Machining method for improving surface integrity of sealing labyrinth of rotating part

A technology of surface integrity and tightly sealing grate teeth, applied in the field of machining, can solve problems such as accidents affecting engine performance, unbalanced stress distribution, stress micro-crack propagation, etc., to ensure precision, improve performance, and improve integrity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

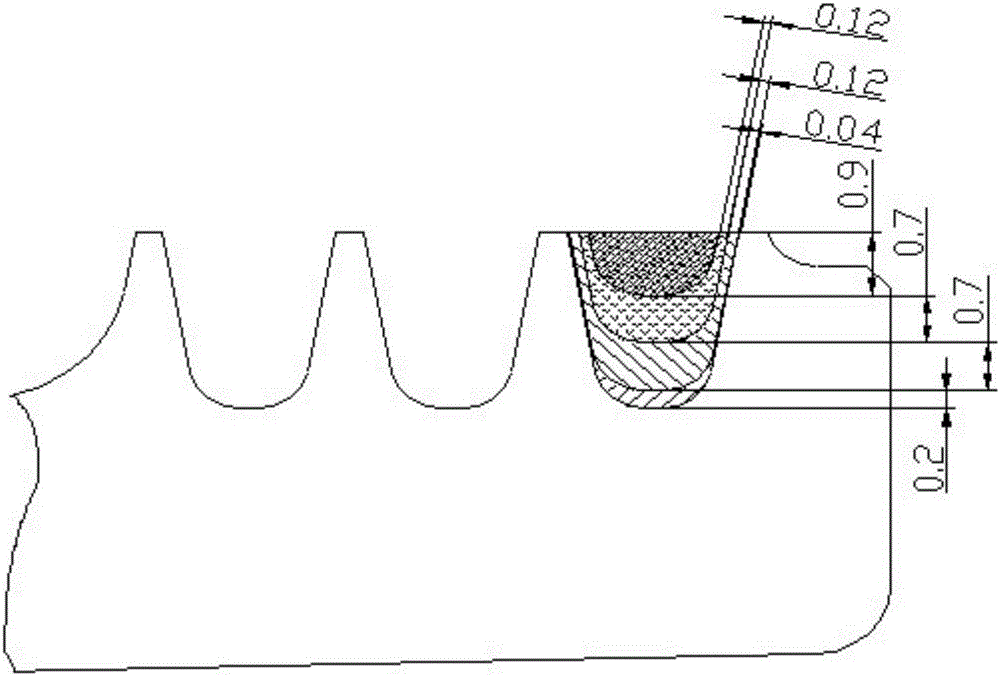

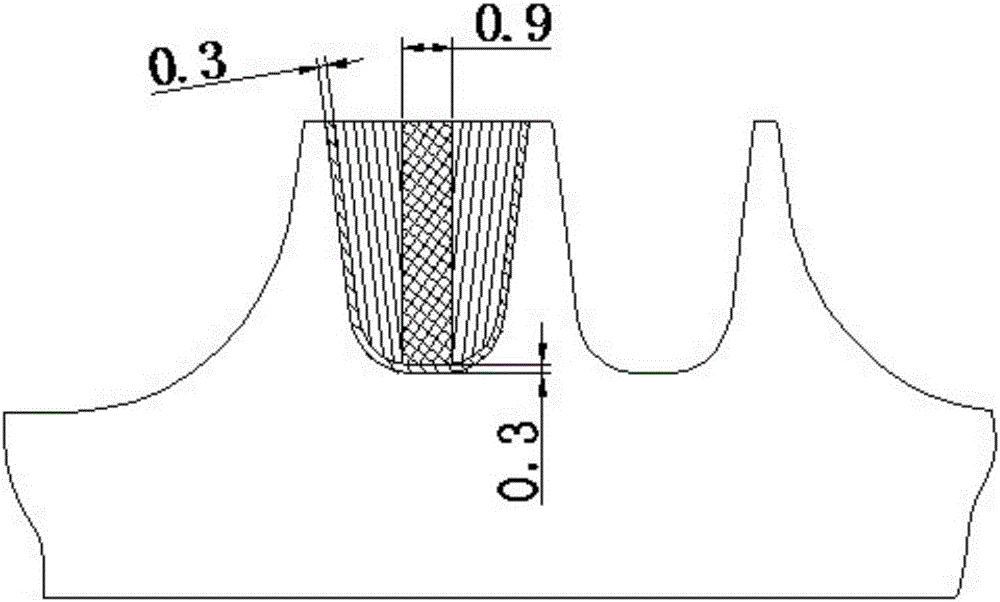

[0026] The present invention is described in further detail below in conjunction with accompanying drawing:

[0027] The invention provides a processing method for improving the integrity of the surface of the sealing grate of the rotating part, which includes the following steps:

[0028] Step 1. The processing equipment for sealing the grate teeth of the engine disc needs to select a CNC lathe that can guarantee its processing range. At the same time, the coolant of the CNC lathe can be sprayed continuously; if the equipment is equipped with a high-pressure pump, the cooling pressure should ensure 4 -10bar; if the cooling system equipped with this equipment has a high-pressure cooling device, the cooling pressure should be guaranteed to be 15-30bar; at the same time, in order to improve the surface integrity of the sealing grate, the sealing grate should be as high as possible while ensuring the size requirements of the sealing grate. The rigidity of the grate tool should be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com