Laser machining process of special-shaped film hole of turbine blade

A technology of laser processing and turbine blades, which is applied in the direction of metal processing equipment, laser welding equipment, manufacturing tools, etc., can solve the problems of difficult manufacturing and repair, high price, and low processing efficiency, so as to reduce the thickness of recasting layer and facilitate scale The effect of streamlining production and improving surface integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

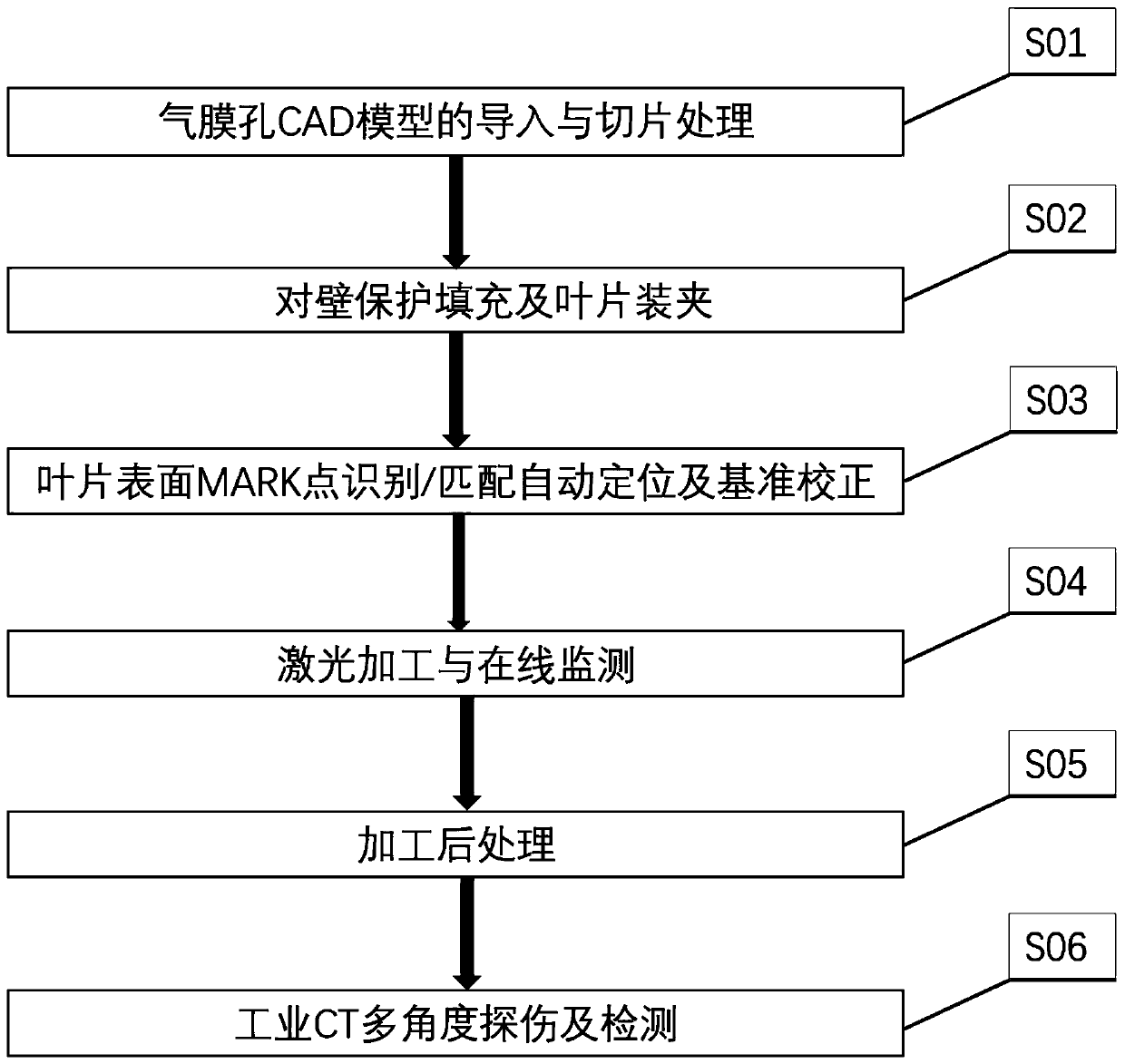

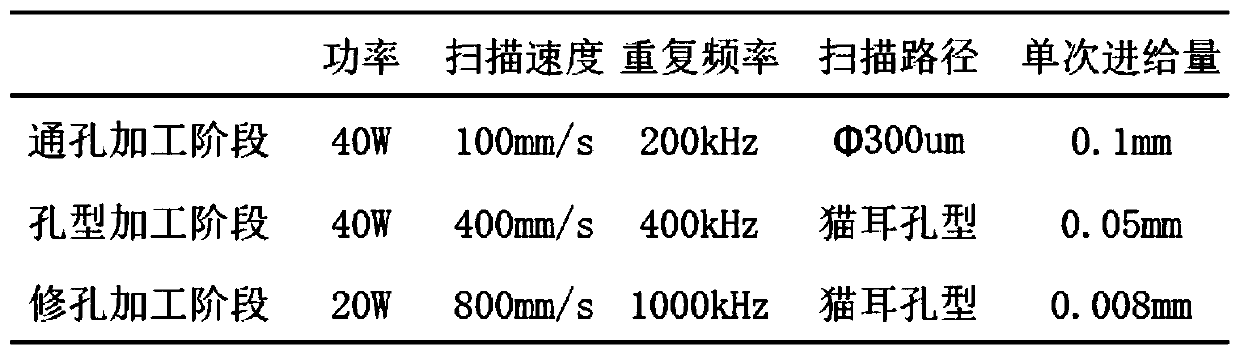

[0066] Attached below figure 1 , attached figure 2 The laser processing technology of the cat-ear special-shaped hole of the DD6 superalloy turbine blade disclosed in this embodiment is further explained:

[0067] Import and slice processing of air film hole CAD model. Import the designed three-dimensional special-shaped hole CAD model file into the air film hole laser automatic processing control software V1.0, perform layered slicing processing and generate CNC code that can drive the five-axis motion system.

[0068] Filling and clamping for wall protection. The black silicon carbide purchased in the market needs to be ground and filtered first, and then the small black silicon carbide particles are poured into the blade flow channel through the hole at the top of the turbine blade to fill the internal cavity of the blade. In this way, when the laser passes through the small hole, it is absorbed, reflected, and scattered by the black silicon carbide particles in the cav...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com