Method for improving completeness integrity of electrospark wire-electrode cutting finished surface

A technology of surface integrity and electric discharge wire, applied in the field of electric discharge machining, can solve problems affecting the integrity of the processed surface, achieve the effect of improving the ability and level of electric discharge machining, quick results, and simple methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

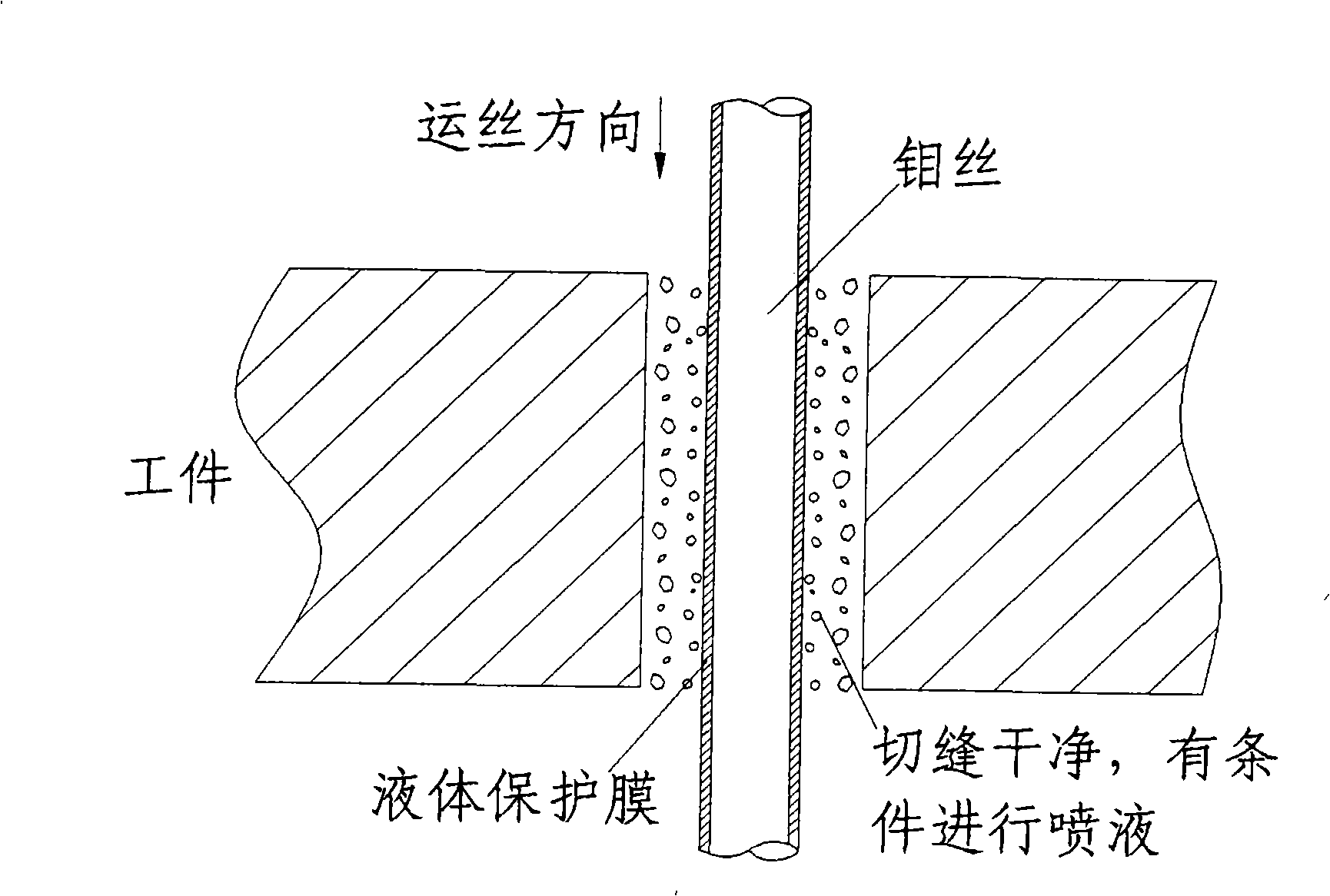

[0032] like image 3 , 4 shown.

[0033] A method of improving surface integrity in wire electric discharge machining comprising preliminary cutting and finishing cutting, wherein the preliminary cutting step comprises:

[0034] a. High speed wire electric discharge cutting (HSWEDM) pulse power supply is used as the working power supply;

[0035] b. Use molybdenum wire, brass wire or alloy wire as the working electrode;

[0036] c. While one-way or two-way wire walking, inject a compound working fluid with good cleaning properties into the slit for cooling, so as to maintain uniform cooling in the slit and discharge the erosion products out of the slit, such as image 3 Shown; control wire speed at: 6~10m / s when two-way wire travels, be 1~10m / min when one-way wire travels; Acid, surfactant, potassium hydroxide, vegetable oil, antirust agent and indus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com