Patents

Literature

280 results about "Surface integrity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Surface integrity is the surface condition of a workpiece after being modified by a manufacturing process. The term was coined by Michael Field and John F. Kahles in 1964. The surface integrity of a workpiece or item changes the material's properties. The consequences of changes to surface integrity are a mechanical engineering design problem, but the preservation of those properties are a manufacturing consideration.

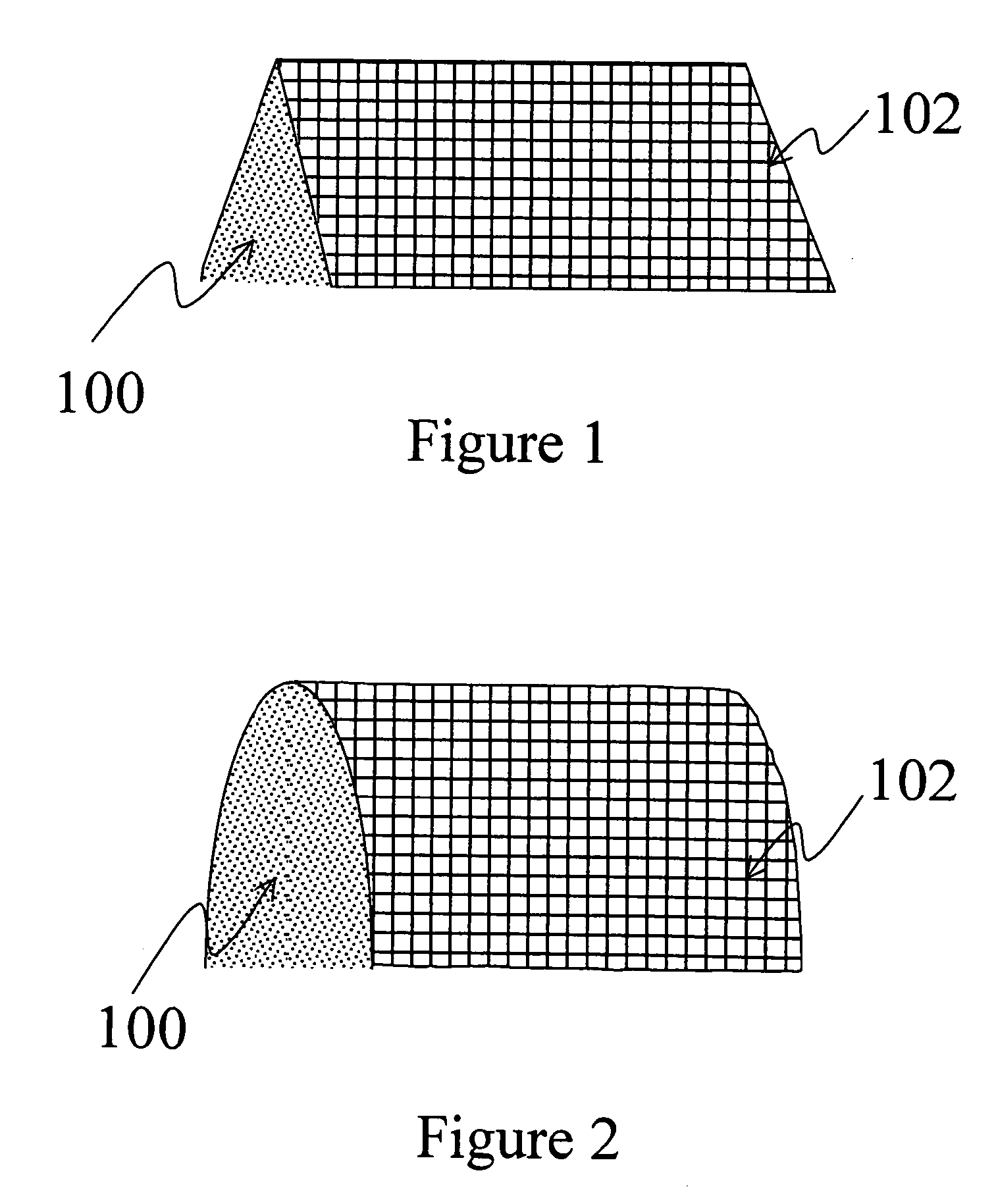

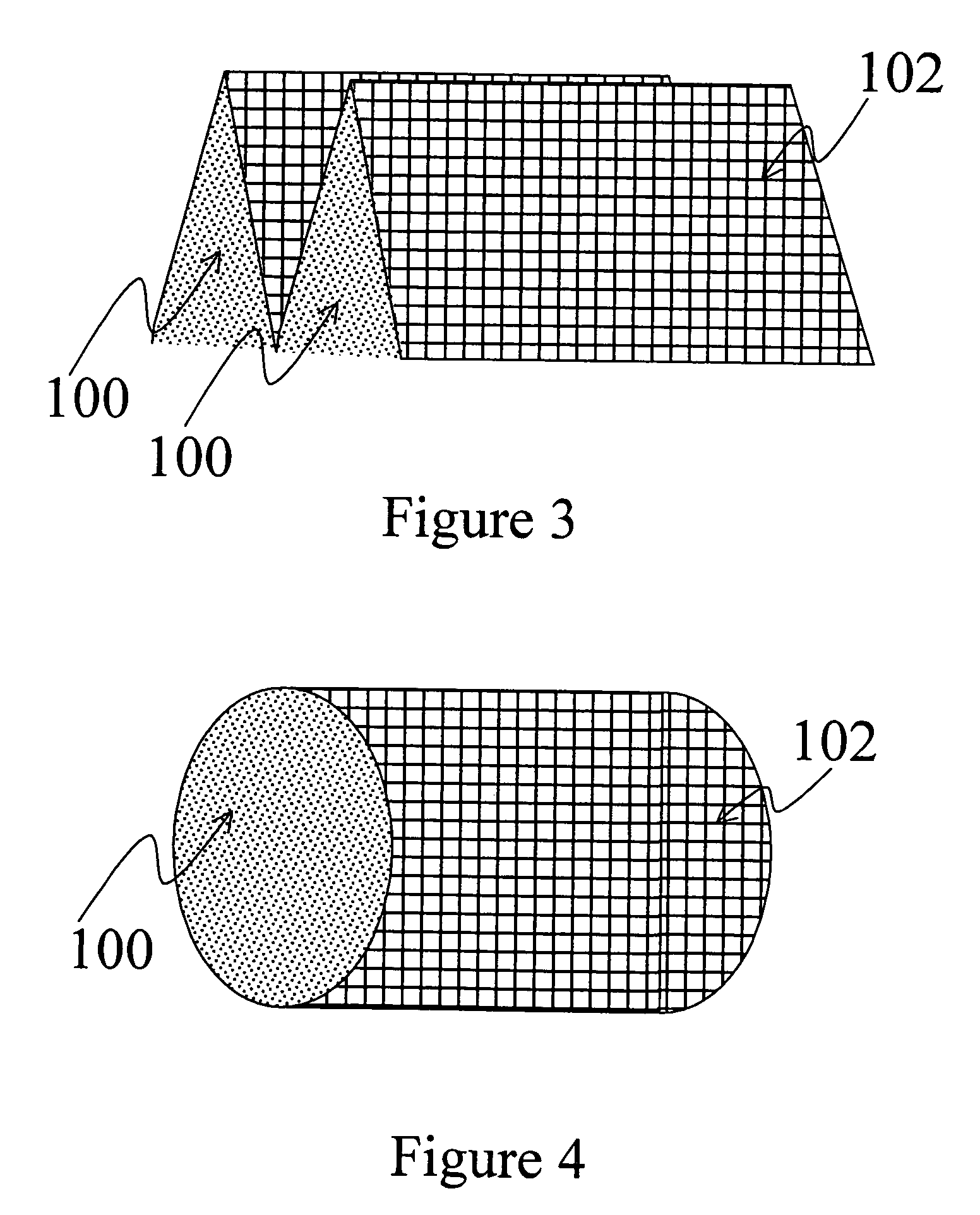

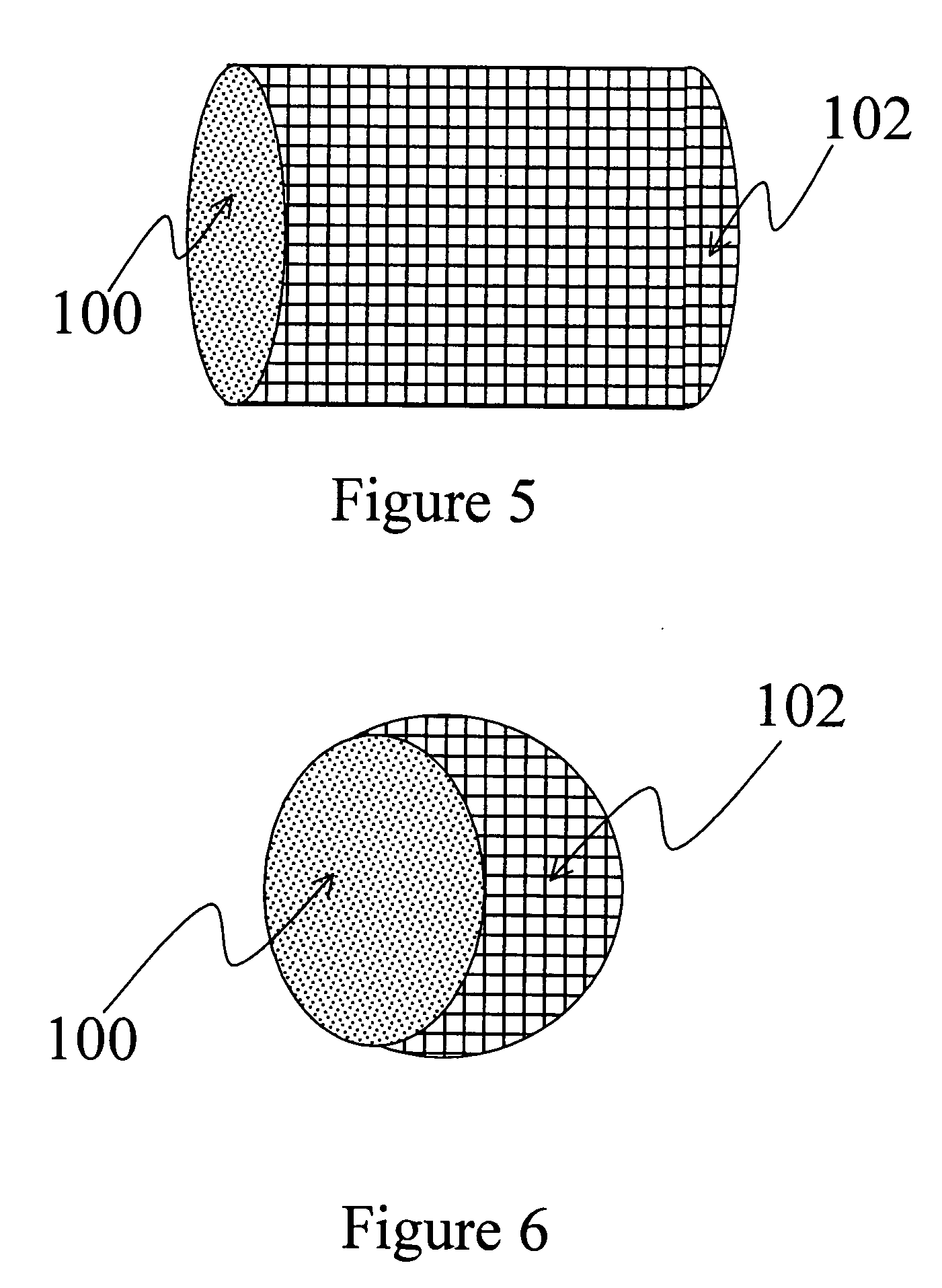

Method of making cell growth surface

InactiveUS20060292690A1Cell density be limitedReduced viabilityCell culture supports/coatingTissue/virus culture apparatusCell adhesionCell growth

The present invention discloses a three-dimensional porous growth surface made from polysaccharide material, especially the alginic acid, to enhance cell growth surface, promote cell adherence, immobilization and propagation, maintain surface structure integrity, enable programmable degradation, and thus increase cellular production. The present invention teaches several methods: a method to enhance the integrity of the growth surface by protecting the growth surface in a rigid solid support; a method of use for enhancing the performance of the surface; and a method of modifying a growth surface for eukaryotic and / or prokaryotic cells comprising the steps of increasing surface area by creating porous and 3-D structure, treating a surface to encourage cell attachment, promoting cell growth and proliferation, and disposing the growth surface in any conventional cell cultivating device. The growth surface is able to program degradation and release the cell / tissue mass after the culture is completed.

Owner:CESCO BIOENGINEERING CO LTD

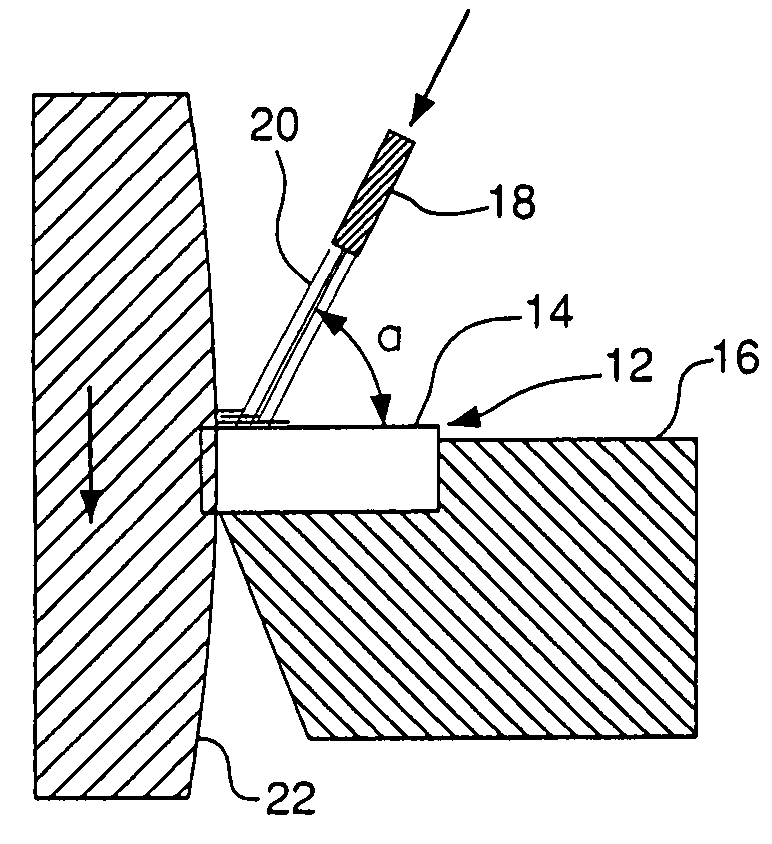

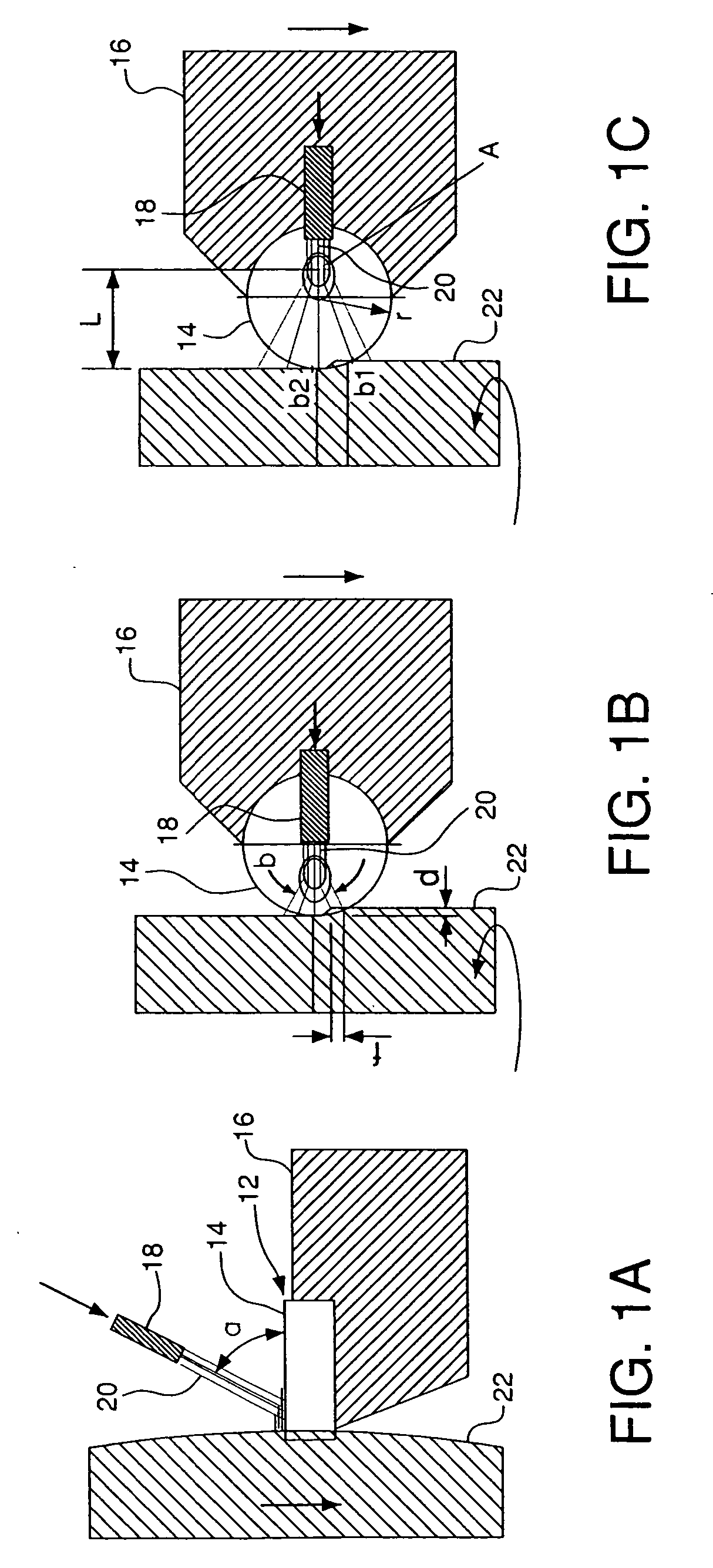

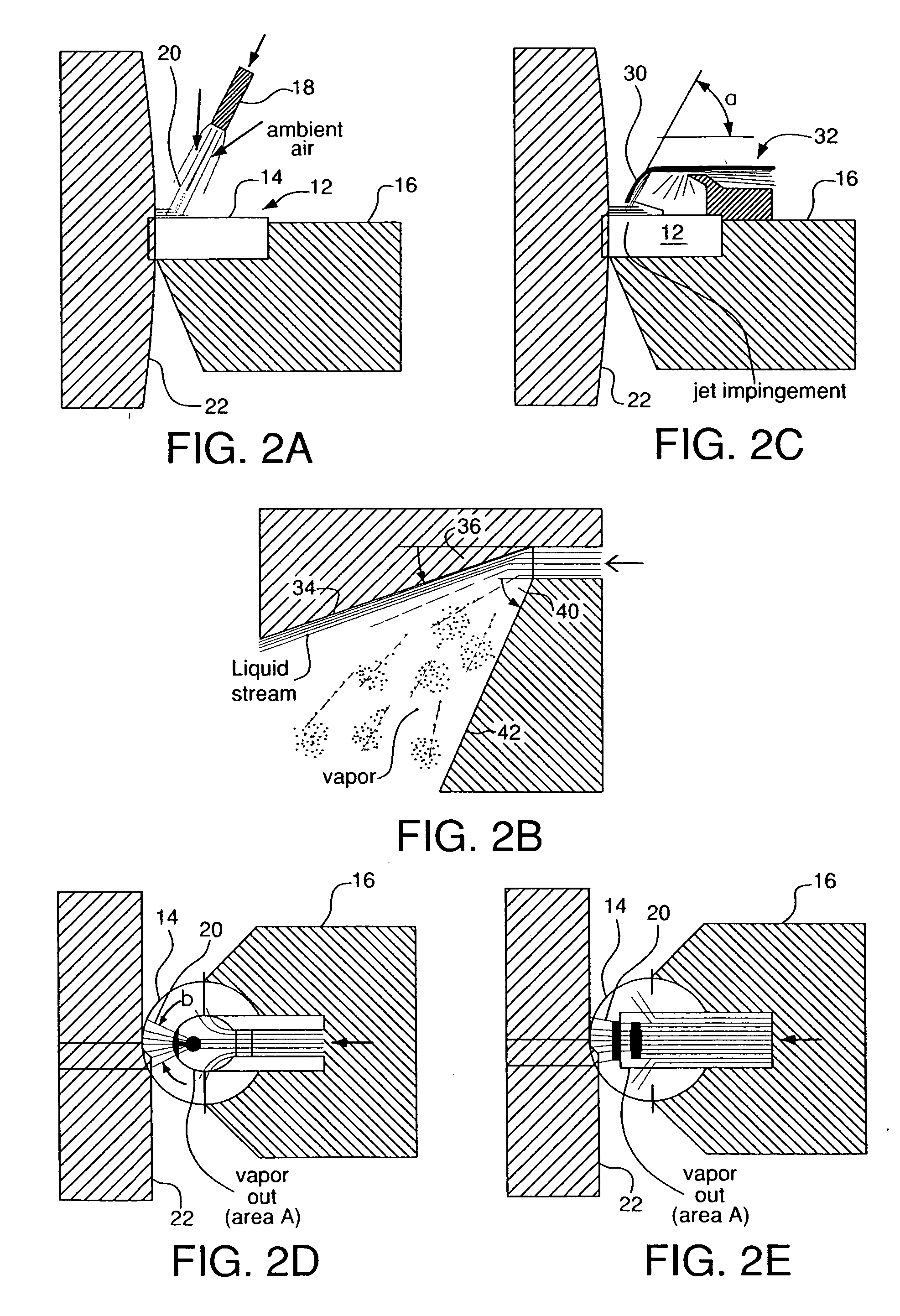

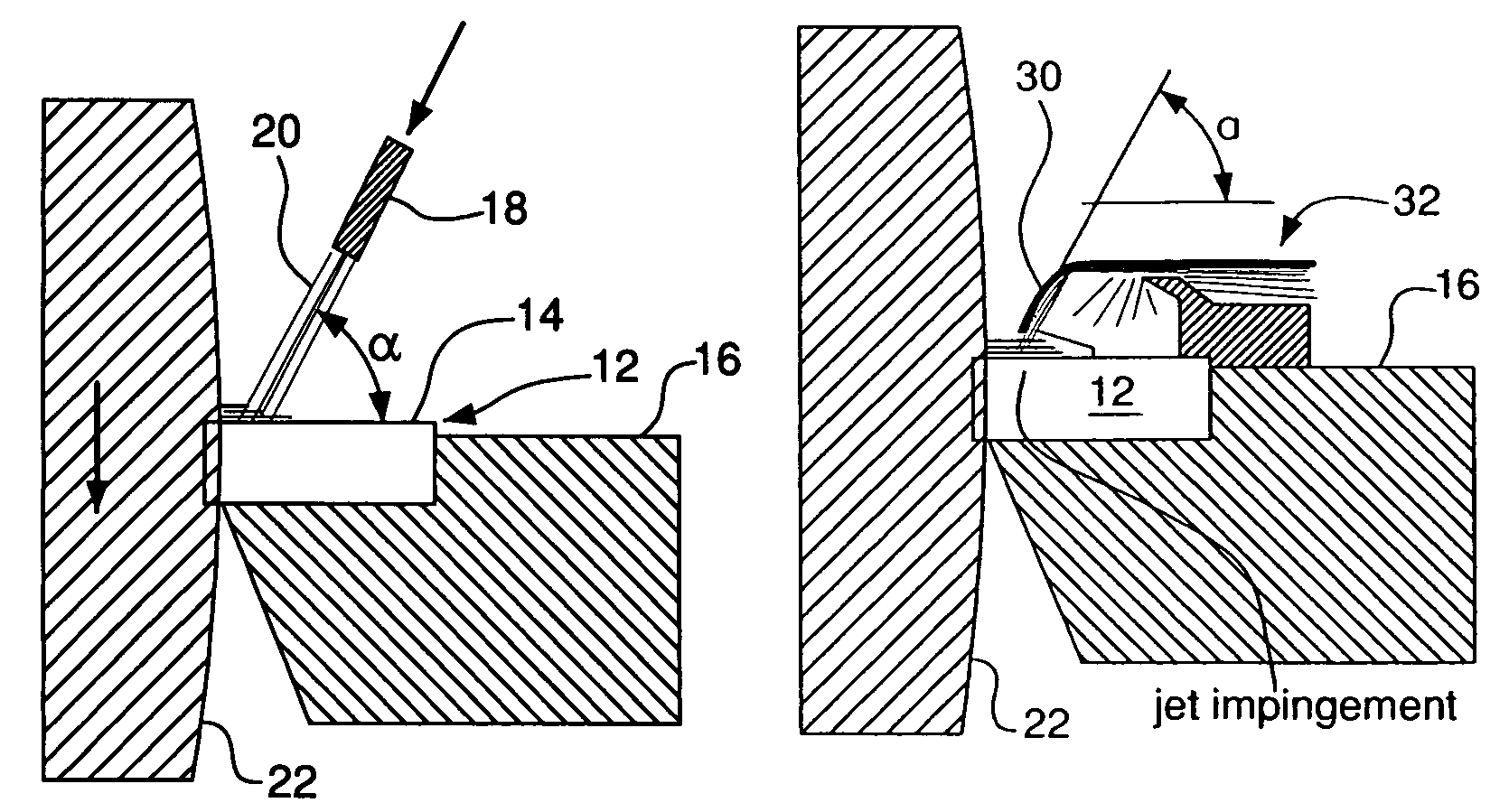

Apparatus and method for improving work surface during forming and shaping of materials

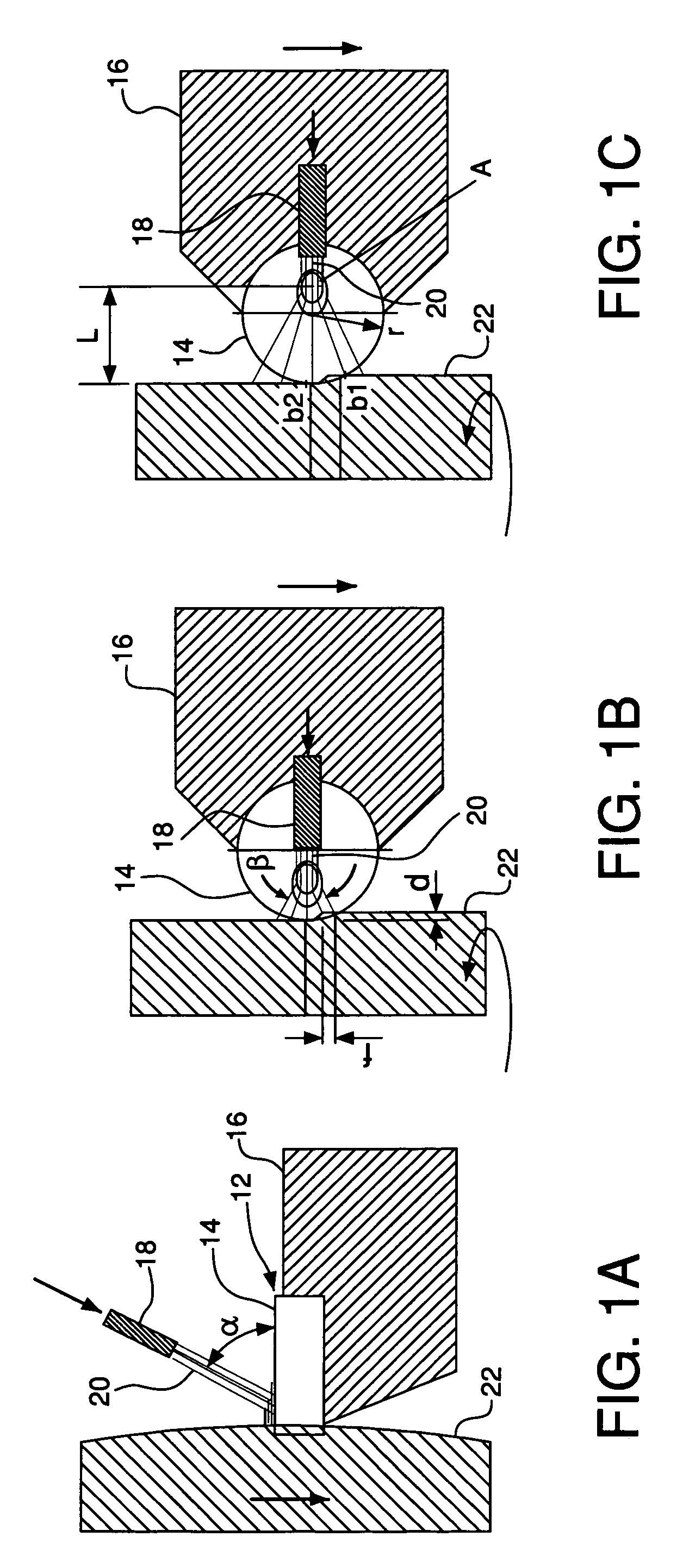

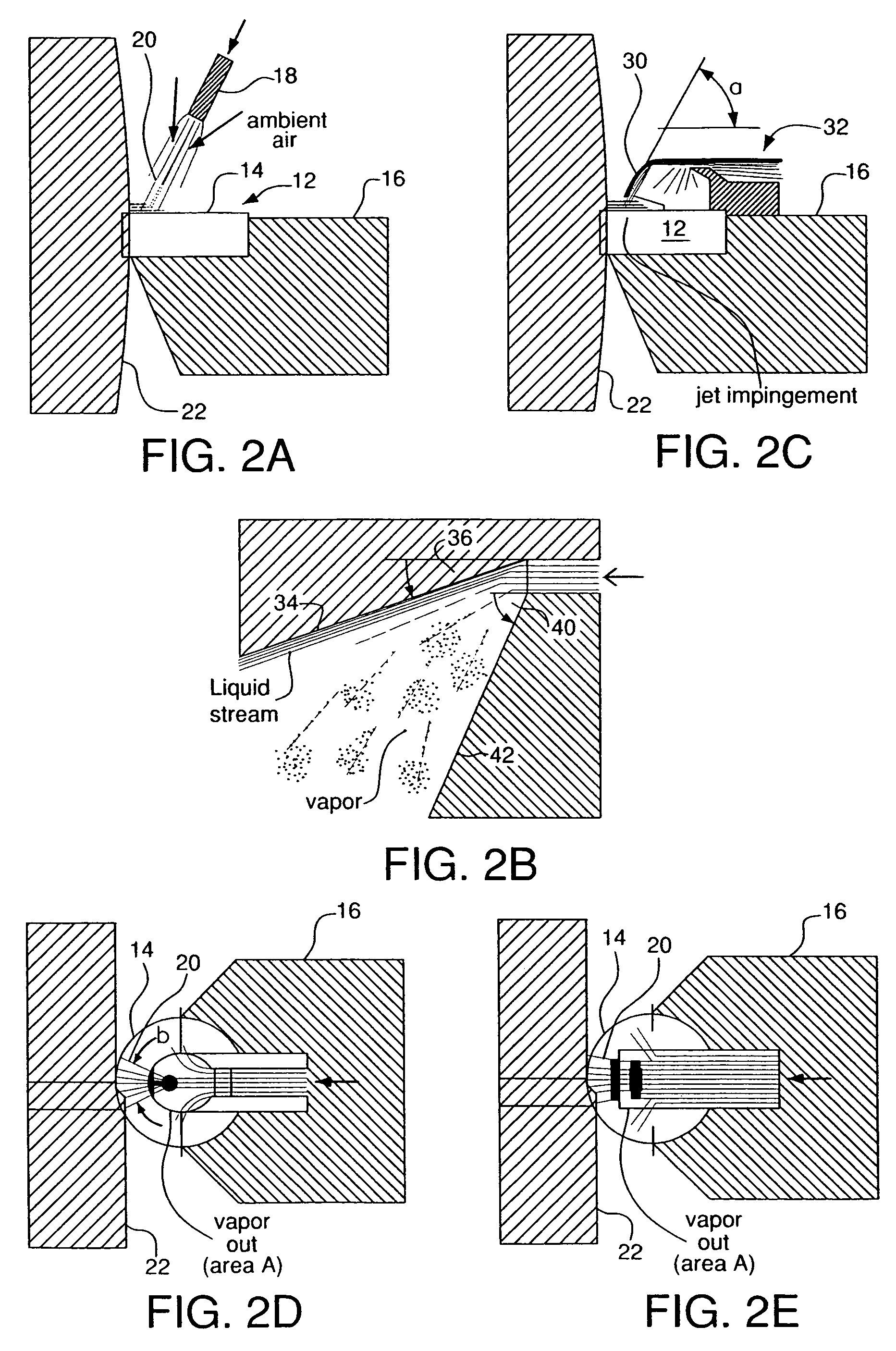

ActiveUS20050211029A1High surface finishImprove surface integrityLiquid surface applicatorsFurnace typesSurface finishHardness

A method and apparatus for improving the surface finish and / or surface integrity of a workpiece formed or shaped with a tool increase the surface hardness of the workpiece during forming or shaping of the workpiece. A method and apparatus for forming or shaping a workpiece also increase the surface hardness of the workpiece during forming or shaping of the workpiece with a tool, as do a method and apparatus for manufacturing a finished part or product from a workpiece. In some embodiments, an expanding jet of cryogen may be jetted to a surface of a workpiece and a tool from a nozzle, wherein the cryogen is at least partially separated into a condensed phase portion and a vapor portion within a downstream portion of the nozzle.

Owner:AIR PROD & CHEM INC

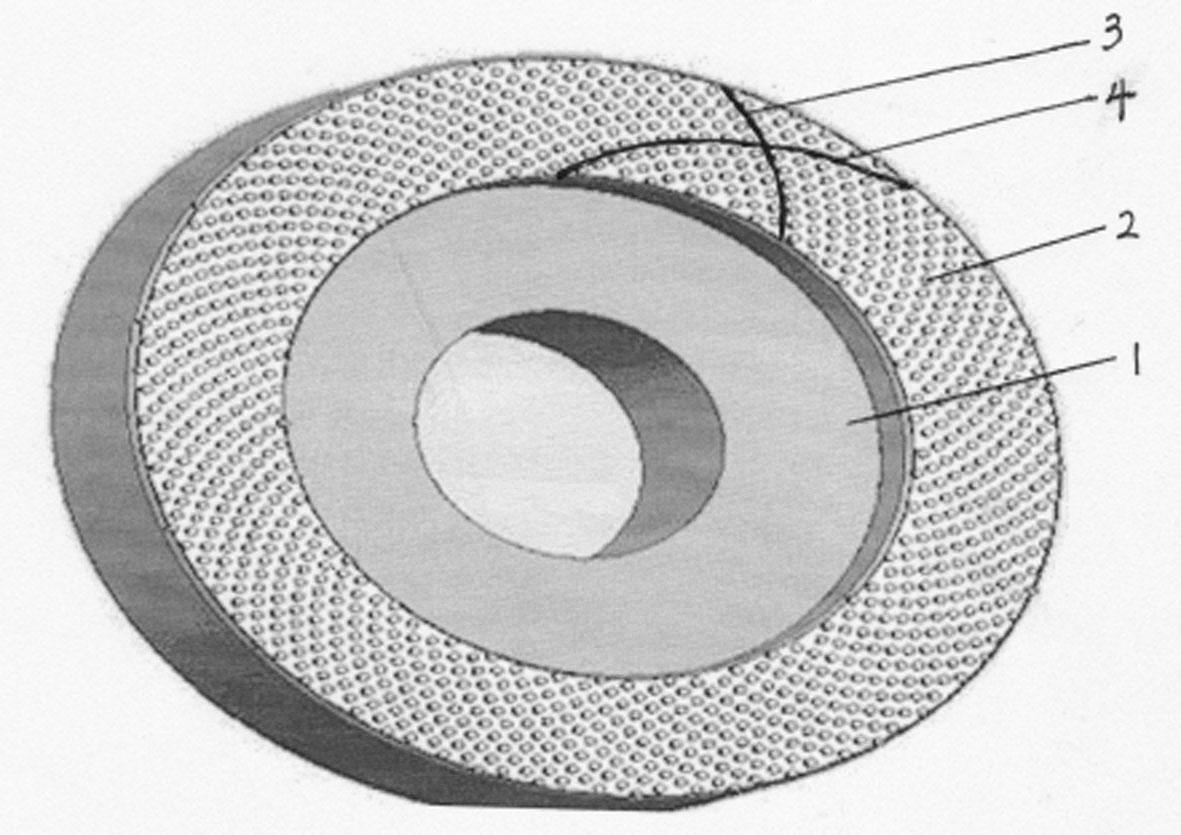

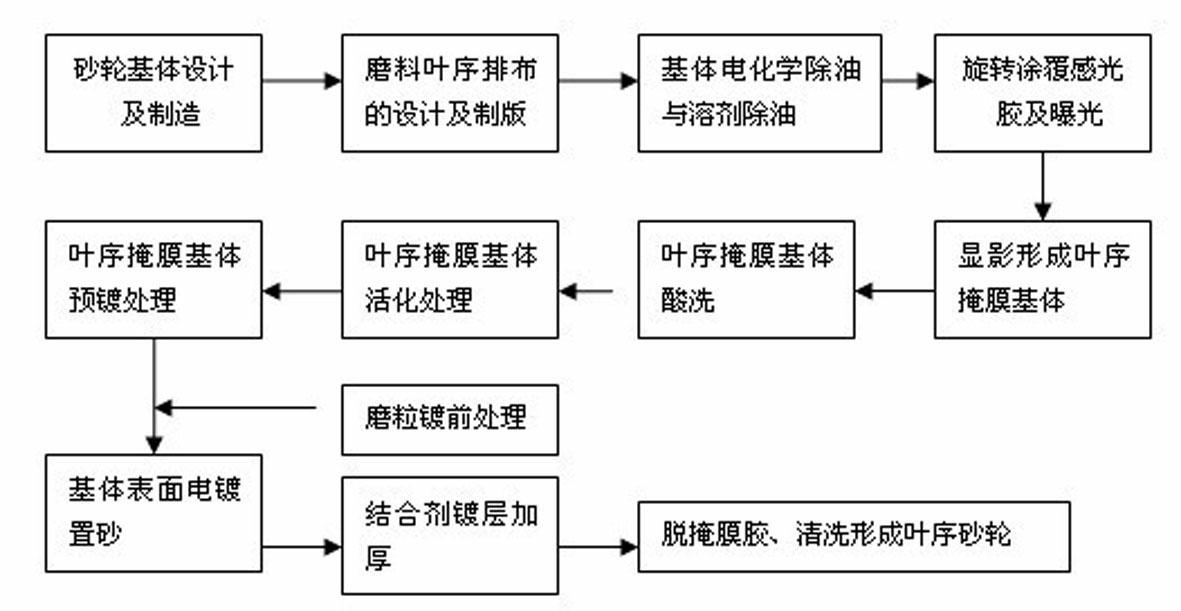

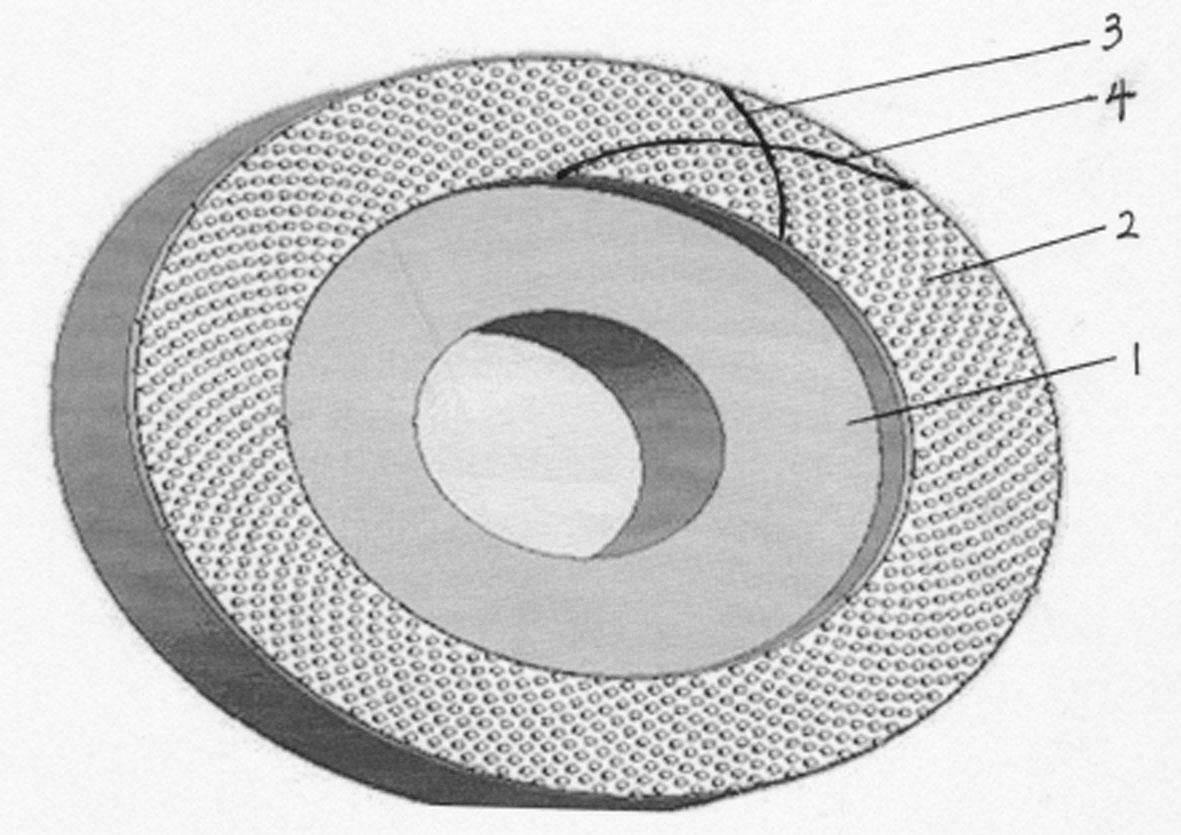

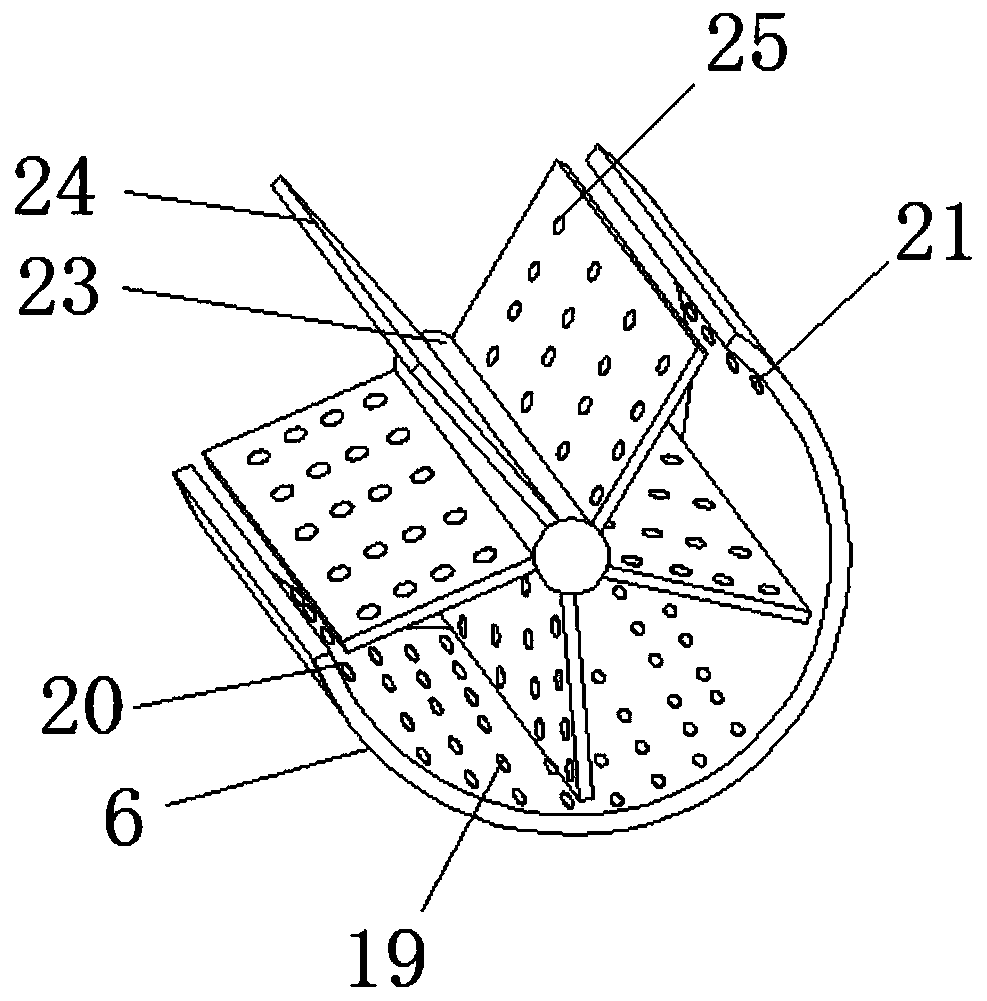

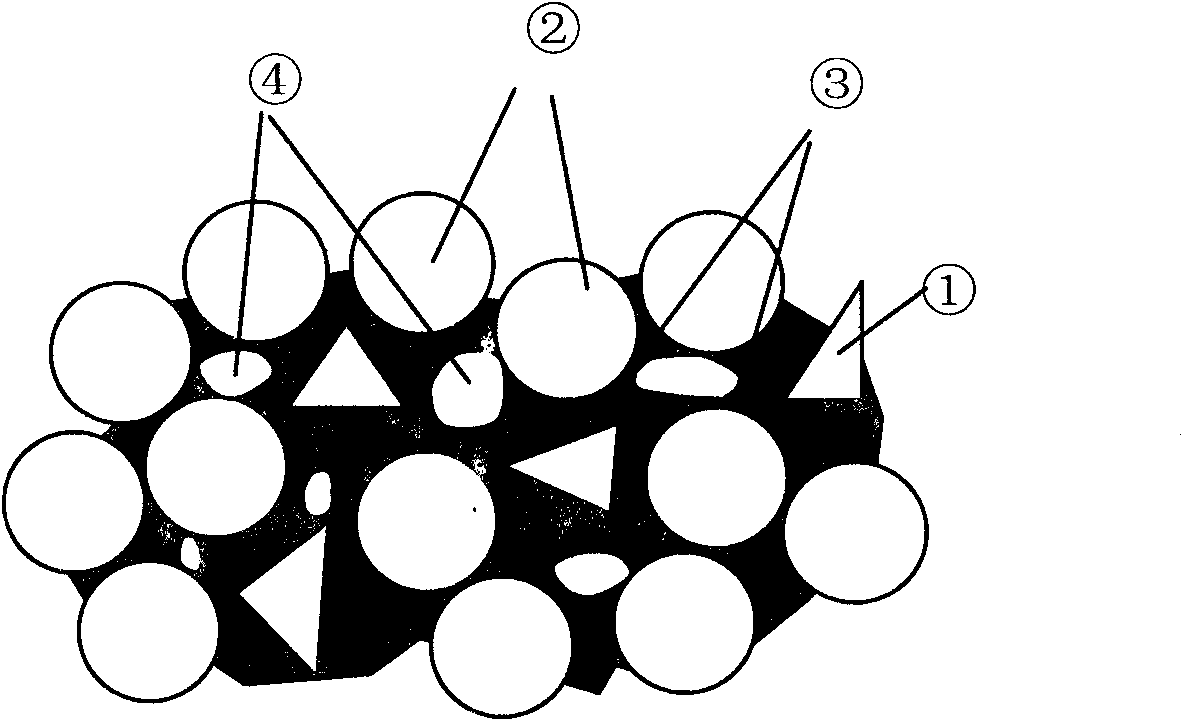

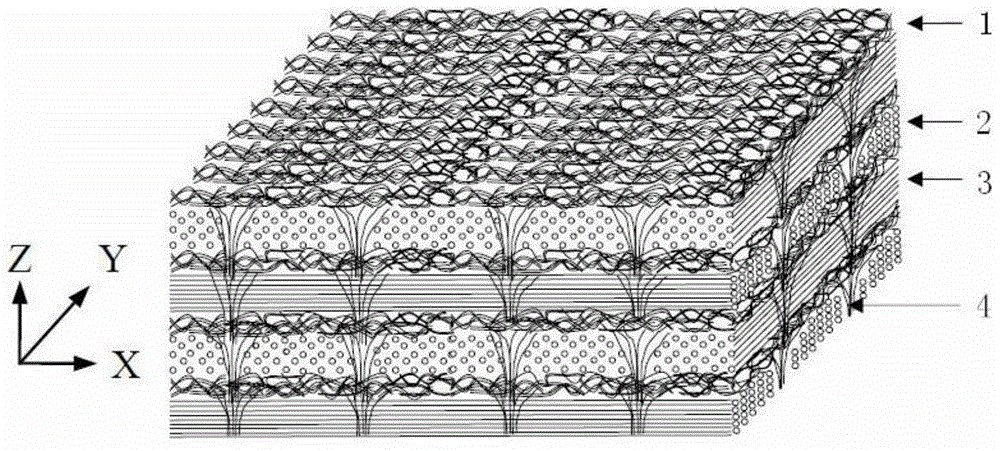

Super-hard abrasive grinding wheel with head face having abrasives in phyllotaxis arrangement and production method thereof

InactiveCN102198641AReduce wearAchieving landform controllabilityBonded abrasive wheelsGrinding devicesWheel wearControllability

The invention discloses a super-hard abrasive grinding wheel with a head face having abrasives in a phyllotaxis arrangement, comprising a grinding wheel basal body. The working surface of the grinding wheel basal body is provided with a plurality of abrasive particles or abrasive particle groups fitting with the biological phyllotaxis theory. The plurality of abrasive particles or abrasive particle groups are fixed on the grinding wheel basal body through a metal bonding agent. According to the biological phyllotaxis theory, the plurality of abrasive particles or abrasive particle groups forma plurality of anticlockwise leaf column line grooves and a plurality of clockwise leaf column line grooves. By means of the invention, the arrangement of the abrasive particles or the abrasive particle groups on the working surface of the grinding wheel fits with the H.Vogel model of the phyllotaxis theory so as to realize the physiographic controllability of the working surface of the grinding wheel. Nickel or nickel-cobalt alloy is adopted to serve as the bonding agent so as to fixedly bond the abrasives. The grinding wheel is capable of controlling the cutting state of the abrasive particles in a grinding region, the cooling liquid distribution and the grinding temperature distribution, and achieving lowest grinding force and specific energy consumption, lowest grinding temperature and burn, lowest abrasion of the grinding wheel, optimal work-surface surface integrity, and the like. The comprehensive grinding performance of the head face grinding of the super-hard abrasive grinding wheel is improved.

Owner:SHENYANG LIGONG UNIV

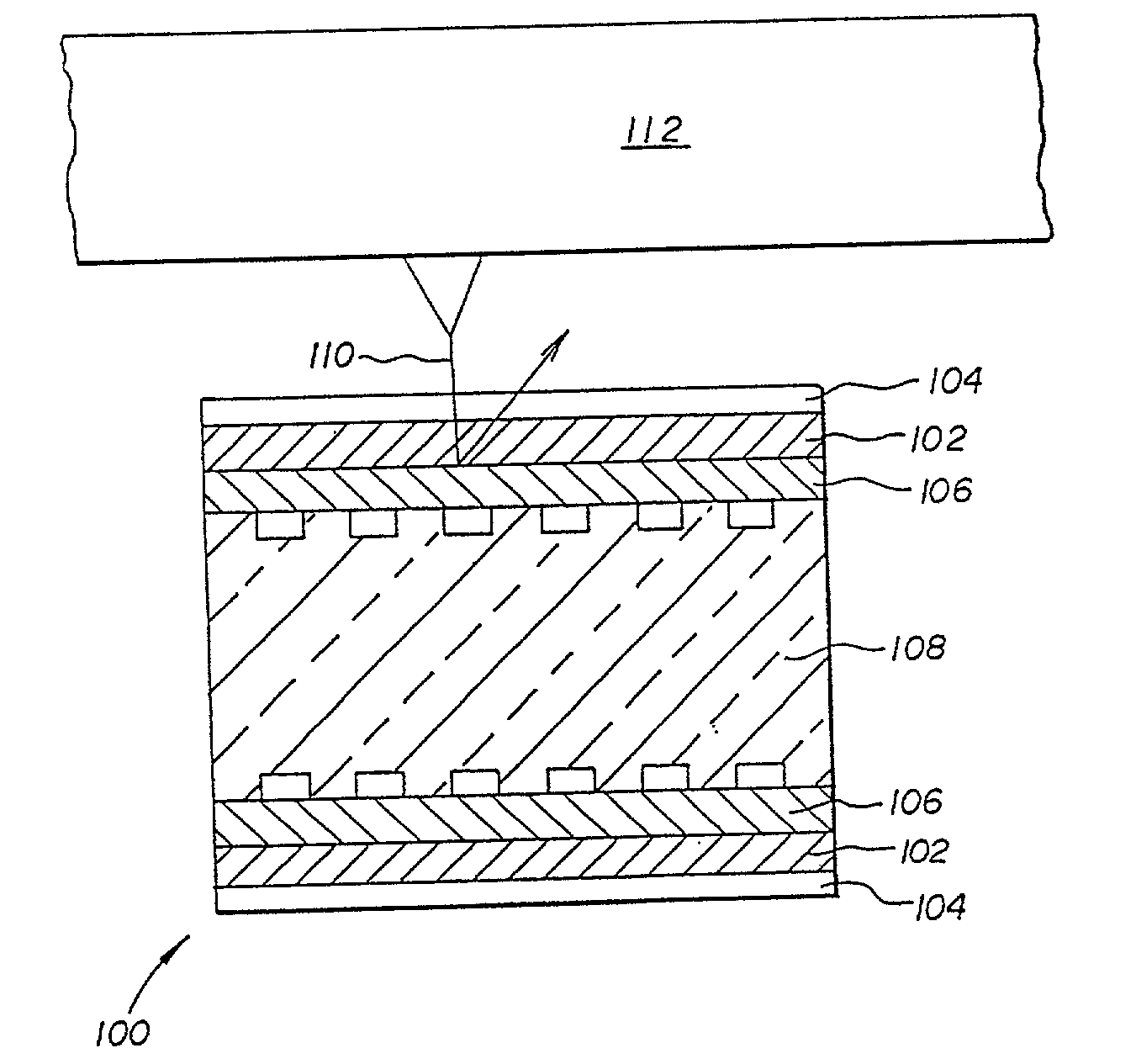

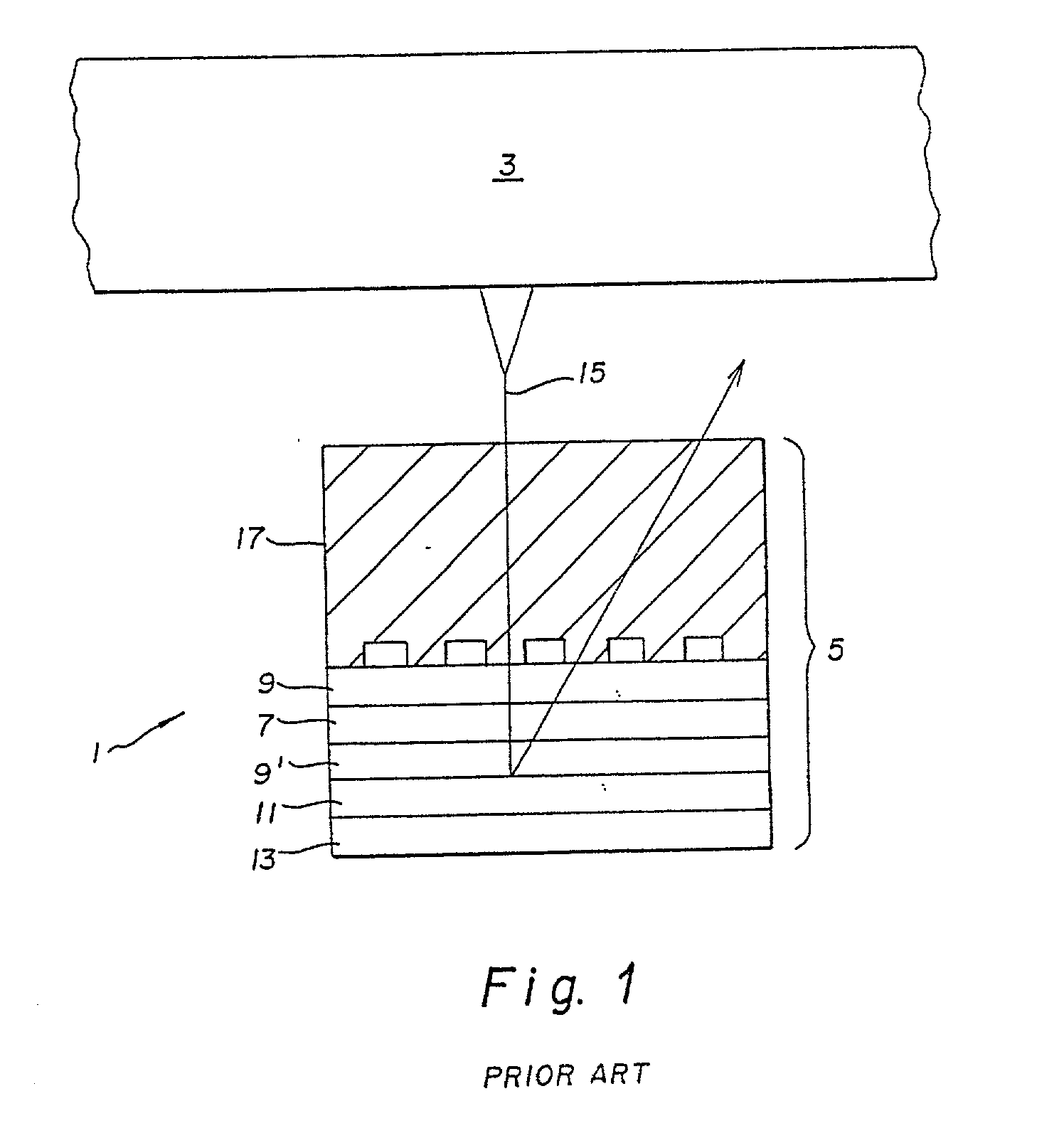

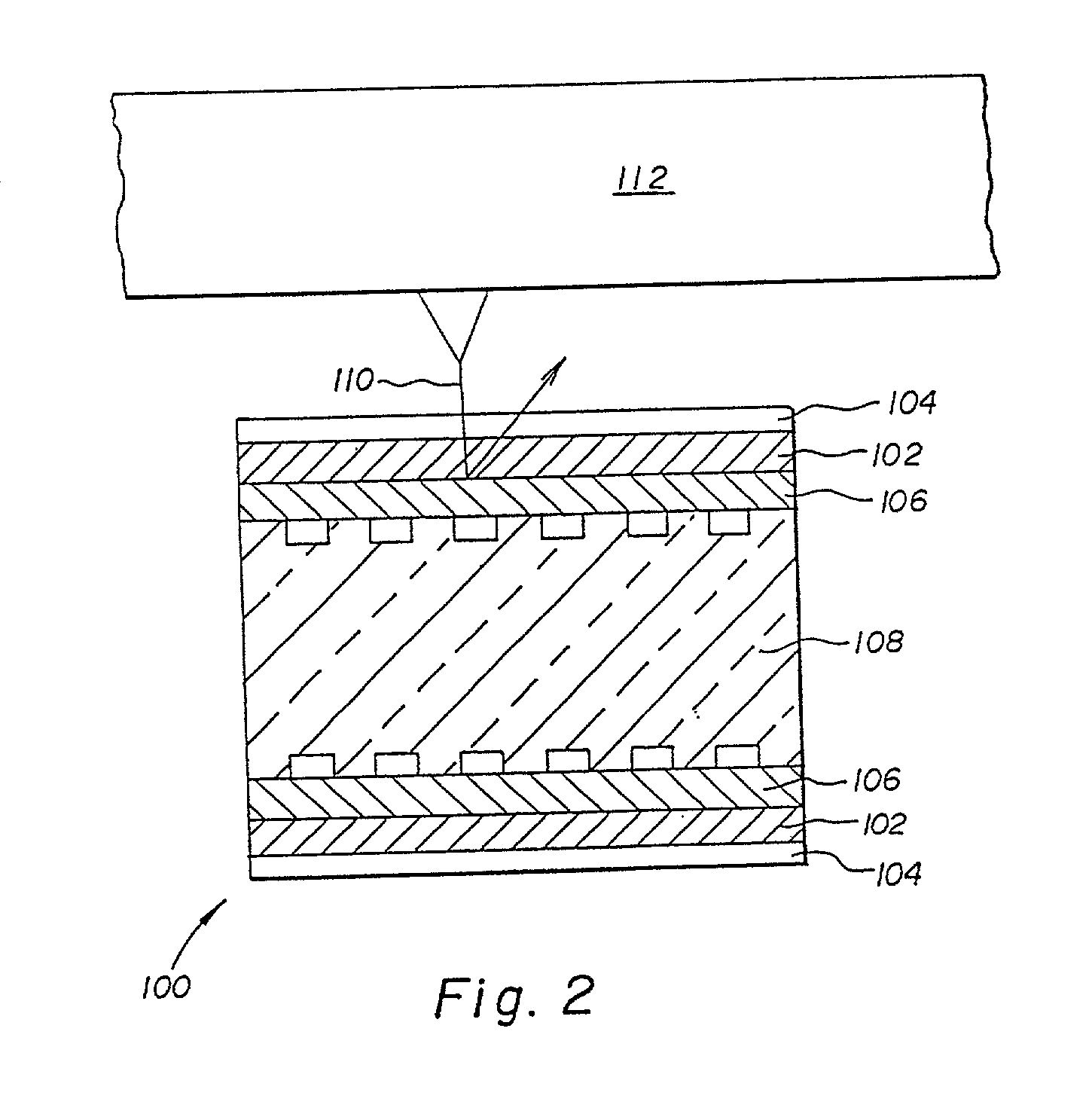

Data storage media

InactiveUS20020048691A1Save energyLinear velocityMaterial nanotechnologyRecord carriersElectricityEngineering

The data storage media comprises, in a preferred embodiment, a homogenous or non-homogenous plastic substrate that can be formed in situ with the desired surface features disposed thereon on one or both sides, a data storage layer such as a magneto-optic material also on one or both sides, and an optional protective, dielectric, and / or reflective layers. The substrate can have a substantially homogenous, tapered, concave, or convex geometry, with various types and geometries of reinforcement employed to increase stiffness without adversely effecting surface integrity and smoothness.

Owner:DAVIS JOHN E +12

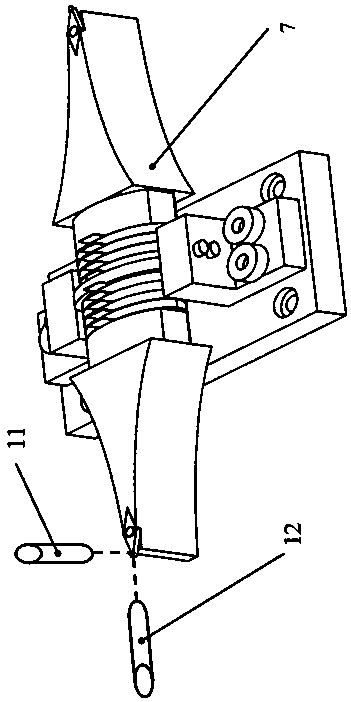

Processing method for realizing integrity of surface of titanium alloy impeller

The invention relates to a processing method for realizing integrity of a surface of a titanium alloy impeller. Through selection for equipment, designs for processes and setting for parameters, the integrity of the surface of the impeller reaches a required standard; meanwhile, in order to ensure a requirement on luminosity of the surface of the impeller, an abrasive particle flow surface polishing technology is adopted. According to the processing method, service life of the impeller is effectively improved, and an effect is obvious when the processing method is applied to an actual processing process for products.

Owner:HARBIN DONGAN ENGINE GRP

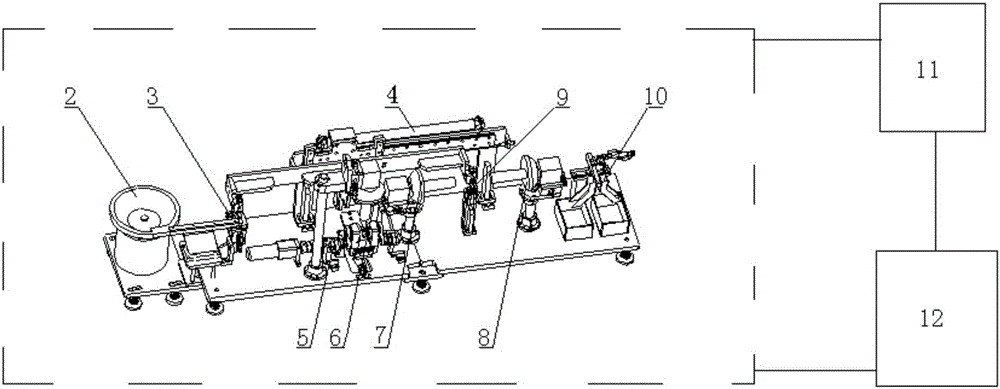

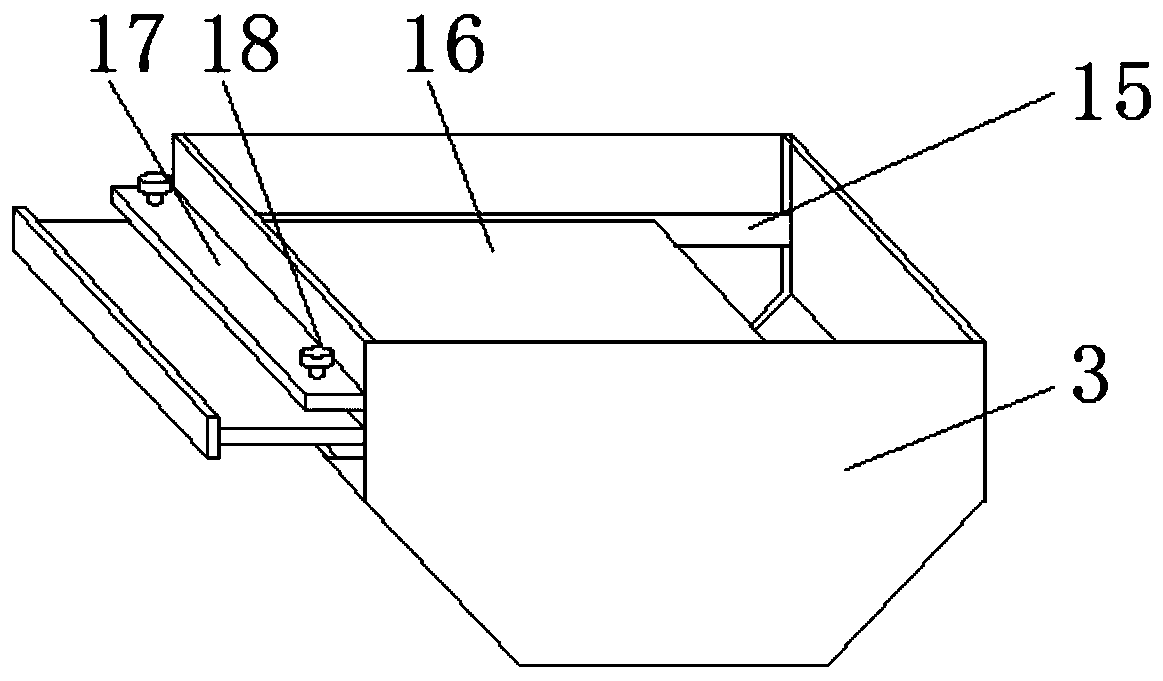

Fuel pellet boundary dimension and apparent defect detection device and method

InactiveCN105737748AEnsure safetySimple methodOptically investigating flaws/contaminationUsing optical meansImaging processingRanking

The present invention relates to a fuel pellet boundary dimension and apparent defect detection device and method. The detection device comprises a mechanical device and two sets of image acquisition devices which are arranged inside a glove box and an image processing system arranged outside the glove box, and measures the diameter and the surface integrity of a fuel pellet automatically via the automatic ranking, feeding, transporting, rotating and discharging operations. The two sets of visual light image acquisition devices acquire the parameters of a cylindrical surface and two end faces of the fuel pellet respectively, and send the acquired complete cylindrical surface and end face images to the image processing system when the fuel pellet arrives at the detection positions orderly, and the image processing system analyzes, processes and determines the results automatically to sort the good and bad materials. The detection method comprises processing the boundary dimension images, the side surface images and the end face images. The detection device and method of the present invention can substitute for the manpower to finish the diameter and appearance integrity inspection of the fuel pellet automatically, and does not lose and cause the new damage during the inspection process.

Owner:CHINA NUCLEAR POWER ENG CO LTD

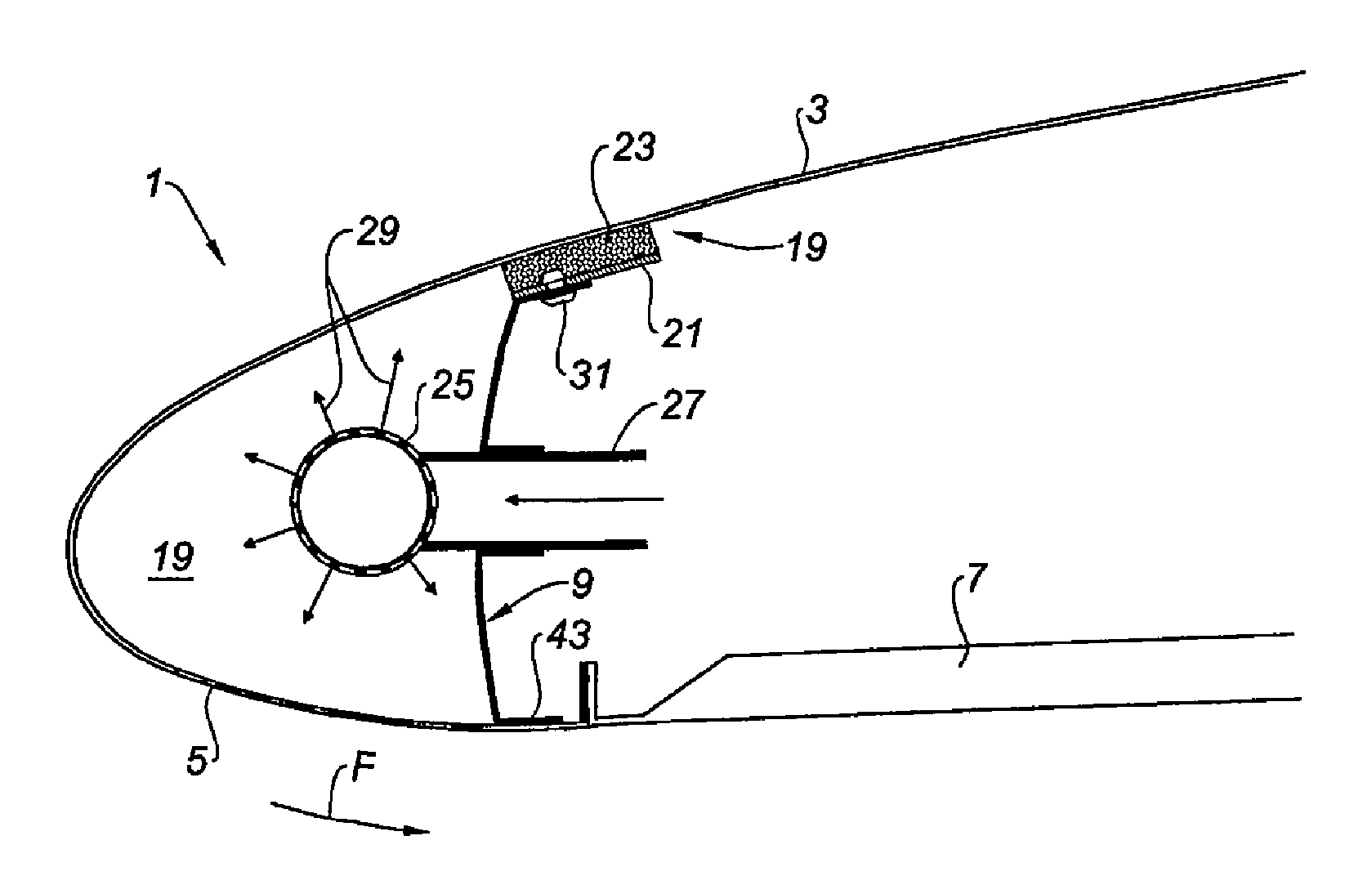

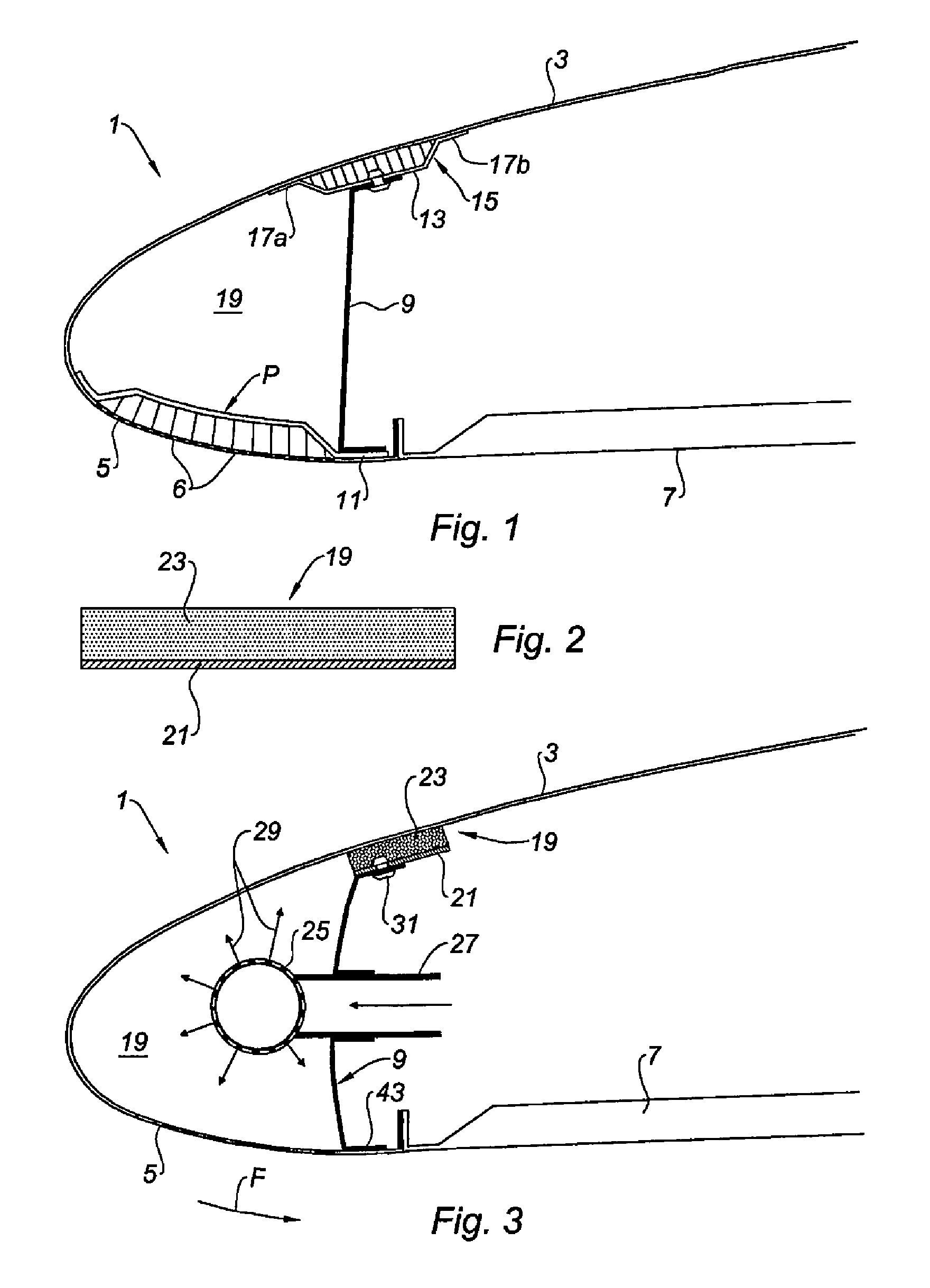

Assembly of components connected by a device that maintains the integrity of the surface of one of the components

InactiveUS20110131945A1Reduce weightPreserve integrityEngine fuctionsLayered productsSurface integrityBiomedical engineering

This assembly comprises a first component (9), a second component (3), and a connecting device (19) for connecting these two components together, this device (19) being of the type that maintains the integrity of the surface of said second component (3), and the assembly being noteworthy in that said connecting device (19) comprises a structural skin (21) fixed to said first component (9) and a porous material (23) attached to this structural skin and fixed by contact to said second component (3).

Owner:AIRCELLE

Preservation of wood products

InactiveUS6753016B2Maintain stabilityMaintain surfaceBiocideHeavy metal active ingredientsInorganic saltsIron salts

A method for the protection of wood and other wood materials without affecting dimensional stability or surface integrity of the treated material is described. The method involves treating wood material with an iron salt and selected oxidants where the iron salt is preferably complexed with organic chelating ligands. Preferably, a microbicidal agent is also incorporated into the method to provide treated wood products that demonstrate excellent surface integrity, dimensional stability and retention of the infused microbicidal agents for extended periods of time without incurring the detrimental environmental effects of conventional chromium or copper-based inorganic salt preservation methods.

Owner:ROHM & HAAS CO

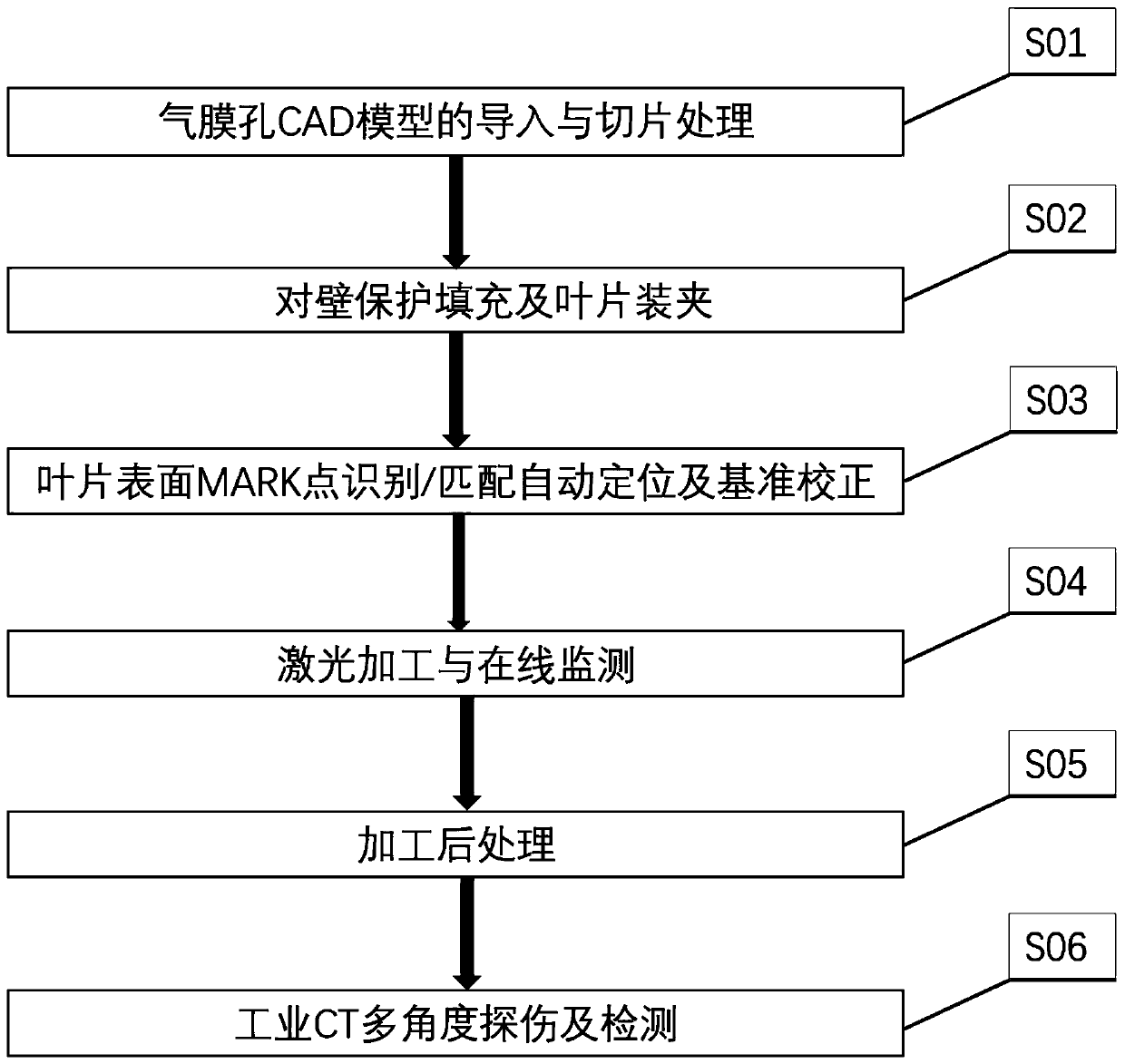

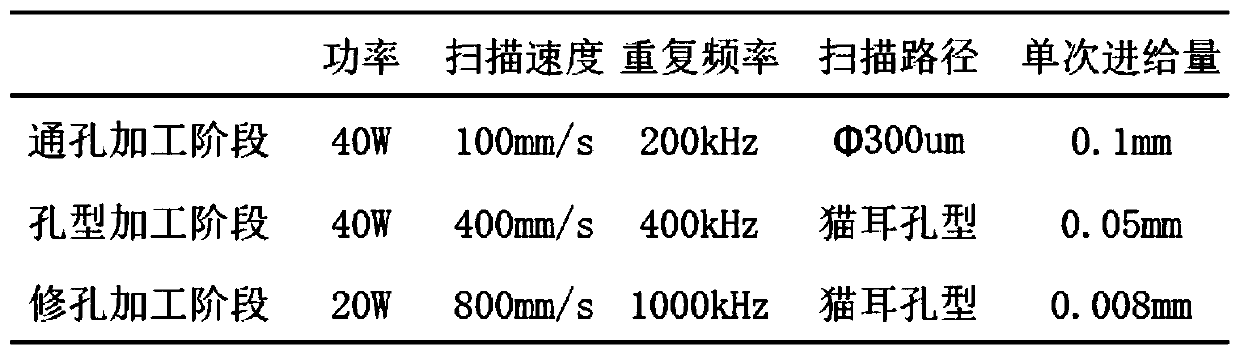

Laser machining process of special-shaped film hole of turbine blade

PendingCN110640339AGuaranteed positioning accuracyReal-time correction of coordinate position deviationLaser beam welding apparatusLaser processingTurbine blade

The invention relates to a laser machining process of a special-shaped film hole of a turbine blade. The process comprises the following steps of film hole CAD model introducing and slicing; wall protecting and filling, and blade assembling and clamping; blade surface MARK point identifying / matching automatic positioning and reference correcting; laser machining and online monitoring; post-machining treatment; and industrial CT multi-angle flaw detection and detecting. The machining process has the beneficial effects of realizing precise machining of the complex special-shaped film hole, improving the surface integrity of film hole machining, having great significance for improving the quality of a turbine engine / gas turbine, and providing technical support for the development of a newgeneration turbine-type aero-engine and marine gas turbine.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

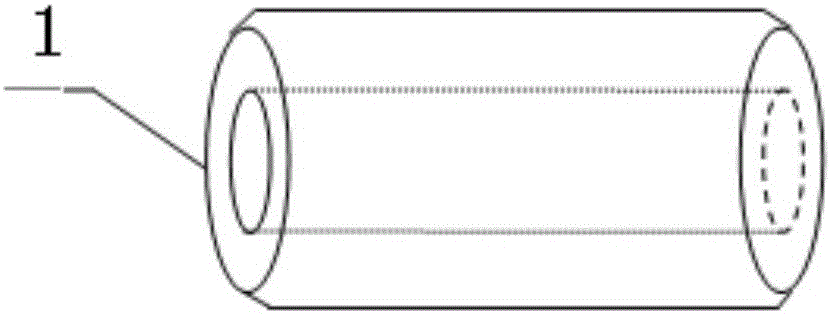

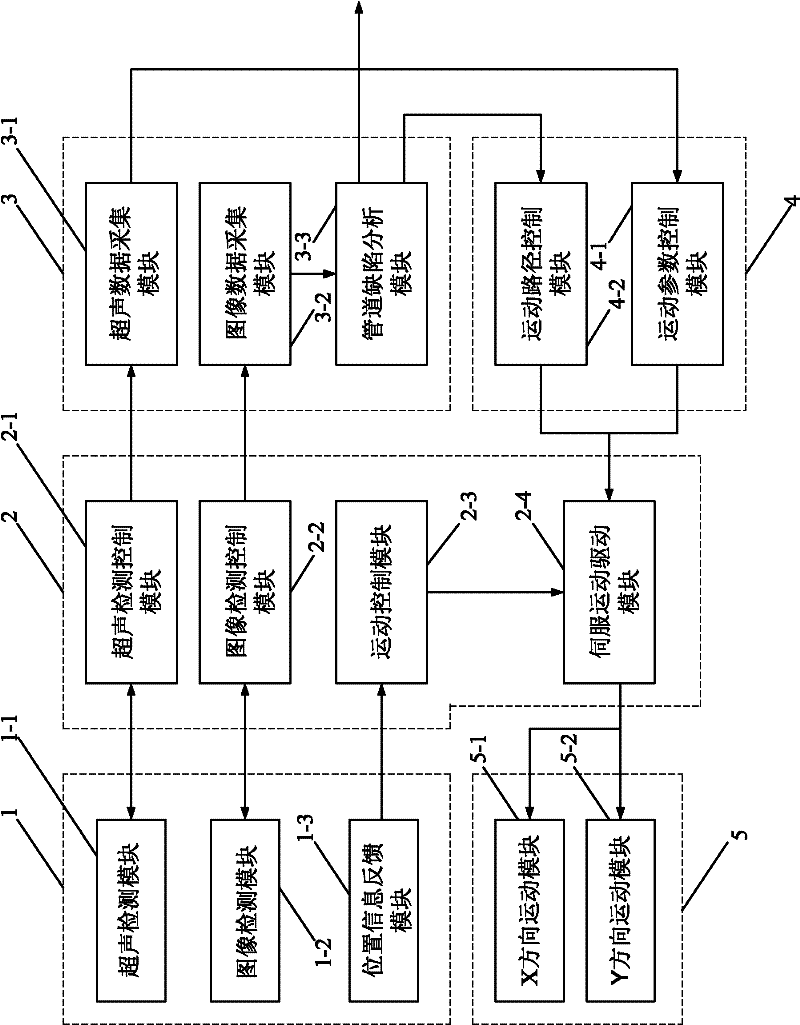

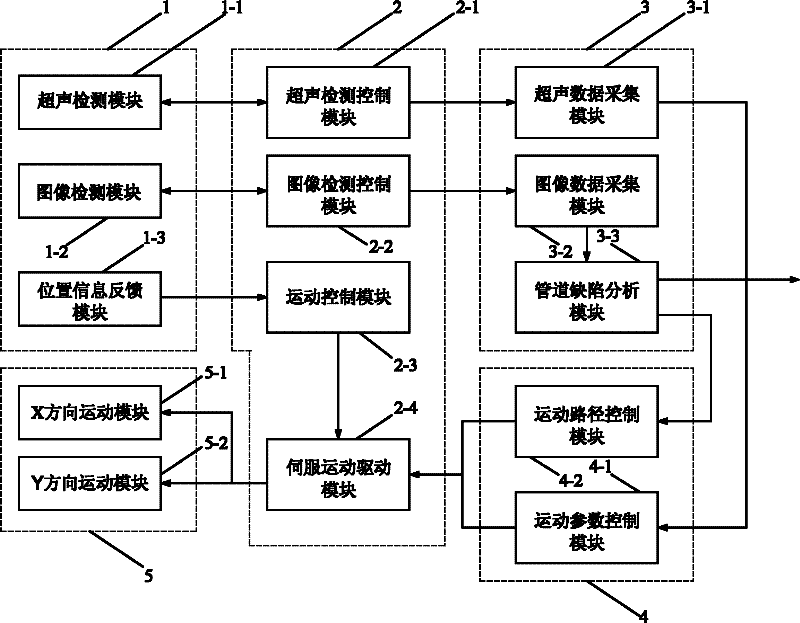

Pipeline defect surface integrity detection device and detection method

InactiveCN102162577AAccurate acquisitionEfficient acquisitionPipeline systemsElement analysisImage detection

The invention discloses a pipeline defect surface integrity detection device and a pipeline defect surface integrity detection method for solving the problem that the damage degree of a pipeline is difficult to judge because the conventional pipe detection device has different detection sensitivities for different materials and defects of different types and the measurement data are independent with one another. The ultrasonic detection data signal output / input end, the image detection data signal output / input end and the position information data output end of a detection assembly are connected with the ultrasonic detection data signal input / output end, the image detection data signal input / output end and the position information data input end of a control assembly respectively. The method comprises the following steps of: 1, acquiring image data of a pipeline damaged surface, and calculating a pipeline defect surface area and a damage characteristic parameter; 2, detecting the thickness information in a limited area; 3, performing integrity three-dimensional entity modeling of the defect surface and the damaged area; and 4, obtaining a result by using a finite element analysis method. The device and the device can accurately judge the damage degree of the pipeline and are applied to the occasions of defect surface integrity detection.

Owner:HARBIN INST OF TECH

Apparatus and method for improving work surface during forming and shaping of materials

ActiveUS7513121B2High surface hardnessLow costLiquid surface applicatorsFurnace typesSurface finishHardness

Owner:AIR PROD & CHEM INC

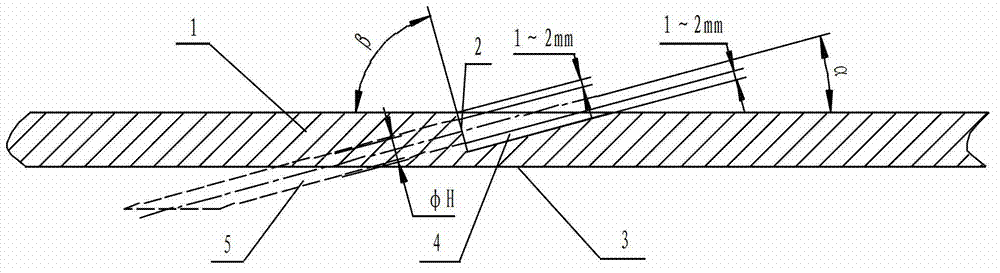

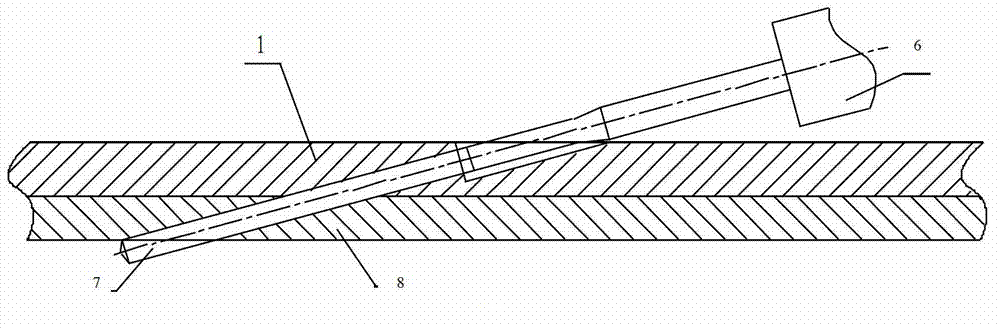

Method for processing deep minipore with large gradient on difficult-to-process material

The invention provides a method for processing a deep minipore with large gradient on a difficult-to-process material. The method comprises the following steps of: adding and fixing a cutting force balancing guide plate with reasonable thickness, excellent cutting performance and good locating cooperation and firm adhesion with a workpiece on the workpiece, milling an inclined plane vertical to the central axis of the hole on the guide plate through a large diameter milling tool, and converting deep inclined minipore processing into common minipore processing to solve the problems of large gradient of the difficult-to-process material, chip breaking, chip discharge, chip removal, cutter back-off, cutter vibration and cutter striking in the deep minipore cutting processing and the problem that the surface roughness and the length dimension of an entrance cannot meet the demand in direct processing, and the method provides reliable technical support for integral surface processing and anti-fatigue manufacturing and provides guarantee for improving the service life and safety of the parts.

Owner:AECC AVIATION POWER CO LTD

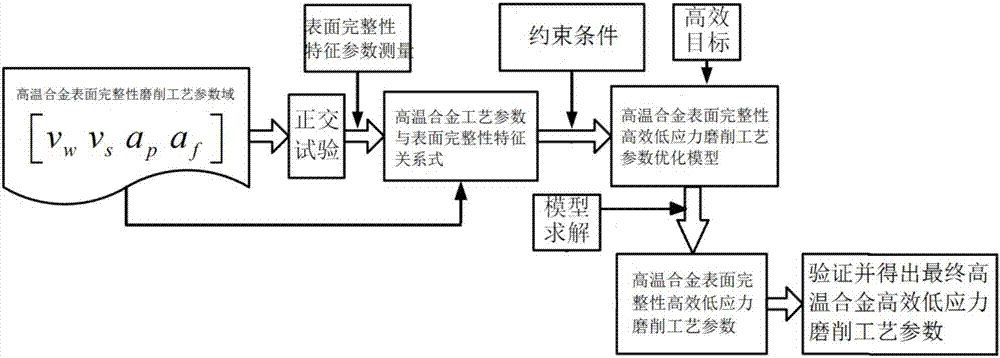

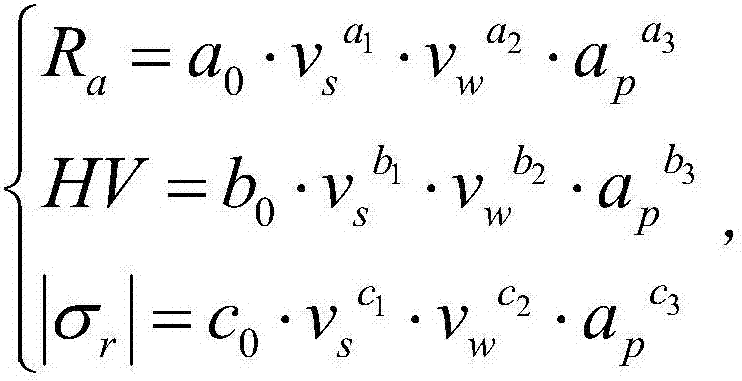

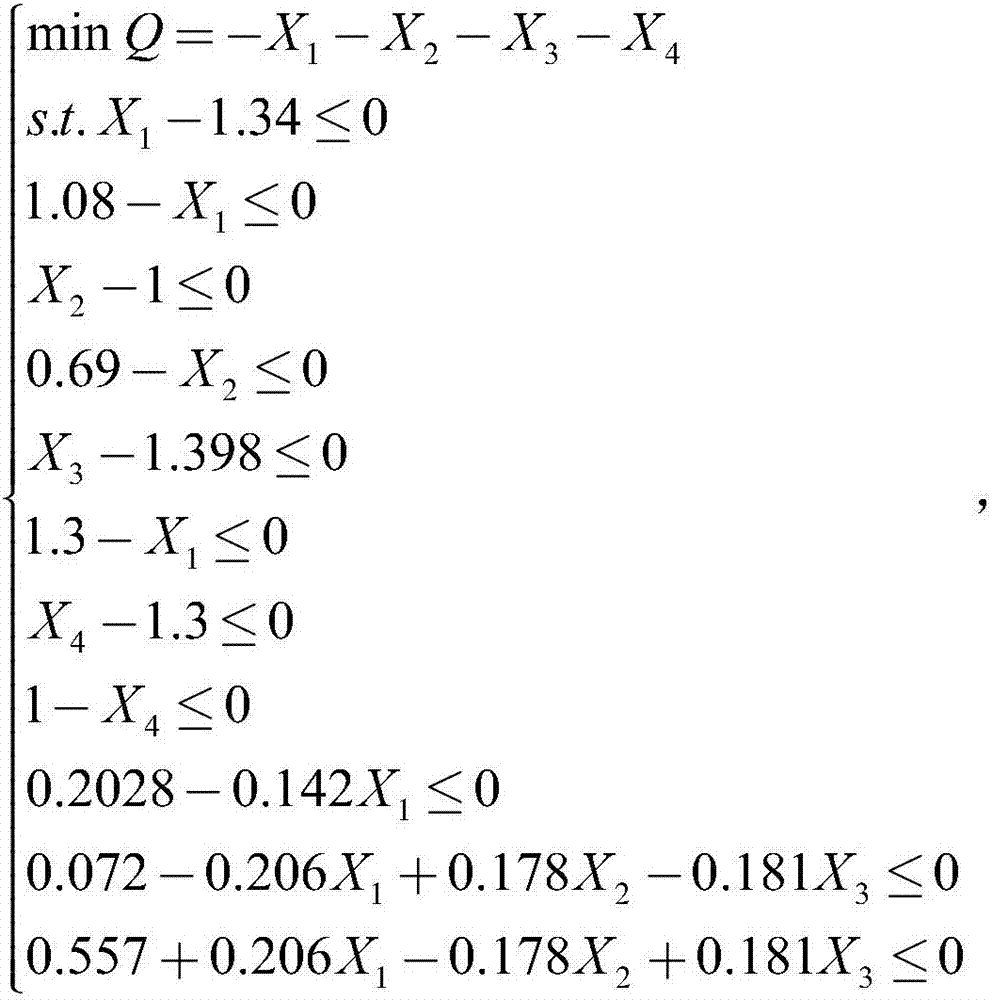

Method for obtaining high temperature alloy efficient low-stress grinding process parameters

ActiveCN106897484AGrinding process parameters are efficientSurface Integrity EfficientGeometric CADDesign optimisation/simulationSuperalloySurface integrity

The invention discloses a method for obtaining high temperature alloy efficient low-stress grinding process parameters. The method is characterized by comprising the steps that 1, a high temperature alloy surface integrity grinding process parameter domain and a relation between high temperature alloy surface integrity grinding process parameters and surface integrity features are established; 2, an objective function is established, linear processing is performed, and high temperature alloy grinding process parameter constraint conditions are established; 3, a high temperature alloy efficient low-stress grinding process parameter optimization model is established, and high temperature alloy efficient low-stress grinding process parameters are obtained; and 4, the high temperature alloy efficient low-stress grinding process parameters are verified to obtain final high temperature alloy efficient low-stress grinding process parameters. Through the method, the problems that in the existing high temperature alloy component grinding process, surface residual stress is large, and grinding efficiency is low are solved.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

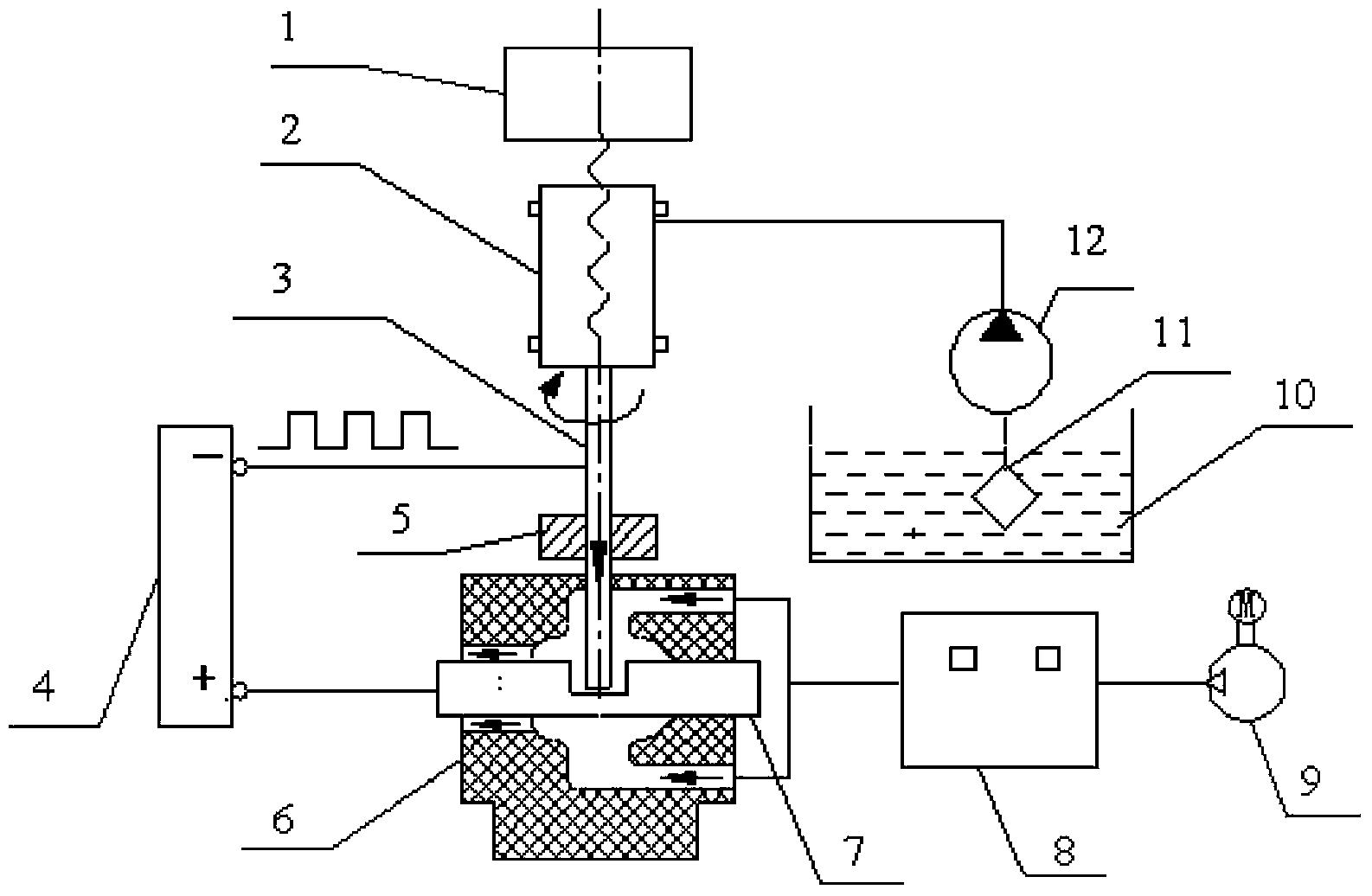

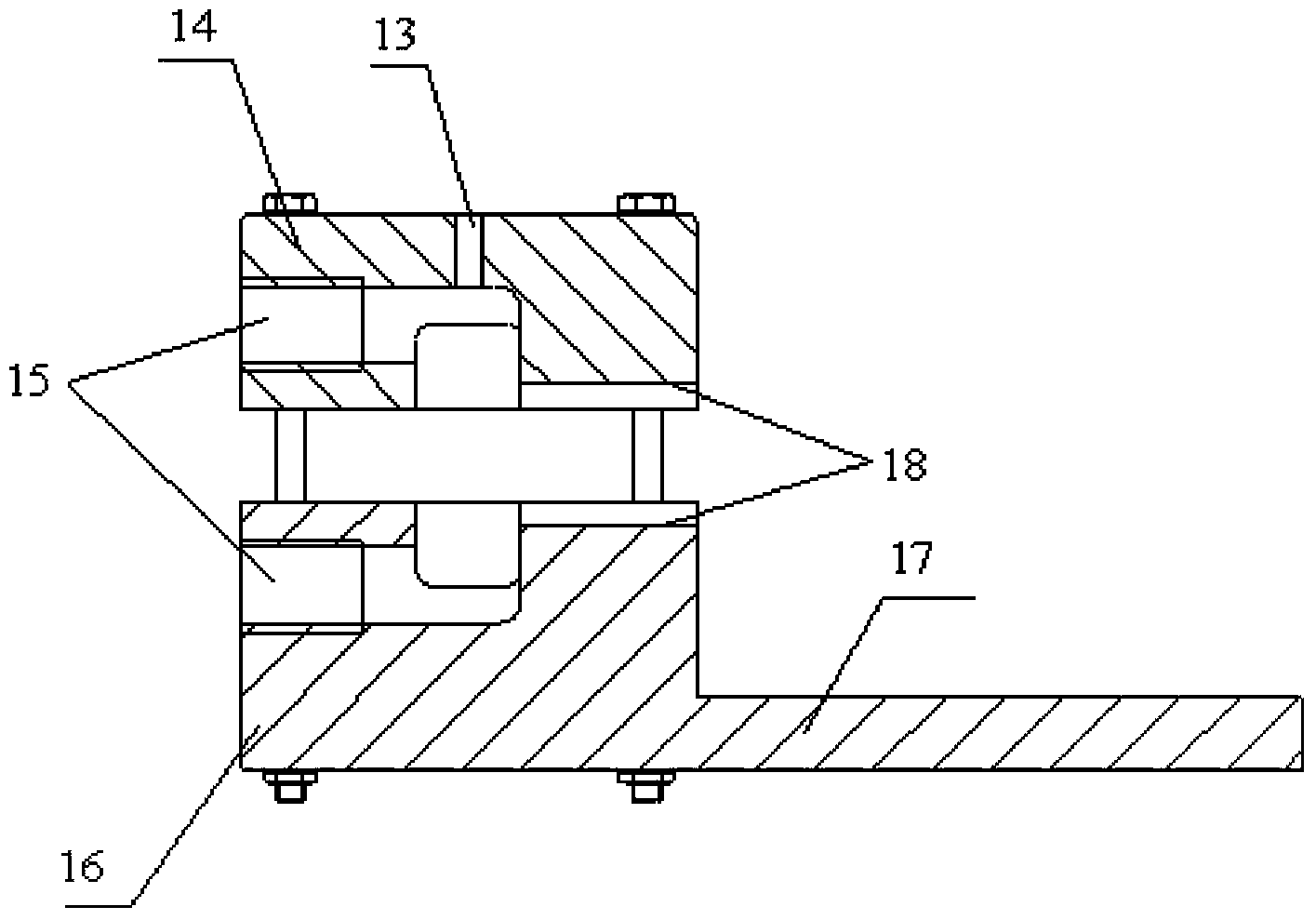

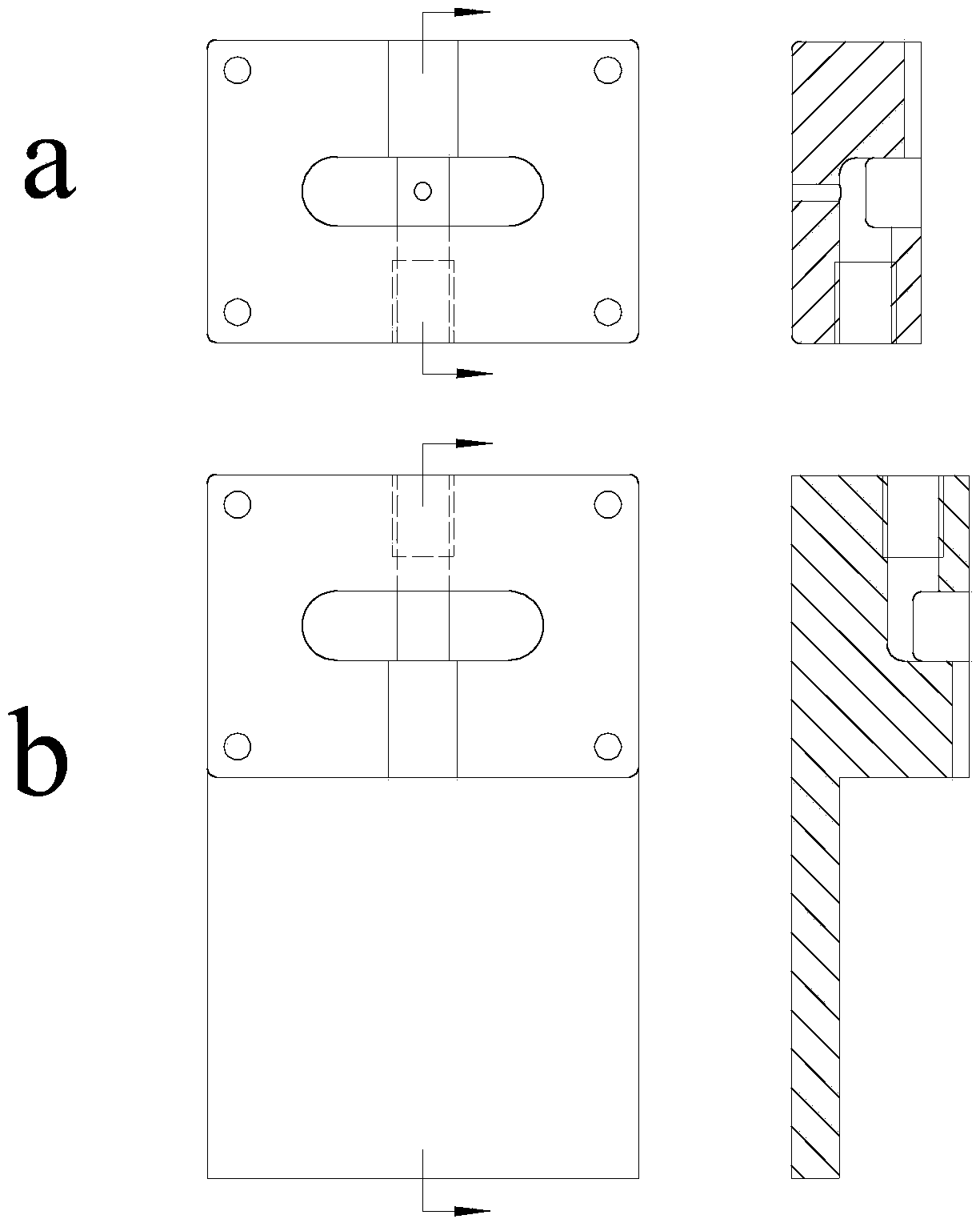

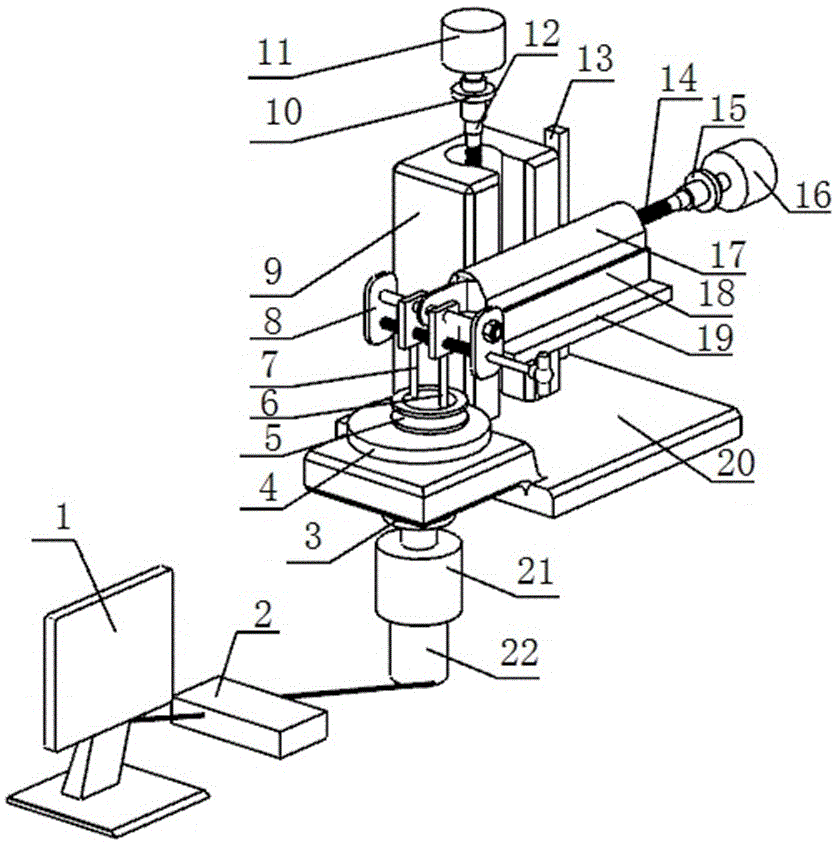

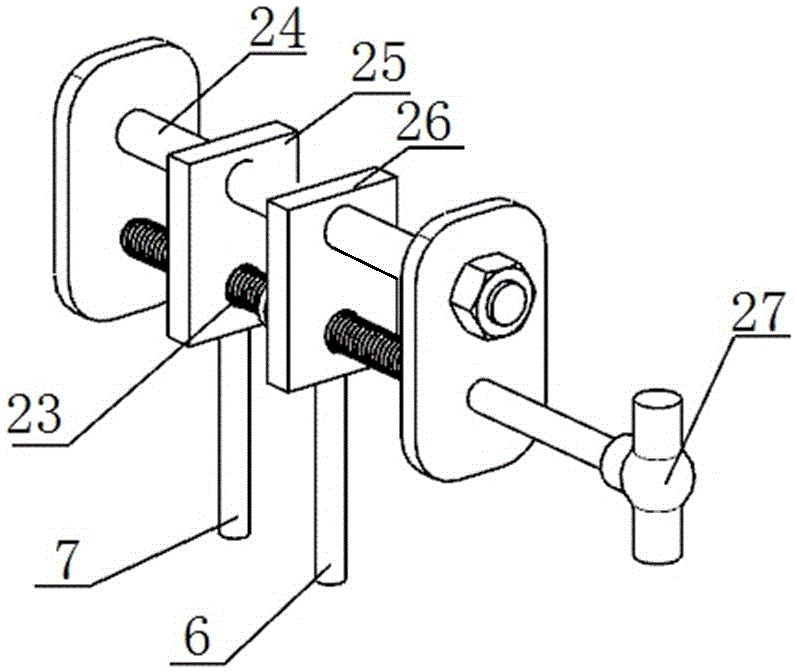

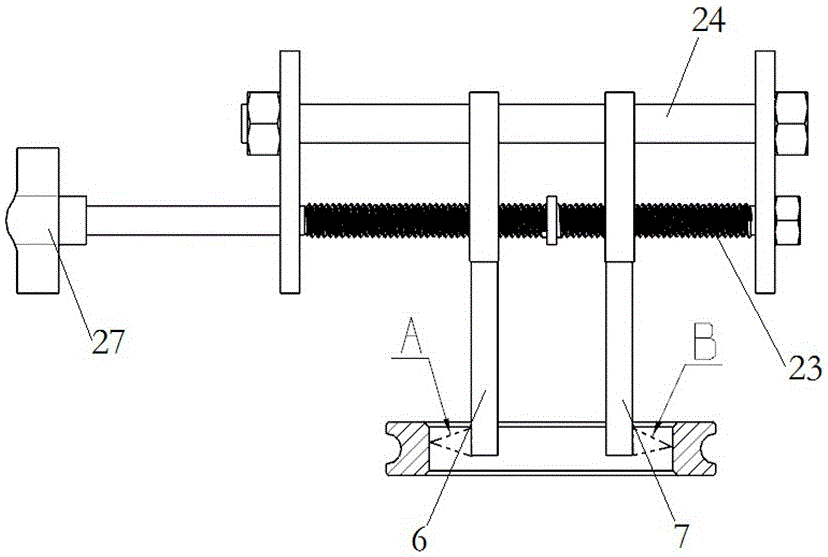

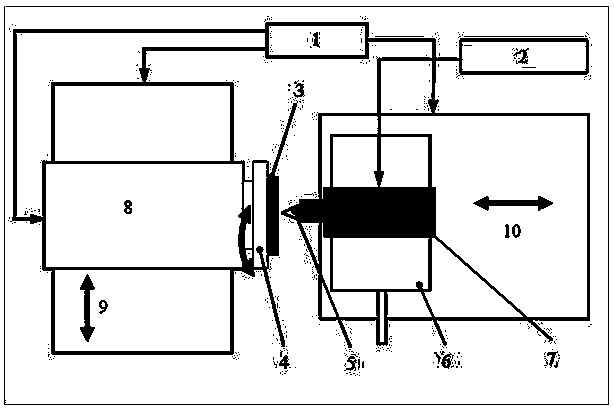

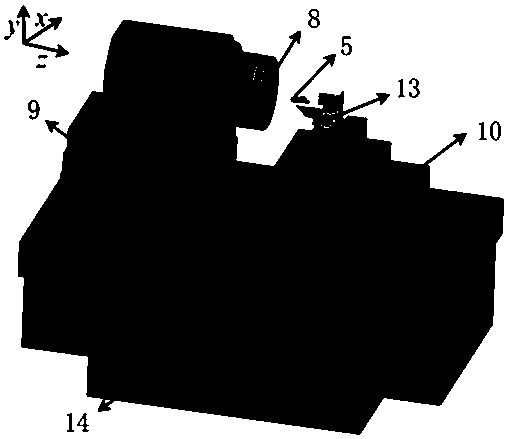

Method and device for improving electric spark high-speed piercing finished surface integrity

ActiveCN103551688AHigh speed conductionAccelerated exclusionElectrical-based auxillary apparatusElectric dischargeHeat-affected zone

The invention relates to an electric spark machining method and device for improving electric spark high-speed perforating finished surface integrity. The method comprises the steps of: when an electric spark high-speed perforating machine is adopted for machining, applying low-temperature water mist at a certain pressure and a certain flow speed to inlet and outlet surfaces of a to-be-machined hole of a work-piece so as to cool and remove a machining product rapidly, reduce a heat affected zone and a secondary electric discharge phenomenon, and realize the purpose of improving finished surface integrity. The device for improving the electric spark high-speed perforating finished surface integrity comprises an electric spark high-speed perforating machine, an air compressor, a minimum quantity lubrication spraying device, a machining work-piece, a tool electrode and a clamp. The method is steady in technology, efficient and low in cost.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

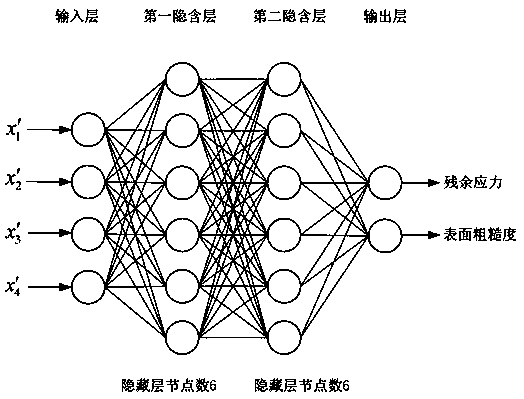

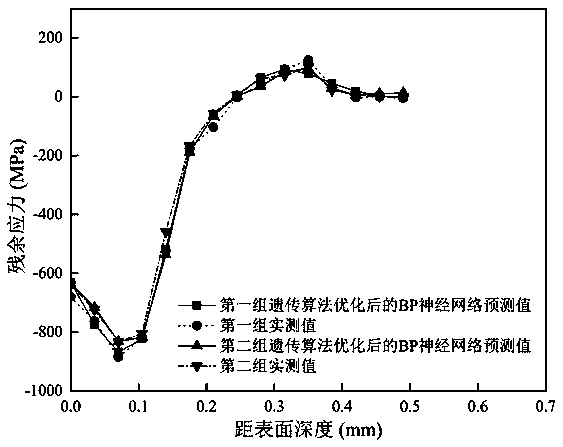

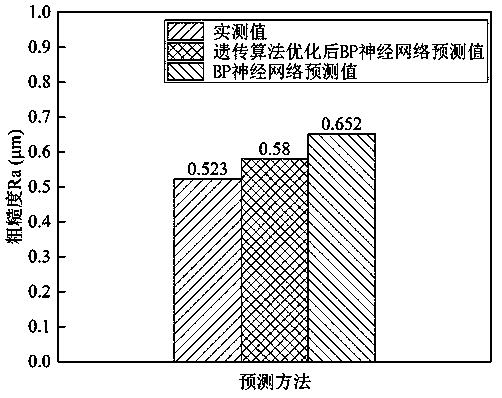

Shot peening strengthening surface integrity prediction method based on BP neural network

PendingCN111401623AAchieving residual stressAchieving Surface RoughnessForecastingProcess efficiency improvementPattern recognitionActivation function

The invention discloses a shot peening strengthening surface integrity prediction method based on a BP neural network. The method comprises the following steps: 1, collecting and arranging part shot peening strengthening test data, and determining input and output parameters of a surface integrity prediction model by analyzing process parameters and surface integrity evaluation indexes influencingshot peening performance in a shot peening strengthening process; preprocessing the data; 2, determining a hidden layer activation function type and a hidden layer node number, and constructing a BPneural network structure; 3, optimizing the initial weight and bias of the BP neural network through a genetic algorithm, and establishing a shot peening strengthening residual stress and surface roughness prediction model; 4, determining the weight and bias in the BP neural network structure according to the precision evaluation parameter R2; 5, predicting the shot peening strengthening residualstress and surface roughness by using the trained model meeting the precision requirement. The test cost of the shot peening strengthening process can be reduced, and the efficiency of the shot peening process is improved.

Owner:CHONGQING UNIV

Preservation of wood products

InactiveUS20030086979A1Shorten treatment timeIncreases level of penetrationBiocideHeavy metal active ingredientsInorganic saltsIron salts

A method for the protection of wood and other wood materials without affecting dimensional stability or surface integrity of the treated material is described. The method involves treating wood material with an iron salt and selected oxidants where the iron salt is preferably complexed with organic chelating ligands. Preferably, a microbicidal agent is also incorporated into the method to provide treated wood products that demonstrate excellent surface integrity, dimensional stability and retention of the infused microbicidal agents for extended periods of time without incurring the detrimental environmental effects of conventional chromium or copper-based inorganic salt preservation methods.

Owner:ROHM & HAAS CO

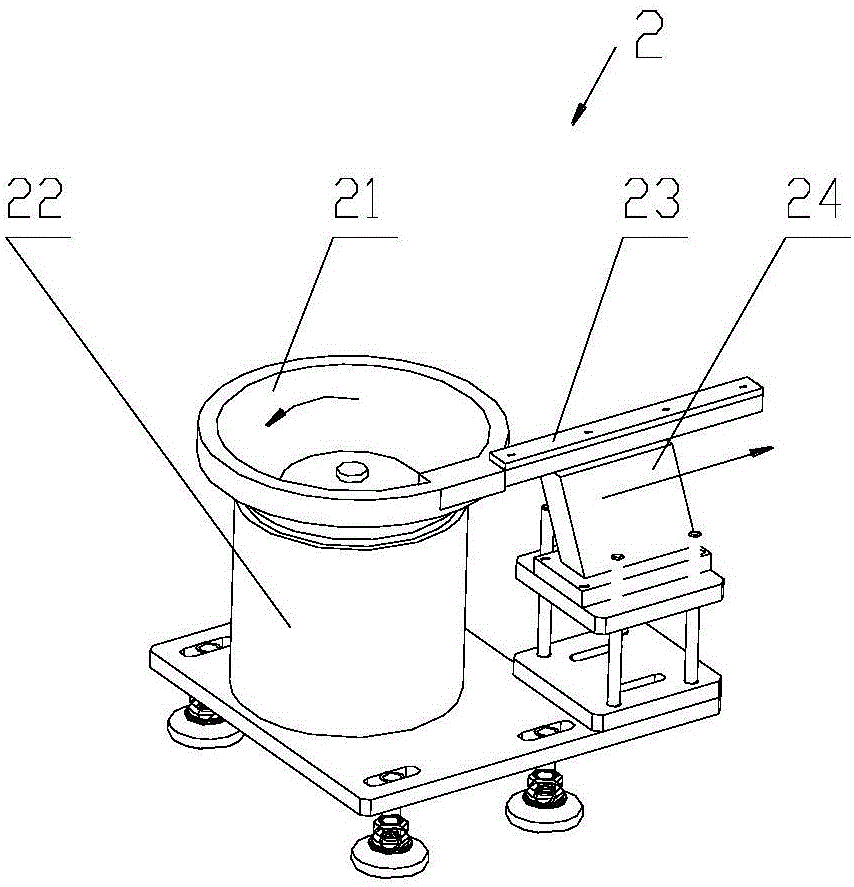

Noncontact bearing ring outside diameter measurement device

InactiveCN106705869AGuaranteed Surface IntegrityAvoid scratchesUsing optical meansMeasurement deviceEngineering

The invention relates to a noncontact bearing ring outside diameter measurement device, comprising a sensor mounting rack, wherein two laser displacement sensors distributed at interval in the radial direction of a bearing ring are arranged on the sensor mounting rack, each laser displacement sensor is provided with a measuring head facing the outer surface of the bearing ring, the measuring heads of the two laser displacement sensors are arranged oppositely, and the measurement device further comprises a rotation driving mechanism for realizing relative rotation between the bearing ring to be measured and the two laser displacement sensors. By adopting the noncontact laser displacement sensors for measuring, parts to be measured can be effectively prevented from being scratched, and the surface integrity of the parts is ensured. Relative rotation between the bearing ring and the two laser displacement sensors is realized by using the rotation driving mechanism, and the outside diameter and outside diameter changes of the bearing ring at different angles can be measured, so that the measurement precision is effectively improved.

Owner:HENAN UNIV OF SCI & TECH

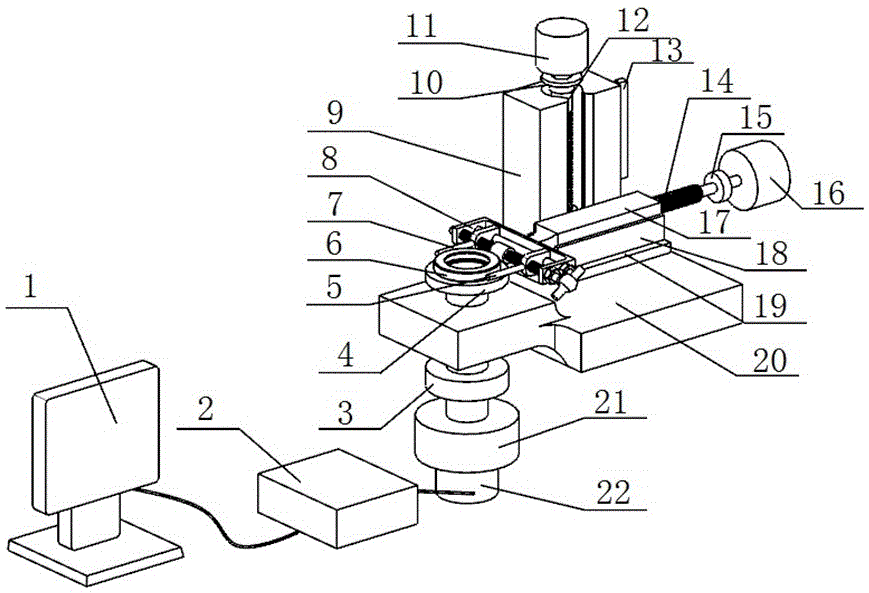

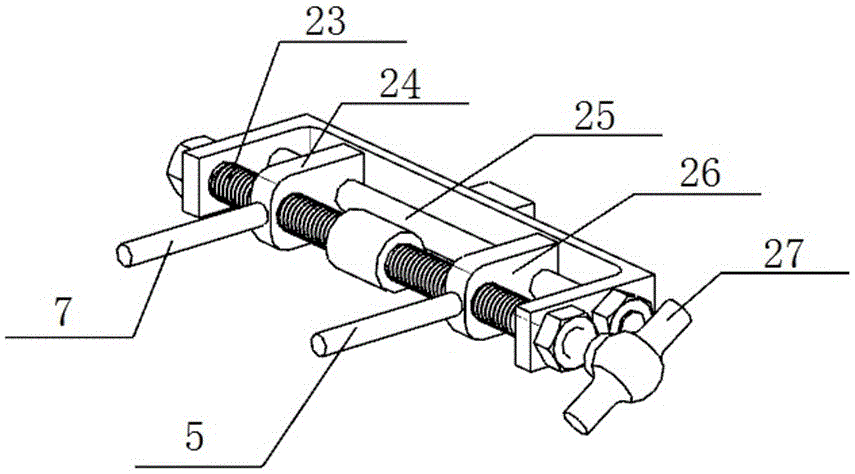

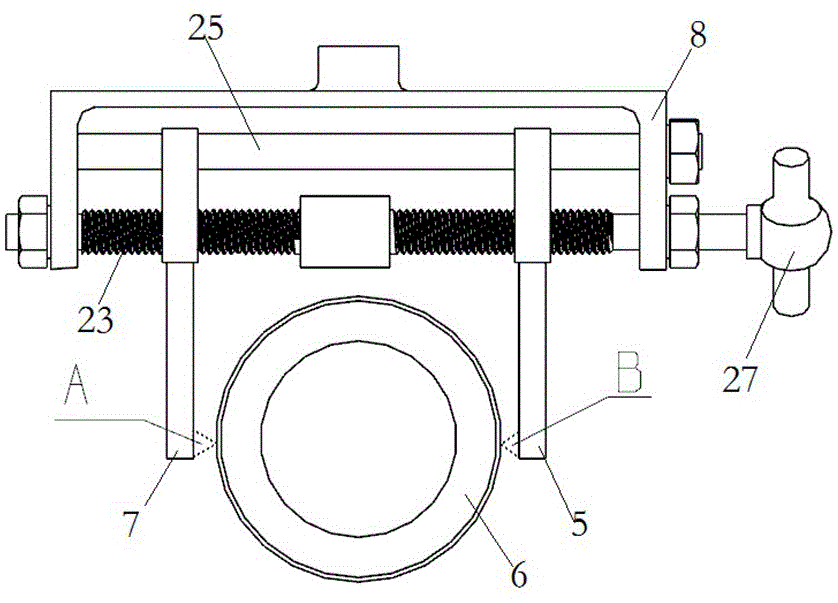

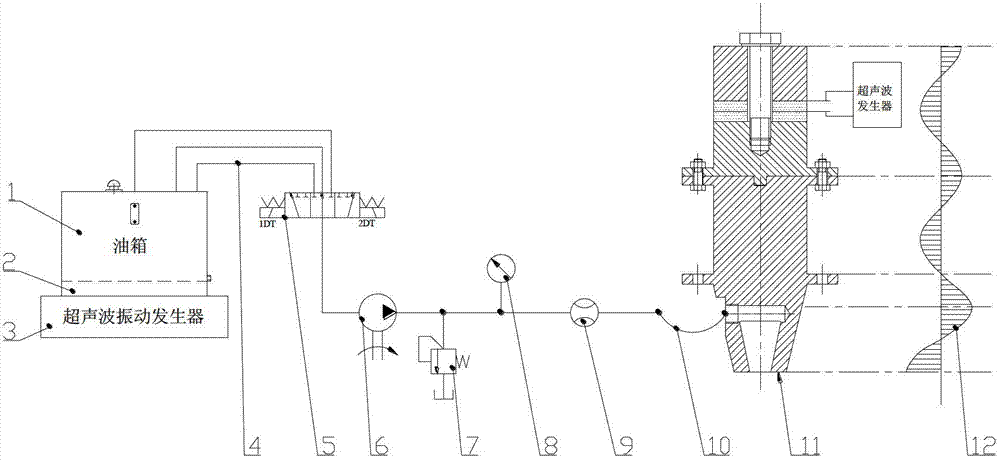

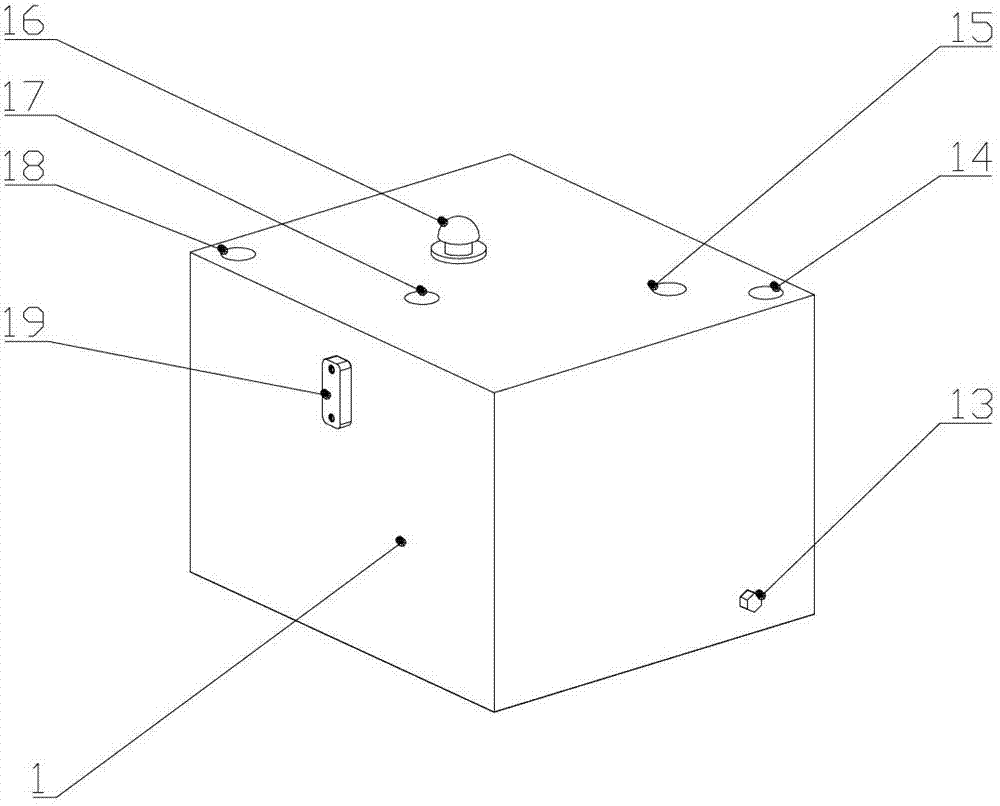

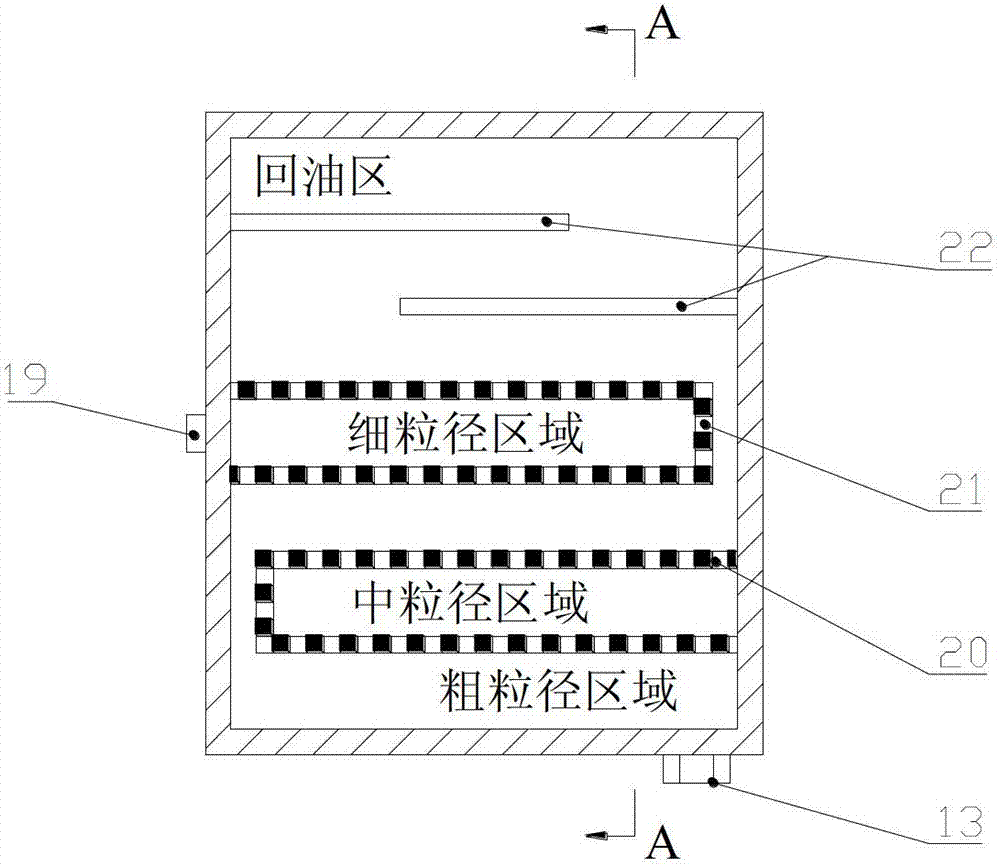

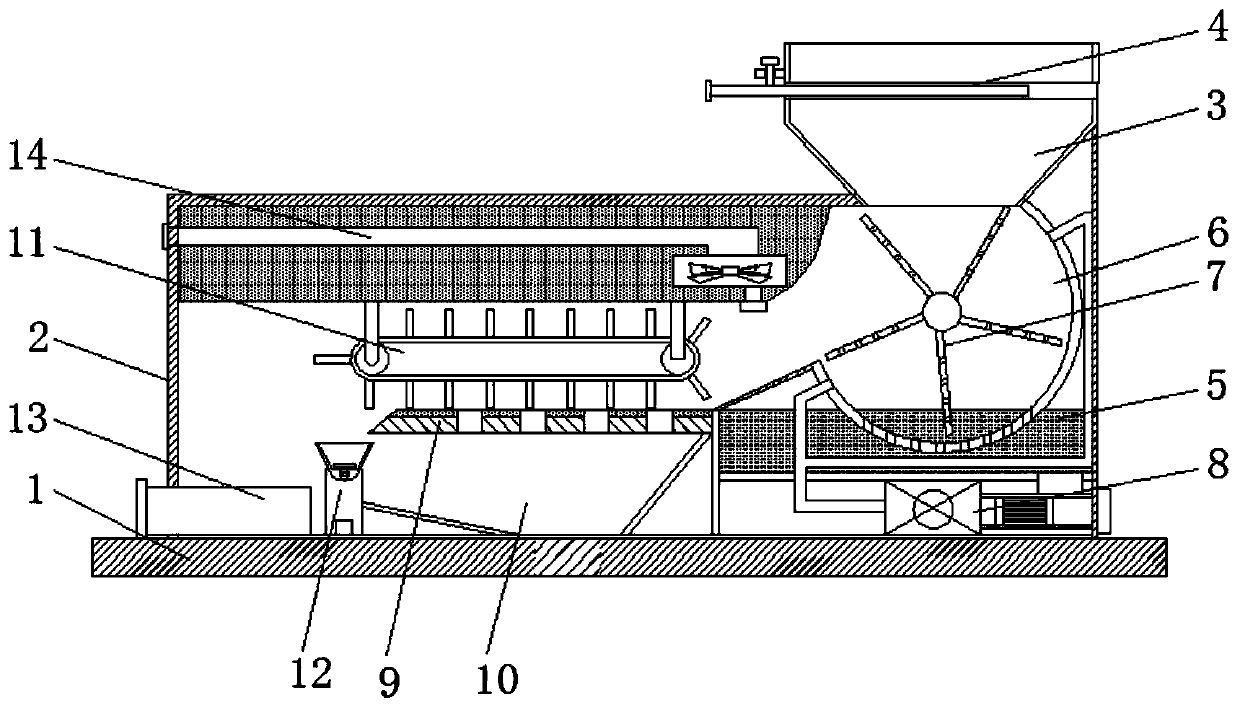

Solid particle grinding fluid combined machining process and device

ActiveCN102729101AImprove abilitiesImprove sharpening effectGrinding/polishing apparatusFuel tankResource saving

The invention relates to a solid particle grinding fluid combined machining process and a solid particle grinding fluid combined machining device. The device comprises an oil tank, wherein the oil tank is connected with an ultrasonic vibration generator through an electromagnet; a coarse particle size region, a middle particle size region and a fine particle size region are formed inside the oil tank; each region is provided with a corresponding oil supply opening and connected with a corresponding hydraulic pipeline; the hydraulic pipelines are connected with an electromagnetic directional valve; an outlet of the electromagnetic directional valve is connected with a slurry pump and an overflow valve through the hydraulic pipelines; the overflow valve is connected with an ultrasonic vibration spray nozzle through a metal hose; and both the ultrasonic vibration generator and the electromagnet are connected with a controller. By the process and the device, workpieces are ground, lapped and polished and subjected to combined machining by an in-process dressing grinding wheel continuously; the advantages that solid particles are high in cooling performance and impact machining performance are fully utilized; grinding burn is effectively avoided; the surface integrity and machining accuracy of the workpieces are improved; a high-efficiency, low-consumption, environment-friendly and resource-saving low-carbon clean production process is realized; and the process and the device have an important significance.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

Non-contact type bearing ring inside diameter measurement device

InactiveCN106767470AGuaranteed Surface IntegrityAvoid scratchesUsing optical meansControl using feedbackMeasurement deviceContact type

The invention relates to a non-contact type bearing ring inside diameter measurement device, which comprises a sensor mounting frame and a rotation drive mechanism; the sensor mounting frame is provided with two laser displacement sensors which are distributed at intervals in the radial direction of a bearing ring and are provided with measurement heads used for facing the inner surface of the bearing ring outwards when the laser displacement sensors are inserted into the bearing ring respectively; and the rotation drive mechanism is used for realizing relative rotation between the bearing ring to be measured and each laser displacement sensor. According to the non-contact type bearing ring inside diameter measurement device, by adopting the non-contact type laser displacement sensors to carry out measurement, a part to be measured can be effectively prevented from being scratched, and the surface integrity of the part is guaranteed; relative rotation between the bearing ring to be measured and each laser displacement sensor is realized by utilizing the rotation drive mechanism, so that the inside diameters and inside diameter change amounts of the bearing rings at different angle positions can be measured, and the measurement accuracy is effectively improved.

Owner:HENAN UNIV OF SCI & TECH

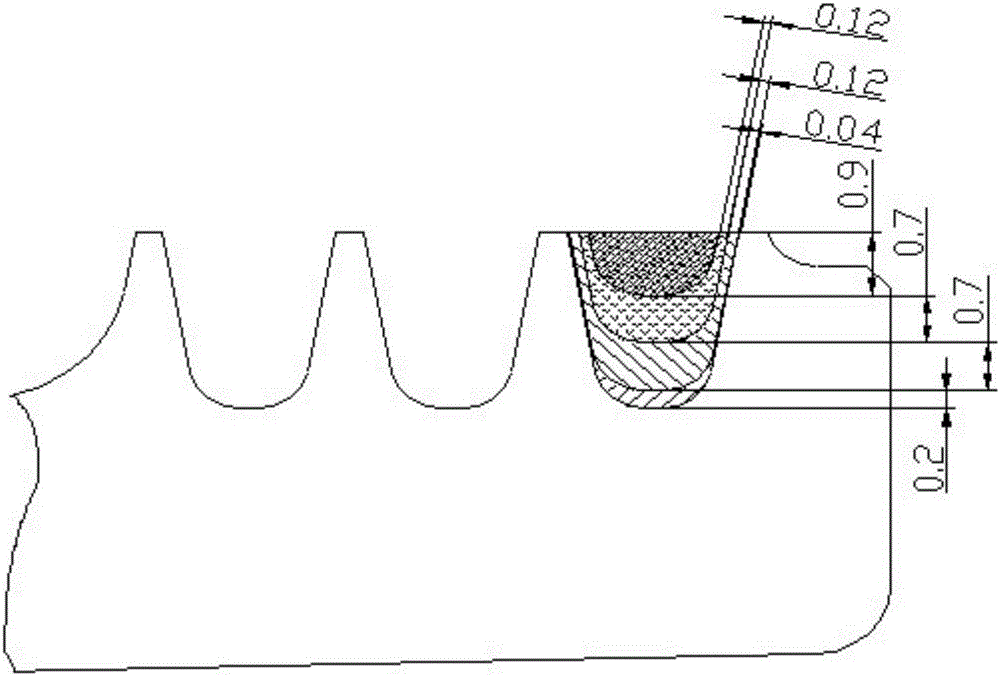

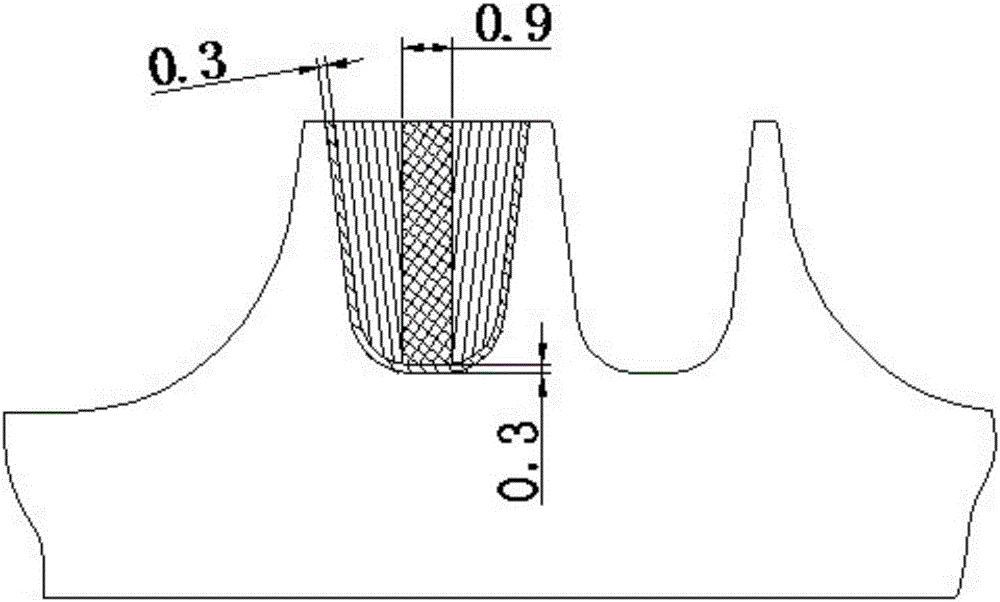

Machining method for improving surface integrity of sealing labyrinth of rotating part

Owner:AECC AVIATION POWER CO LTD

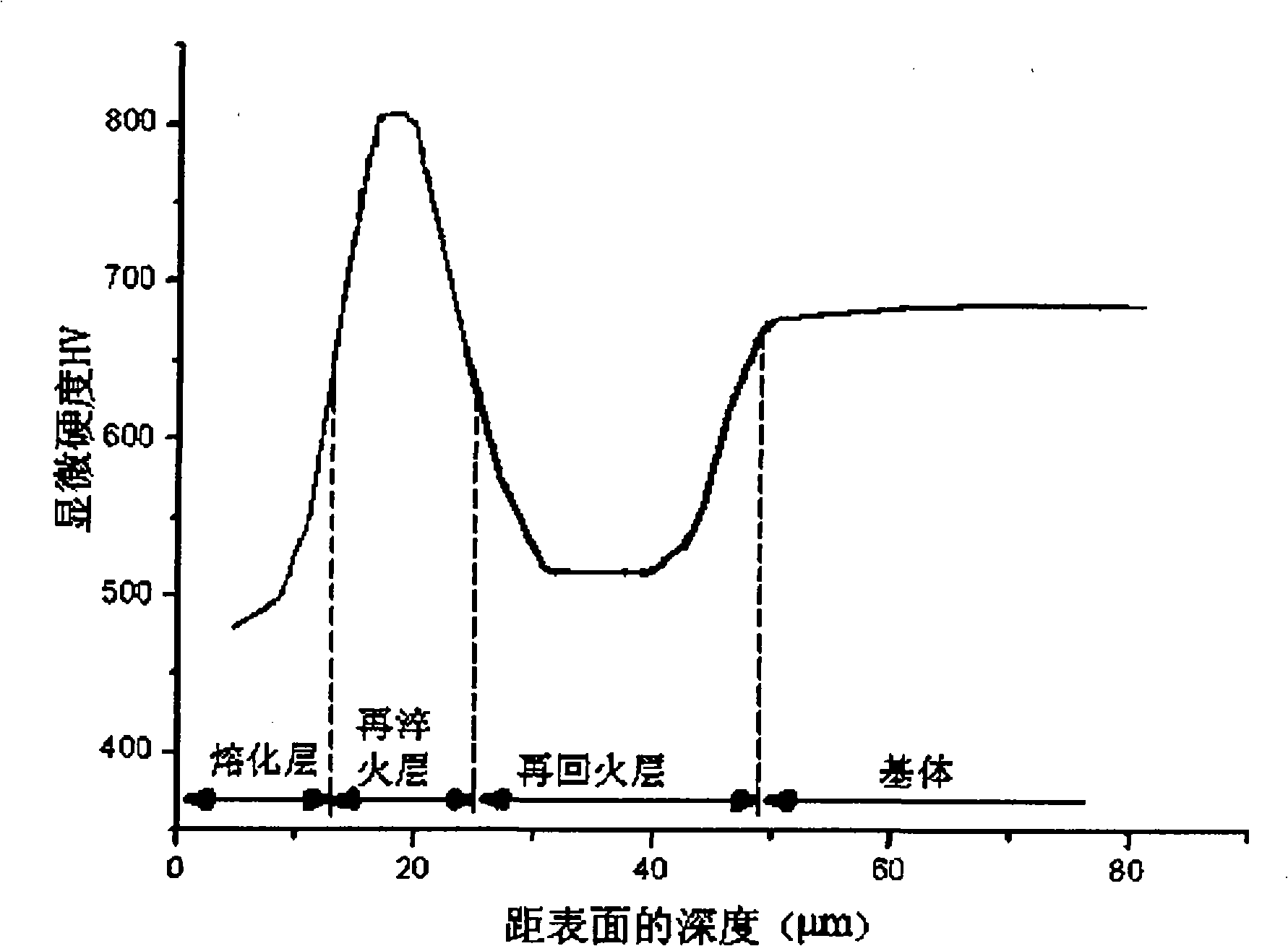

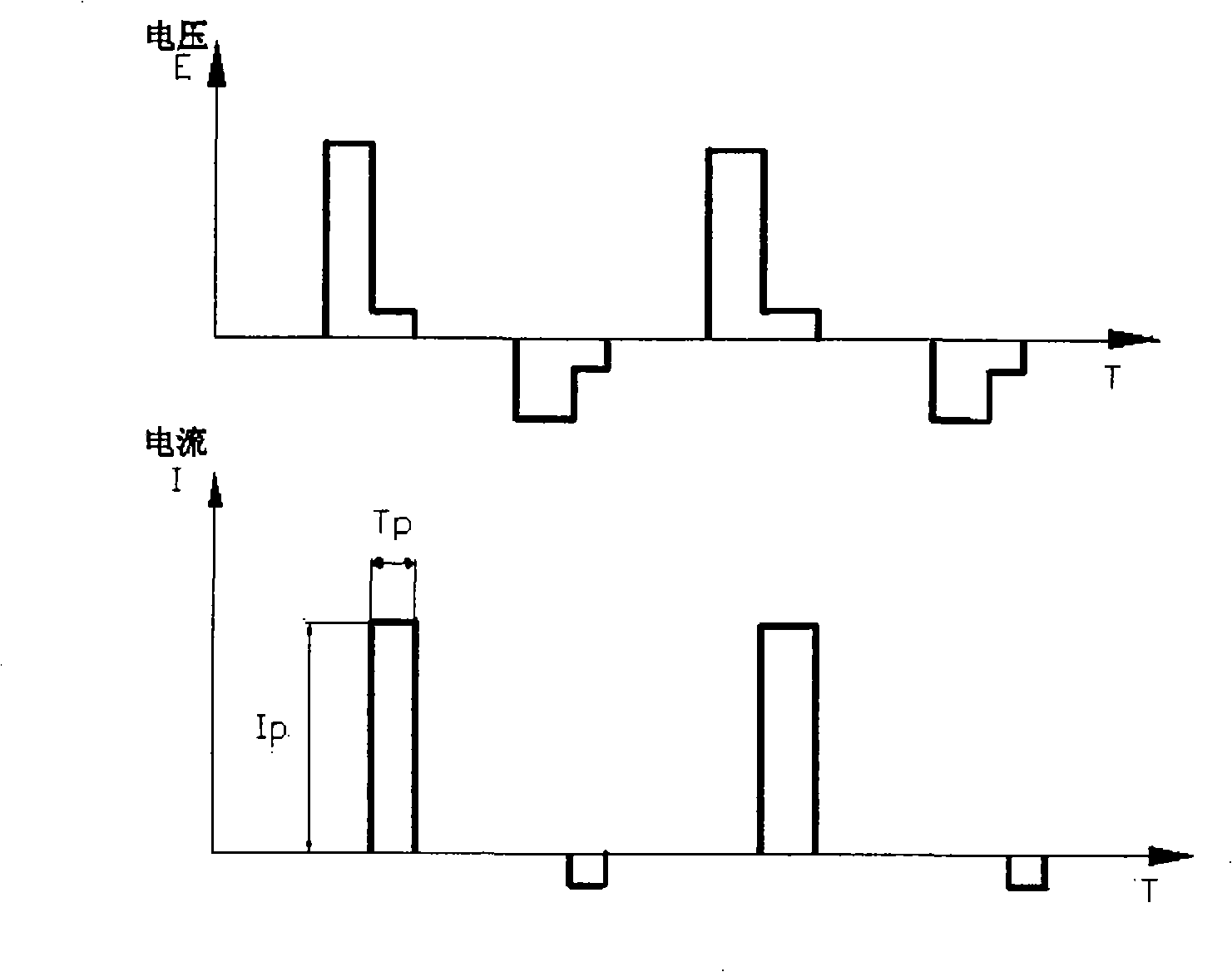

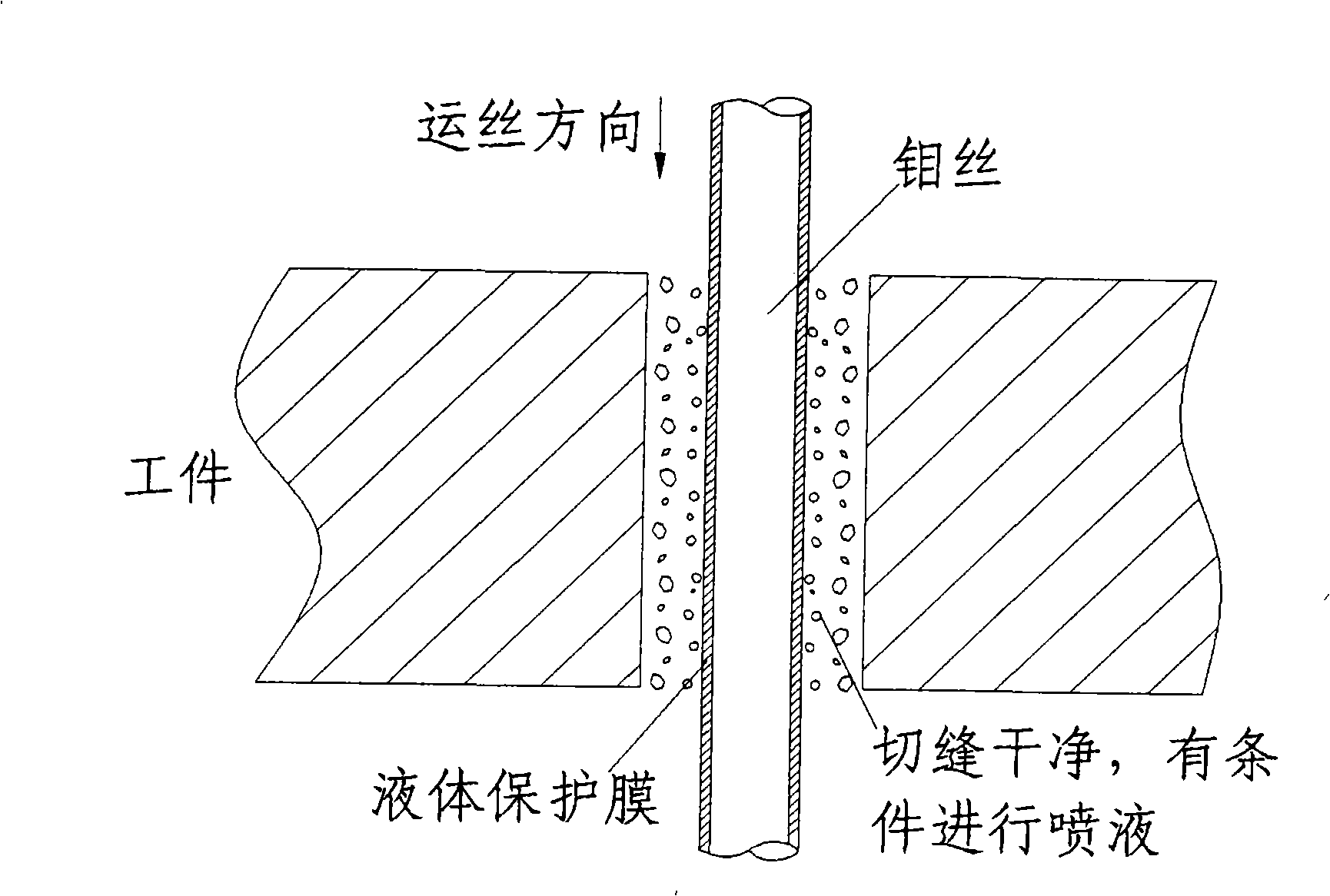

Method for improving completeness integrity of electrospark wire-electrode cutting finished surface

The invention discloses a method of promoting the integrity of the cutting and machining surface of the electrical discharge wire. The method is characterized by comprising two steps including preliminary cutting and finish cutting. The water-soluble working liquid is utilized as the cooling medium in the preliminary cutting. In the finish cutting, the oil liquid is poured or the oil mist is sprayed into the discharge cutting seam under the high pressure to be served as the discharge medium for cooling the discharge surface, thereby achieving the purpose of promoting the integrity of the cutting surface and eliminating the surface softening layer caused by electric erosion or electrolysis. The invention is different from LSWEDM using the anti-electrolysis power supply to solve the problem, and complete the wire cutting with the higher surface integrity only by changing the working medium and utilizing the high-frequency power supply with the ordinary peak voltage and peak current, thereby being favorable for promoting the machining quality of the electrical discharge wire. The method also has the advantages of simple method, easy implementation, low investment and quick results.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Cultivation and screening device for fine varieties of water chestnuts

ActiveCN110558585AReduce the chance of damageEasy to cleanSievingSeed and root treatmentWater ChestnutsFiltration

The invention discloses a cultivation and screening device for fine varieties of water chestnuts, and belongs to the technical field of agricultural planting devices. A material transfer cylinder is arranged in a cleaning mechanism, and used in combination with a material turning mechanism and a water circulation mechanism. A half of the material transfer cylinder is immersed in the interior of the cleaning mechanism, so that raw materials can be soaked and decontaminated before filtering, thereby improving cleaning effect on surfaces of the water chestnuts. A weighing mechanism is arranged ina box. A pressure sensor in the weighing mechanism is used to weigh weight of the water chestnuts,and a controller is used to control rotation of a servo motor, so as to pick seeds according to weight control of the water chestnuts. A filter plate is arranged in the box. A rubber cushion on the top of the filter plate can avoid damage to surfaces of the water chestnuts in a filtration process, thereby ensuring surface integrity of the water chestnuts.

Owner:芜湖光丰农业科技开发有限公司

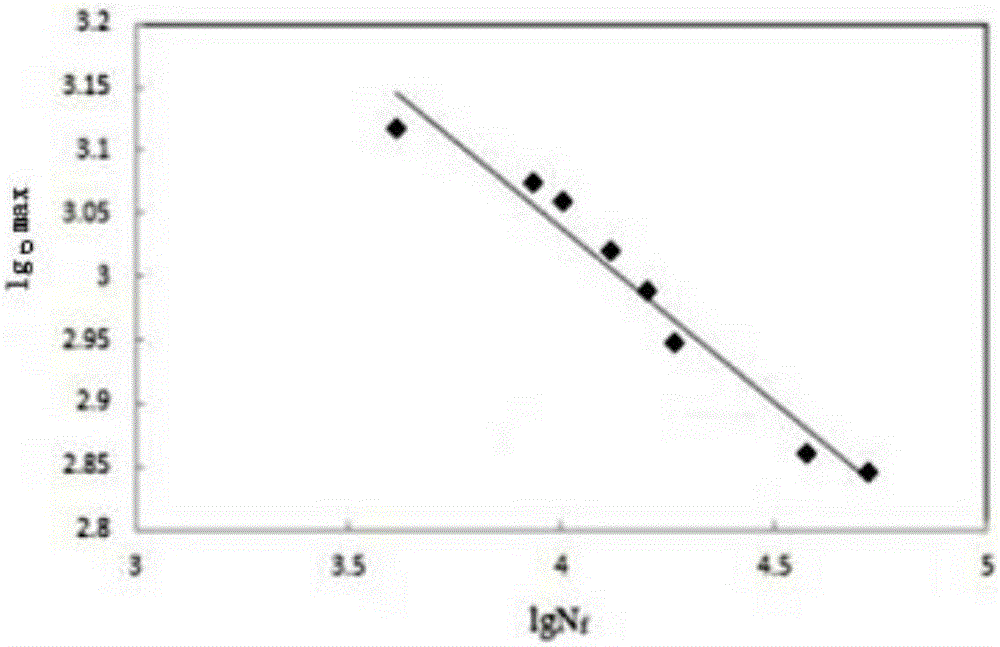

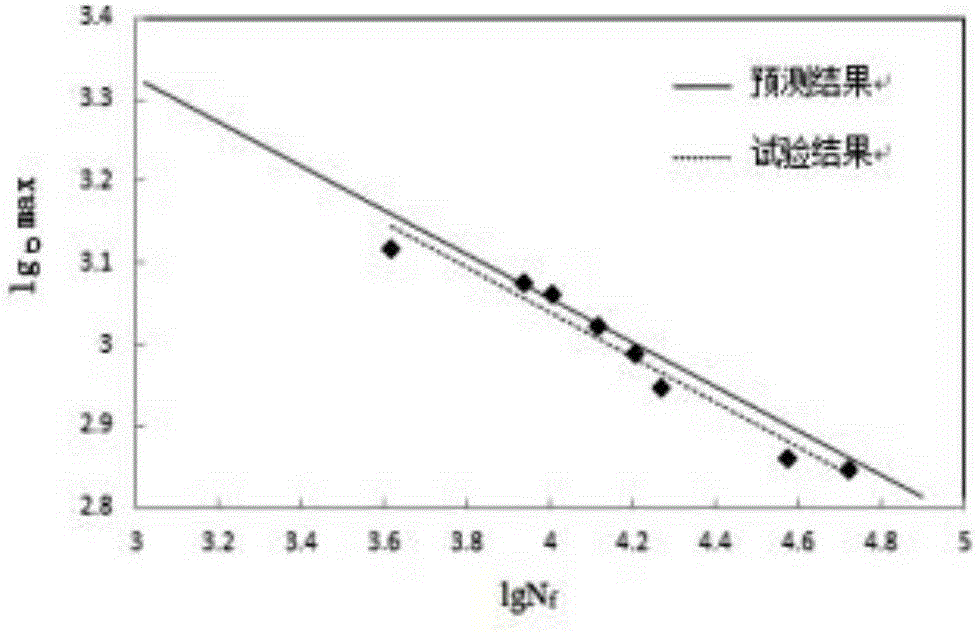

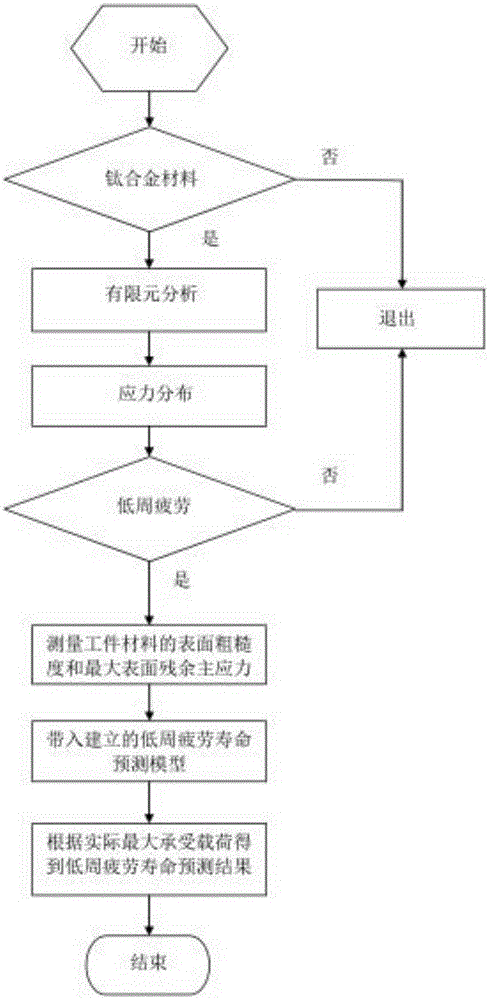

Method for predicting low-cycle fatigue life of titanium alloy material based on surface integrity

ActiveCN105203392AAvoid errorsImprove stabilityMaterial strength using tensile/compressive forcesPredictive methodsPolynomial regression model

The invention discloses a method for predicting the low-cycle fatigue life of a titanium alloy material based on the surface integrity. The low-cycle fatigue failure mode of the titanium alloy material under the pulling-pressing loading condition is considered, index parameters of the surface integrity serve as bases, a polynomial regression model is combined with a sine and cosine regression model, a predicting model for evaluating the low-cycle fatigue life of the titanium alloy material by adopting a combination of the surface roughness Ra and the maximum surface residual main stress sigmar is built, and finally a method for predicting the low-cycle fatigue life of the titanium alloy material based on the surface integrity is provided. By means of the method, the low-cycle fatigue life of the titanium alloy material can be easily, rapidly and accurately predicted, theoretical bases can be provided for reliable design of parts, practical production can be guided, and the certain engineering application value can be achieved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

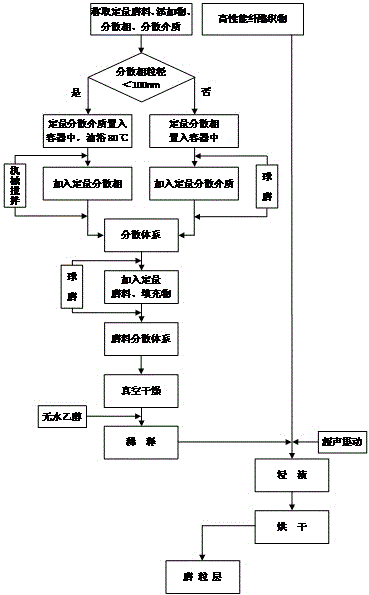

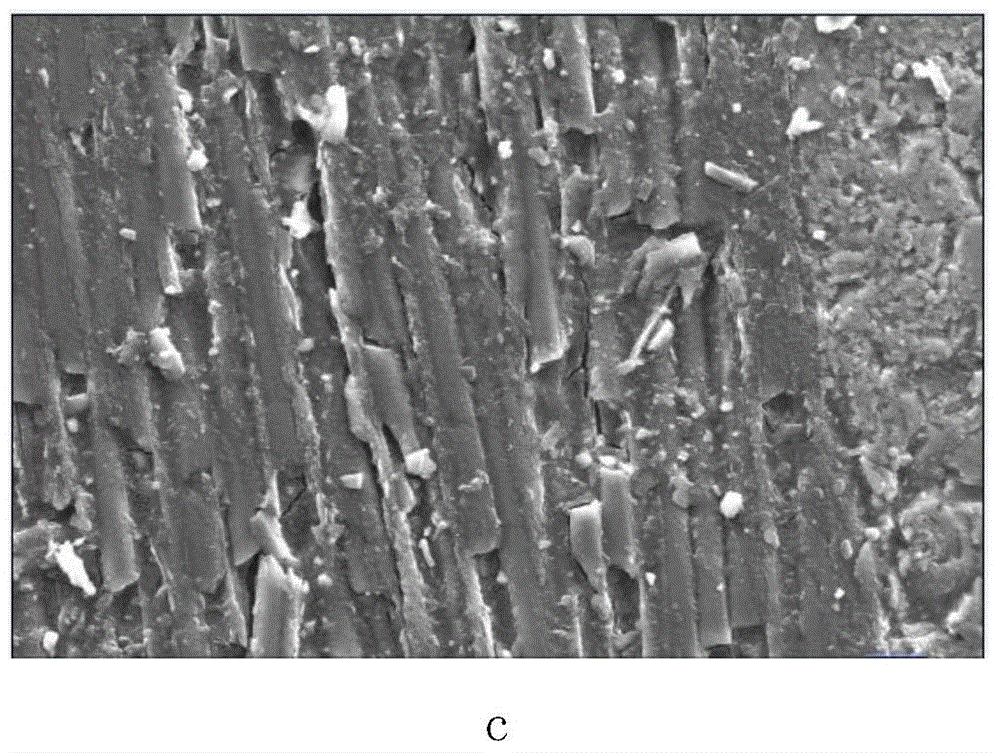

Titanium alloy ultraprecision machining method based on ultrasonic elliptical vibration cutting technology

ActiveCN109048390AInstantaneous depth of cut is smallReduce cutting forceMeasurement/indication equipmentsMetal working apparatusMachined surfaceTitanium alloy

The invention discloses a titanium alloy ultraprecision machining method based on an ultrasonic elliptical vibration cutting technology. The titanium alloy ultraprecision machining method comprises the following steps: I, adjusting and controlling the temperature, the humidity and the air cleanliness of an ultraprecision machining laboratory; II, performing a pilot run on a machine tool; III, debugging an ultrasonic elliptical vibration cutting system; IV, mounting an ultrasonic elliptical vibration cutting device; V, mounting a titanium alloy material; VI, performing rough cutting; VII, performing semi-finished cutting; VIII, performing finish cutting; IX, performing ultrasonic elliptical vibration assisted cutting; and X, stopping an ultraprecision machine tool and the ultrasonic elliptical vibration cutting system, taking down a titanium alloy workpiece, cleaning the titanium alloy workpiece with absolute ethyl alcohol, performing drying, and then storing the titanium alloy workpiece to obtain an ultraprecision titanium alloy surface machined by the ultrasonic elliptical vibration cutting technology. The ultrasonic elliptical vibration cutting technology is adopted to realize ultraprecision machining of titanium alloy. The titanium alloy ultraprecision machining method has the advantages that abrasion of a cutter can be effectively inhibited, pits and microcracks on a machined surface are inhibited, the surface integrity of the workpiece is improved, and the damage degree of a subsurface of the workpiece can be effectively reduced.

Owner:HARBIN INST OF TECH

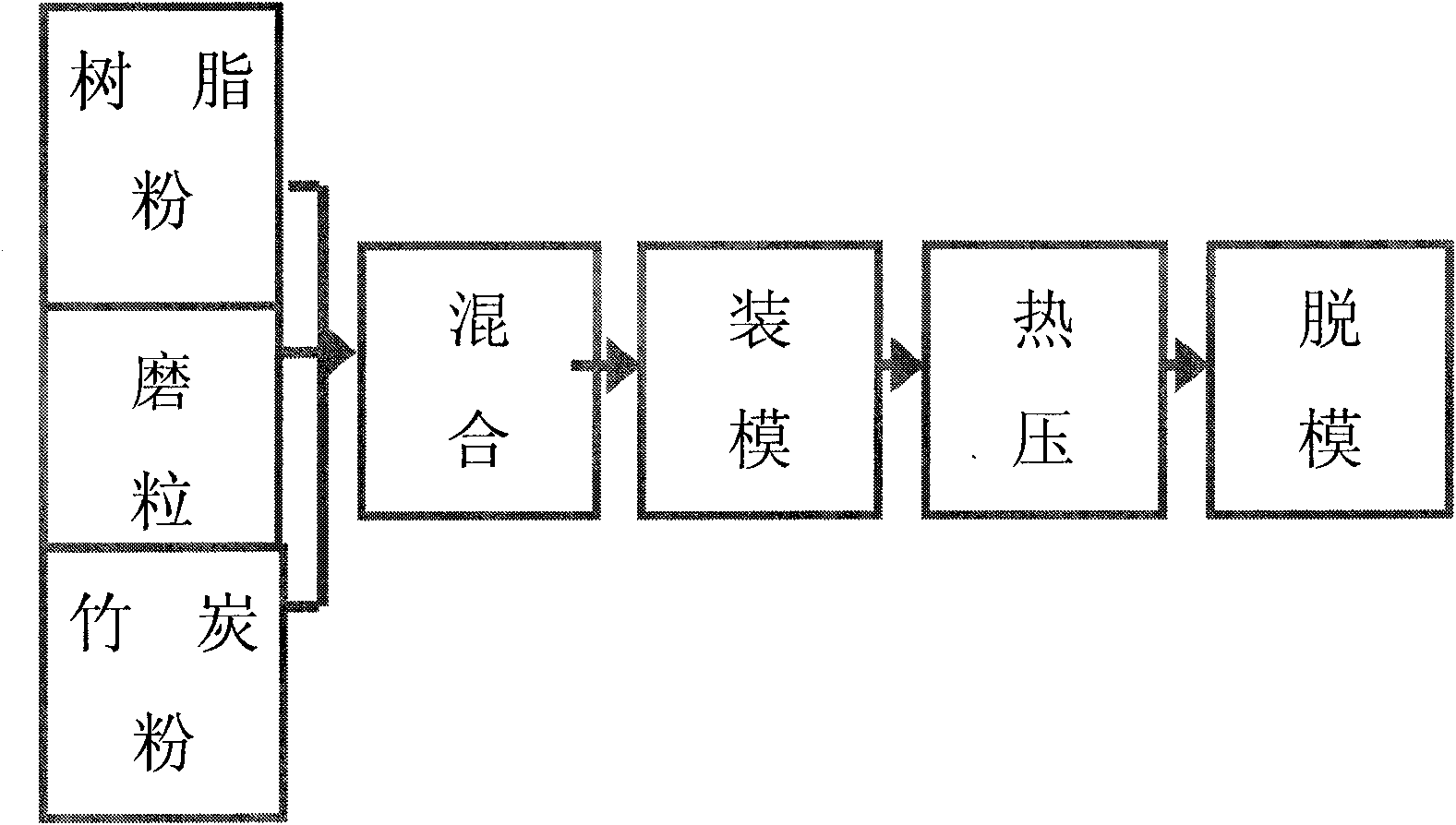

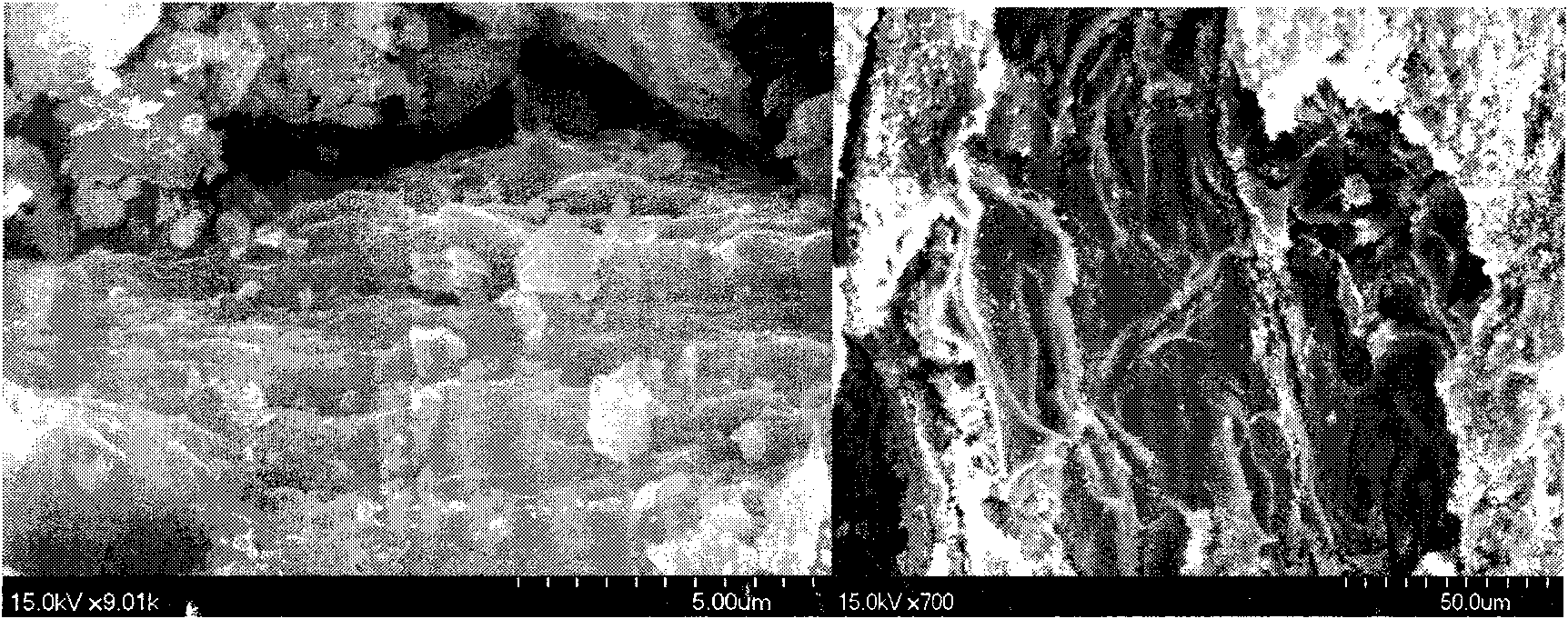

Bamboo ceramic grinding wheel, preparation method and application thereof

InactiveCN101590626AImprove surface qualityRich in resources and environmentally friendlyAbrasion apparatusGrinding devicesEnvironmental resistanceMetallurgy

The invention discloses a bamboo ceramic grinding wheel, a preparation method and application thereof. The bamboo ceramic grinding wheel is prepared by obtaining a blank grinding wheel by the following raw materials through mixing, mold feeding, hot press molding and stripping, and roasting the blank grinding wheel; and the raw materials comprise 20 to 30 percent of phenolic resin, 20 to 30 percent of abrasive particles, and 40 to 60 percent of bamboo charcoal powder according to the mass ratio. The bamboo ceramic grinding wheel is used for ELID grinding, and can ensure that the processed surface has better quality. Compared with the prior art, the invention introduces bamboo charcoal into the raw materials; the bamboo charcoal has rich resources and is environment-friendly; and the bamboo charcoal contributes to the grinding due to the fact that the bamboo charcoal has a microporous structure. The grinding wheel has simple preparation; and the bamboo ceramic grinding wheel ensures that processed surfaces have extremely high surface integrity and cleanliness, has high processing efficiency, can process hard-to-cut materials such as cohesive materials, soft materials and the like, provides a new way for grinding processing, and is environment-friendly and pollution-free.

Owner:ZHEJIANG UNIV OF TECH

Method for detecting titanium alloy impeller surface completeness

InactiveCN102998312AScientific and accurate measurementForce measurementOptically investigating flaws/contaminationImpellerCase hardening

The invention relates to a method for detecting titanium alloy impeller surface completeness. The method for detecting the titanium alloy impellor surface completeness comprises the steps of setting measurement steps reasonably and selecting parameters so as to achieve the operation program and an operation method for detecting the surface toughness, the surface residual stress, the surface micro defects, grinding burn and surface hardening of a titanium alloy impellor; and the surface completeness of the impeller after machining is measured scientifically and accurately, and reliable data are provided for the design calculation and analyzing the fatigue service life of the impeller.

Owner:HARBIN DONGAN ENGINE GRP

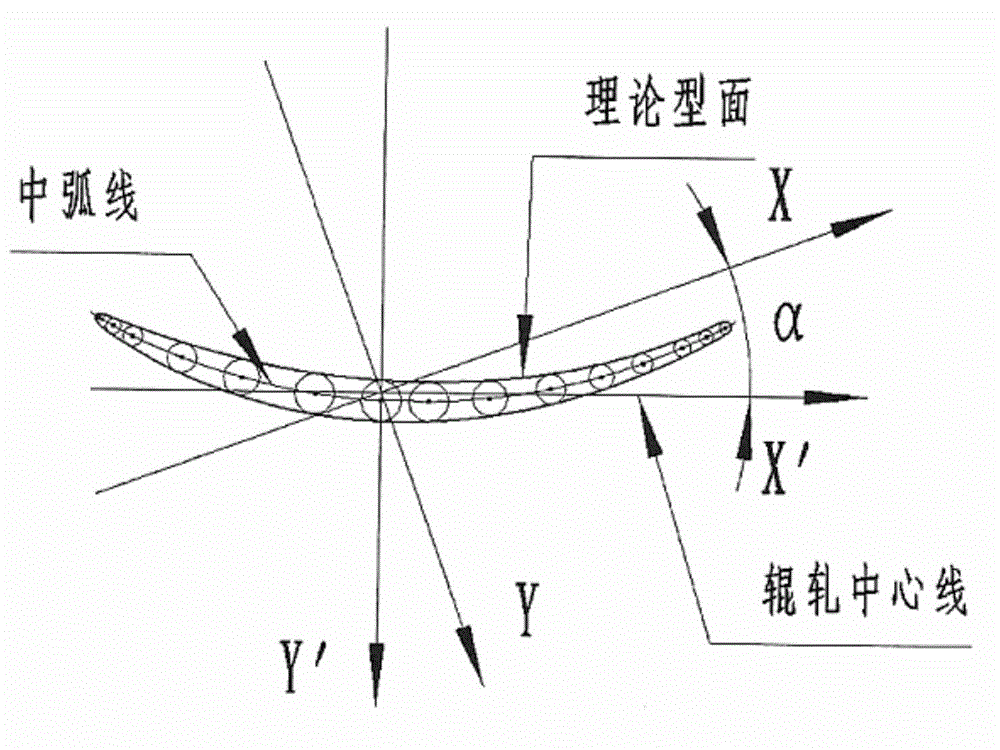

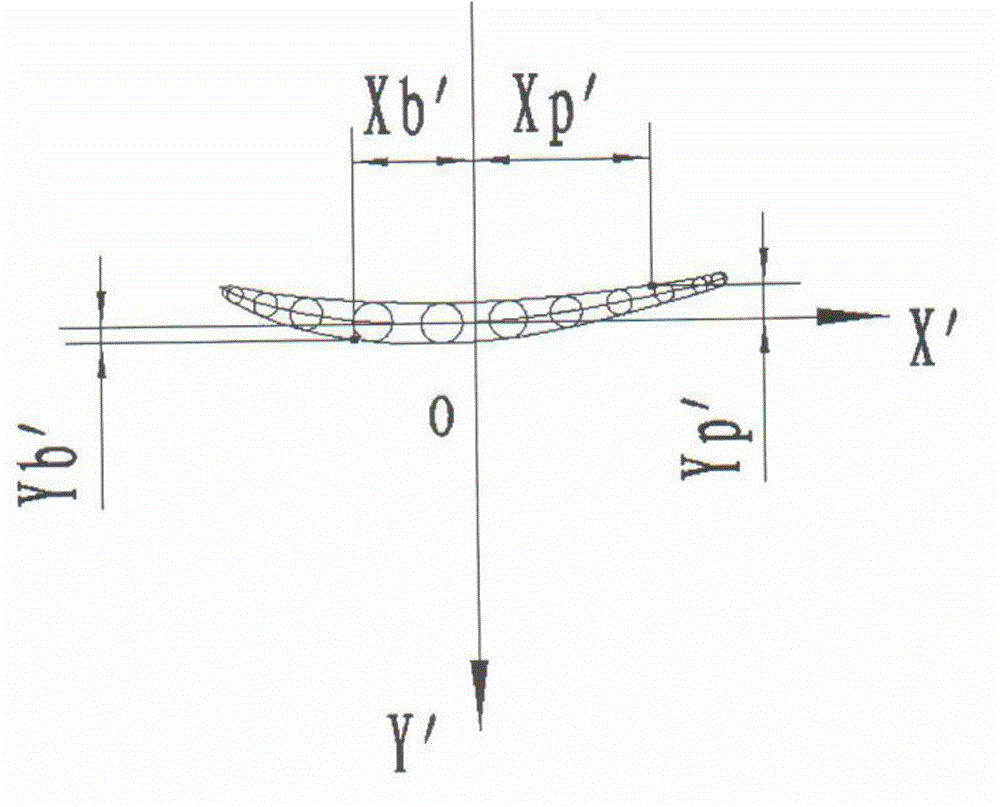

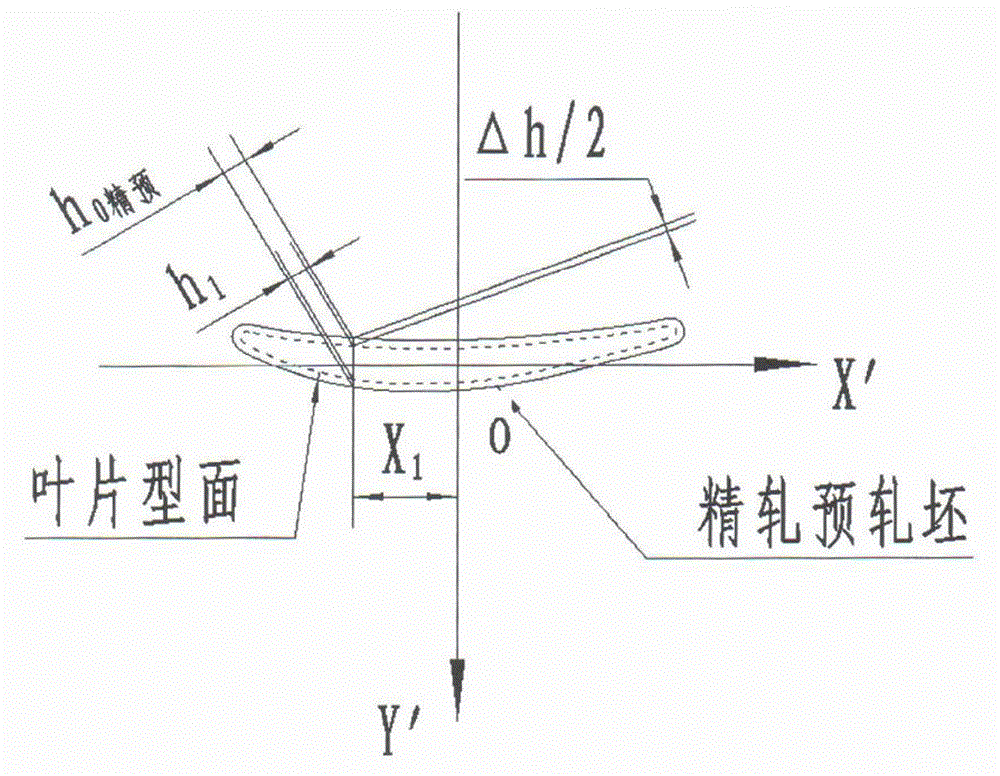

Method for preparing tenon-free depth end bent blade

ActiveCN103600012AImprove output pass rateImprove pass rateMetal rollingSurface integritySurface mass

The invention discloses a method for preparing a tenon-free depth end bent blade. The method includes the steps: feeding a plate; jointly milling and roughly rolling a pre-rolled blank; roughly rolling the pre-rolled blank; precisely rolling the pre-rolled blank; precisely rolling the blade; determining the pre-rolled blank; designing a roll mould. The method is a qualitative leap of cold rolling technology and can solve the problems of high manual profile polishing and repairing cost, unstable surface quality and the like of a tenon-free blade body profile, the pre-rolled blank is precisely rolled and matched with the mould in refined design, the non-cutting level of the blade profile is finally realized, the mould is high in yield and stable in forming, the rolled blade is fine in surface integrity and excellent in performance, and the method has a wide and excellent application prospect in terms of manufacture of high-performance blades needed by high-performance engines.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

Grinding tool with high tangential grinding force and low normal grinding force

ActiveCN106737247AHigh removal rateGood grinding surface integrityAbrasion apparatusGrinding headsMaterial removalHigh surface

The invention discloses a grinding tool with high tangential grinding force and low normal grinding force, and belongs to the technical field of efficient and precise grinding of materials difficult to machine. In order to solve the problems that in traditional grinding machining, the high tangential grinding force and the low normal grinding force cause low material removal rate, grinding tool and workpiece damage and deformation, grinding vibration, grinding wheel blockage, poor workpiece surface integrity, frequent grinding burning and the like, the novel grinding tool is provided; and a similar body armor principle is used, abrasive particles generate a constellation effect under impulse loads, the tangential grinding force instantly increases, and the normal grinding force instantly decreases. The novel grinding tool is composed of three parts including a matching ring, a base ring and an abrasive material layer with the abrasive particle constellation effect. The abrasive material layer is bonded to the base ring through a heat bonding method, the base ring is assembled to the matching ring, and therefore the novel high-precision high-self-sharpening grinding tool is manufactured. According to the grinding tool, high-efficiency, high-precision and high-surface-integrity grinding machining of the difficult-to-machine materials such as crisp and hard materials or aerospace composite materials can be achieved with the high tangential grinding force and the low normal grinding force.

Owner:SHANDONG UNIV OF TECH

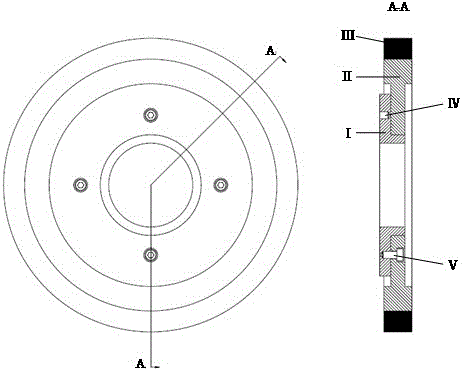

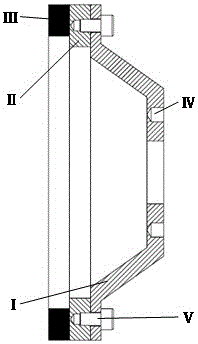

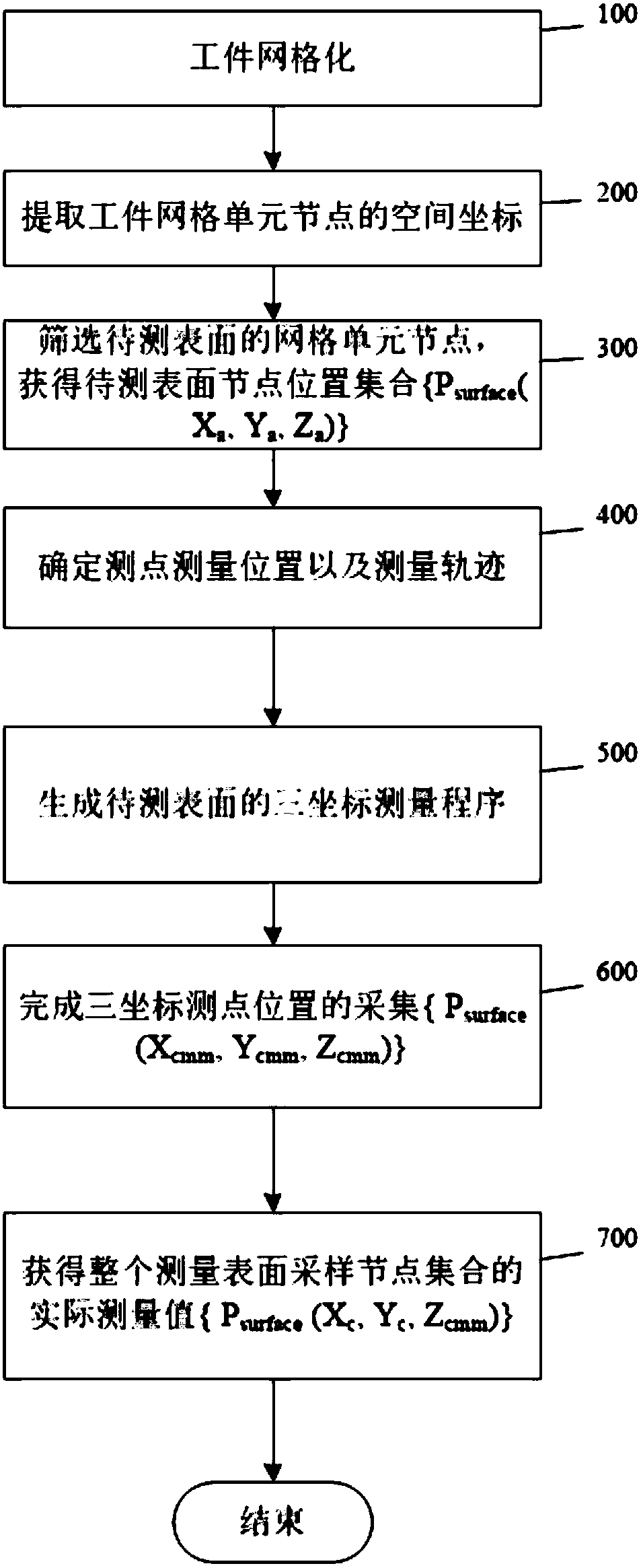

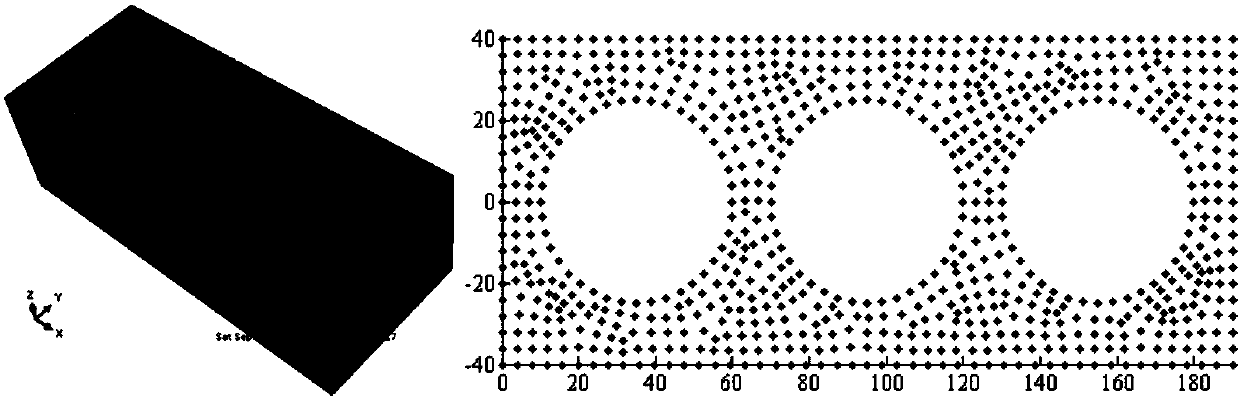

Three-coordinate measuring machine measuring method of complex workpiece surface flatness measurement

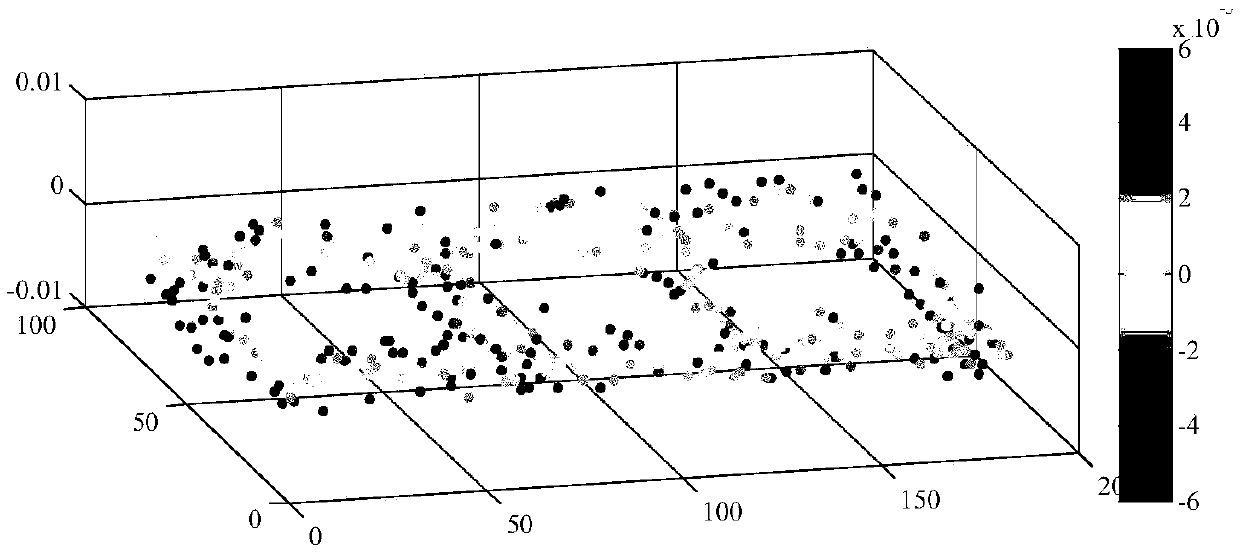

ActiveCN108050981ARealize measurementUniform samplingMeasurement devicesCoordinate-measuring machineGrid cell

The invention discloses a three-coordinate measuring machine measuring method of complex workpiece surface flatness measurement and relates to the simulation measurement field. The method comprises the following steps of carrying out workpiece gridding; extracting a space coordinate of a workpiece grid unit node; screening a grid unit node of a surface to be measured; determining a measuring position of a measuring point and a measuring track; generating a three-coordinate measuring program of the surface to be measured; completing acquisition of three-coordinate measuring point positions; andfinally acquiring an actual measuring value of a whole measuring surface sampling node set. The method does not depend on a specific sampling curve and a regular sampling area, and the measuring point of a complex workpiece surface can be rapidly generated; based on a condition that measuring surface integrity is guaranteed, sampling uniformity is ensured; and measuring point distribution and measuring path planning are less dependent on manpower, and the method possesses good adaptability to measurement of different complex surface components.

Owner:SHANGHAI JIAO TONG UNIV

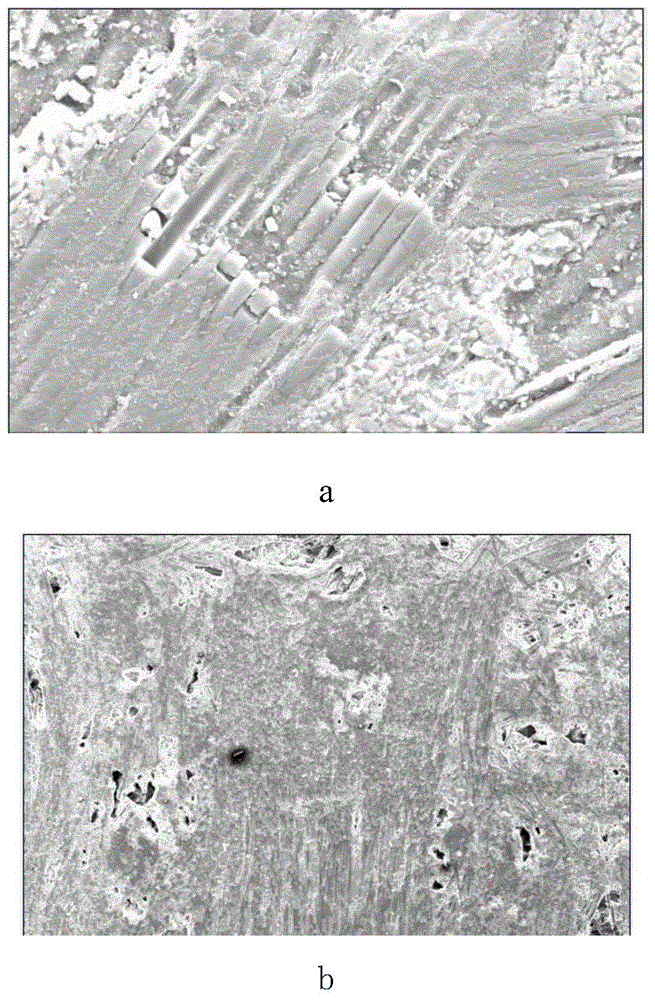

Evaluation method of surface roughness of fiber reinforced composite material

The invention relates to an evaluation method of surface roughness of a fiber reinforced composite material, and belongs to the technical field of material surface integrity evaluation. According to the method, firstly, a non-contact test instrument is selected and used for extracting original data of the machined surface of the material; secondly, the gross error theory is used, and filtering gross errors, namely, manufacturing defects of the material itself are filtered out; at last, analysis software is used for analyzing and processing the filtered-out data to obtain corresponding surface roughness data. Due to the fact that the manufacturing defects of the material itself are filtered out, the three-dimensional roughness data are used as evaluation data, and authentic evaluation on roughness of the machined surface of the material can be achieved.

Owner:BEIJING XINGHANG MECHANICAL ELECTRICAL EQUIP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com