Method for preparing tenon-free depth end bent blade

A blade, depth technology, applied in the field of blade preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0089] The present invention is specifically described below in conjunction with accompanying drawing, as Figure 1-Figure 6 As shown, the present invention includes the following steps: plate blanking; combined milling and rough rolling pre-rolling; rough rolling pre-rolling; finish rolling pre-rolling; finish-rolling blades. The rough rolling pre-rolling; the finishing rolling pre-rolling; the finishing rolling blade step and the method of rolling die design are:

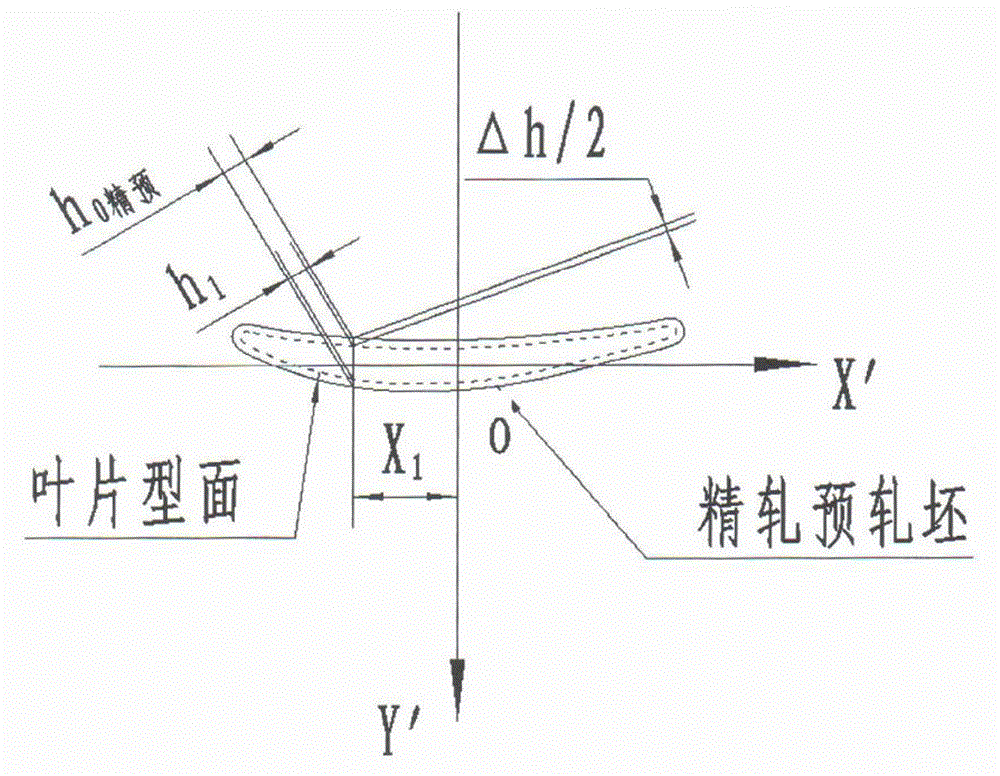

[0090] 1) Design of pre-rolled slab for finishing rolling

[0091] (1) Determination of the cross-sectional graphics of the pre-rolled slab

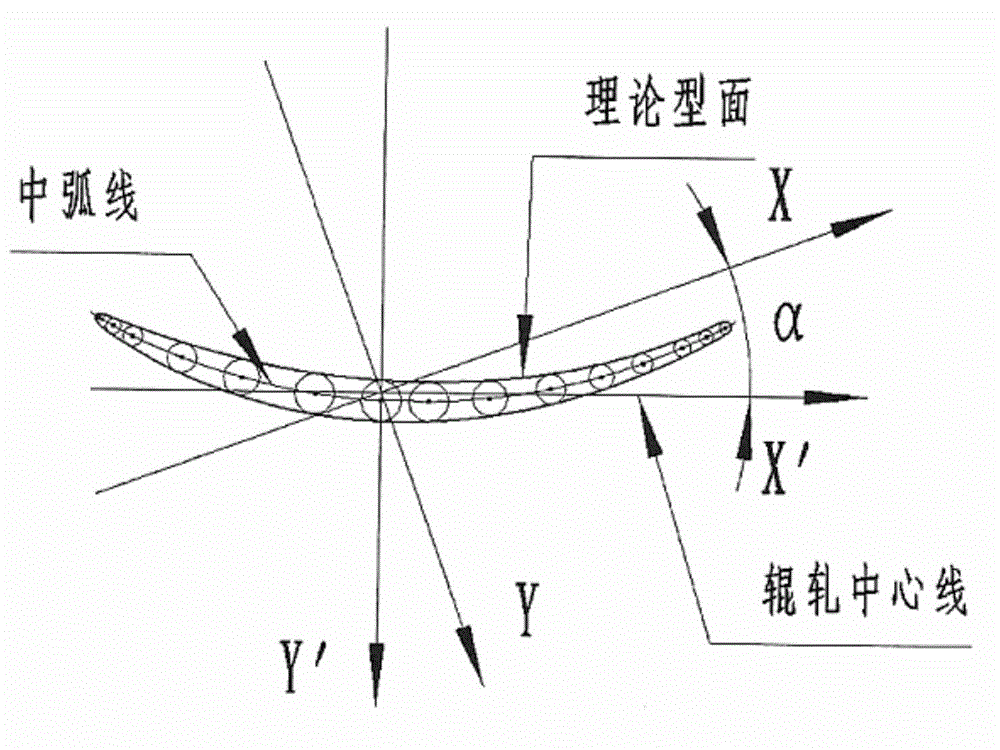

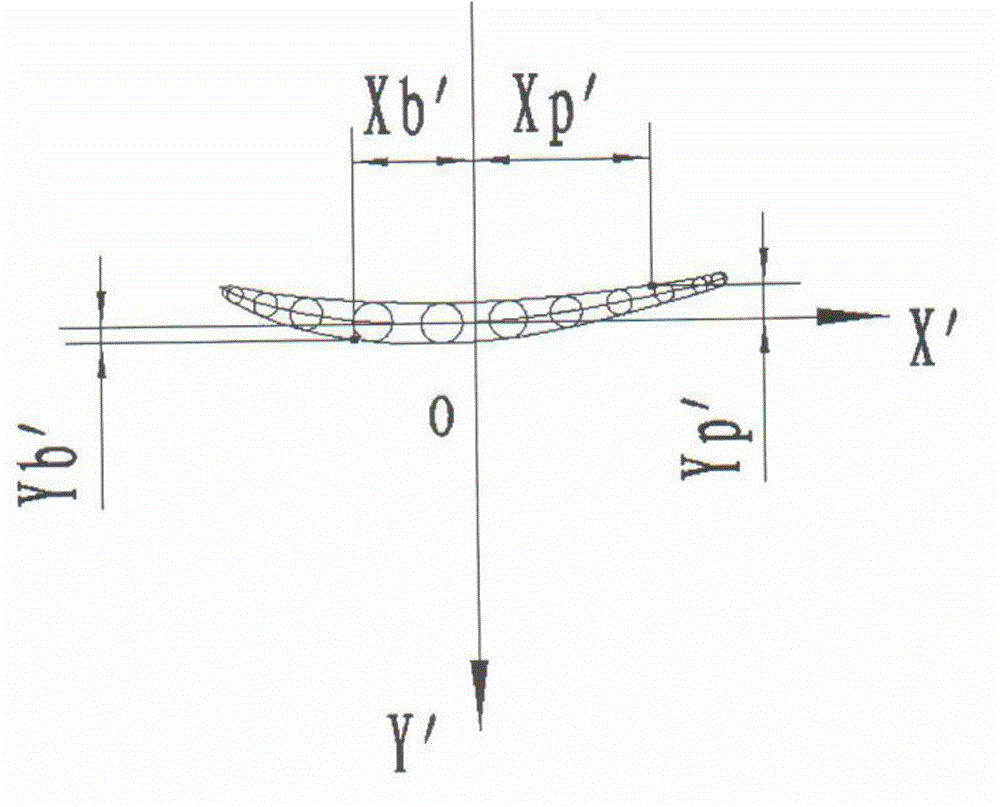

[0092] Such as figure 1 , figure 2 As shown, ① Rotate the selected section of the blade profile counterclockwise α to make the selected section flat, and rotate the rest of the section accordingly. After the rotation, the relative twist angle to the selected section is zero, that is, the chord tangent of all sections is parallel on the rotated X' axis; obtain the Xp', Y...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com