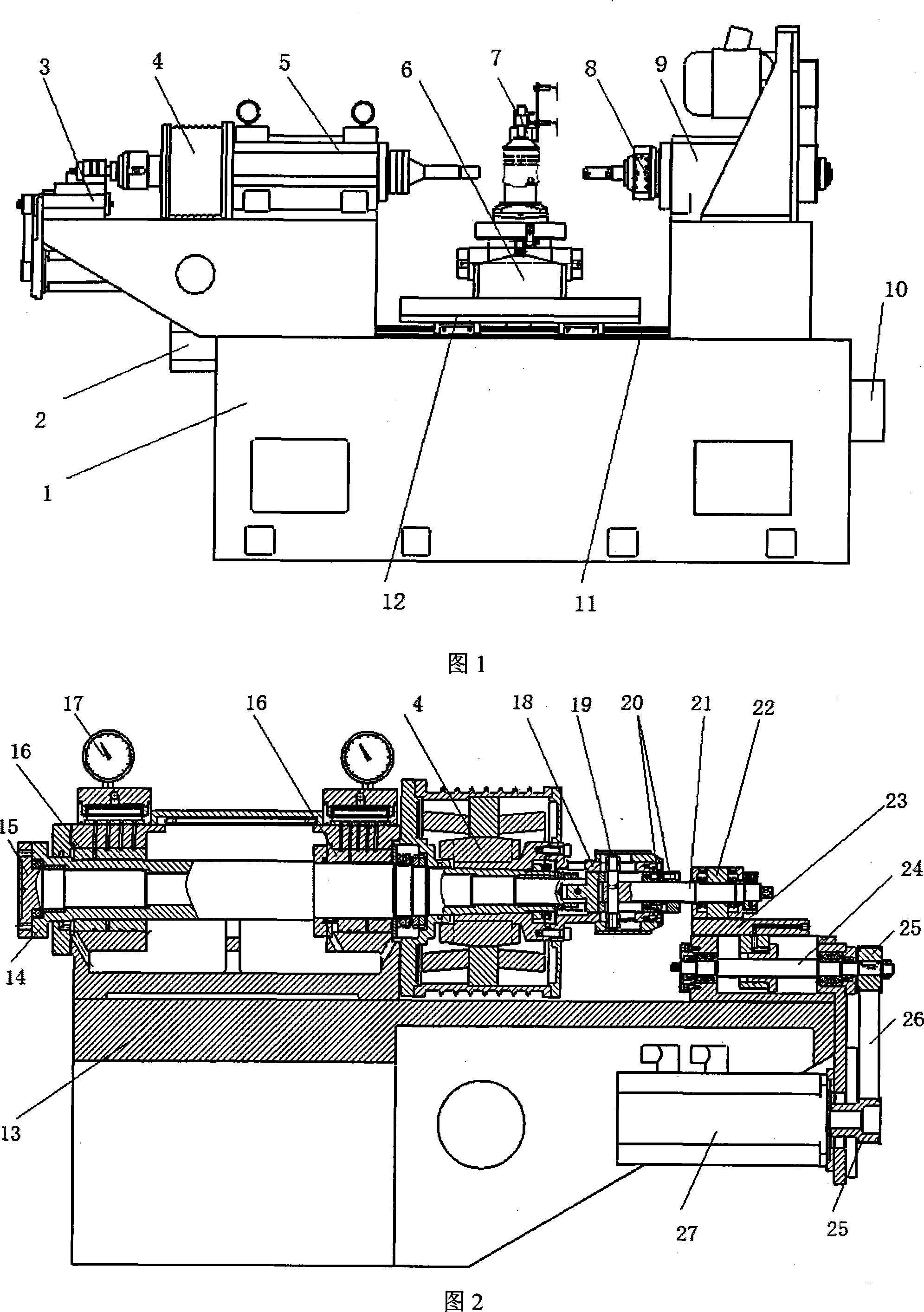

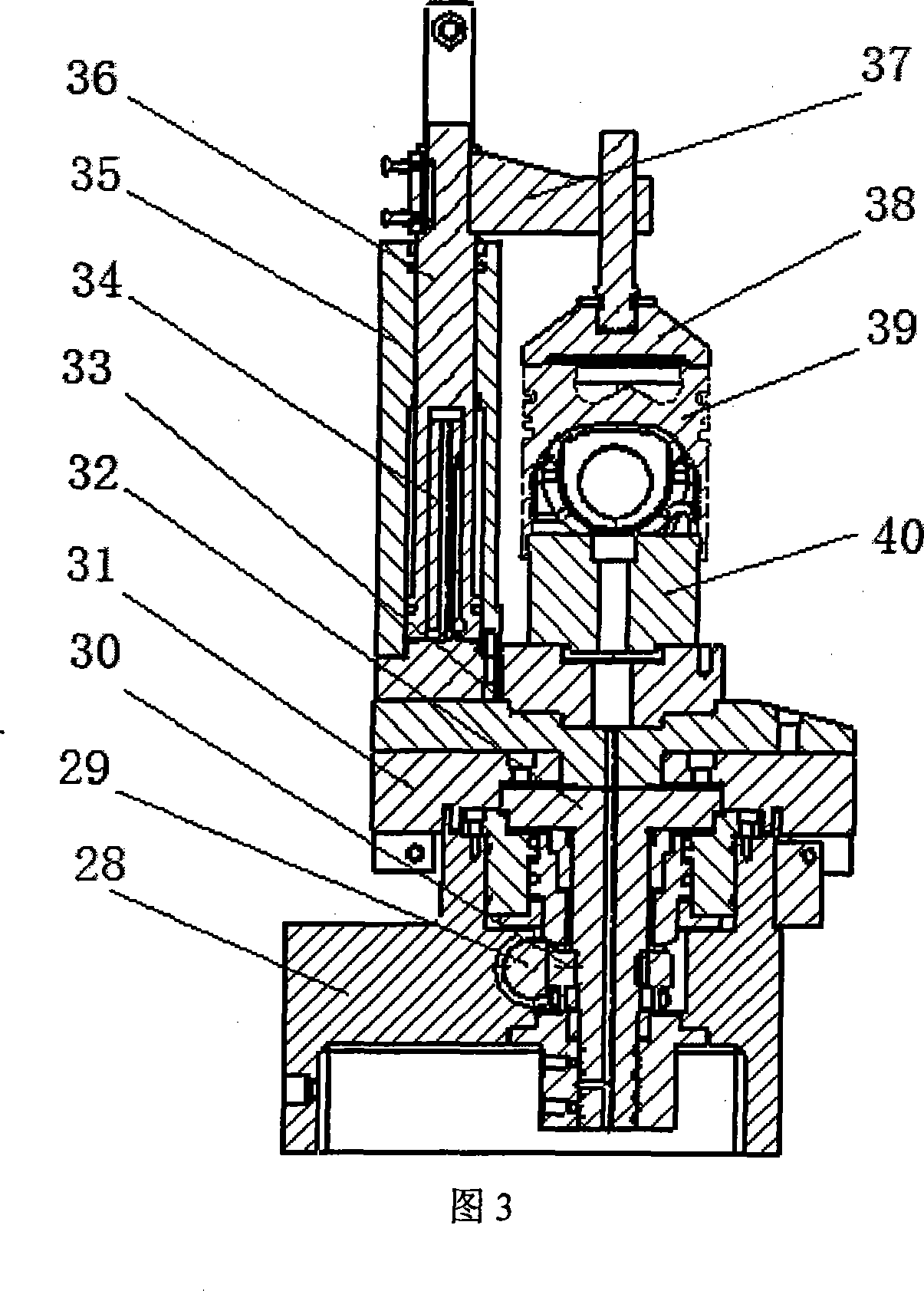

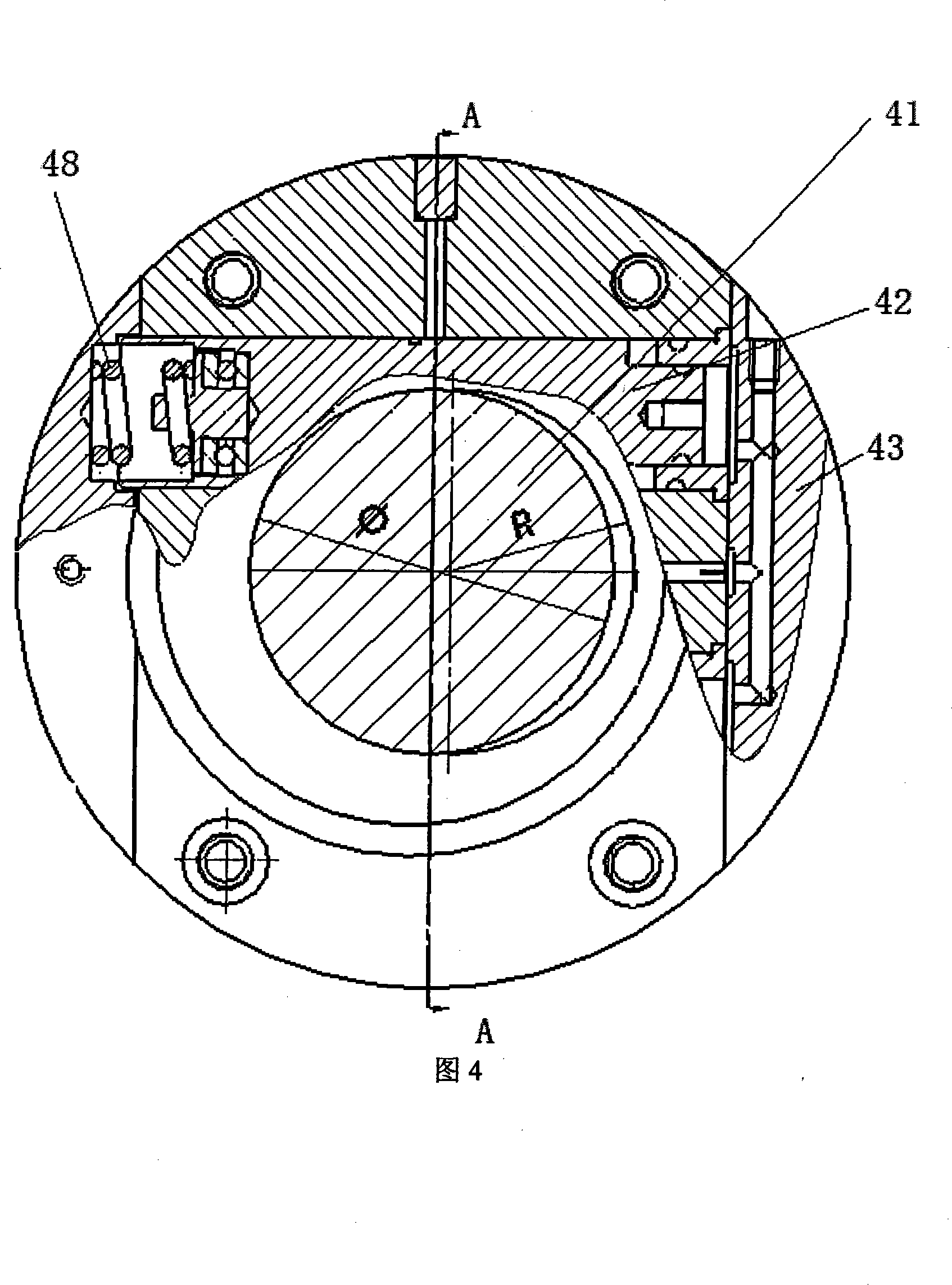

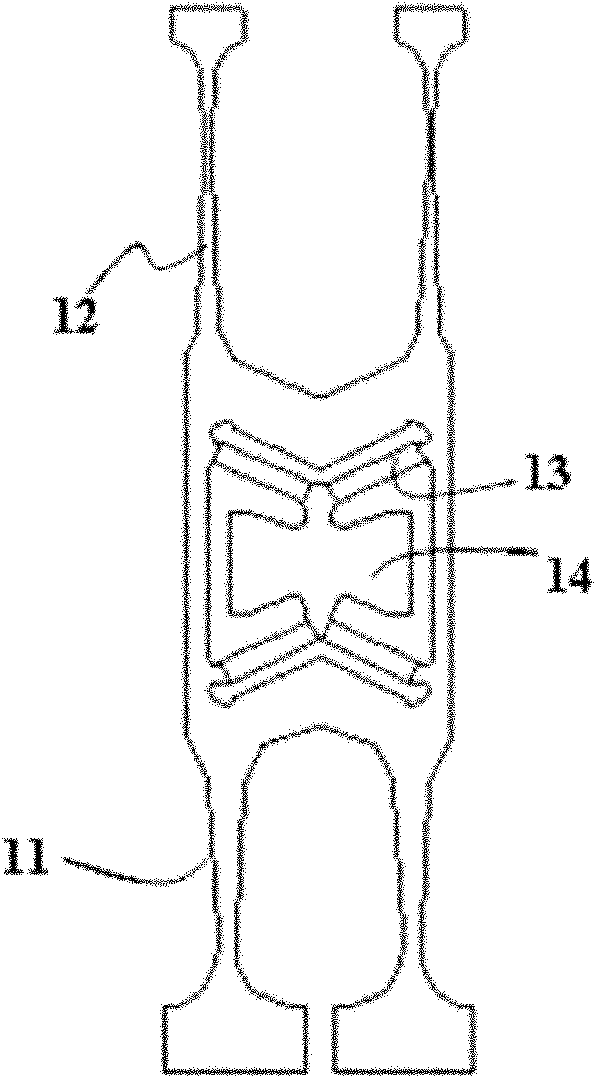

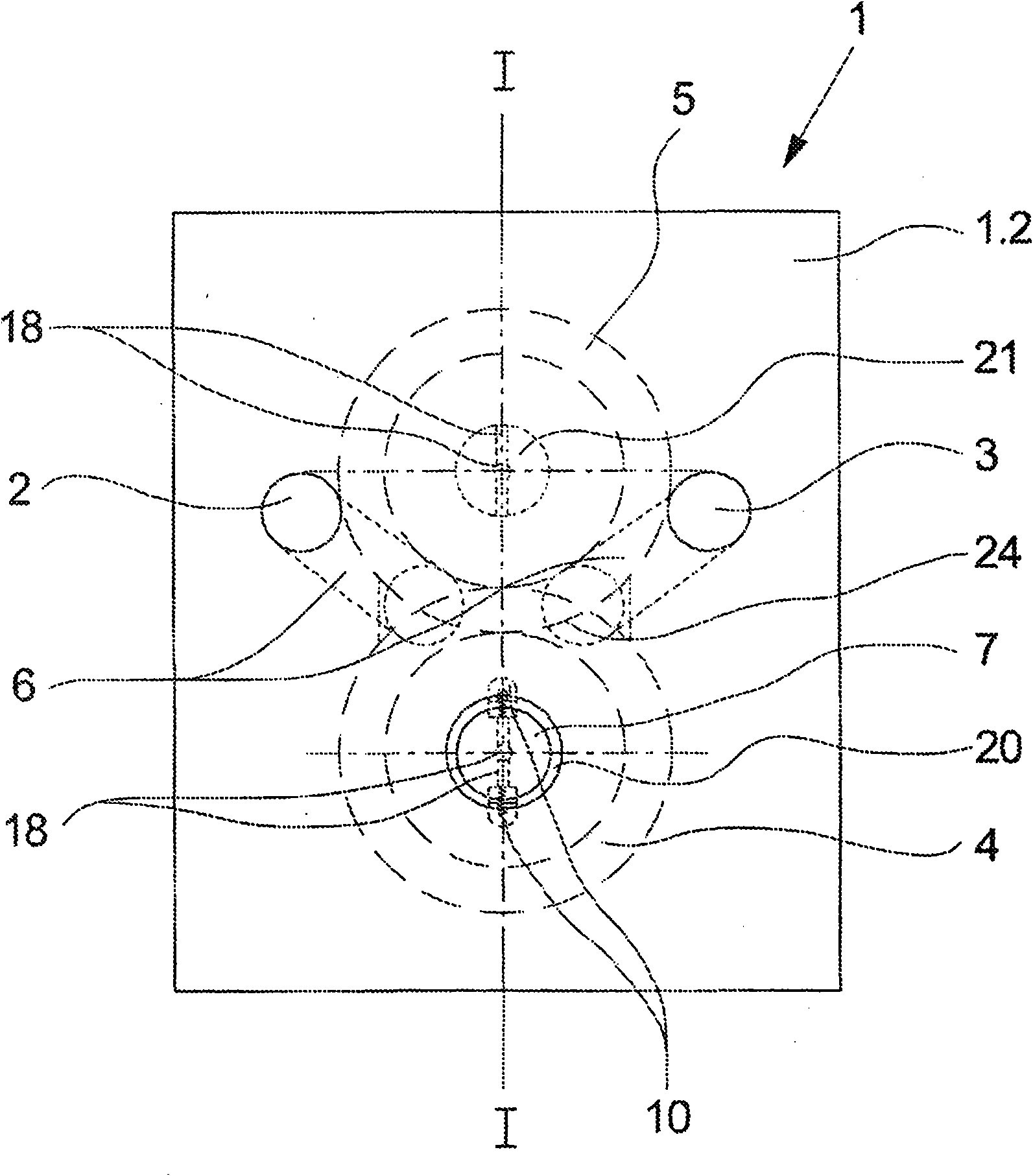

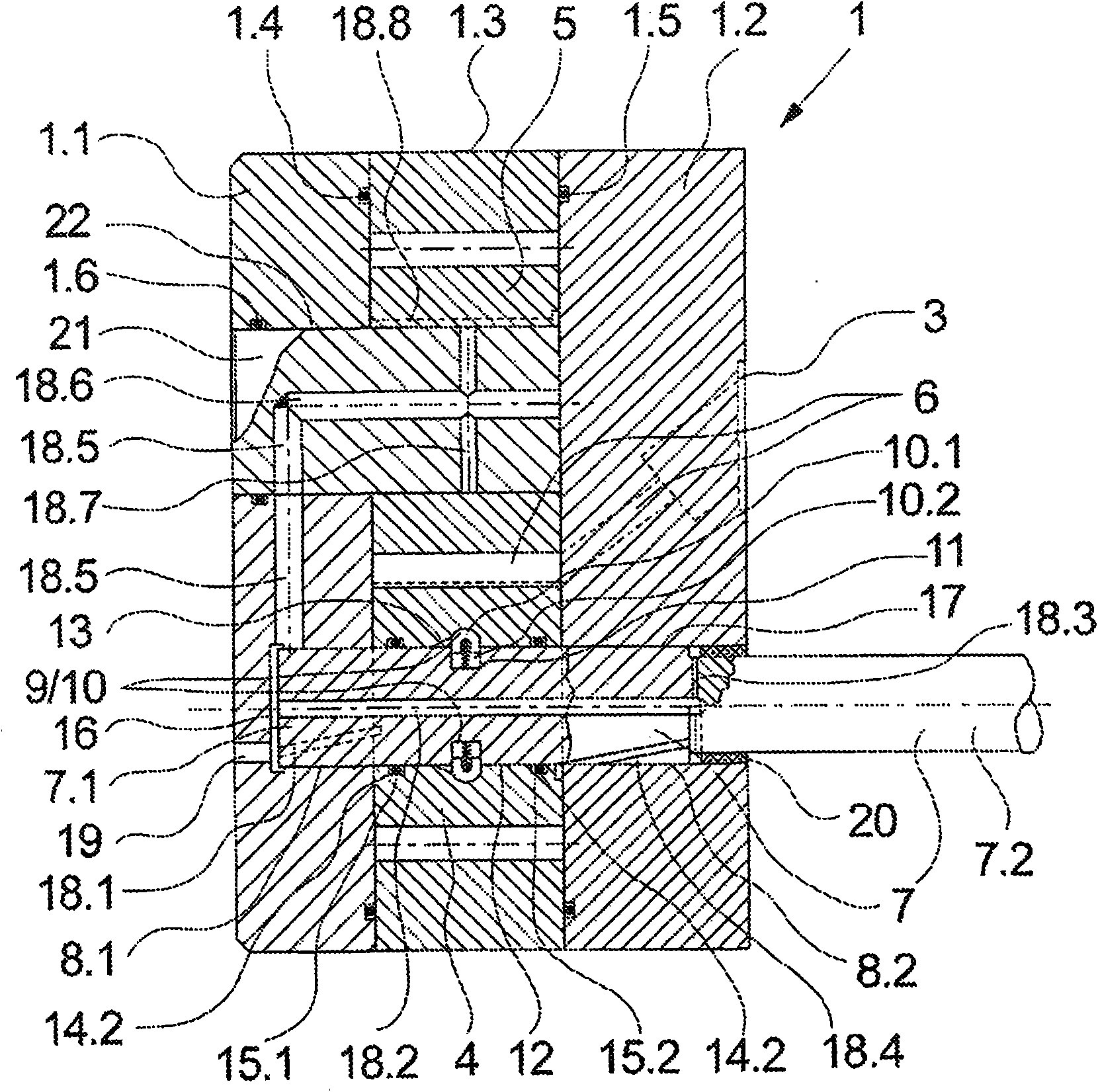

Non-conventional type hole combined boring mill

ActiveCN101116915AAvoid vibrationAvoid heating phenomenonLarge fixed membersPositioning apparatusEngineeringMachine tool

The invention relates to an profile hole assemble boring machine, which comprises a machine tool base, a principal axis motor, a gyrus worktable and a chucking mechanism which are arranged on the machine tool base. A clamp spring groove and an inner-outer chamfer angle and outside chamfer angle boring feed mechanism are arranged one side of the machine tool base. The rotor of the principal axis motor is directly connected with the principal axis. The invention adopts the direct connection transmission of the motor rotor and the principal axis to improve the processing precision. Because of without the belt unloading system, the vibration of the machine tool due to belt chattering is avoided, thereby reducing breakdown and avoiding the boring head heating-up phenomenon due to bearing heating. Because the clamp spring groove and the inner-outer rotating angle boring feed mechanism are arranged on the machine tool base, the precise processing of a piston profile hole, the clamp spring groove, the inner chamfer angle and outer chamfer angle are realized, thereby reducing the processing sequence, decreasing the processing error and improving the processing precision.

Owner:BINZHOU BOHAI PISTON CO LTD +1

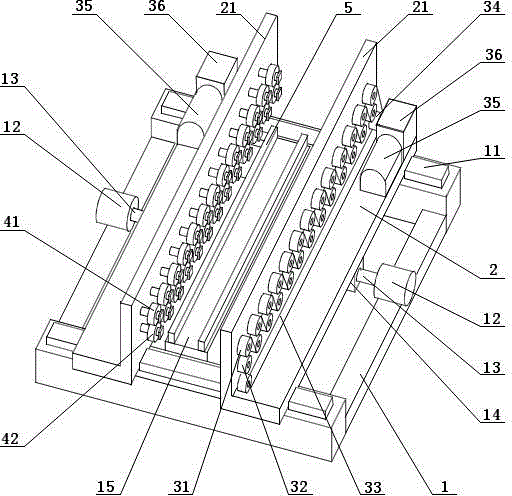

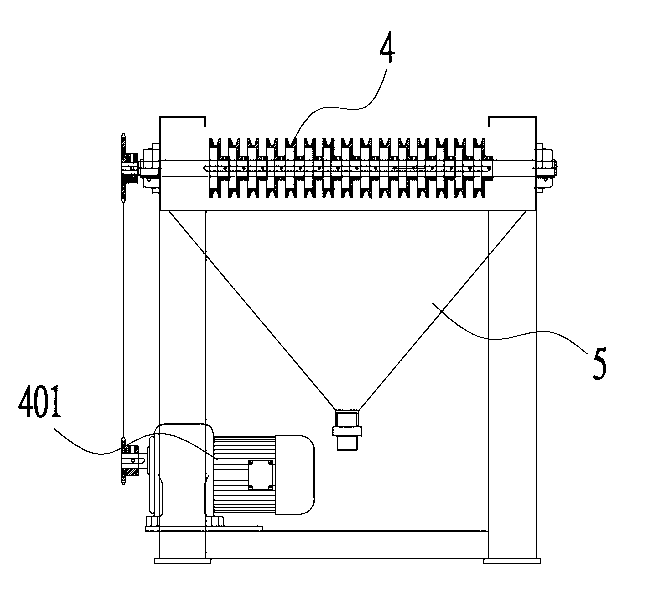

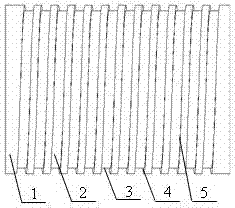

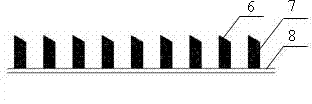

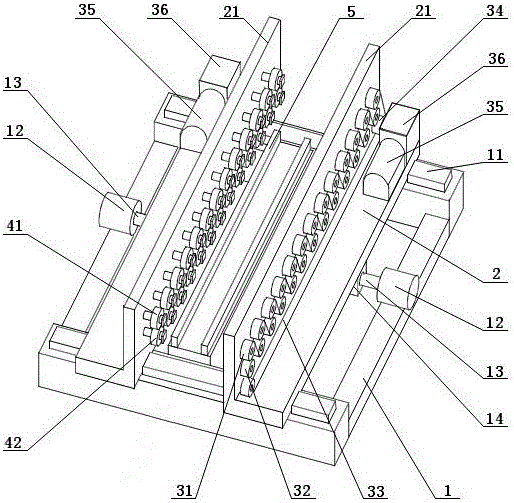

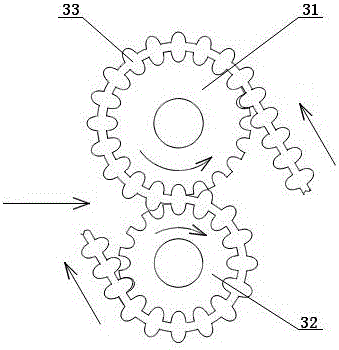

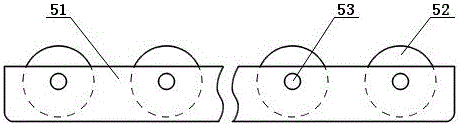

Rolling edge folding machine

ActiveCN104785598AHem shape is not the sameAchieve precision machiningMechanical engineeringEngineering

The invention discloses a rolling edge folding machine which comprises a base and two roll frames. The two roll frames are located on the two sides of the base respectively. Roll plate frames are arranged on the roll frames and are vertical plate-shaped bodies. The two roll plate frames are parallel to each other. A plurality of rolling edge folding mechanisms are arranged on the inner sides of the roll plate frames. Each rolling edge folding mechanism is composed of an upper edge folding roll and a lower edge folding roll. The axes of the upper edge folding roll and the lower edge folding roll of each rolling edge folding mechanism are located on the same vertical line. Press plate clearances are arranged between the upper edge folding rolls and the lower edge folding rolls. The press plate clearances of the rolling edge folding mechanisms are located on the same horizontal plane. The upper edge folding rolls and the lower edge folding rolls are connected with synchronous power mechanisms. At least one of the upper edge folding roll and the lower edge folding roll of each rolling edge folding mechanism is provided with an edge folding mold strip portion. The shape of the edge folding mold strip portions of the rolling edge folding mechanisms is gradually changed from one ends to the other ends. Plates are driven by press plate traction portions of the upper edge folding rolls and the lower edge folding rolls to move along the rolling edge folding mechanisms, and edge folding is carried out on the plates according to the edge folding mold strip portions with the shape gradually changed.

Owner:ANHUI KINGPOWER EQUIP & MOLD MFR

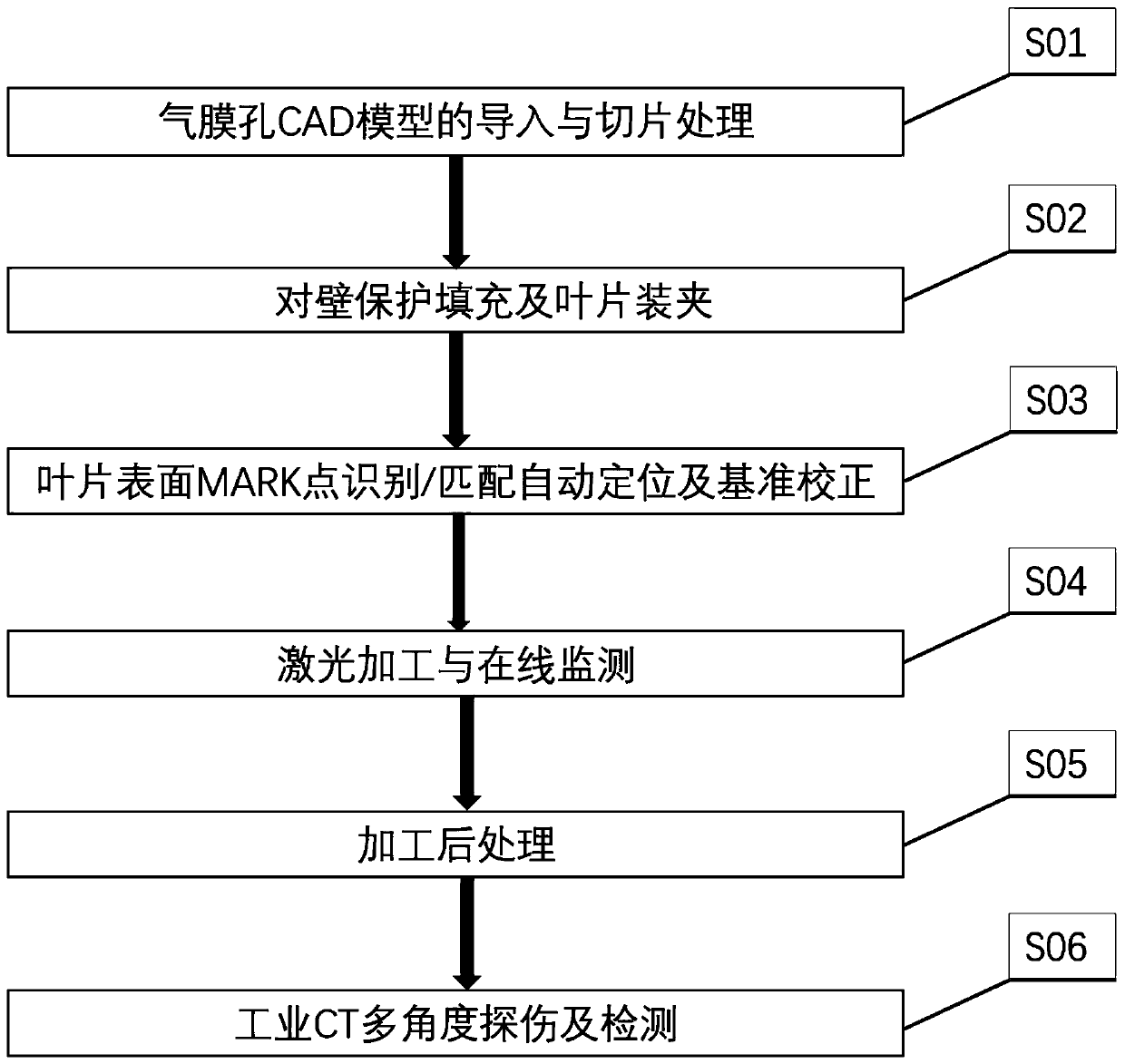

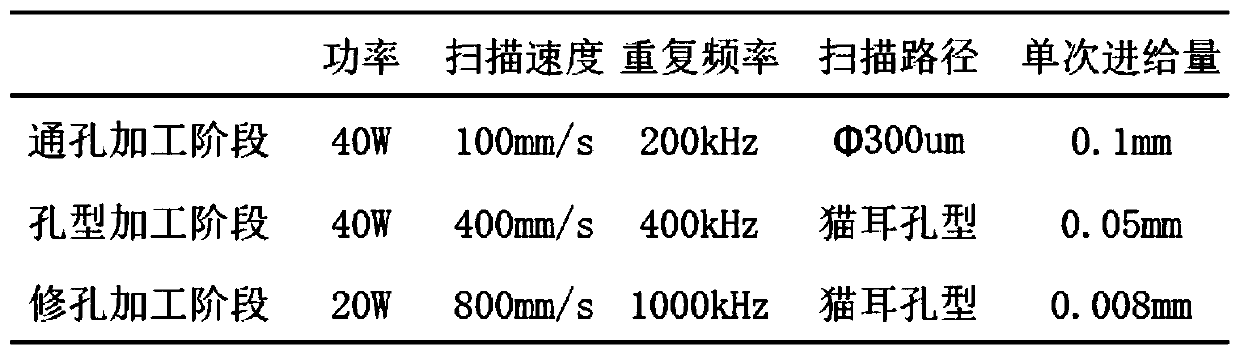

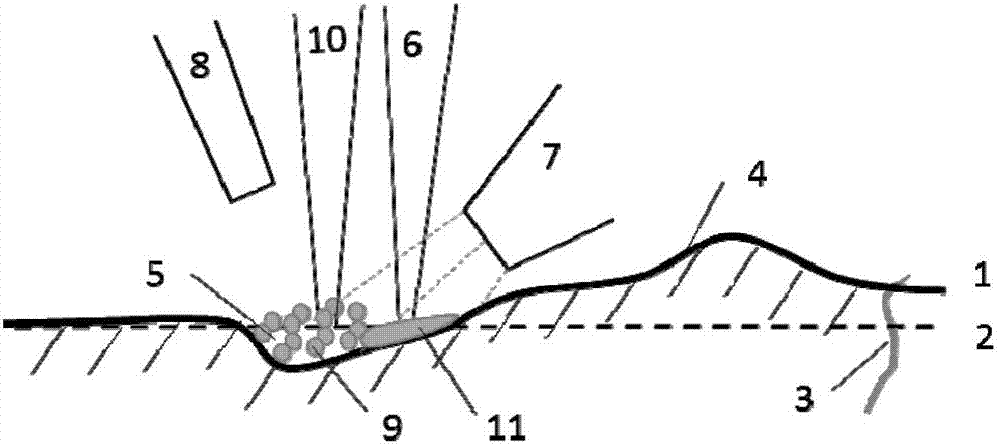

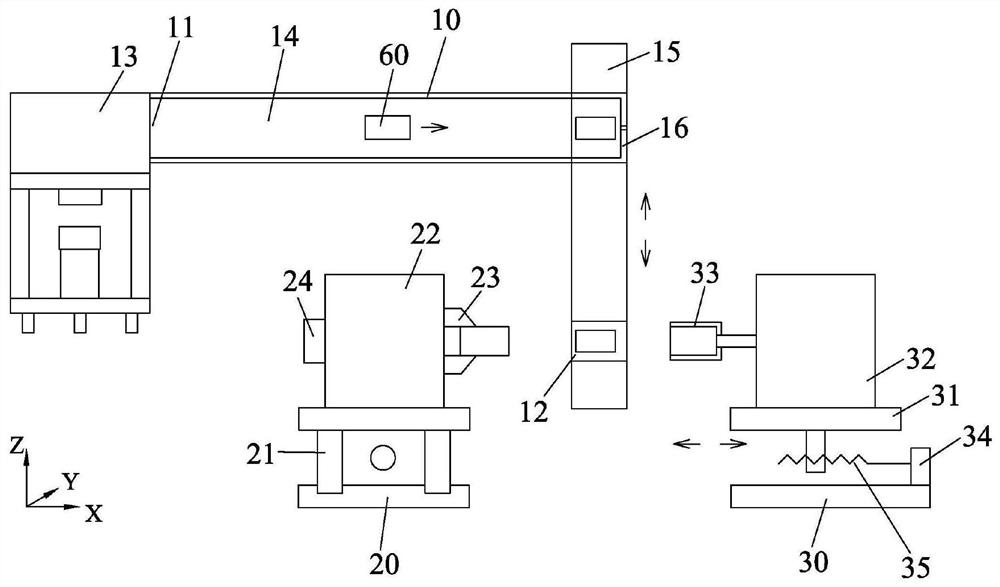

Laser machining process of special-shaped film hole of turbine blade

PendingCN110640339AGuaranteed positioning accuracyReal-time correction of coordinate position deviationLaser beam welding apparatusLaser processingTurbine blade

The invention relates to a laser machining process of a special-shaped film hole of a turbine blade. The process comprises the following steps of film hole CAD model introducing and slicing; wall protecting and filling, and blade assembling and clamping; blade surface MARK point identifying / matching automatic positioning and reference correcting; laser machining and online monitoring; post-machining treatment; and industrial CT multi-angle flaw detection and detecting. The machining process has the beneficial effects of realizing precise machining of the complex special-shaped film hole, improving the surface integrity of film hole machining, having great significance for improving the quality of a turbine engine / gas turbine, and providing technical support for the development of a newgeneration turbine-type aero-engine and marine gas turbine.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

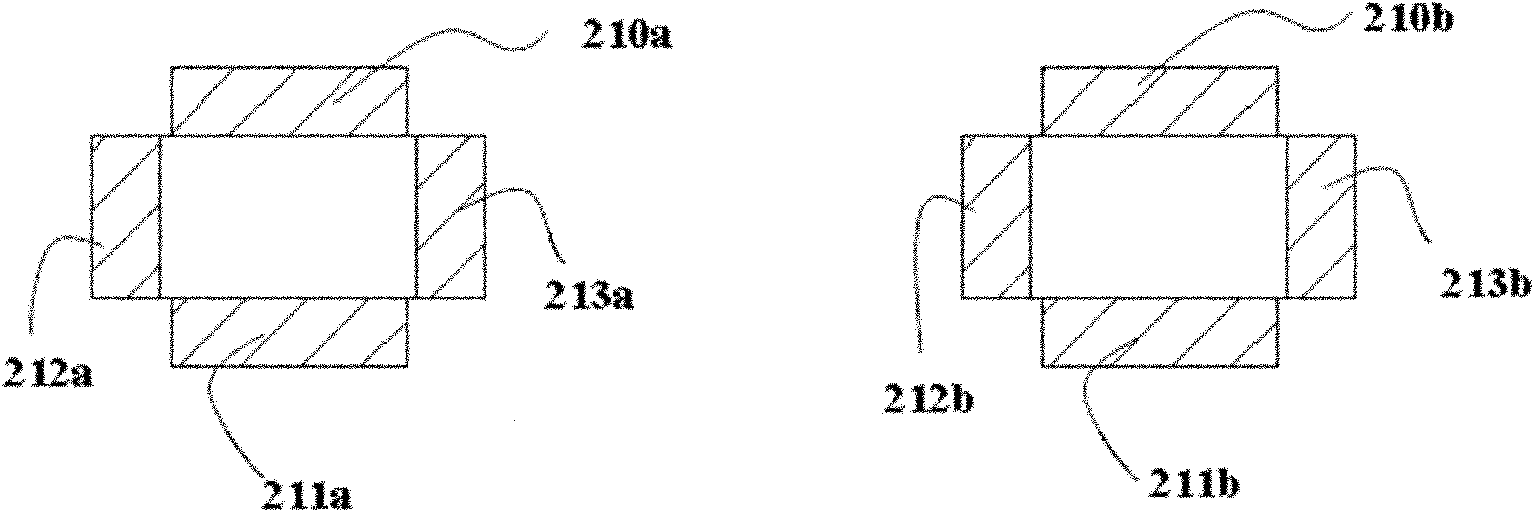

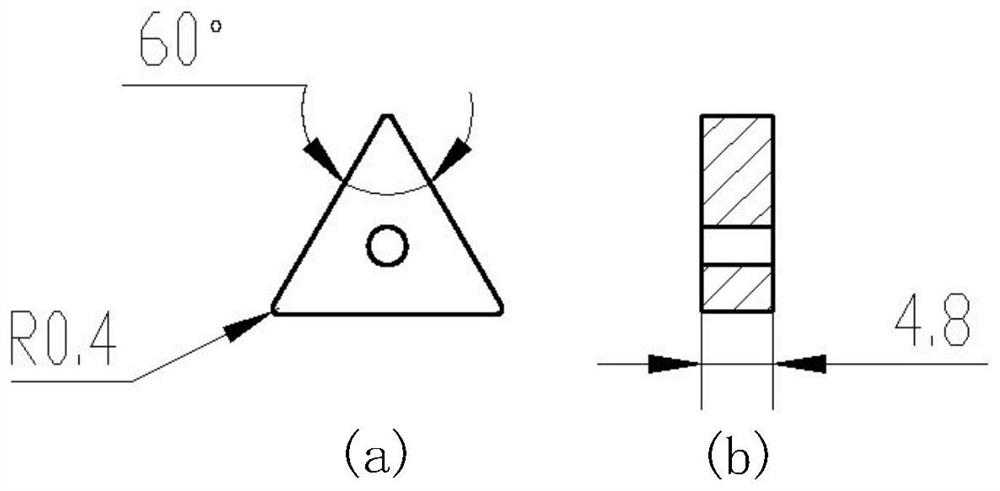

Method for machining micro-mechanical quartz tuning fork gyro sensitive structure

ActiveCN102009945ARealize structural processingRealize processingDecorative surface effectsTurn-sensitive devicesPhysicsPosition error

Owner:BEIJING AUTOMATION CONTROL EQUIP INST

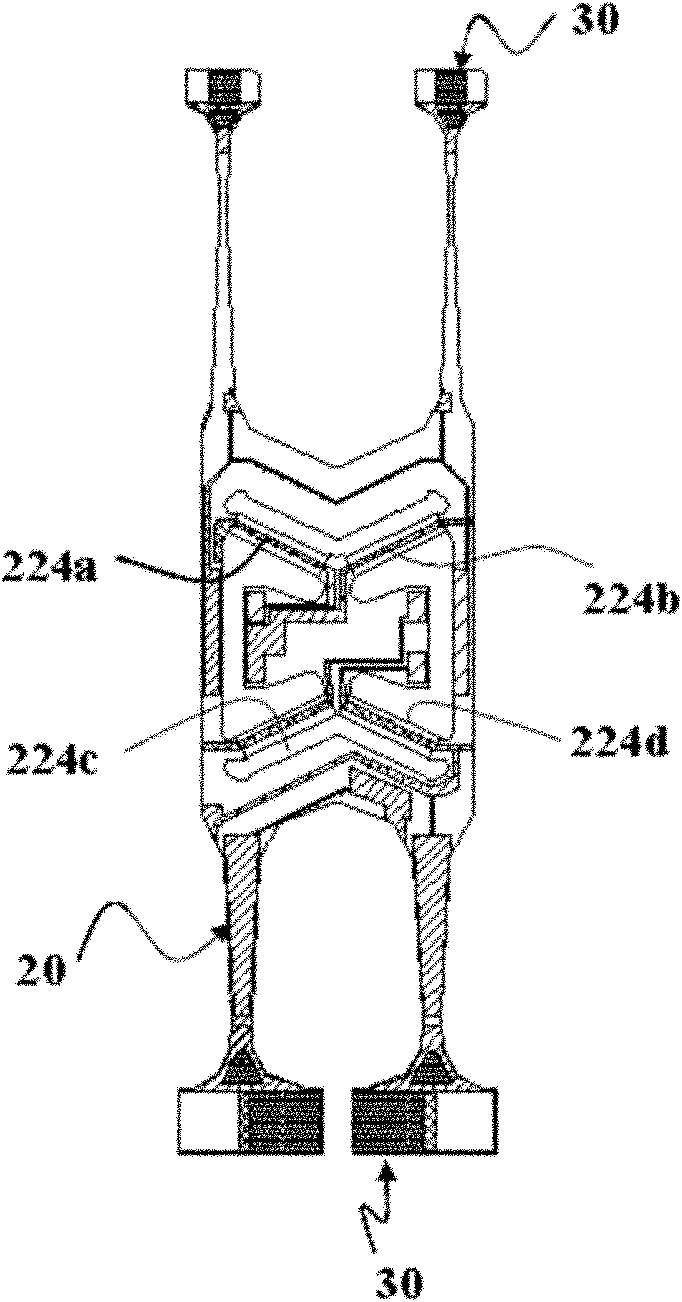

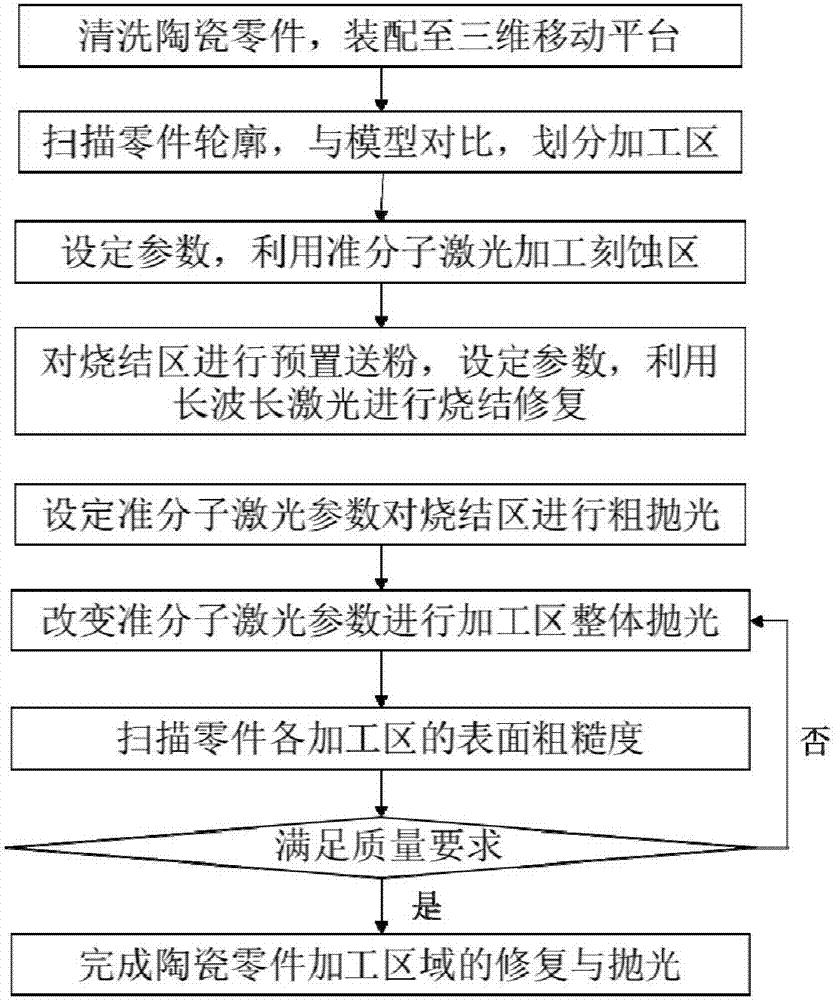

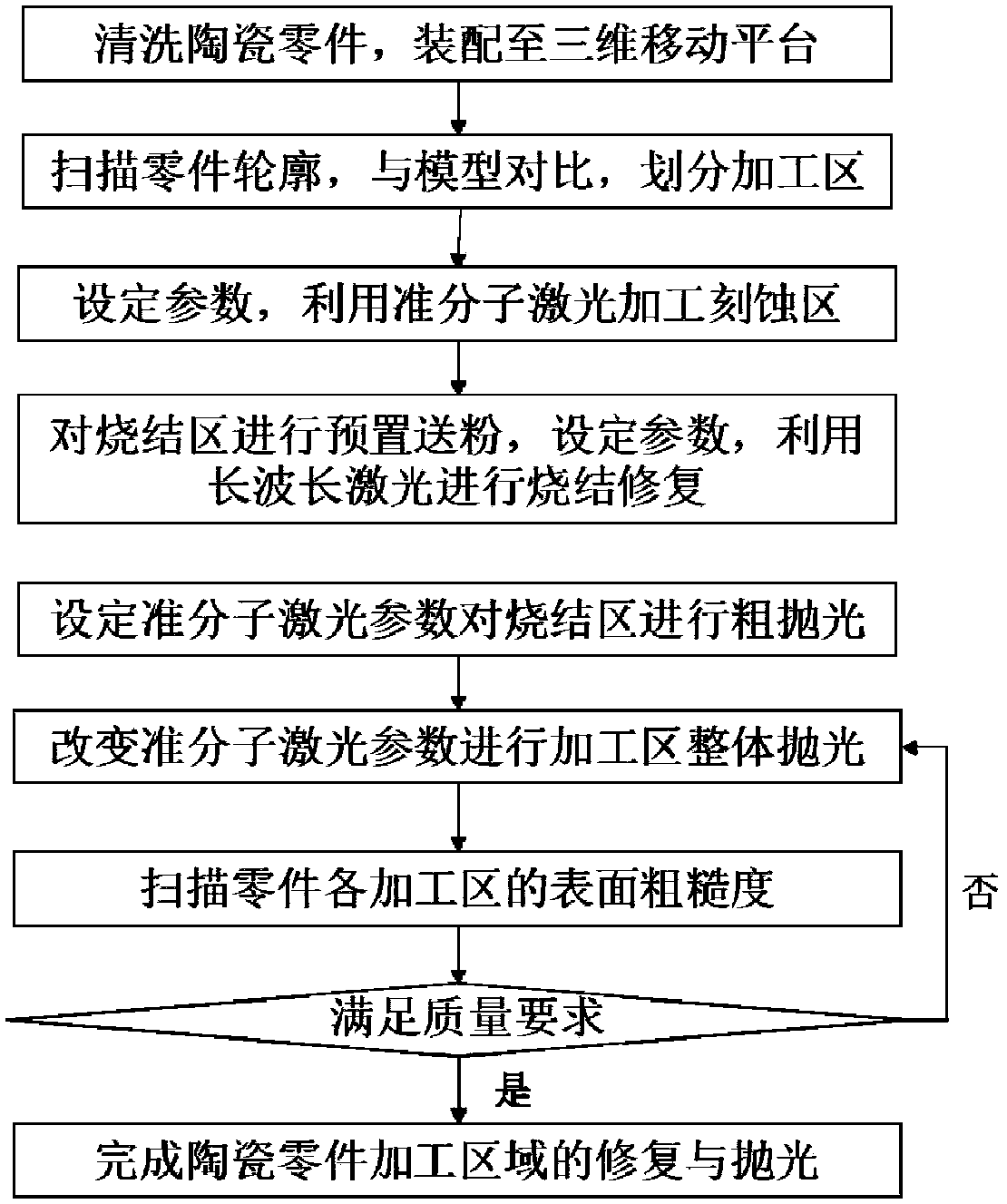

Method for repairing and polishing ceramic part through laser

ActiveCN107378276ARealize modelingAchieve fixWelding/soldering/cutting articlesLaser beam welding apparatusMetallurgySurface roughness

The invention discloses a method for repairing and polishing ceramic parts through laser. The method comprises the steps of S1, cleaning the ceramic part, and assembling the ceramic part to a three-dimensional moving platform; S2, scanning the surface contour of the ceramic part, comparing the scanned contour model with a standard model, and dividing the surface of the ceramic part into an etching region, a polishing region and a sintering region; S3, processing the etching region by using excimer laser equipment; S4, carrying out preset powder feeding on the sintering region, and carrying out sintering repair by using long-wavelength laser; S5, carrying out rough polishing on the sintering region; S6, carrying out overall polishing on the processing area; and S7, scanning the surface roughness of the ceramic part, executing the step S6 if the roughness does not meet the requirement, and completing the excimer laser polishing process if the roughness meets the requirement. The method has the advantages that the controllability is good, the automatic production can be realized conveniently, the precise processing of the micro-area can be realized, any curved surface and any part can be treated, the influence on a ceramic matrix is remarkably reduced, and the precision, the quality and the efficiency of part repairing and polishing are guaranteed.

Owner:RAINBOW SOURCE LASER RSLASER

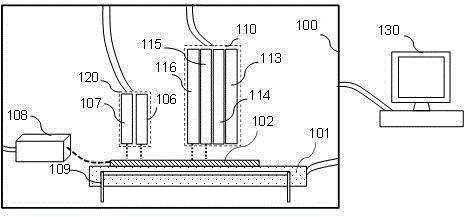

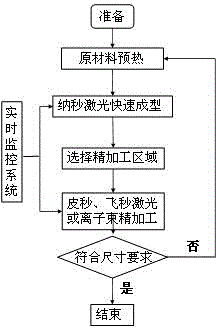

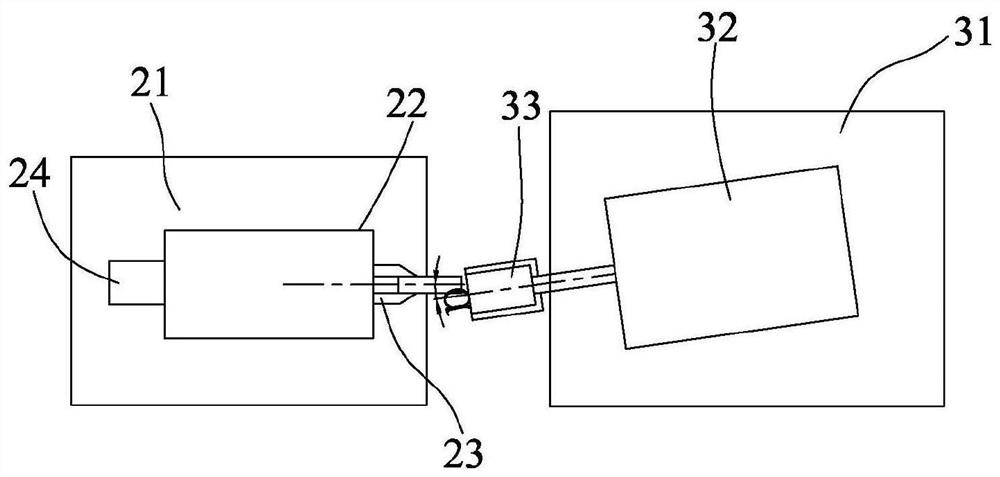

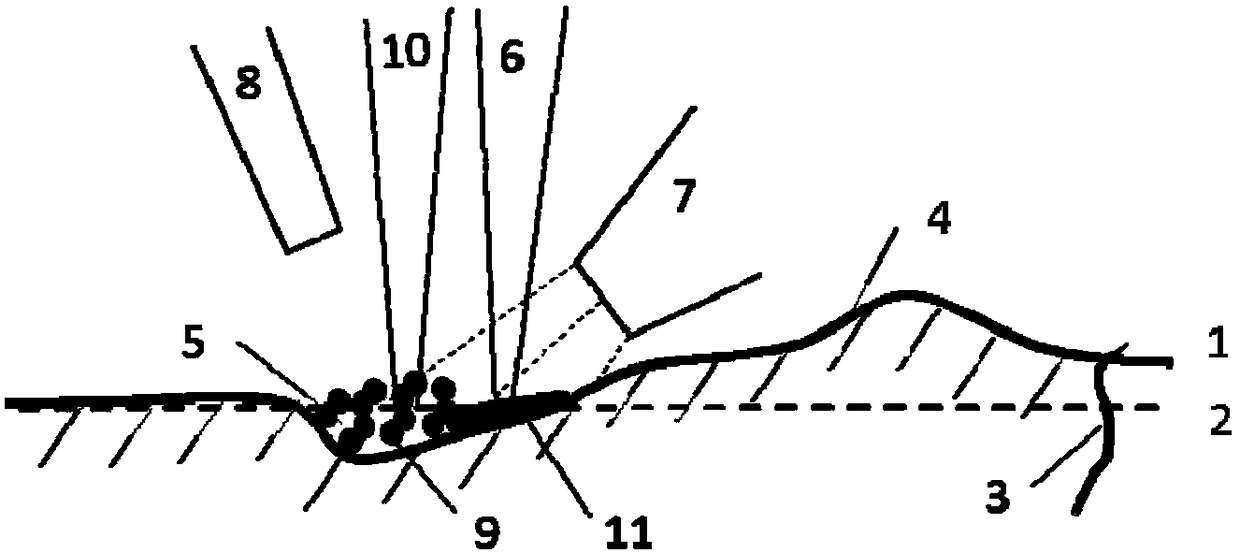

Quick forming device and method based on femtosecond laser and ion beam composite technology

ActiveCN104889570ARapid prototypingRealize point-by-point controlLaser beam welding apparatusPicosecond laserClosed loop

The invention provides a quick forming device and method based on a femtosecond laser and ion beam composite technology. The device mainly comprises a nanosecond-picosecond-femtosecond laser device, an ion beam device and a real-time monitoring system, nanosecond laser is used for conducting scanning sintering on raw materials, the real-time monitoring system performs real-time processing, part morphology, microcosmic structure and ingredient measurement and analysis and feeds analysis results to a control system, and the nanosecond-picosecond-femtosecond laser, ion beams and the real-time monitoring system forma closed-loop system so as to effectively machining and detection coordination if picoseconds laser, femtosecond laser or ion beams are needed to perform further finish machining. The quick forming device and method achieve quick forming of complicated parts and precise machining of the microcosmic structure, improve the microcosmic structure and quality control capacity by using the real-time monitoring system and is used for manufacturing high-strength, high-accuracy and complicated-structure parts.

Owner:WUHAN FINEMEMS

Brazing type diamond grinding wheel used for high-precision grinding and manufacturing method

InactiveCN105945737AAchieve precision machiningImprove gripBonded abrasive wheelsGrinding devicesManufacturing technologyElectroplating

The invention discloses a brazing type diamond grinding wheel used for high-precision grinding and a manufacturing method and belongs to the technical field of precise grinding of high-end glass and material grinding. A diamond brazing layer is arranged at the upper portion of a metal machine body. Diamond abrasive particles are arranged in the diamond brazing layer. Micro grooves are formed in the surface of the metal machine body and are arranged in the surface of the metal machine body in an ordered or disordered manner. The diamond brazing layer comprises an outer circle face and grinding grooves, and the shape of the grinding grooves is determined according to workpiece machining requirements. By means of the brazing type diamond grinding wheel, the number and the diameter of the grooves can be customized at will; and the diamond abrasive particles are subjected to multi-layer brazing; the diamond abrasive particles maintain high holding force in the highly-bare state, and the service life is long. Compared with sintering type and electroplating type manufacturing technologies, the service life is greatly prolonged, and the machining quality is greatly improved; and the diamond abrasive particles still have the high holding force in the highly-bare state, a collapse opening of an outer circle of ground glass is smaller, and the service life is obviously prolonged.

Owner:JIAXING WORLDIA DIAMOND TOOLS CO LTD

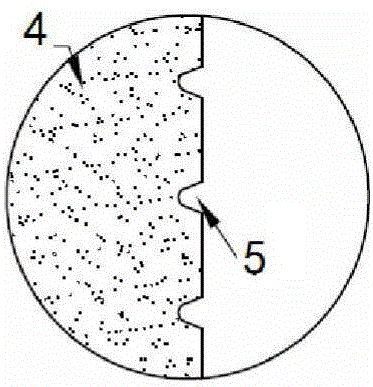

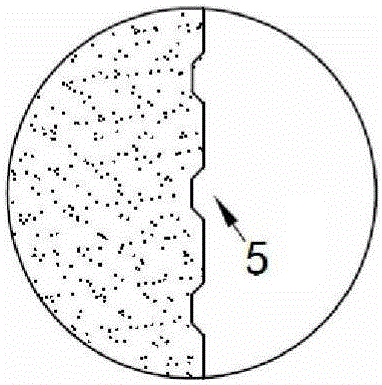

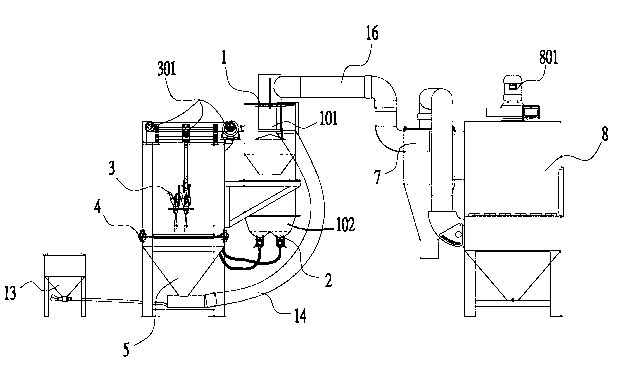

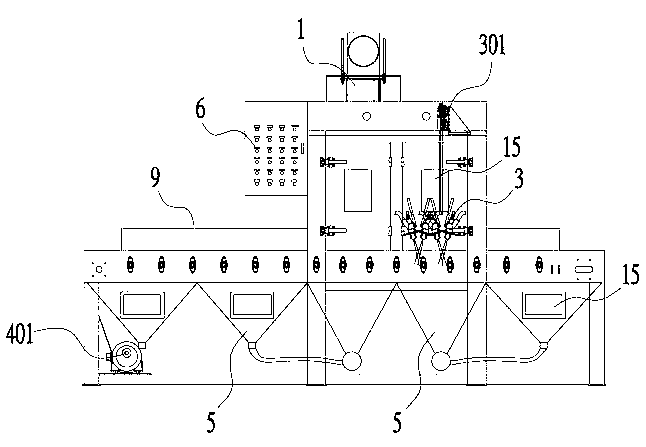

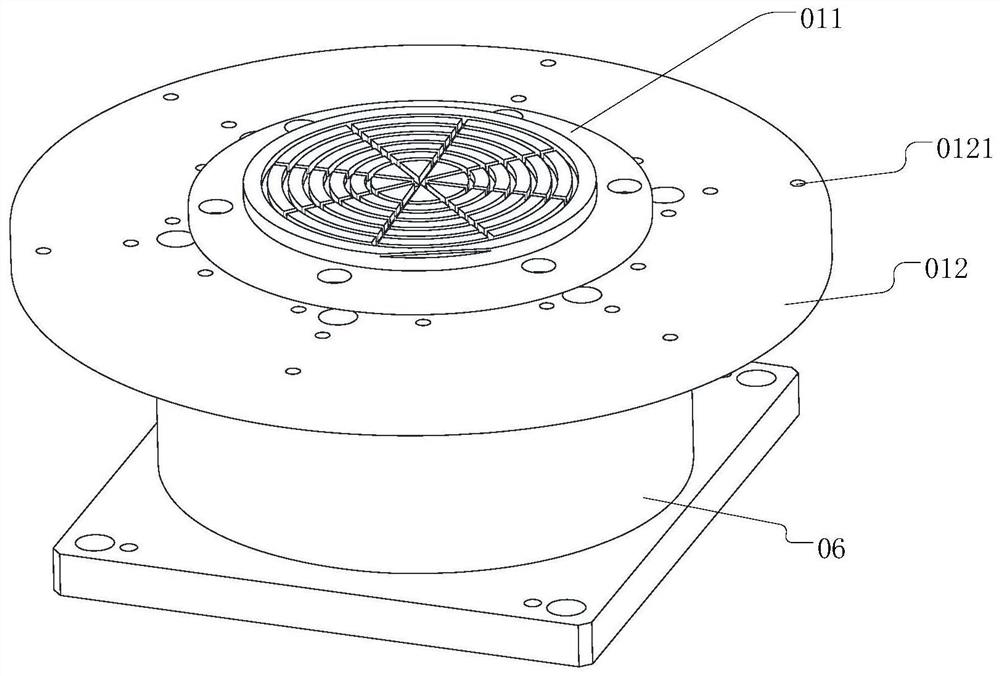

Accurate sand-blasting processing machine for thinned fragile slabs and machining method

InactiveCN102699823AAchieve precision machiningReduce wasteAbrasive feedersAbrasive machine appurtenancesProcessing accuracyEtching

The invention discloses an accurate sand-blasting processing machine for thinned fragile slabs and a machining method. The accurate sand-blasting processing machine comprises a primary cyclone separation device, a constant sand feeder, a sand blasting device, an air compressor, a thinned fragile slab conveying device, a sand recycling device and a control device, wherein the primary cyclone separation device is used for separating sand materials and dust from the sand recycling device and feeding the sand materials to the constant sand feeder; the constant sand feeder is used for conveying the sand materials at a constant flow velocity to the sand blasting device; the sand blasting device is used for jetting the sand materials to the thinned fragile slabs; the air compressor is used for supplying compressed air to the sand blasting device; the thinned fragile slab conveying device is used for horizontally conveying the thinned fragile slabs; the sand recycling device is arranged under the thinned fragile slab conveying device and is used for receiving the sand materials and the dust, and the output end of the sand recycling device is communicated with the primary cyclone separation device; and the control device is used for controlling each device to operate. When the accurate sand-blasting processing machine is used for processing the thinned fragile slabs to a plurality of products with specific shapes, the chemical etching is avoided, the environmental protection is realized, the product cost is low, and the production speed is high, and the processing accuracy and product yield are high.

Owner:广东旭泰智能表面处理有限公司

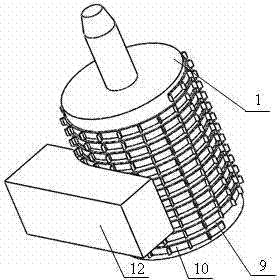

Spiral grinding wheel with composite material fiber micro blade

The invention discloses a spiral grinding wheel with a composite material fiber micro blade. The spiral grinding wheel comprises fiber micro blades, grinding belts, a thin-strip-shaped metal sheet, a blade grinding layer and a grinding wheel base body, each fiber micro blade has a zero anterior angle through blade grinding, the grinding belts are fixedly bonded on the thin-strip-shaped metal sheet by the fiber micro blades at equal intervals through electroplating orientation, and the blade grinding layer of the spiral grinding wheel is formed by a plurality of grinding belts which are bonded in a spiral groove of the grinding wheel base body and distributed in a spiral-belt-shaped manner. Zero anterior angle grinding processing is realized by utilizing the fiber micro blades, and generation of grinding heat is reduced; the grinding belts are distributed in a spiral-belt-shaped manner, so that chip containing space and chip discharging capability of the grinding wheel are increased, blockage of the grinding wheel is reduced, and grinding liquid is facilitated to enter a grinding area for lubricating and cooling. The spiral grinding wheel has the advantages that the spiral grinding wheel generates little grinding heat and is excellent in lubricating and cooling performance, a grinding blade is good in wearing-resistant performance, high in hardness, good in tenacity, reproducible and repairable and the like, and the spiral grinding wheel is suitable for high-efficiency precise processing of difficult-to-process materials such as hard and brittle materials.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

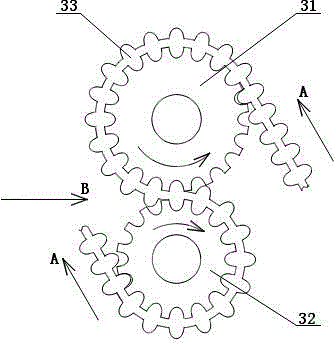

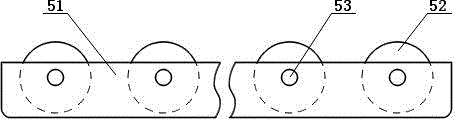

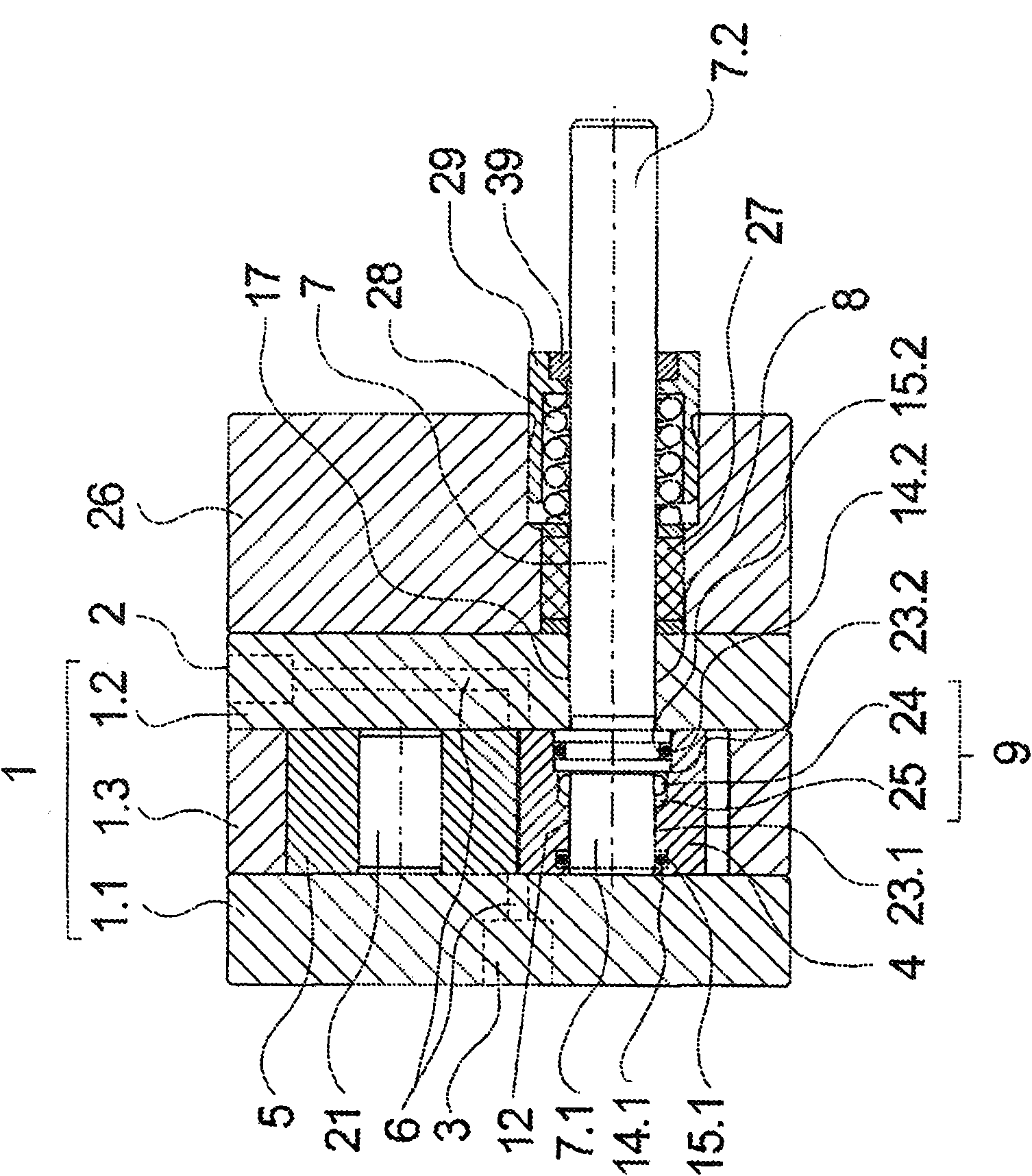

Gear wheel pump

ActiveCN101657643AFirmly connectedEasy connection and disassemblyRotary piston pumpsRotary piston liquid enginesGear pumpGear wheel

The invention relates to a gear wheel pump with two meshing gear wheels which are rotatably mounted within a pump housing by means of a driven driveshaft and a crankshaft journal and which form a pumping channel system between a pump inlet and a pump outlet. Several gaps are formed between the pump housing, the gear wheels, the driveshaft, and the crankshaft journal. One of the gaps between the driveshaft and one of the gear wheels contains means for the rotationally fixed connection of the driveshaft to the gear wheel. In order to prevent leakages penetrating to the connecting means, according to the invention the gap between the driveshaft and the gear wheel is sealed, with respect to the front faces of the gear wheel, by means of a sealant.

Owner:OERLIKON TEXTILE GMBH & CO KG +1

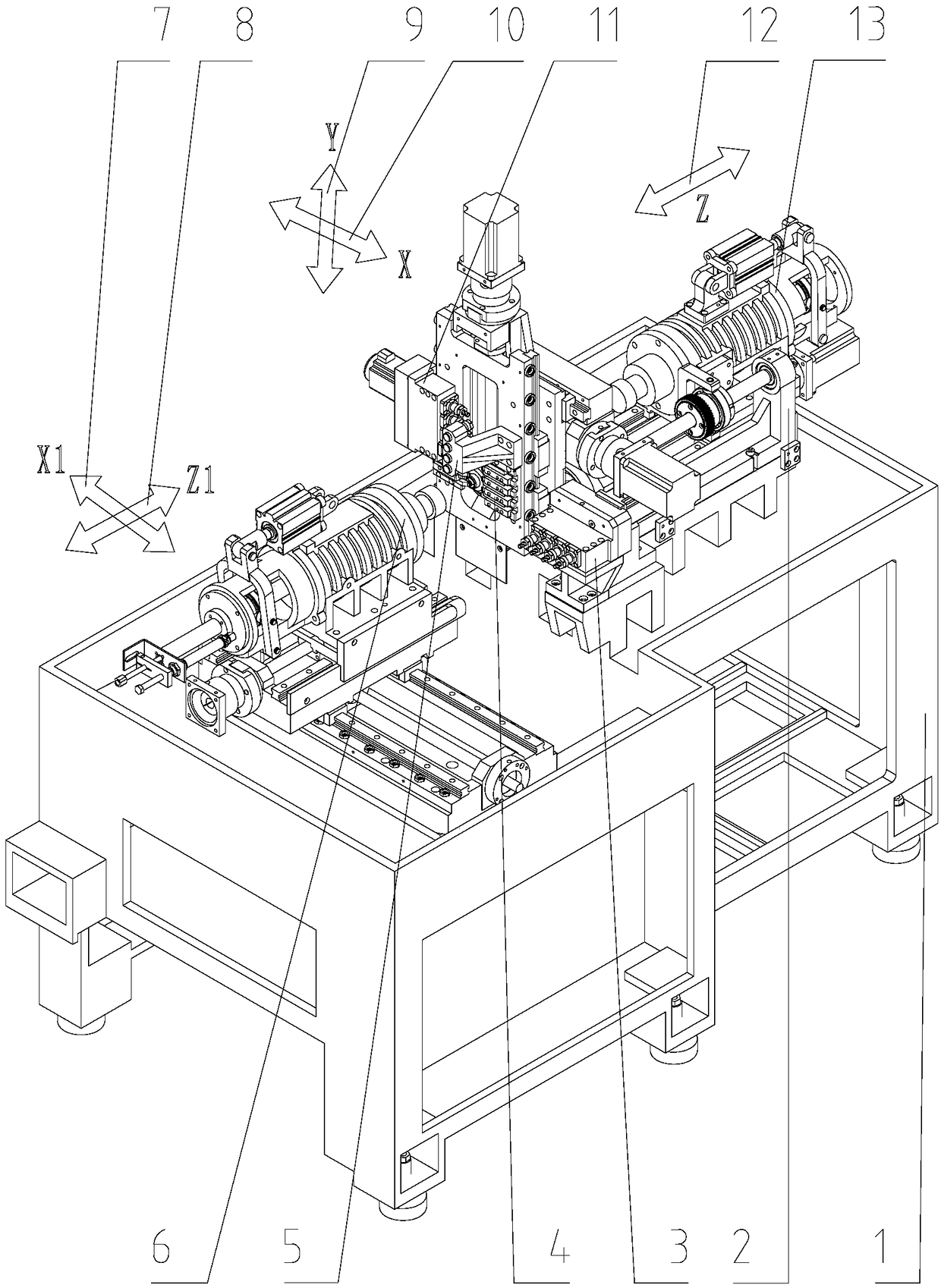

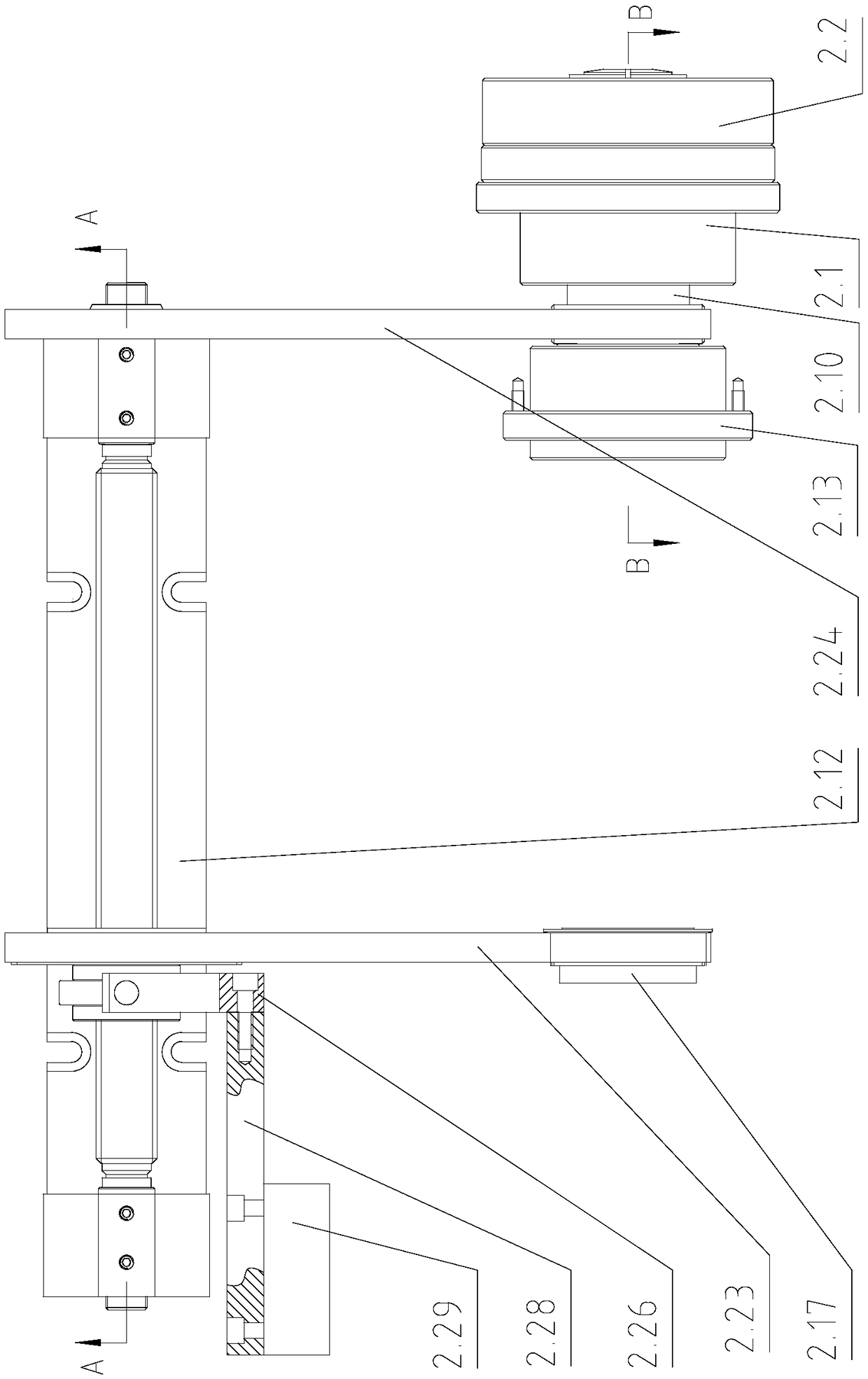

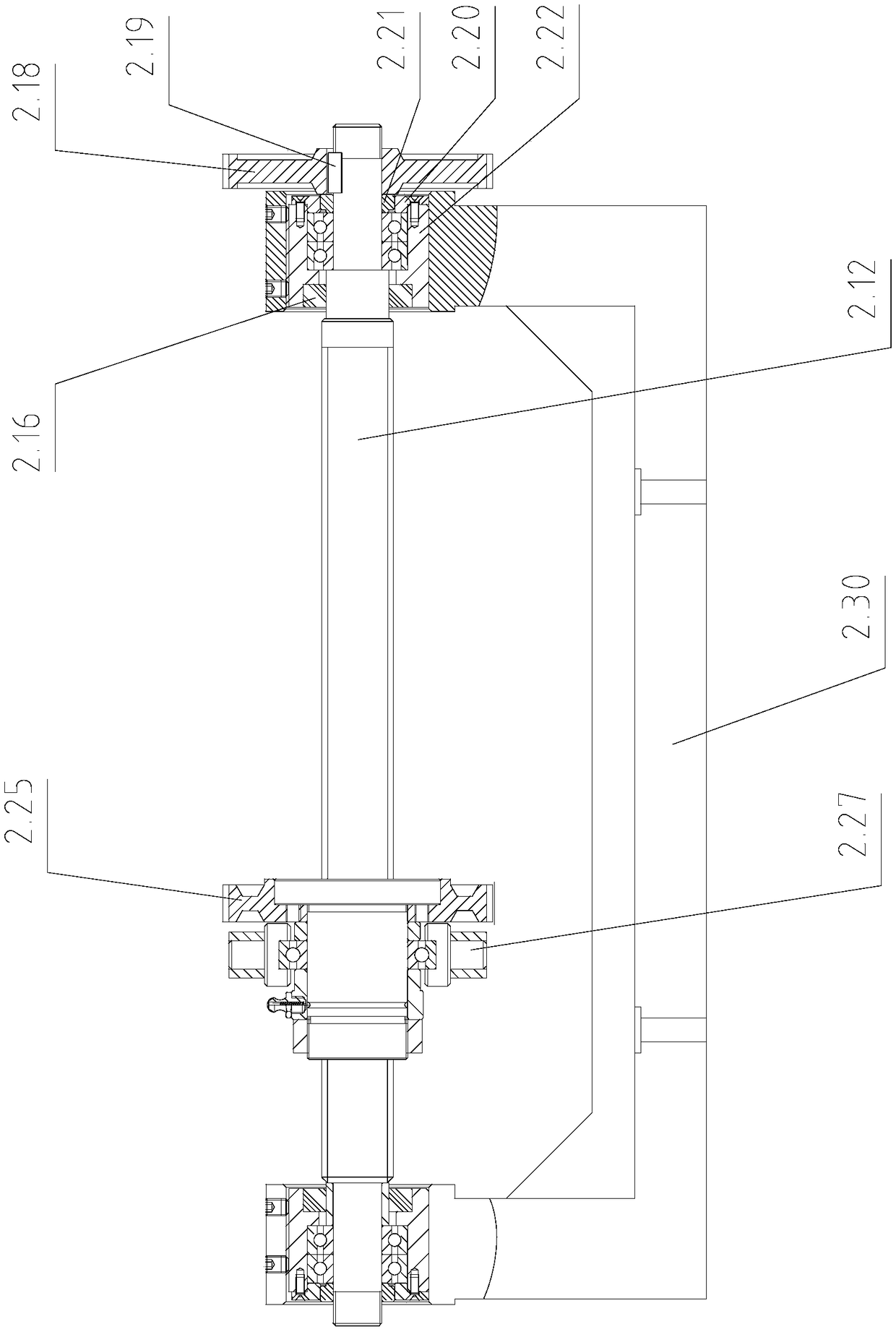

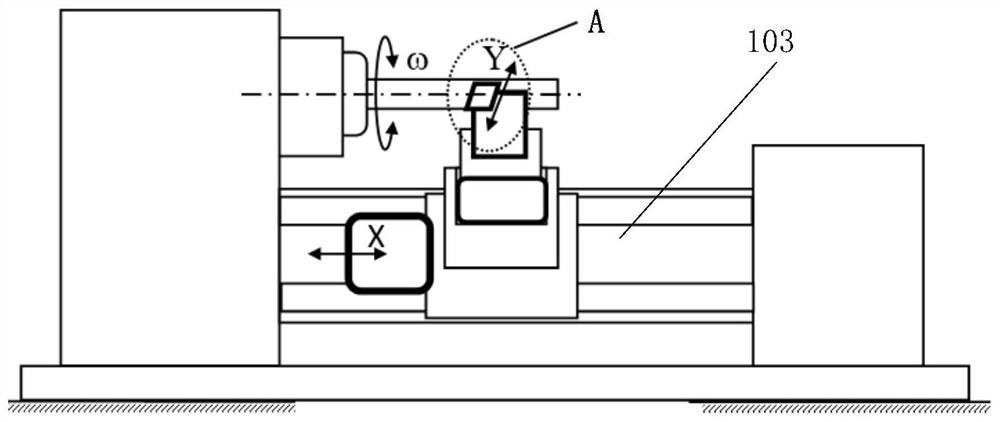

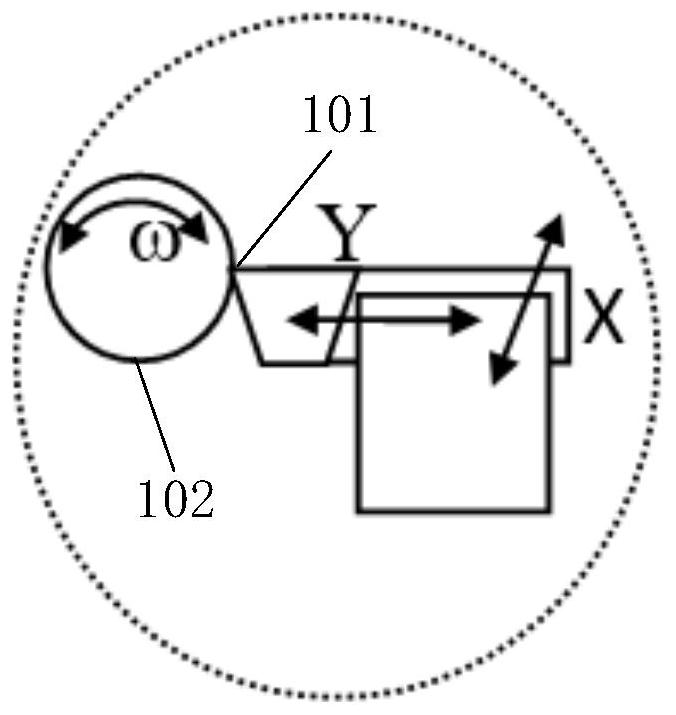

Longitudinal cutting turning and milling compound machine tool

PendingCN109128835AImprove versatilityEasy maintenance and operationOther manufacturing equipments/toolsFailure rateEngineering

The invention provides a longitudinal cutting turning and milling compound machine tool, and solves the technical problems of weaker performances of function parts, base parts, standard parts, nonstandard parts, auxiliary fittings and electric fittings of domestic high-top machine tools and higher failure rate. The longitudinal cutting turning and milling compound machine tool comprises a stand, adriving system, a synchronous guide sleeve system, a cutter system and a transmission system; the driving system comprises a main shaft part and a secondary main shaft part; the synchronous guide sleeve system comprises a synchronous guide sleeve part and a transmission part; the cutter system comprises a side surface power milling part, an axial power milling part, a drilling cutter base part and a turning cutter part; and the transmission system comprises an X-axle feeding transmission part, a Y-axle feeding transmission part, an X1-axle feeding transmission part, a Z1-axle feeding transmission part and a Z-axle feeding transmission part. The longitudinal cutting turning and milling compound machine tool can be widely applied to machining of complicate precise parts.

Owner:WEIHAI BEST PRECISION MACHINERY

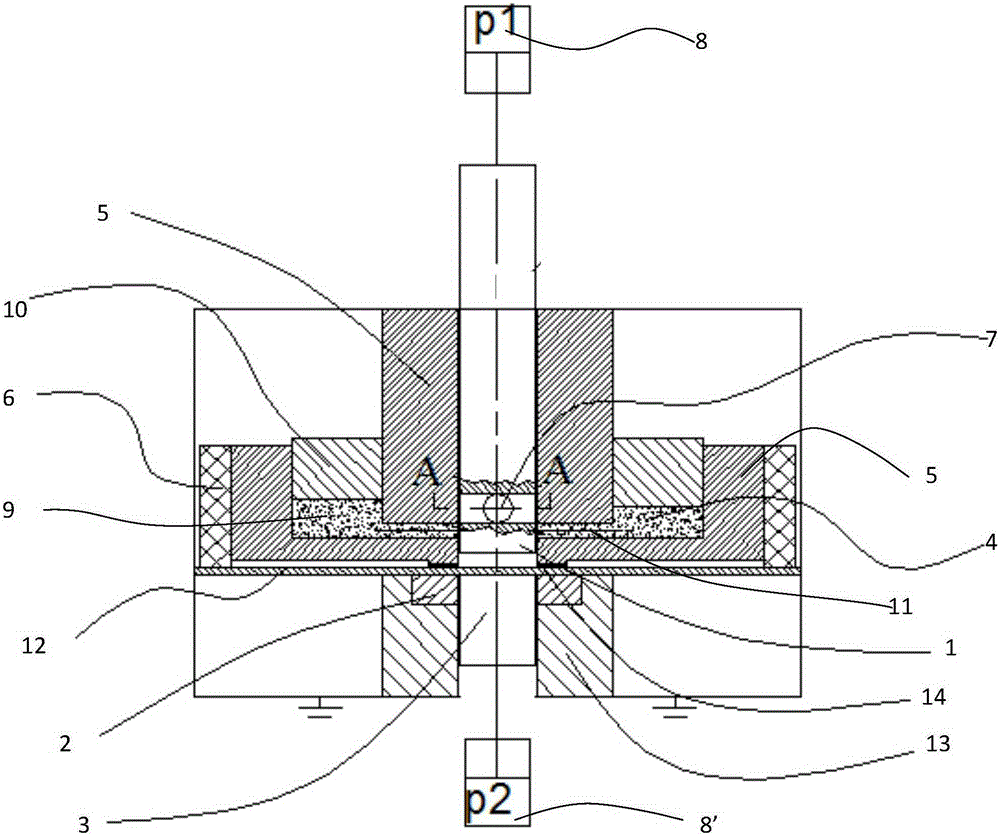

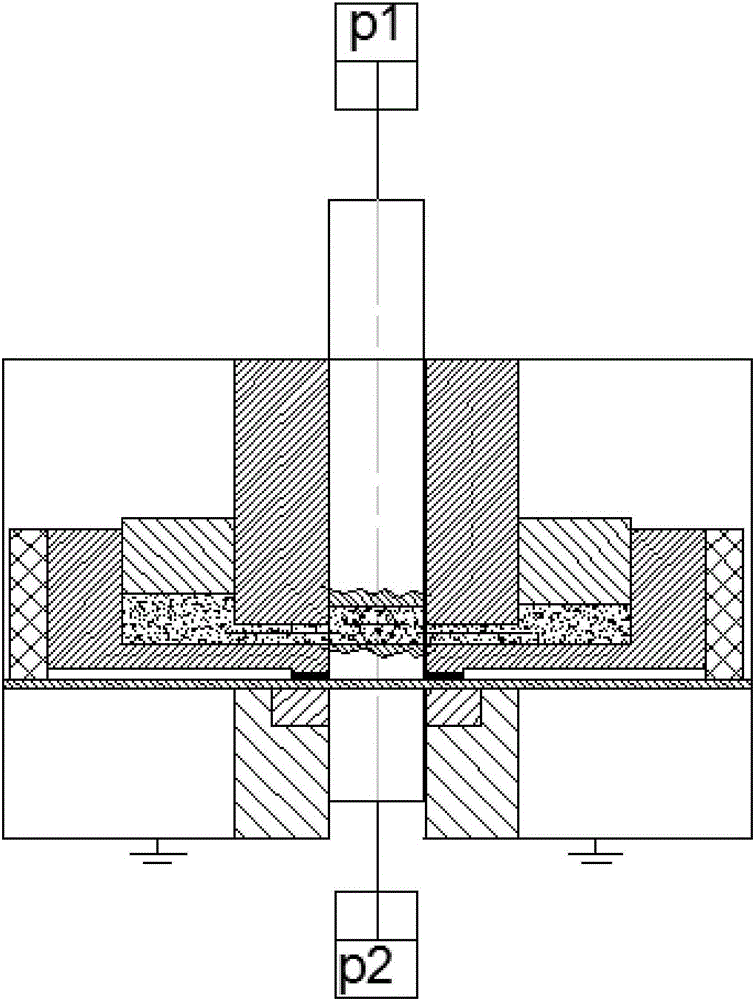

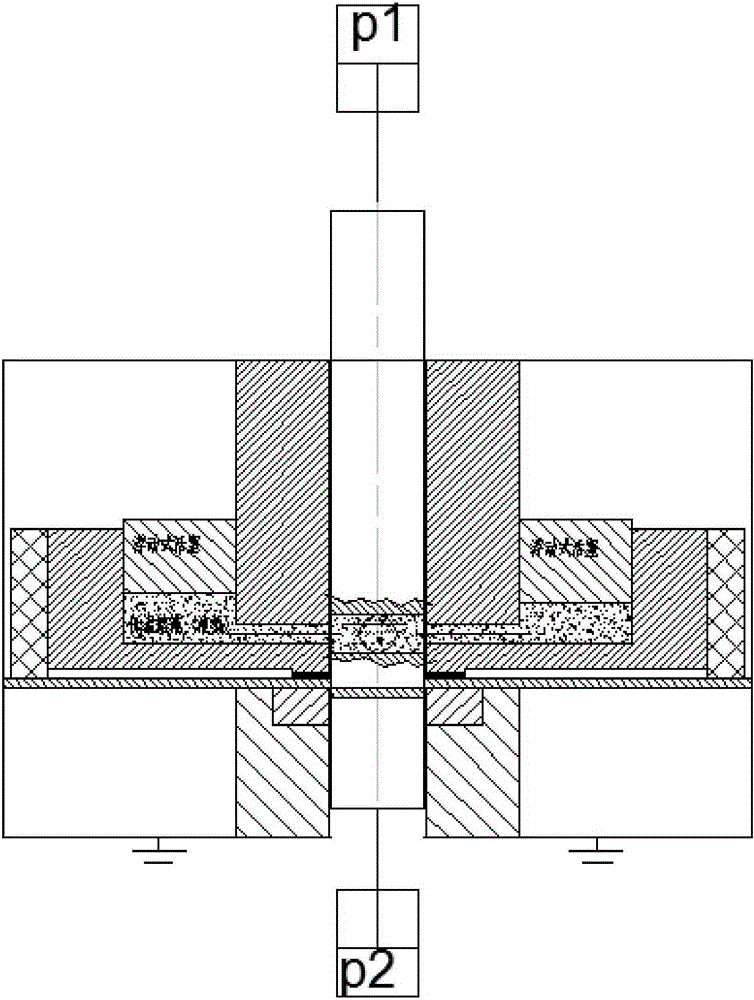

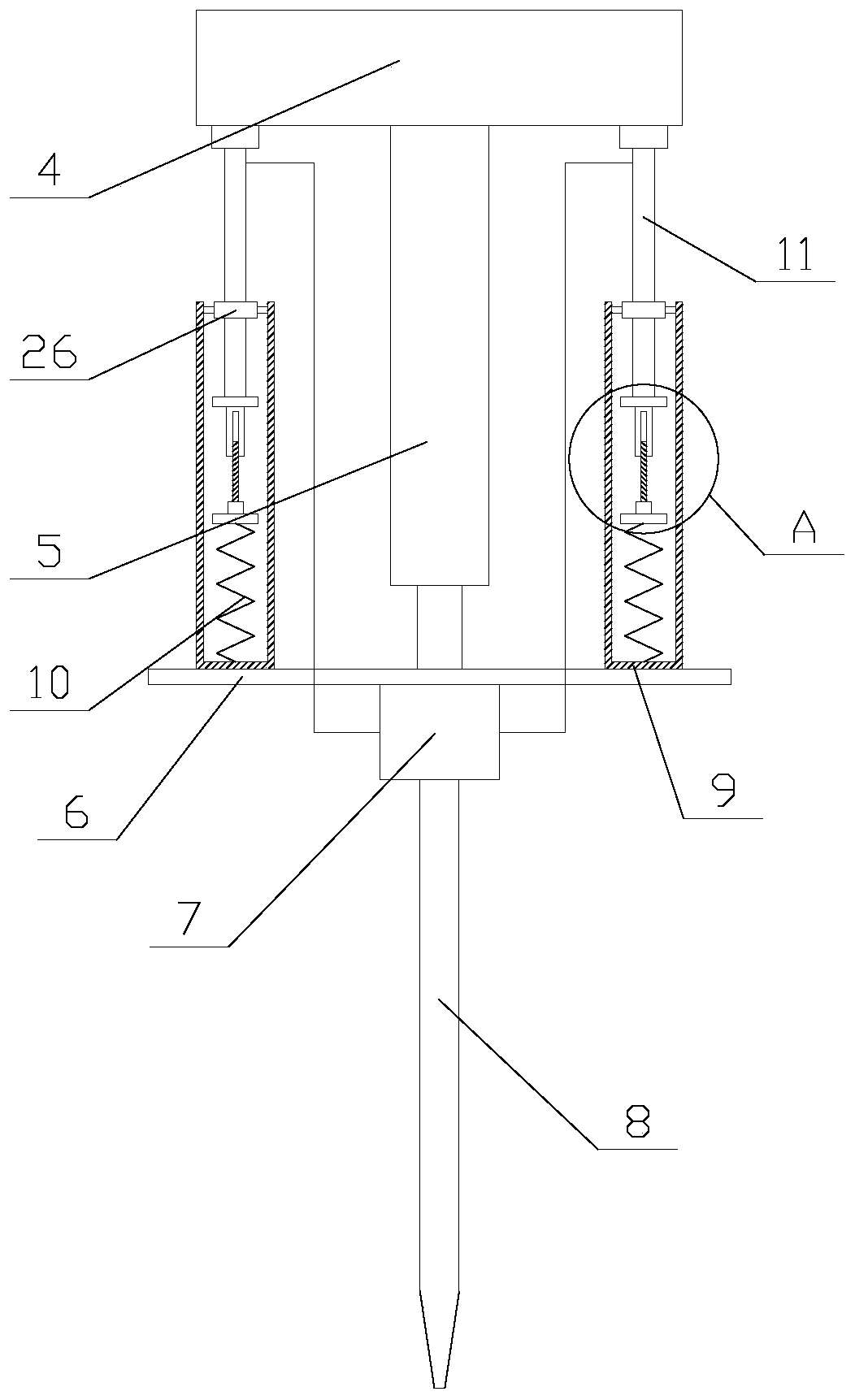

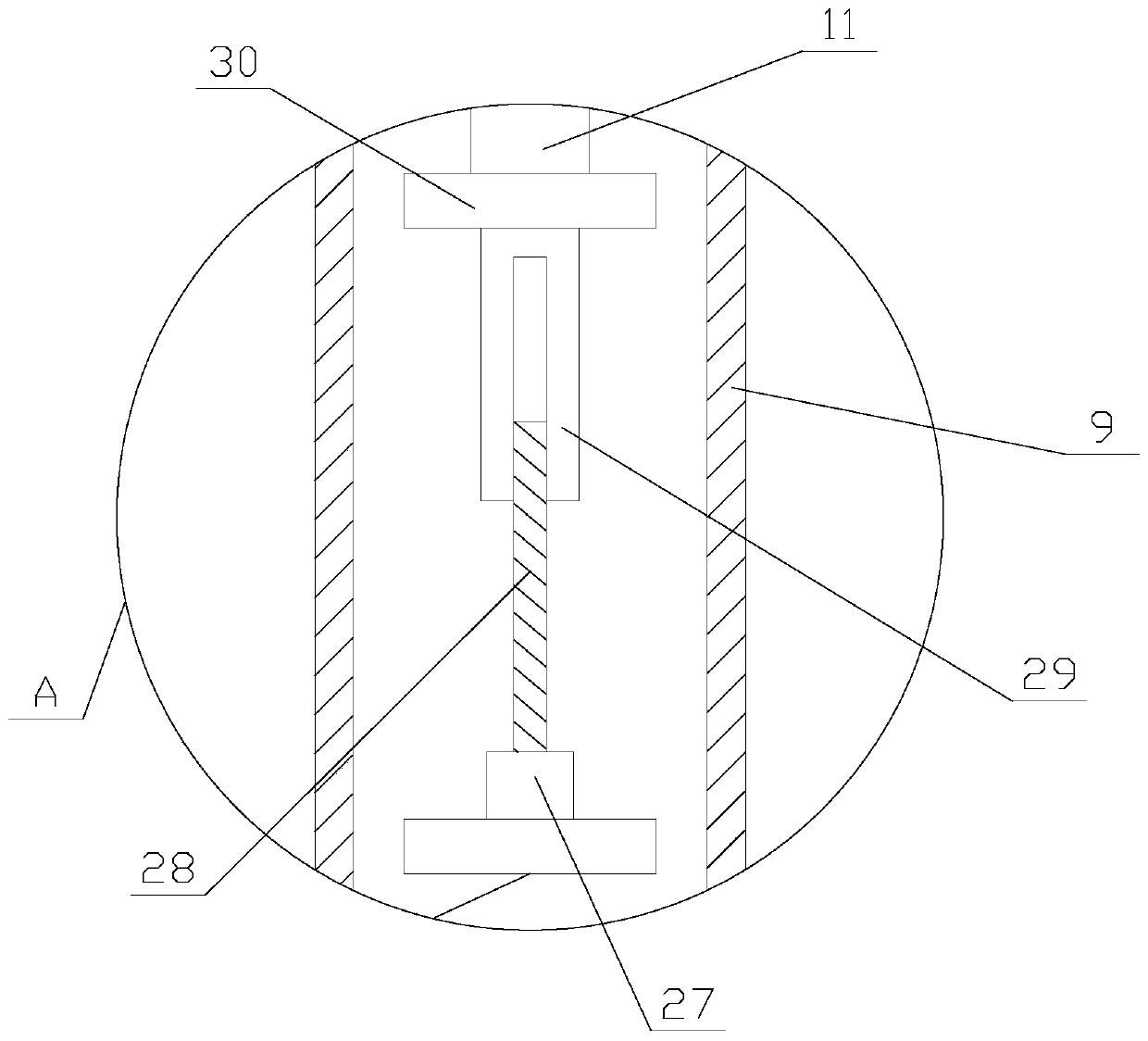

Cryogenic stamping, shearing and forming device with terrace die for micro workpieces and forming method using cryogenic stamping, shearing and forming device

InactiveCN105328003APrevent downward flowAchieve precision machiningShaping toolsHydraulic cylinderPiston

The invention relates to a cryogenic stamping, shearing and forming device with a terrace die for micro workpieces and a forming method using the cryogenic stamping, shearing and forming device, and belongs to the field of mechanical engineering. The cryogenic stamping, shearing and forming device comprises the terrace die, a hollowing block, an ejector rod, a low-temperature solution, a blank holder, a heat insulating material and a terrace die supporting base, wherein the side wall of the terrace die is locally provided with a through hole; a hydraulic cylinder drives the terrace die to move in the blank holder; the hollowing block is fixed in a hollowing block supporting base; the hydraulic cylinder drives the ejector rod to move in the hollowing block; a storage slot capable of accommodating the low-temperature solution is formed in the blank holder; the top of the storage slot is provided with a floating type piston; and the inner side wall of the blank holder is provided with a side wall hole capable of allowing the low-temperature solution to flow. The forming method based on the device comprises the five steps of clamping plates, cooling, stamping and shearing, drawing the plates out of the die and carrying out shape inspection. According to the cryogenic stamping, shearing and forming device with the terrace die for micro workpieces and the forming method using the cryogenic stamping, shearing and forming device, the advantages are that precision processing for micro workpieces is realized, deckle edges and burrs are reduced in a facilitated mode, section is flattened, section forming precision and forming precision for forming the workpieces are improved, and batched production is realized.

Owner:JILIN UNIV

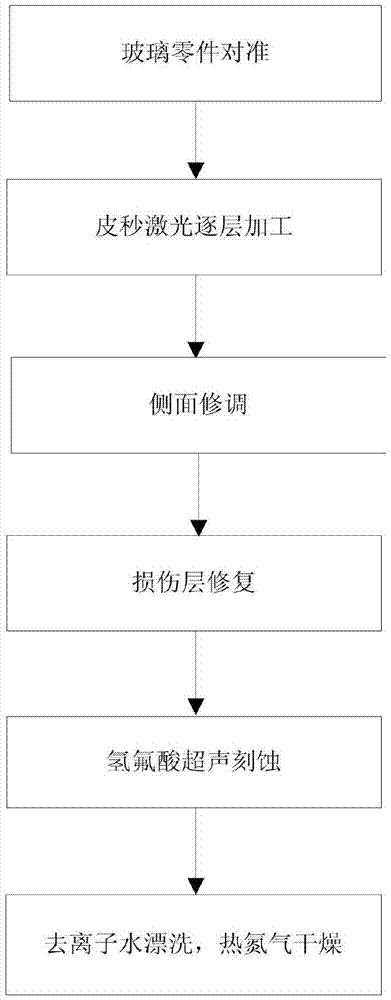

A glass microstructure processing method

ActiveCN106891092AEasy to processImprove machining accuracyLaser beam welding apparatusPicosecond laserEtching

The invention provides a glass microstructure processing method comprising the steps of adjusting the position of a glass part; processing the glass part by using picosecond laser layer-by-layer material removing processing technology; performing side surface trimming; performing repair on defect layers; performing ultrasonic etching by using a diluted hydrofluoric acid solution; performing deionized water rinsing and nitrogen drying. The picosecond laser layer-by-layer material removing technology is employed for processing glass part microstructures and one-time processing is performed on special shapes of glass parts, so that technological procedures of processing can be effectively simplified, the processing precision can be improved and error caused by multiple times of mask making and etching can be avoided. The method can effectively process transition zones of inclined surfaces of parts, so that the processing angles at the inclined surfaces are controllable; by reducing the viscosity of glass, subsurface layer damage and surface roughness caused in laser processing can be effectively reduced, so that the using properties of processed structures are improved; the diluted hydrofluoric acid solution is used for ultrasonic etching, so that the roughness of processed surfaces is further reduced and surface quality of glass parts processed with picosecond laser can be improved.

Owner:航天科工惯性技术有限公司

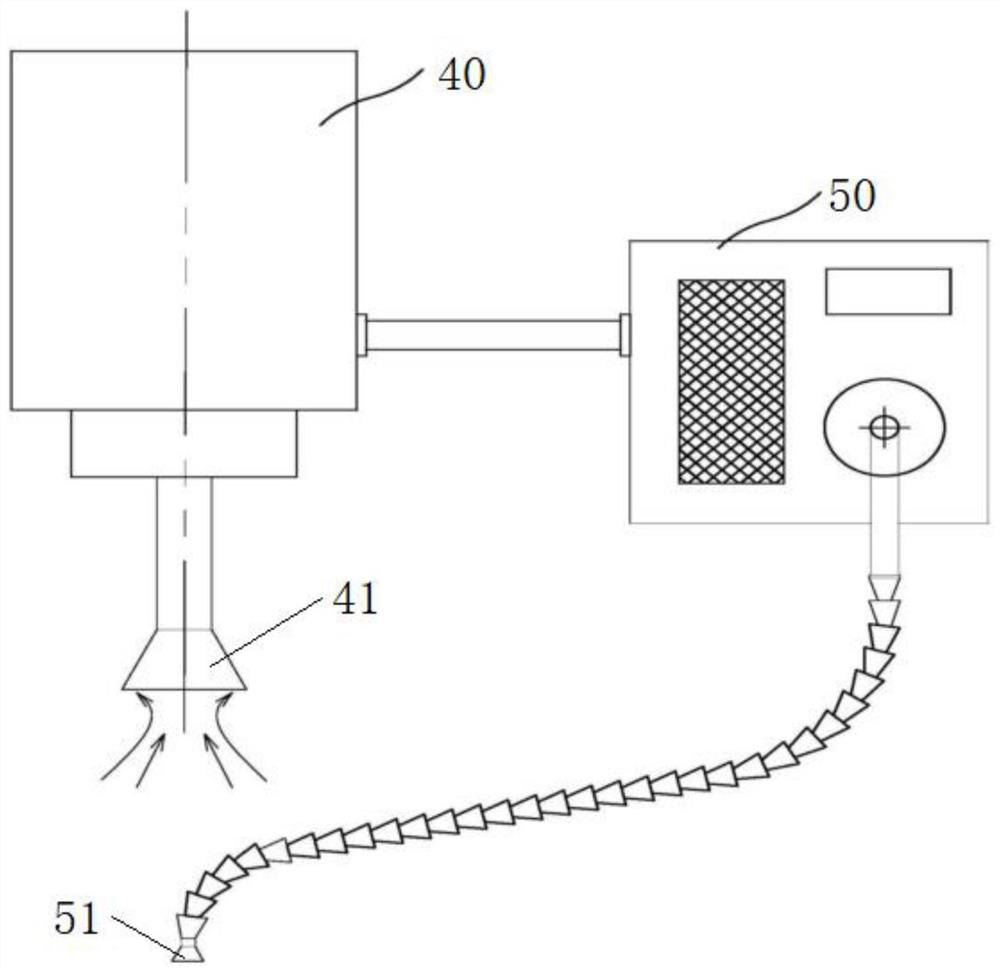

Silicon wafer cutting device and method

PendingCN112809170AAchieve precision machiningEfficient removalSemiconductor/solid-state device manufacturingLaser beam welding apparatusLight beamEngineering

The invention relates to the field of laser cutting, and discloses a silicon wafer cutting device and method. The silicon wafer cutting device comprises a laser beam module, a wafer fixing module, an air blowing and dust exhausting module and a kerf observation module; the laser beam module is provided with a laser emitting end, the air blowing and dust exhausting module comprises a side air blowing port, a direct air blowing port and a dust exhausting port, and the side air blowing port and the dust exhausting port are formed at the two opposite sides of the laser emitting end; the direct air blowing port is used for generating airflow towards a silicon wafer, the side air blowing port is used for generating airflow flowing to the dust exhausting port, and the dust exhausting port is used for generating negative pressure within a specified pressure range so that dust can be discharged from the dust exhausting port; and the kerf observation module is used for observing or acquiring an image of a cutting part of the silicon wafer. According to the silicon wafer cutting device, dust generated during laser cutting is effectively removed by arranging the air blowing and dust exhausting module, dust adhering near a kerf is prevented, and meanwhile precise machining of a silicon wafer is achieved by arranging the kerf observation module.

Owner:HANS LASER TECH IND GRP CO LTD

Machining device for machining tool

InactiveCN108436195ALow costHigh precisionThread cutting machinesMaintainance and safety accessoriesSwarfScrap

The invention discloses a machining device for a machining tool. The machining device structurally comprises a power distribution cabinet, a control cabinet, a transverse sliding rail, a longitudinalsliding rail, a cutter clamping groove, a movable rectangular supporting column, a cutter, a workpiece, a workpiece thread groove machining device, a scrap input groove, a fixing framework, a scrap collecting box, a base and trundles. According to the workpiece thread groove machining device, a workpiece rotating driving mechanism can fix workpieces of different models and drive the workpieces torotate uniformly, by means of the lead axial turning mechanism, in the rotating process of the workpieces, the cutter can be driven to move accurately and uniformly in the axial direction of the workpieces, thus, precision and efficiency of thread workpiece production are improved, by means of the scrap collecting mechanism, scraps and metal dust generated in the turning process can be collected automatically, the scraps can be reutilized, and while the production cost is reduced, the metal dust is prevented from polluting air.

Owner:高顺

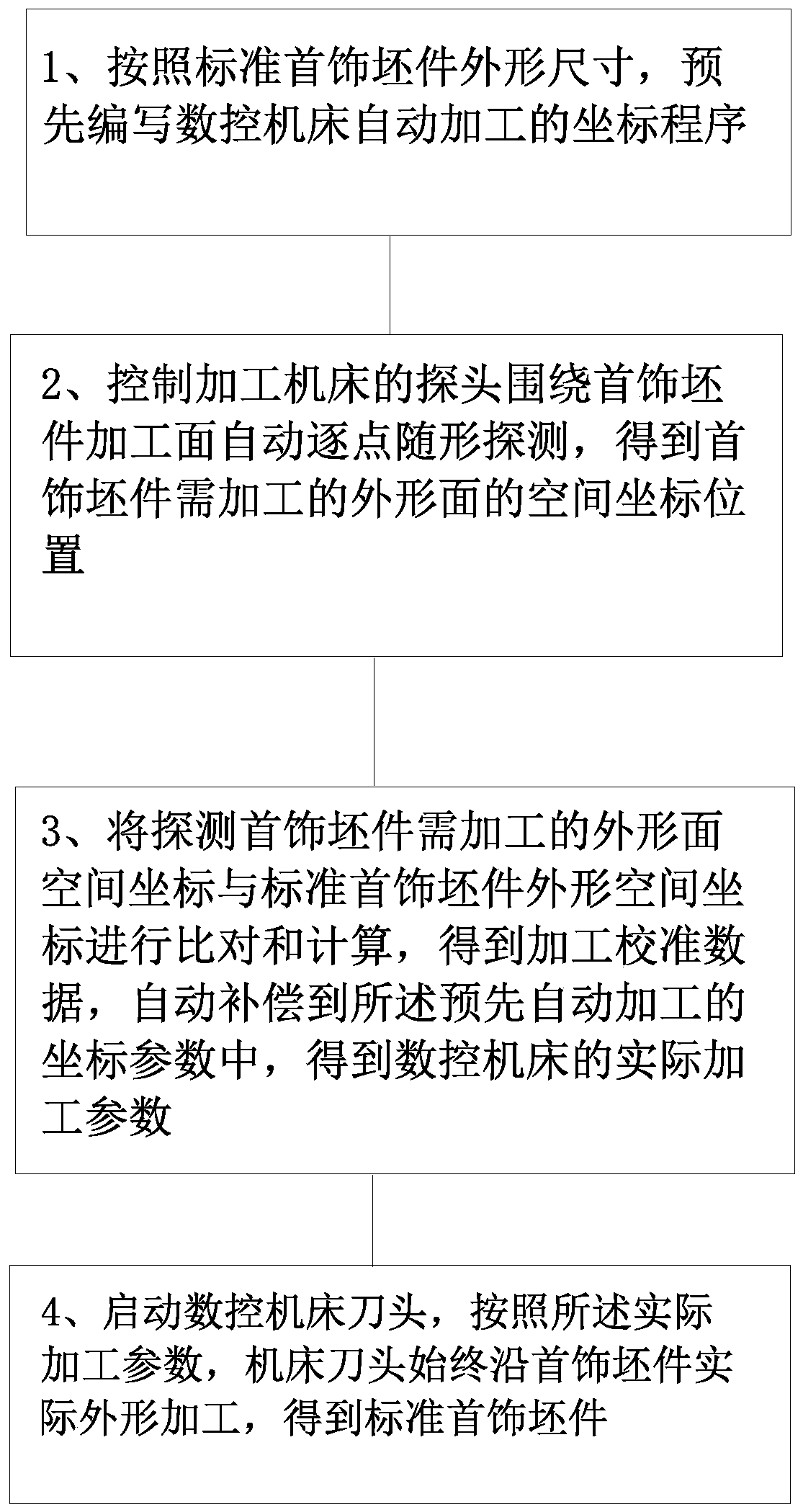

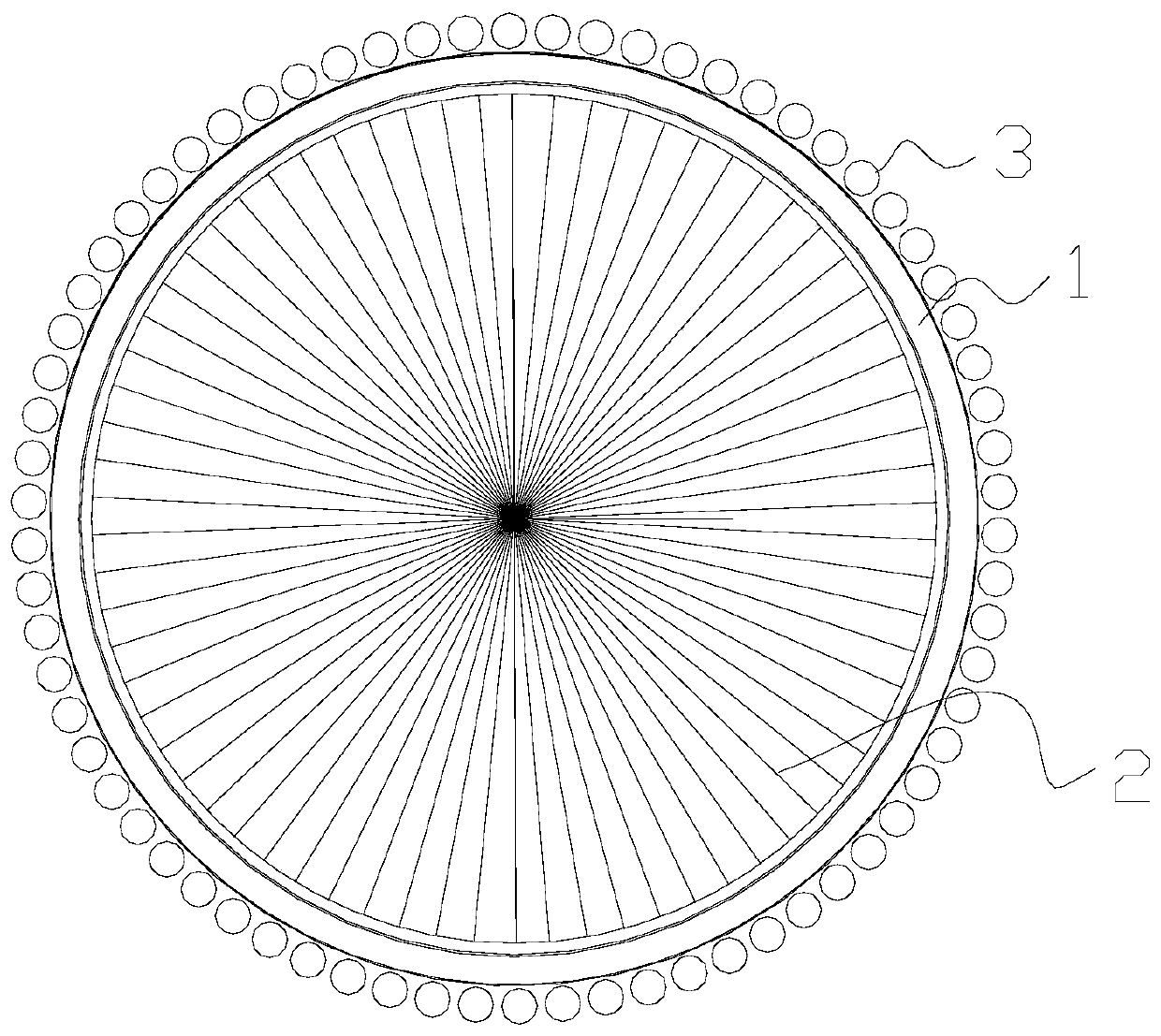

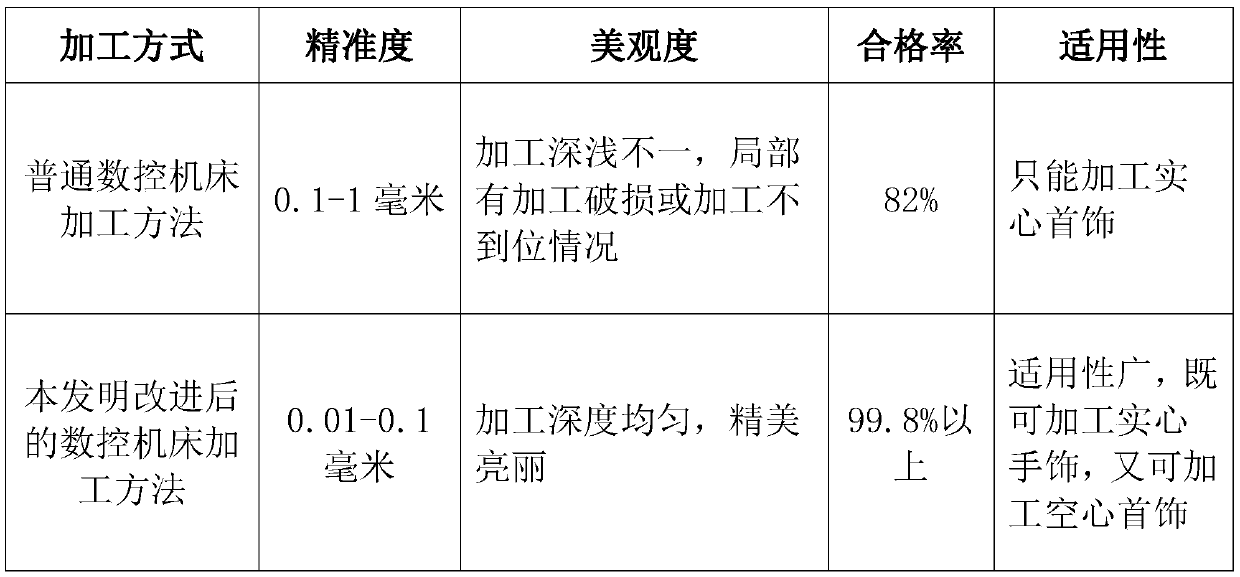

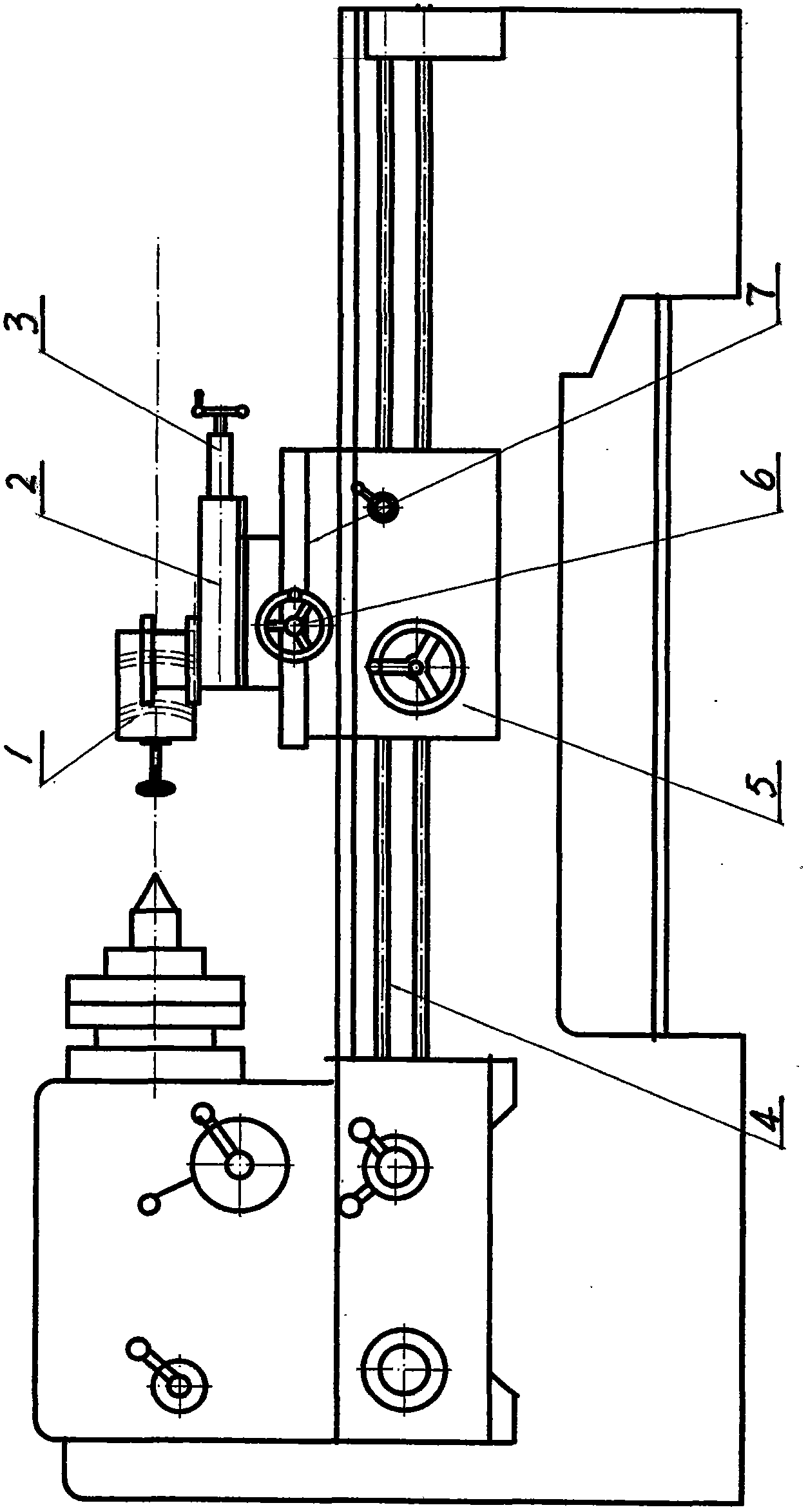

Machining control method for follow-up measurement and application thereof in jewelry processing field

ActiveCN111300212AAchieve precision machiningRealize industrialized environmental protection productionGrinding feed controlUsing optical meansNumerical controlTool bit

The invention discloses a machining control method for follow-up measurement and application thereof in jewelry machining field. The method comprises the following steps of S1, pre-programming a coordinate program for automatic machining of a numerical control machine tool according to the boundary dimension of a standard jewelry blank; S2, controlling a probe of a machining tool to detect the jewelry blank point by point automatically in a follow-up manner to obtain a spatial coordinate position of a shape surface needed to be machined for the jewelry blank and feeding the position back to acomputer of the numerical control machine tool; S3, comparing and calculating the spatial coordinate position of the shape surface of the detected jewelry blank and the shape spatial coordinate of thestandard jewelry blank to obtain machining calibration data, and compensating the machining calibration data to a coordinate parameter of automatic machining in advance automatically to obtain the actual machining parameter of the numerical control machine tool; and S4, starting a tool bit of the numerical control machine tool to machine to obtain the standard jewelry blank. Each piece of jewelrycan be measured dynamically in a follow-up manner, and deviation is calibrated and compensated automatically and precisely, so that the machining precision of the numerical control machine tool is improved greatly, and therefore, the machining percent of pass of jewelry of various types reaches over 99.8%, and the rejection rate is reduced obviously.

Owner:SHENZHEN UNITED BLUEOCEAN TECH DEV

Accurate grinding method for tiny ball nuts

InactiveCN103419108ASolve grinding problemsAchieve precision machiningGrinding machinesBall screwSurface roughness

Disclosed is an accurate grinding method for tiny ball nuts. According to the method, the problems of the background technology that only ball nuts with pitch diameter larger than phi 16 can be machined even if a grinder is used, and the accuracy and the surface roughness cannot meet requirements even if the ball nuts can be machined. The method is characterized in that longitudinal lead screws 4, a transverse lead screw 6 and a knife rest T-shaped lead screw 3 on a common lathe are changed into precise ball screws. A large support plate 5, a small support plate 7 and a small support plate 2 are adjusted to be mutually matched. An electric spindle grinding head and a helix angle adjusting mechanism 1 are mounted on a knife rest. A grinding cooling lubrication system is arranged according to grinding requirements. The accurate grinding method has the advantages that the problem of grinding of tiny pitch-diameter ball nuts is solved, and the tiny pitch-diameter ball nuts are accurately machined; an internal thread grinder can be replaced, the internal thread grinding range is expanded; transformation costs for one grinder through the technology of the method is 6, 5000 yuan, but an internal thread grinder costs more than 300, 000 yuan; the method is used for grinding of ball nuts with pitch diameter larger than phi 16.

Owner:安顺虹特滚珠丝杠有限责任公司

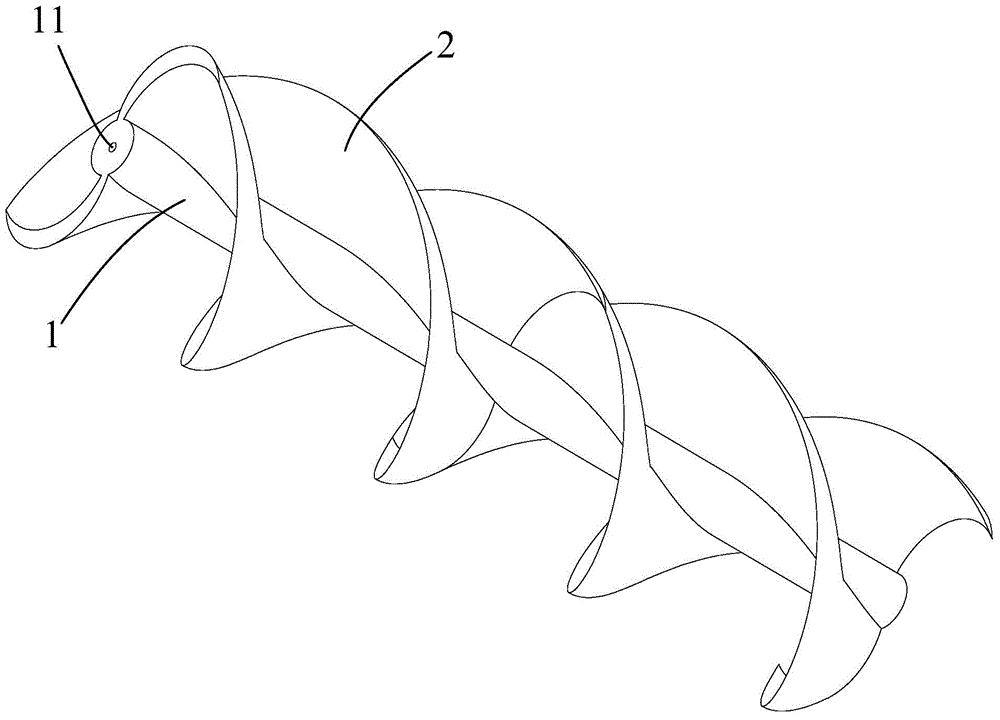

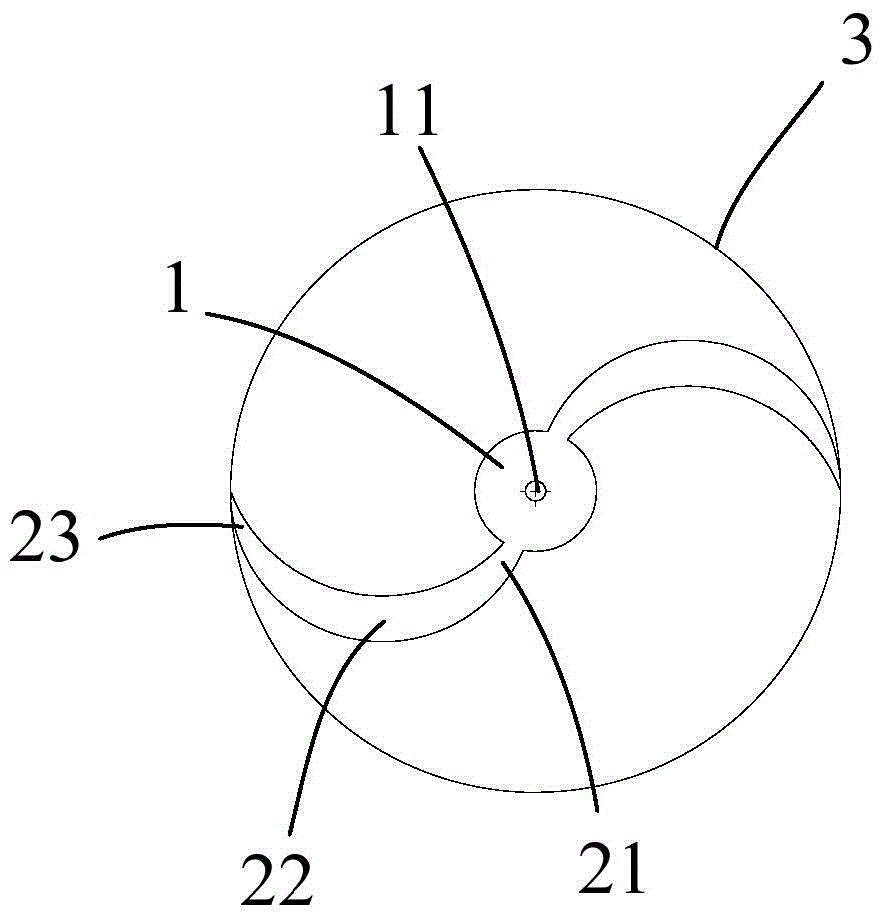

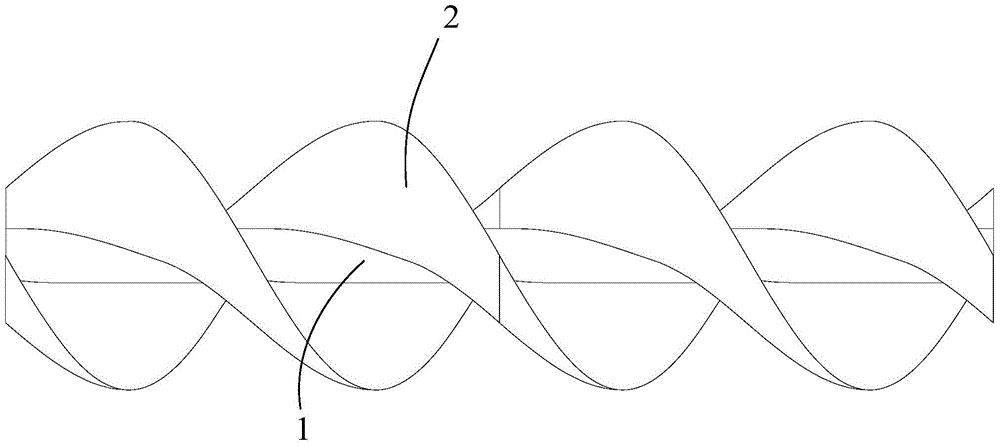

Screw wheel structure

The invention provides a screw wheel structure which comprises a central shaft, wherein at least one screw blade is arranged on the central shaft; each screw blade at least forms a complete circle on the central shaft; the projection of the screw blade in the axial direction of the central shaft is a circle; the external edge of the screw blade is tangent to the circle projection; the radial thickness of the screw blade decreases gradually from the middle part to the external edge; and an edge part is formed on the external edge of the screw blade. The screw blade of the screw wheel structure is projected to form a regular circle, so, when the screw wheel structure is applied in the field of transmission, the edge part of the screw blade can be tightly fitted with the inner wall of a pipe to convey all materials out, and the sealing effect between the edge part of the screw blade and the inner wall of the pipe is excellent; and when the screw wheel structure is applied in the field of machining, the screw wheel can be mounted at the tail part of a drill to serve as a tool and is used for polishing the inner wall of a drilled hole to implement precise machining or for drilling the earth surface to achieve a good effect.

Owner:CHONGQING DEGU TECH

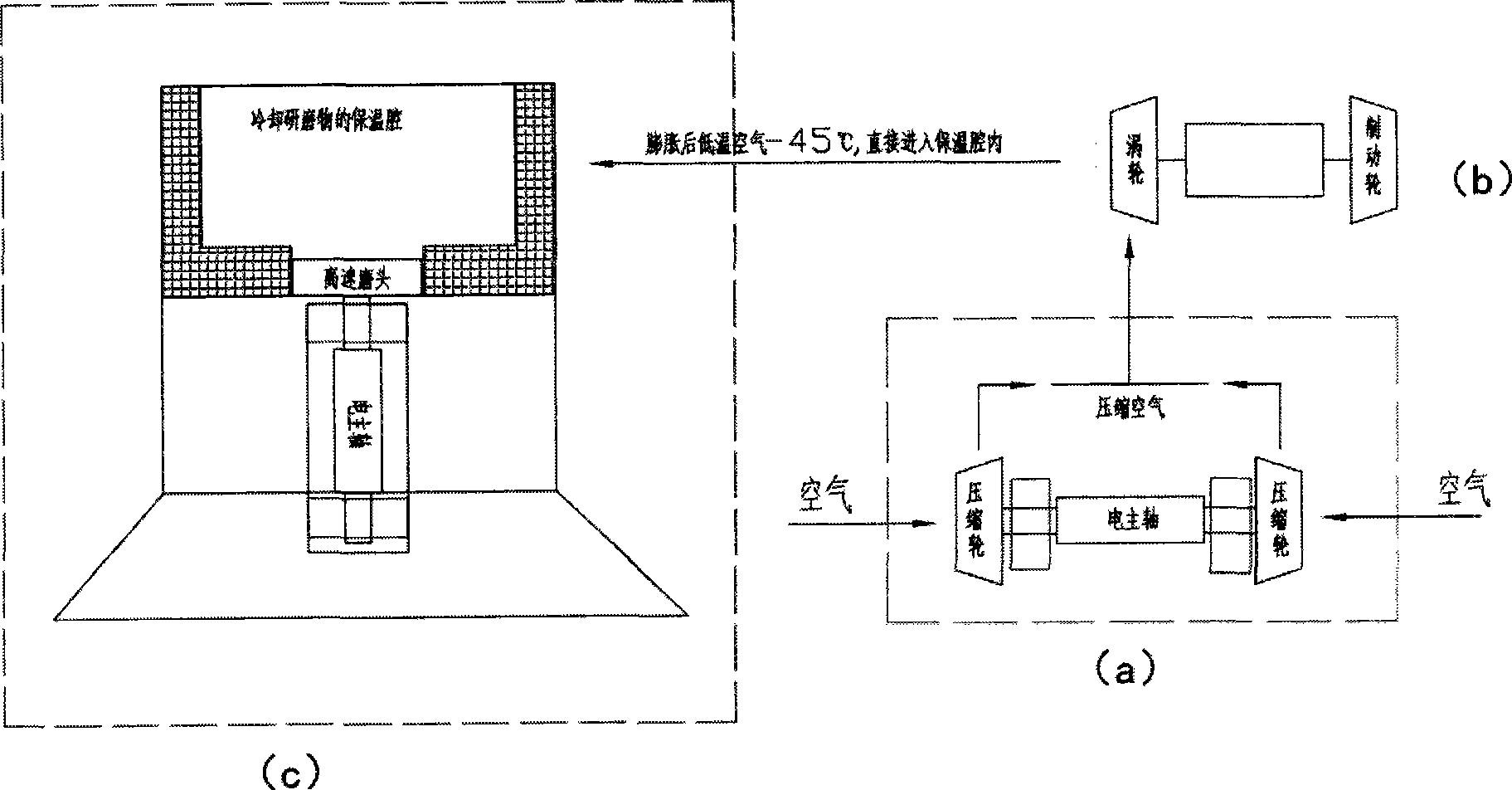

Turbine expansion refrigeration high-speed grinder

InactiveCN103862359AImprove surface accuracyReduce processing costsSuperfinishing machinesGrinding/polishing safety devicesHigh-speed grindingHardness

The invention belongs to the technical field of grinding equipment and discloses a turbine expansion refrigeration high-speed grinder. The turbine expansion refrigeration high-speed grinder mainly comprises three parts, i.e. a high-speed air compressor, a turbine expander and a high-speed motor grinder, wherein air is compressed through the high-speed air compressor, the compressed air is guided into the turbine expander and is cooled to low temperature through the turbine expander, then air with temperature of negative 45DEG C is directly fed into a heat preserving chamber of the high-speed motor grinder and finally an electric spindle is adopted in the heat preserving chamber to drive a high-speed grinding head to realize cooling grinding to an object. The surface precision of the ground object is high, the stability is good, consumables are not needed during grinding, the machining cost is low, the efficiency is high, the turbine expansion refrigeration high-speed grinder not only is applicable to grinding and polishing of hard and fragile materials such as optical glass, ceramic and gemstones, but also is applicable to the grinding and polishing of steel materials with higher hardness, and the precision machining of the object is realized.

Owner:河北维森通用设备科技开发有限公司

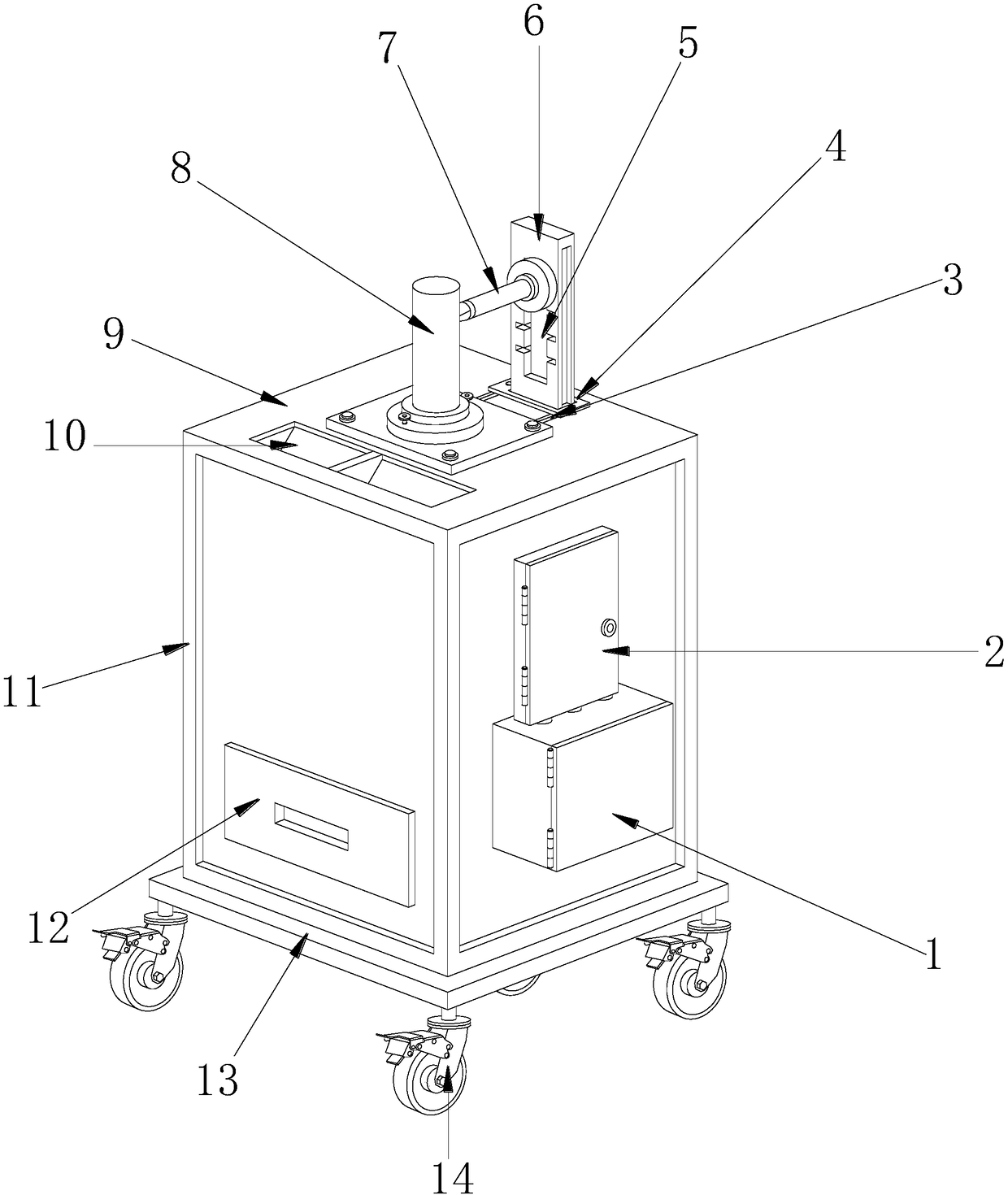

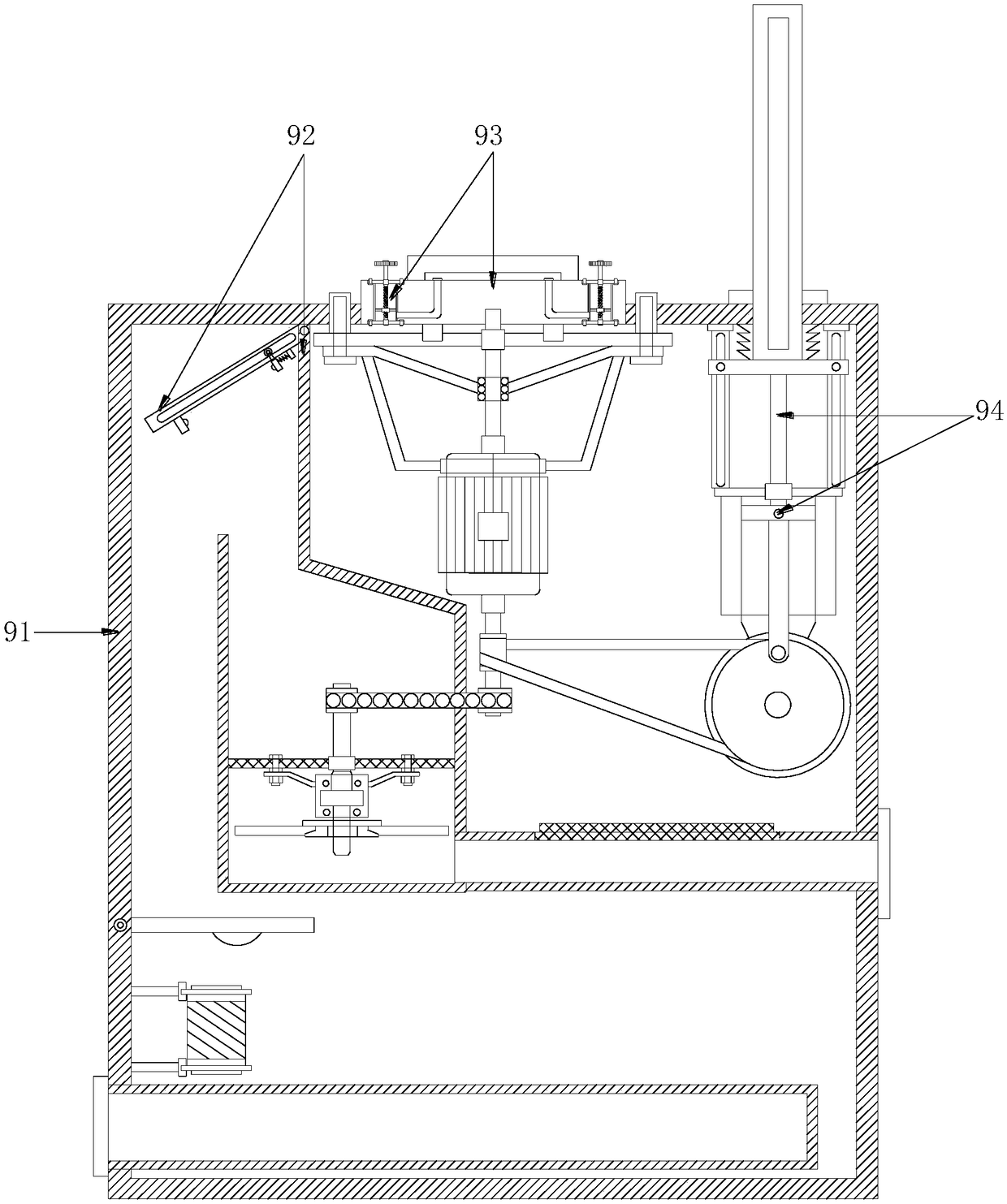

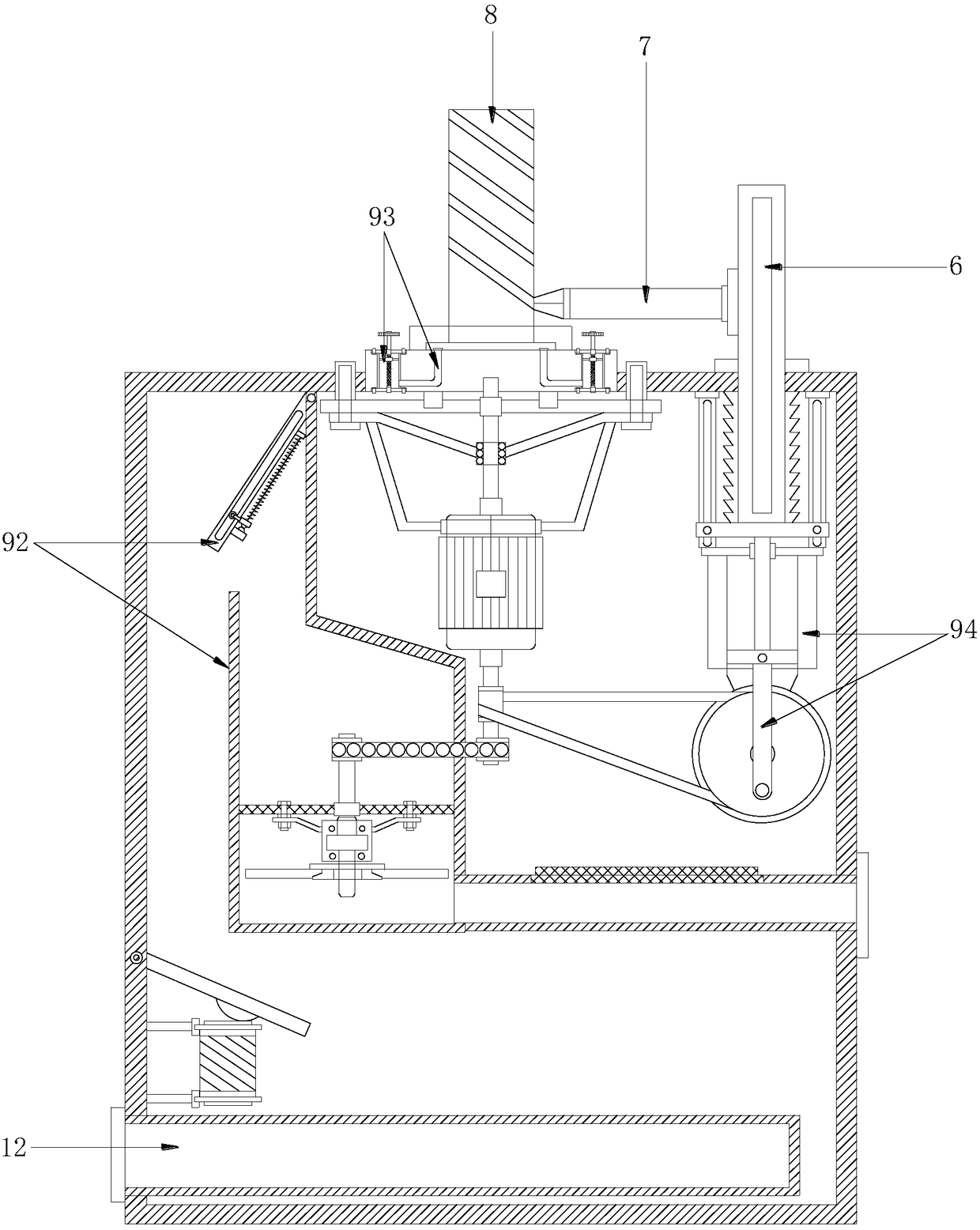

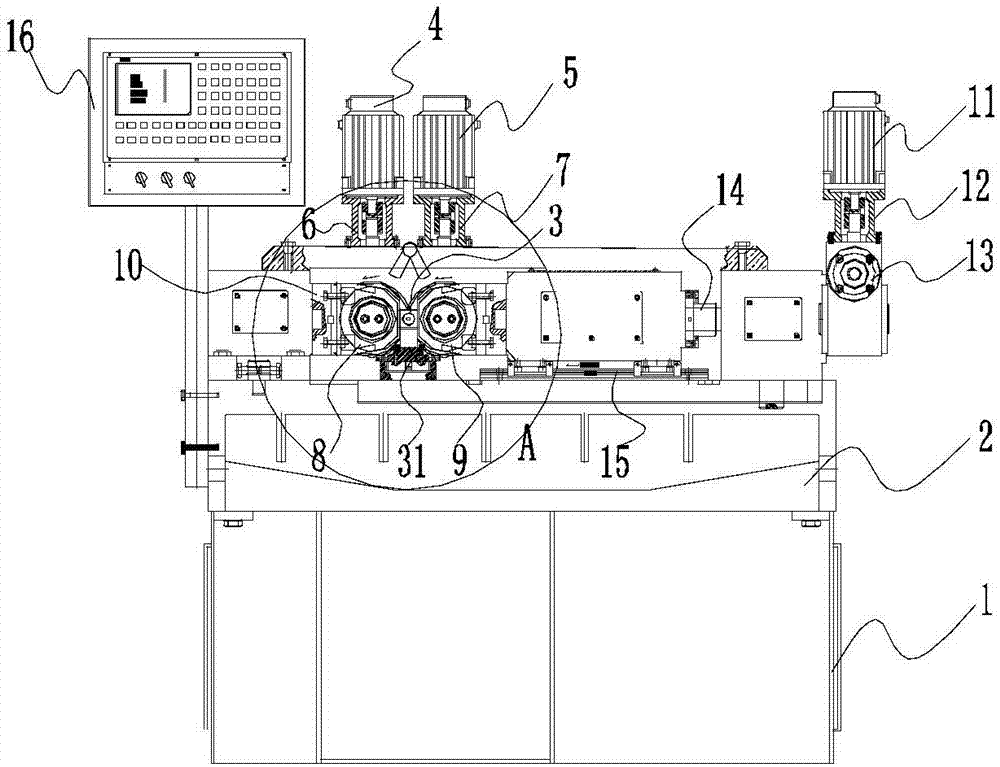

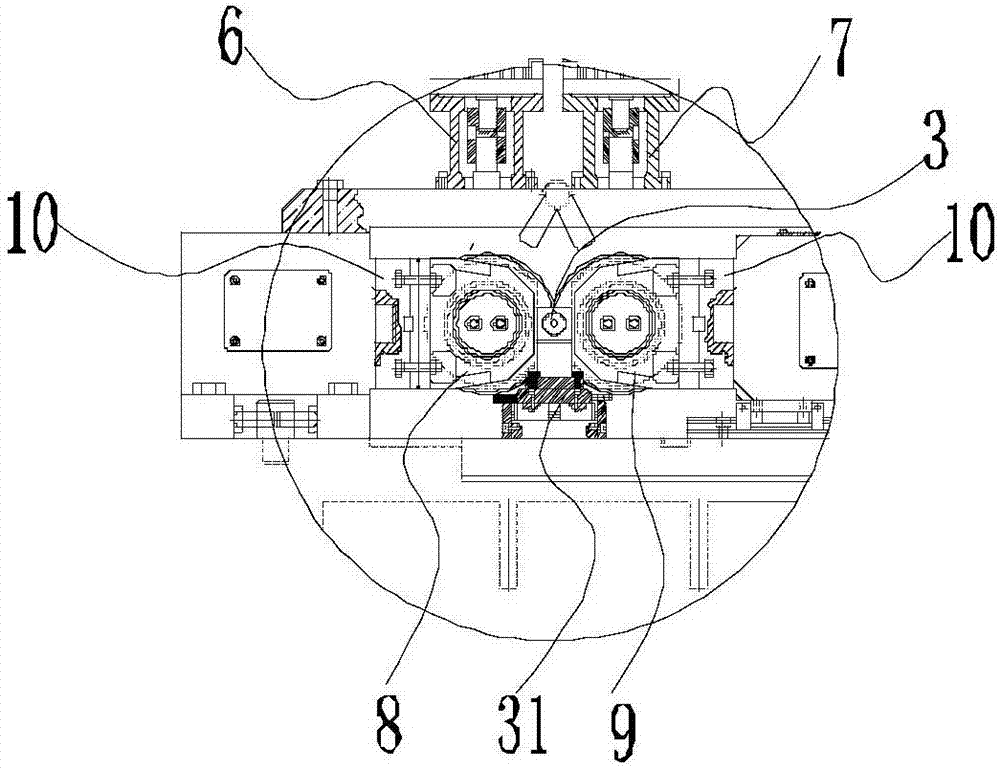

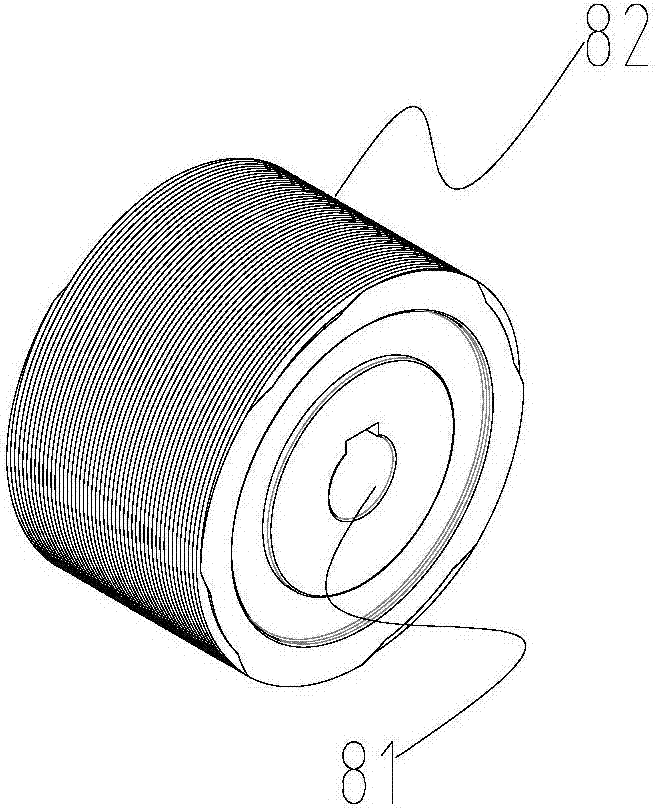

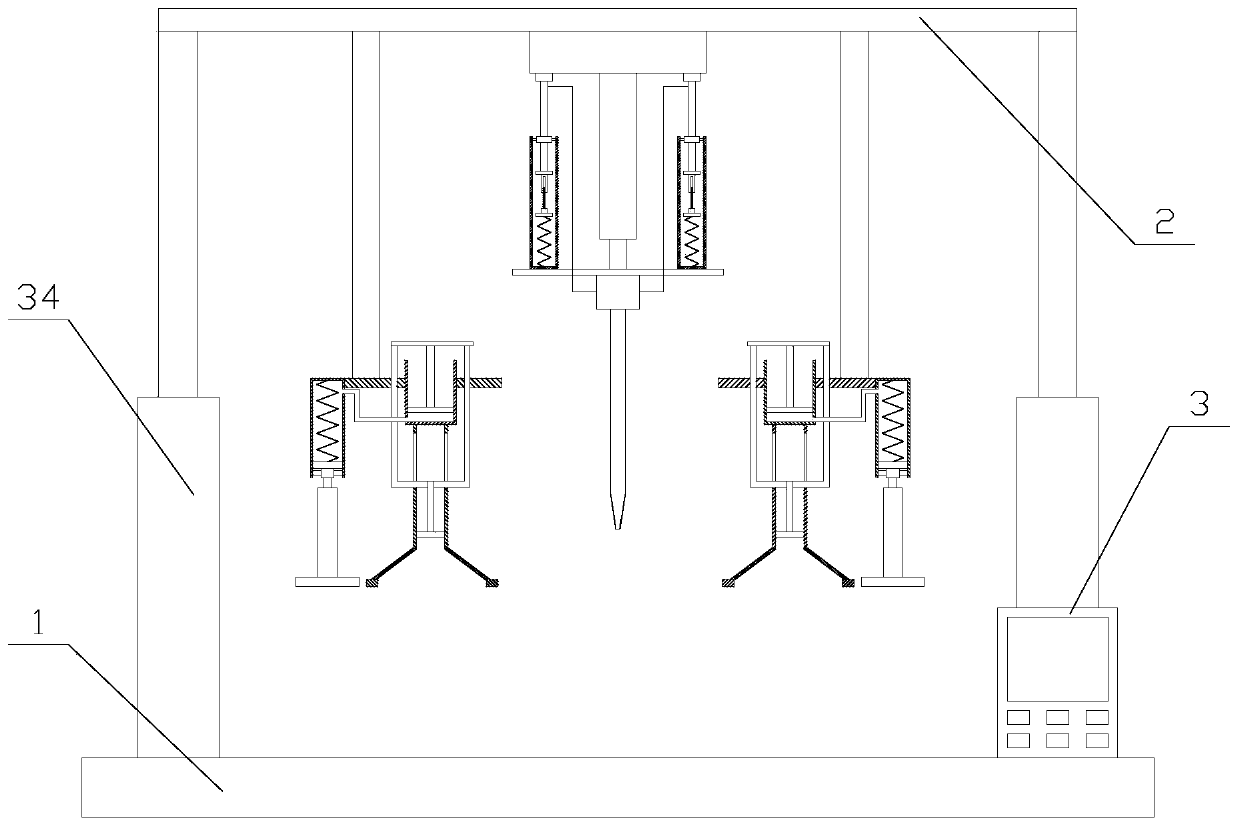

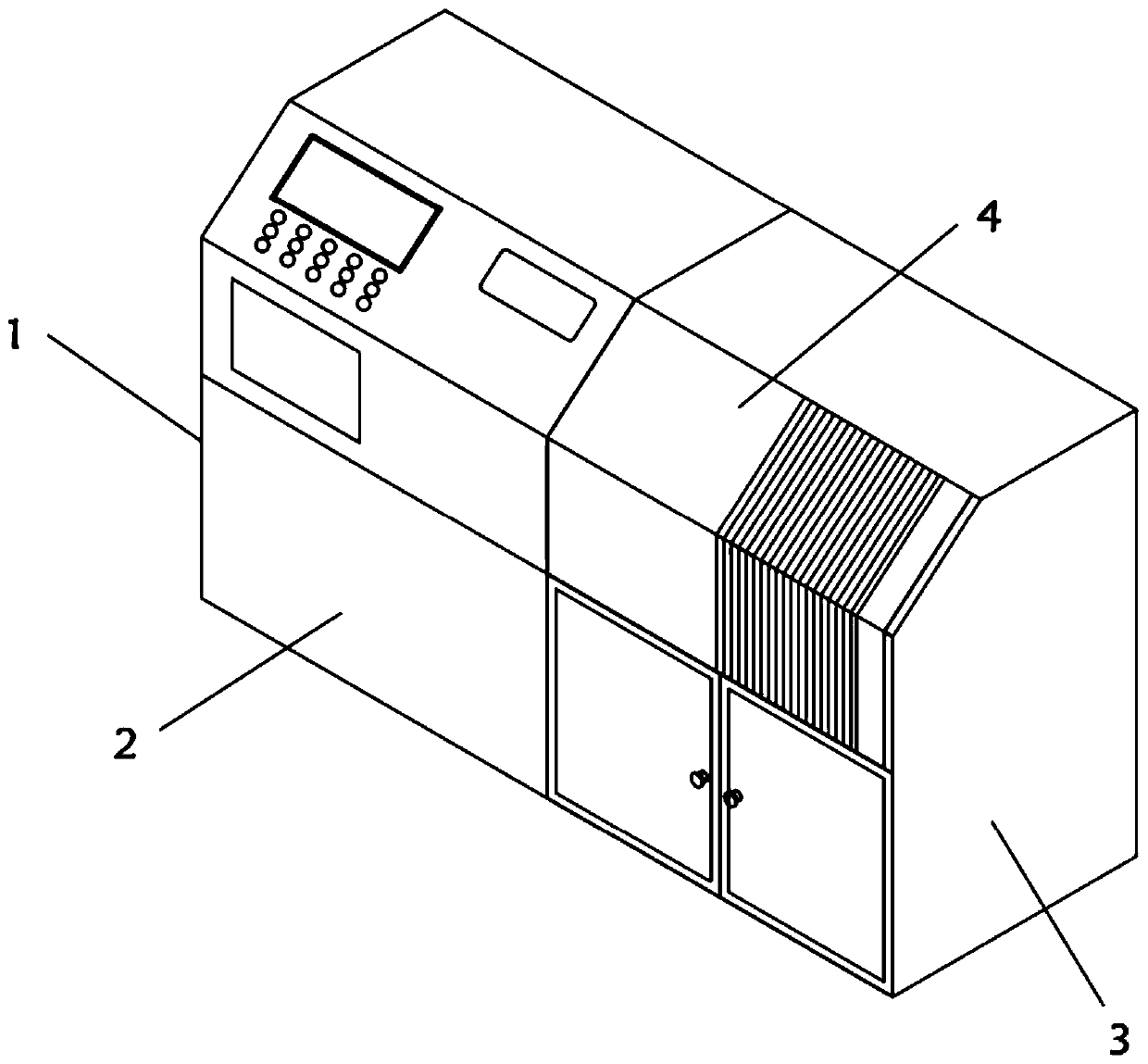

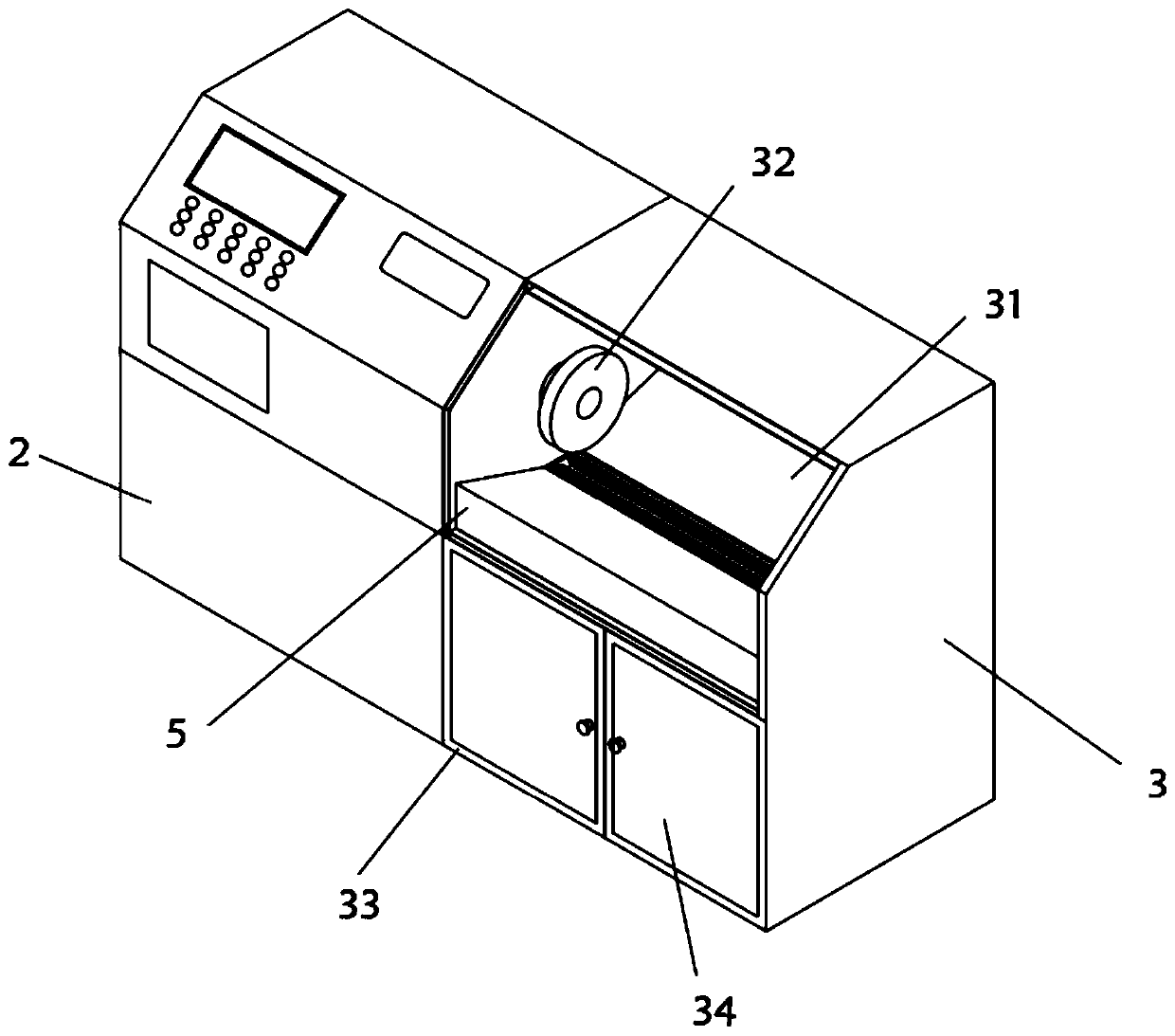

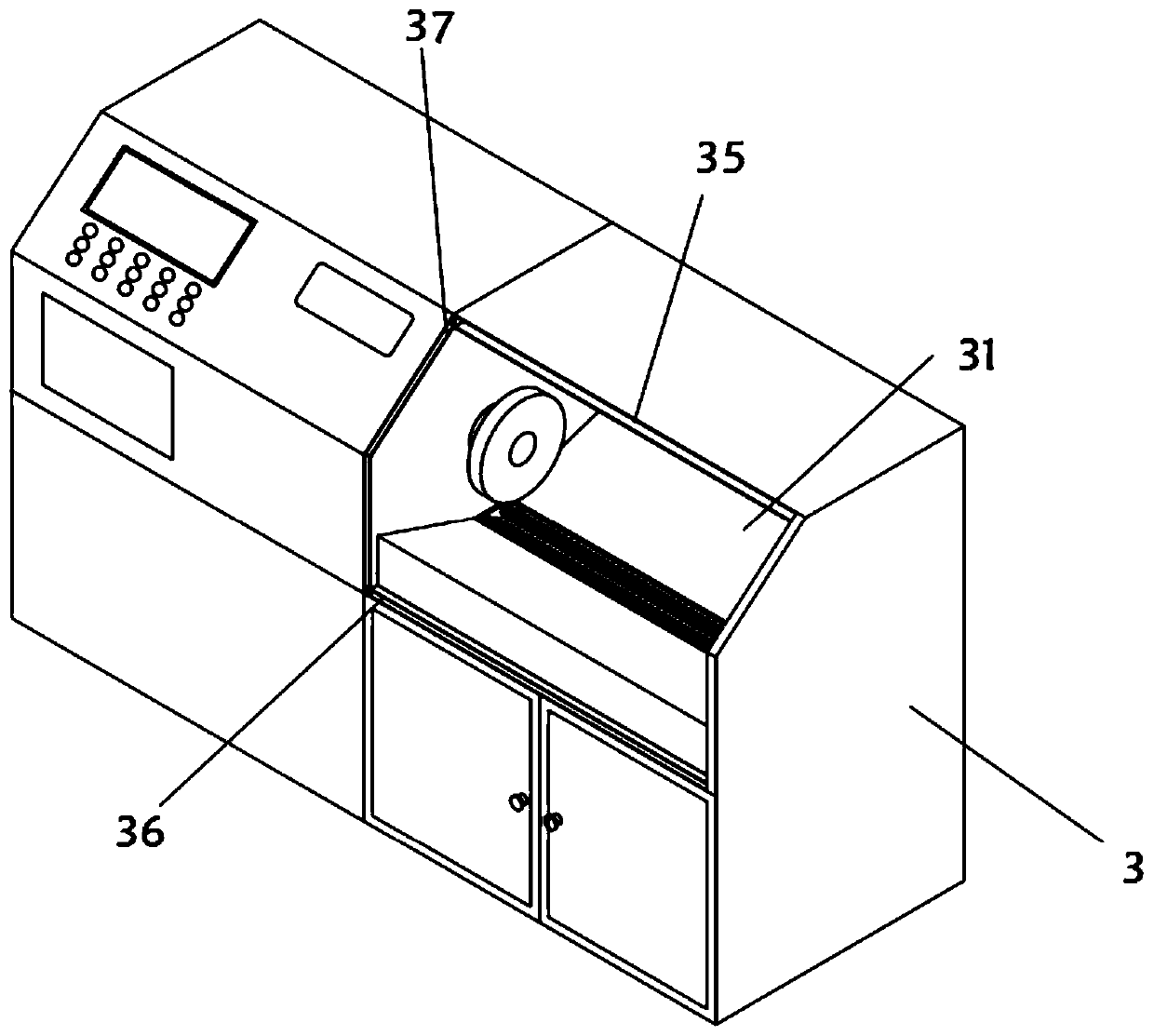

Numerically-controlled precise thread rolling machine and multi-head lead screw for automobile

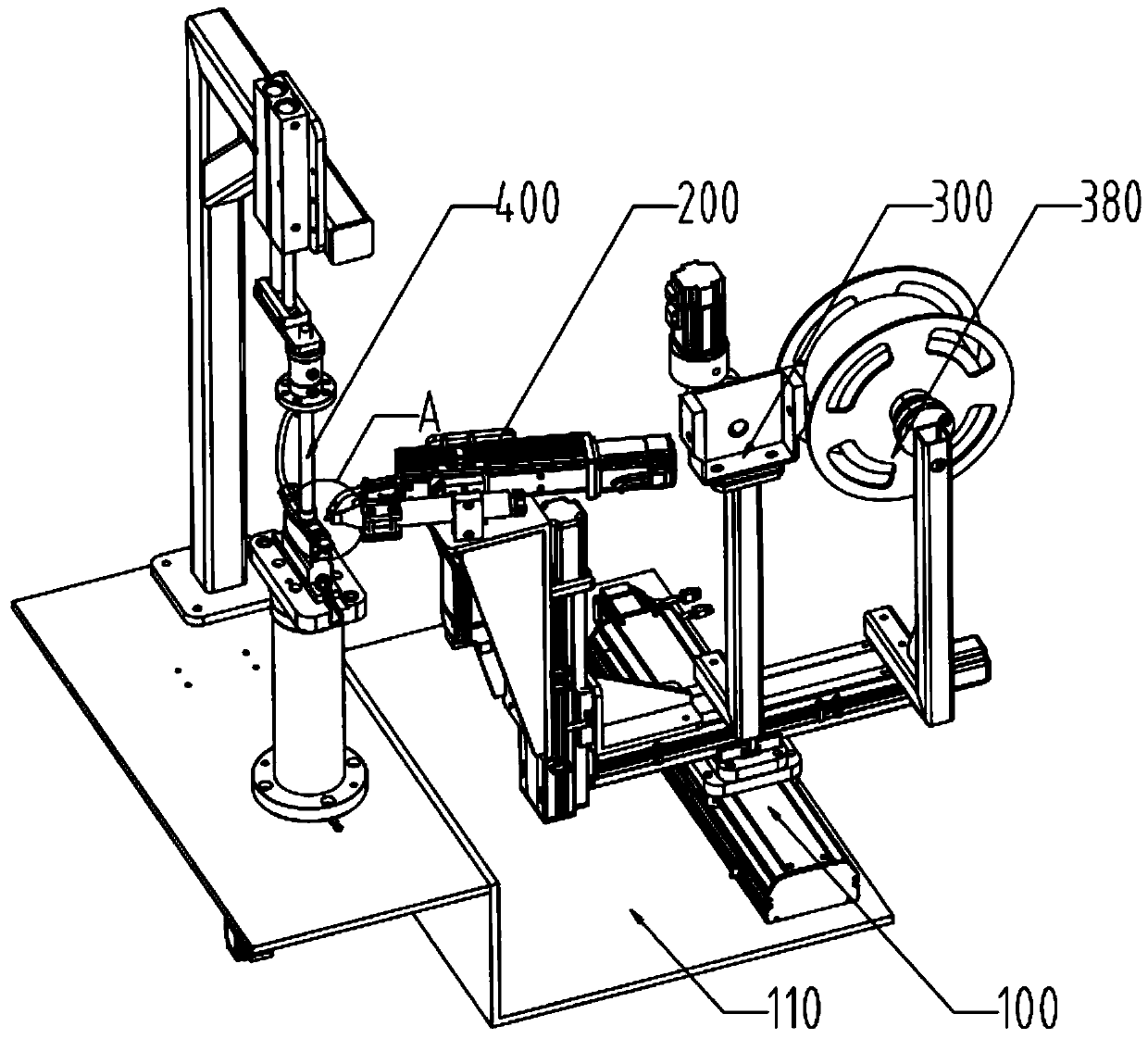

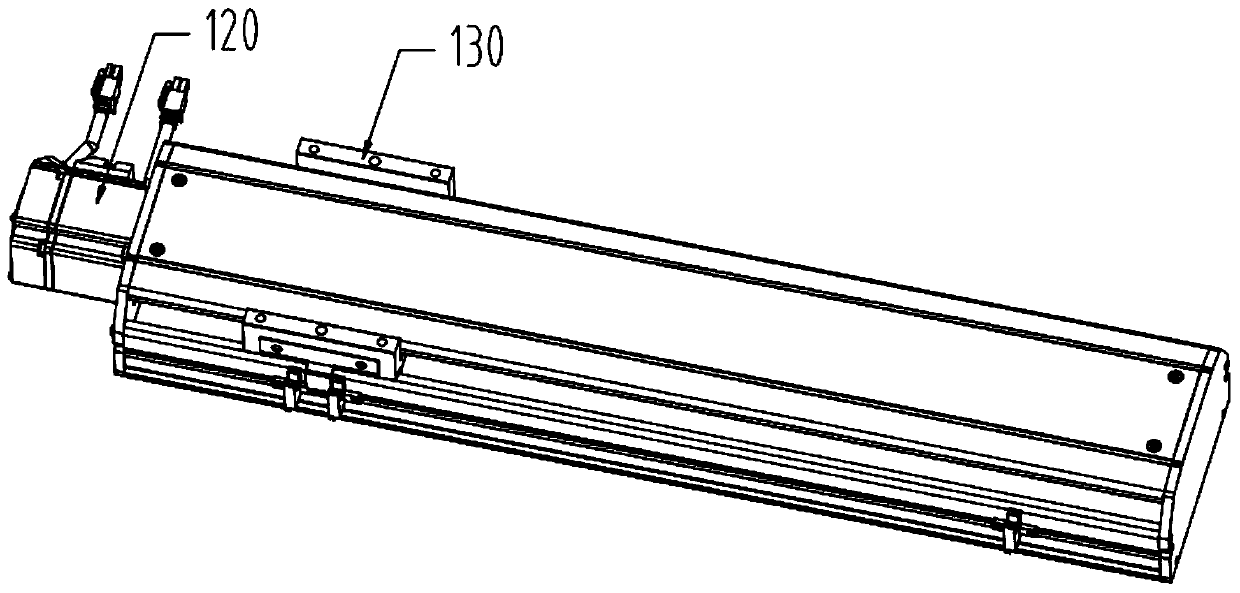

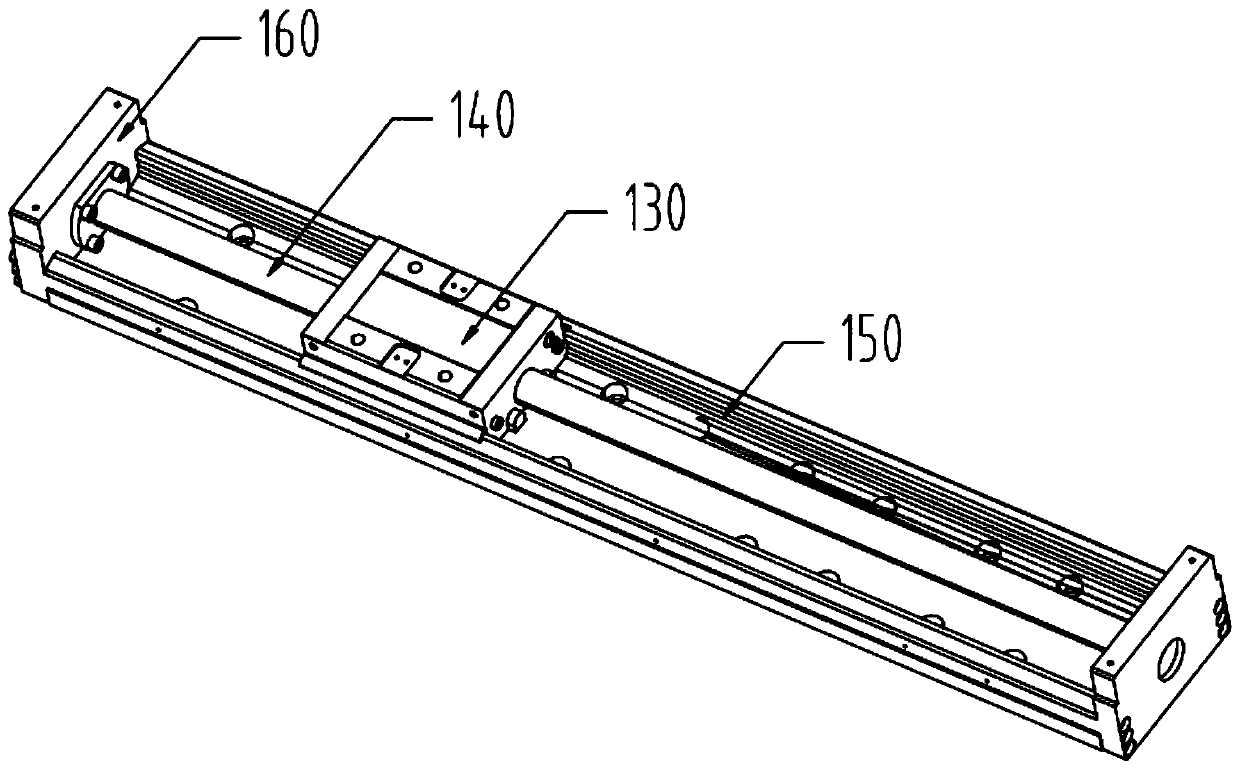

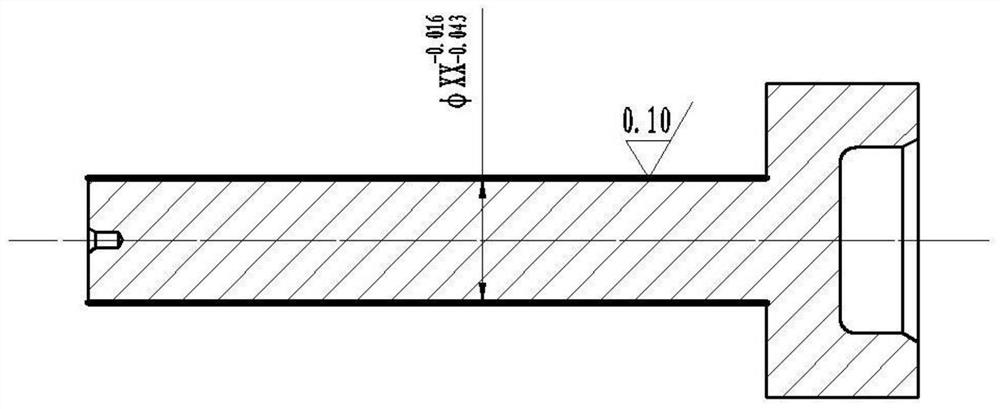

InactiveCN106984748AAchieve precision machiningReduce repetitive positioning errorsGearingScrew-threads articlesEngineeringMachining

The present invention proposes a CNC precision thread rolling machine and a multi-head screw for automobiles. The invention includes a base and a workbench arranged on the base for processing the lead screw. The workbench is provided with a transmission unit for rolling the lead screw. The transmission unit is arranged on both sides of the lead screw, and a feed unit is arranged on one side of the workbench. The power output end of the feed unit is connected to one of the transmission units. The worktable is provided with a straight line for the feed unit to move linearly. Guide rail, the feed unit moves linearly on the linear guide rail, driving one of the transmission units to approach or move away from the other transmission unit. The present invention realizes three-axis interlocking and repeatable precise positioning, each axis performs differential compensation, small repeated positioning error, low product defect rate, simple control, and realizes the precision of multi-head screw processing.

Owner:QINGDAO ZHANGSHI MACHINERY

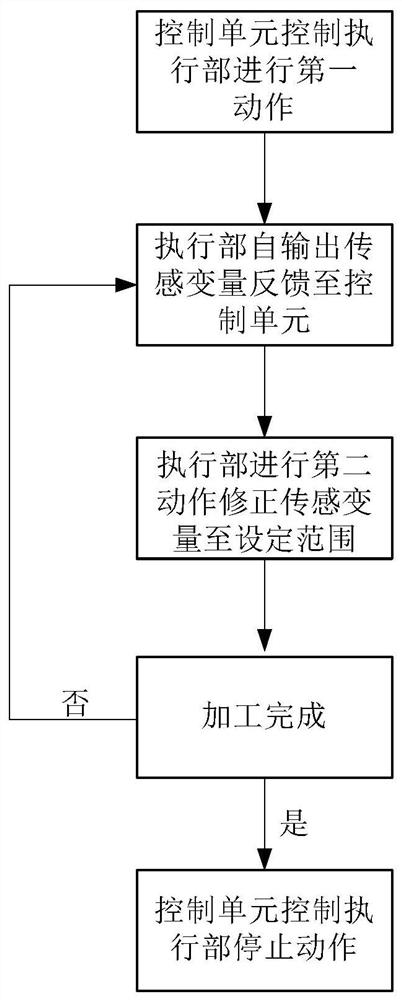

Error sensing compensation method for precision machining

ActiveCN113400089AAchieve high precision machiningImprove continuityAutomatic control devicesFeeding apparatusControl engineeringControl cell

The invention provides an error sensing compensation method for precision machining. The error sensing compensation method comprises the following steps that S1, a control unit receives a machining instruction and outputs a first control command to control an execution part to perform a first action; S2, the execution part automatically outputs a sensing variable in the action process and feeds back the sensing variable to the control unit; S3, the control unit outputs a second control command to control the execution part to perform a second action so as to correct the sensing variable to a set range; S4, if machining is continued, a system returns to S2; and if machining is completed, the control unit controls the execution part to stop acting. According to the method, force and / or displacement adjustment of a tool nose and a workpiece is finally realized through self-sensing and self-driving of a tool according to various complex factors influencing the machining precision, so that accurate error compensation is realized, the final machining precision is further realized, the complex problem is simplified, and the machining precision is greatly improved.

Owner:NANJING LINGJI YIDONG DRIVING TECH CO LTD

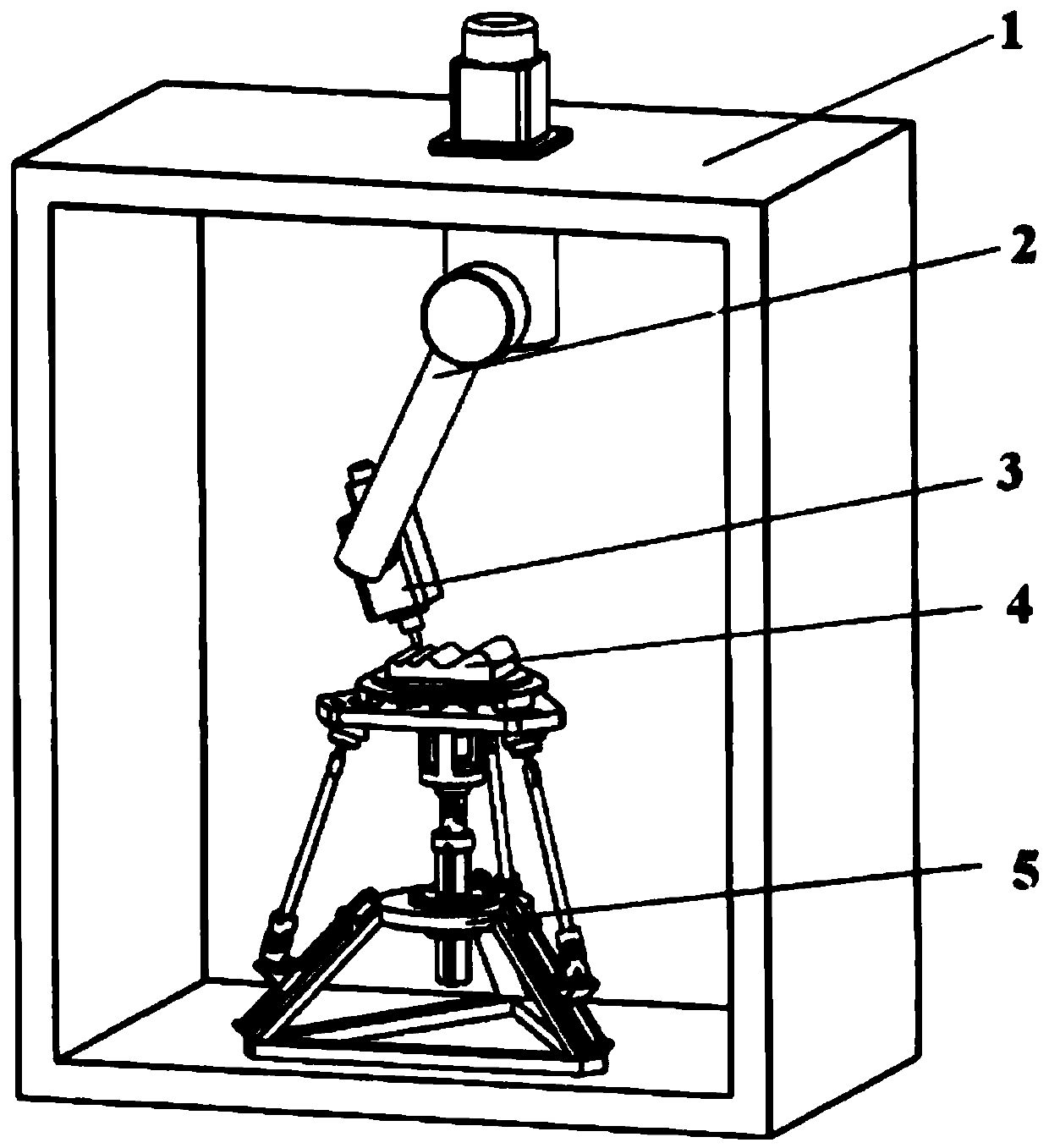

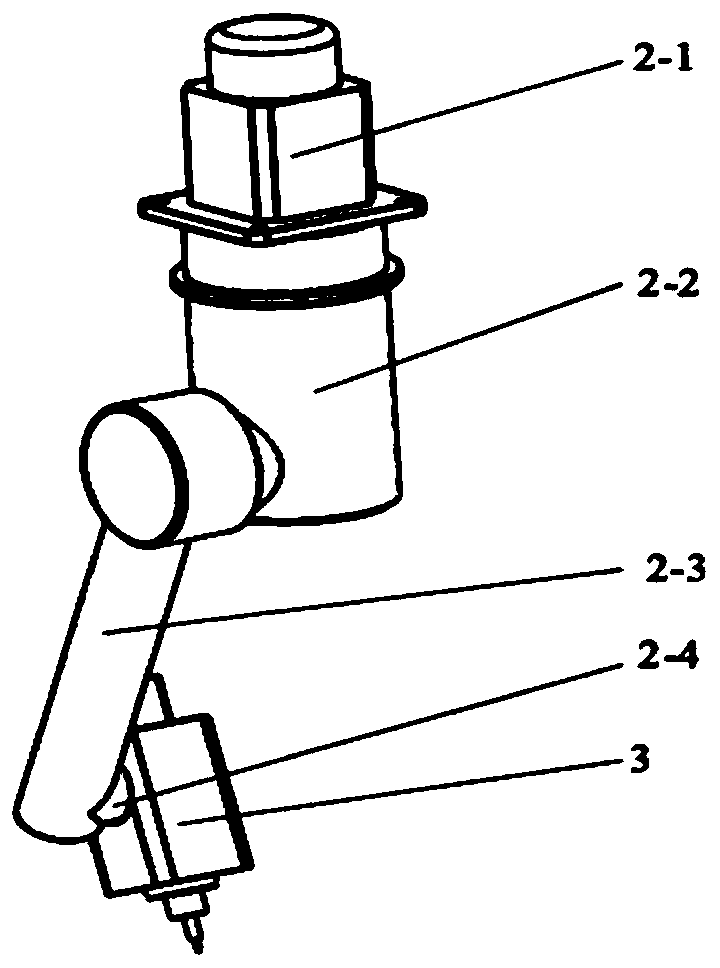

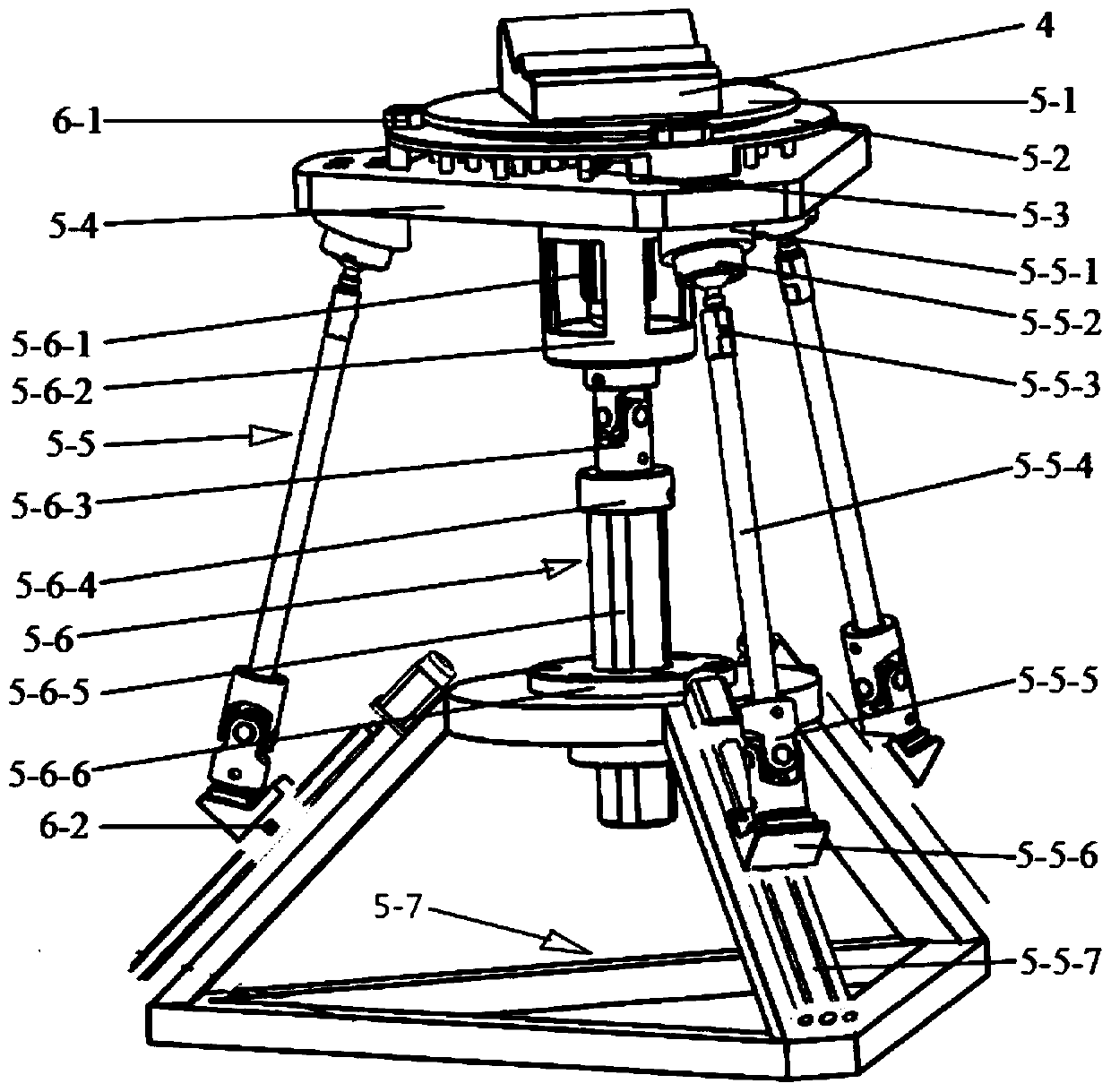

Multi-robot machining equipment of complex surface part

InactiveCN110421567ACompact structureThe overall rigidity of the system is largeProgramme-controlled manipulatorEngineeringRobot machining

The invention discloses multi-robot machining equipment of a complex surface part. The multi-robot machining equipment comprises an equipment supporting frame, a series machining robot, a parallel supporting robot and a co-melting control detection system, wherein the series machining robot comprises a first rotating joint, a second rotating joint, a third rotating joint and a machining tool system; the parallel supporting robot comprises a supporting base, a supporting platform, a PUS driving chain and a PU constraint chain, the supporting platform is provided with a supporting cylinder, theoutput end of the supporting cylinder is connected with a pneumatic supporting table, the pneumatic supporting table is rotationally connected with a rotating supporting table through an annular sliding rail, a rotating servo motor is arranged at the bottom of the supporting platform, and the output end of the rotating servo motor penetrates through the supporting platform and the pneumatic supporting table is connected with the rotating supporting table. The equipment is compact in structure, good in motion flexibility and high in machining precision; and the aim of machining complex surfacetype parts by utilizing multiple robot interaction co-melting and cooperative work can be realized.

Owner:CHINA UNIV OF MINING & TECH

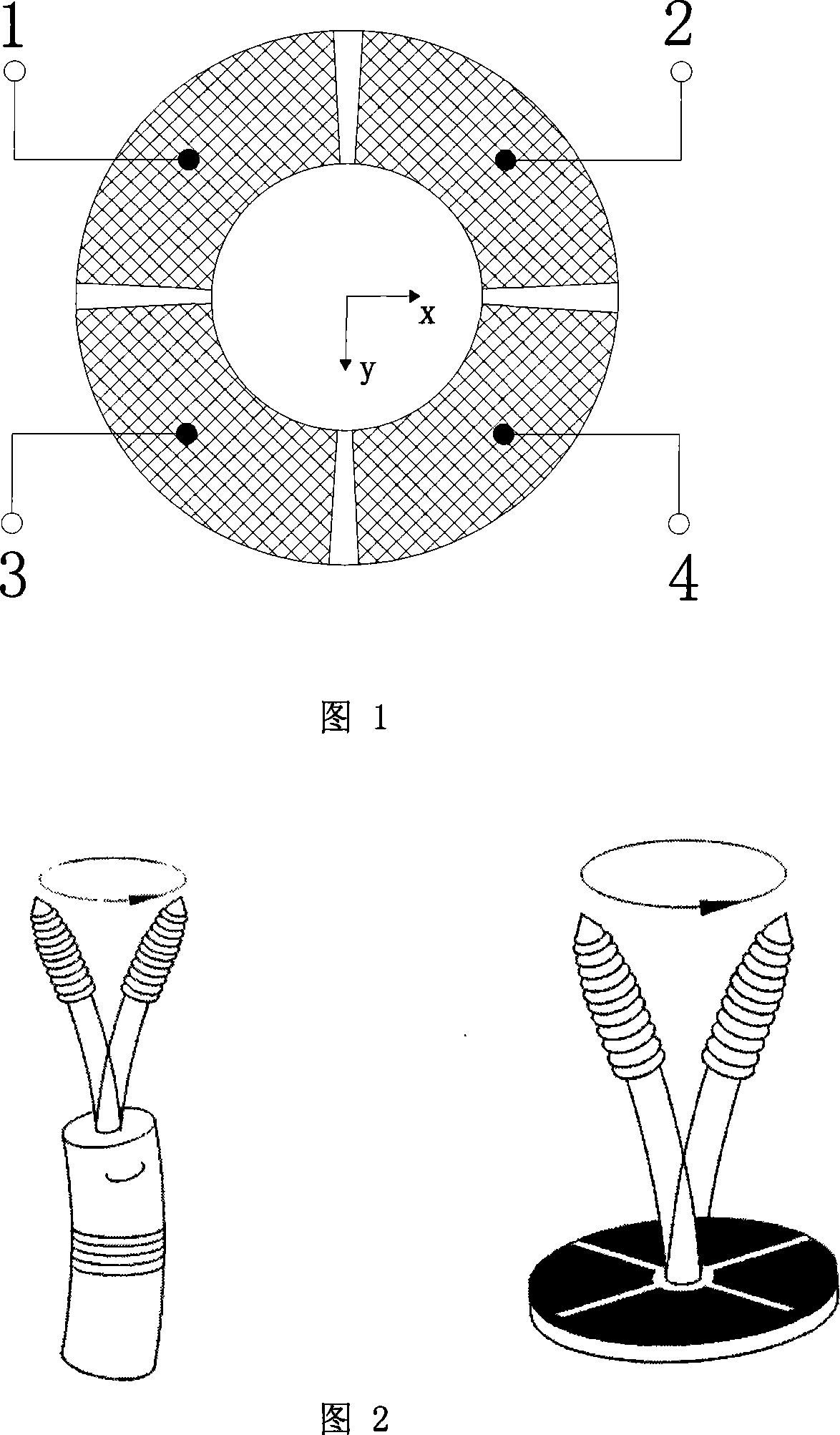

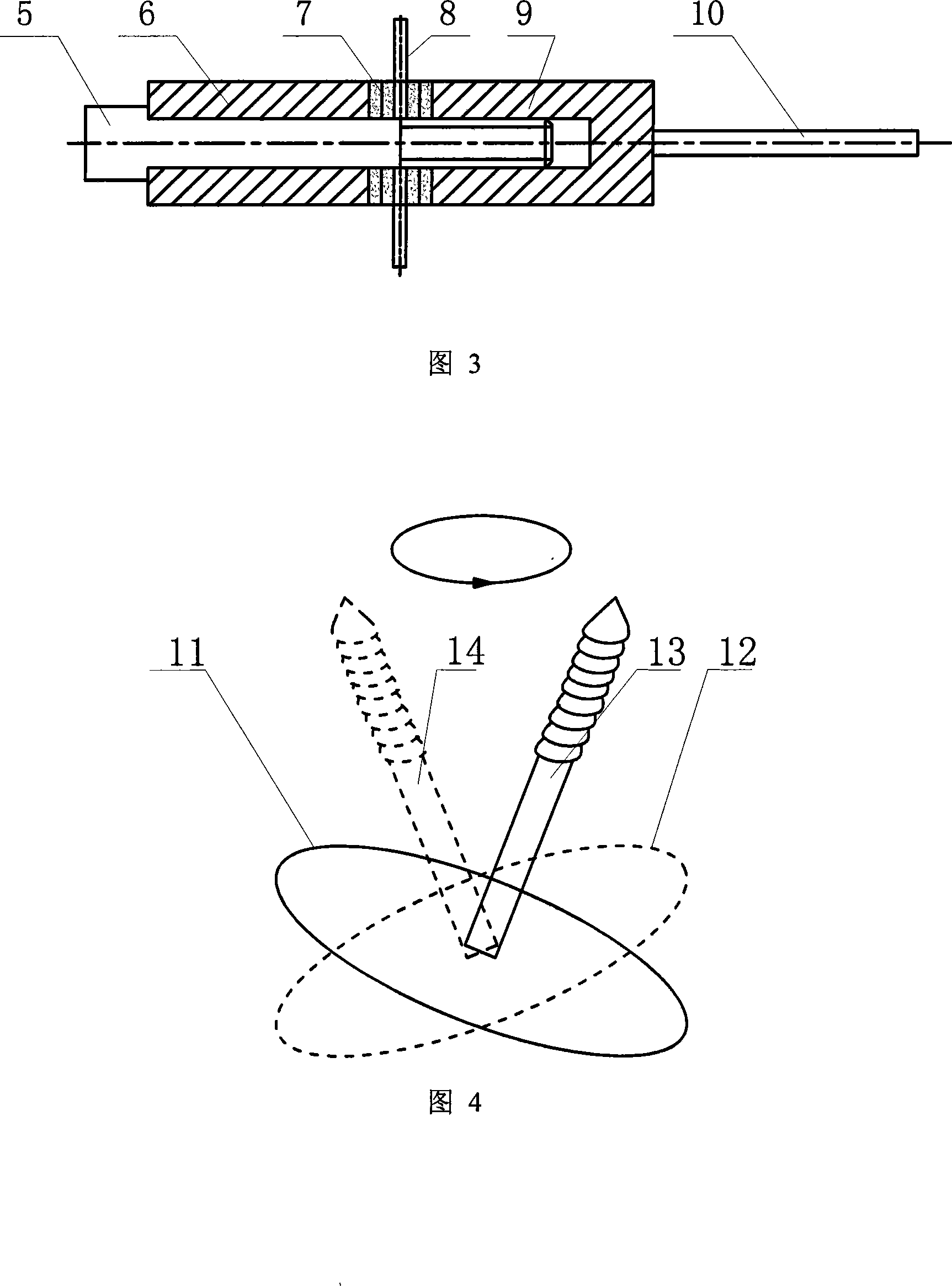

Swing type ultrasonic vibration drill

InactiveCN101179233AAchieve precision machiningOperational securityPiezoelectric/electrostriction/magnetostriction machinesPortable drilling machinesMicrometerUltrasonic vibration

Disclosed is an oscillating ultrasonic vibration drill belonging to the ultrasonic vibration drill field, which comprises a stator component, a rotor and a broach. The stator component comprises a first stator body (6), a second stator body (9), a stator board (8) and a unidirectional polarizing polarized piezoelectric ceramic ring (7) fixed on the stator board, and the rotor is a rod-shaped stator rod connected with the end portion of the second stator body. The surface of the piezoelectric ceramic ring is plated with sector electrodes which are equally partitioned along the circumference. Driving signal is supplied to the piezoelectric ceramic ring through different sector electrodes to facilitate the stator body to generate circumferential traveling wave to drive the stator rod to perform the oscillating movement, thereby realizing the rotating cutting on the end portion of the stator rod. The ultrasonic vibration drill stator rod directly drives the end portion of the stator rod to perform the micrometer amplitude movement to obtain a rotating cutting force, with a high efficiency, an accurate processing, safety and reliability.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Numerical control machine tool with automatic control and fastening functions

ActiveCN110919405AGuaranteed fastening effectAchieve precision machiningAutomatic control devicesFeeding apparatusElectric machineryAutomatic control

The invention relates to a numerical control machine tool with automatic control and fastening functions. The numerical control machine tool comprises a workbench, a top plate, a controller, a machining mechanism, multiple fastening mechanisms and two supporting mechanisms, wherein the machining mechanism comprises a power supply, an air cylinder, a slab, a first motor, a drill pipe and two powersupply modules; each power supply module comprises a telescopic pipe, a first spring, a conducting rod and an adjusting unit; and each fastening mechanism comprises a fixed plate, a sucker, a suctionpipe, a transverse plate, a first vertical rod and an extrusion assembly. According to the numerical control machine tool with automatic control and fastening functions, extrusion plates in the fastening mechanisms prop against parts and the suckers suck parts, so that the fastening effect on the parts is guaranteed, effects of deflection and shaking of parts on machining accuracy during machiningare avoided, moreover, the drilling depth of parts can be automatically adjusted by the machining mechanism, precise machining of the parts is realized, and the practicability of the equipment is improved.

Owner:LINYI GAISHI MACHINERY

A roll folding machine

Owner:ANHUI KINGPOWER EQUIP & MOLD MFR

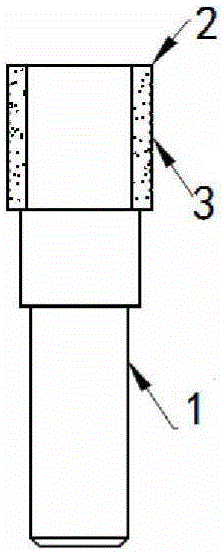

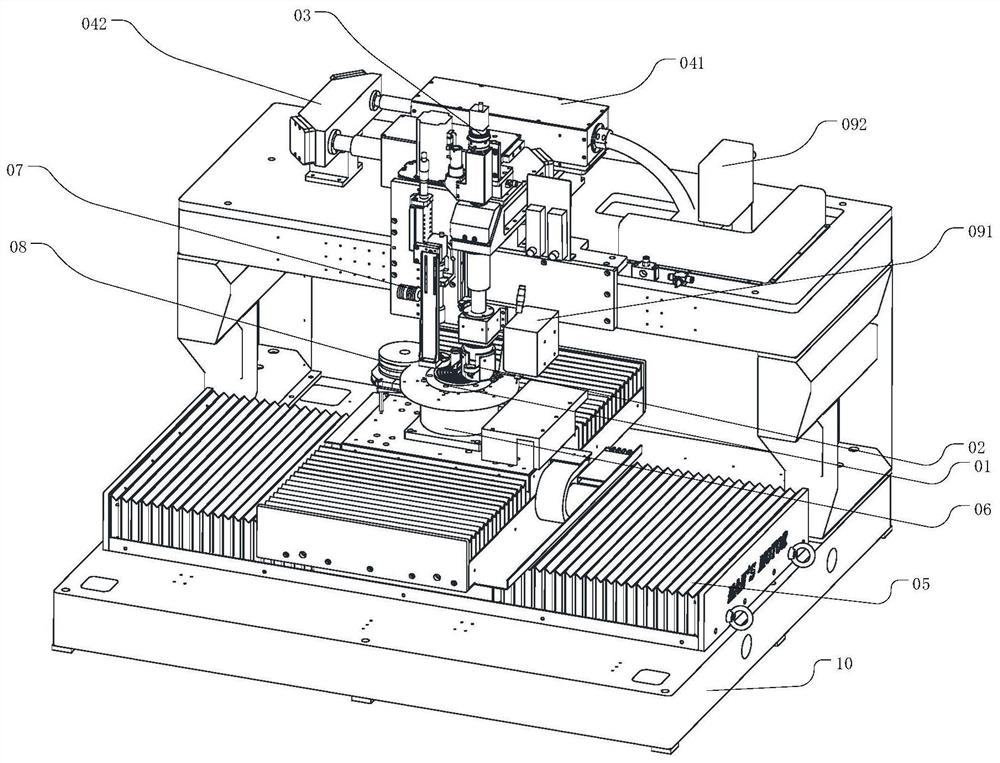

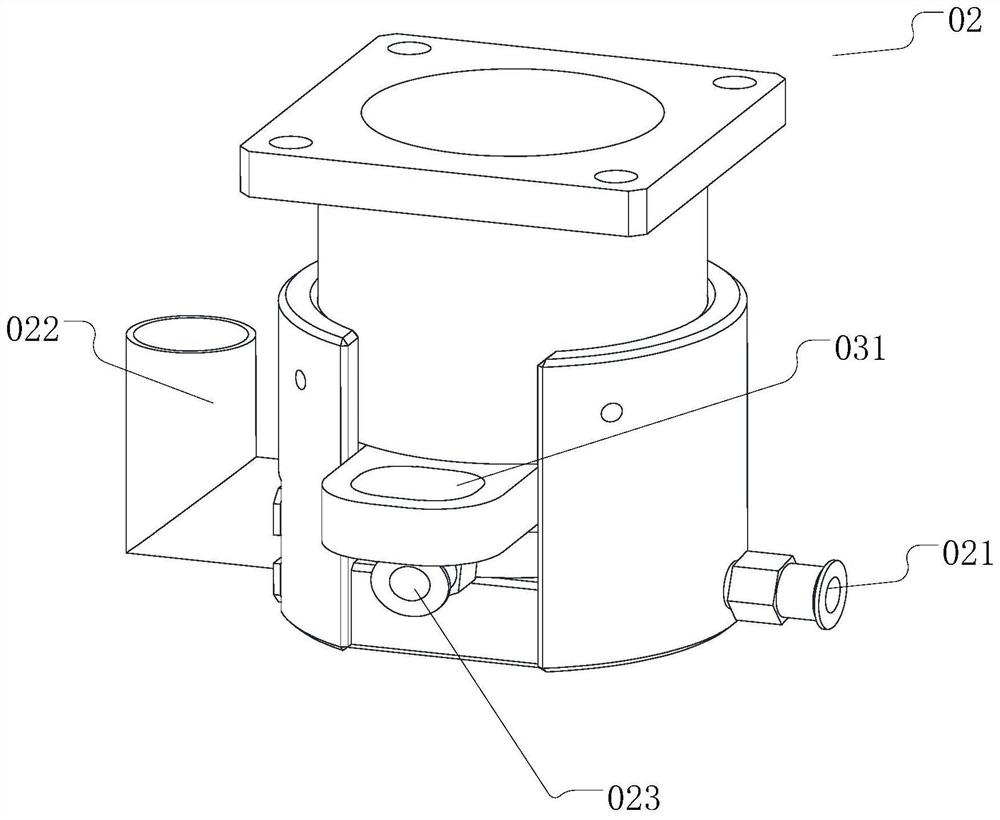

Device and method for pretreatment of end face of small optical fiber ceramic ferrule

PendingCN111890150AImprove preprocessing accuracyImprove efficiencyGrinding drivesGrinding feed controlEngineeringMechanical engineering

The invention discloses a device and method for pretreatment of an end face of a small optical fiber ceramic ferrule. The device comprises an automatic loading-unloading system, a workpiece clamping main shaft system and a grinding main shaft system, wherein the automatic loading-unloading system is provided with an feeding hole and an discharge hole which are used for transmitting the optical fiber ceramic ferrule to the discharge hole, the workpiece clamping main shaft system is disposed at the lateral side of the discharge hole and the grinding main shaft system is disposed at one side, inthe horizontal direction, of the workpiece clamping main shaft system; the workpiece clamping main shaft system comprises a workpiece clamping assembly, and the workpiece clamping assembly is used forclamping the optical fiber ceramic ferrule which is transmitted to the discharge hole; and the grinding main shaft system comprises a horizontal motion platform and a grinding assembly, the grindingassembly is connected to the horizontal motion platform, and the horizontal motion platform is used for driving the grinding assembly to move along the horizontal direction so as to approach the end face of the optical fiber ceramic ferrule, so that the end face of the optical fiber ceramic ferrule can be pre-treated. The device and method disclosed by the invention eliminate uncertain factors caused by manual operations and increase accuracy and efficiency of end face pre-treatment.

Owner:T&S COMM

High-precision five-axle argon arc welding machine

InactiveCN110666306AAchieve precision machiningAchieve high precision controlWelding/cutting auxillary devicesAuxillary welding devicesBall screwEngineering

The invention relates to the technical field of argon arc welding machines, in particular to a high-precision five-axle argon arc welding machine. Through arrangement of three linear modules perpendicular to each other and an A-axle rotating module, a TIG welding gun of the argon arc welding machine can finish complex motions of three-dimensional space; and workpieces are rotated through a R-axlemodule to form five-axle linkage to realize complex welding way welding. In addition, through skillful arrangement of such structures as a servo motor, a speed reducer and a precise ball screw, the high-precision control of five-axle motions can be realized; a wire filling head is not arranged on a plane of the TIG welding gun and a welding way; and through rotation of an A axle of the TIG weldinggun, the difficulty of no position interference in welding of an arc welding way with a radius smaller than 7 mm is solved. Through the arrangement, the precise machining of the workpieces can be realized; and under the condition of workpiece materials as AMS-5599, the strict requirements that the inner and outer welding line heights of the workpieces with the wall thicknesses of 1 mm are not higher than 0.25 mm and the inner and outer welding line heights of the workpieces with the wall thicknesses of 1.2 mm are not higher than 0.29 mm are met during single-surface welding and double-surfacemolding.

Owner:成都环龙智能机器人有限公司

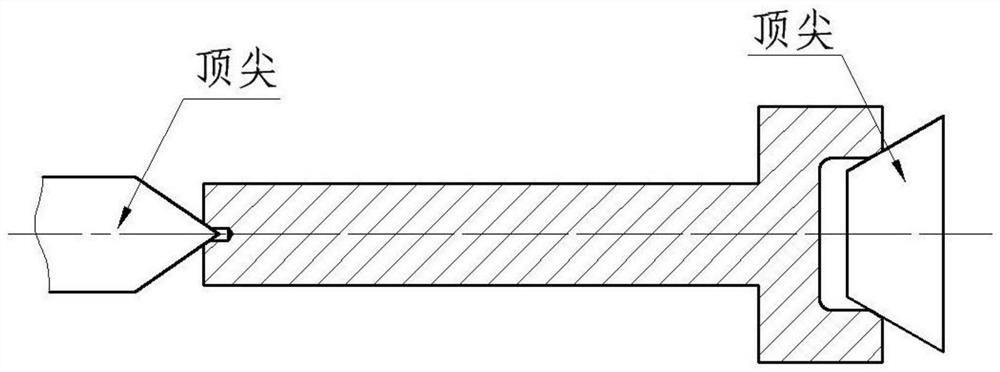

Process method for precisely machining piston rod part of aero-engine actuator cylinder

The invention discloses a process method for precisely machining a piston rod part of an aero-engine actuator cylinder, and belongs to the technical field of aero-engine actuator cylinders. The process method for precision machining of the piston rod part of the aero-engine actuator cylinder comprises the following steps that S1, the piston rod part is roughly turned, a turning tool blade is adopted for turning the outer circle of the piston rod part, the rotating speed of a lathe spindle is 1200 r / min, the feeding amount is 0.1 mm / r, and the back engagement of the cutting edge is 0.2 mm; S2, the piston rod part is subjected to finish turning, the turning tool blade is adopted for turning the outer circle of the piston rod part, the rotating speed of the lathe spindle is 2,000 r / min, the feeding amount is 0.5 mm / r, and the back engagement of the cutting edge is 0 mm; and S3, the piston rod part is machined through Hauck energy, an oblique line feeding mode is adopted, the rotating speed of the lathe spindle ranges from 800 r / min to 1000 r / min, the feeding amount ranges from 0.2 mm / r to 0.25 mm / r, and the back engagement of the cutting edge is 0.4 mm. According to the process method for precision machining of the piston rod part of the aero-engine actuator cylinder, mirror surface machining of the piston rod part can be achieved, and the use reliability and service life of a piston and assemblies are improved.

Owner:SHENYANG LIMING AERO PARTS MFG

A method of laser repairing and polishing ceramic parts

ActiveCN107378276BRealize modelingAchieve fixWelding/soldering/cutting articlesLaser beam welding apparatusMetallurgySurface roughness

The invention discloses a method for repairing and polishing ceramic parts through laser. The method comprises the steps of S1, cleaning the ceramic part, and assembling the ceramic part to a three-dimensional moving platform; S2, scanning the surface contour of the ceramic part, comparing the scanned contour model with a standard model, and dividing the surface of the ceramic part into an etching region, a polishing region and a sintering region; S3, processing the etching region by using excimer laser equipment; S4, carrying out preset powder feeding on the sintering region, and carrying out sintering repair by using long-wavelength laser; S5, carrying out rough polishing on the sintering region; S6, carrying out overall polishing on the processing area; and S7, scanning the surface roughness of the ceramic part, executing the step S6 if the roughness does not meet the requirement, and completing the excimer laser polishing process if the roughness meets the requirement. The method has the advantages that the controllability is good, the automatic production can be realized conveniently, the precise processing of the micro-area can be realized, any curved surface and any part can be treated, the influence on a ceramic matrix is remarkably reduced, and the precision, the quality and the efficiency of part repairing and polishing are guaranteed.

Owner:RAINBOW SOURCE LASER RSLASER

Flying-dust-proof machine tool suitable for precision machining

InactiveCN111318918AAvoid driftingAchieve precision machiningGrain treatmentsMaintainance and safety accessoriesEngineeringMachine tool

The invention relates to the technical field of machining tools, in particular to a flying-dust-proof machine tool suitable for precision machining. The machine tool comprises a machine tool body, wherein the machine tool body comprises an operation box and a machining box, a working cavity is formed inside the machining box, a grinding disc is mounted inside the working cavity, and a protective cover is mounted on the outer wall of the working cavity. According to the flying-dust-proof machine tool suitable for precision machining, the working cavity is formed, and the protective cover is mounted outside the working cavity, so that it is guaranteed that a workpiece is machined in a sealed mode when machined in the machining cavity, the working cavity is not influenced by the external environment, precision machining is achieved, and meanwhile, flying dust is prevented from drifting; the flying dust enters a discharging box from a leaking hole, the flying dust is prevented from being accumulated, and flying dust clearing is facilitated; and waste chips are crushed through gear shafts rotating relatively, so that the leaking hole is prevented from being blocked.

Owner:张文杰

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com