Evaluation method of surface roughness of fiber reinforced composite material

A technology of surface roughness and composite materials, applied in the direction of measuring devices, instruments, etc., can solve the problems of inaccurate, contact probe wear measurement, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to make the purpose, content, and advantages of the present invention clearer, the present invention will be further described by taking the C / SiC material as an example below in conjunction with the accompanying drawings and specific testing methods and steps:

[0033] C / C, C / SiC composite materials due to the limitations of their own molding process, the porosity in the material preparation process is qualified within a certain range, and the porosity is an important factor affecting the surface roughness, in order to solve the problem of processing The influence of the surface roughness of the material, the invention proposes a new method for evaluating the surface roughness of the fiber reinforced composite material.

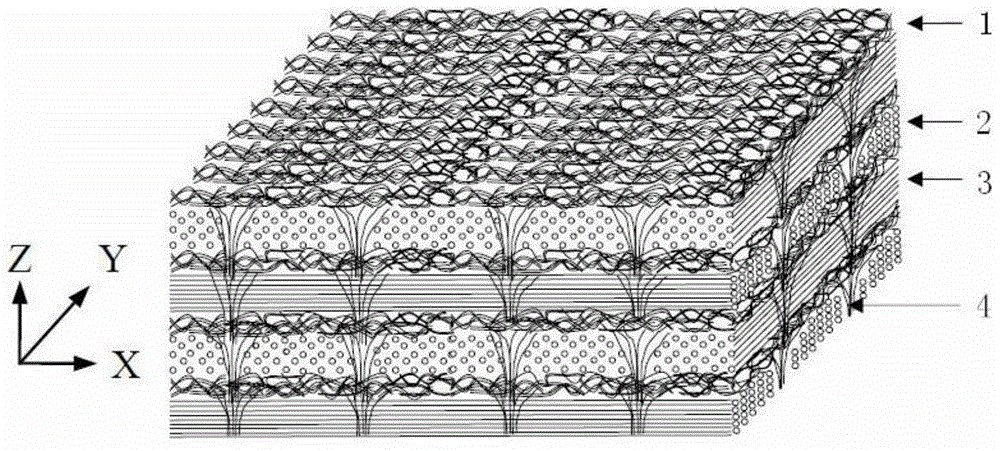

[0034] The C / SiC composite fiber prefabricated body used in the present invention is a three-dimensional acupuncture structure, see figure 1 As shown, 1 is the mesh tire, 2 is the X-direction fiber layup, 3 is the Y-direction fiber layup, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com