Patents

Literature

30 results about "Polishing teeth" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

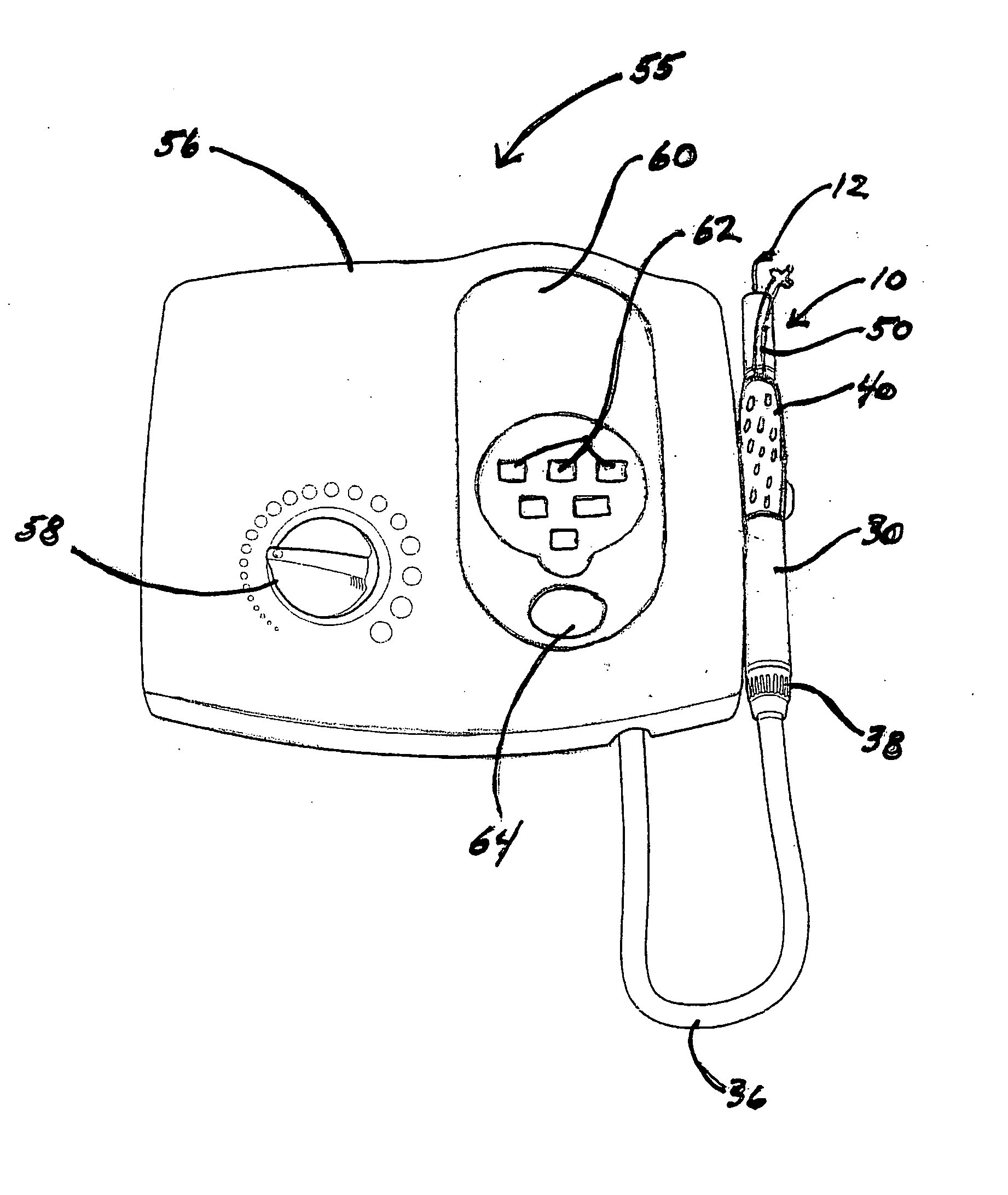

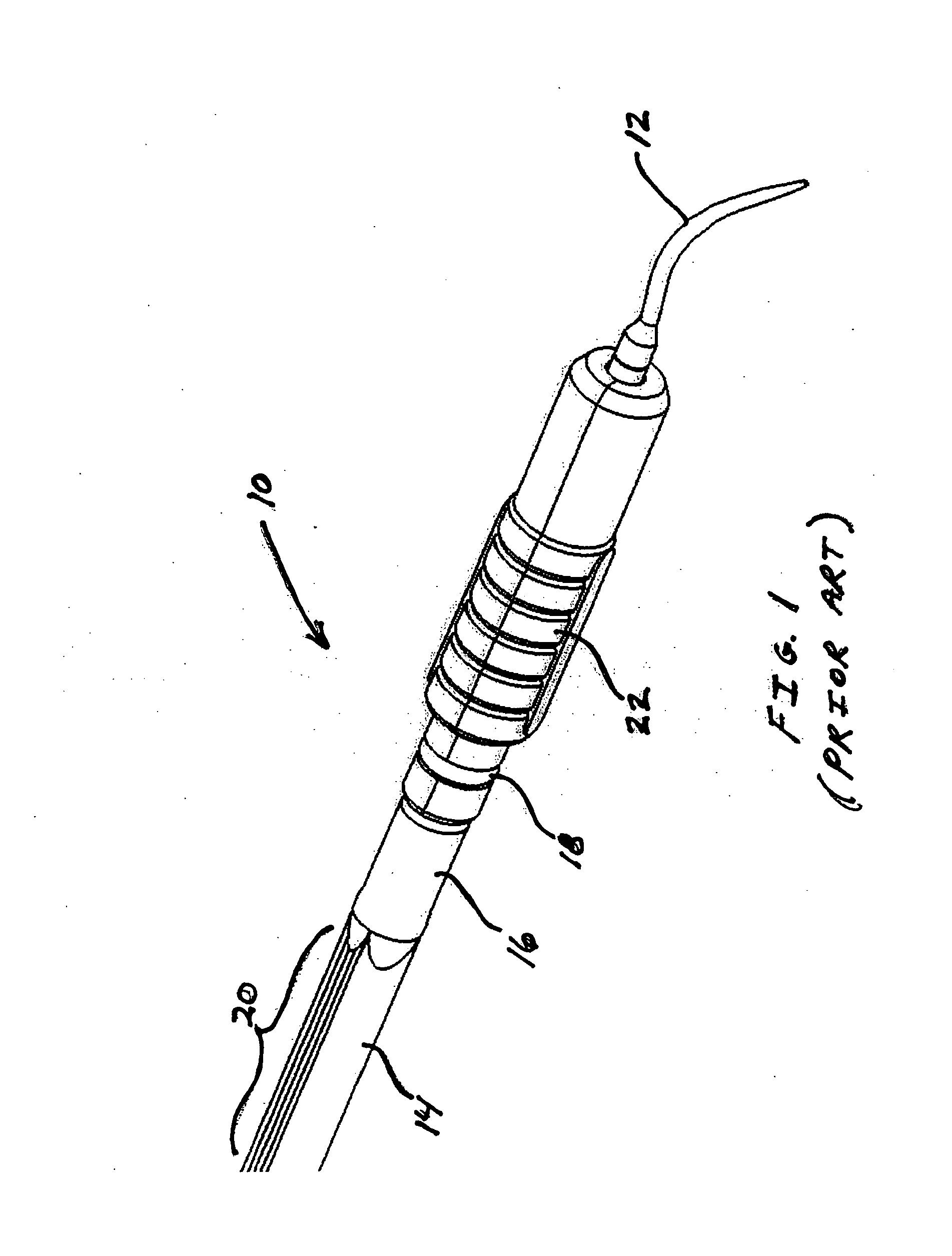

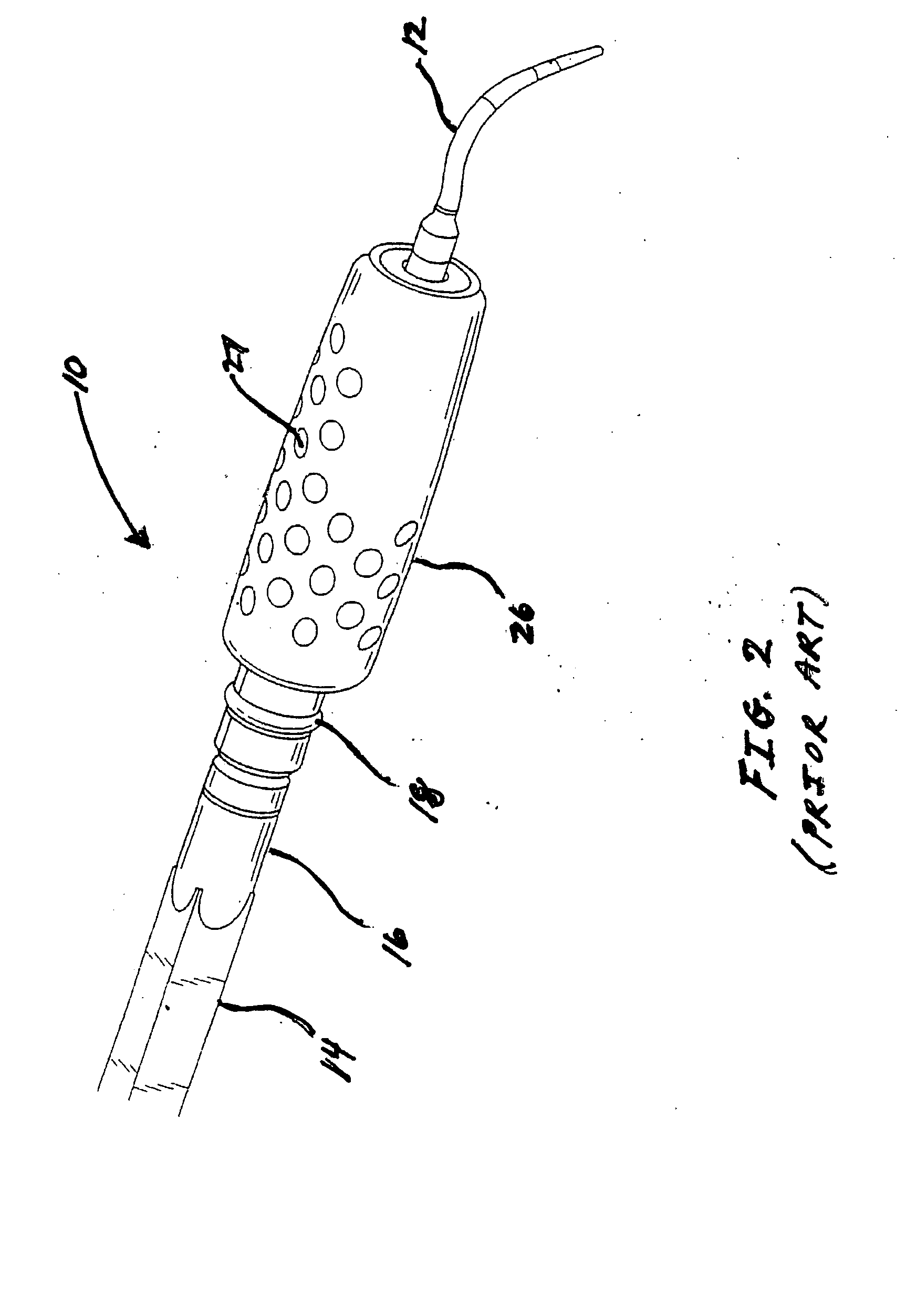

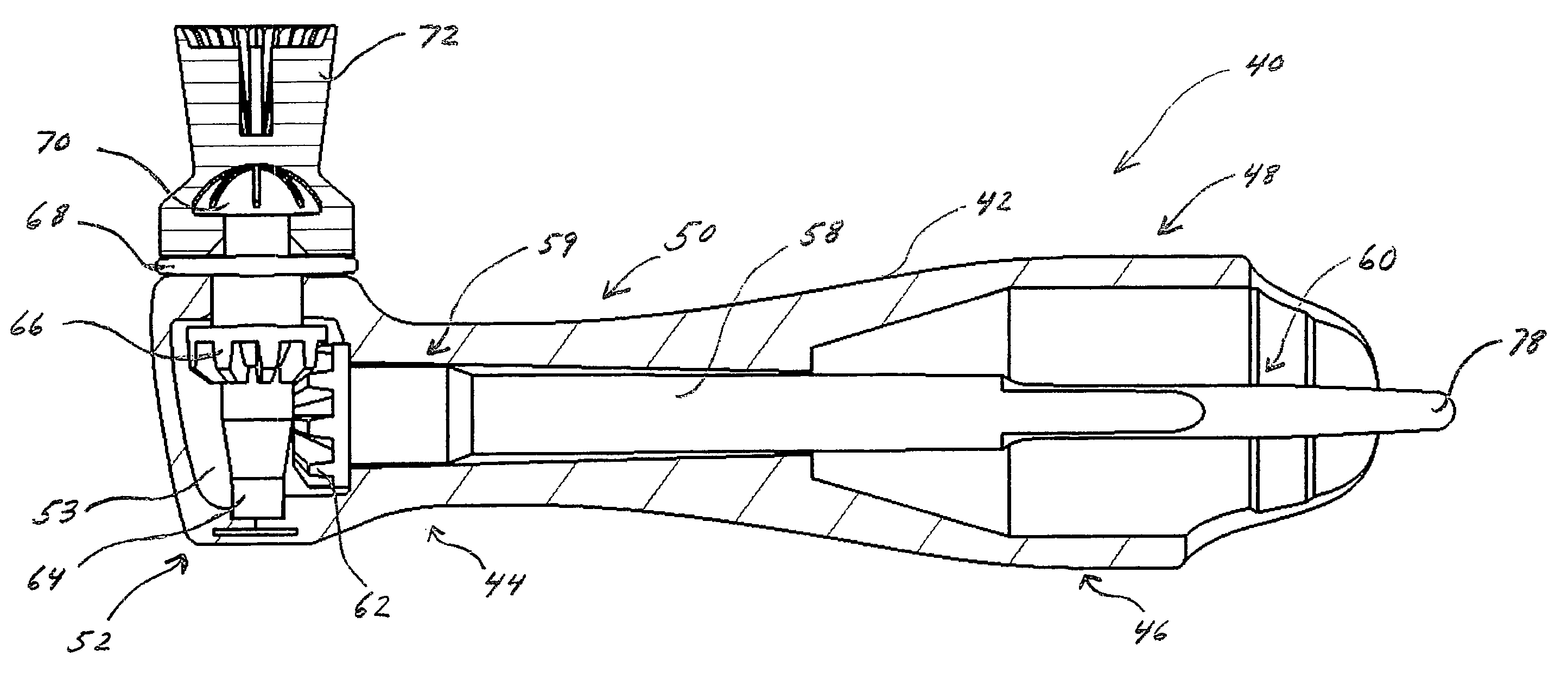

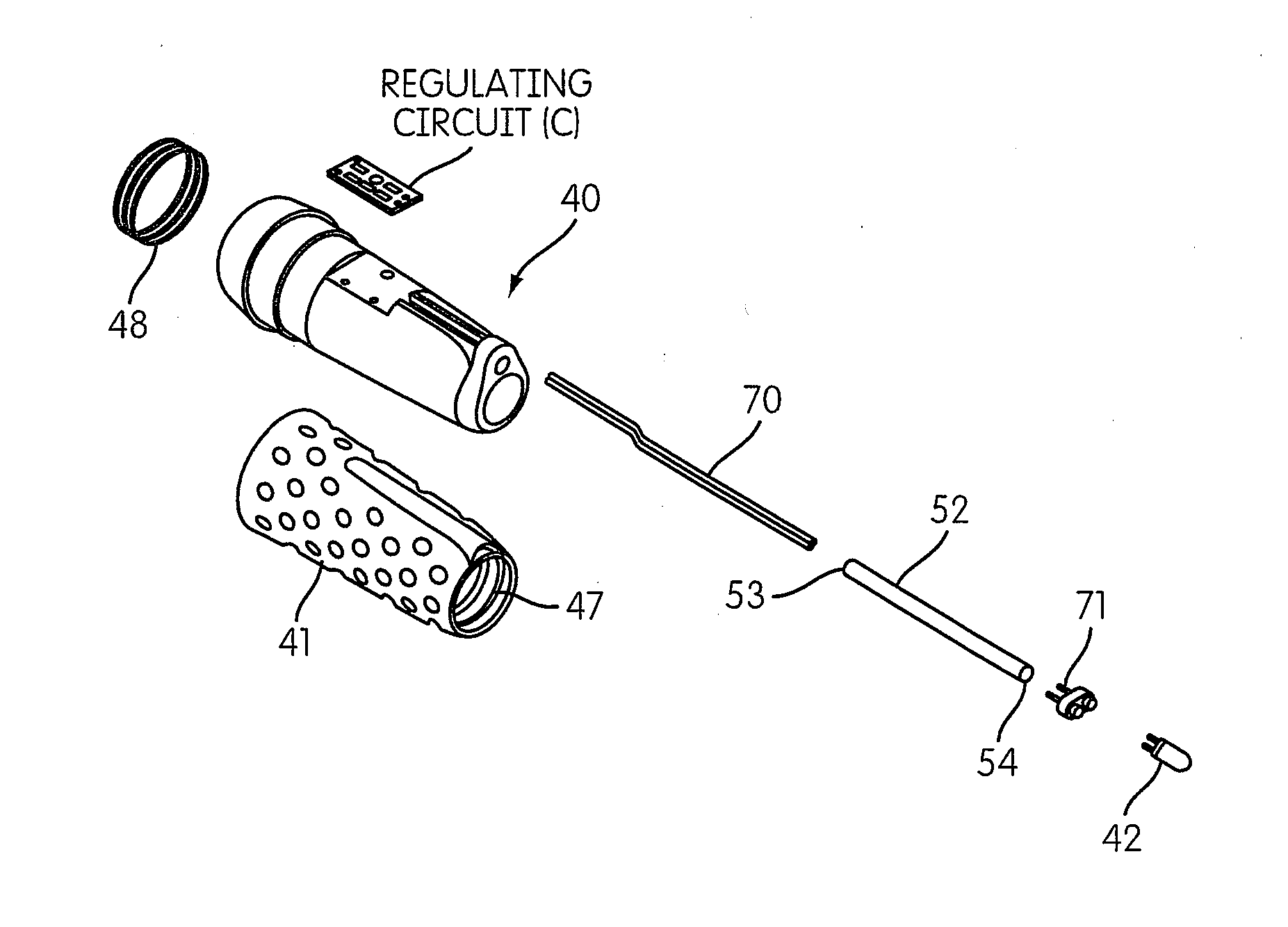

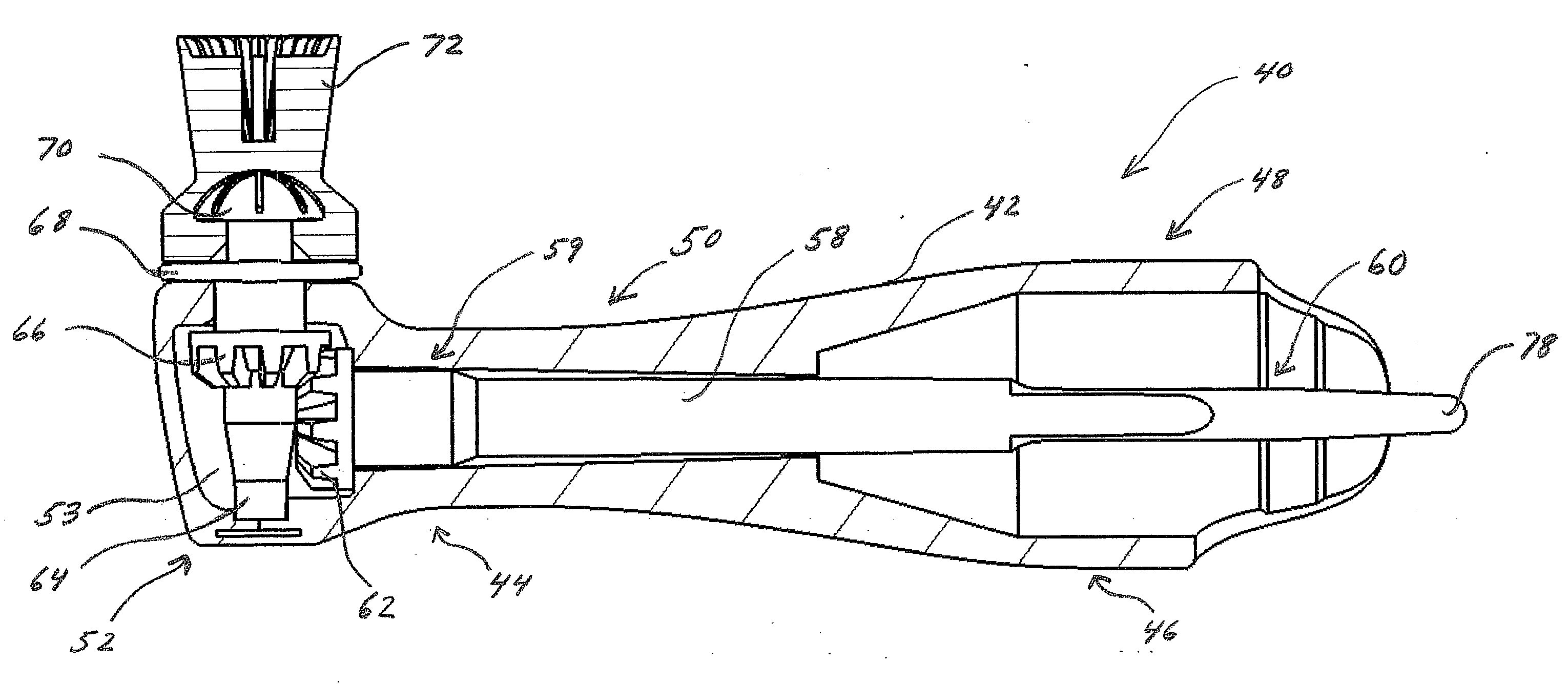

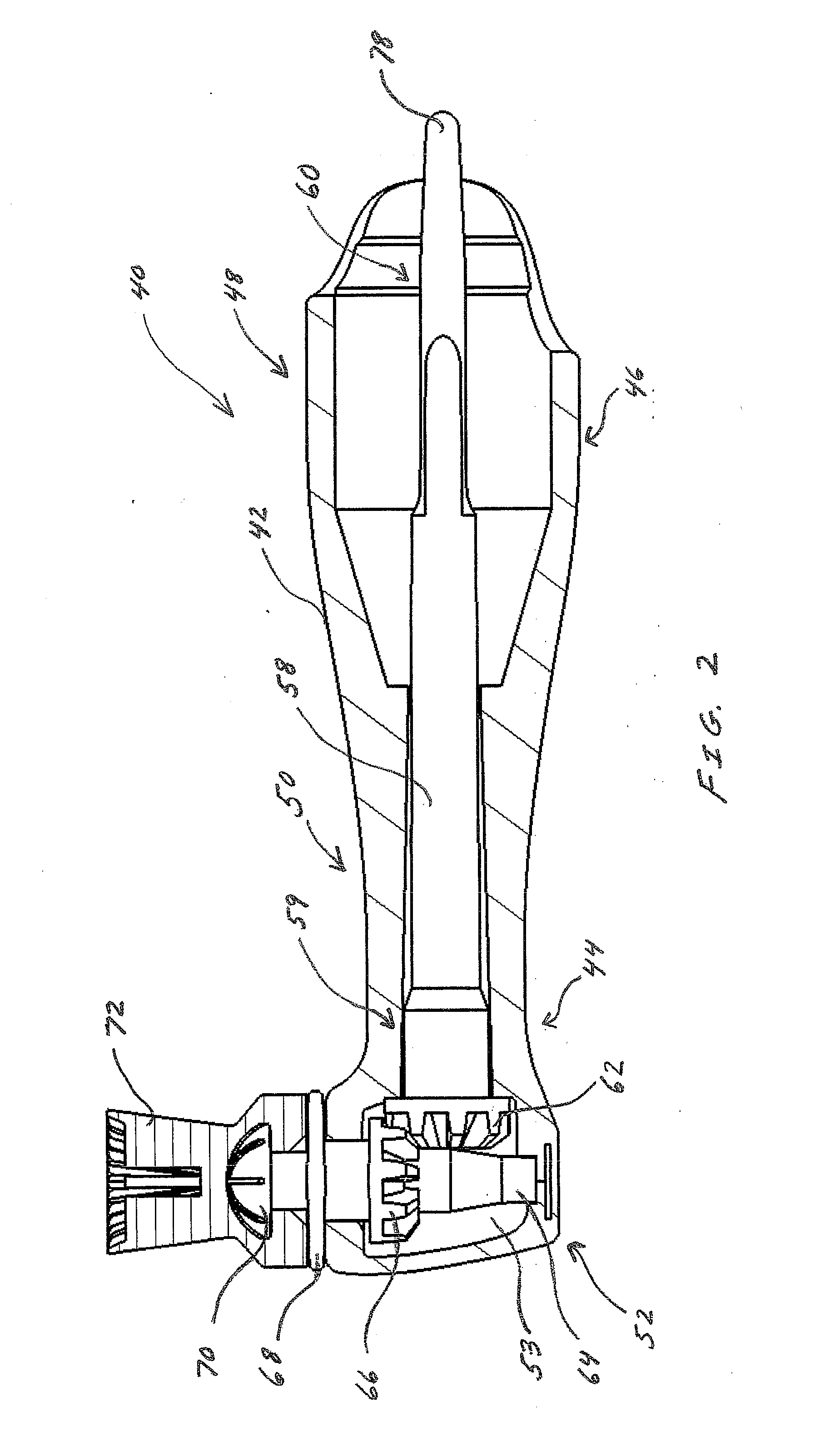

Ultrasonic dental insert and lighted handpiece assembly

An ultrasonic dental handpiece and insert assembly is provided. Scaler inserts that can be used to clean and polish tooth surfaces are particularly preferred. A sleeve is removably mounted on the handpiece. The handpiece contains a primary coil and the sleeve encloses a secondary coil, which are inductively coupled together so that electromagnetic energy can be transferred between them. A flexible light guide member having a light source such as a light-emitting diode extends from the sleeve. The light guide can bend and flex in any direction allowing the light source to emit light in any direction.

Owner:WERNER PETER +2

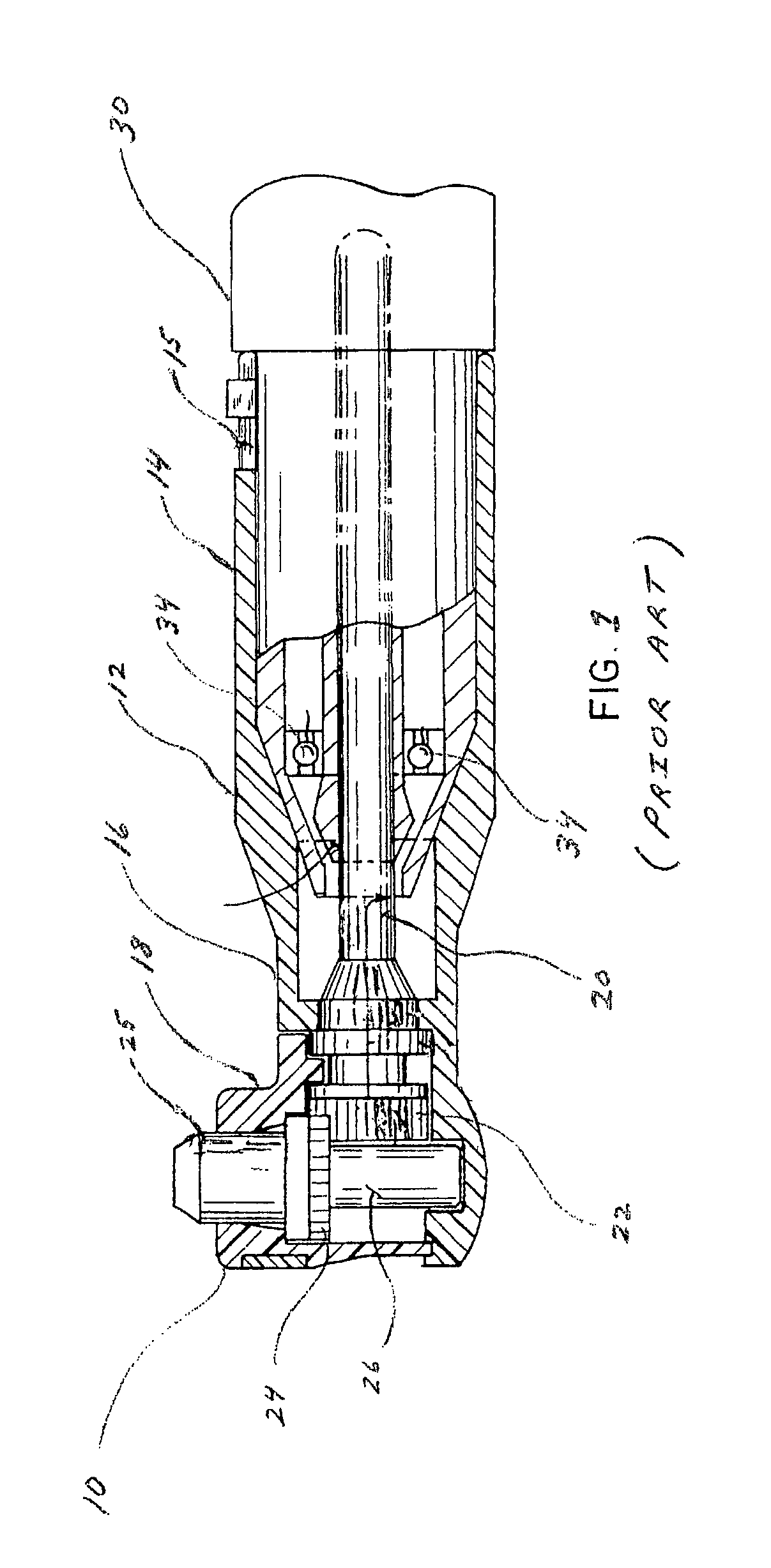

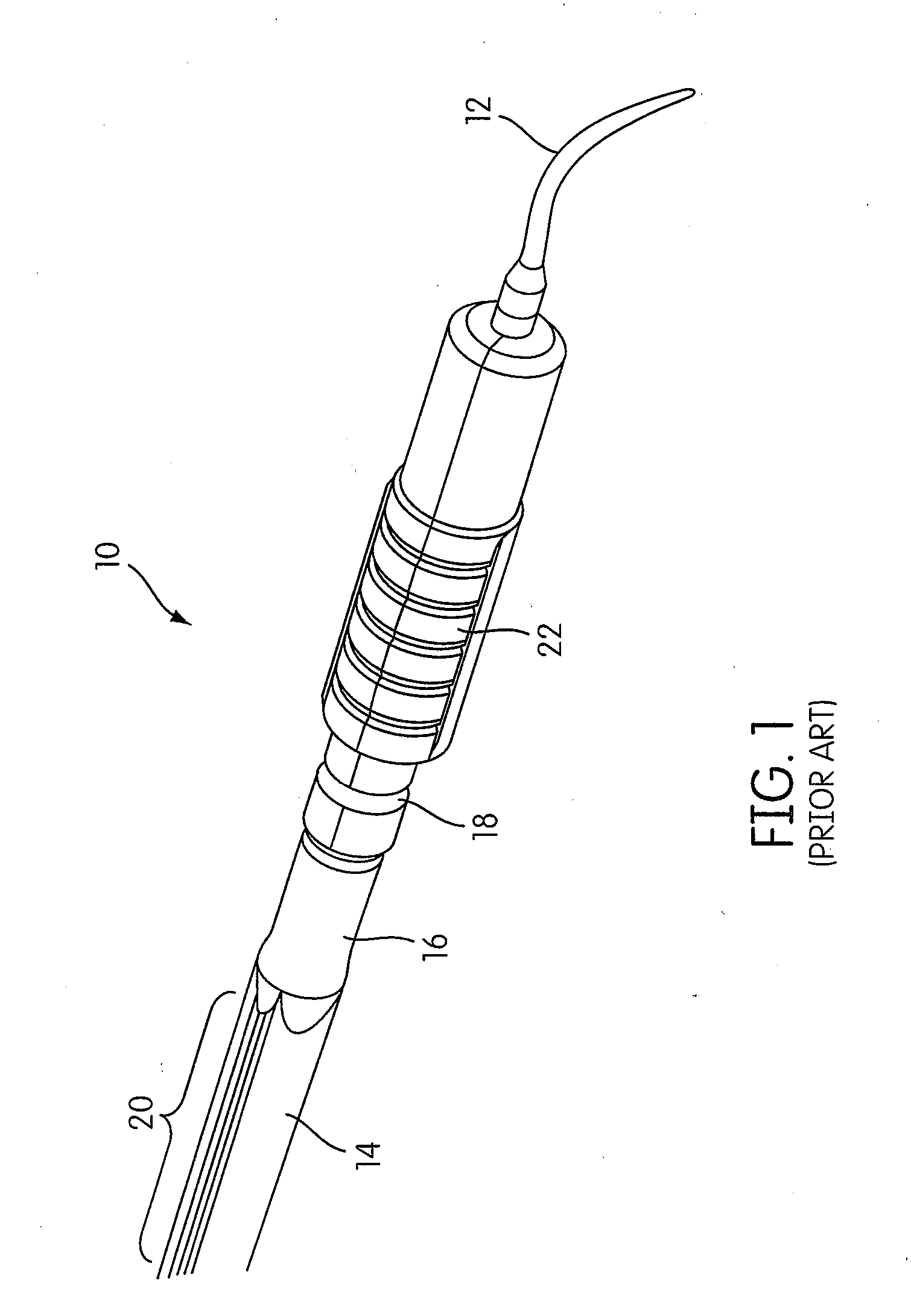

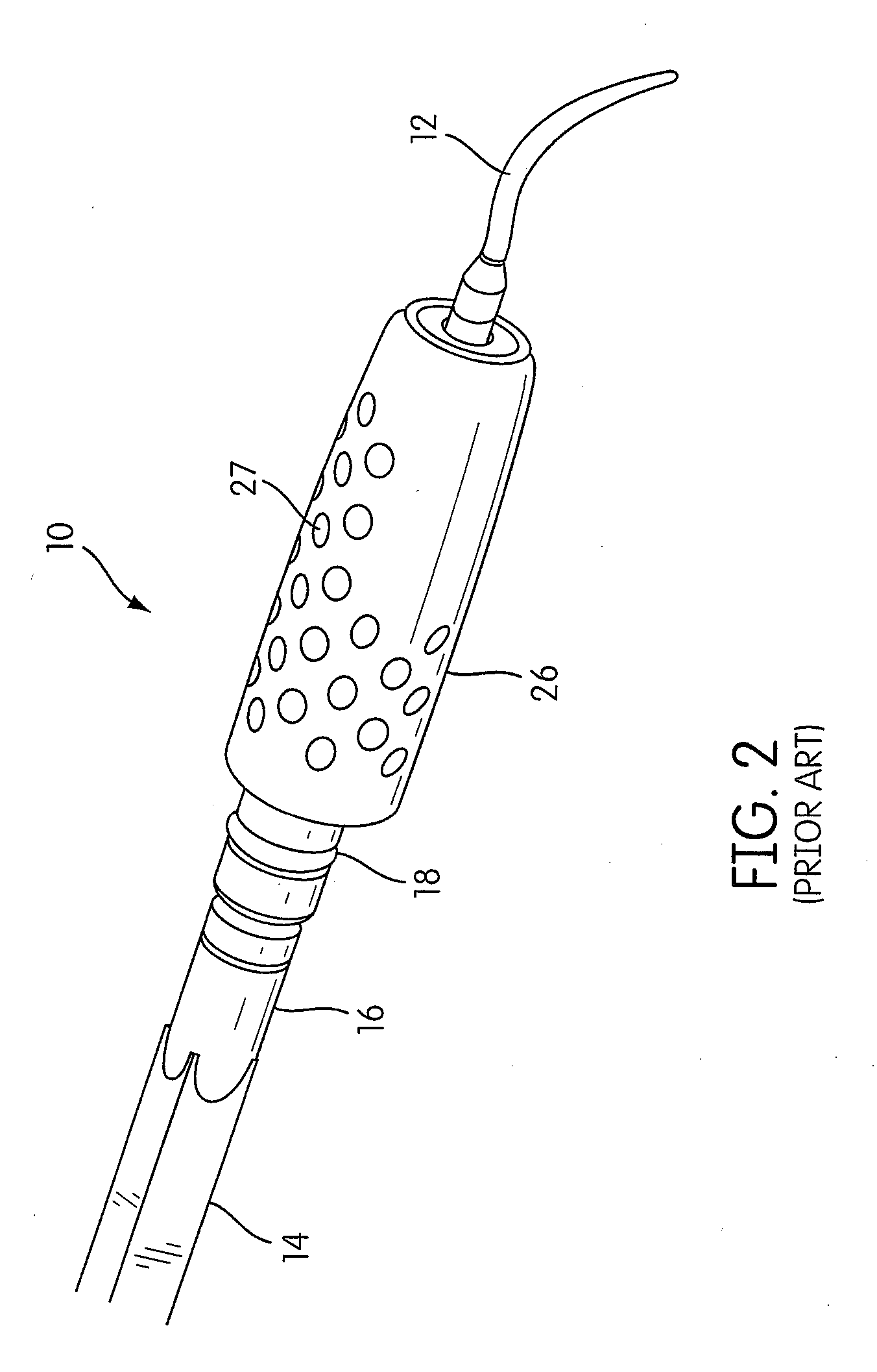

Splatter shield for dental cleaning instrument

A disposable guard device for removable attachment to a dental cleaning instrument which uses a prophy angle with a spinning prophy cup to polish tooth surfaces. The device is formed of a flexible, resilient material and includes an attachment portion and an integral dome portion. The attachment portion is structured and disposed for removable, snug fitted receipt over the head and neck of the prophy angle to securely hold the dome portion in surrounding relation to the prophy cup, thereby providing a shield that prevents splatter of cleaning paste and bodily fluids when cleaning the teeth of a patient. The wall forming the dome portion is transparent to allow visibility of the prophy cup against the tooth surfaces during cleaning.

Owner:LEES SHON T +1

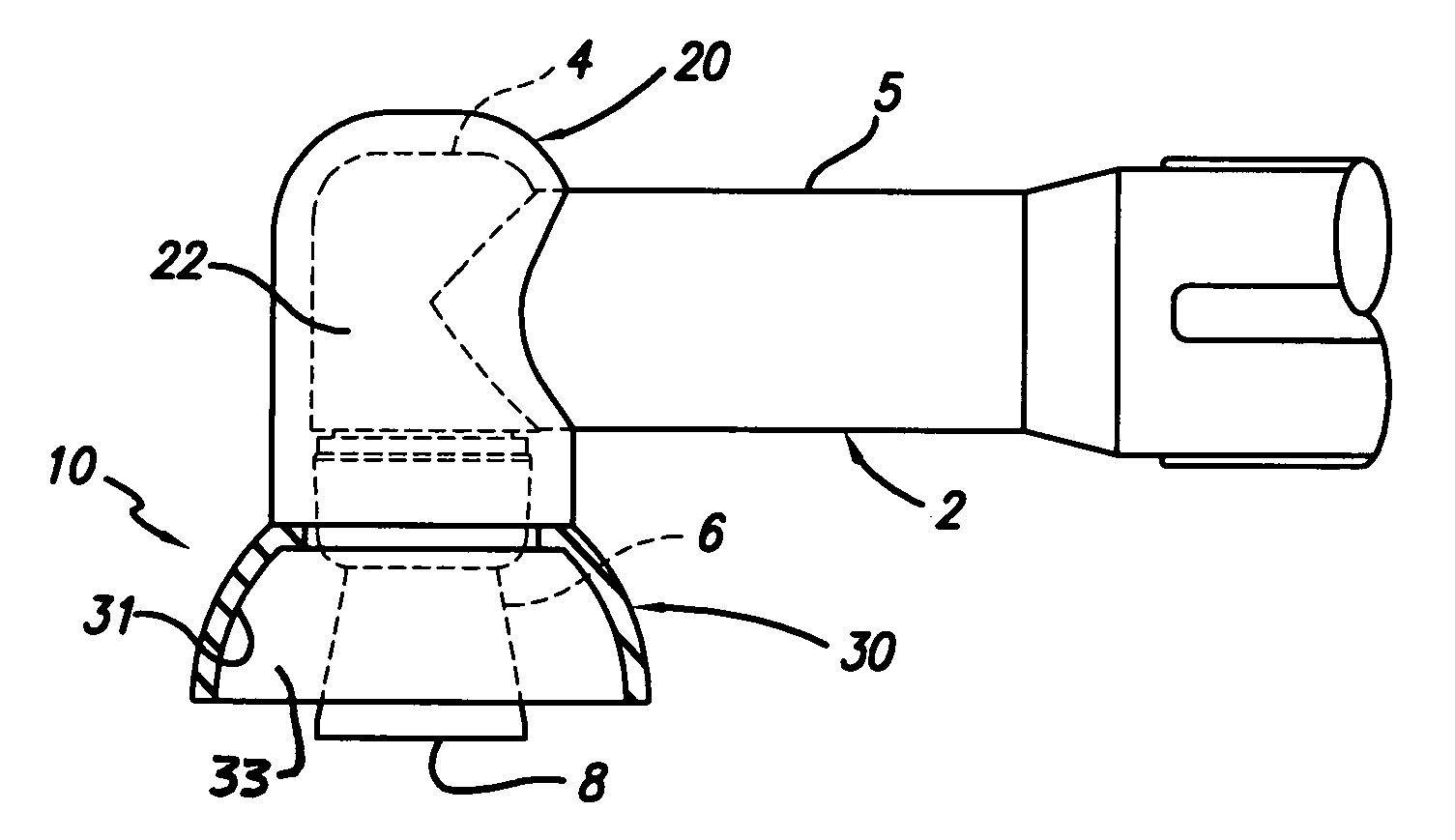

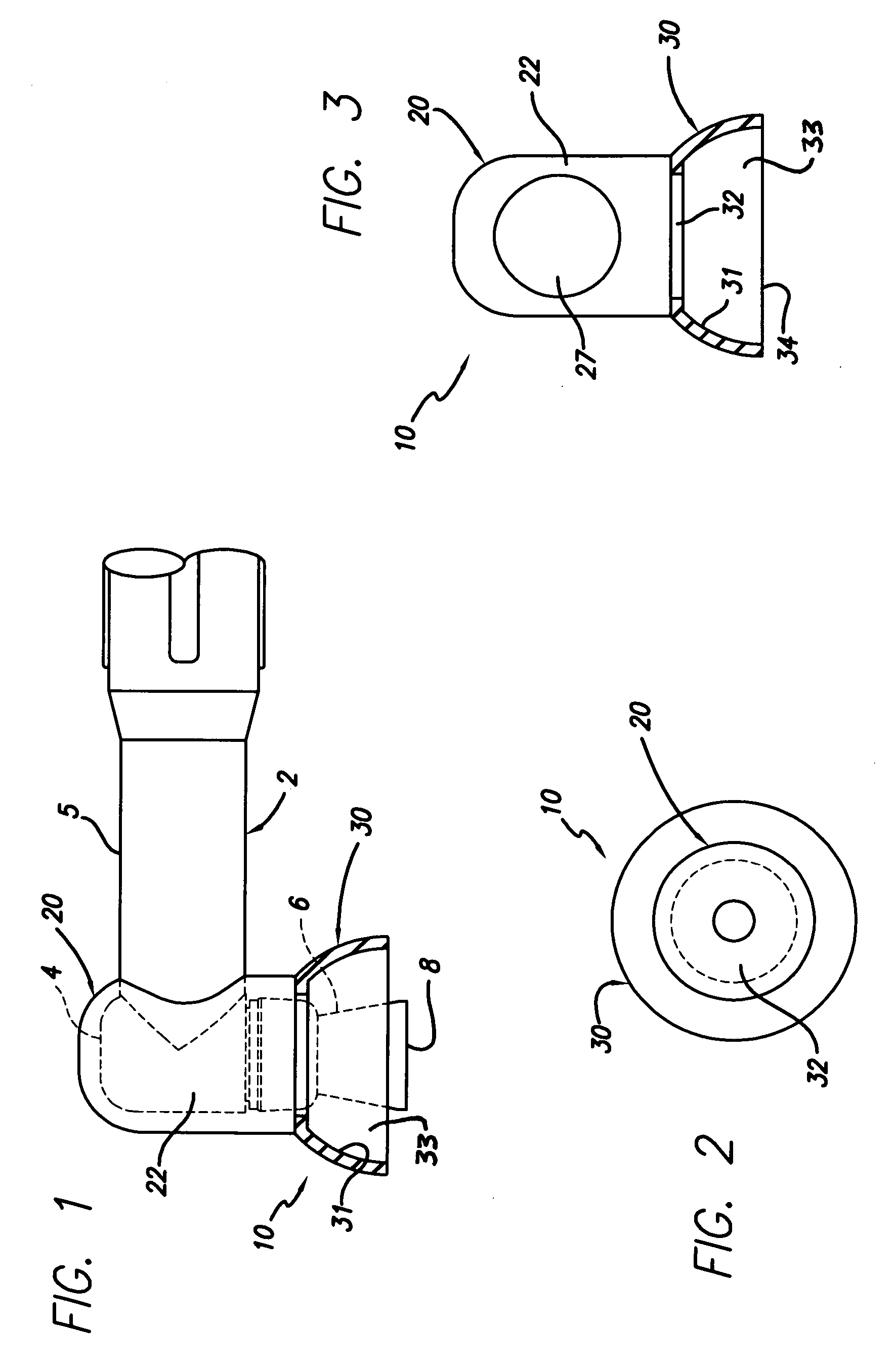

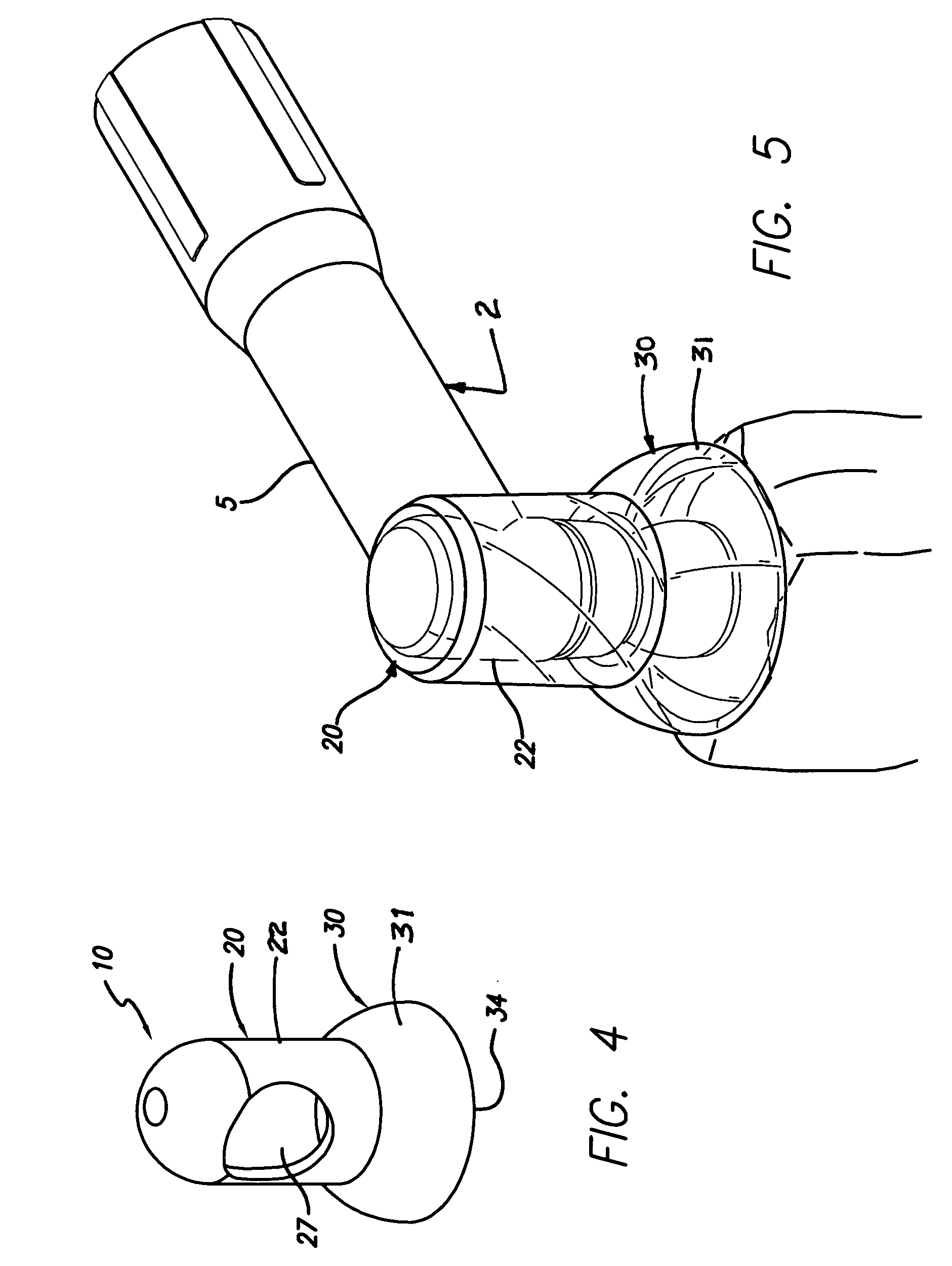

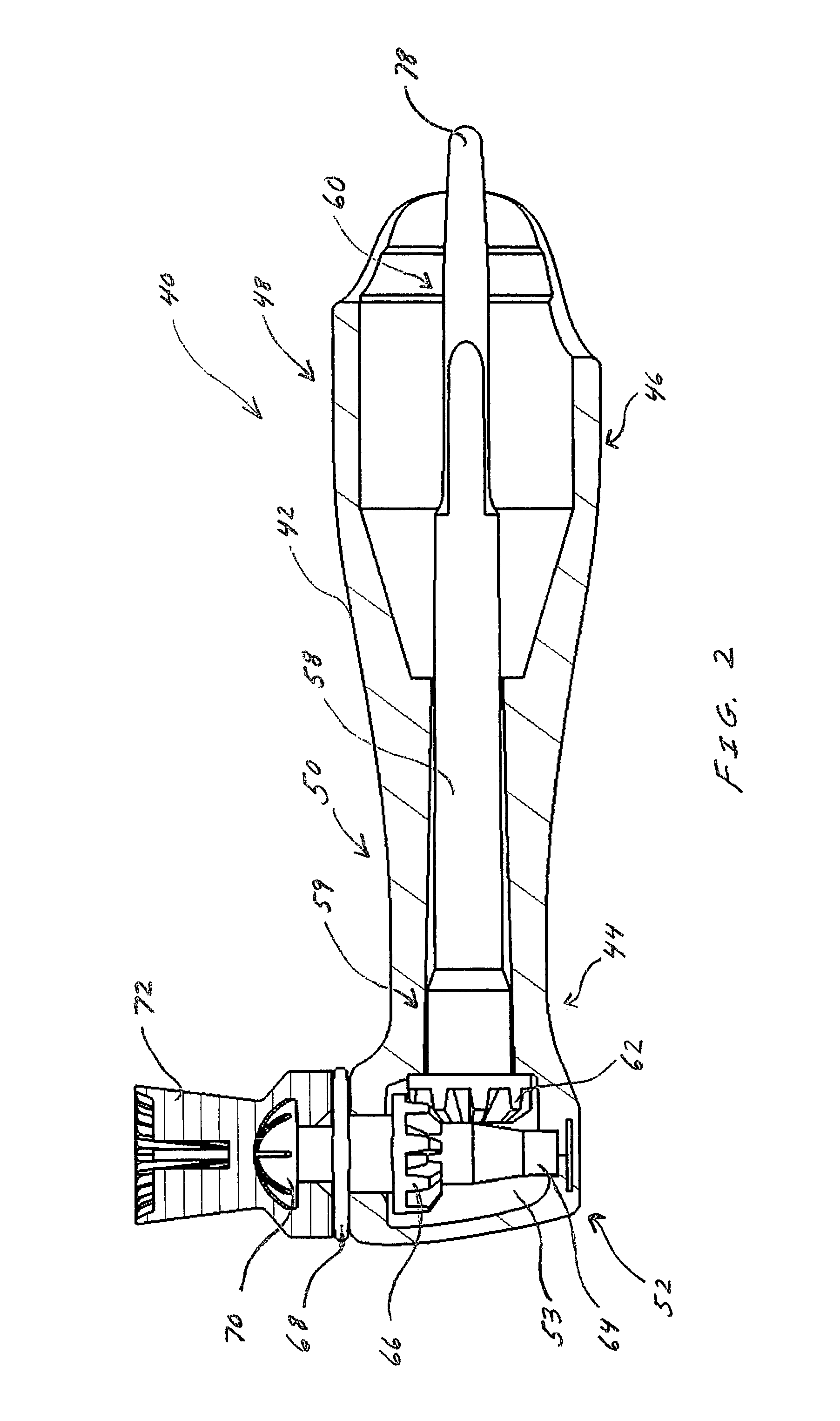

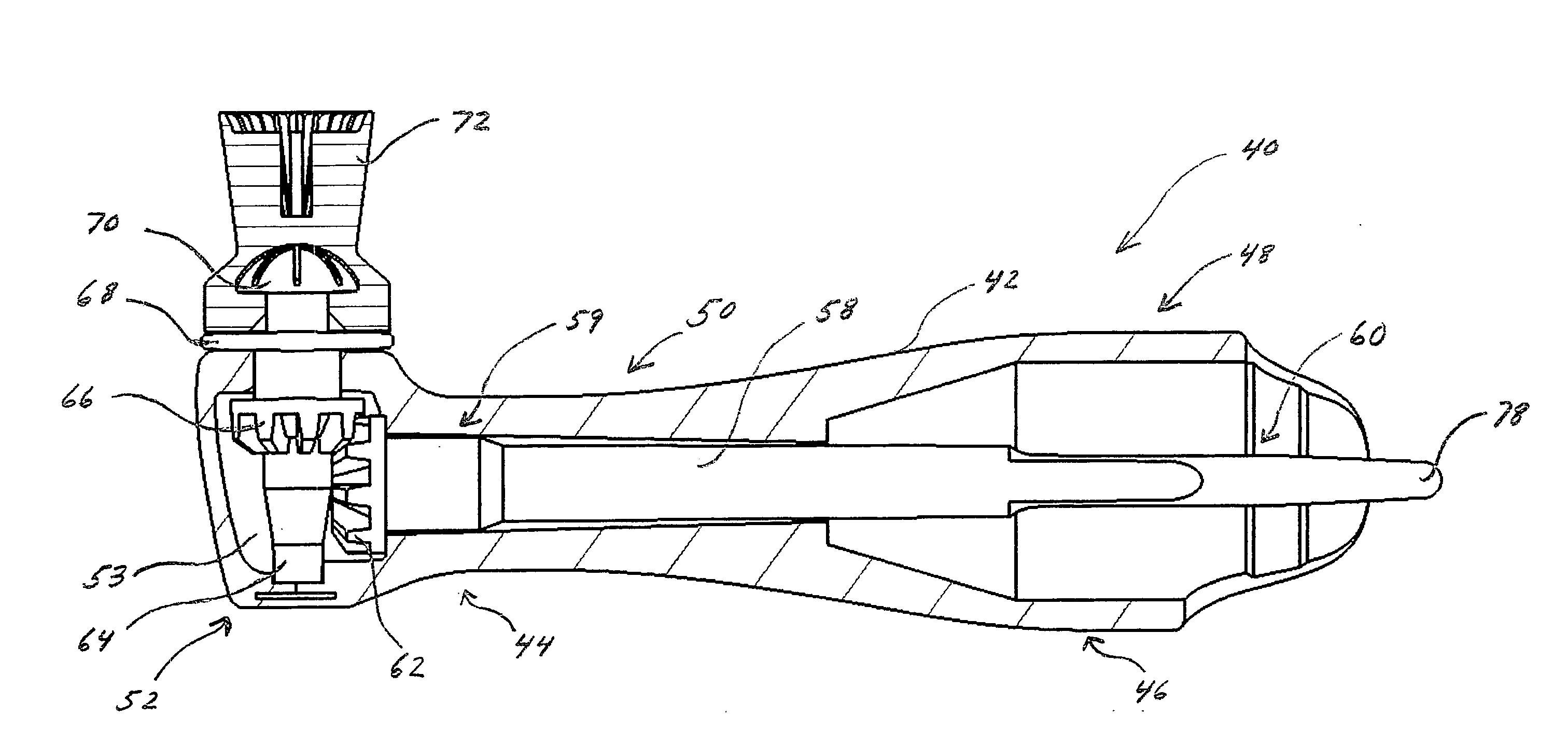

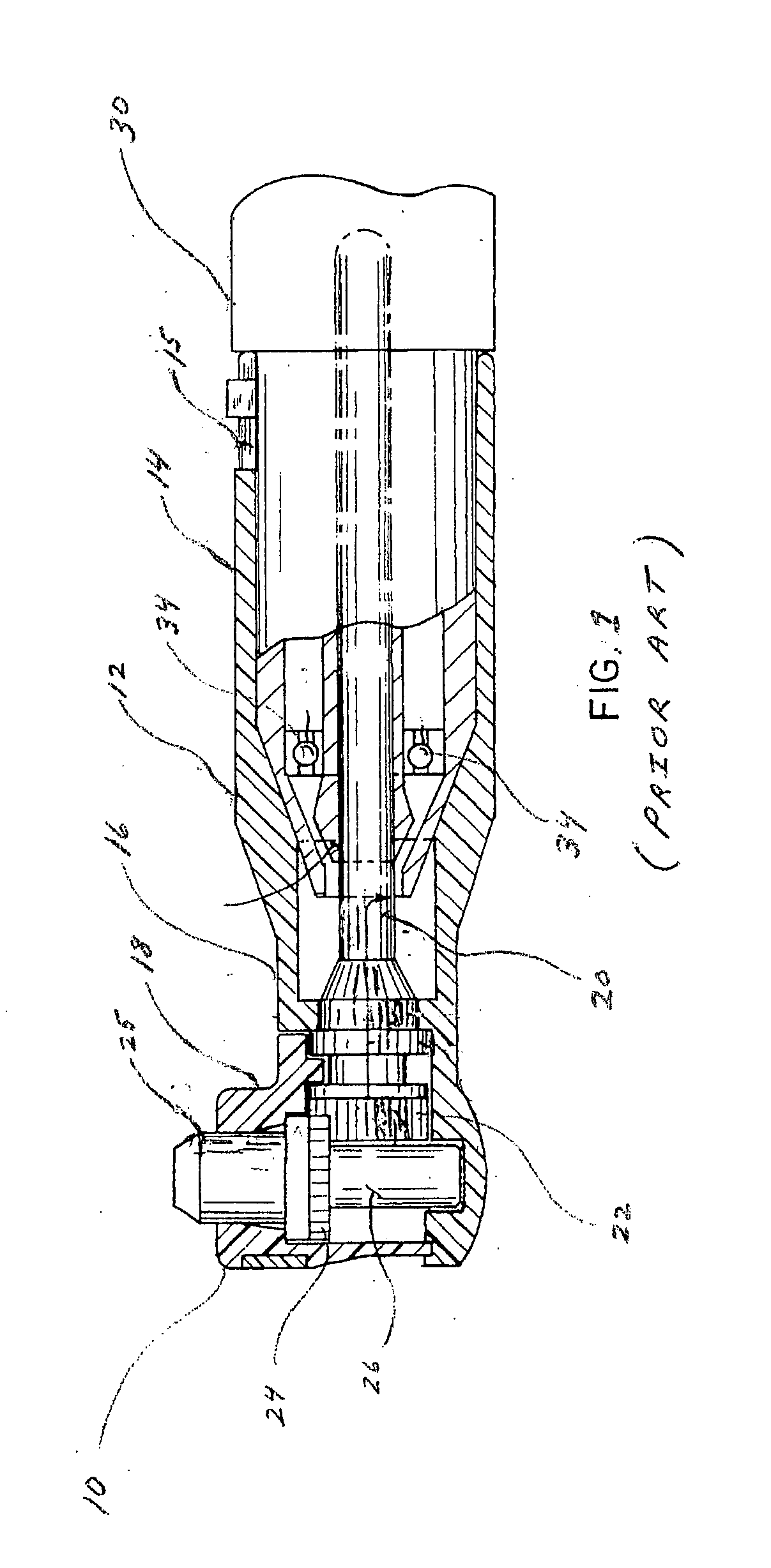

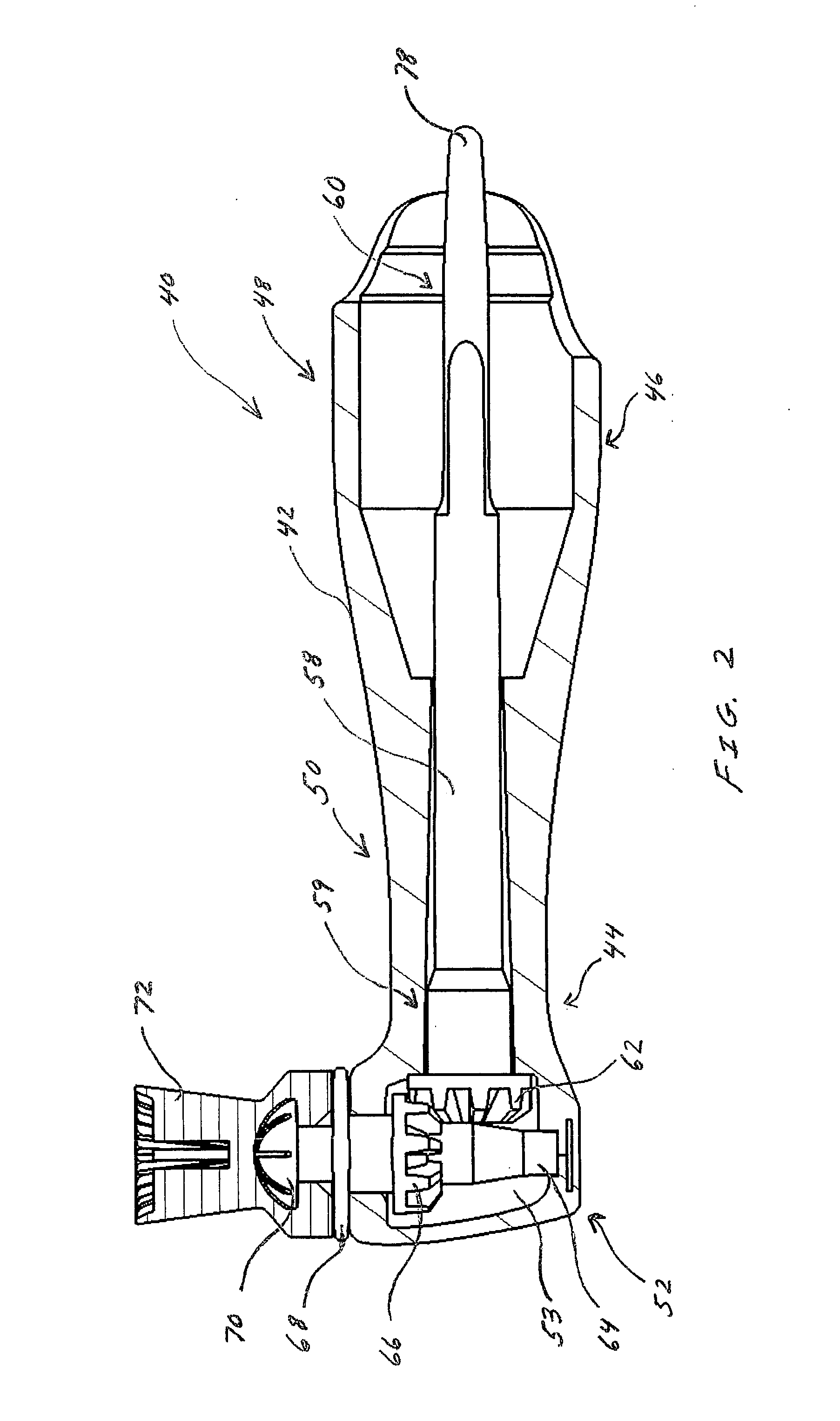

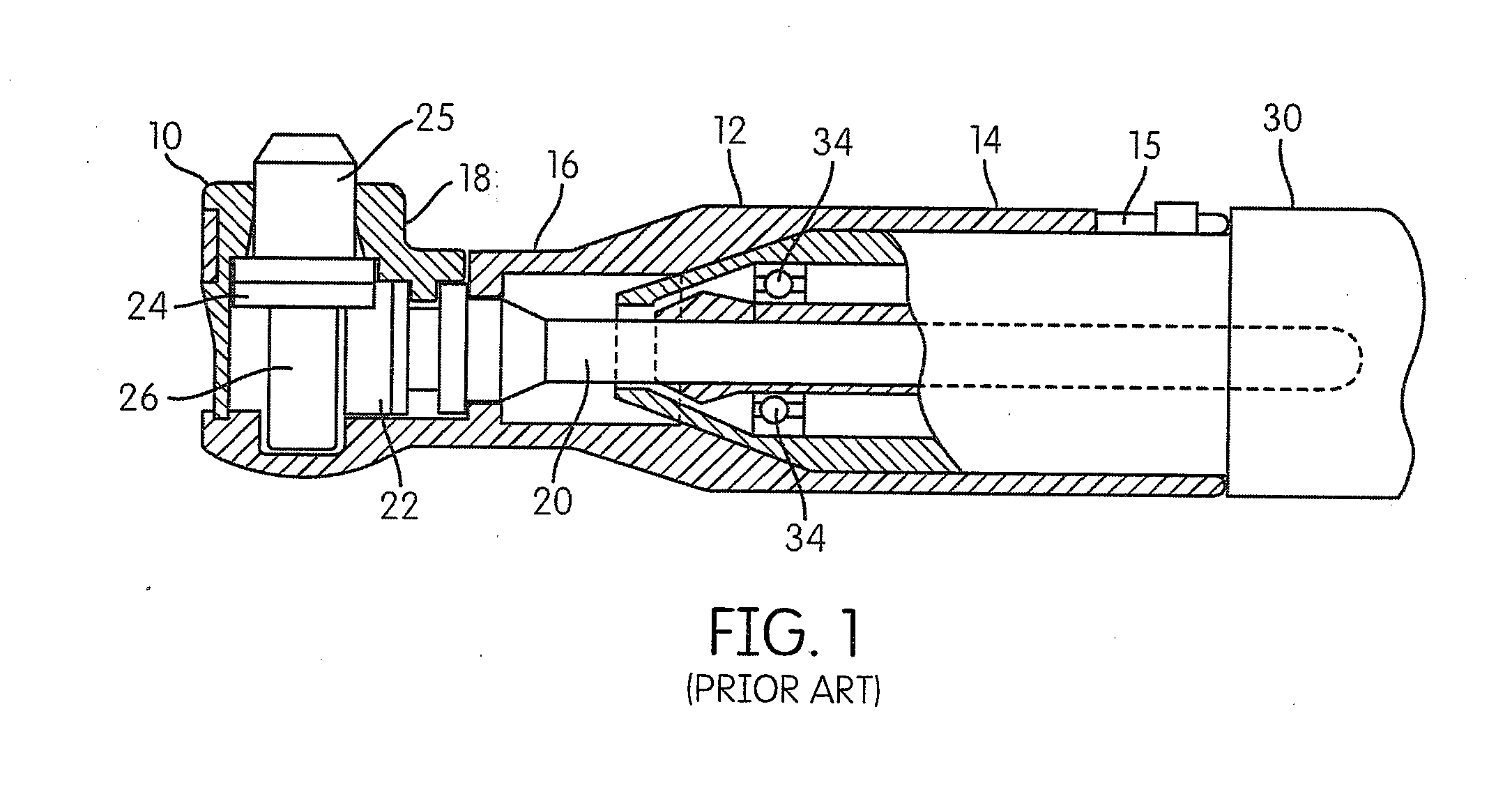

Dental prophylaxis angle and handpiece assembly

A dental prophylaxis angle and handpiece assembly for cleaning and polishing teeth is provided. The dental prophylaxis angle is removably attached to the dental handpiece by an interlocking mechanism that includes extension locking tabs, a locking annular member, and an interlocking drive member in the handpiece. The prophy angle is securely snap-fitted onto the handpiece and locked in place so that it has minimal lateral movement. After the prophy angle has been used to treat a patient, it can be removed easily from the handpiece and disposed thereof.

Owner:DENTSPLY SIRONA INC

Dental prophylaxis angle and handpiece assembly

A dental prophylaxis angle and handpiece assembly for cleaning and polishing teeth is provided. The dental prophylaxis angle is removably attached to the dental handpiece by an interlocking mechanism that includes extension locking tabs, a locking annular member, and an interlocking drive member in the handpiece. The prophy angle is securely snap-fitted onto the handpiece and locked in place so that it has minimal lateral movement. After the prophy angle has been used to treat a patient, it can be removed easily from the handpiece and disposed thereof.

Owner:DENTSPLY SIRONA INC

Hygiene instrument for cleaning and polishing the surface of the teeth and the composite materials of dental fillings

Hygiene instrument for removing stains, cleaning and polishing the surface of the teeth and the composite materials of dental fillings.The structure of the hygiene instrument is made up of fibers and optionally a load of particles embedded in a resinous matrix giving the working surface of the hygiene instrument a continuous abrasive power.

Owner:ABRASIVE TECH FRANCE

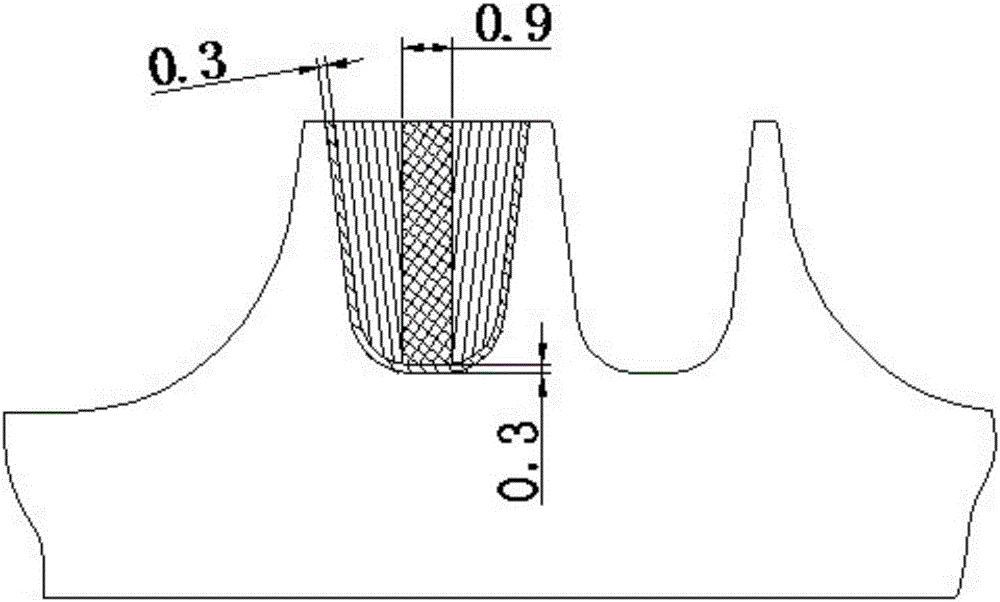

Machining method for improving surface integrity of sealing labyrinth of rotating part

Owner:AECC AVIATION POWER CO LTD

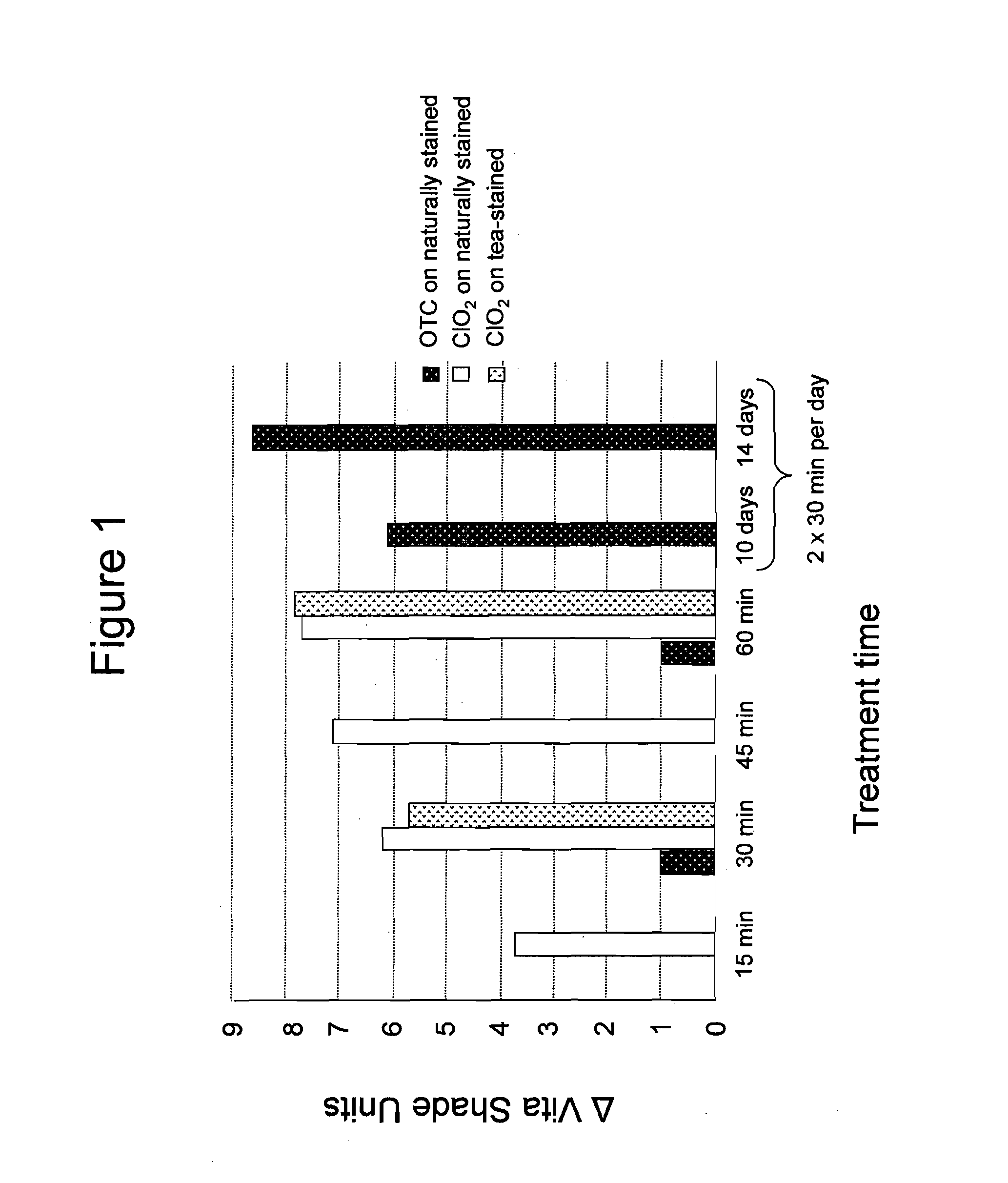

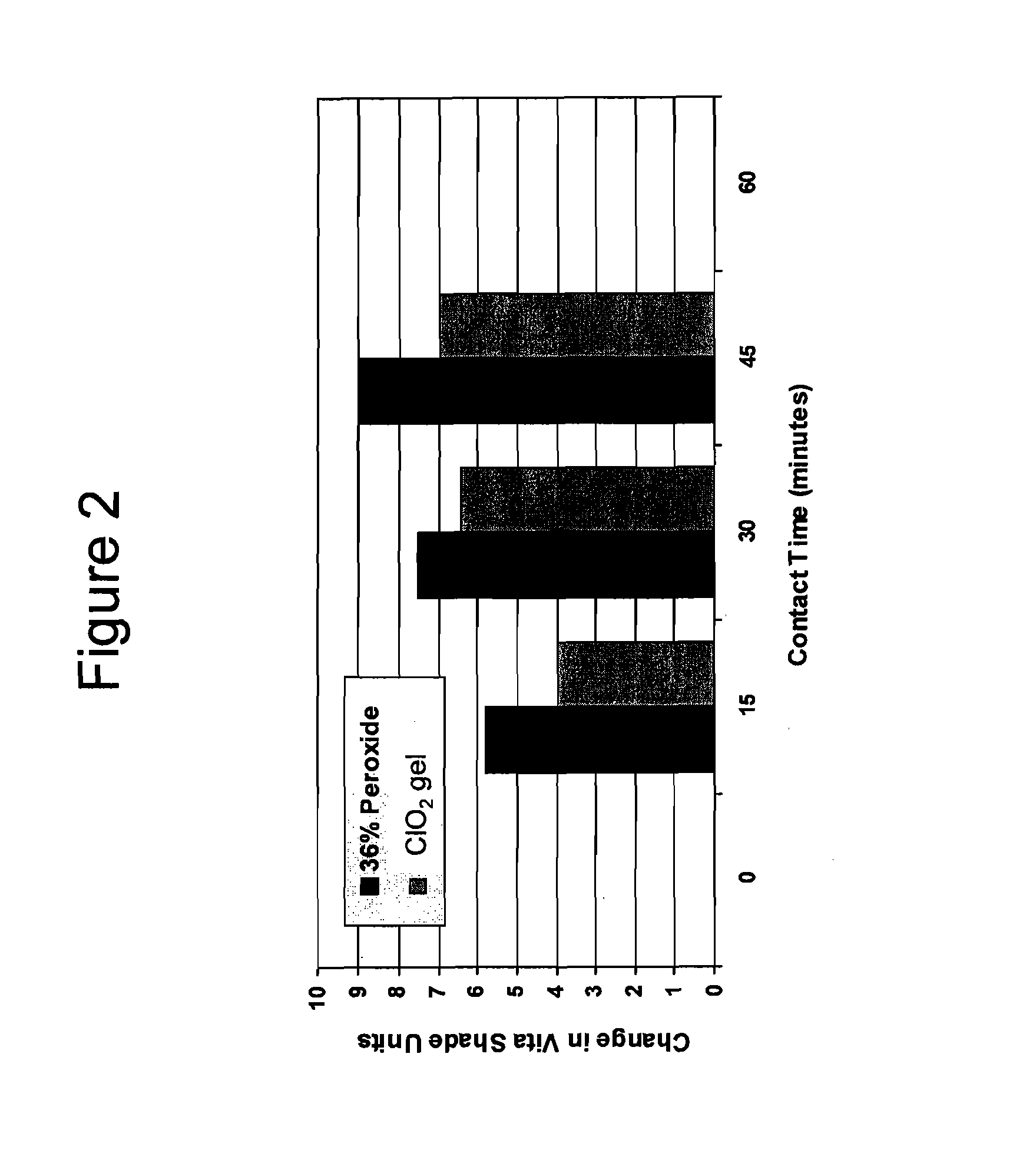

Tooth polishing compositions and methods of tooth polishing without mechanical abrasion

InactiveUS8518382B2Reduce surface roughnessBig contactCosmetic preparationsBiocideTooth polishingDentistry

A method of polishing a tooth surface without mechanical abrasion is provided. Kits and compositions are also provided.

Owner:BASF CORP

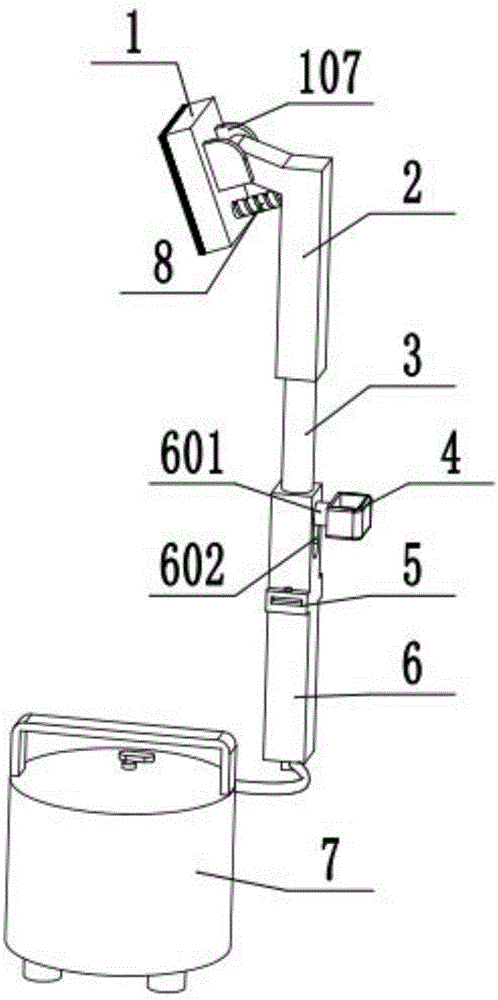

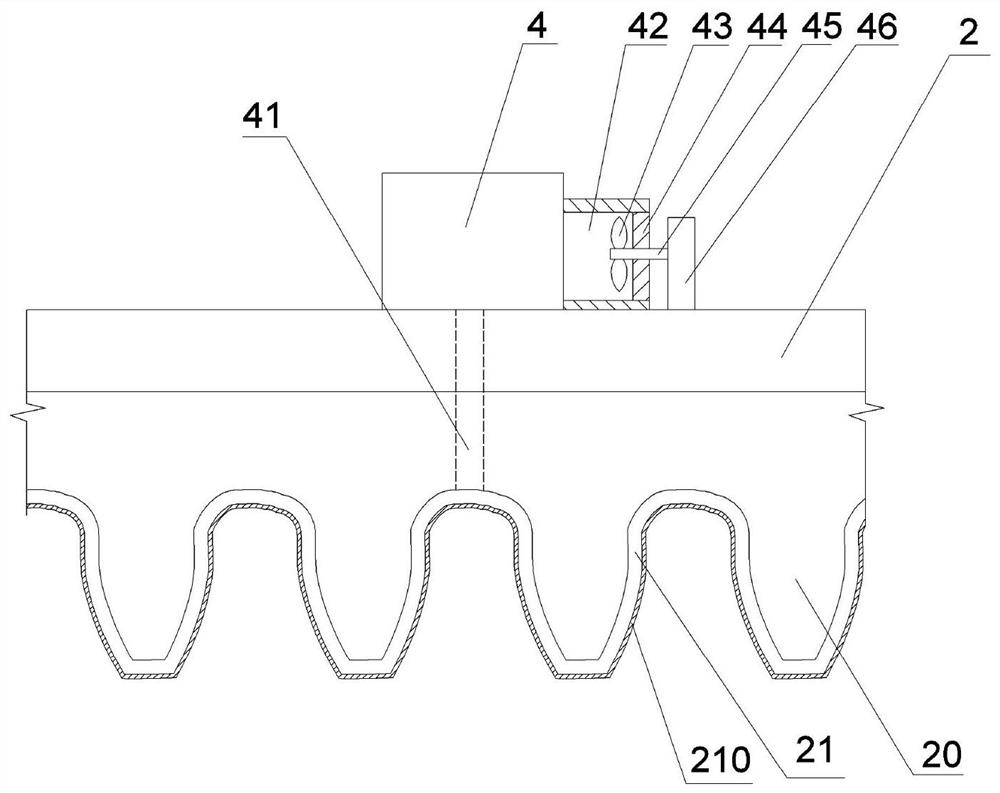

Building wall polishing device

InactiveCN107520702AAvoid interferenceCooperate wellPlane surface grinding machinesGrinding/polishing safety devicesPolish teethArchitectural engineering

The invention discloses a building wall polishing device. The building wall polishing device consists of a polishing device, a dust sucking device, a support rod, an auxiliary belt and an operation handle; the polishing device consists of a polishing box, an extension cover and a polishing belt; the polishing belt is rotationally connected with the polishing box through a bearing; polishing teeth are arranged on the polishing belt; the extension cover fixedly connected is arranged at an opening end of the polishing box; a dust sucking hole is formed in a receiving box, and is provided with a dust sucking pipe; a connecting plate is arranged at the back end of the polishing box, and is rotationally connected with the support rod; and the support rod consists of an upper support rod, a connecting column and a lower support rod. The support rod can be fixed on a body through cooperation of an insertion port and an insertion head to share the weight of an arm, so that the operation is easier; and the building wall polishing device can realize adjustment of the polishing angle and polishing of a top wall.

Owner:WUHAN YIWEIDENG TECH DEV

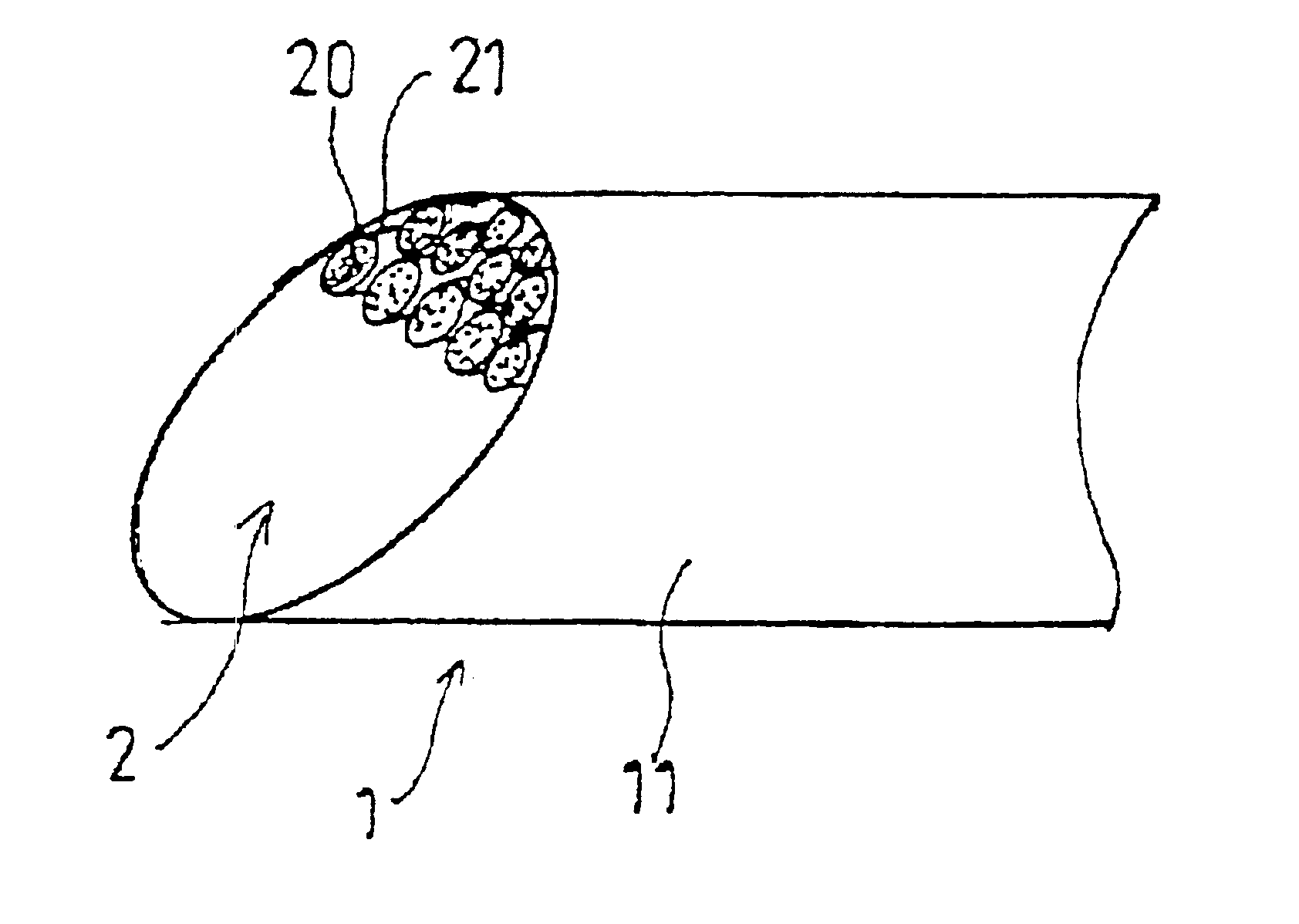

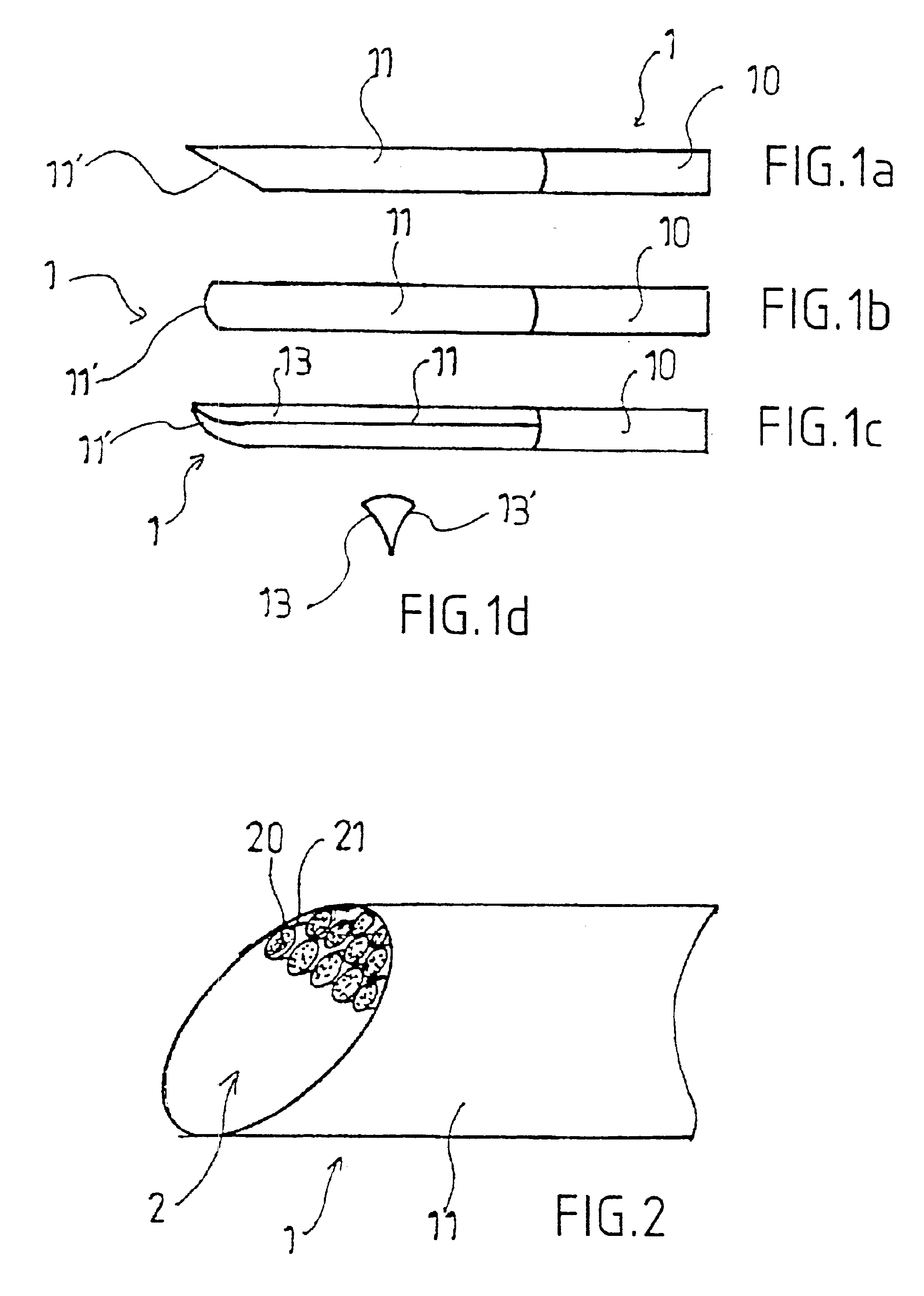

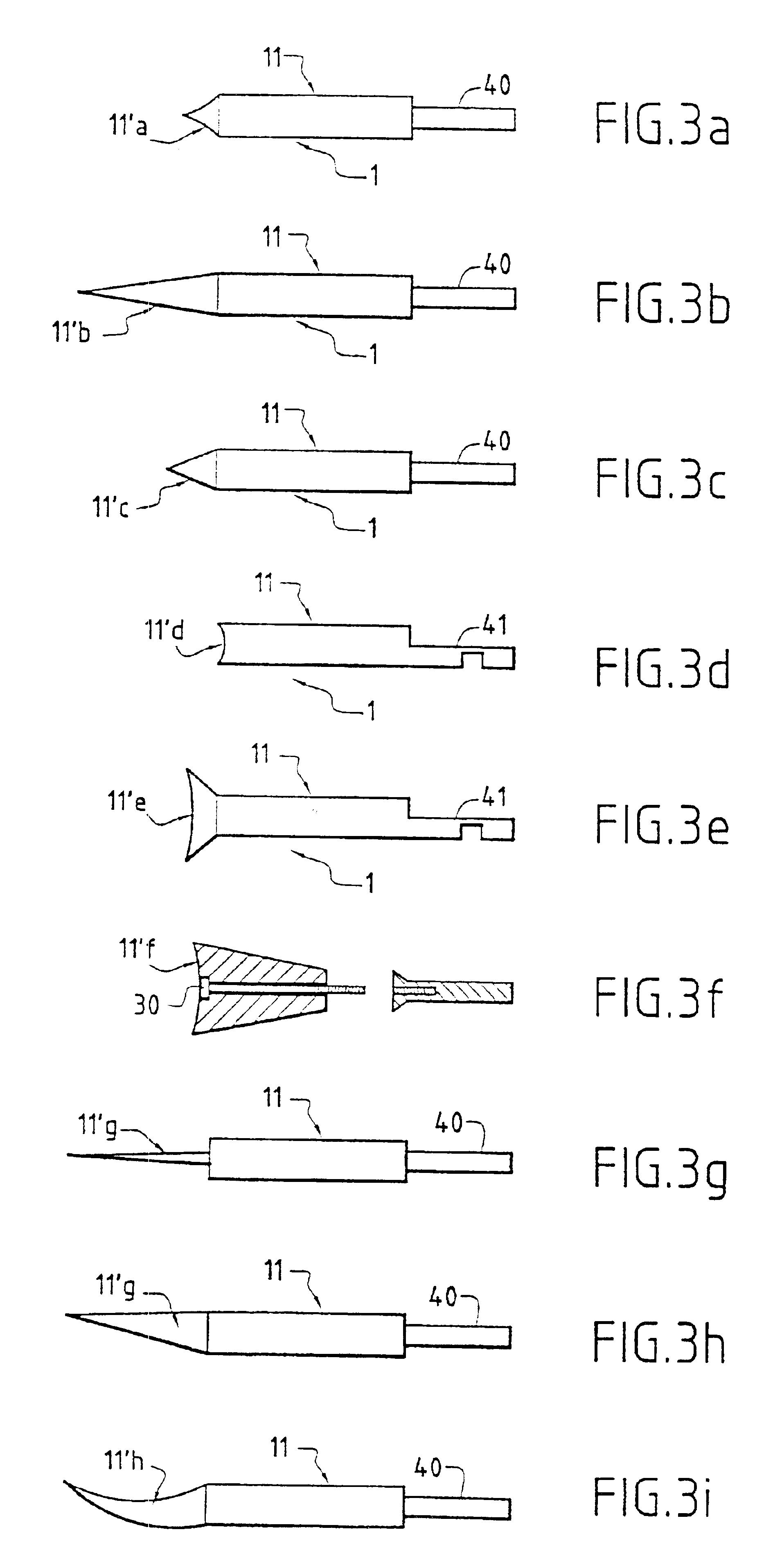

Ultrasonic dental insert and lighted handpiece assembly

An ultrasonic dental handpiece and insert assembly is provided. Scaler inserts that can be used to clean and polish tooth surfaces are particularly preferred. A sleeve is removably mounted on the handpiece. The handpiece contains a primary coil and the sleeve encloses a secondary coil, which are inductively coupled together so that electromagnetic energy can be transferred between them. A flexible light guide member having a light source such as a light-emitting diode extends from the sleeve. The light guide can bend and flex in any direction allowing the light source to emit light in any direction.

Owner:WERNER PETER +2

Dental prophylaxis angle and handpiece assembly

InactiveUS20120107769A1Feel goodEasy to holdDental toolsMetal working apparatusEngineeringDental Prophylaxis

A dental prophylaxis angle and handpiece assembly for cleaning and polishing teeth is provided. The dental prophylaxis angle is removably attached to the dental handpiece by an interlocking mechanism that includes extension locking tabs, a locking annular member, and an interlocking drive member in the handpiece. The prophy angle is securely snap-fitted onto the handpiece and locked in place so that it has minimal lateral movement. After the prophy angle has been used to treat a patient, it can be removed easily from the handpiece and disposed thereof.

Owner:DENTSPLY SIRONA INC

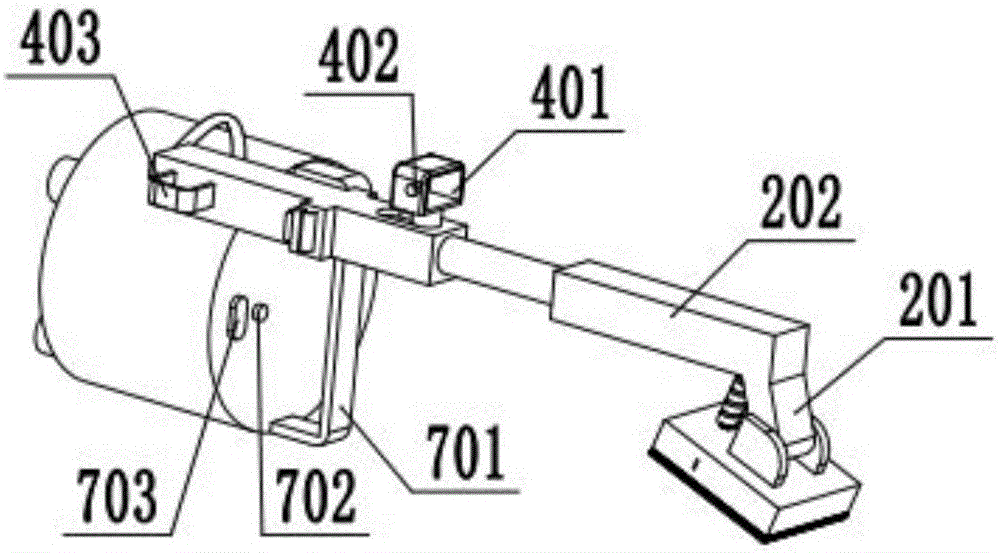

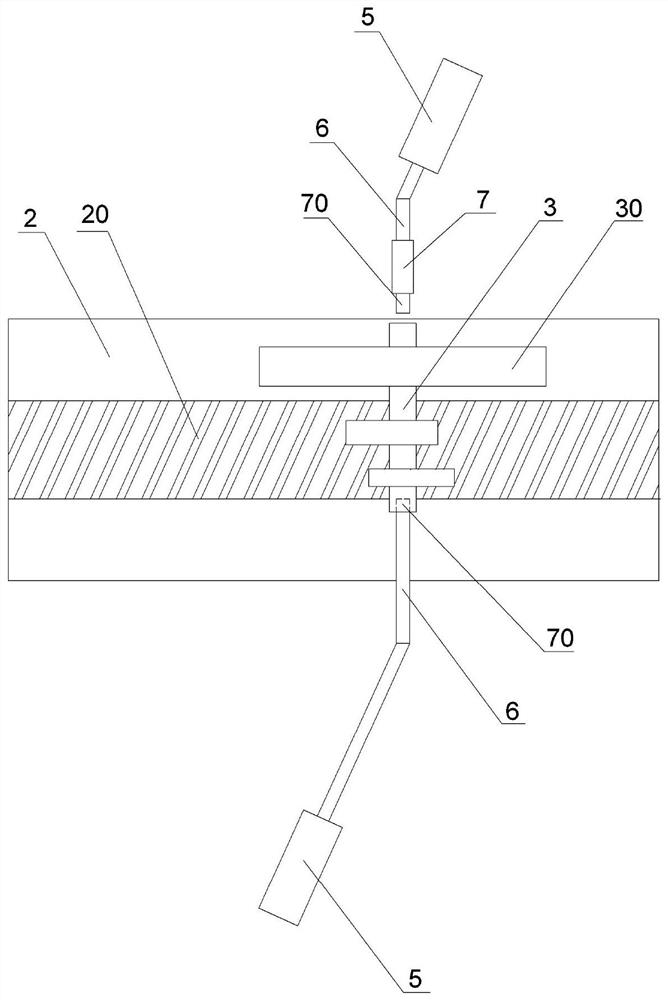

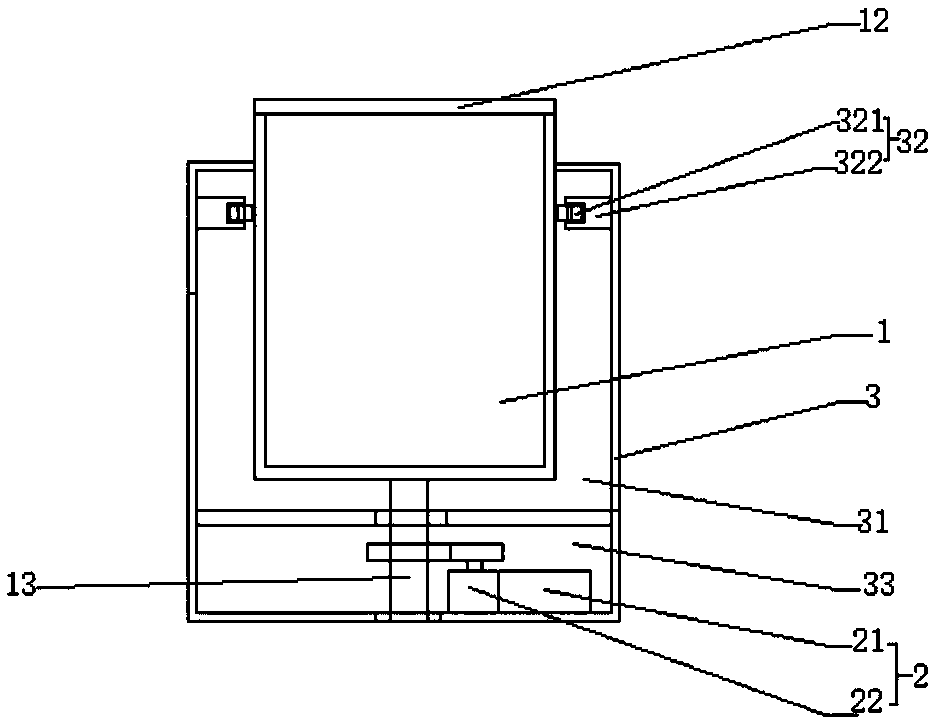

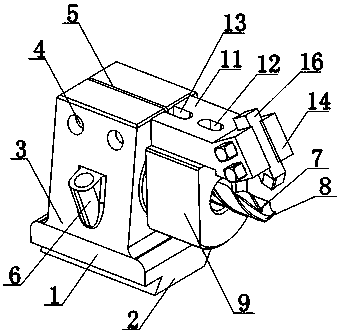

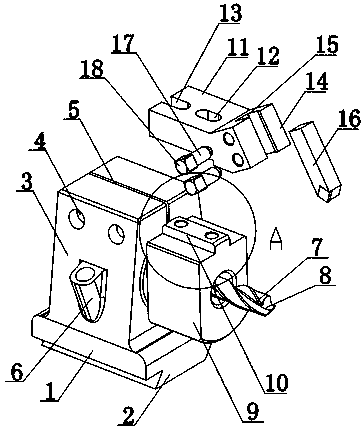

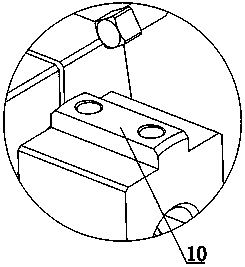

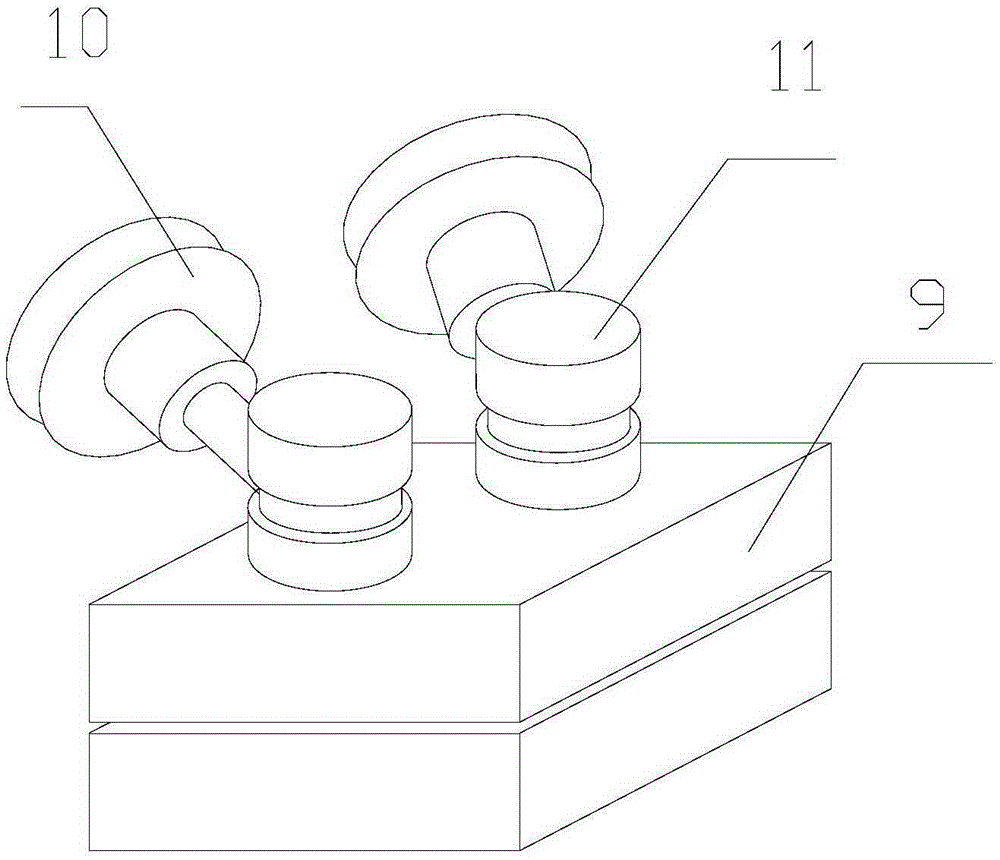

Powder recycle device of bamboo splint polisher

InactiveCN102975122AEasy to operateAvoid sweepingGrinding/polishing safety devicesBiomedical engineeringPolishing teeth

A powder recycle device of a bamboo splint polisher relates to the technical field of bamboo weaving. The powder recycle device of the bamboo splint polisher comprises a polisher. Polishing teeth are arranged on the polisher. The powder recycle device of the bamboo splint polisher is characterized that a collecting device is arranged outside the polishing teeth. The collecting device is in a box-shaped structure. The collecting device is arranged below the polishing teeth. The lower portion of the collecting device is connected with a recycling pipe. The recycling pipe is made of flexible plastics. One end of the recycling pipe is connected with a recycling box. The powder recycle device of the bamboo splint polisher is of being reasonable in structure, easy to install and convenient to operate.

Owner:蒋克红

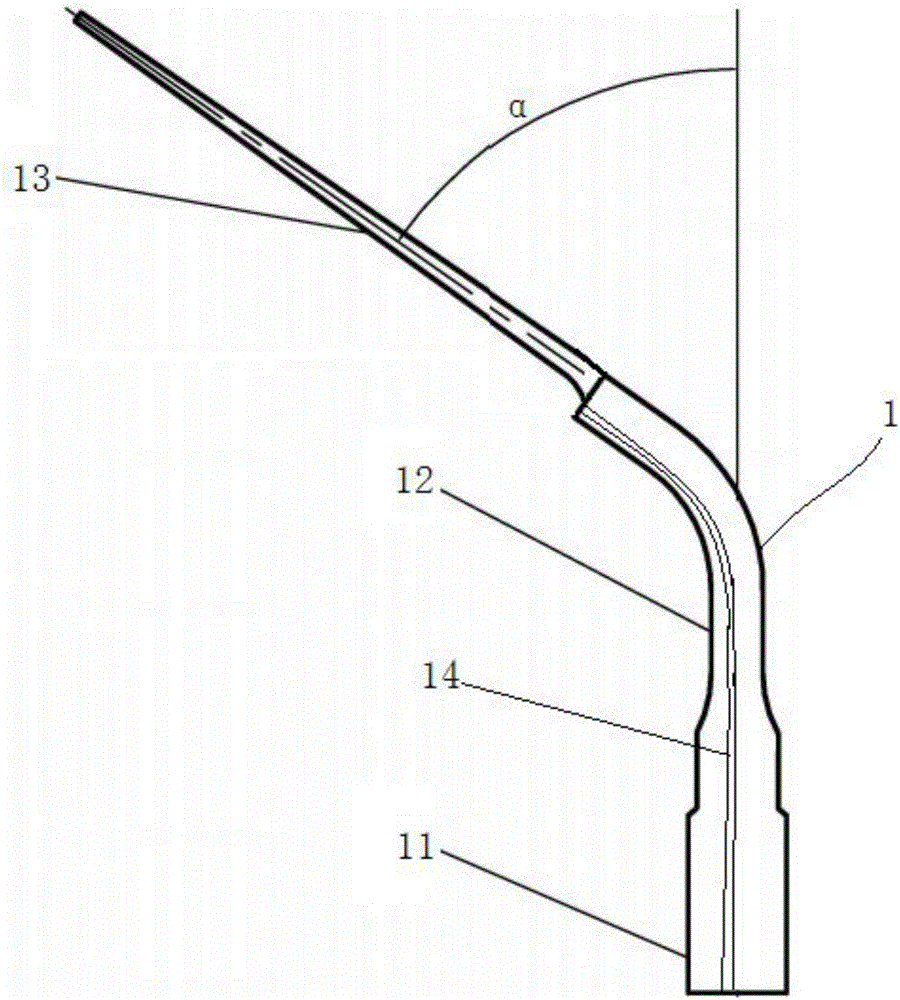

Personal exclusive tooth cleaning suit and disinfection box for disinfecting suit

The invention relates to a tooth cleaning suit which comprises a working tip unit, a polishing unit and a fixing frame unit, wherein the working tip unit comprises a tooth cleaning working tip for gum, a tooth cleaning working tip for shallow periodontal parts and a tooth cleaning working tip for deep periodontal parts; the polishing unit comprises a polishing brush for polishing tooth surfaces as well as a polishing cup; and the fixing frame unit comprises a fixing plate positioned at the upper layer and a support plate positioned at the lower layer. When the tooth cleaning suit is used, firstly the tooth cleaning working tip for gum is used for removing calculus on the gum and tooth neck, dental plaque and cusp hard matters; then the tooth cleaning working tip for the shallow periodontal parts is used for removing calculus and dental plaque on the shallow periodontal parts; the tooth cleaning working tip for the deep periodontal parts is used for removing calculus on the deep periodontal parts; and then the polishing brush is used for preliminarily polishing the cleaned tooth surfaces, and the polishing cup is used for finely polishing the cleaned tooth surfaces, thereby ensuring that the tooth surfaces are flat and smooth. The tooth cleaning suit provided by the invention can be used as a personal exclusive tooth cleaning suit, is further safe and sanitary, and is capable of thoroughly cleaning teeth while flattening and polishing the tooth surfaces.

Owner:NANNING WEIYE ELECTROMECHANICAL TECH CO LTD

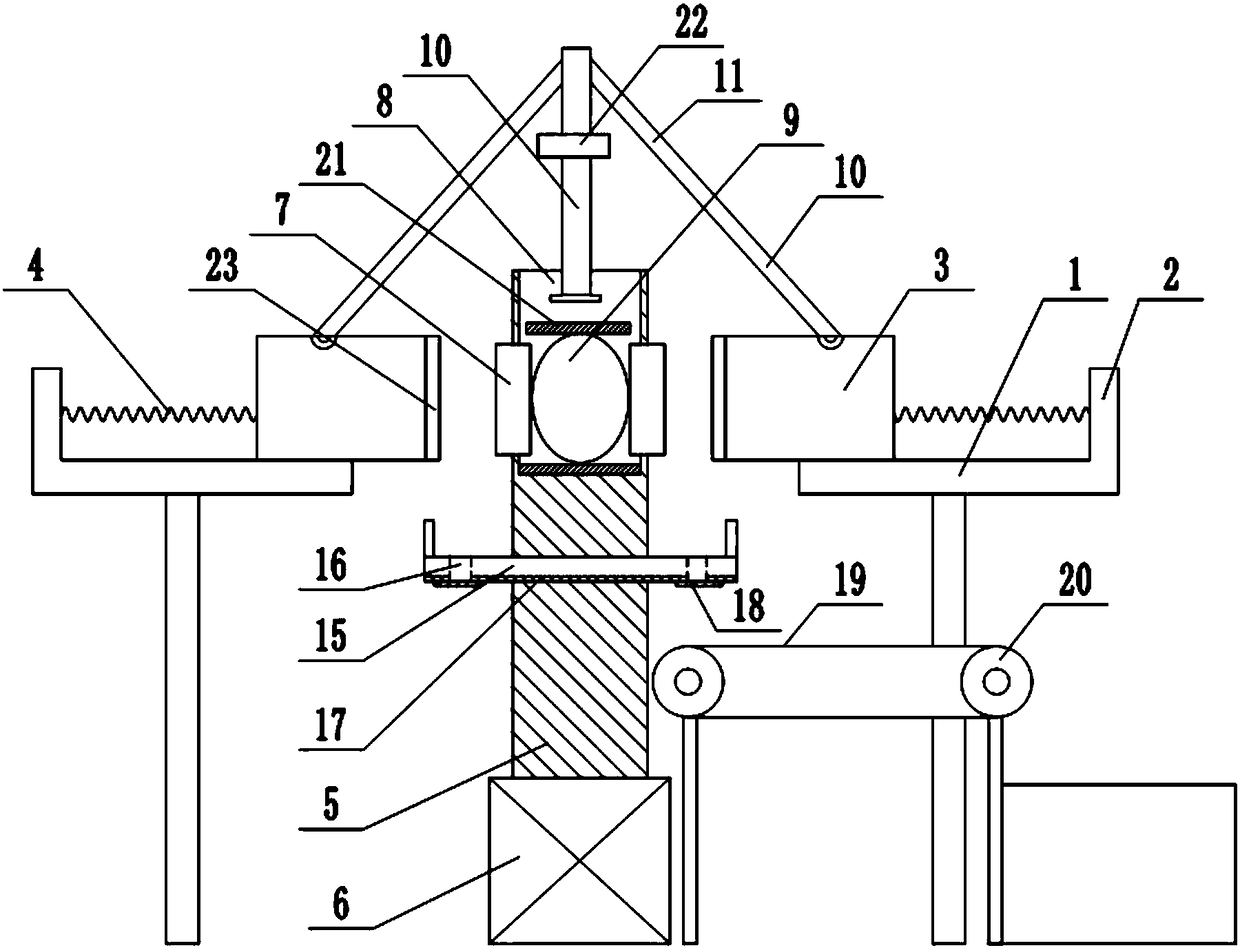

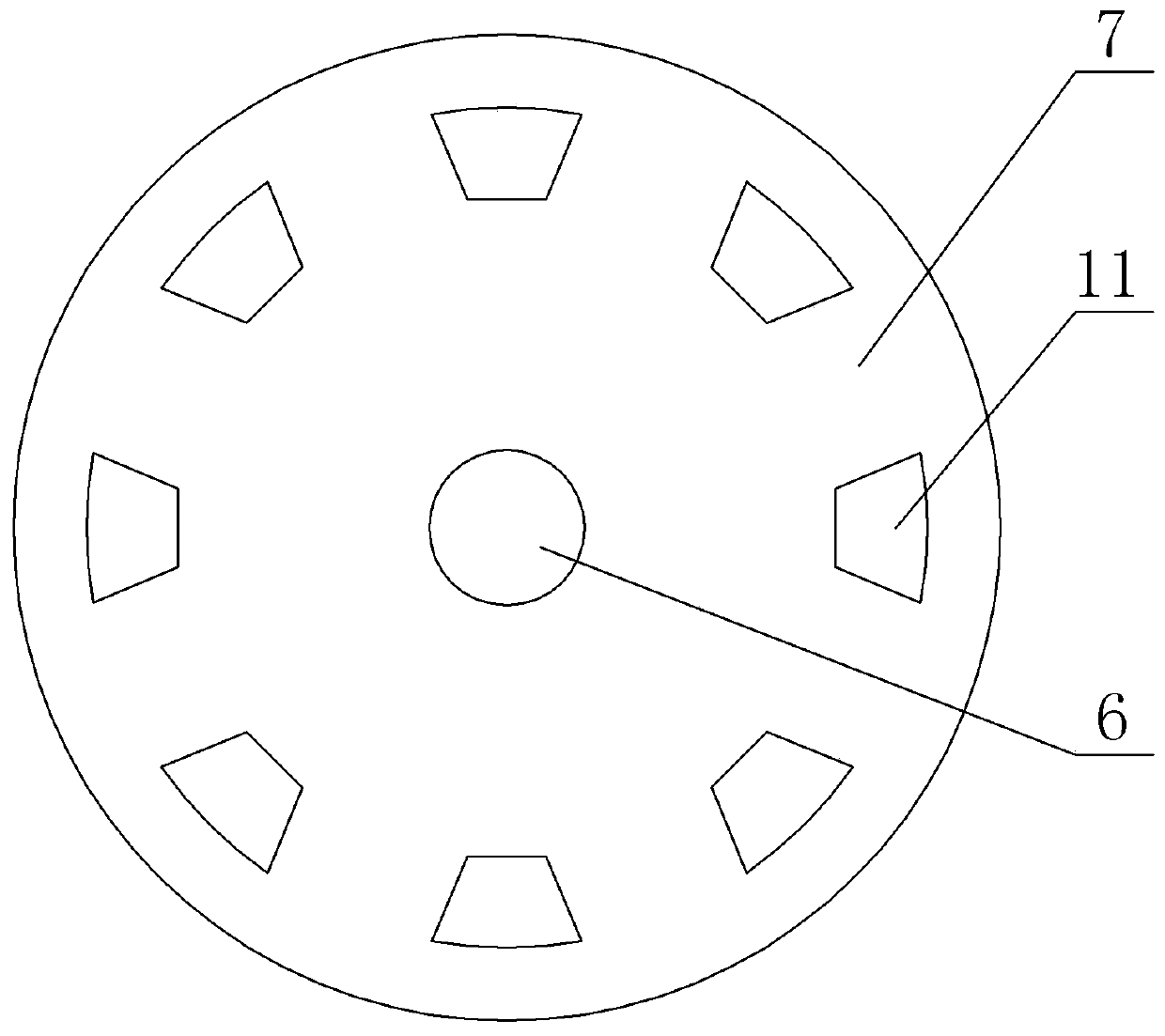

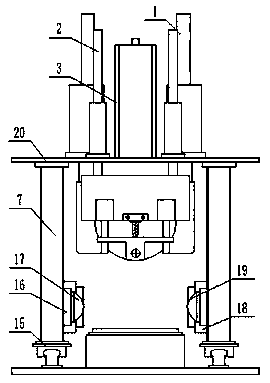

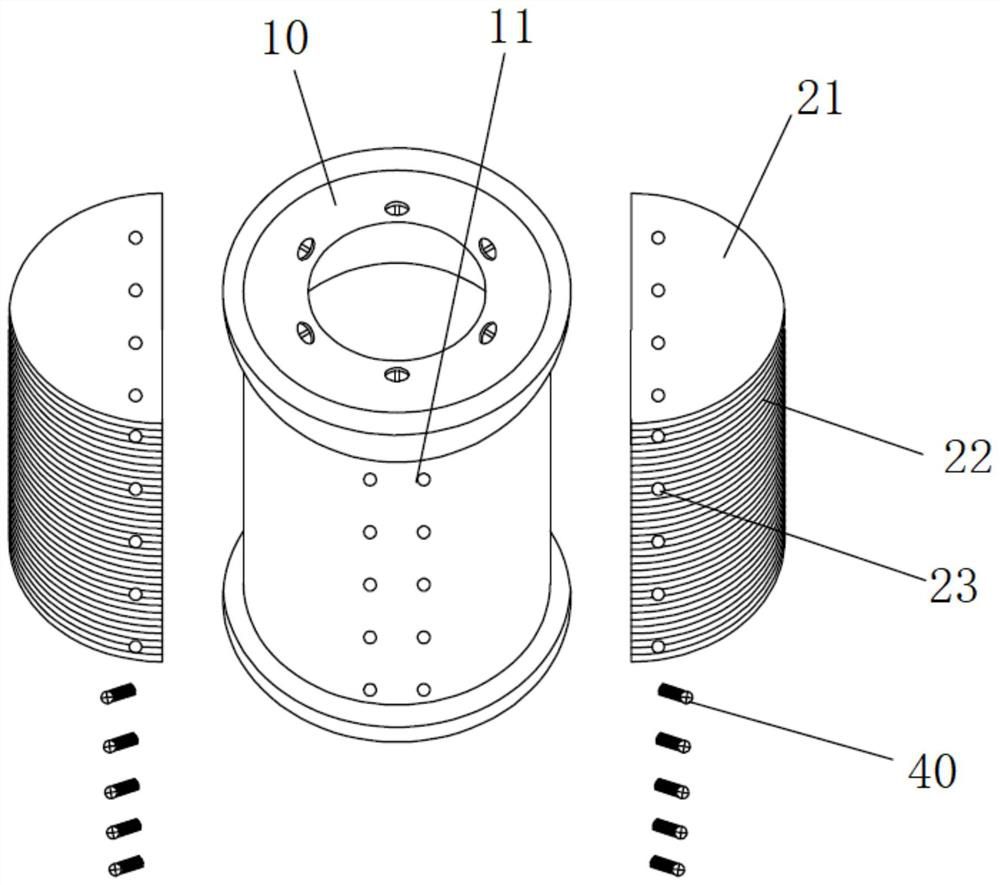

Polishing machine suitable for gears with different bore diameters

InactiveCN110860741APrevent throwingDriving apparatusGear-cutting machinesGear wheelElectric machinery

The invention discloses a polishing machine suitable for gears with different bore diameters. The polishing machine comprises a work box and a work cavity formed in the work box. The right side of thework cavity is opened upwards, a moving device is fixedly arranged in the work box and comprises a conductive magnet arranged in a sliding mode, the moving device can make the conductive magnet to slide left and right, and a motor is fixedly arranged on the upper end face of the conductive magnet. The polishing machine can polish gears with different pore diameters; a gear needing to be polishedis clamped to a fixing plate, and the gear surface is polished through polishing teeth; in the polishing process, a protection device of the polishing machine can prevent the gear from being thrown out, an adsorption device can adsorb iron scraps generated in polishing, the iron scraps are uniformly collected to the upper surface of a magnet adsorption plate in a collecting cavity and are subjected to recovery processing and reused after polishing is finished.

Owner:LISHUI ZHONGYING MACHINERY TECH CO LTD

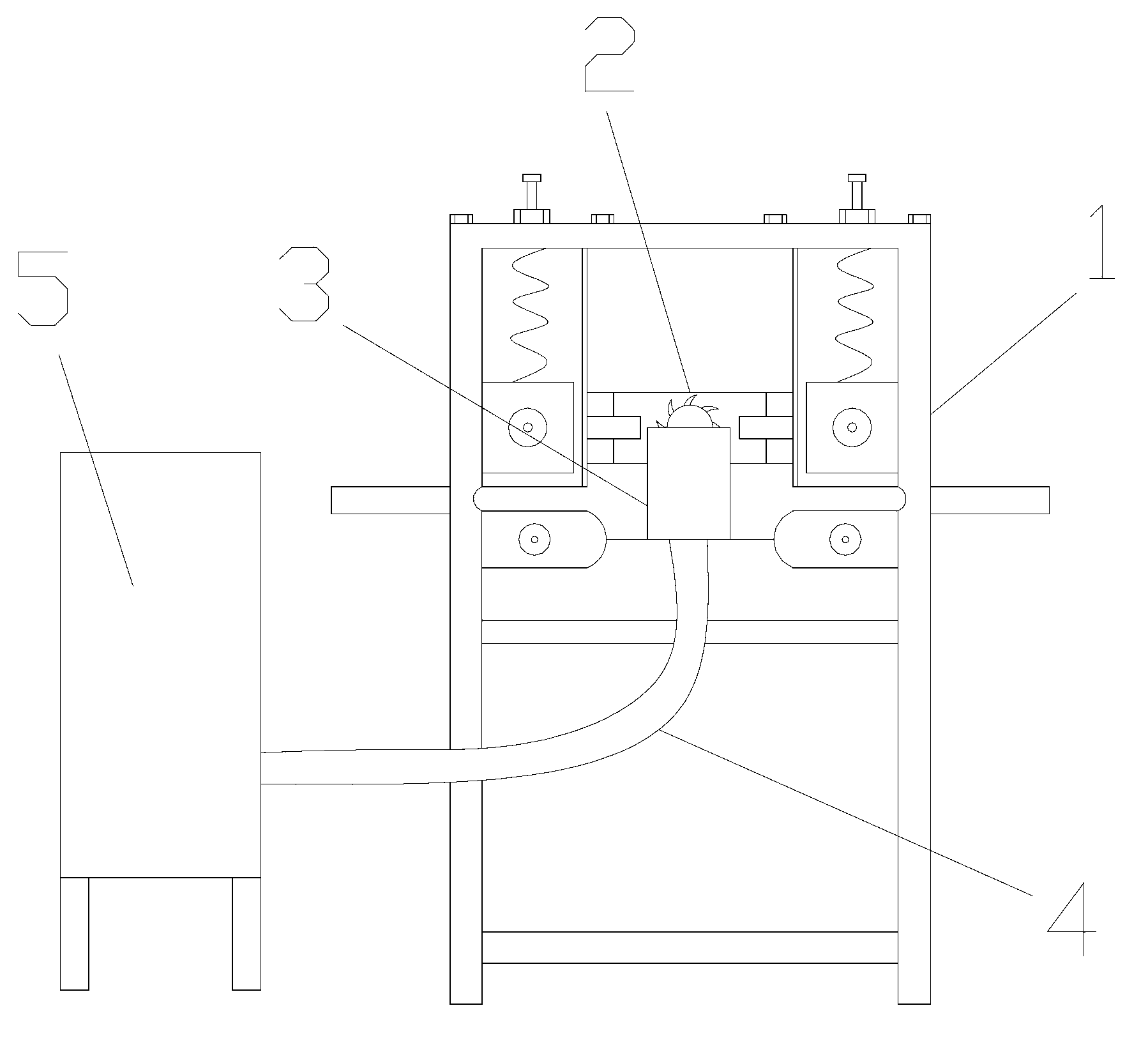

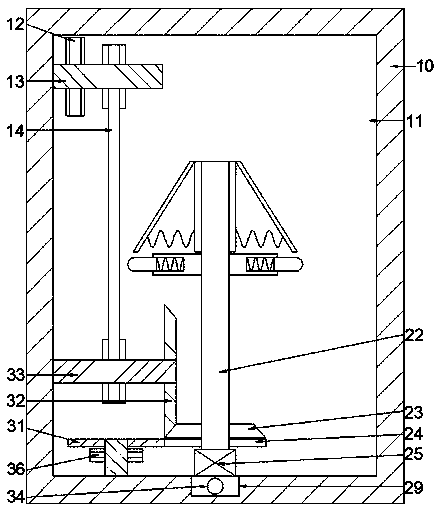

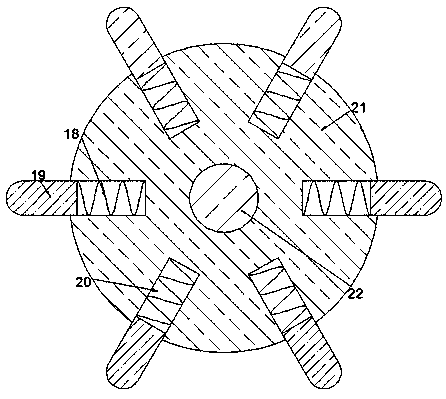

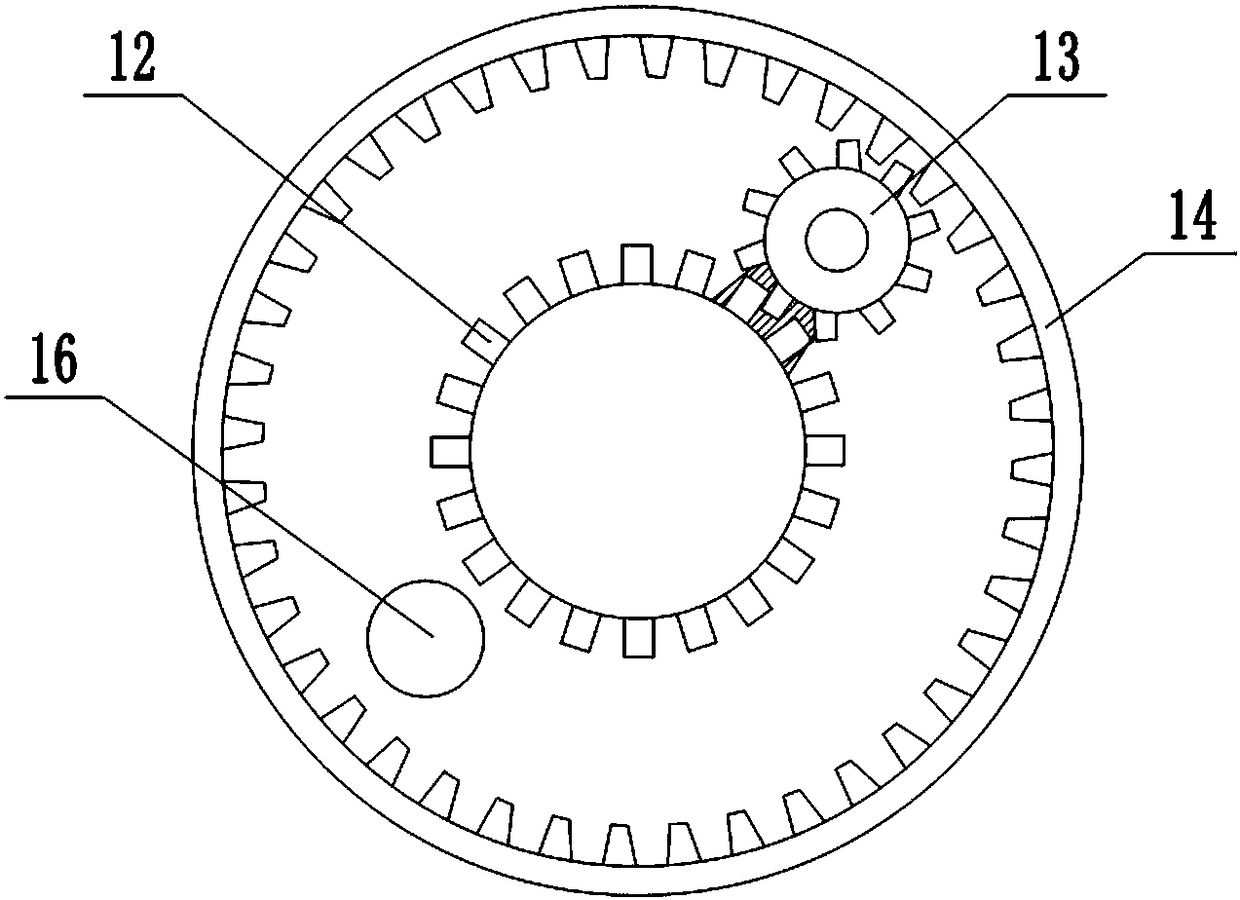

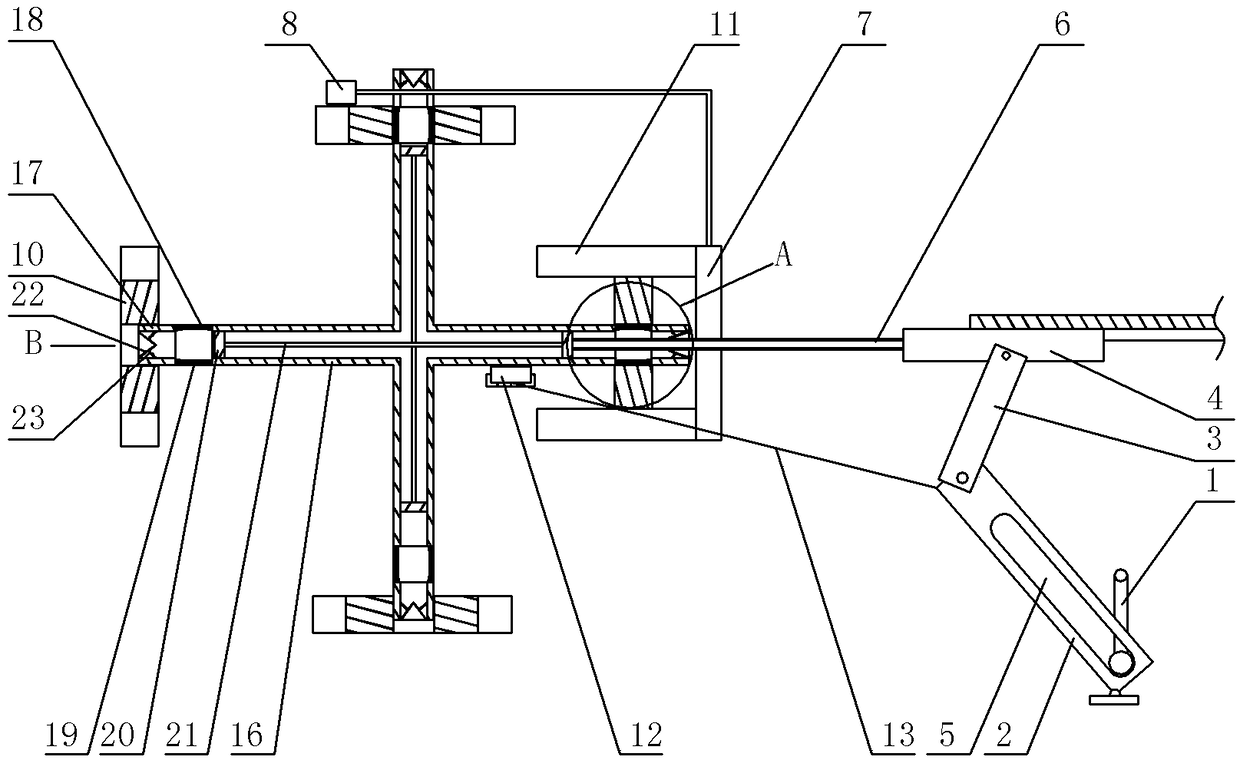

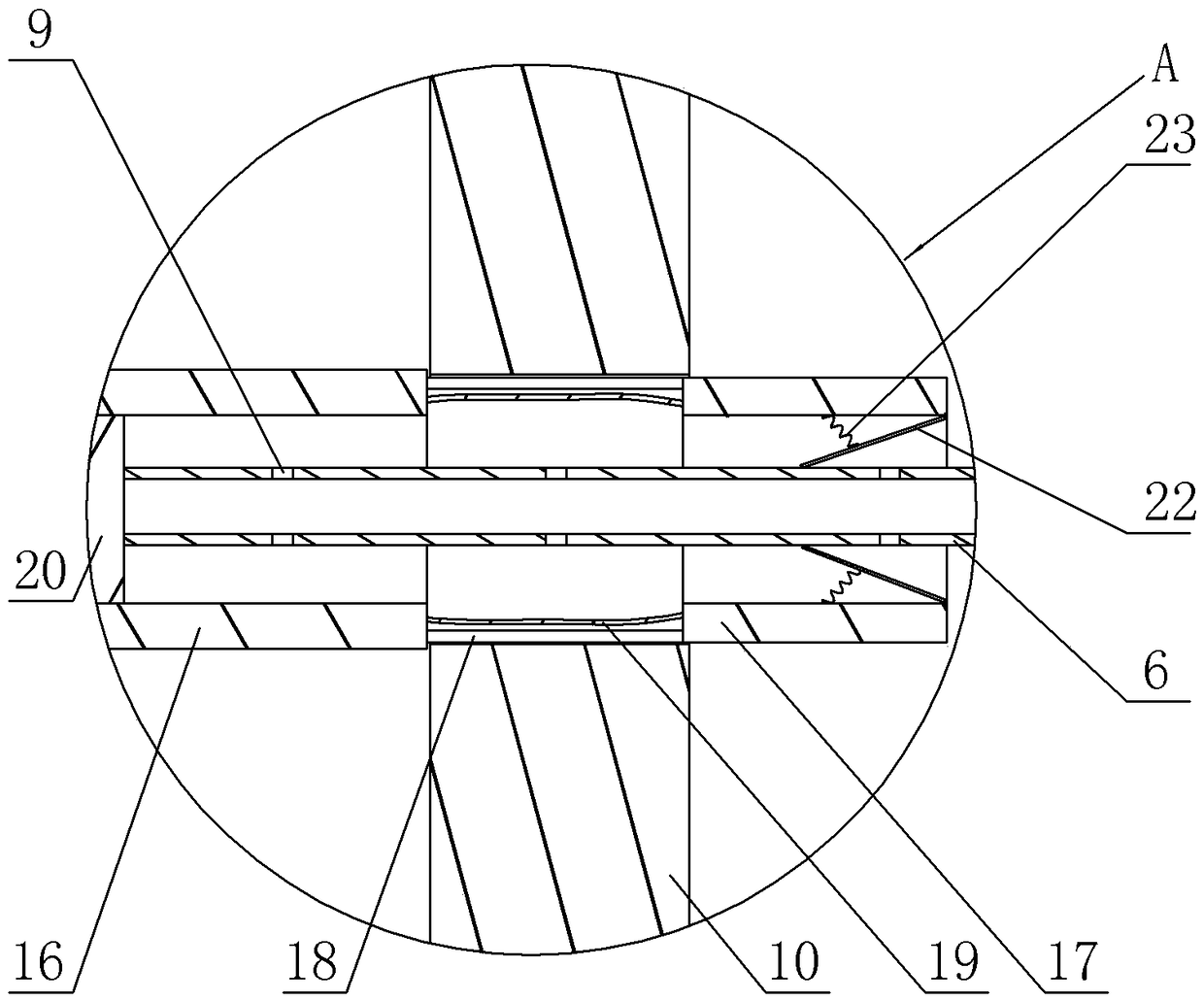

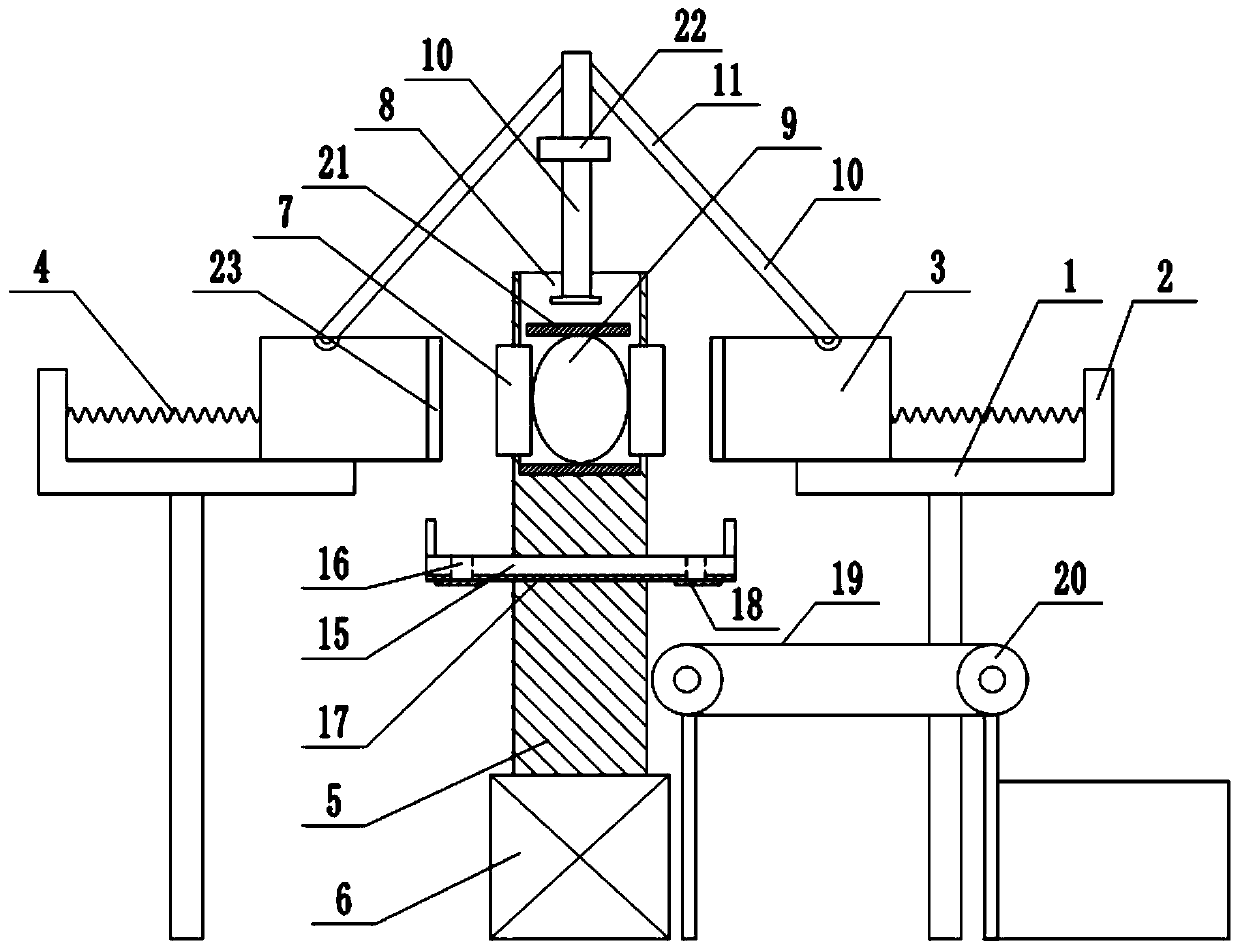

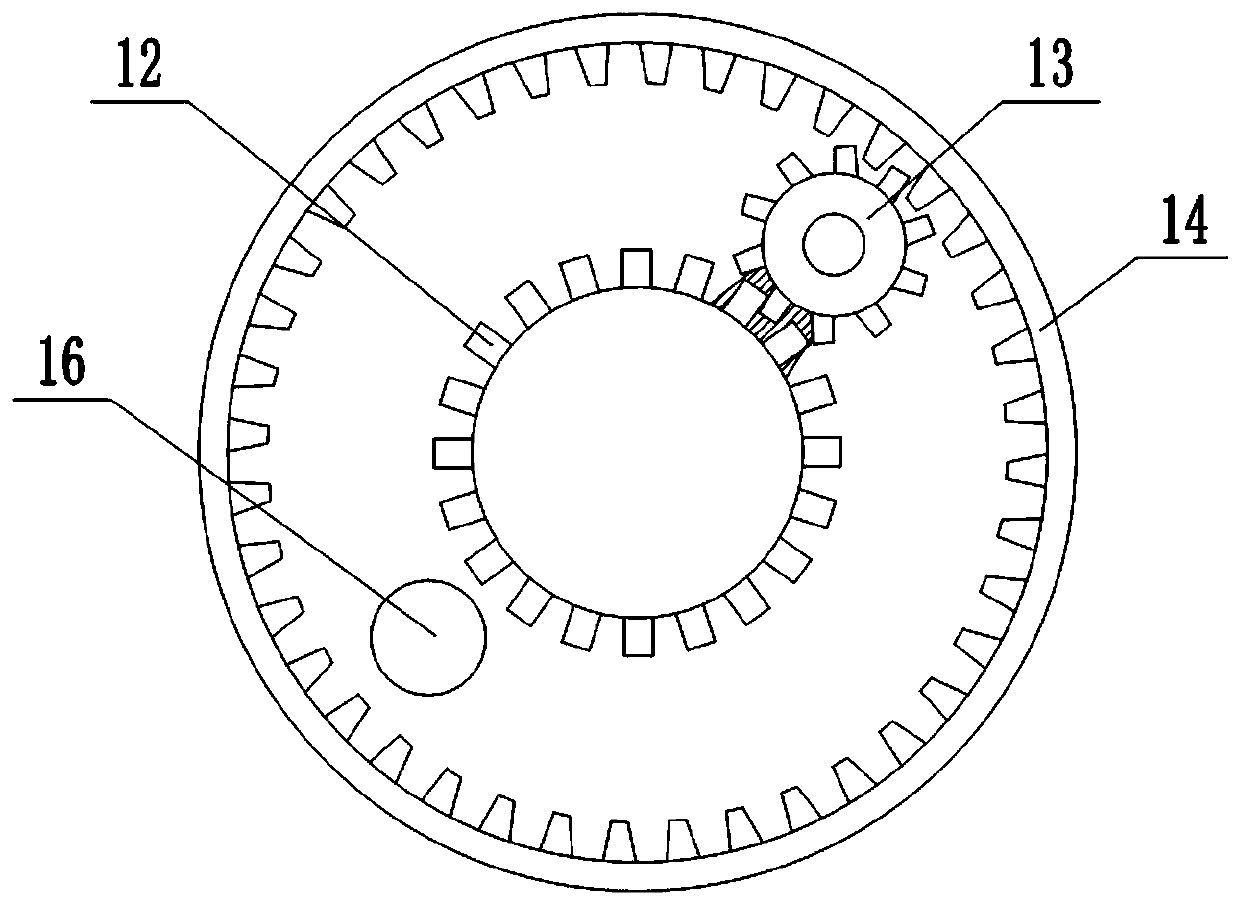

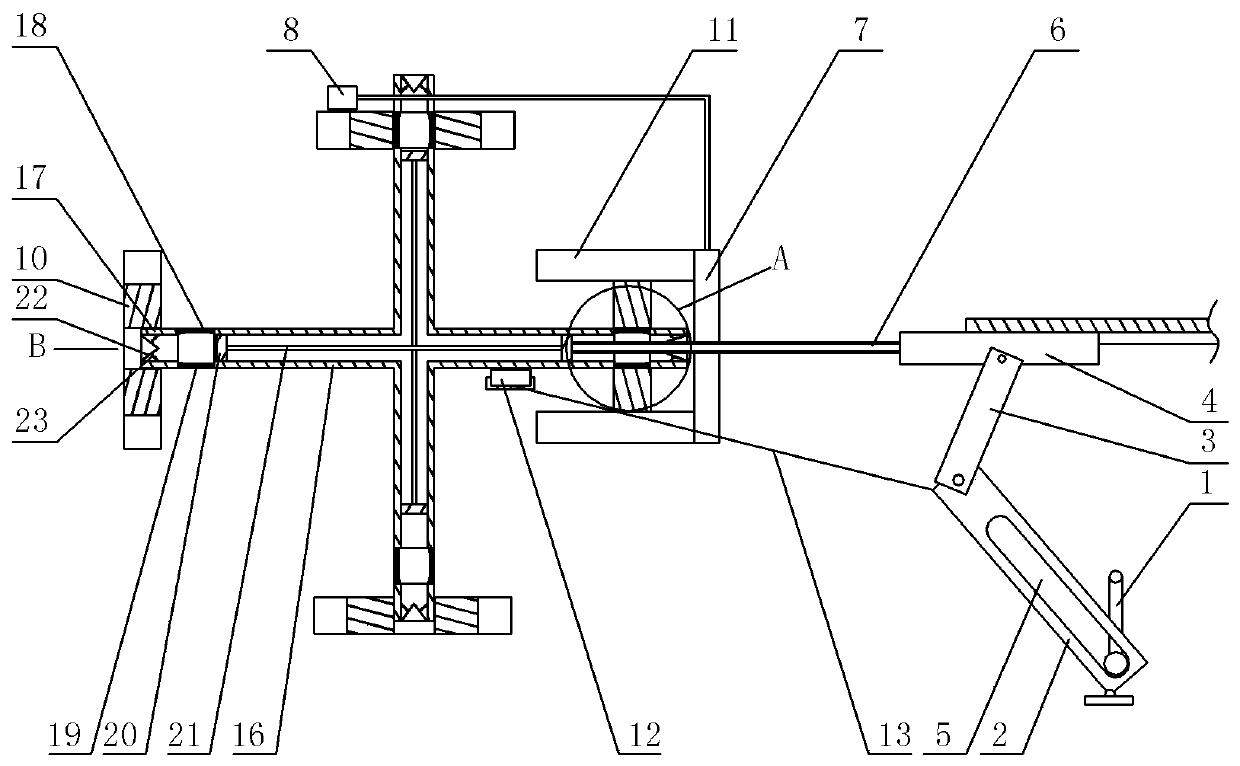

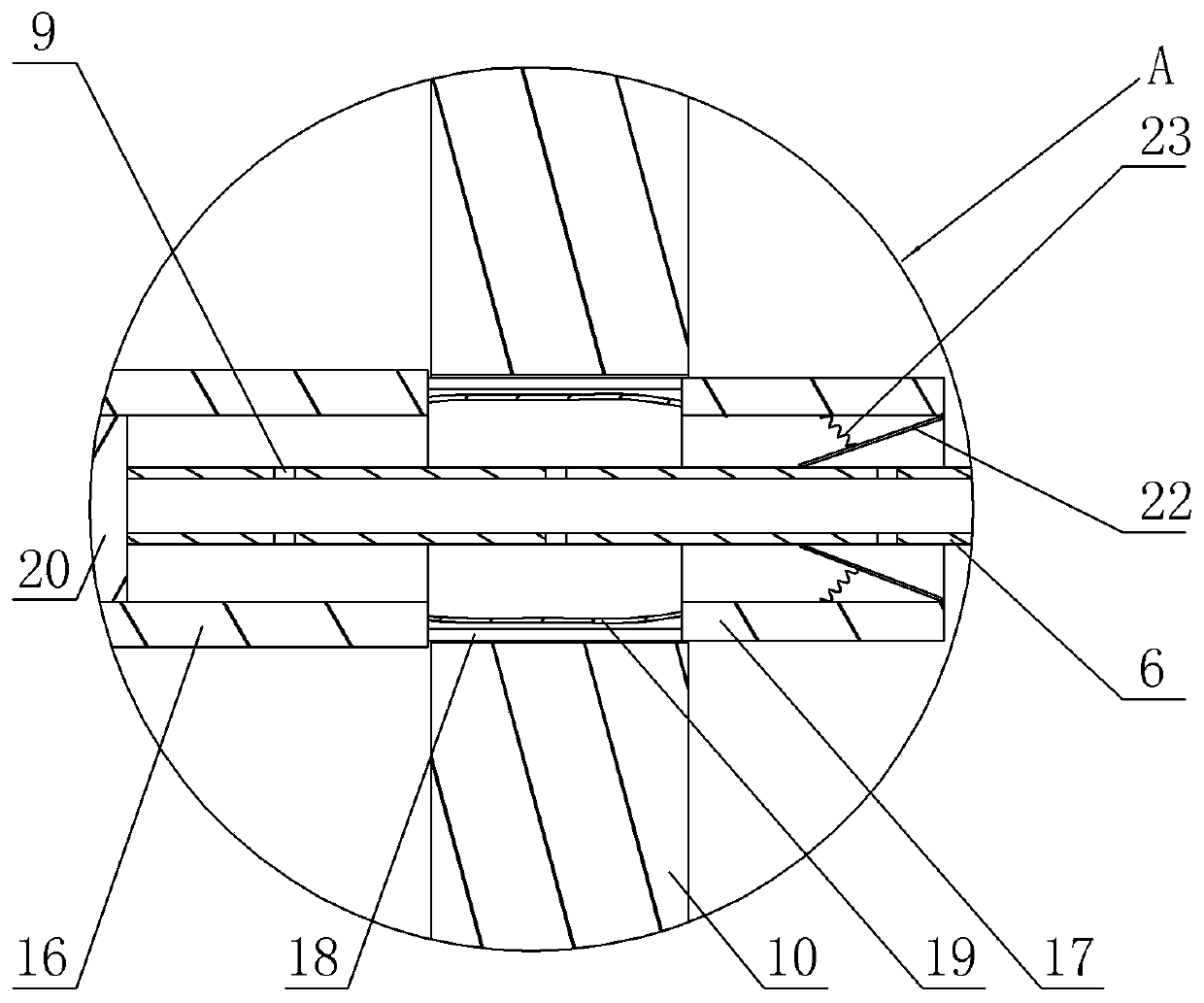

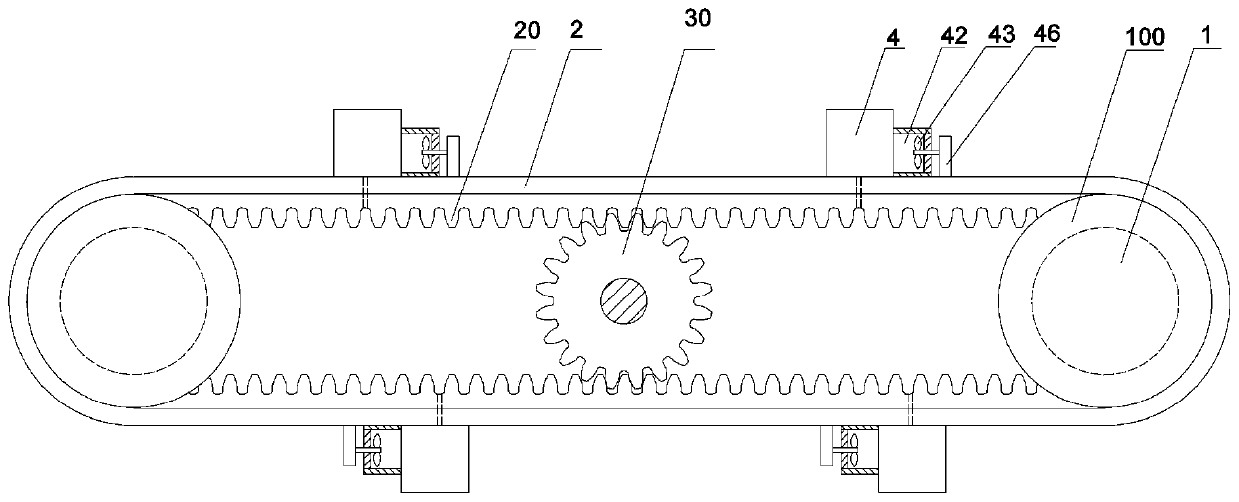

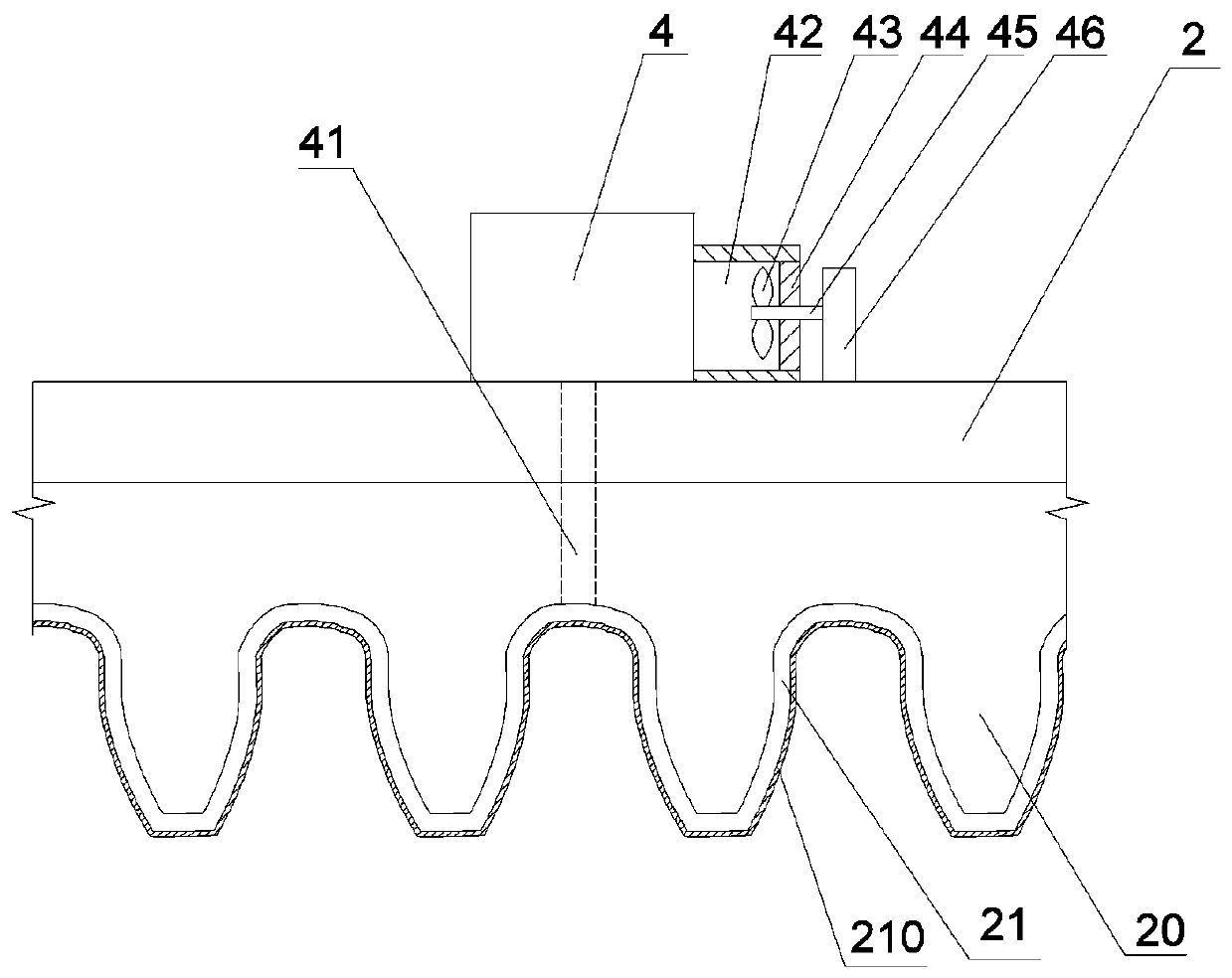

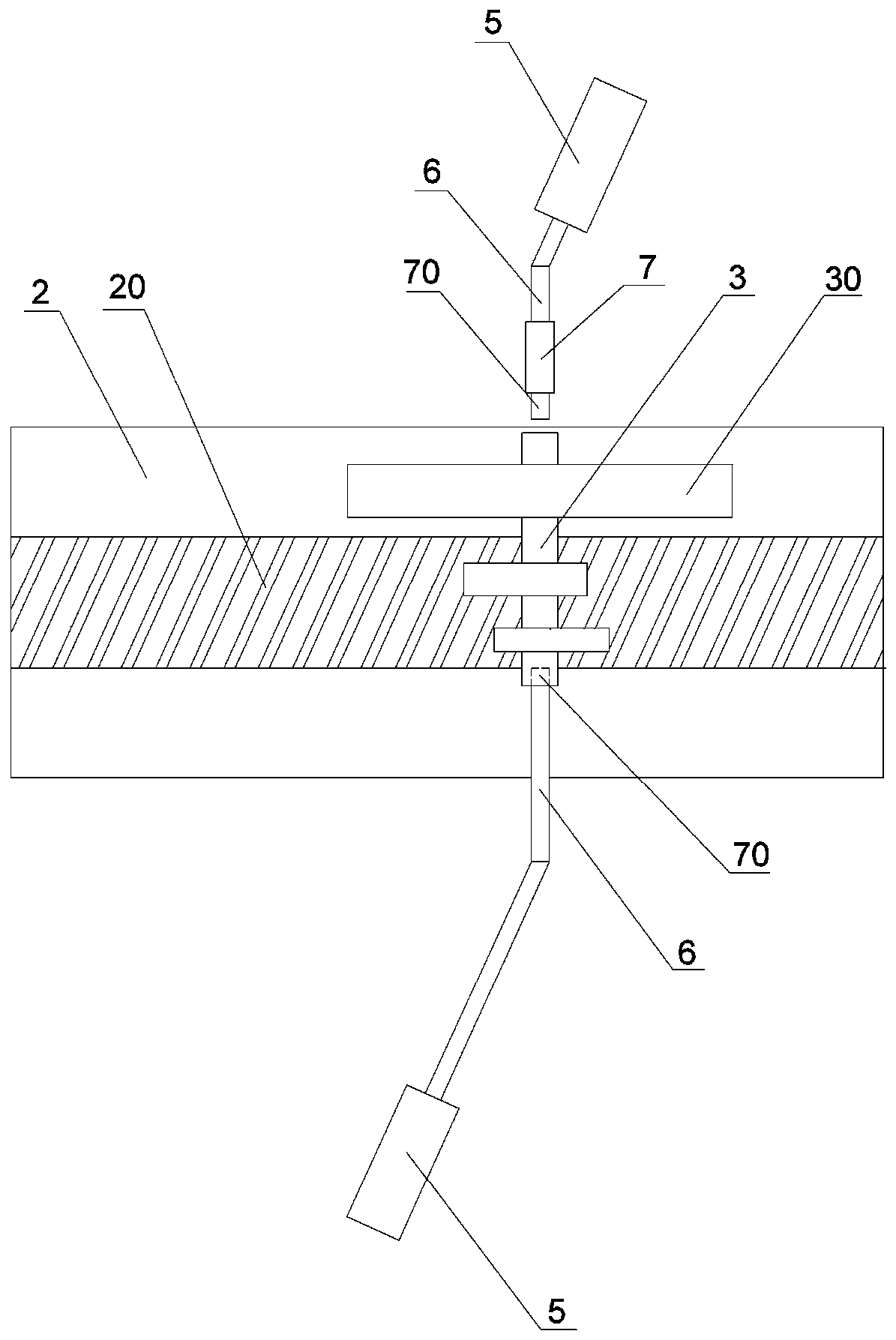

Gear polishing device

ActiveCN108326651AAvoid affecting the grinding accuracyGuaranteed cleanlinessGrinding carriagesRevolution surface grinding machinesPolishing teethMagnet

The invention relates to a gear polishing device. The gear polishing device comprises a rack, support tables are arranged on the rack, clamping blocks are glidingly connected with the support tables,and support springs are arranged between the clamping blocks and the support tables; the gear polishing device also comprises a polishing shaft, polishing teeth are glidingly connected onto the polishing shaft, a cavity is formed in the polishing shaft, an air bag is arranged in the cavity, a downward press rod glidingly connected onto the rack is arranged above the air bag, connecting rods are hinged to two sides of the downward press rod respectively, and the other ends of the connecting rods are hinged to the clamping blocks; a collecting plate is arranged on the polishing shaft, a first magnet is arranged at the bottom of the collecting plate, a falling port is formed in the collecting plate, a baffle is rotationally connected at the falling port, a second magnet is arranged on the baffle, and magnet poles of opposite sides of the first magnet and the second magnet are opposite; a conveying belt and a conveying wheel are arranged below the collecting plate, a third magnet is arranged on the conveying belt, magnet poles of opposite sides of the third magnet and the second magnet are opposite, and the magnetic force of the third magnet is larger than that of the first magnet. Thedevice solves the problem of small application range of traditional polishing devices.

Owner:重庆台华传动技术有限公司

Nail burnishing stick and preparation method thereof

PendingCN106723871AAchieve visual effectGuaranteed aestheticsManicure/pedicureMedicinePolishing teeth

The invention discloses a nail burnishing stick and a preparation method thereof. The nail burnishing stick comprises a substrate and a polishing layer; the polishing layer comprises multiple polishing teeth which are densely distributed; the bottom of the polishing teeth is fixed on the substrate. The polishing stick can polish the surface of nails so that the surface of nails presents bright and beautiful color; nail surfaces can be beautified without the use of harmful nail polish or nail polish removers; manicure effect is obtained. The invention also discloses a preparation method of the nail polishing stick.

Owner:秦燕云

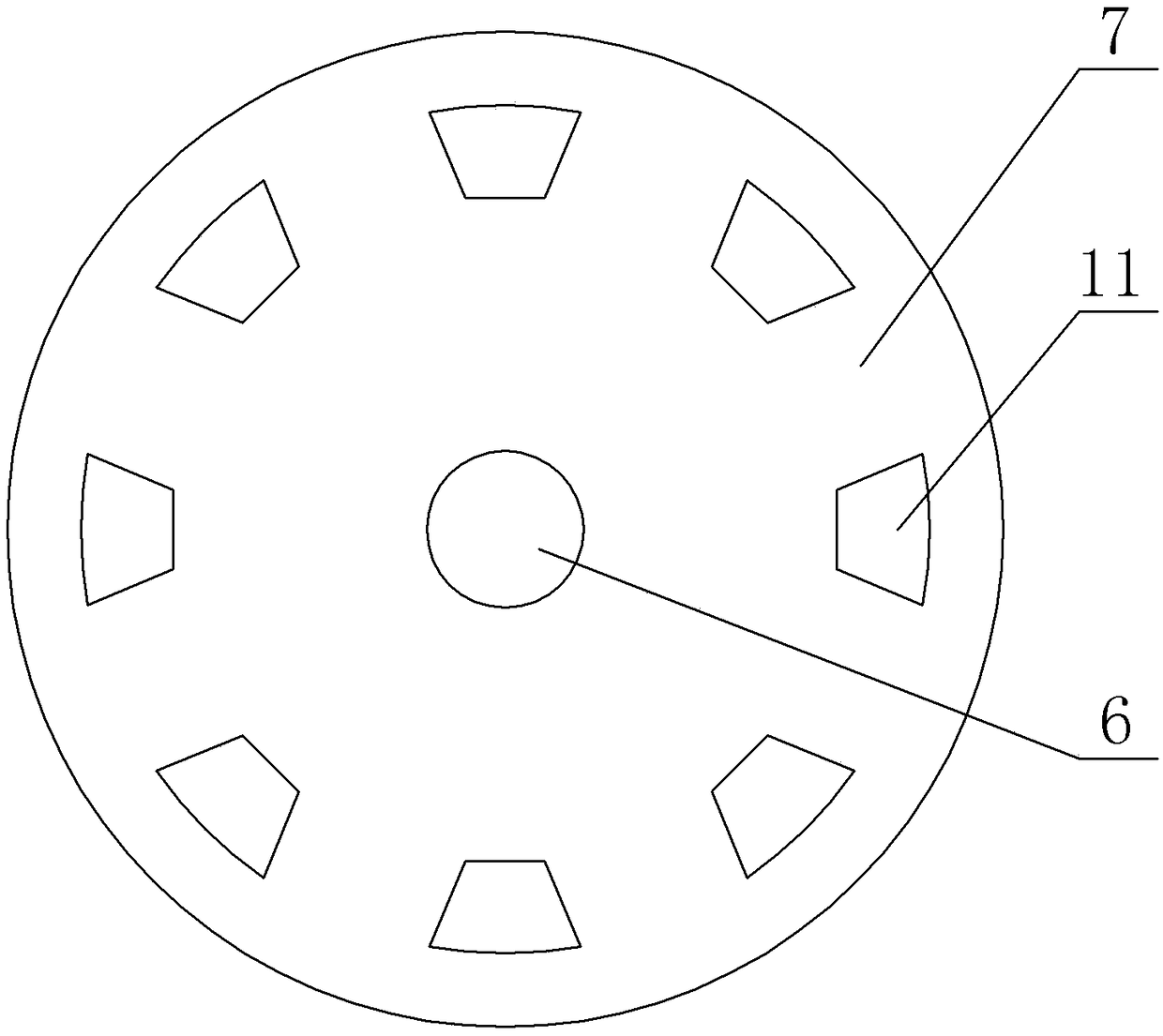

Gear machining device

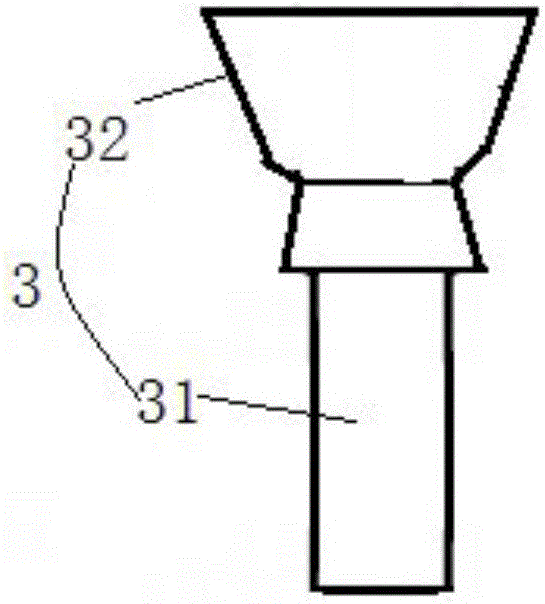

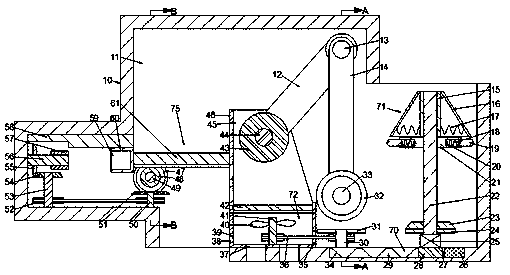

ActiveCN108723507AImprove grinding efficiencyRealize automatic unloadingGear-cutting machinesGear teethEngineeringMachining

The invention relates to the field of gear machining, in particular to a gear machining device. The gear machining device comprises a polishing and discharging mechanism, a resisting mechanism and a rotating mechanism, wherein the polishing and discharging mechanism comprises a polishing and discharging unit and a transfer unit for driving the polishing and discharging unit to reciprocate; the polishing and discharging unit comprises a discharging pipe and a polishing disc; holes are formed in the wall of the discharging pipe; polishing teeth matched with tooth grooves are arranged on the polishing disc; the rotating mechanism comprises a plurality of rotating units; each rotating unit comprises a rotating pipe, a plurality of supporting rods and a supporting pipe; the middle part of the rotating pipe is rotatably arranged on a rack; the plurality of supporting rods are fixed at the two ends of the rotating pipe; the supporting pipe is fixedly connected to the rotating pipe through thesupporting rods; air bags with openings at two ends are connected between the rotating pipe and the supporting pipe; the supporting rods are distributed on the peripheries of the air bags; two pistons are arranged in the rotating pipe in a sliding manner and are connected through a connecting pipe; and an air leaking mechanism which is matched with the discharging pipe and leaks air in the air bags is arranged at the free end of the supporting pipe. The gear machining device adopting the technical scheme can improve the polishing efficiency of gears.

Owner:SUZHOU HAOLI CULTURE MEDIA TECH CO LTD

Gear grinding device

ActiveCN108326651BAvoid affecting the grinding accuracyGuaranteed cleanlinessGrinding carriagesRevolution surface grinding machinesGear grindingGear wheel

The invention relates to a gear polishing device. The gear polishing device comprises a rack, support tables are arranged on the rack, clamping blocks are glidingly connected with the support tables,and support springs are arranged between the clamping blocks and the support tables; the gear polishing device also comprises a polishing shaft, polishing teeth are glidingly connected onto the polishing shaft, a cavity is formed in the polishing shaft, an air bag is arranged in the cavity, a downward press rod glidingly connected onto the rack is arranged above the air bag, connecting rods are hinged to two sides of the downward press rod respectively, and the other ends of the connecting rods are hinged to the clamping blocks; a collecting plate is arranged on the polishing shaft, a first magnet is arranged at the bottom of the collecting plate, a falling port is formed in the collecting plate, a baffle is rotationally connected at the falling port, a second magnet is arranged on the baffle, and magnet poles of opposite sides of the first magnet and the second magnet are opposite; a conveying belt and a conveying wheel are arranged below the collecting plate, a third magnet is arranged on the conveying belt, magnet poles of opposite sides of the third magnet and the second magnet are opposite, and the magnetic force of the third magnet is larger than that of the first magnet. Thedevice solves the problem of small application range of traditional polishing devices.

Owner:重庆台华传动技术有限公司

Brake gasket polishing device capable of collecting polishing chips

PendingCN108581758AEasy to collectReduce noiseGrinding machinesGrinding feedersEngineeringPolishing teeth

The invention discloses a brake gasket polishing device capable of collecting polishing chips. The device comprises a polishing main body; a mounting base is welded on one side of the bottom end of the polishing main body; a groove is formed in the top of the polishing main body; a collecting groove is formed in the groove wall of the groove, and communicates with the groove; and a support rod iswelded on the edge of the groove. Multiple polishing teeth, distributed from the center to the periphery, are arranged on a polishing disc; the diameter of the polishing disc is twice of the thicknessof an eccentric rotating ring; when the polishing disc is clockwise rotated for polishing, one half of the area on the polishing disc performs the polishing work; inclined surfaces of the polishing teeth in the clockwise rotating process are downwards rotated to guide the chips generated in the polishing process into a through groove on the lower side; and the chips enter a chip groove from the through groove for collection, so that the chips generated in the polishing process are preferably collected, and the design is more novel.

Owner:DEQING COUNTY HAICHANG AUTO PARTS CO LTD

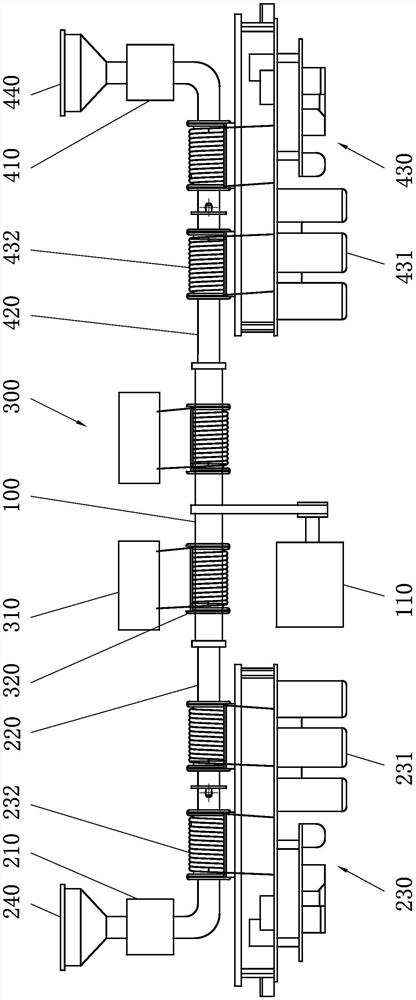

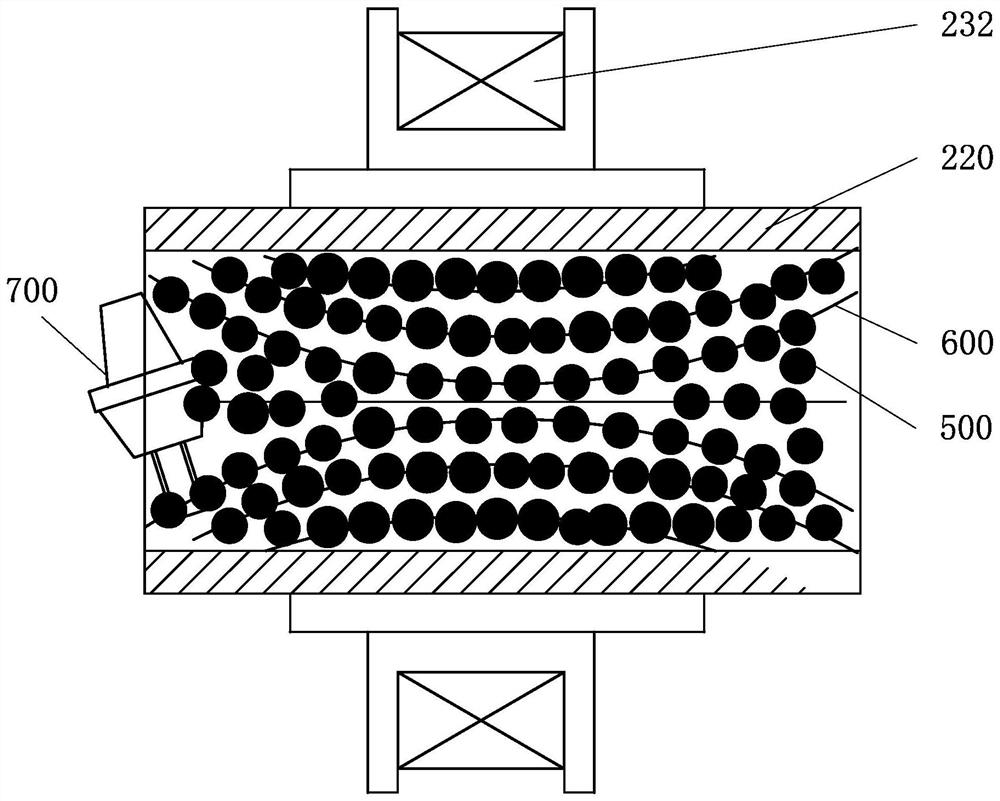

Medical implant tooth abutment polishing device

ActiveCN114043320AImprove polishing efficiencySolving Magnetorheological PolishingDental implantsPolishing machinesEngineeringDentistry

The invention discloses a medical implant tooth abutment polishing device which is used for polishing a tooth abutment and comprises a left liquid inlet pipe, a left speed reducer, a left magneto-rheological accelerator, a rotating pipe, a magneto-rheological speed regulator, a rotating motor, a right liquid inlet pipe, a right magneto-rheological accelerator, a right speed reducer and magneto-rheological polishing liquid. The left magneto-rheological accelerator is arranged in the middle of the left liquid inlet pipe, one end of the rotating pipe is rotationally communicated with the left liquid inlet pipe, and the other end of the rotating pipe can be rotationally communicated with the right liquid inlet pipe; the left speed reducer is arranged at the end, away from the rotating pipe, of the left liquid inlet pipe, the rotating pipe is driven by the rotating motor to rotate, and the magneto-rheological speed regulator is arranged on the rotating pipe; the right magneto-rheological accelerator is arranged in the middle of the right liquid inlet pipe, the right speed reducer is arranged at the end, away from the rotating pipe, of the right liquid inlet pipe, and the volume of the magneto-rheological polishing liquid is smaller than the sum of the containing volumes of the left liquid inlet pipe, the right liquid inlet pipe and the rotating pipe. The medical implant tooth abutment polishing device is used for performing multi-dimension polishing on the tooth abutment, and the accelerated and reciprocating polishing is realized by adopting the magnetorheological accelerators.

Owner:ZHEJIANG CANWELL MEDICAL DEVICES CO LTD

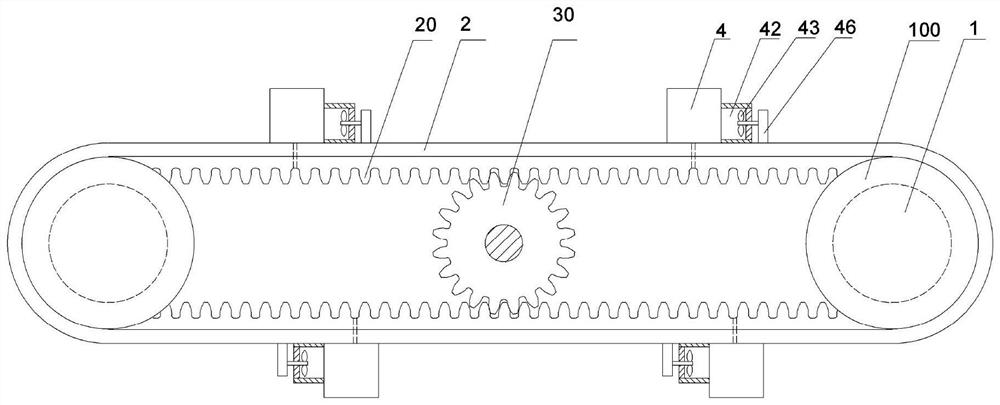

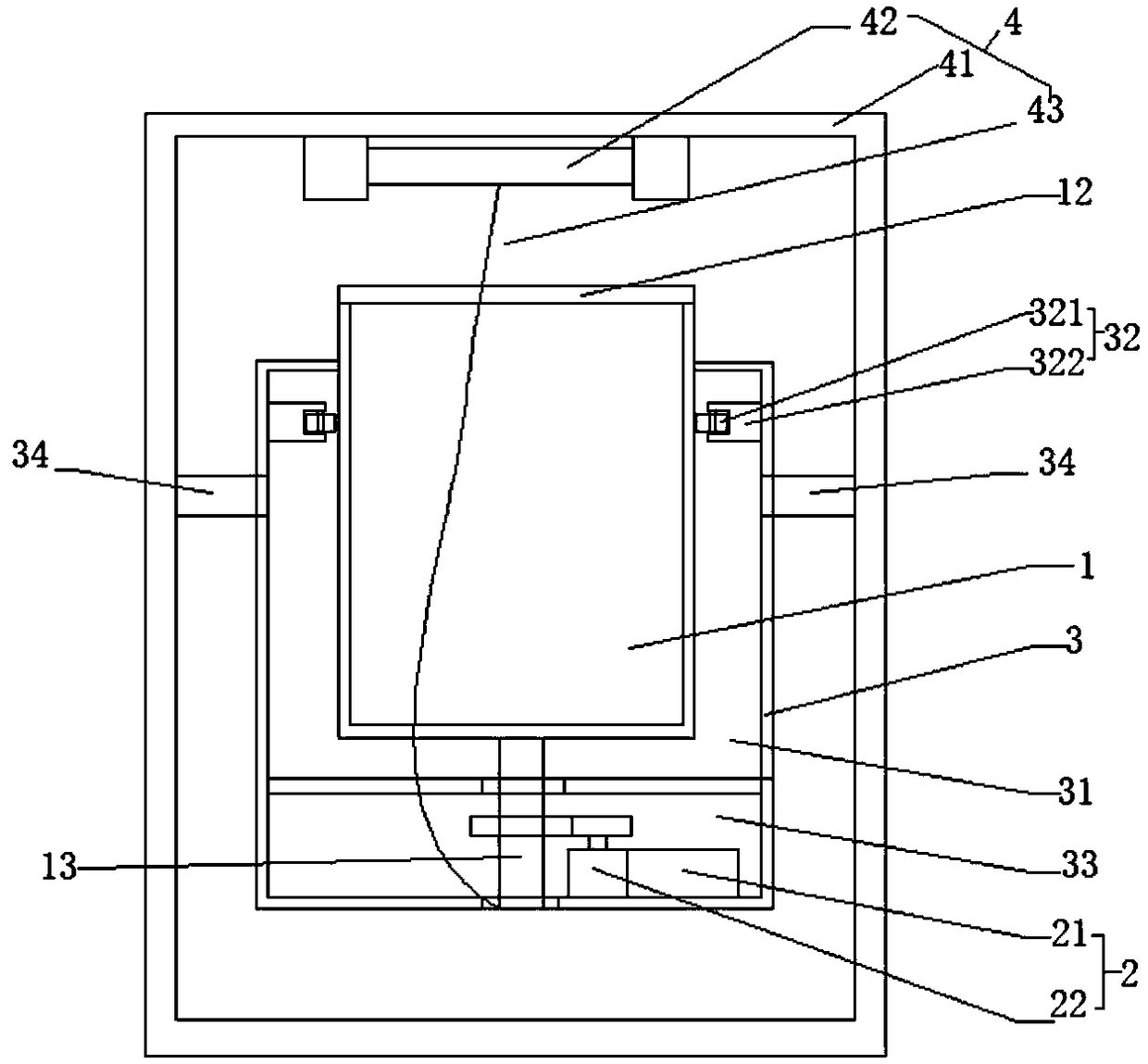

General-purpose mechanical camshaft gear manufacturing device

ActiveCN110653688BAchieve grindingImprove grinding efficiencyValve arrangementsSeat surface grinding machinesMachine buildingGear wheel

The invention belongs to the field of machine manufacturing and particularly discloses a device for manufacturing a gear for a universal machinery cam shaft. The device comprises a moving mechanism for driving a cam shaft gear to move and a tooth slot polishing mechanism for polishing the tooth slot of a cam shaft gear; the tooth slot polishing mechanism comprises two rotating rollers and a belt wound on the two rotating rollers; polishing teeth meshed with the teeth slot of the cam shaft gear are arranged on the inner side of the belt; an air sac wrapping the polishing teeth is arranged outside the polishing teeth; a polishing layer is arranged on the outer surface of the air sac; the air sac is connected with an air inflating and releasing mechanism; the moving mechanism comprises two support pieces and a motion driving piece; the two support pieces are used for clamping and supporting the cam shaft from the two ends of the cam shaft; and the motion driving piece is used for drivingthe support pieces to move in the length direction of the polishing teeth on the belt.

Owner:重庆九方铸造有限责任公司

Gear processing device

ActiveCN108723507BAvoid reverse rotationGuaranteed alignmentGear-cutting machinesGear teethEngineeringMachining

Owner:SUZHOU HAOLI CULTURE MEDIA TECH CO LTD +1

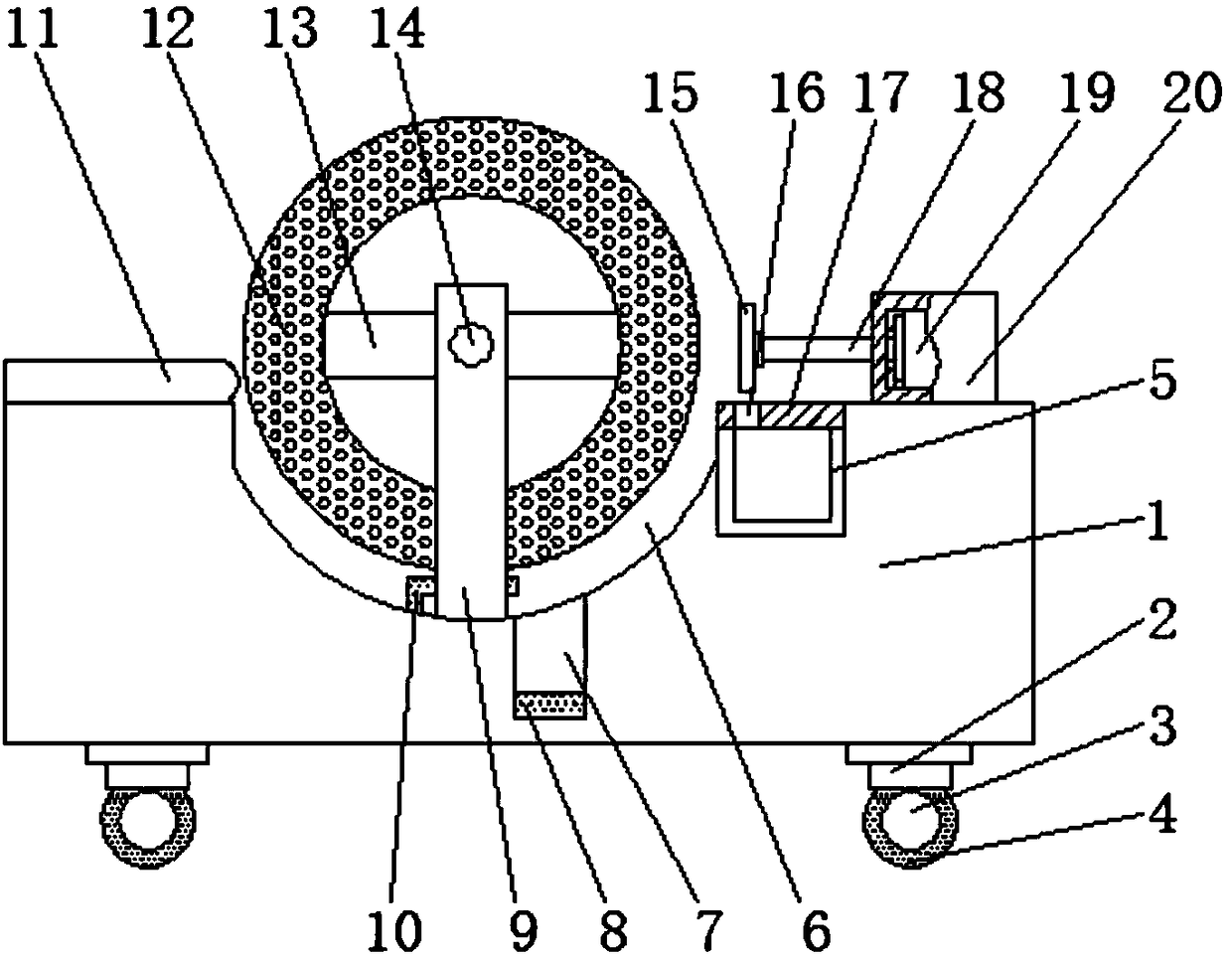

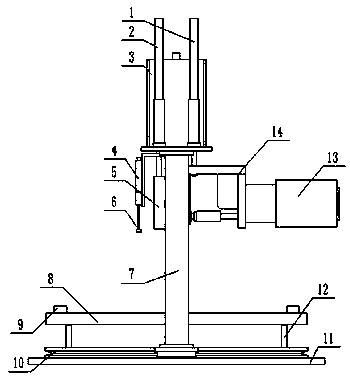

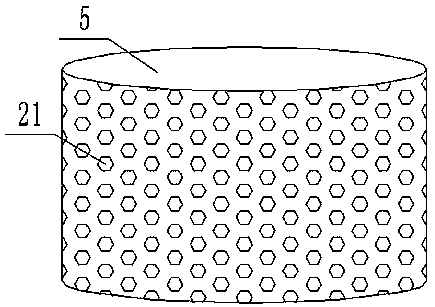

Vertical-type polishing machine for myotonin

PendingCN108722525ASimple structureAvoid breakingGrain huskingGrain polishingEngineeringMechanical engineering

The invention discloses a vertical-type polishing machine for myotonin. The machine comprises a polishing drum, a driving device and a housing. A first cavity with an opening in the upper end is arranged in the housing. The polishing drum is a circular drum which is rotatably arranged in the first cavity and has an upward opening. Polishing teeth are uniformly arranged on the inner side wall of the polishing drum at intervals. The driving device is in driving connection with the polishing drum and used for driving the polishing drum to rotate around the axis of the polishing drum in the firstcavity. Therefore, a myotonin groove for myotonin granules in the polishing drum is polished. The machine is simple in structure. The inner wall of the polishing drum is equipped with arc strip-shapedprotruding strips. The myotonin groove for myotonin is polished by means of the arc strip-shaped protruding strips on the inner side wall during the rotation of the polishing drum.

Owner:湖北天明粮油设备有限公司

Anodic oxidation carved round pipe end polishing device

The invention discloses an anodic oxidation carved round pipe end polishing device. The device comprises a base; a motor box is arranged on the base; a driving motor is arranged in the motor box; a polishing shaft is arranged on the outer side wall of the motor box; one end of the polishing shaft is connected with the driving motor; polishing teeth are arranged at the other end of the polishing shaft; a protecting base is arranged on the outer side wall of the motor box; the polishing shaft penetrates through the protecting base; a positioning block is arranged at the end part of the protecting base; a fixed base is arranged on the protecting base; an observing groove is formed in the end part of the fixed base; an open groove is formed in one side of the fixed base; a guide base is arranged on the other side of the fixed base, is inclined, and is provided with a guide groove; an adjusting block is arranged in the guide groove; the upper end of the adjusting block is a free end, and the lower end of the adjusting block corresponds to the polishing teeth; a positioning groove is formed in the bottom of the fixed base; the observing groove and the open groove communicate with the positioning groove; and the positioning block is clamped into the positioning groove. The device can stably polish the end parts of anodic oxidation carved round pipes.

Owner:杨静

Furniture grinding device

InactiveCN109227278ASimple processLow costEdge grinding machinesGrinding carriagesHydraulic cylinderEngineering

The invention discloses a furniture grinding device, which comprises a polishing lubricating wheel, a nozzle, an mounting plate and a grinding head, wherein the two grinding hydraulic rods are arranged on the right side of the two lubricating hydraulic rods respectively; a lubricating hydraulic cylinder is arranged between the grinding hydraulic rods and the lubricating hydraulic rods; the grinding hydraulic rods, the lubricating hydraulic rods and the lubricating hydraulic cylinder are fixed on the upper fixing plate; the lubricating hydraulic cylinder is connected with the pressure cylinderthrough a hose; the lower thread of the pressure cylinder is connected with the nozzle; the lower part of the lubricating hydraulic rod is connected with the polishing lubricating wheel by going through the upper fixing plate; the polishing lubricating wheel is uniformly provided with hole grooves, and the inner hole groove is provided with polishing teeth. The lower part of the grinding hydraulicrod is connected with a fixing connection frame by going through the upper fixing plate. The other end nesting of the fixing connection frame is connected with the grinding head. The front and rear sides of the upper fixing plate are respectively welded to connection sliding rods. The inner side of each sliding rod is welded to a front telescopic rod. The furniture grinding device integrates grinding, polishing and lubricating treatment, simplifying the process and reducing cost.

Owner:扬州华瑞家居用品有限公司

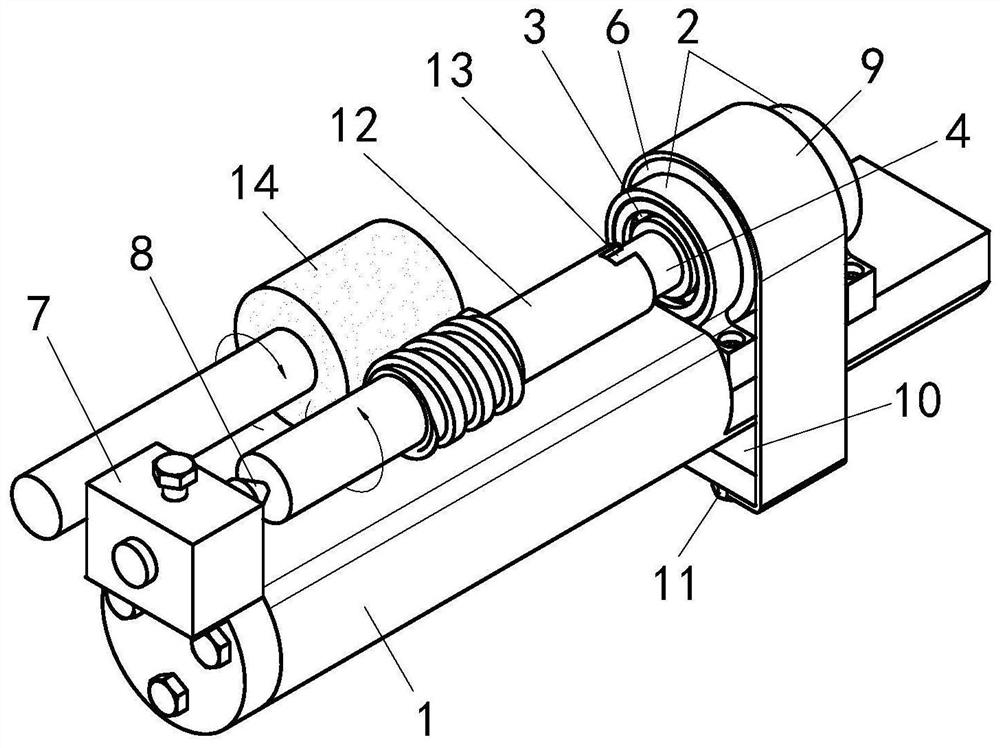

Method and fixture for polishing tooth surface of worm by using numerical control lathe

PendingCN112296451AControllable polishing timePolished evenlyGear-cutting machinesGear teethNumerical controlEngineering

The invention discloses a method and a fixture for polishing a tooth surface of a worm by using a numerical control lathe. The method comprises the steps that a worm is clamped on a tool rest of the numerical control lathe through the fixture, then a polishing wheel is clamped on a lathe head of the numerical control lathe, and the numerical control lathe drives the polishing wheel to rotate; andthen the tool rest is controlled to horizontally move the worm to make contact with the polishing wheel rotating at a high speed, and the tooth surface of the worm is polished through friction betweenthe polishing wheel and the tooth surface of the worm. Worms with different parameters ca be clamped by replacing different wheel shafts for polishing operation; an operator does not need to fix theworm with hands, and potential safety hazards can be eliminated; and the numerical control lathe can control polishing time and improve efficiency, the polishing wheel drives the worm to rotate, the polishing uniformity of the tooth surface is guaranteed, quality stability is improved, and popularization is facilitated.

Owner:GUIZHOU QUNJIAN PRECISION MACHINERY

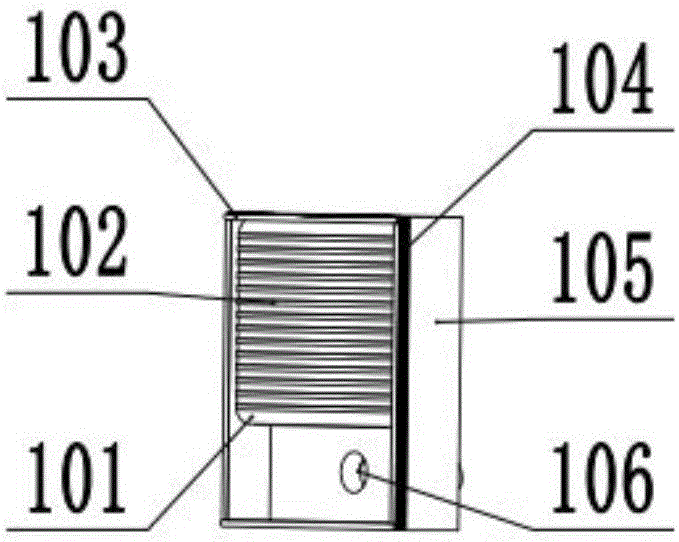

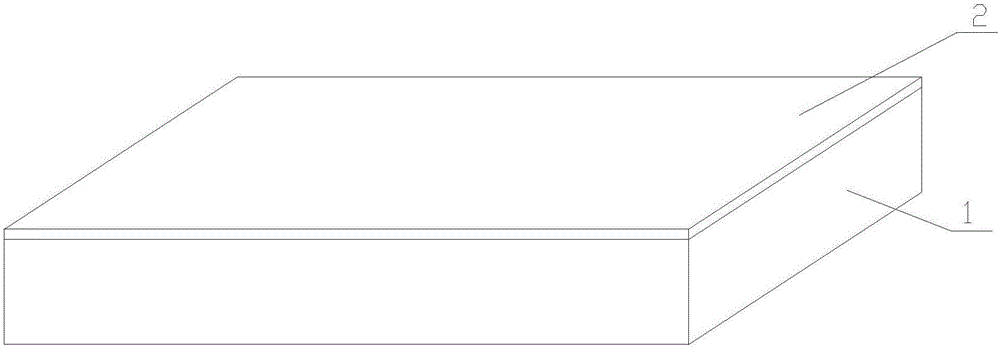

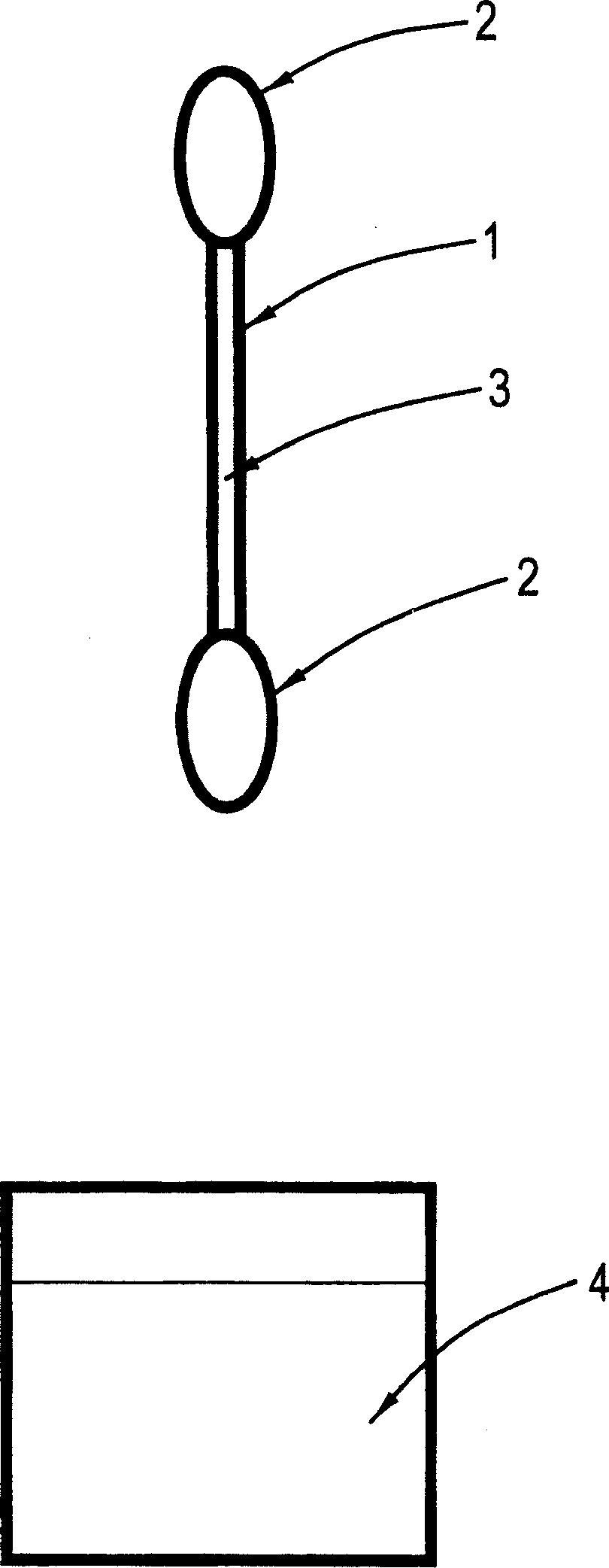

Tooth whitening means

InactiveCN1671332ALow costEasy to operateCosmetic preparationsTeeth fillingTooth whiteningDental surgeon

A tooth whitening means utilizing a simple and economical process of whitening and polishing teeth that does not require assistance or application by a professional such as a dentist. The present invention comprises of a cotton swab applicator with one or more absorbent tip (2) and a hollow body (1) which contains the liquid (3) activating agent of the tooth whitening compound and a tooth whitening compound (4) in the form of a solid powder wherein the liquid activating agent is released into the absorbent tip of the cotton swab applicator and allowed to contact the solid powder compound which is then applied to the surfaces of the tooth with the tip to whiten and polish the tooth.

Owner:曹荣华

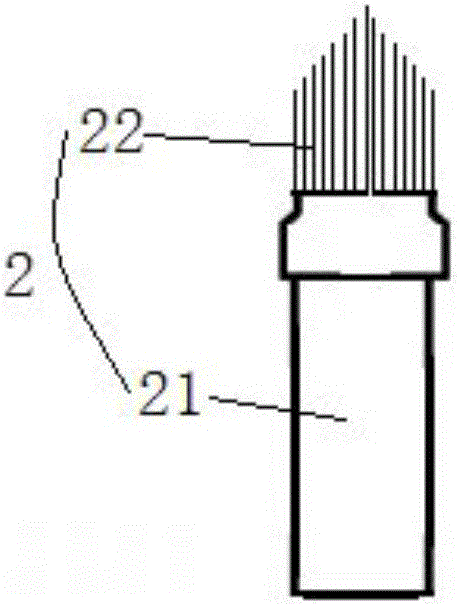

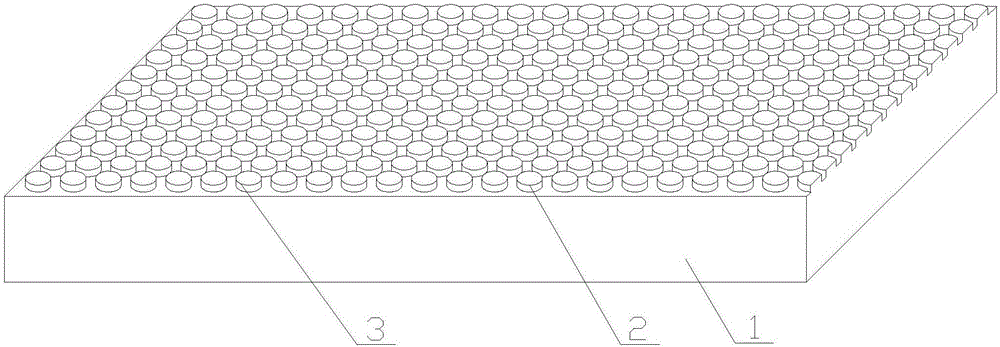

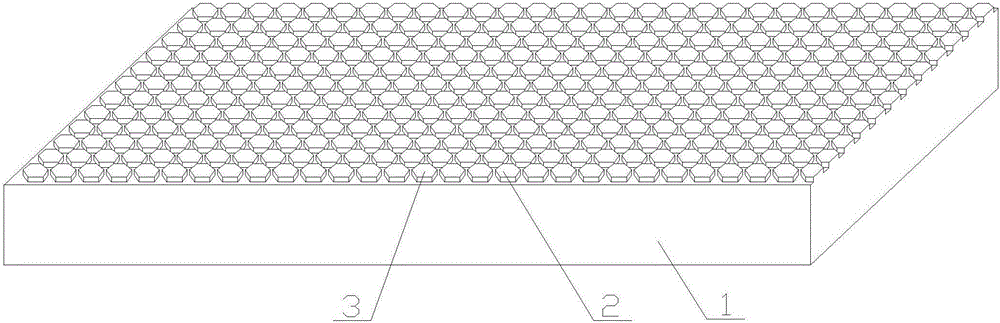

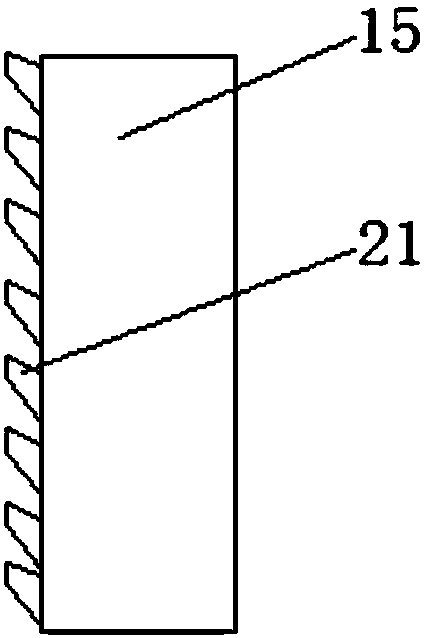

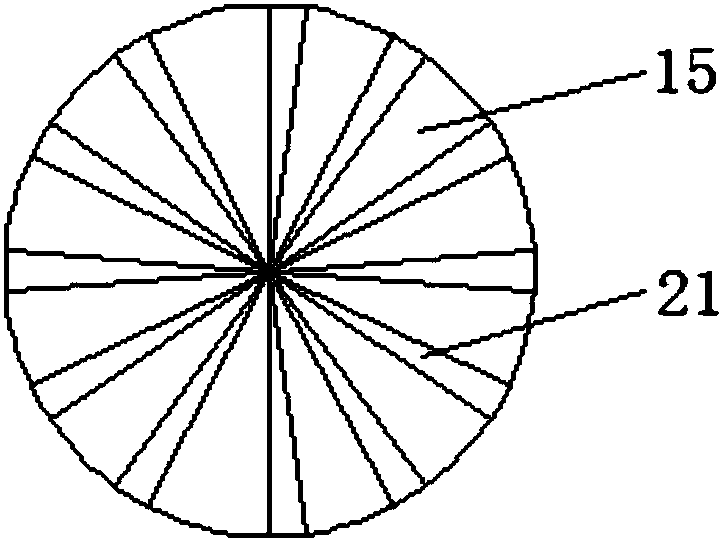

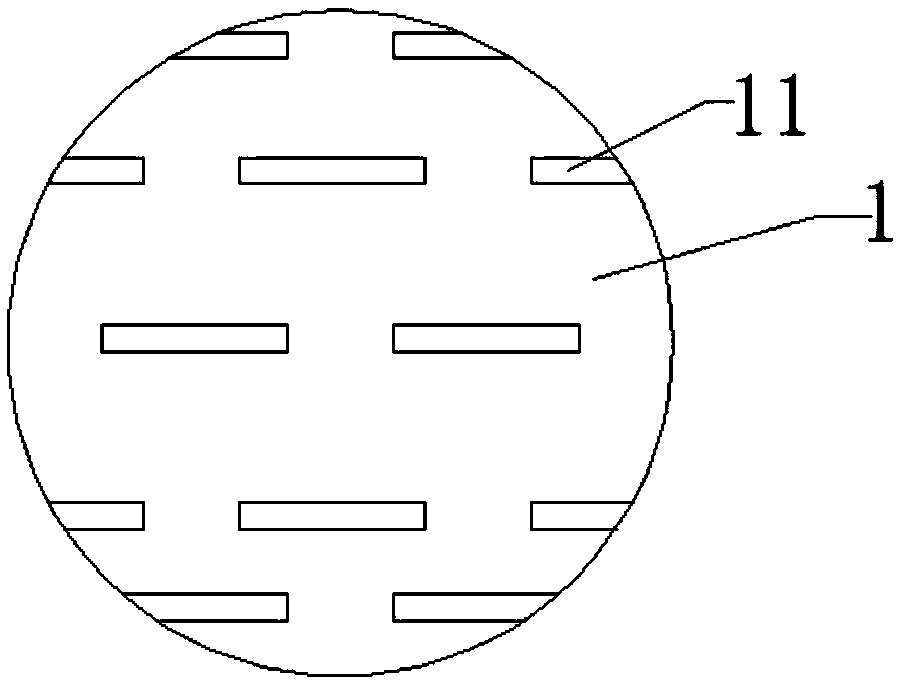

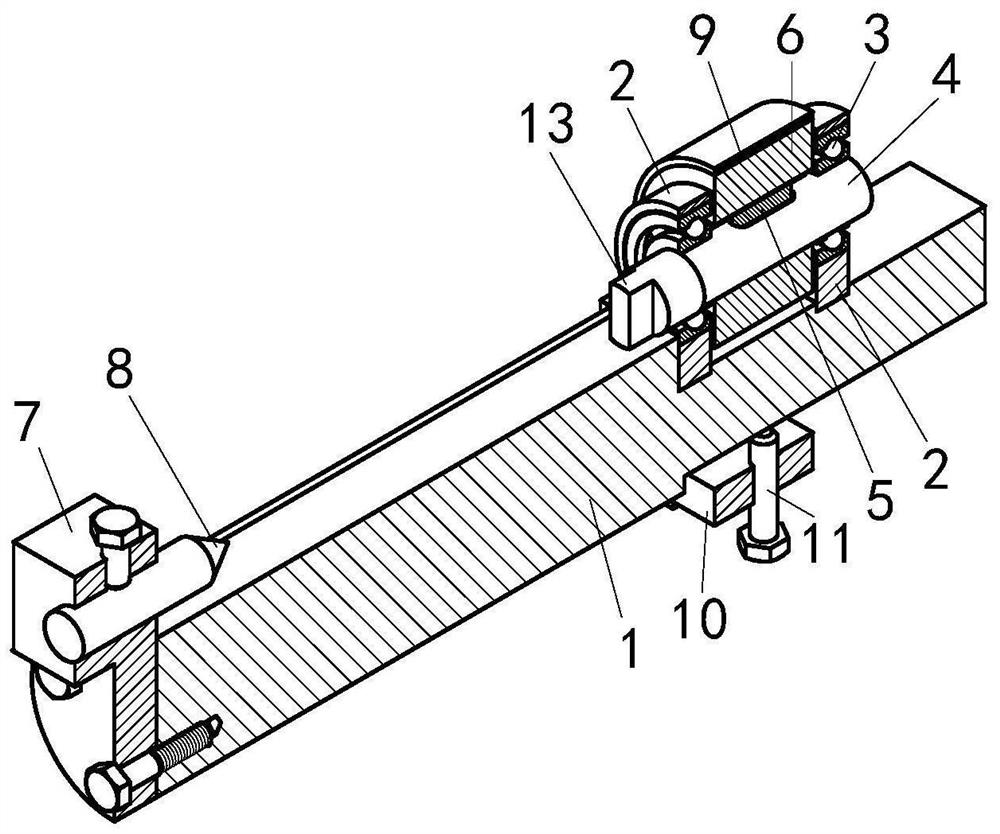

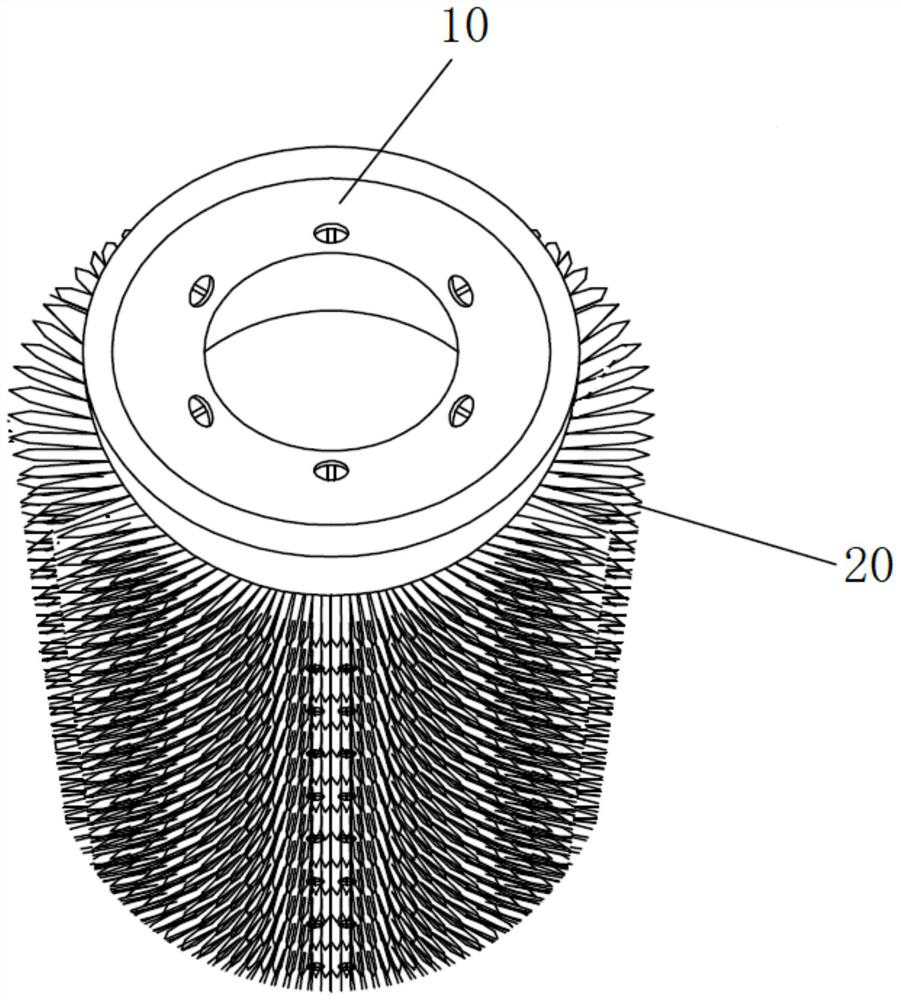

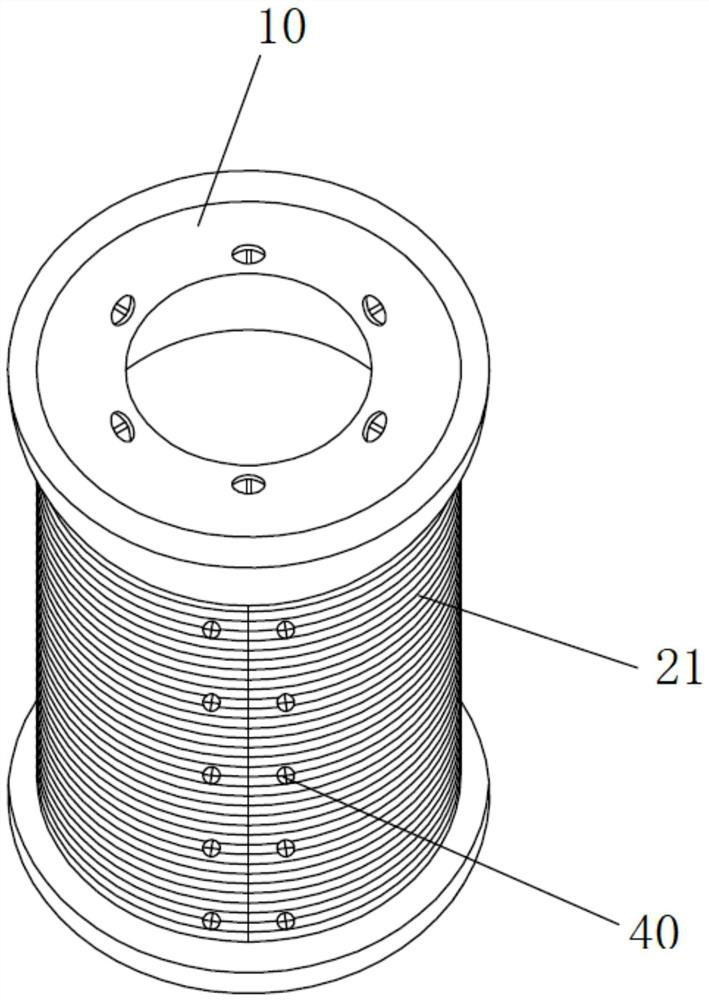

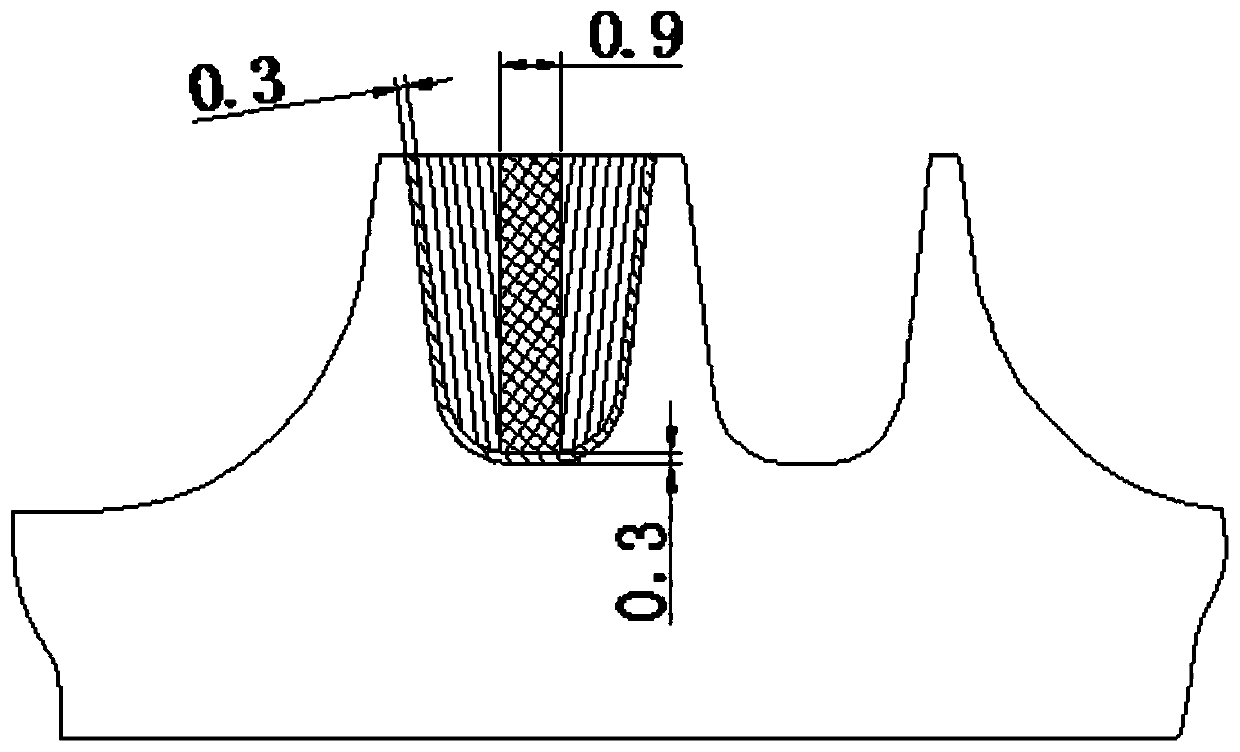

Polishing layer for polishing brush, polishing brush, polishing machine, and related preparation method

PendingCN112059878AEasy to fixEffective sandingPolishing machinesGrinding devicesPolishing teethPolish tooth

The invention discloses a polishing layer for a polishing brush, the polishing brush, a polishing machine, and a related preparation method. The polishing layer for the polishing brush comprises a fixing layer and at least one polishing rack; a plurality of fixing grooves are formed in the outer surface of the fixing layer and used for fixing the polishing racks; the fixing layer is in the shape of all or part of a cylindrical cambered surface, and the multiple fixing grooves are expansion lines of a spiral curve extending along the outer surface of the fixing layer; each of the polishing racks comprises a plurality of polishing teeth; a plurality of through holes are formed in the ends, away from the polishing teeth, of the polishing racks at intervals; and at least one polishing rack isfixed inside the fixing grooves of the fixing layer. After the polishing racks are fixed in the fixing grooves, the spiral or partially spiral polishing layer is formed, so that an axial gap is not prone to being formed between every two adjacent polishing teeth, and the side edge of a workpiece can be effectively ground and polished. The multiple through holes are formed in the polishing racks atintervals, and when gel is used for fixing, the gel penetrates through the through holes of the polishing racks to fix more firmly.

Owner:嘉贺光电科技(惠州)有限公司

Device for manufacturing gear for universal machinery cam shaft

ActiveCN110653688AAchieve grindingImprove grinding efficiencyValve arrangementsSeat surface grinding machinesMachine buildingGear wheel

The invention belongs to the field of machine manufacturing and particularly discloses a device for manufacturing a gear for a universal machinery cam shaft. The device comprises a moving mechanism for driving a cam shaft gear to move and a tooth slot polishing mechanism for polishing the tooth slot of a cam shaft gear; the tooth slot polishing mechanism comprises two rotating rollers and a belt wound on the two rotating rollers; polishing teeth meshed with the teeth slot of the cam shaft gear are arranged on the inner side of the belt; an air sac wrapping the polishing teeth is arranged outside the polishing teeth; a polishing layer is arranged on the outer surface of the air sac; the air sac is connected with an air inflating and releasing mechanism; the moving mechanism comprises two support pieces and a motion driving piece; the two support pieces are used for clamping and supporting the cam shaft from the two ends of the cam shaft; and the motion driving piece is used for drivingthe support pieces to move in the length direction of the polishing teeth on the belt.

Owner:重庆九方铸造有限责任公司

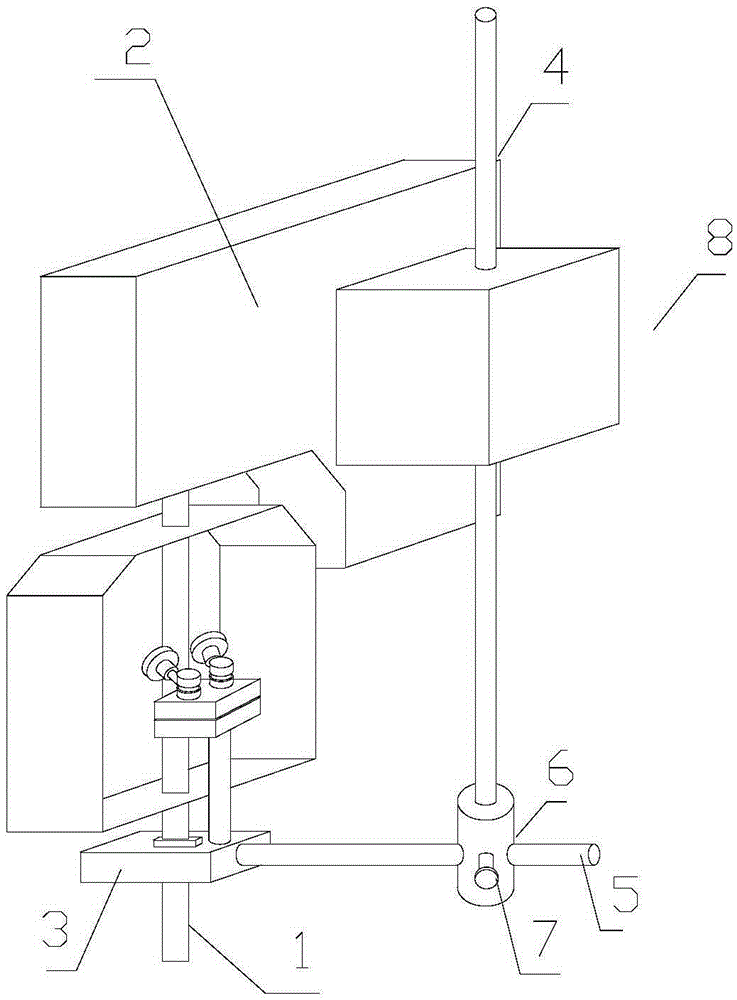

Saw blade polishing mechanism and truncation device

ActiveCN105382341AOvercome the problem of collapseTruncated implementationMetal sawing tool makingSawing tools dressing arrangementsEngineeringMechanical engineering

The invention discloses a saw blade polishing mechanism and a truncation device. The saw blade polishing mechanism comprises a bottom plate (9), a polishing disc (10) and a connecting post (11), wherein the connecting post is vertically arranged on the bottom plate (9), the polishing disc (10) is rotationally connected to the connecting post (11), and polishing teeth are arranged on the side surface of the polishing disc. According to the saw blade polishing mechanism and the truncation device, the problem that a saw blade is broken down in the using process of the saw blade in the prior art is solved, and the saw blade is truncated after being polished.

Owner:安徽麦克威链传动制造有限公司

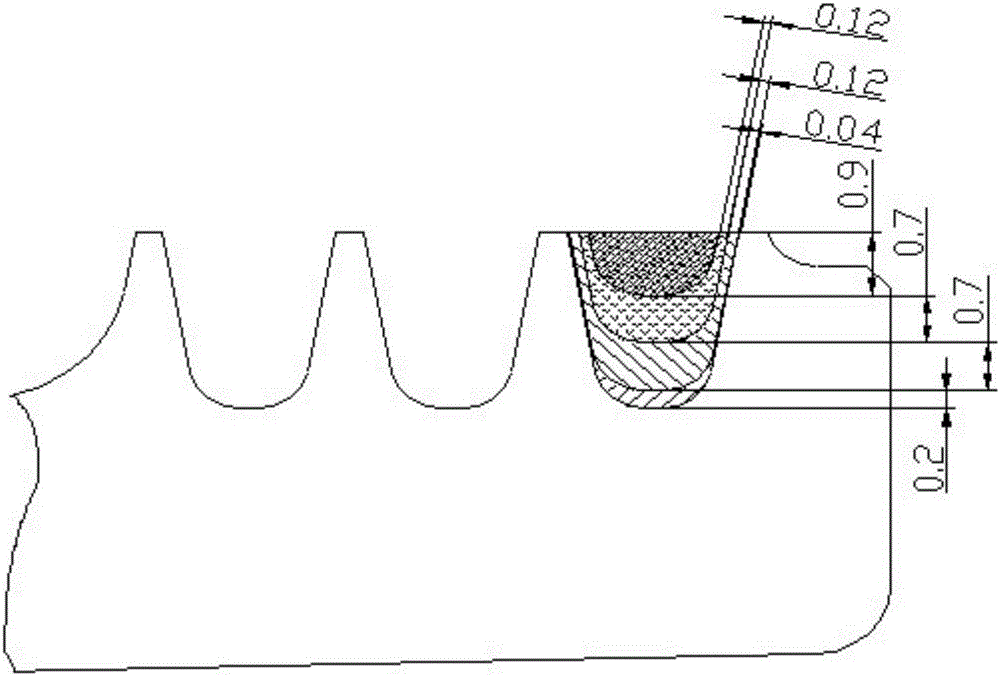

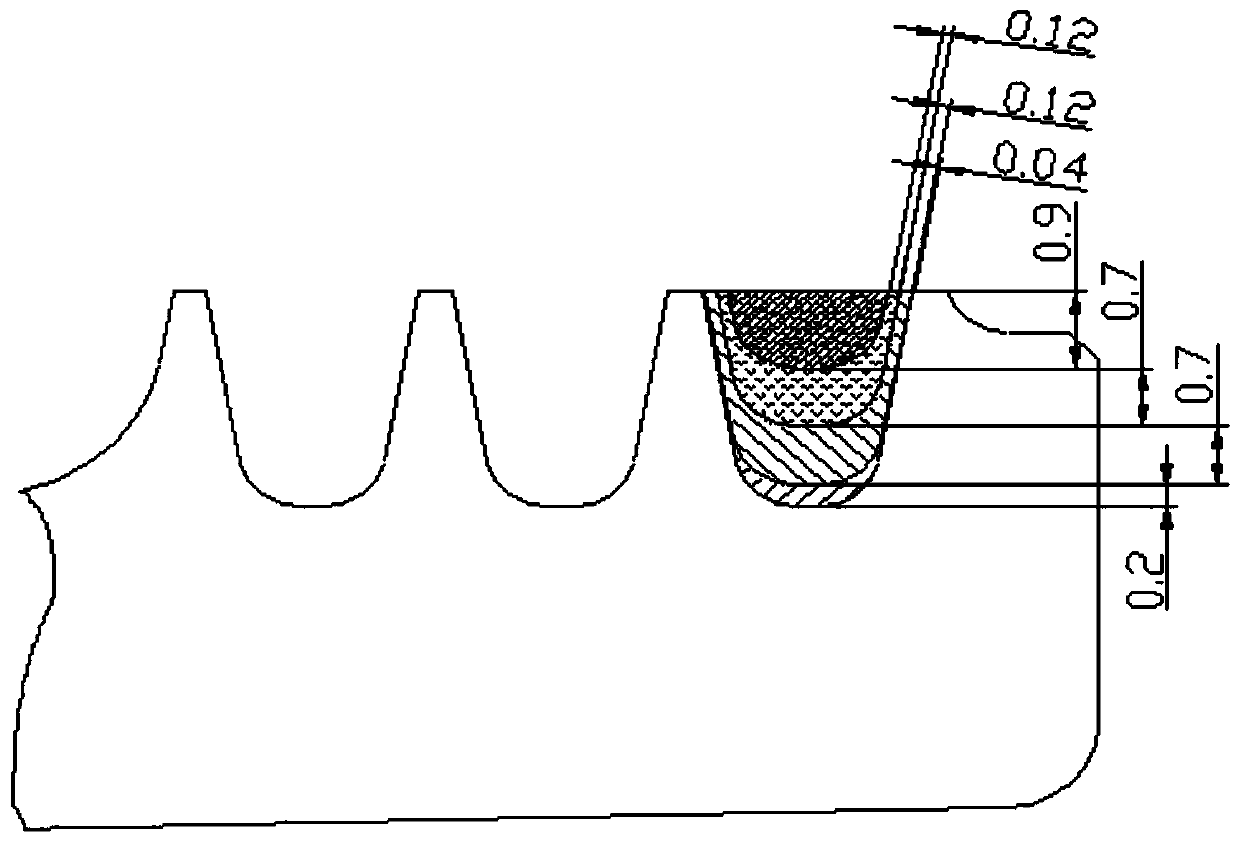

A processing method for improving the surface integrity of sealing grate teeth of rotating parts

The invention discloses a machining method for improving surface integrity of a sealing labyrinth of a rotating part. The machining method includes the steps of firstly, placing a sealing labyrinth workpiece on a machining platform, and enabling a machine tool to select a sealing labyrinth cutter which is provided with a cooling device connected with a machining tool cooling system; secondly, selecting a main axis rotating speed, the feeding number and the feeding quantity according to a structure and a material of the sealing labyrinth, and cleaning and cooling the cutter and the workpiece by the cooling device during machining; thirdly, obtaining the sealing labyrinth after machining in the step 2; fourthly, burring and polishing tooth tops of the sealing labyrinth so as to obtain a sealing labyrinth finished product; fifthly, subjecting the sealing labyrinth to macroscopic assessment so as to obtain the qualified sealing labyrinth. The machining method for improving the surface integrity of the sealing labyrinth of the rotating part has the advantages that the surface integrity of the sealing labyrinth of an engine wheel disc is improved, cracking failure of the engine wheel disc is reduced and the engine performance is improved.

Owner:AECC AVIATION POWER CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com