Patents

Literature

1273results about How to "Realize automatic unloading" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

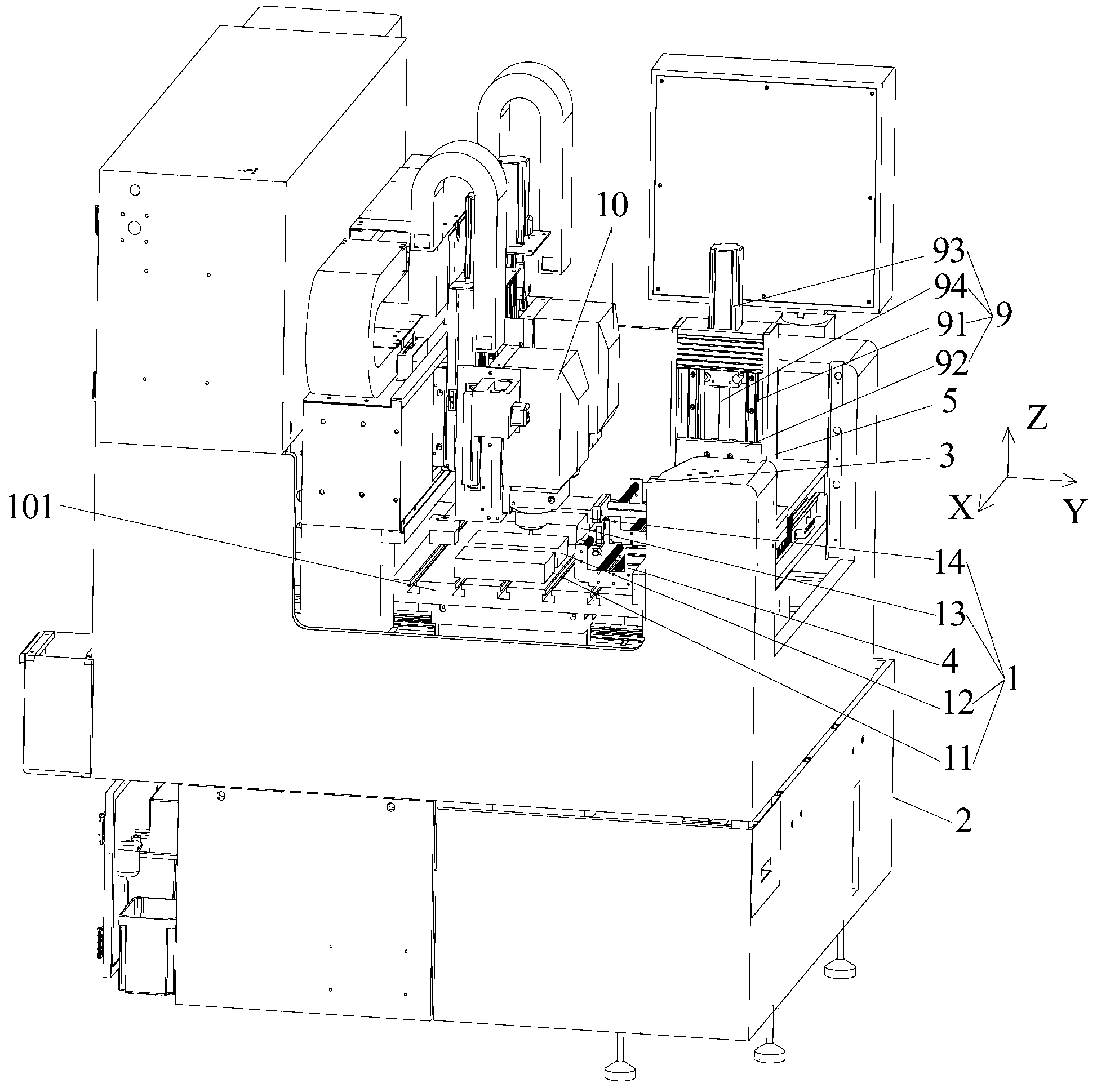

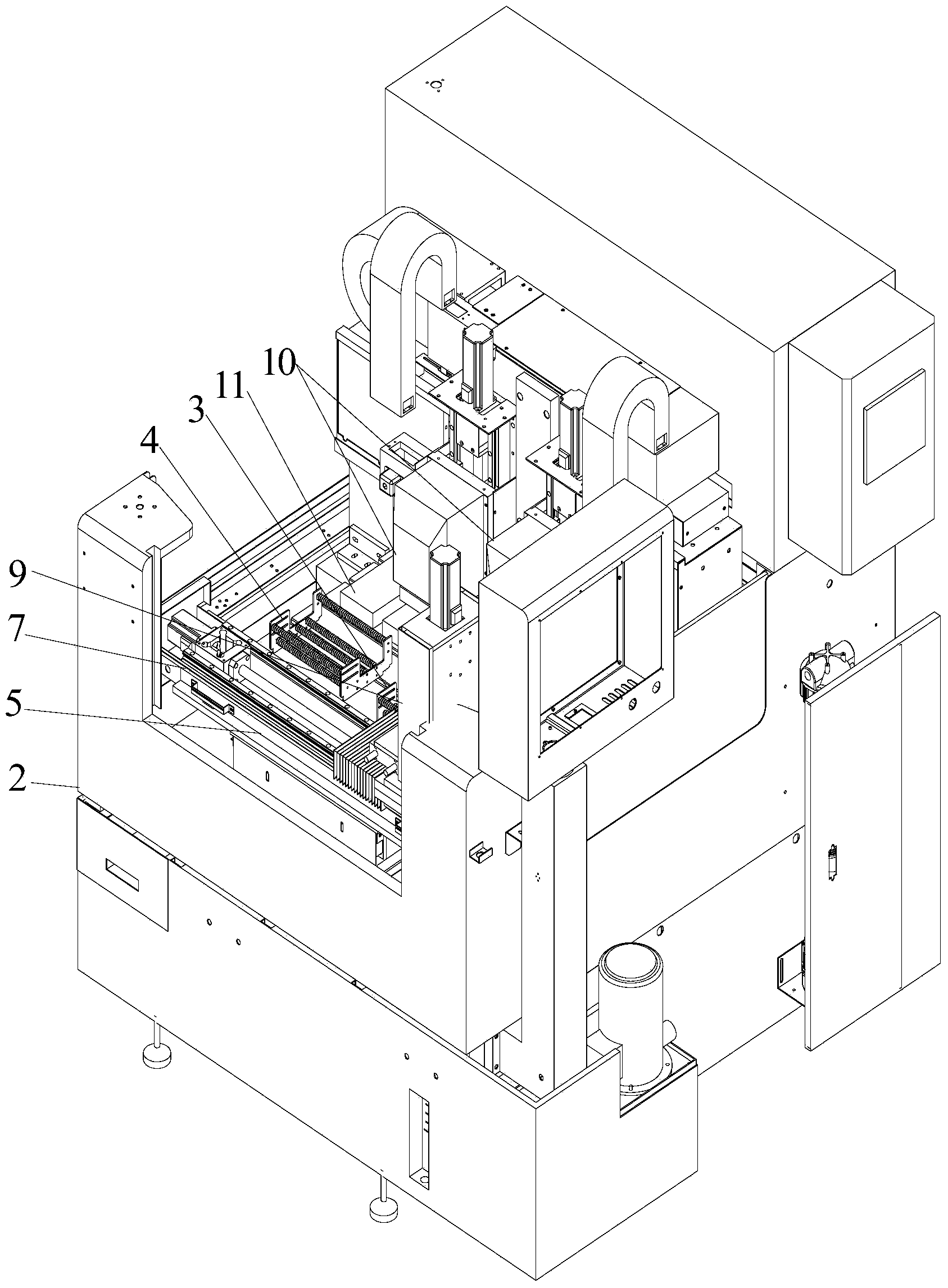

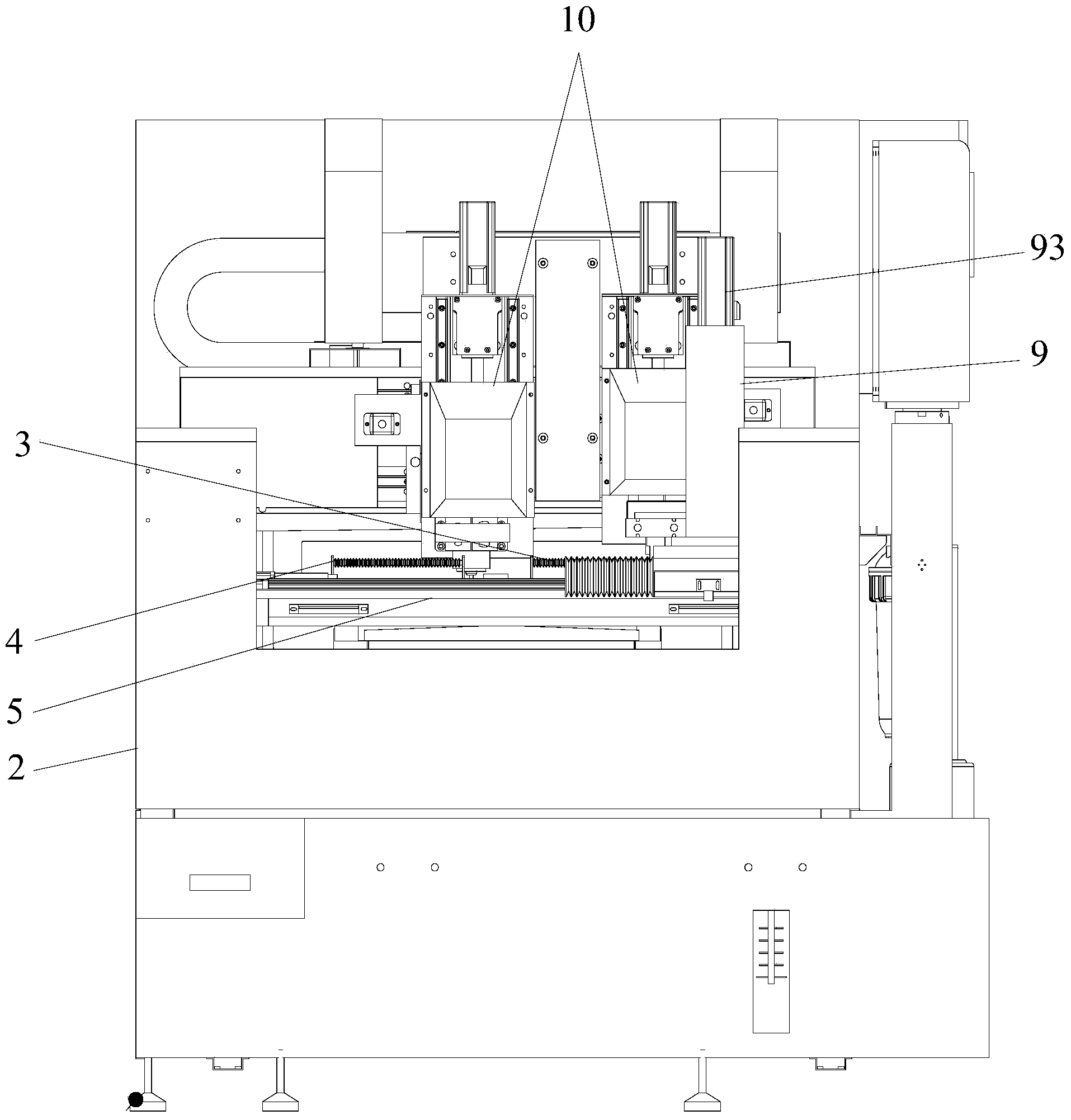

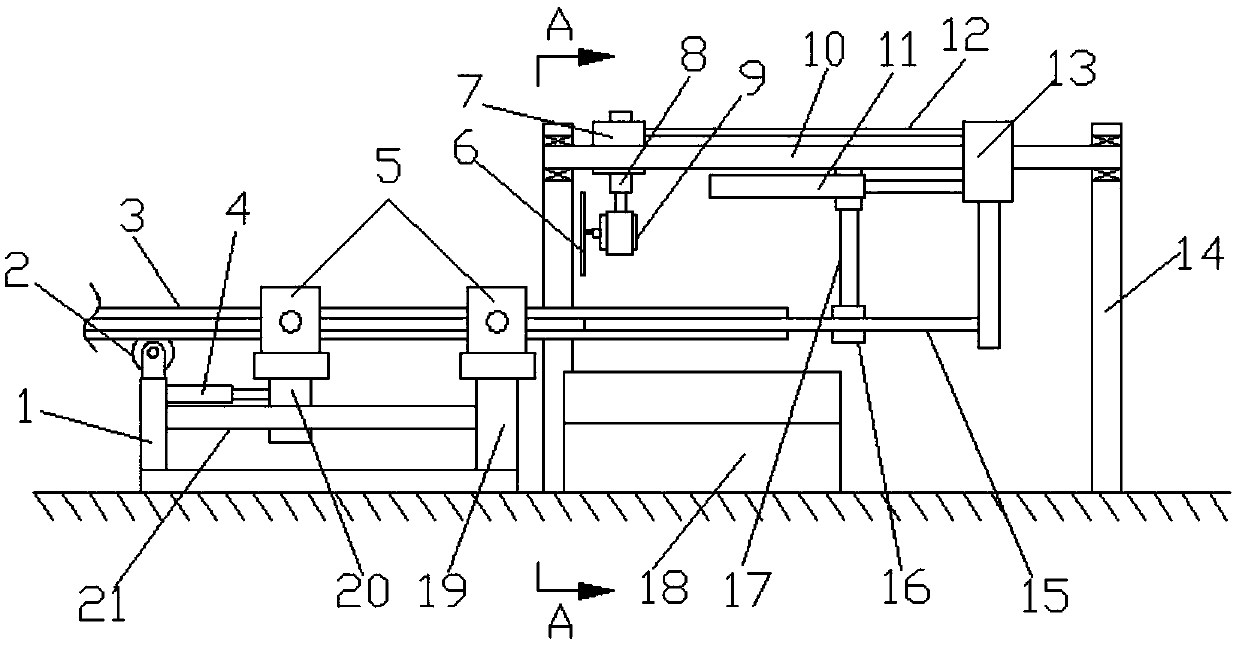

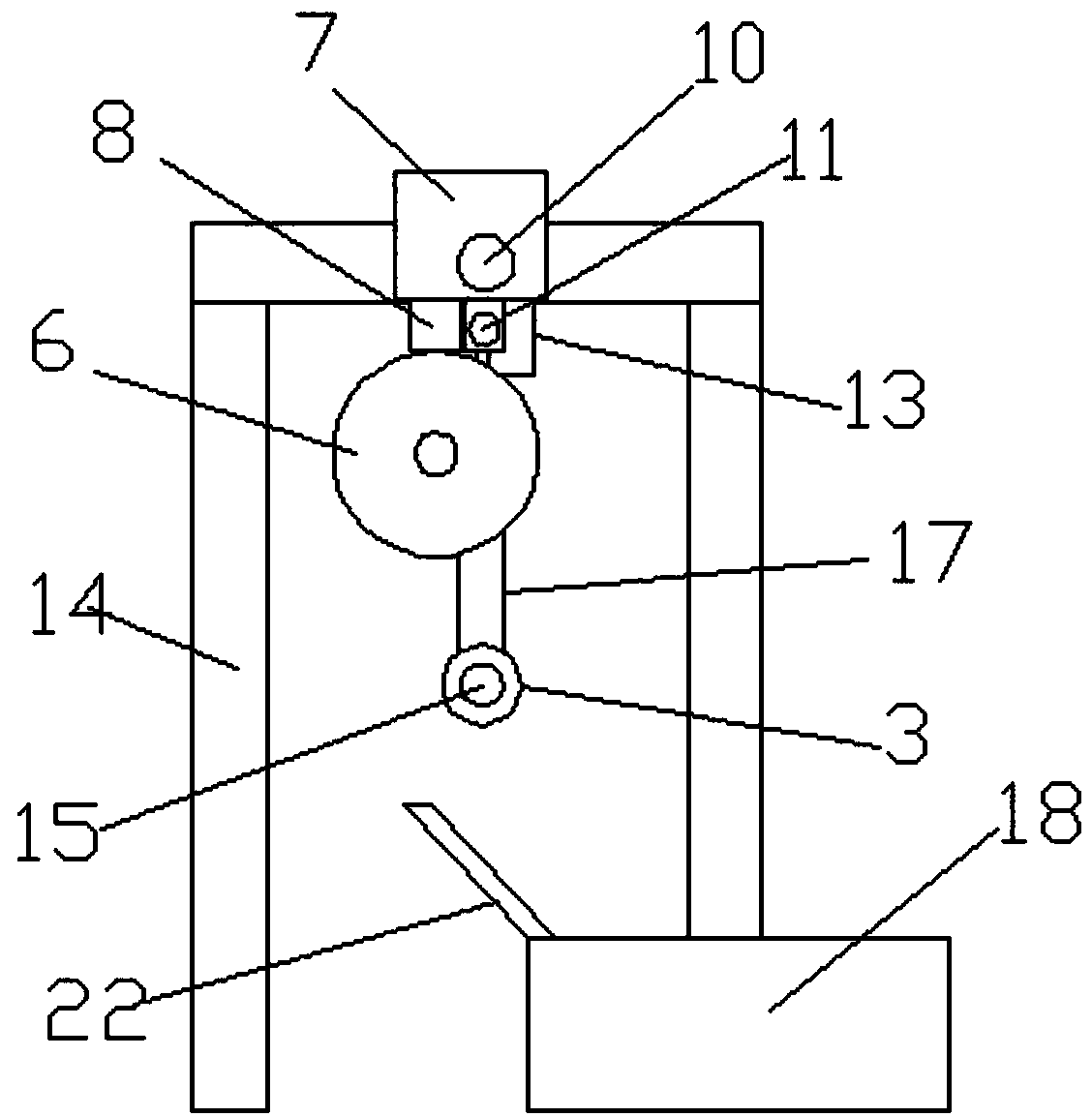

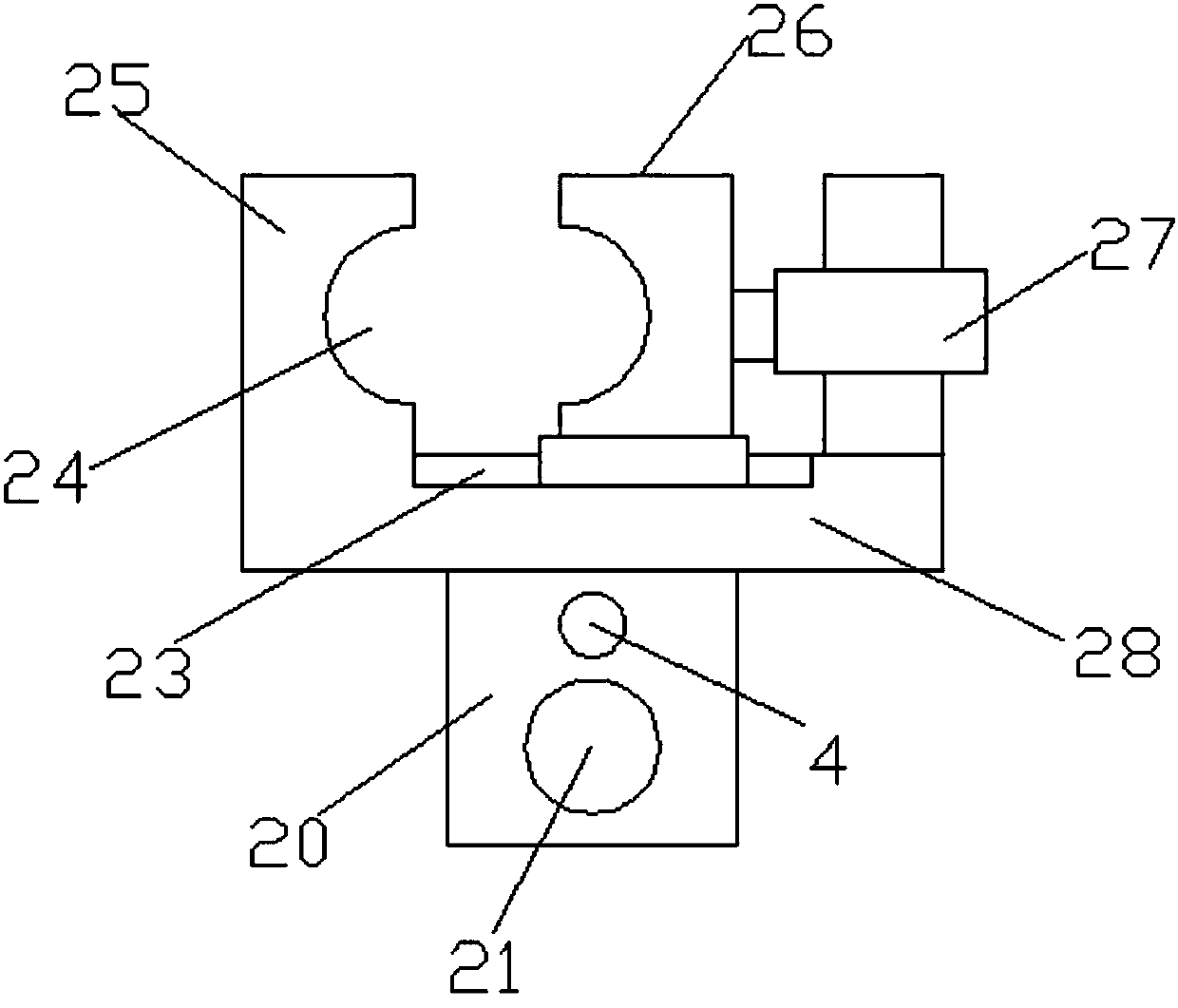

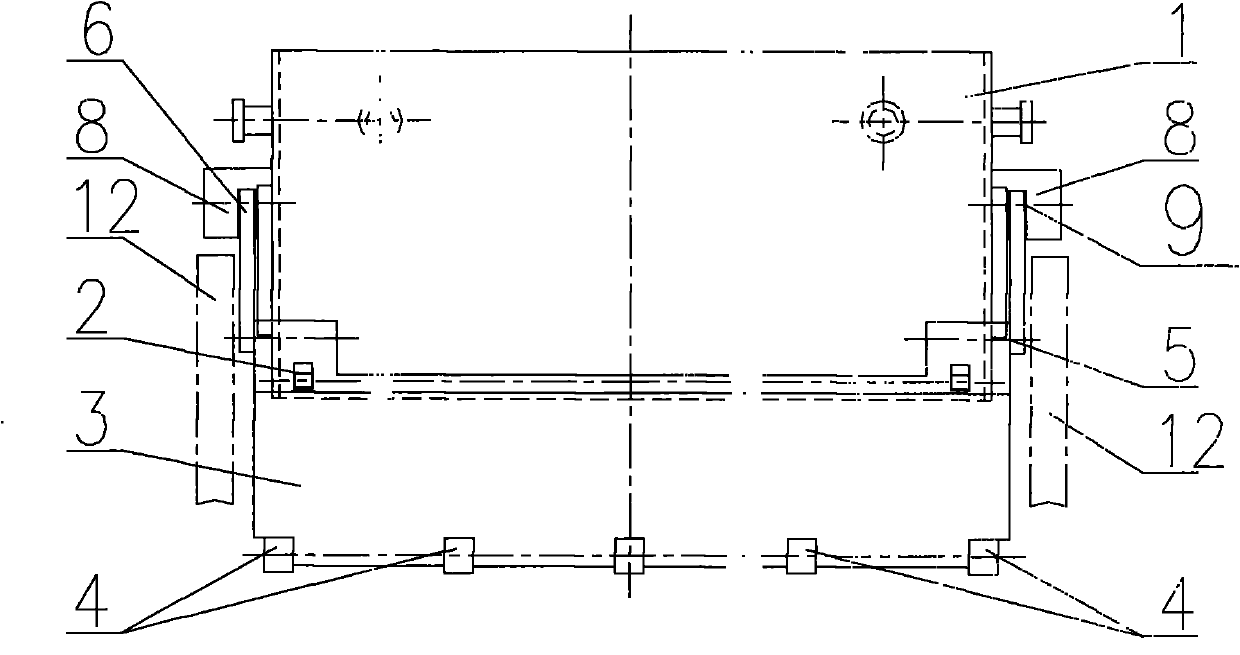

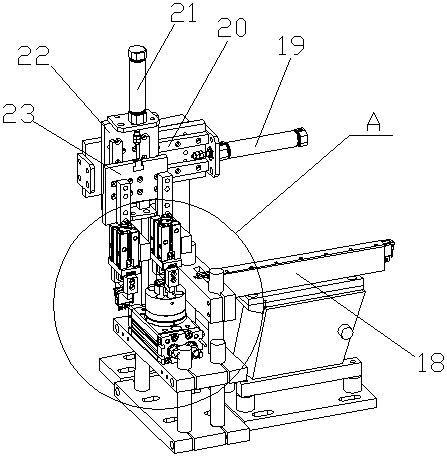

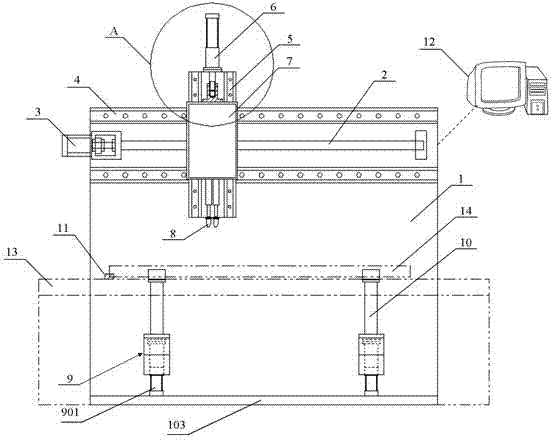

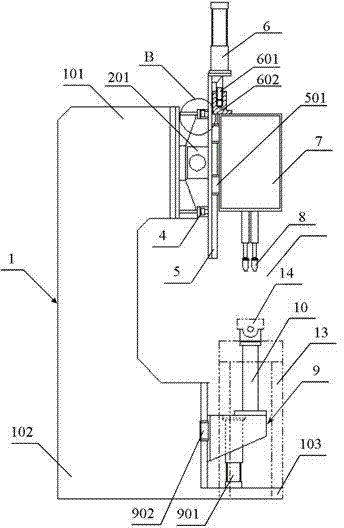

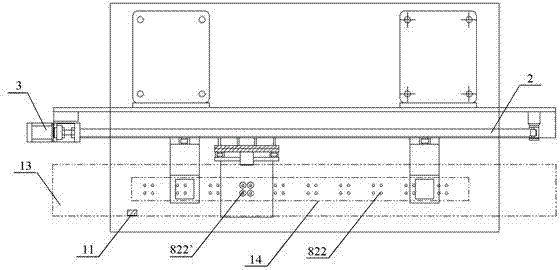

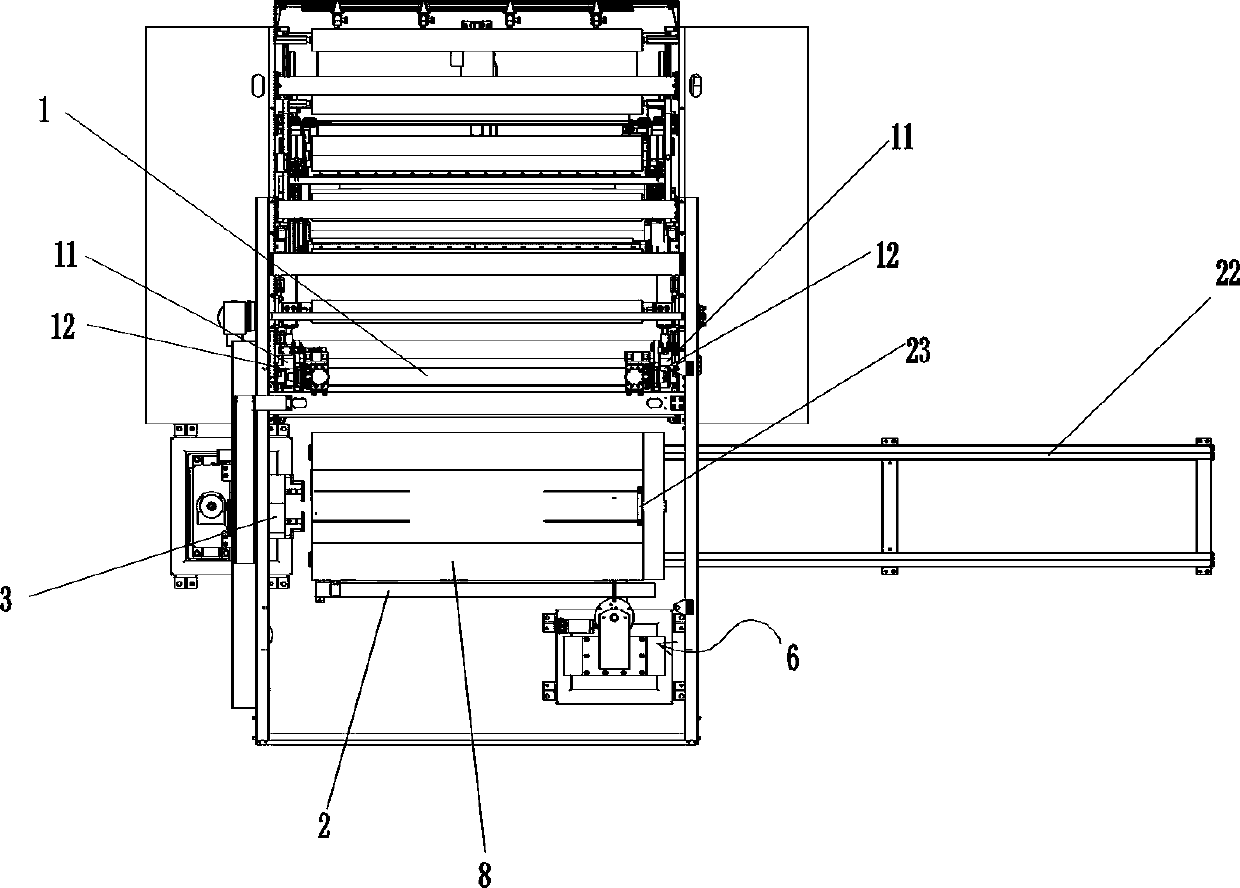

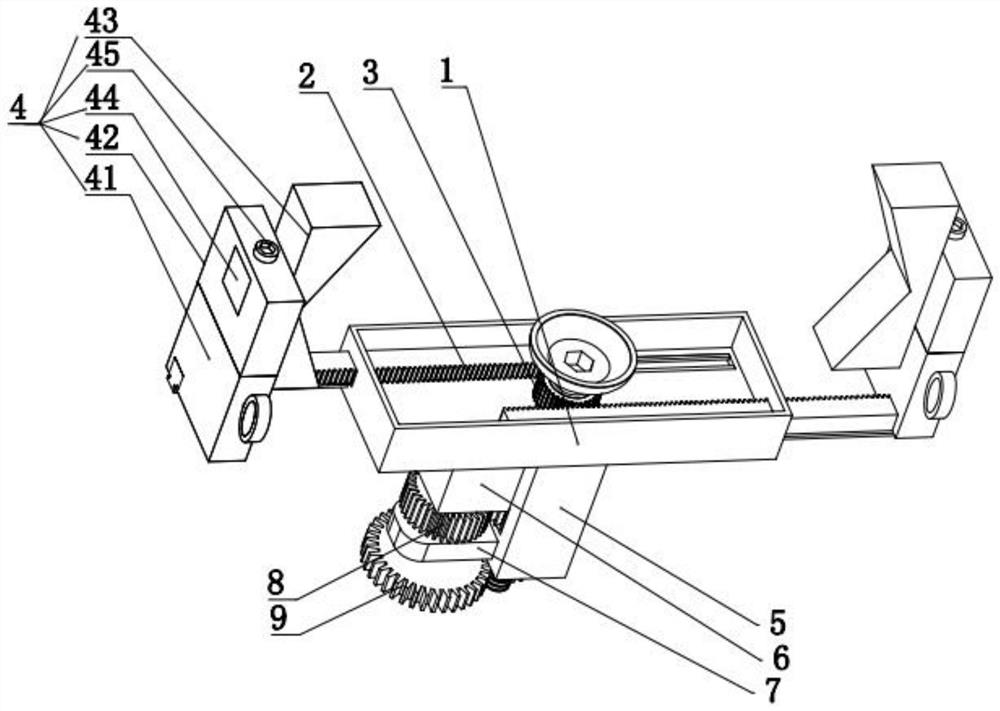

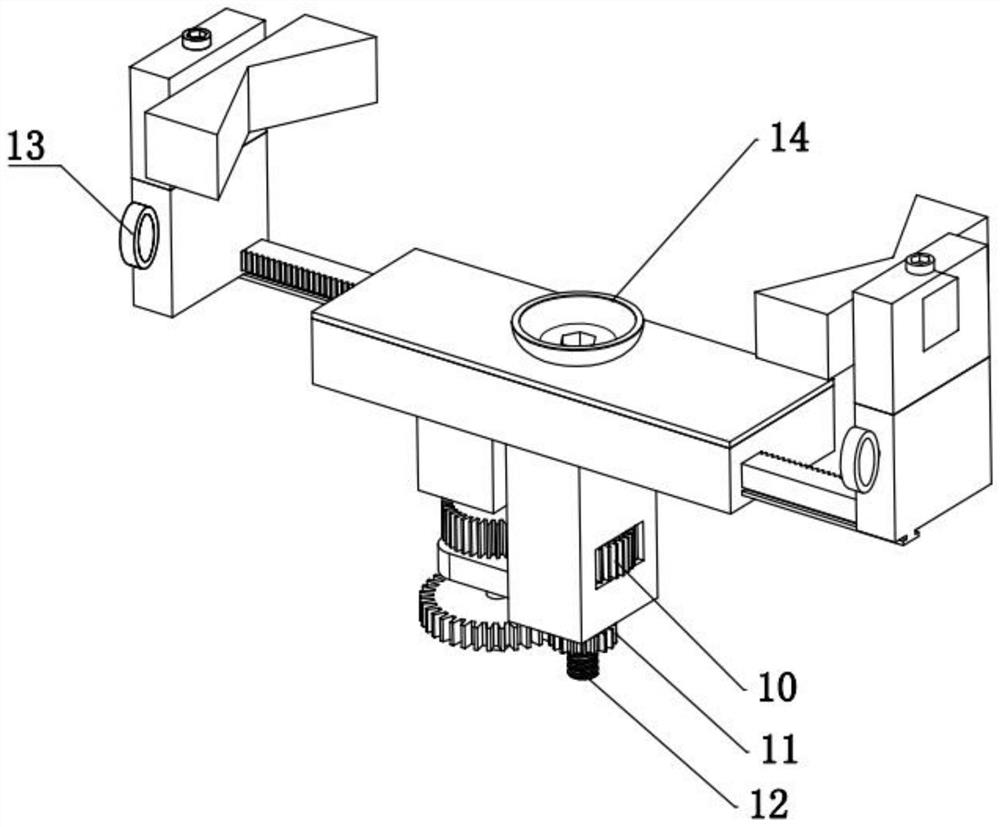

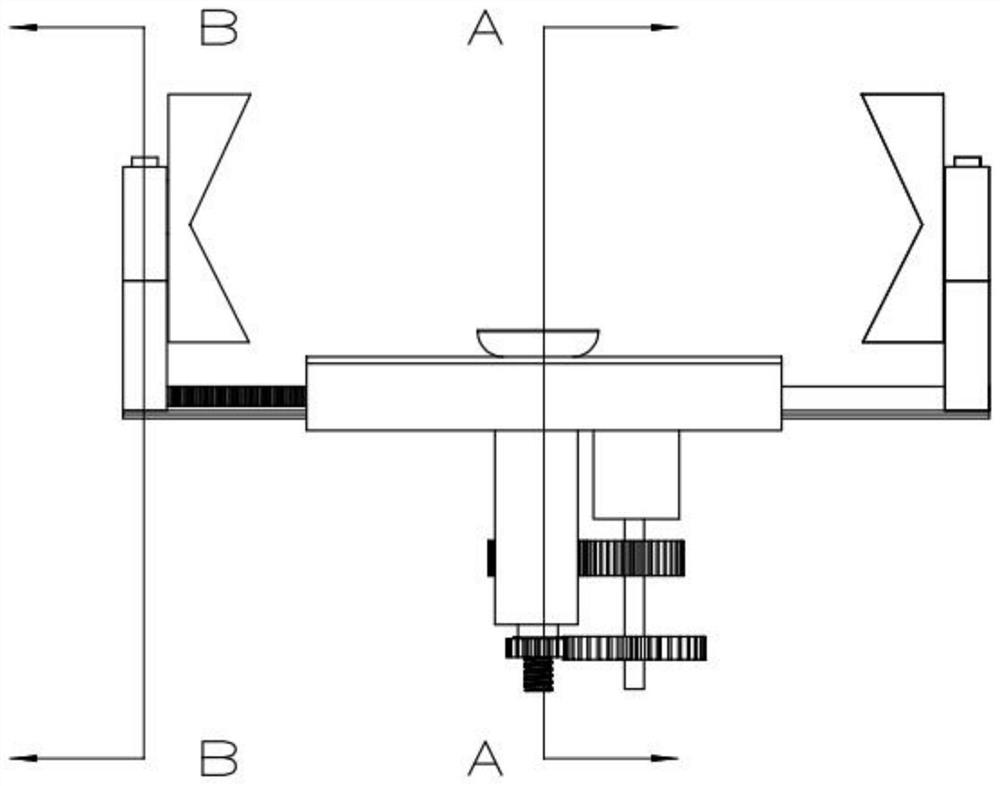

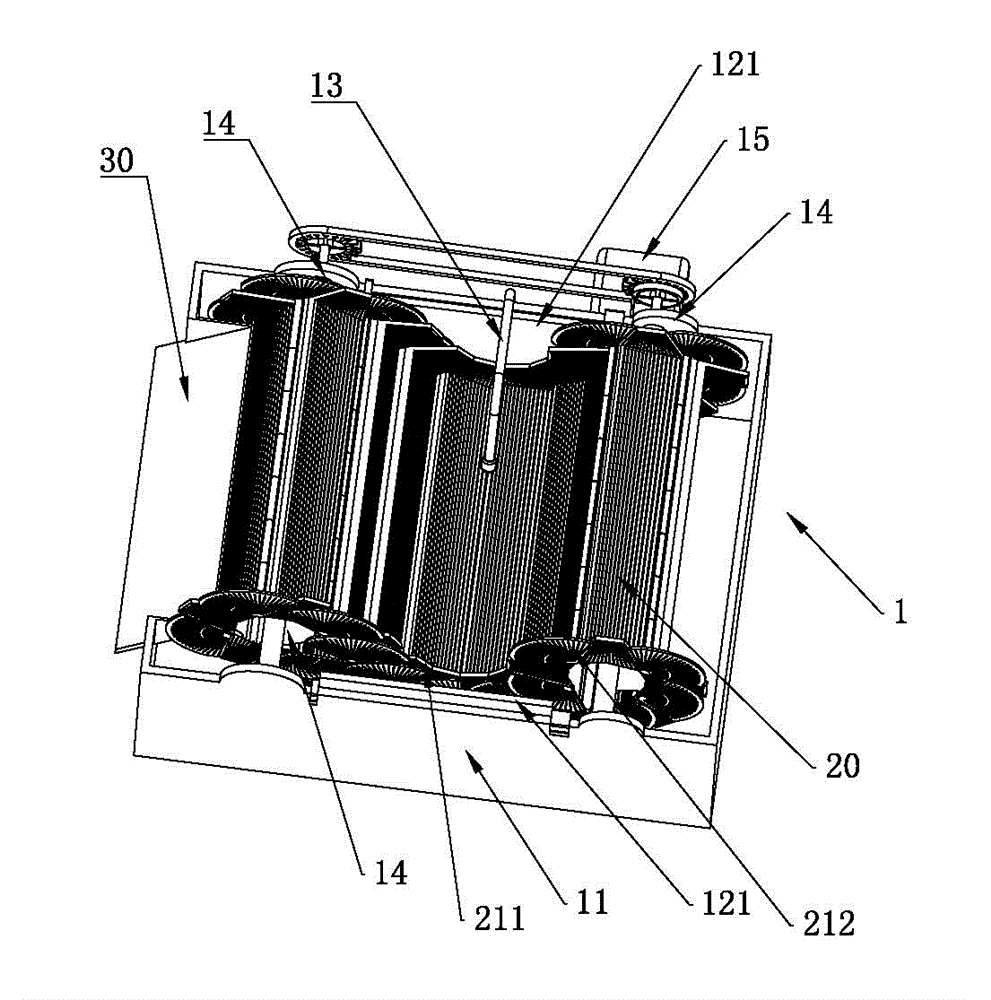

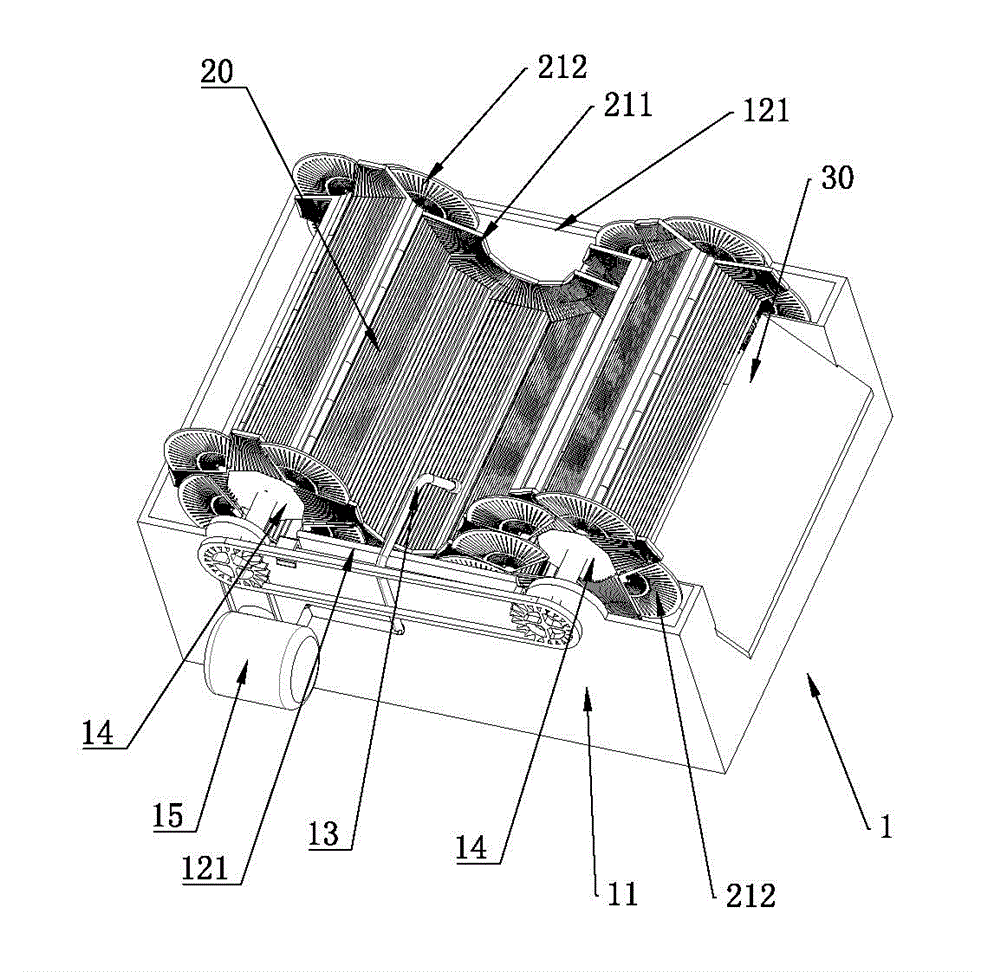

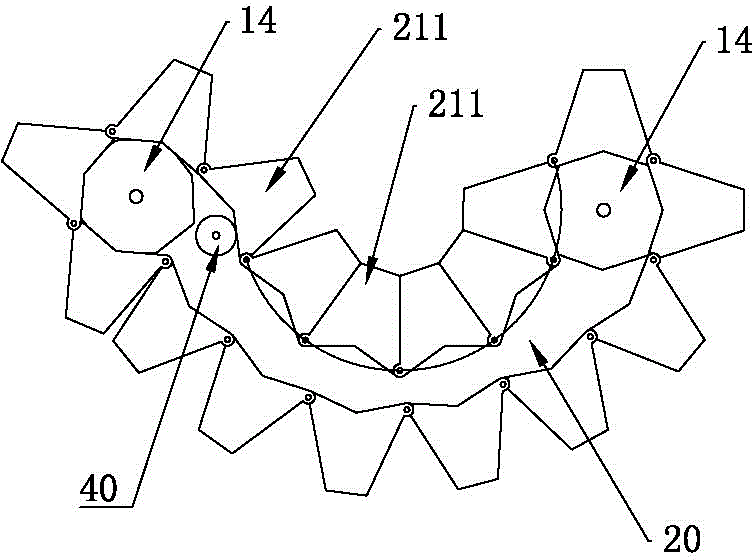

Automatic loading and unloading device for numerically-controlled machine tool

ActiveCN104354097ARealize automatic loading and unloadingRealize automatic feeding processWorking accessoriesGrinding feedersNumerical controlEngineering

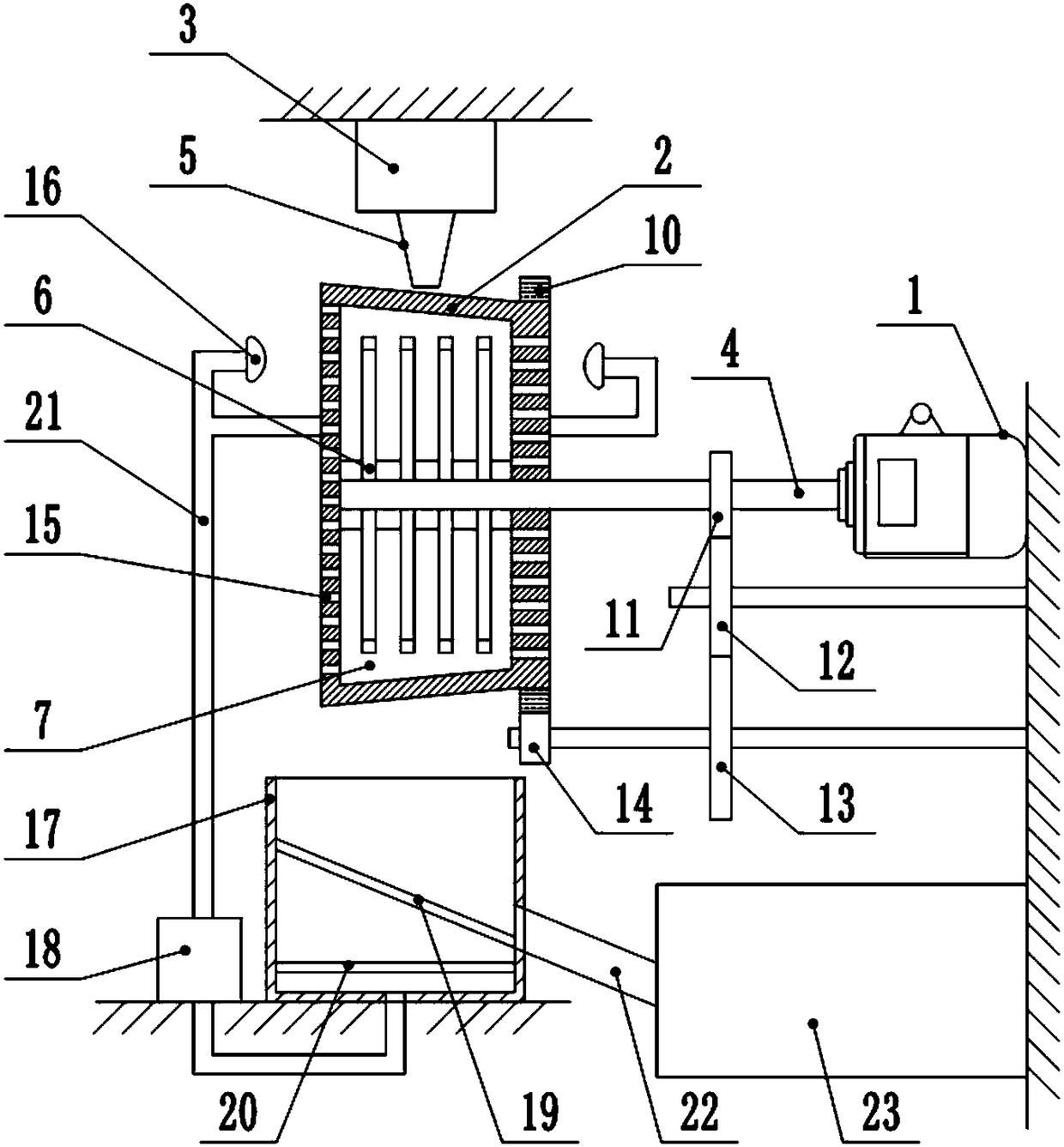

The invention discloses an automatic loading and unloading device for a numerically-controlled machine tool. The automatic loading and unloading device is driven by using an axis-X driving structure and an axis-Z driving device, and a glass workpiece is grabbed by virtue of a flexible air cylinder, a rotating air cylinder and a vacuum sucking disc, so that automatic loading of glass pieces to be machined and automatic unloading of the machined glass workpiece are realized; because the numerically-controlled machine tool is in a double-head design, four positioning jigs are provided, and a second positioning jig and a fourth positioning jig load during the machining of a first poisoning jig and a third positioning jig, so that automatic loading and unloading can be realized, circulating machining without stopping is also realized, and the machining efficiency is greatly improved.

Owner:SHENZHEN YUANYANG XIANGRUI MACHINERY

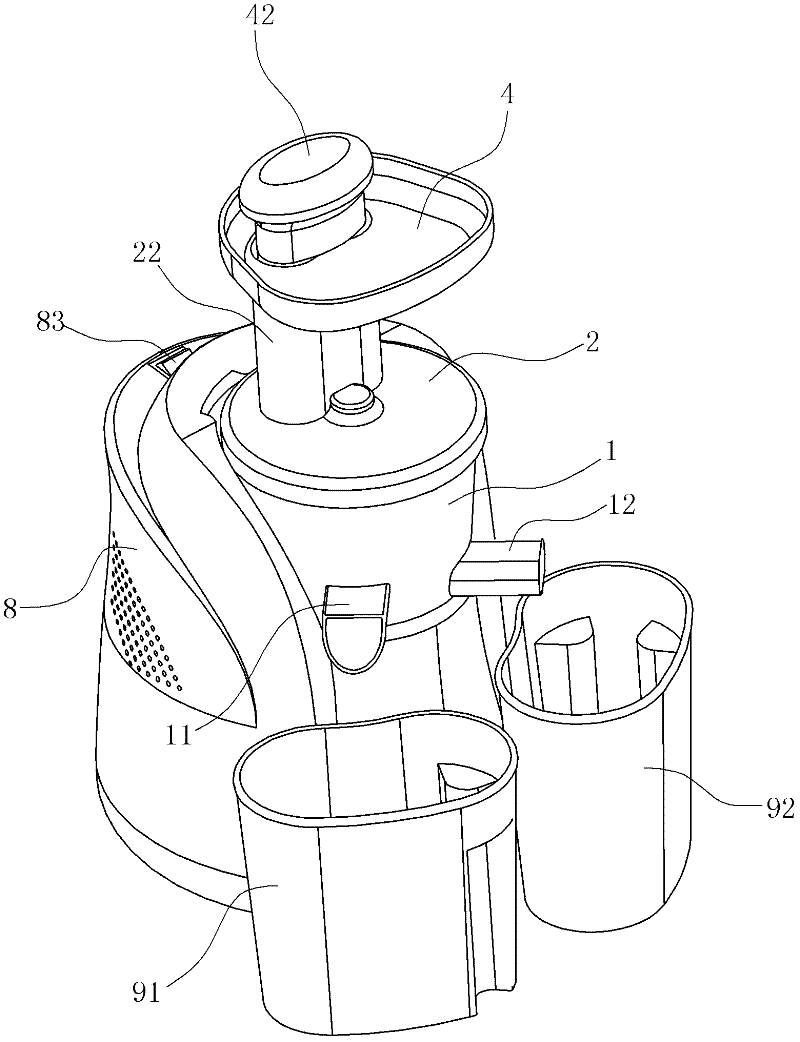

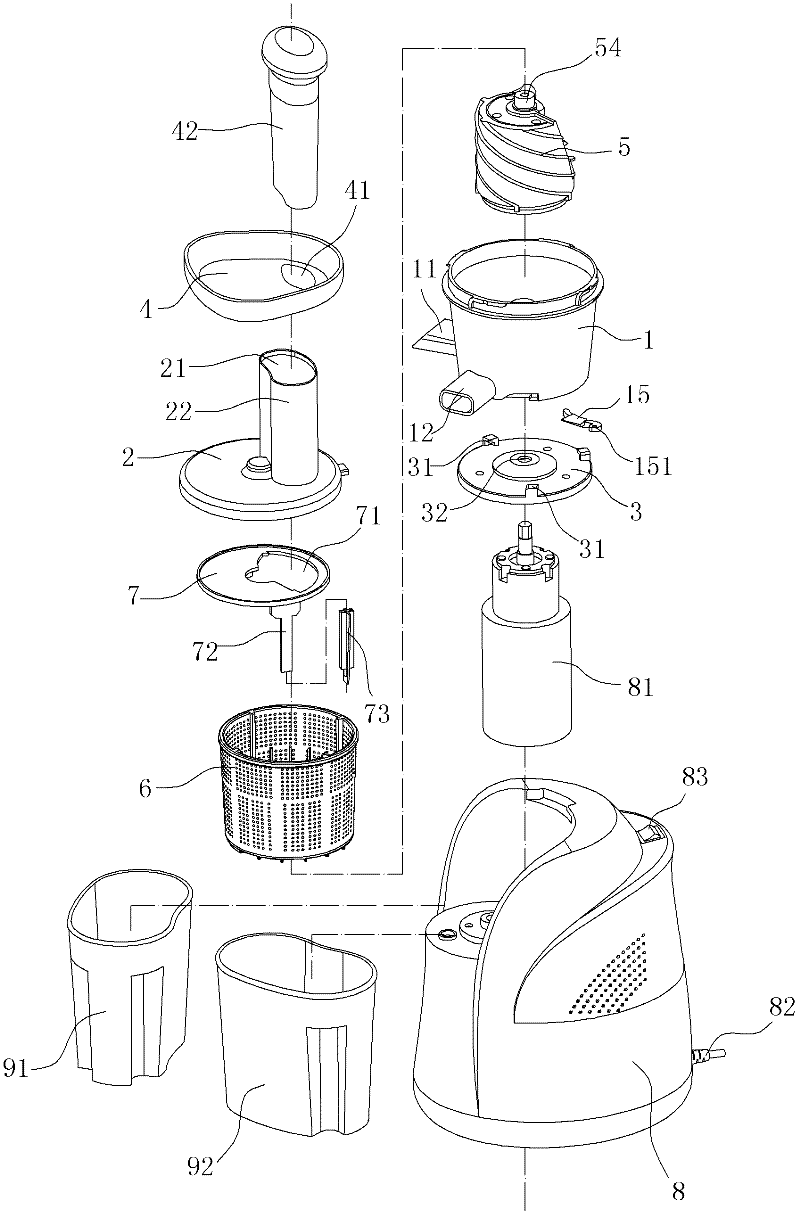

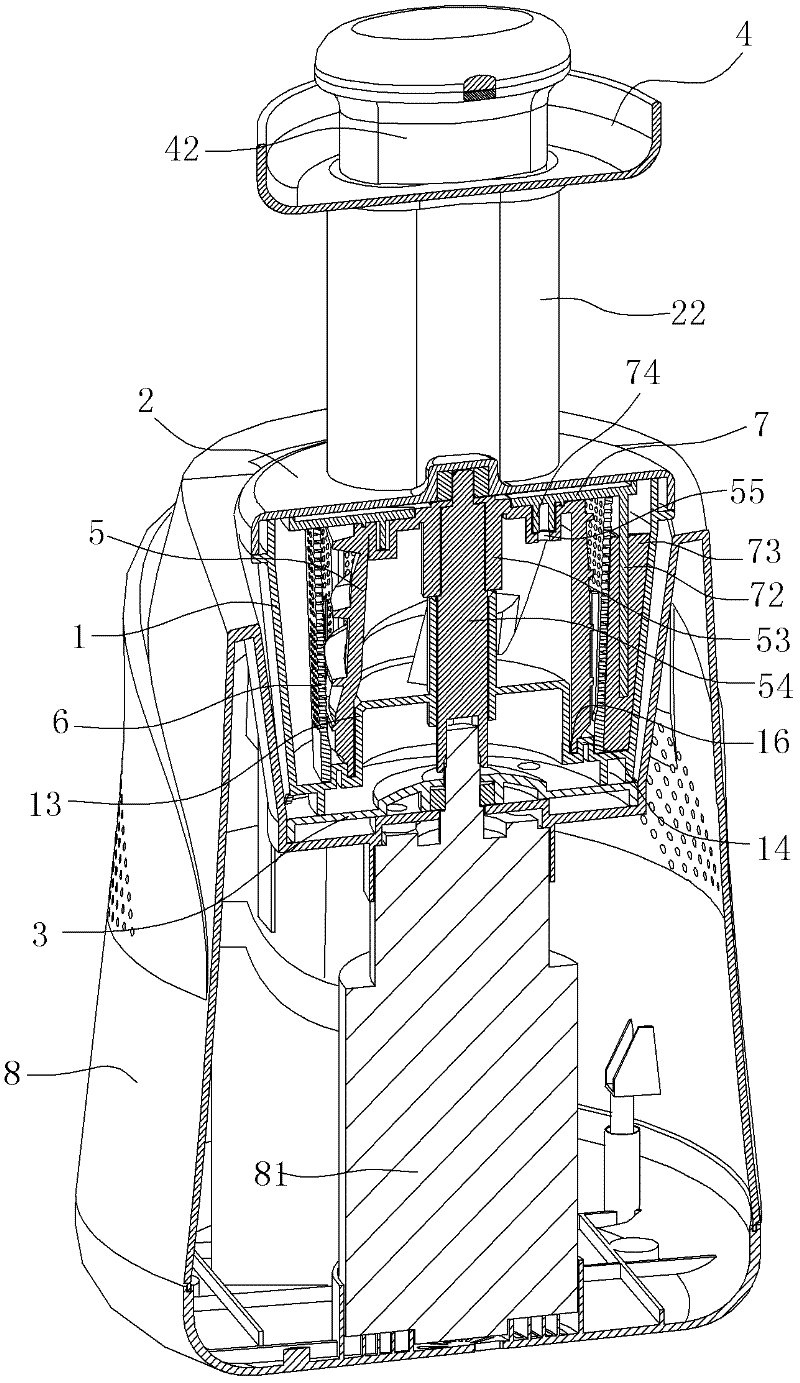

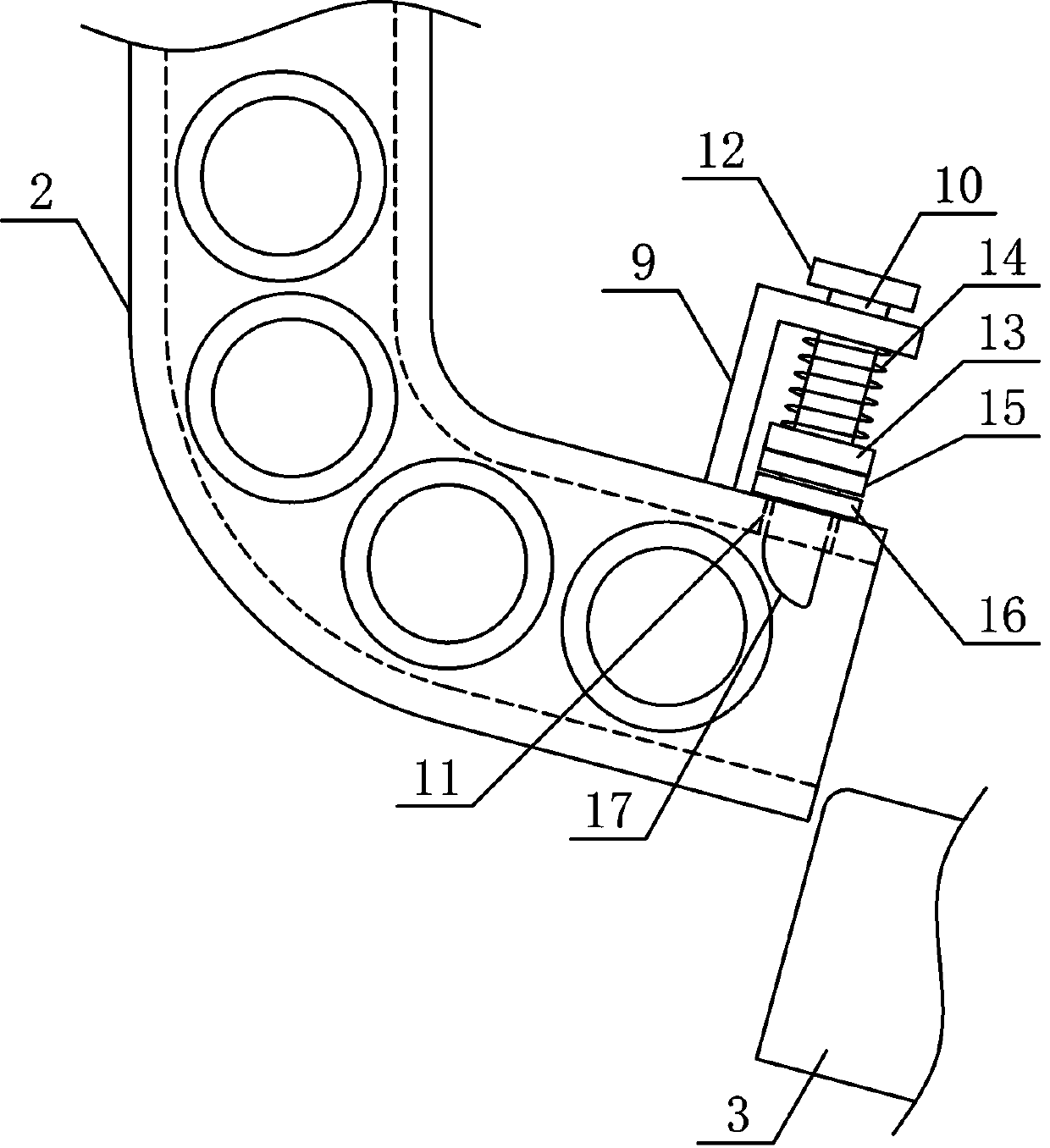

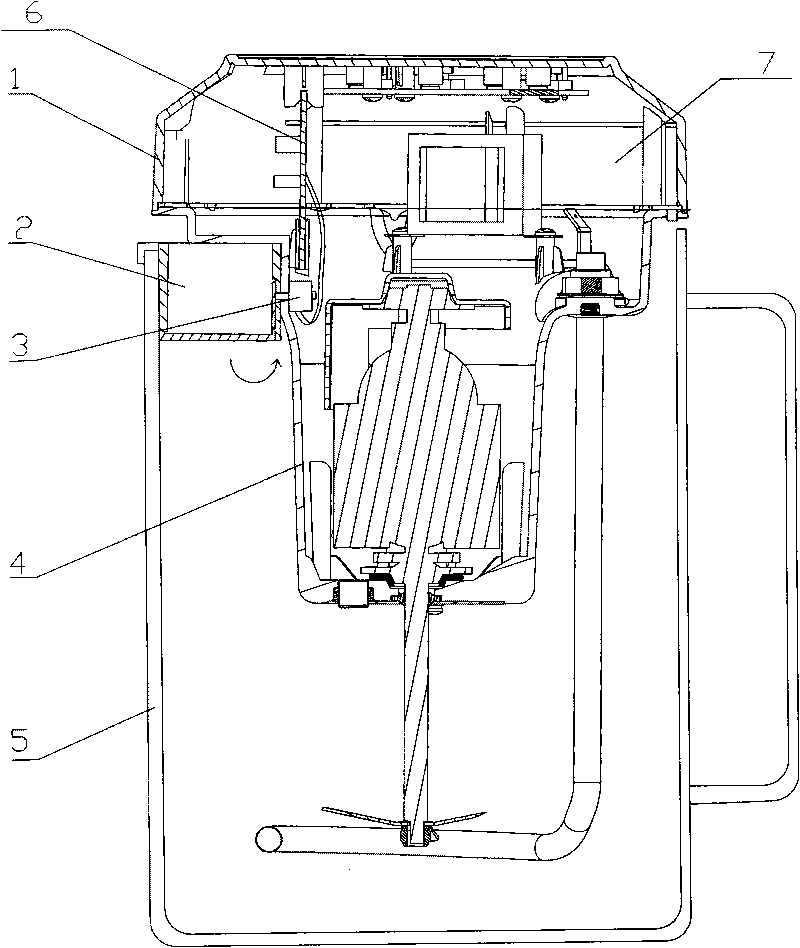

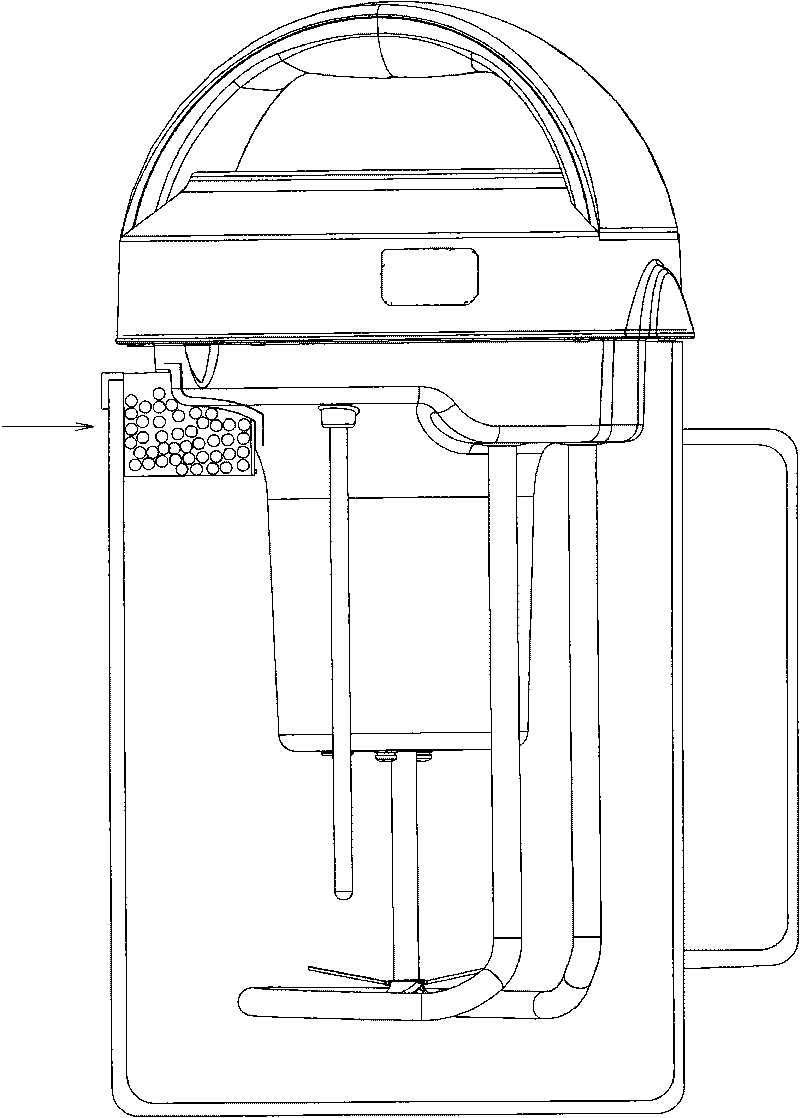

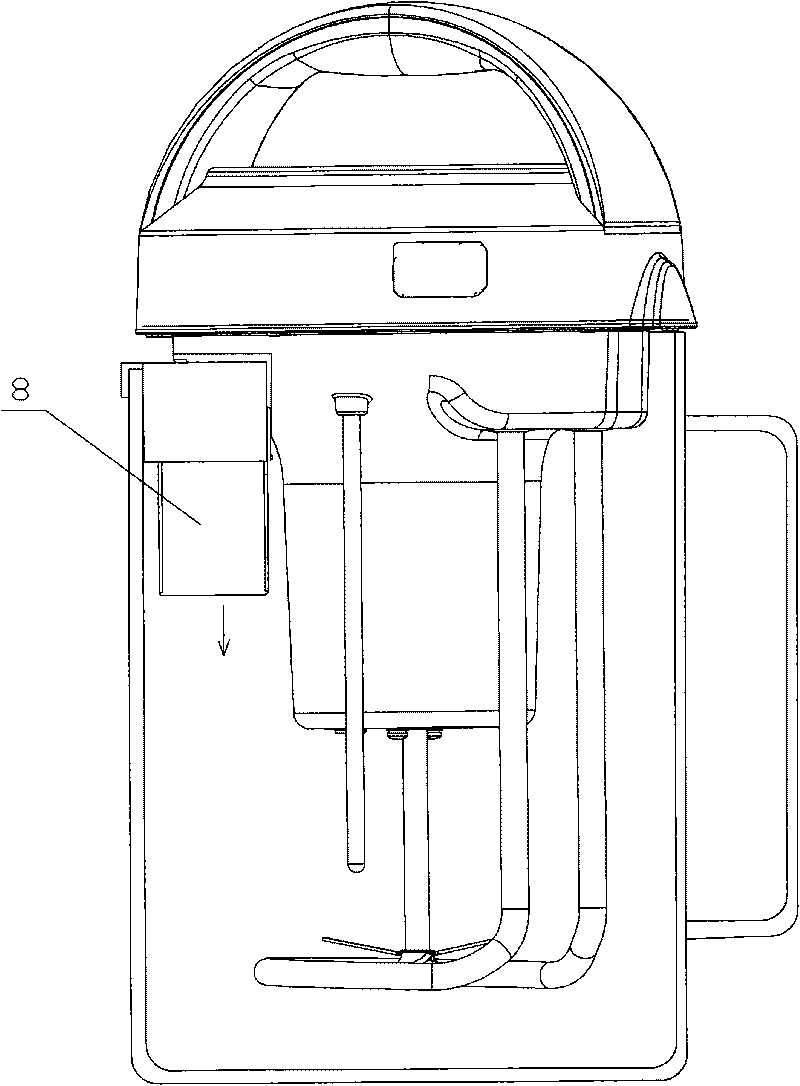

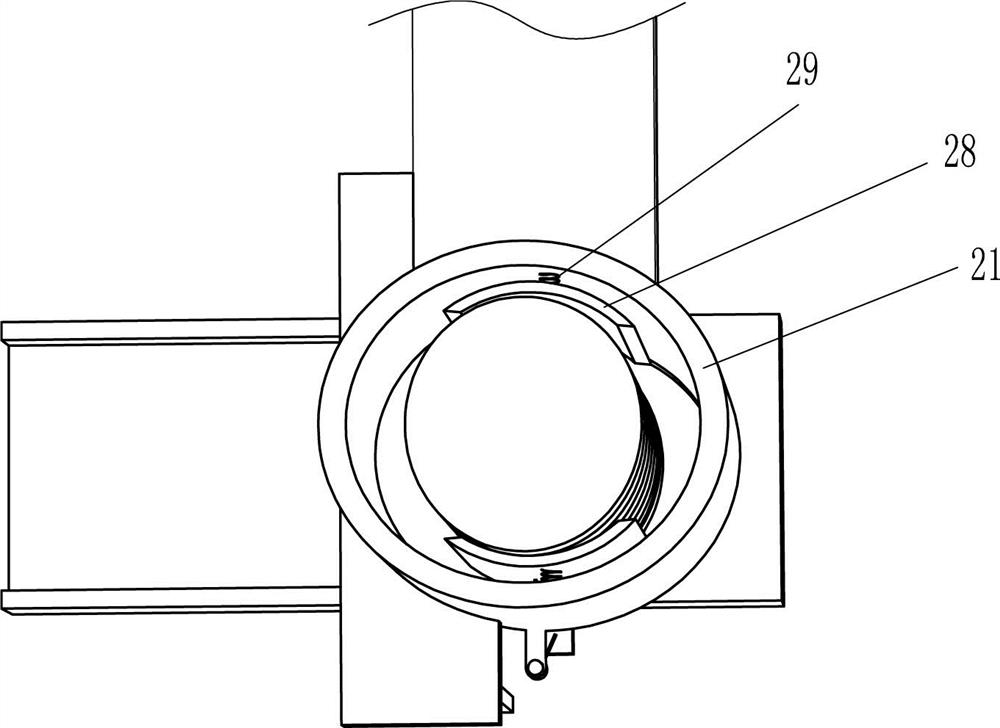

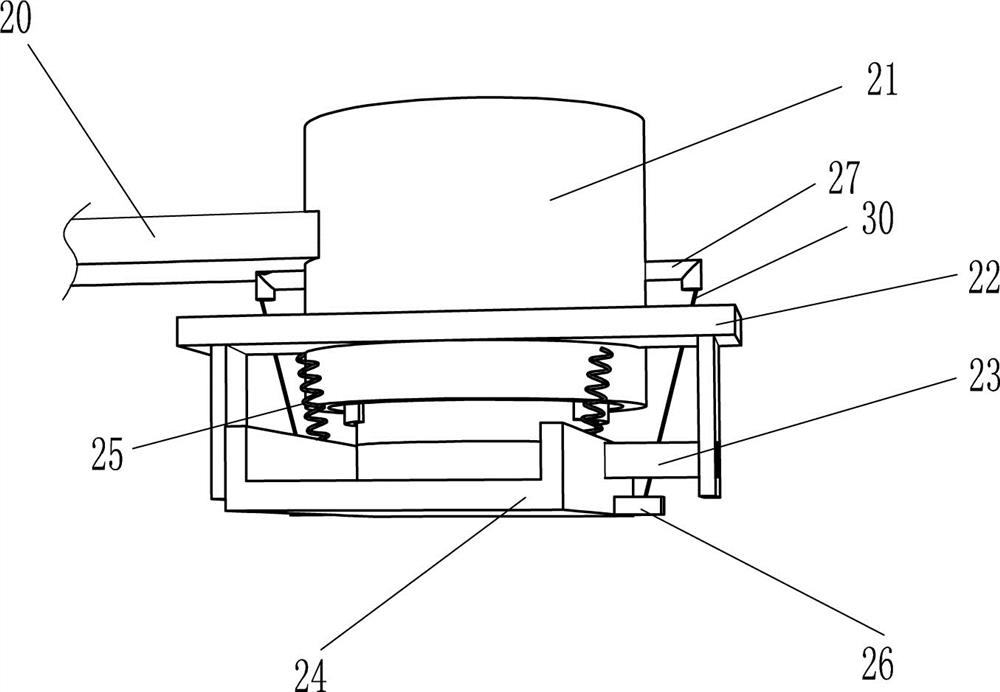

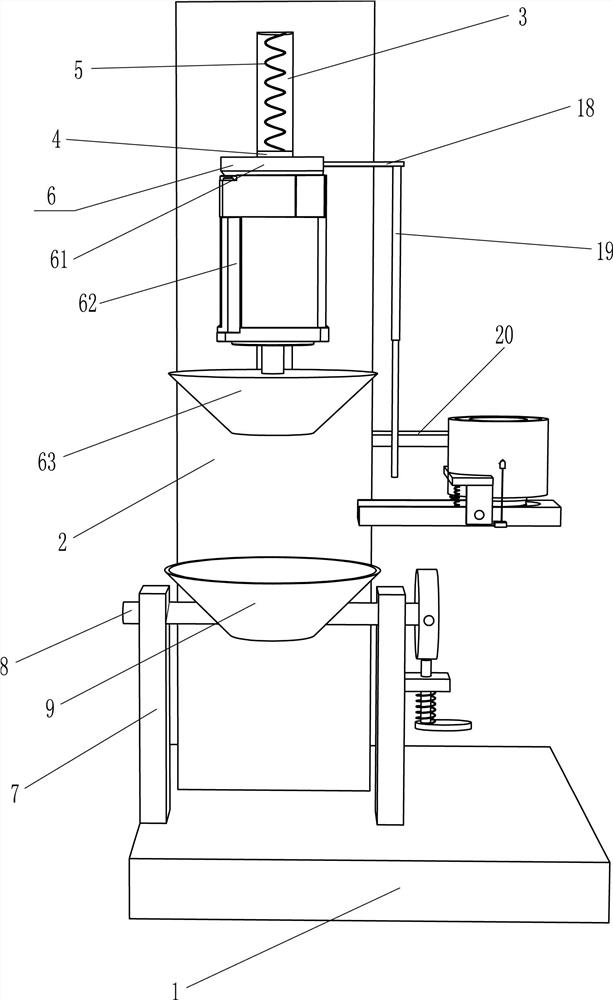

Juice extractor

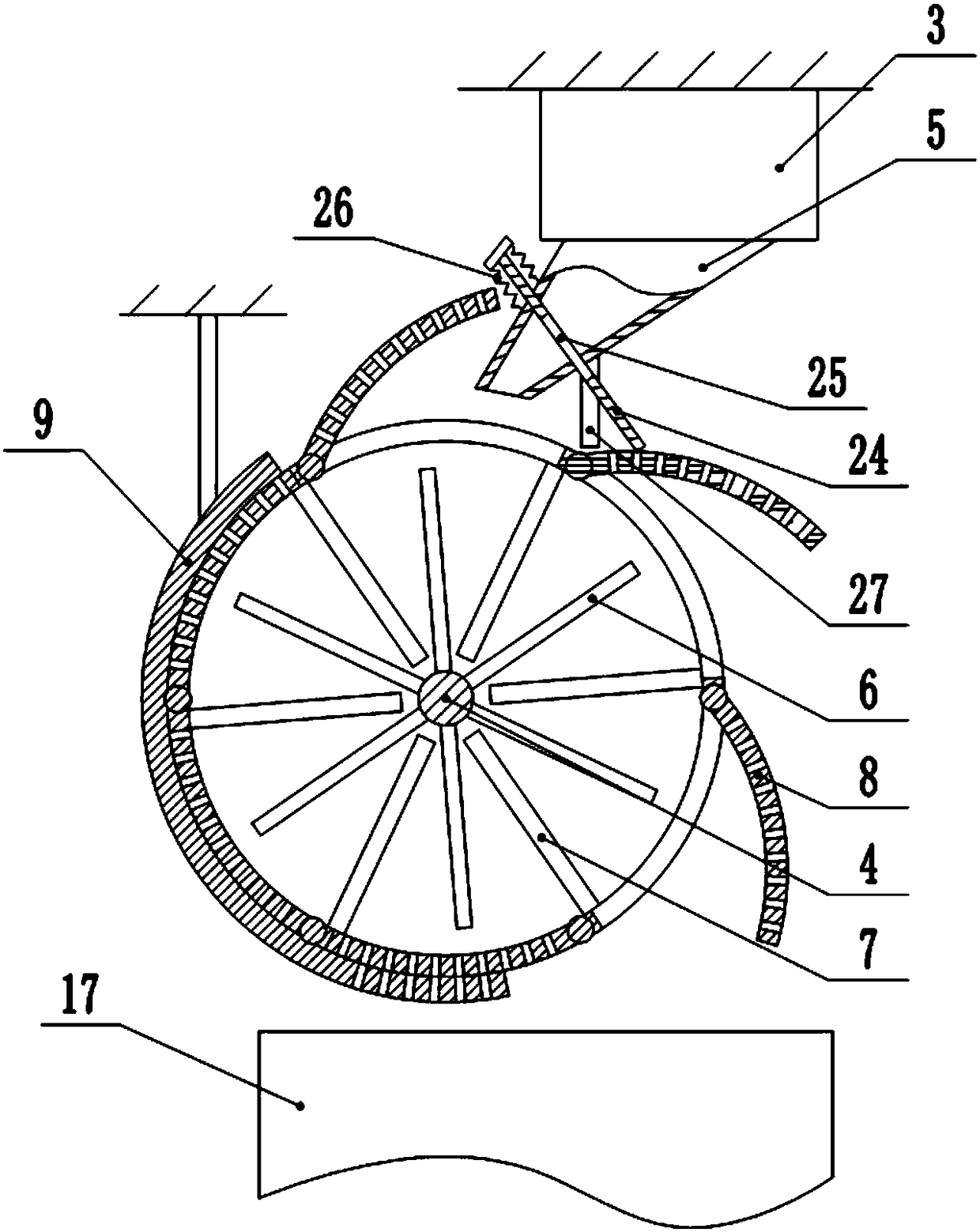

The invention relates to a juice extractor. The juice extractor comprises a shell, a juice extracting component and a driving component, wherein a feed inlet, a juice outlet and a dreg outlet are formed in the shell; the juice extracting component is arranged in the shell; and the driving component is used for driving the juice extracting component to work and arranged below the shell. The juice extractor is characterized in that: the juice extracting component comprises a juice extracting body and a filtering screen; the juice extracting body is a columnar rotor which can be driven to rotate by the driving component; a notch which can be correspondingly communicated with the feed inlet of the shell is formed on the upper half part of the juice extracting body; spiral teeth are formed on the juice extracting body along an outer circumferential surface; the juice extracting body is arranged in the filtering screen in a rotatable way; and the filtering screen is fixedly arranged in the shell. The juice extractor has a more simple overall structure, a small number of parts, low production cost and high juice extracting efficiency and is safely used; automatic blanking can be realized in the rotating process of the juice extracting body; and the two ends of the juice extracting body are not required to be fixed, so that the juice extracting body can be directly connected with the driving component, and the juice extractor is more convenient to mount.

Owner:张建民

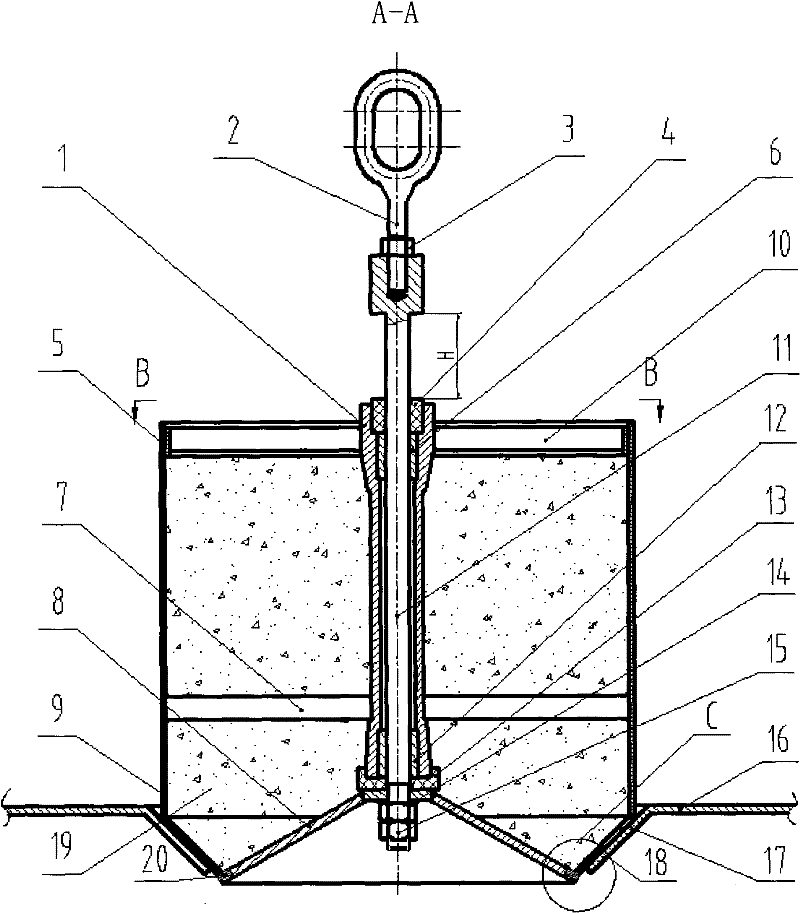

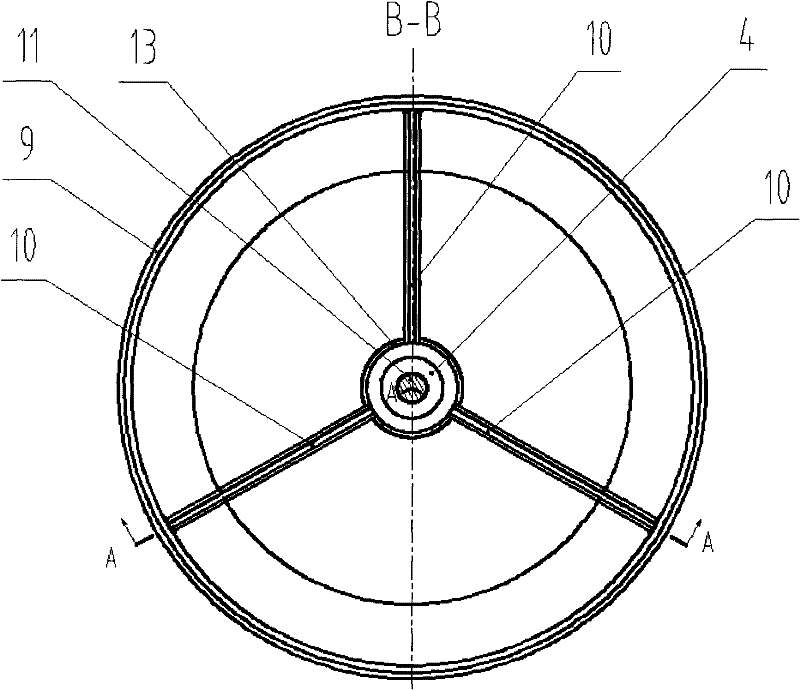

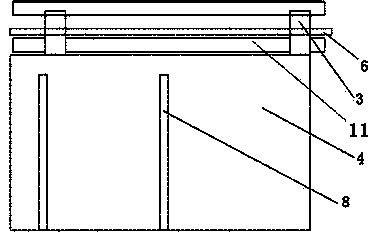

Open-bottom automatic discharging tank device

InactiveCN101746580AImprove sealingRealize automatic unloadingFlexible coversWrappersCharge and dischargeCushion

The invention discloses an open-bottom automatic discharging tank device for charging and discharging bulk materials, which belongs to the technical field of bulk material charging and discharging machinery. The device is structurally characterized in that a cylindrical tank of which the lower part is provided with a conical discharge hole can be positioned on a box-shaped bin of which the upside is provided with a trumpet-shaped opening, and the trumpet-shaped opening is jointed with the conical discharge hole; a tubular boom sliding way is fixed at the central line position of the tank through a support frame; a sliding bearing and a cushion are arranged at the upper end part and the lower end part in the boom sliding way; a boom capable of sliding up and down in the boom sliding way runs through the central line of the boom sliding way; and the upper end of the boom is connected with a lifting ring, while the lower end is connected with a lampshade-shaped bell. The device has the advantages of realizing mechanical and automatic charging and discharging of the bulk materials and improving the work efficiency of assembly and disassembly.

Owner:TAIYUAN UNIVERSITY OF SCIENCE AND TECHNOLOGY

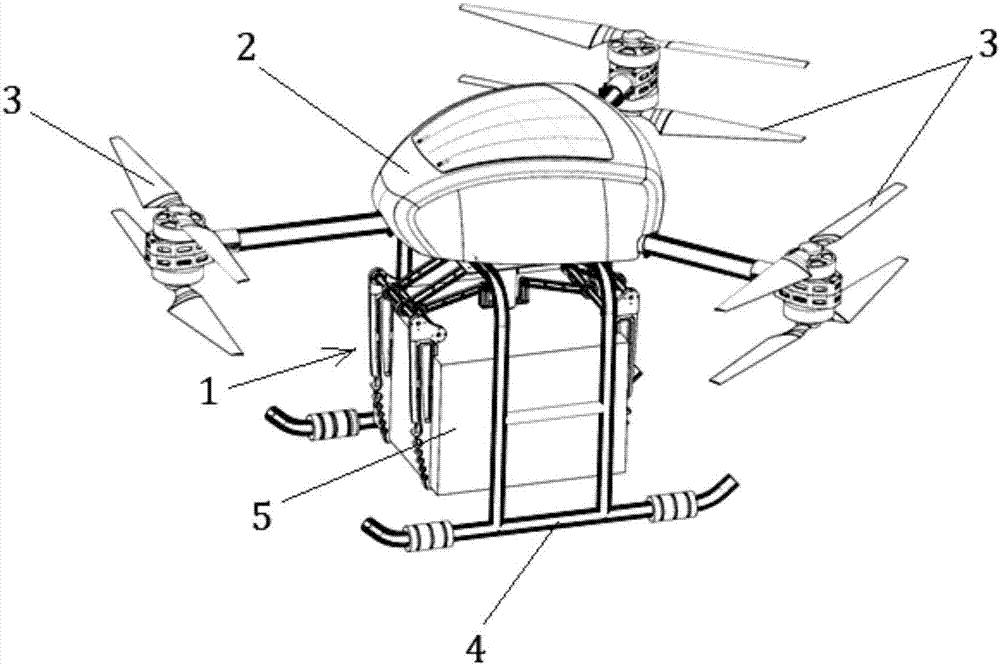

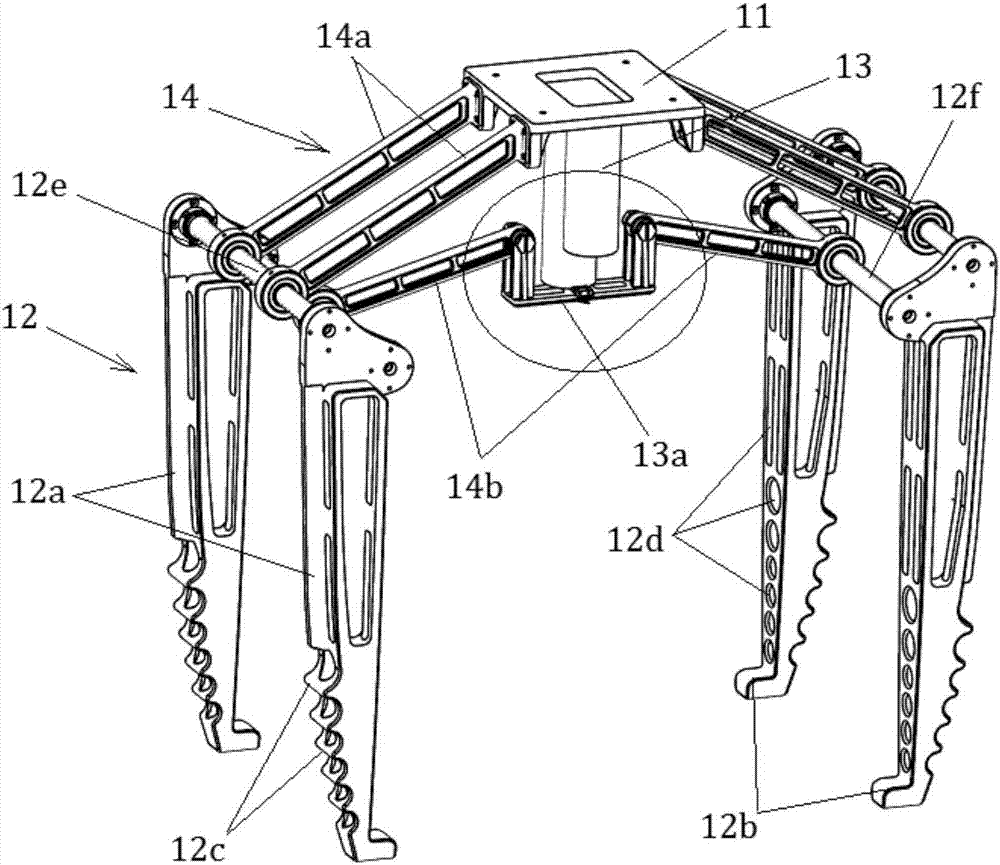

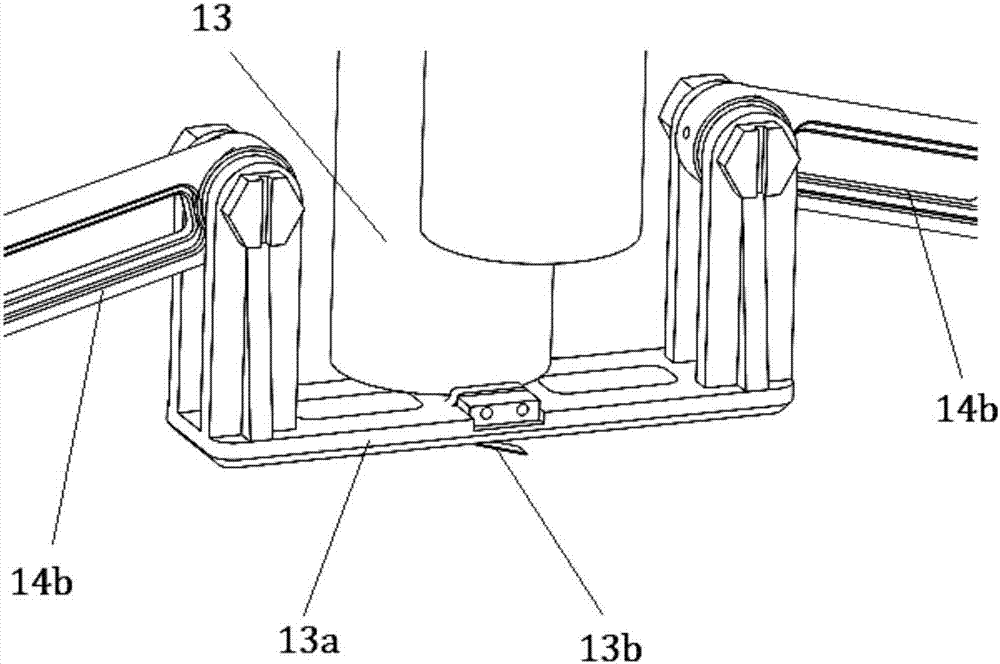

Automatic unloading carrier and unmanned aerial vehicle

PendingCN106892119AImprove carrying capacityAchieve releaseGripping headsRemote controlled aircraftUncrewed vehicleEngineering

Owner:BEIJING JINGDONG QIANSHITECHNOLOGY CO LTD

Zero-damage high precision plastic pipe cutting device

InactiveCN107856089AAvoid deformationImprove qualityMetal working apparatusHydraulic cylinderEngineering

The invention relates to the technical field of tube processing, in particular to a zero-damage high precision plastic pipe cutting device including a feeding mechanism and a cutting mechanism. The cutting mechanism includes a support arranged close to the feeding mechanism, a first guide bar is horizontally arranged above the support, and a first sliding base and a second sliding base are slidably arranged at the first guide bar; and a connecting rod is horizontally connected between the first sliding base and the second sliding base, a vertical second hydraulic cylinder is arranged at the first sliding base, and a cutting motor is connected at the lower end of the second hydraulic cylinder. The zero-damage high precision plastic pipe cutting device uses a horizontally-arranged core rod to reinforce a plastic pipe from the inside during cutting, the deformation of the plastic pipe caused by cutting can be effectively prevented, the cutting precision is improved, the good character offinished products can be guaranteed, and automatic discharging can be achieved through shrinkage fit between the core rod and a sliding sleeve, so that the automation degree is high.

Owner:HEBEI JISHUO PIPE IND

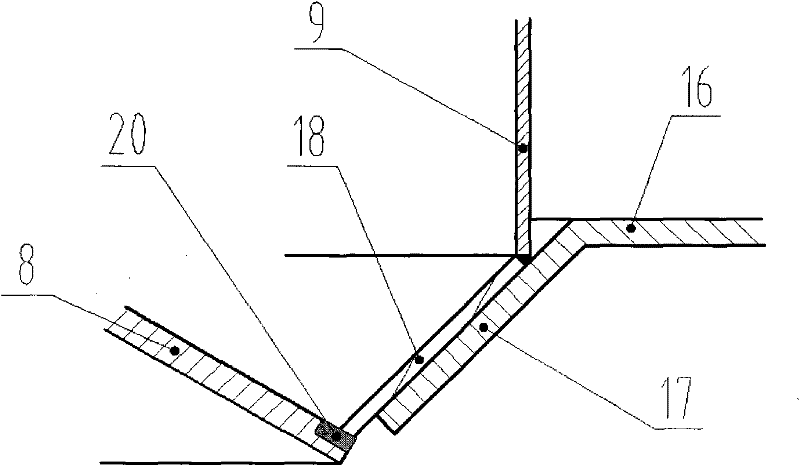

Self-locking bottom opening trough

InactiveCN101905788ARealize automatic unloadingRealize the automatic closing and locking of the swing doorLarge containersSelf lockingShock absorber

The invention discloses a self-locking bottom opening trough, which comprises a trough and is characterized in that: the bottom of the trough is provided with two swing doors which are connected with the trough by a hinged shaft A and can swing around the hinged shaft A; weight sliders are arranged on the two sides of the trough and connected with the swing doors through connecting rods; and external supports are arranged below the weight sliders. When the trough falls, the weight sliders rise relative to the trough with the support of the external supports; the connecting rods drive the swing doors to swing around the hinged shaft A and open; and thus, feed in the trough falls automatically. In the invention, the automatic discharge of the bottom opening trough and the automatic closing and locking of the swing doors are realized by the self-locking function generated by the weight sliders and the swing doors and the gravity of the trough, and the falling speed of the materials can be controlled by a damper. The self-locking bottom opening trough has a simple structure and works reliably.

Owner:CISDI ENG CO LTD

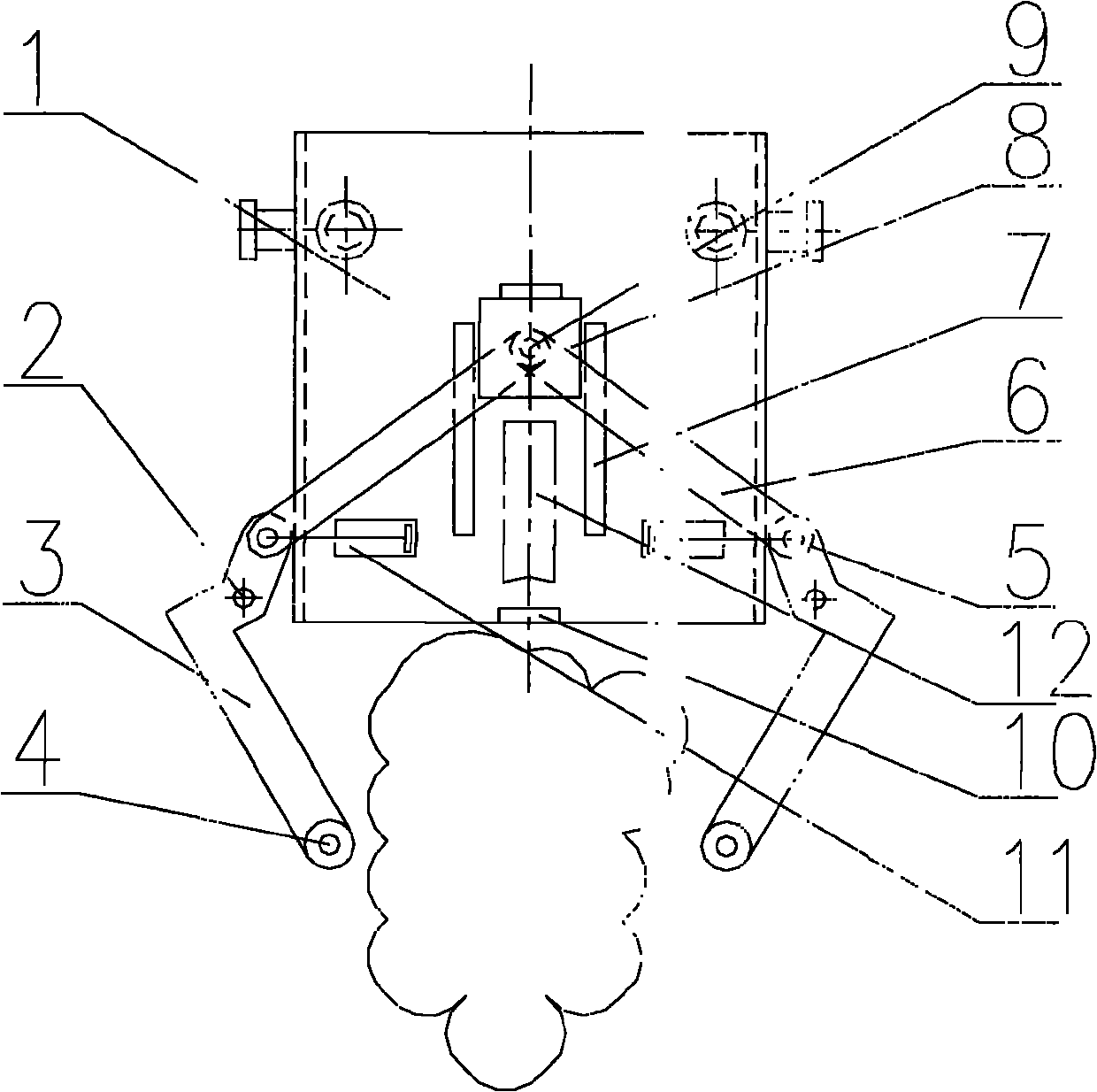

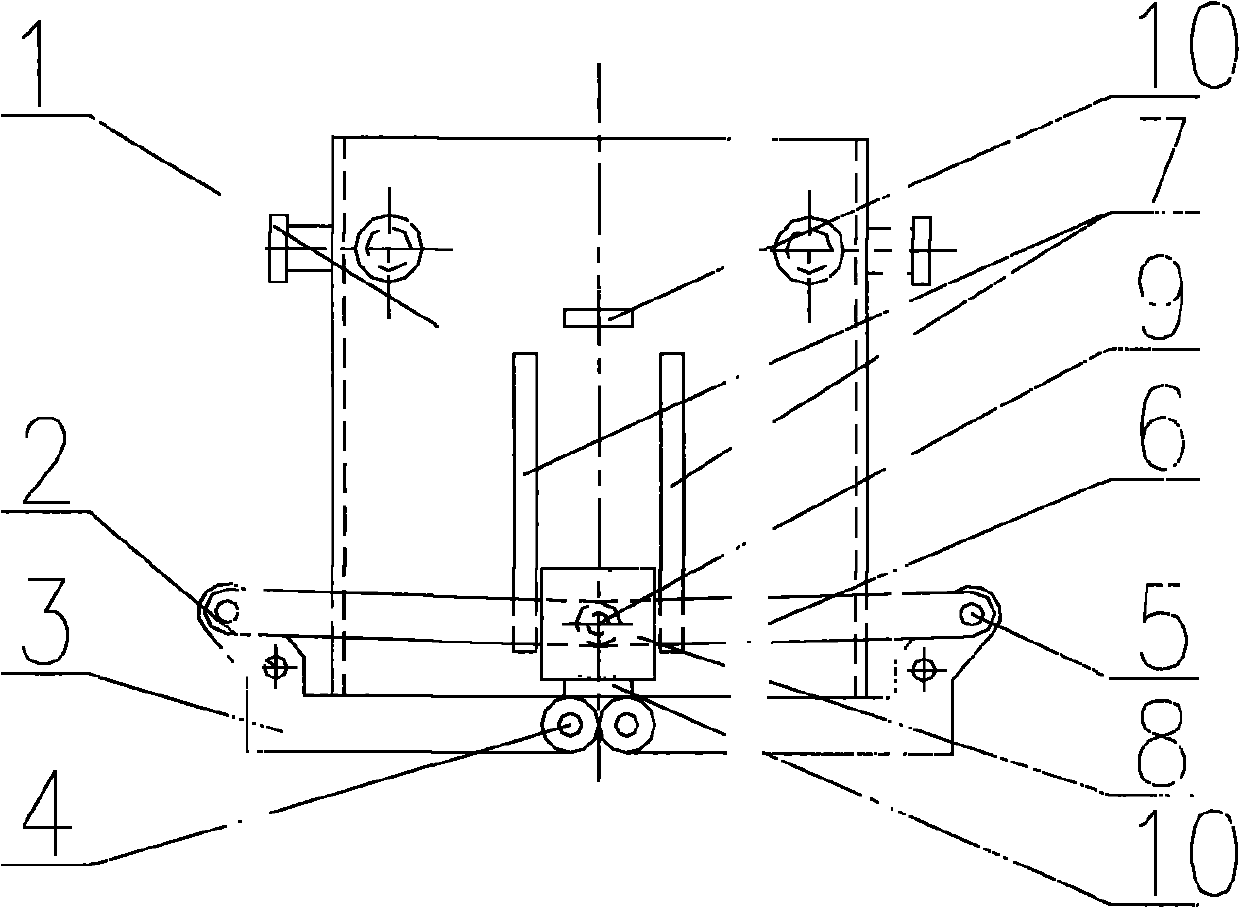

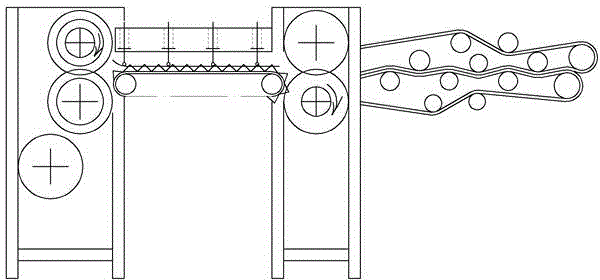

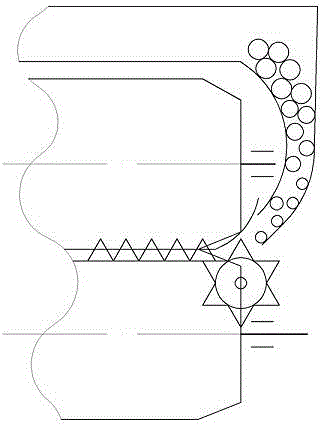

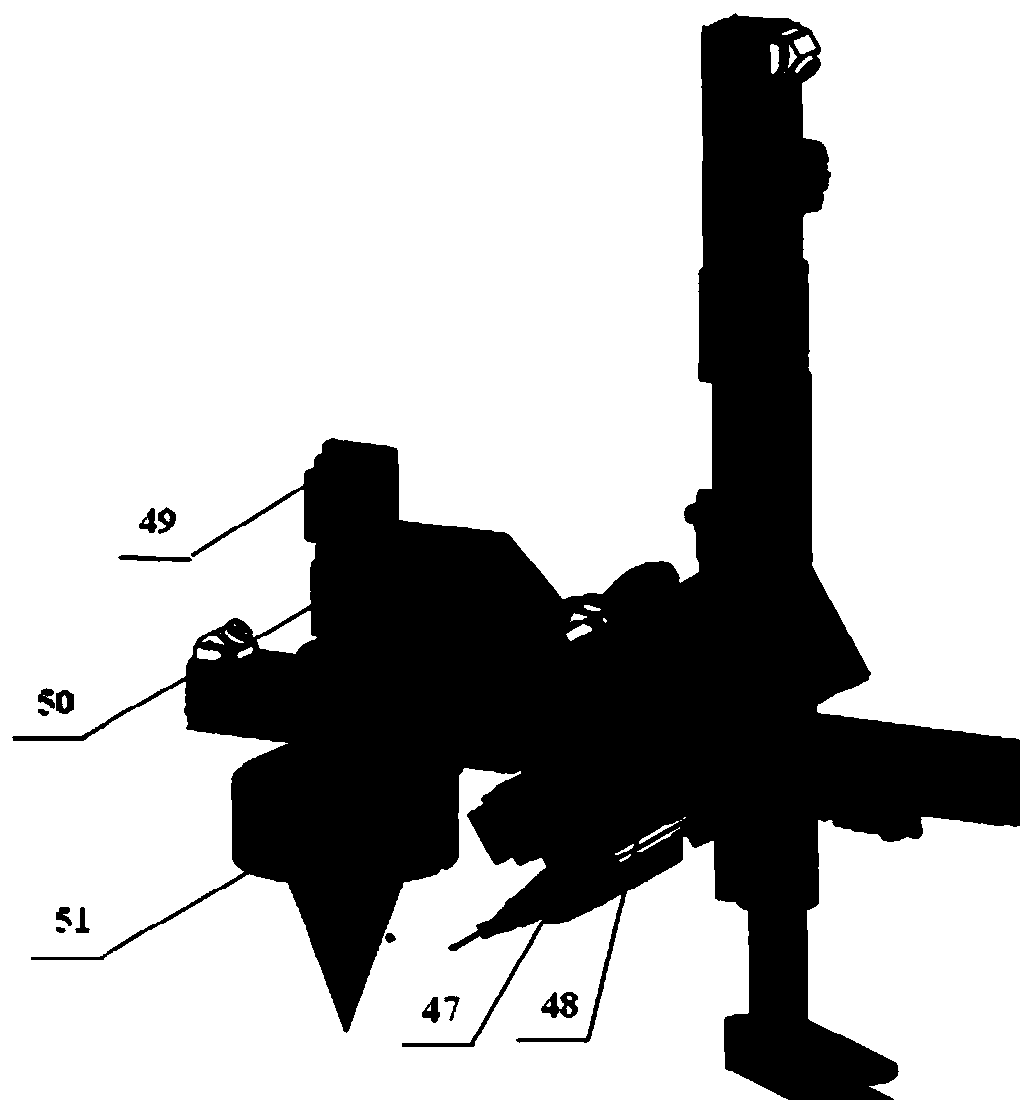

Automatic high-efficiency ramie peeling machine

ActiveCN104641807AContinuous automatic desensitizationIncrease productivityThreshersFiberCounter-pull

The invention discloses an automatic high-efficiency ramie peeling machine, which solves the technical difficulty of the prior art that the ramie peeling efficiency is not high and the combined harvesting cannot be realized. The automatic high-efficiency ramie peeling machine consists of three ramie peeling mechanisms and a ramie stalk and fiber clamping conveying mechanism, a ramie stalk is fed and peeled on the front section of a left ramie peeling mechanism, the counter-pulling clearing is carried out on the rear section of the left ramie peeling mechanism, and the feeding and ramie peeling and the counter-pulling clearing are respectively completed by a middle ramie peeling mechanism and a right ramie peeling mechanism. The ramie stalk and fiber clamping conveying mechanism and the ramie peeling mechanism are obliquely arranged, a ramie stalk feeding chain and a ramie stalk withdrawing clamping chain are slightly overlapped in an end-to-end manner on the same straight line so as to complete the reversing connection, a ramie stalk clamping counter-pulling feeding chain and a fiber clamping conveyor belt are connected in an overlapping manner in an end-to-end manner, and after the basic part is peeled, the fiber is pulled out in an opposite direction by the fiber clamping conveying mechanism. The automatic high-efficiency ramie peeling machine is mainly used for the centralized primary processing of ramie fibers and for being matched with a ramie cutting machine to realize the combined harvesting.

Owner:XIANNING AGRI ACADEMY OF SCI

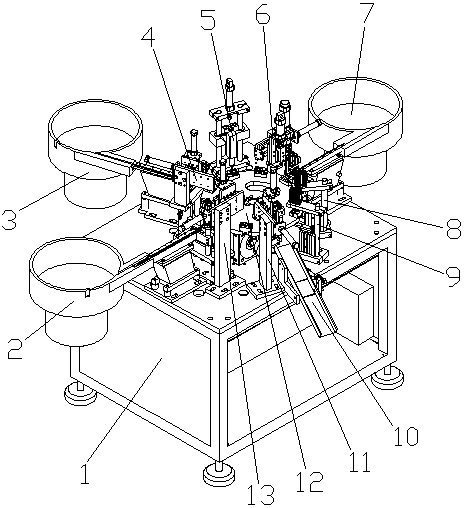

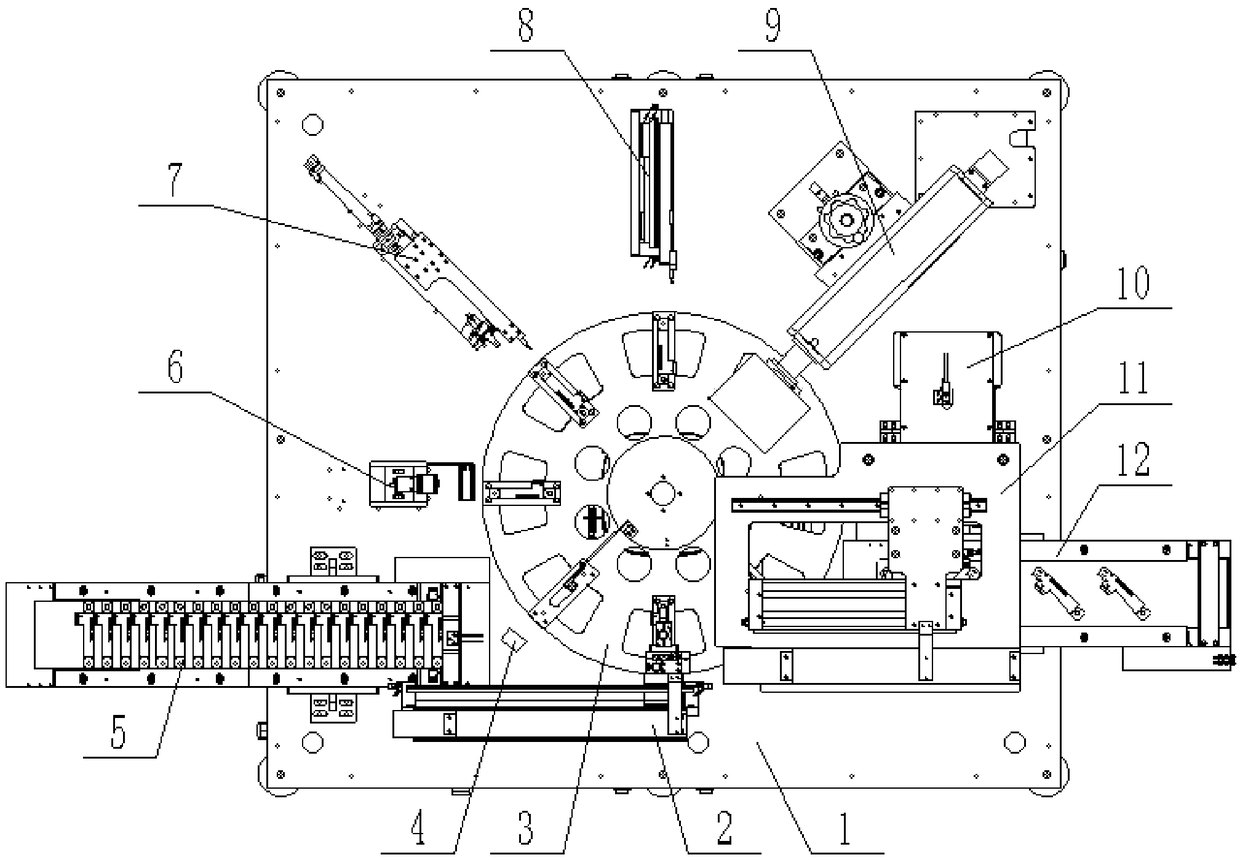

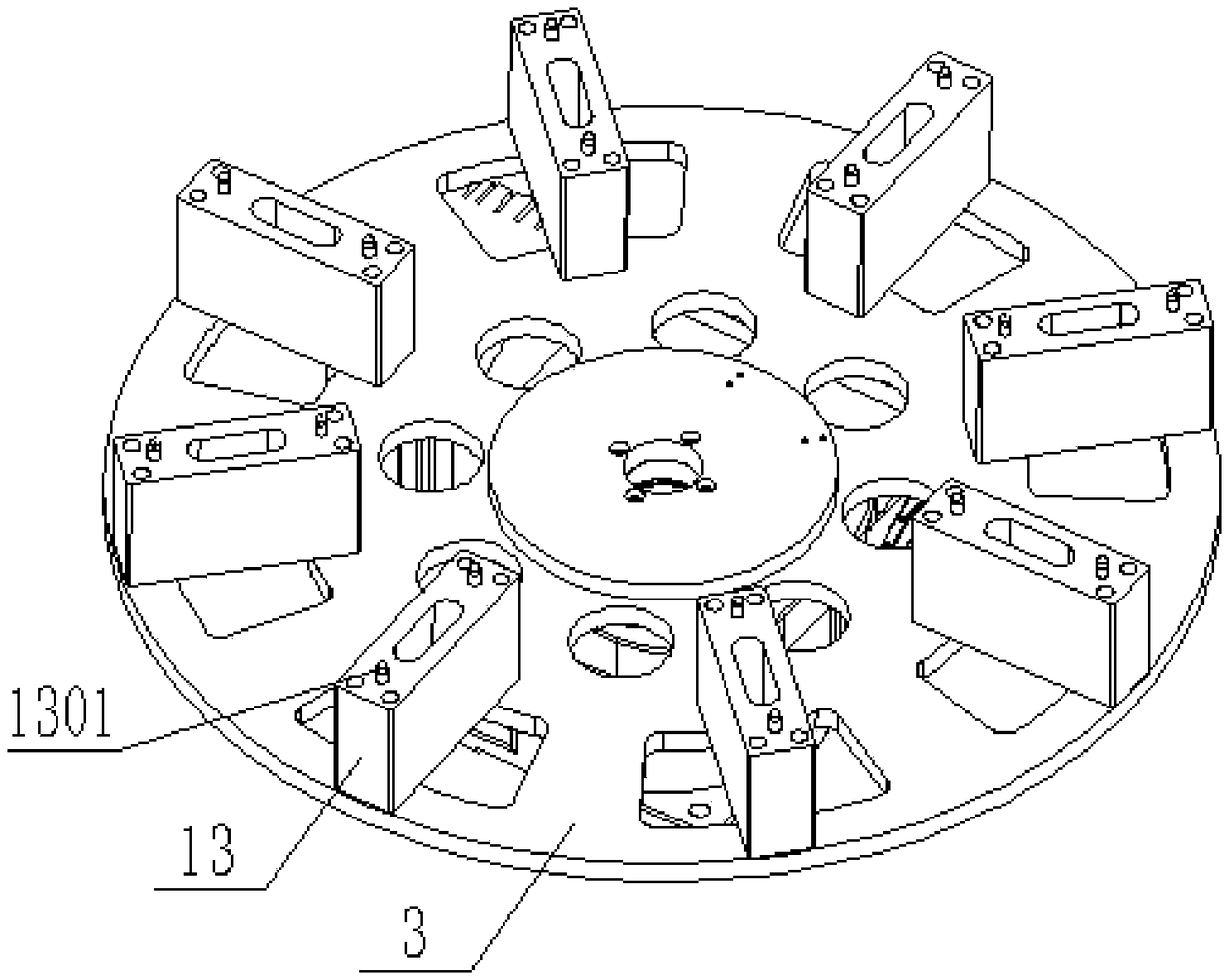

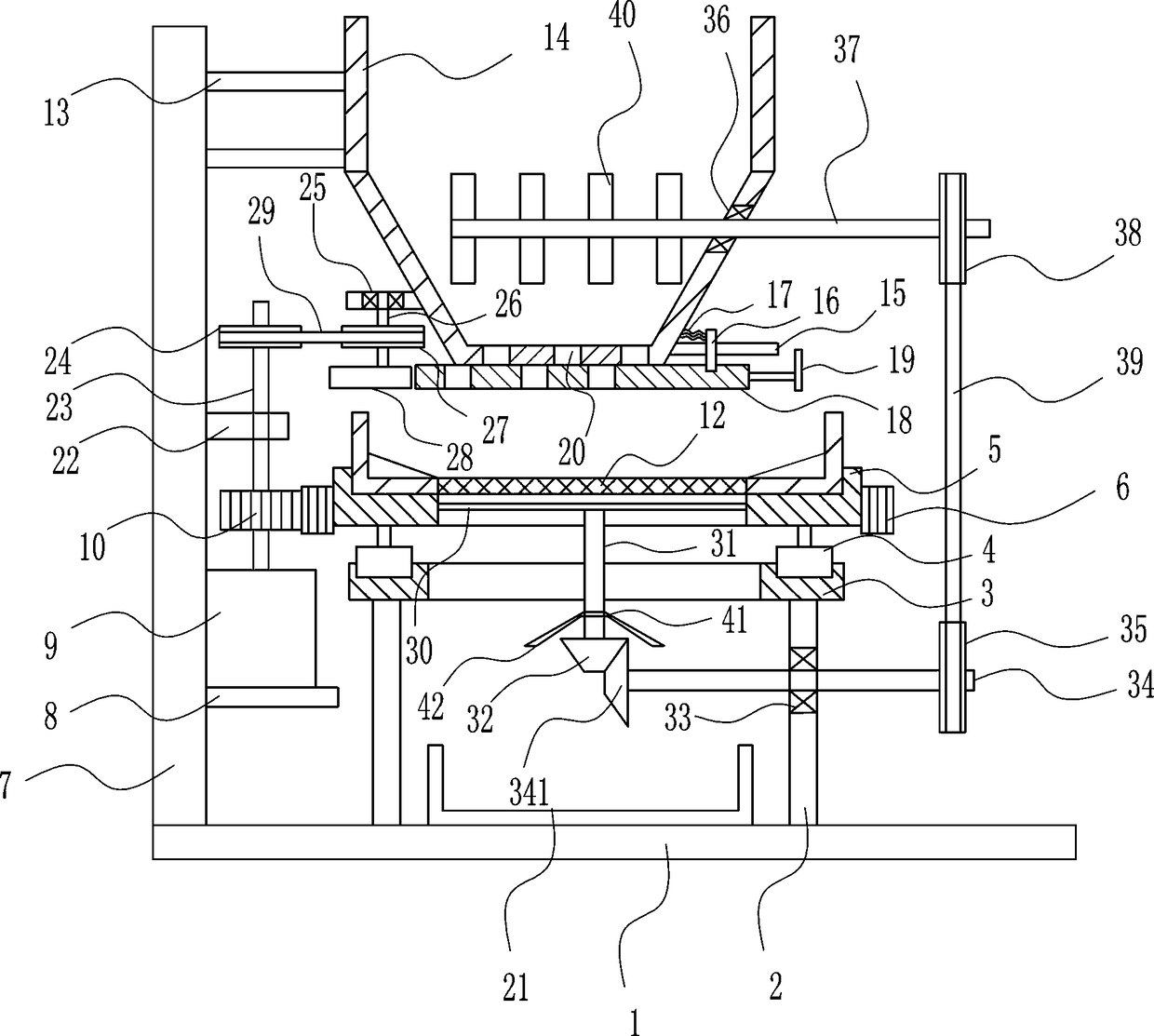

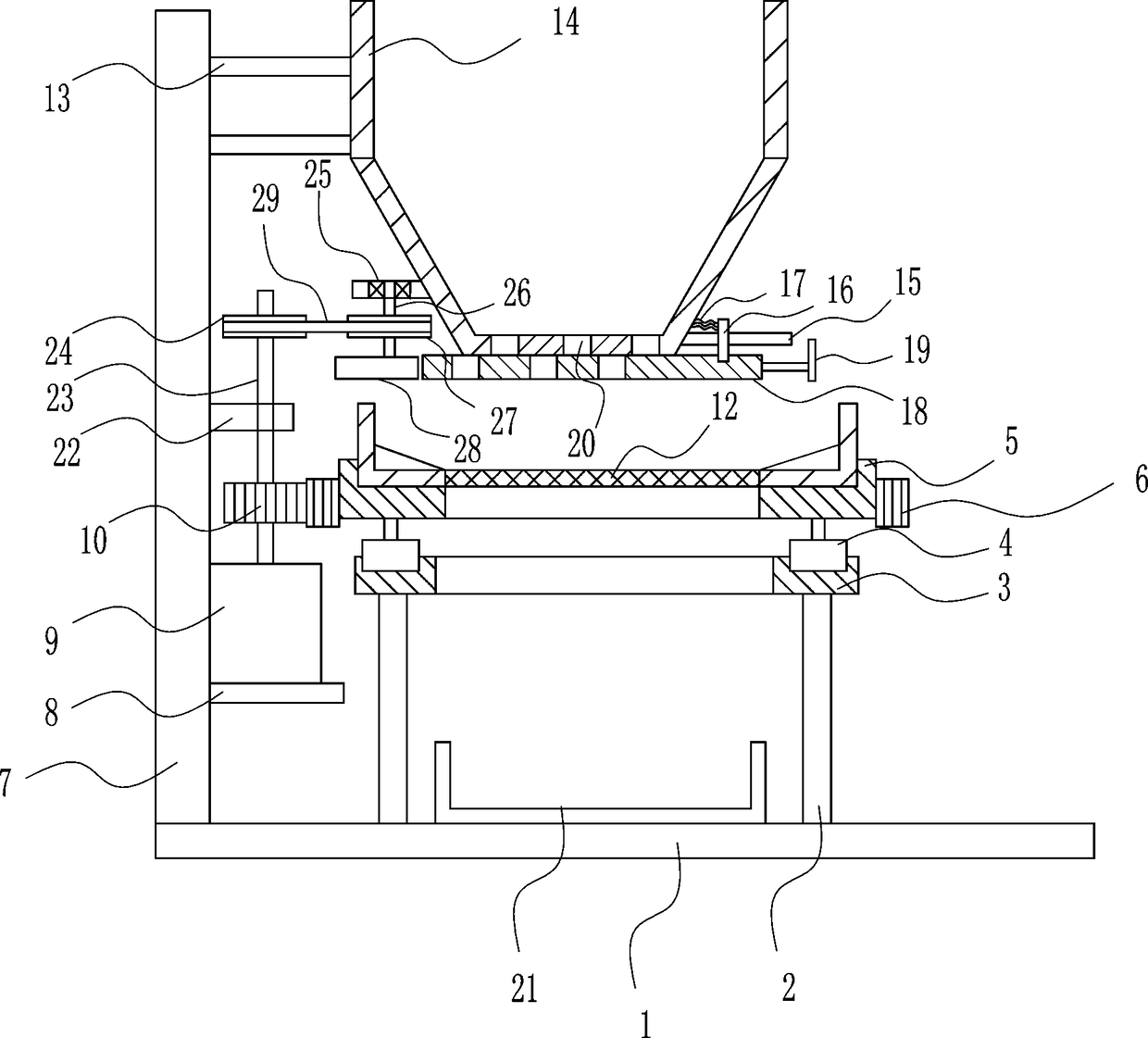

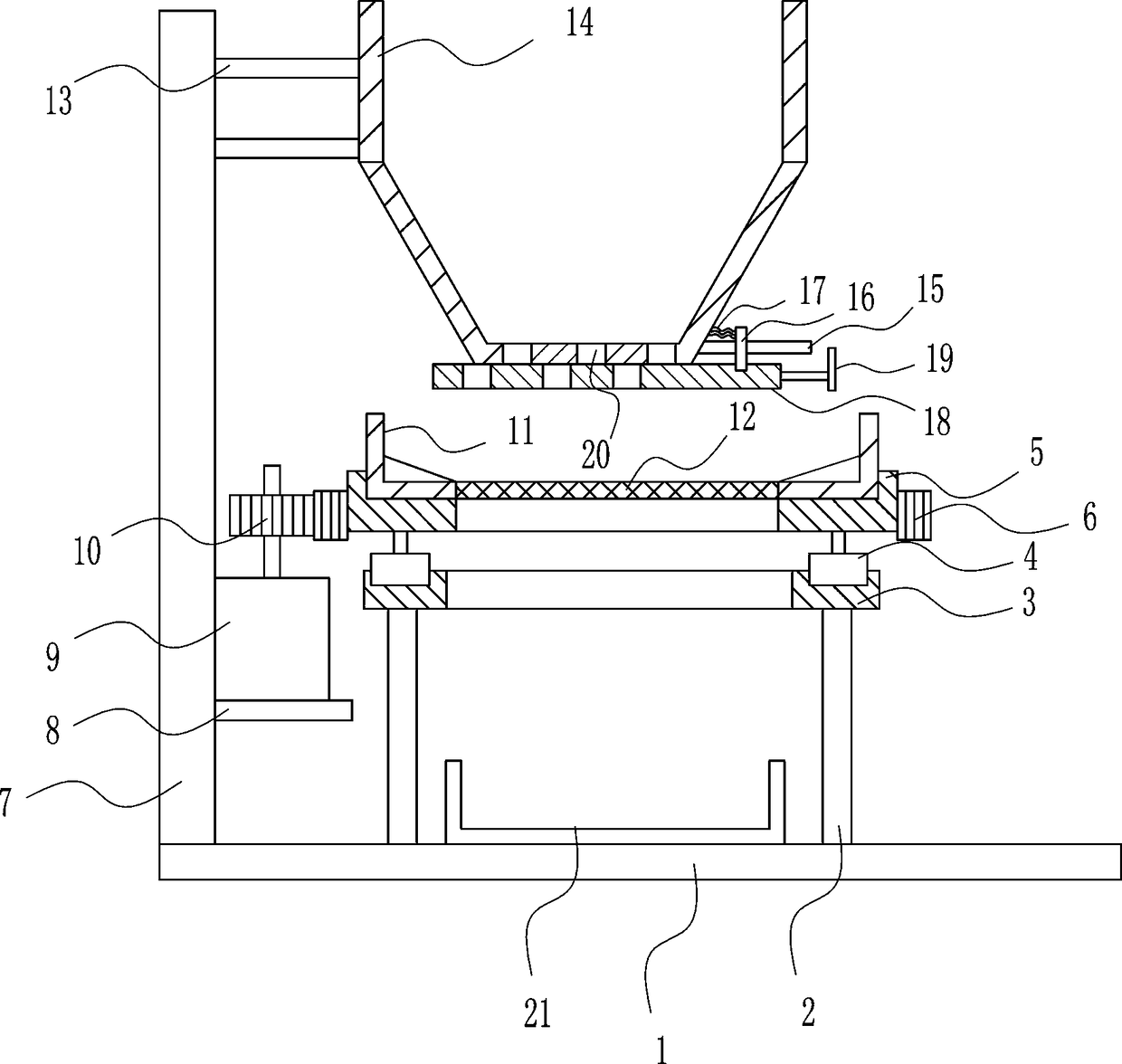

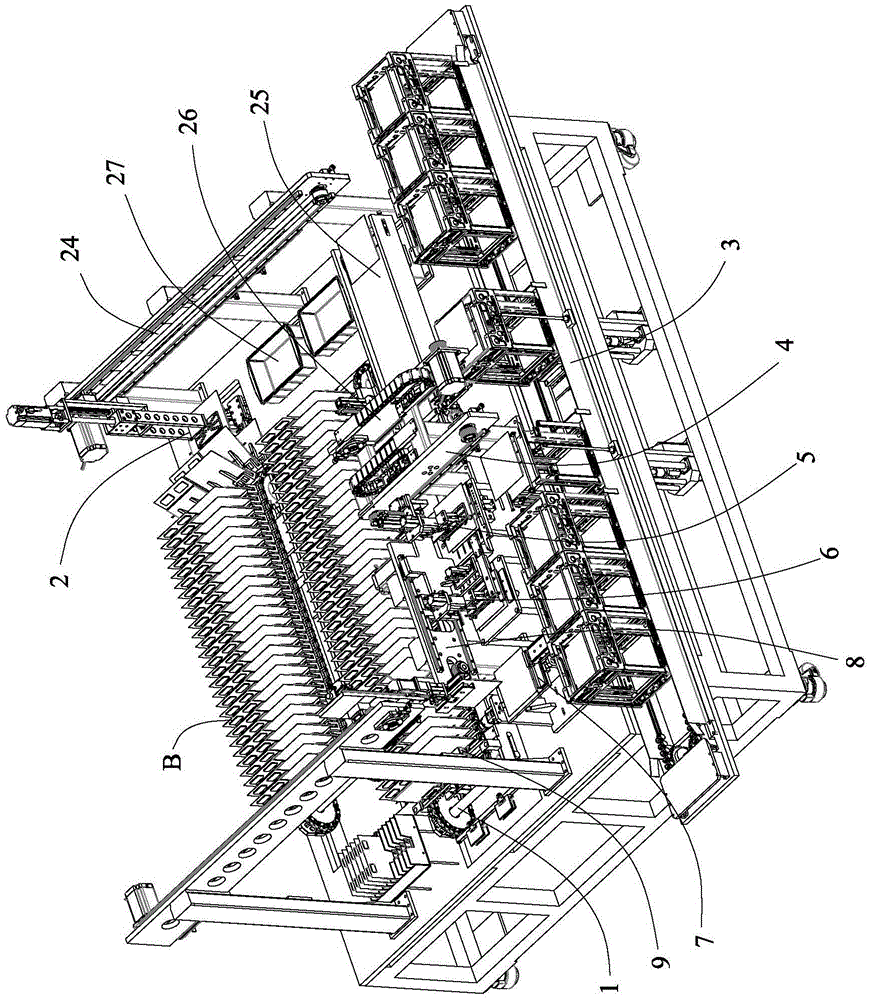

Automatic assembly machine for elastic piece type switches

InactiveCN108470654AImprove assembly efficiencyAccurate and continuous placementElectric switchesDistribution controlEngineering

The invention relates to switch assembly equipment, in particular to an automatic assembly machine for elastic piece type switches. The automatic assembly machine comprises a rack, a power distribution control box, a turntable, a turntable driving device and clamps, wherein the turntable and the turntable driving device are arranged on the rack and cooperated with each other, the clamps are uniformly arranged on the edge of the turntable and cooperate with workpieces; the periphery of the turntable is sequentially provided with a rubber shell feeding device, an elastic piece feeding device, aglue dispensing device and a button feeding device which correspond to the positions of the clamps in a rotating direction, and the devices above are all electrically connected with the power distribution control box and controlled by the power distribution control box. By arranging the turntable and sequentially arranging a rubber shell mounting station, an elastic piece mounting station, a gluedispensing station and a button mounting station on the turntable, integrated assembly of a rubber shell, an elastic piece and a button is completed on the turntable; by turning on and turning off a detection station, detection of a switched-on state and a switched-off state of the elastic piece switches is completed, and the efficiency of assembling the elastic piece switches is improved.

Owner:DONGGUAN UNIV OF TECH

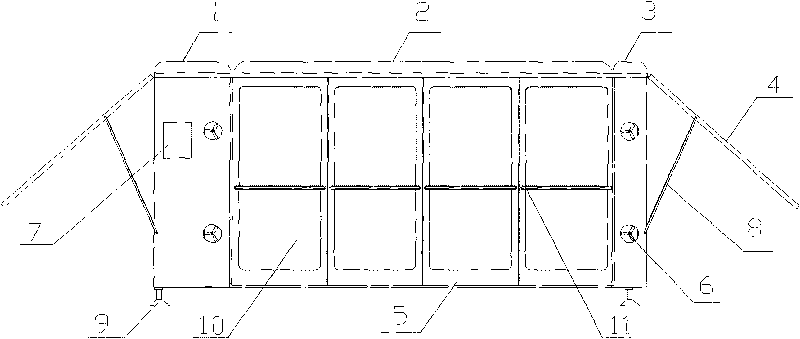

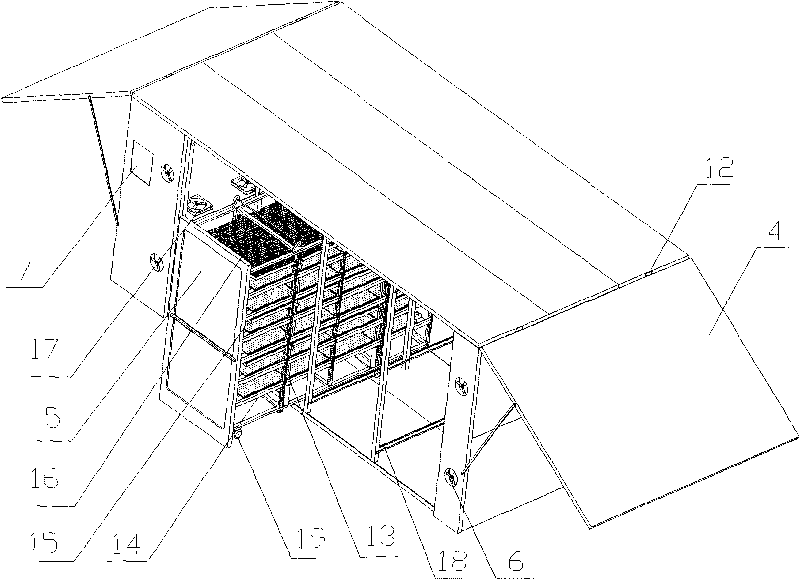

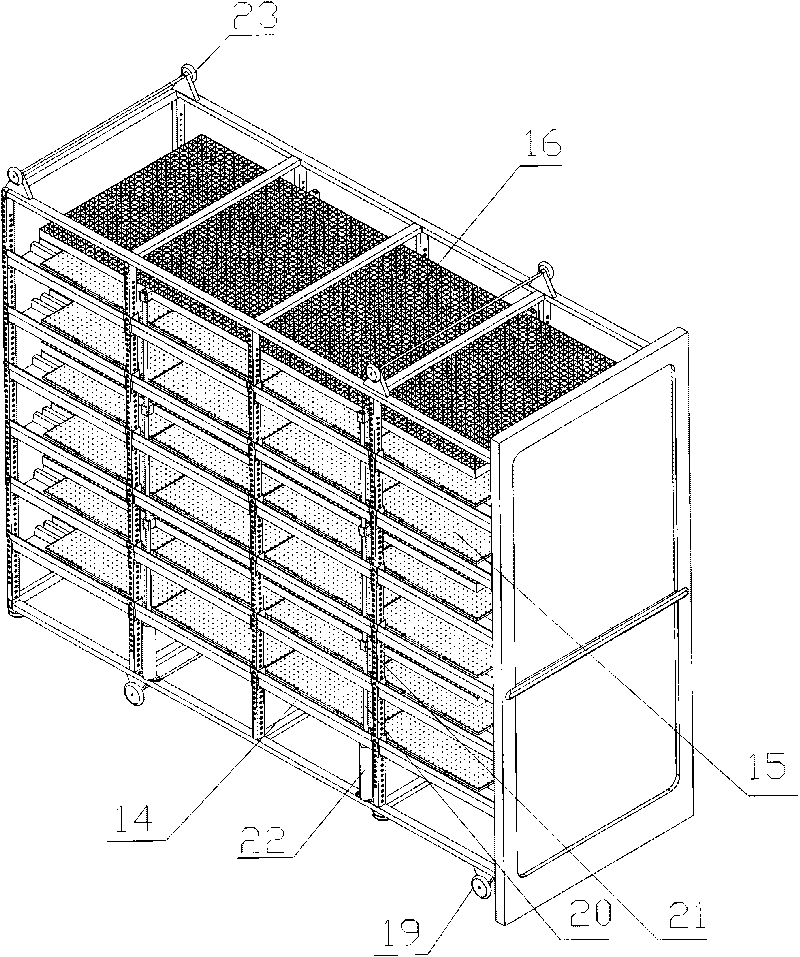

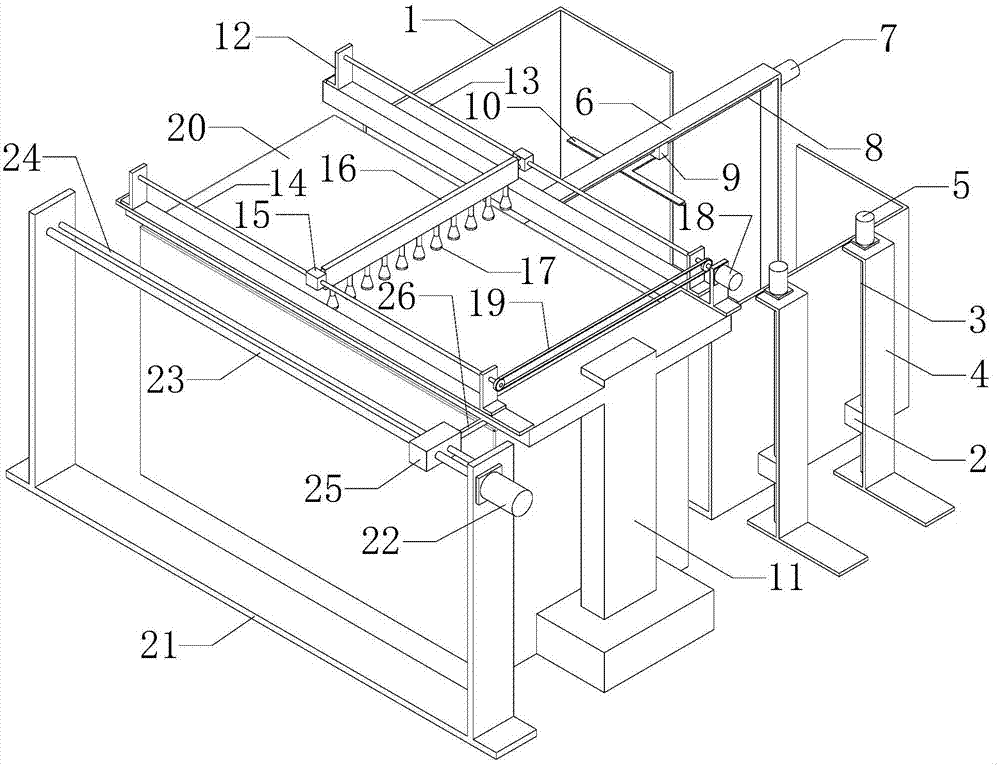

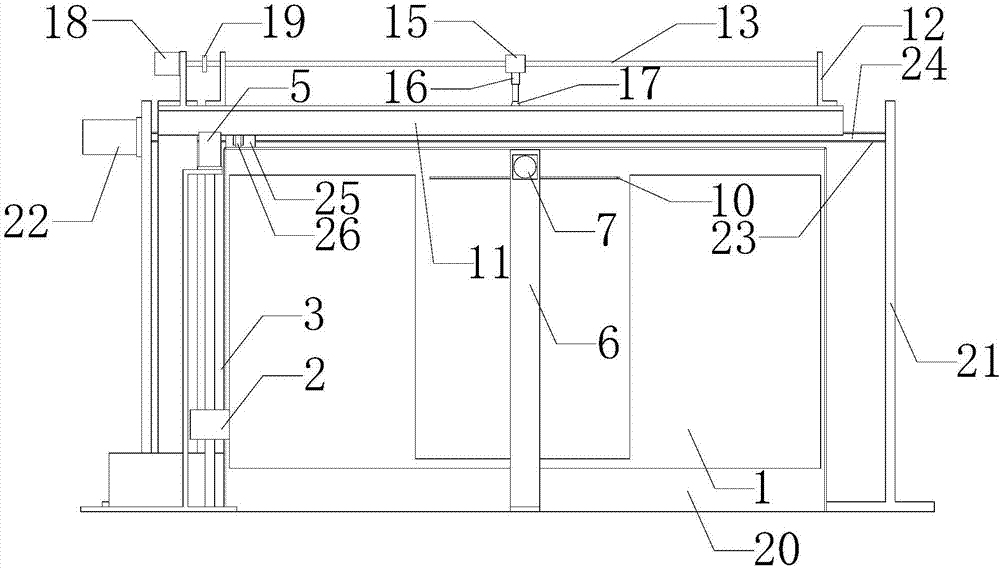

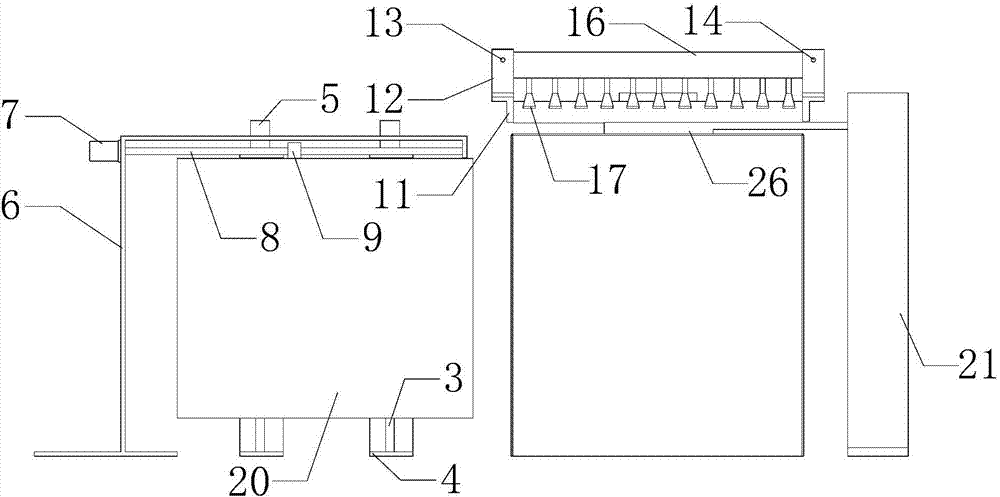

Botanical seedling culturing machine

ActiveCN101743861ARealize intelligent scientific seedling cultivationShorten the growth cycleCultivating equipmentsPolystyreneEngineering

The invention discloses a botanical seedling culturing machine. A control system and a water pump, an air compressor, an air conditioner and a pre-heater which are electrically connected with the control system are arranged in a primary unit segment and an external ventilator and an internal gas circulator which are electrically connected with the control system arranged in the primary unit segment are arranged in an auxiliary unit segment, at least one group of culturing chests of drawers (5) and sliding rails (18) for drawer; each group of culturing chests of drawers (5) are provided with operation shelves (13), working inter-layers (14) and movable meshes (16), and movable working discs (15); ventilation and fertilizer feed holes are arranged at the bottom of the movable working disc (15), a light strip module (28), a spraying pipeline and a nozzle (29), a high-pressure air pipe (30), and the reflux tank (32) of an irrigation tank (31) are arranged in the rippled grooves downwards of a plurality of notches on the working inter-layer (14). The invention is a plastic potted tray botanical seedling culturing machine without foam, polystyrene, and polypropylene capable of high-quality industrialized, intensified and entire-year seedling culturing seedling production of scale.

Owner:湖南省湘晖农业技术开发有限公司

Sensor coil coding detection device

PendingCN108971030AImprove quality and efficiencyIncrease productivitySortingLaser beam welding apparatusElectricityEngineering

The invention discloses a sensor coil coding detection device which comprises a stand; the upper end of the stand is provided with a rotary table; the outer side of the rotary table is clockwise and sequentially provided with an emptying mechanism, a material existence detection mechanism, a CCD camera, a first electric performance testing mechanism, a second electric performance testing mechanism, a laser coding machine, an unqualified product unloading mechanism and a qualified product unloading mechanism according to the positions of work stations; one side of a rack is provided with a material supplying mechanism; and a material fetching mechanism is installed between the unqualified product unloading mechanism and the qualified product unloading mechanism. The sensor coil coding detection device has the beneficial effects that the sensor coil coding detection device can automatically perform terminal position degree, electric performance detection and laser coding on a sensor coil, is simple, convenient and rapid to operate, is beneficial to improving the production quality and the production efficiency of the sensor coil, can realize automatic material supplying and loading of the sensor coil and automatic unloading of qualified products and unqualified products, is high in automation degree, greatly lowers the labor intensity of an operator and is beneficial to improvingthe production efficiency.

Owner:无锡铭方科技有限公司

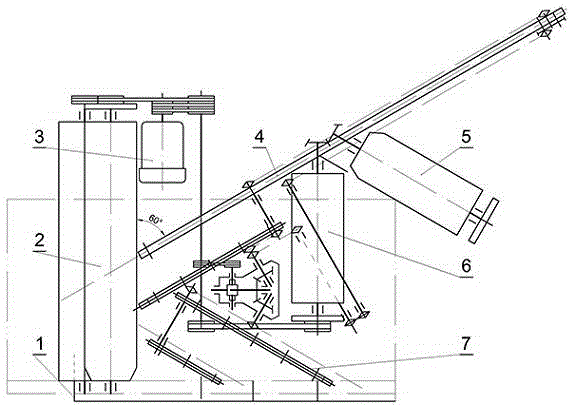

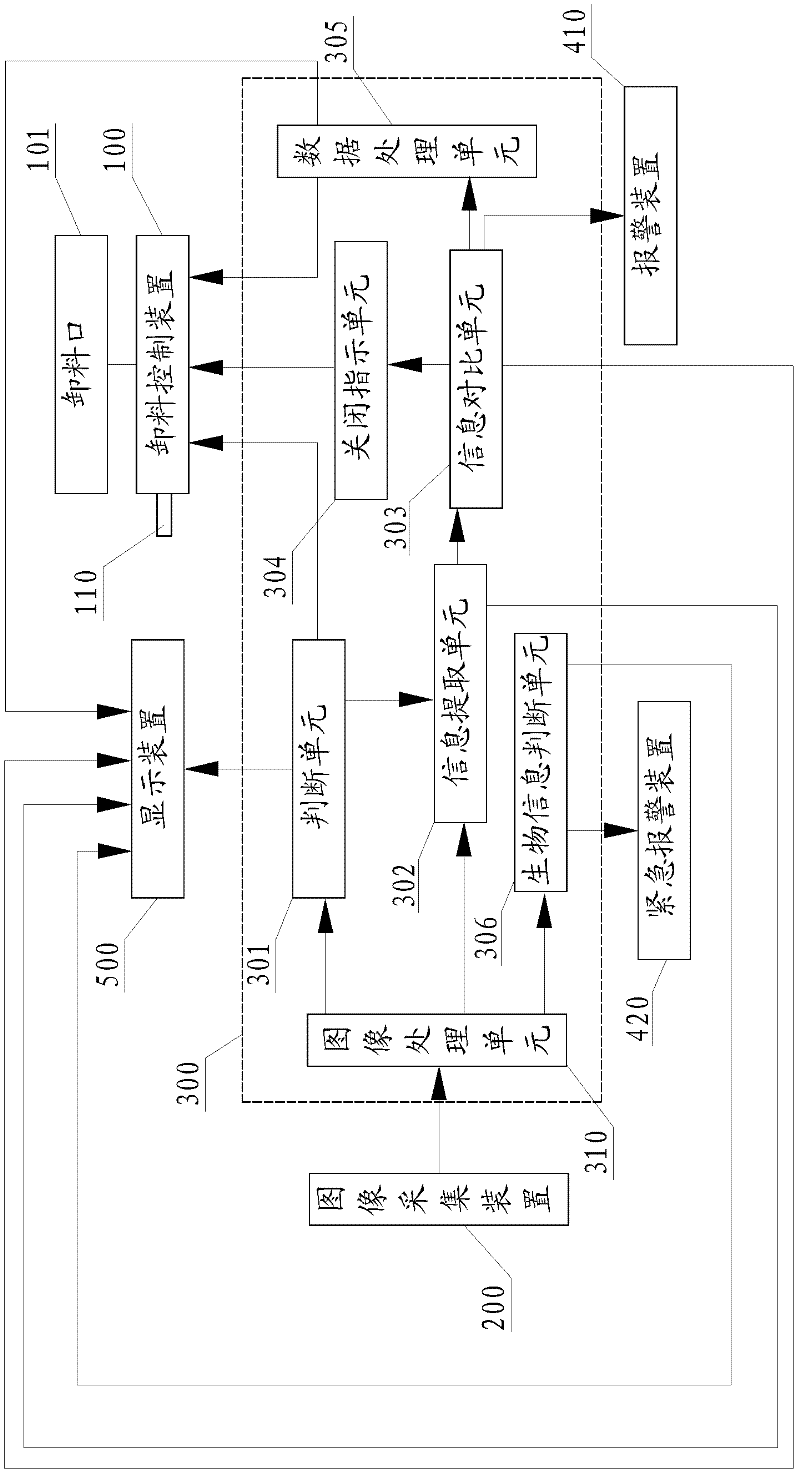

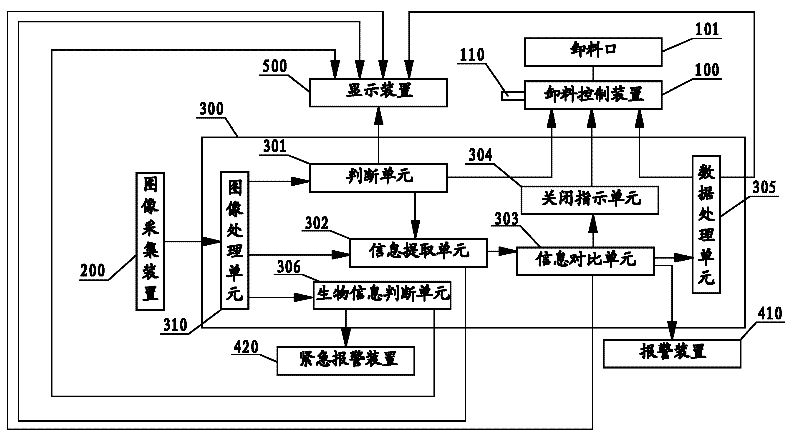

Mixing station or mixing building and system for controlling mixing station or mixing building

ActiveCN102225589ARealize automatic unloadingReduce labor intensityControl apparatusMixing operation plantImaging processingControl system

The invention discloses a mixing station or a mixing building and a system for controlling the mixing station or the mixing building. The disclosed control system comprises an image acquisition apparatus and a central processor, the central processor comprises an image processing unit and a determine unit; a mark information is formed by the image processing unit according to the image information collected by the image acquisition apparatus; the determine unit determines whether a conveying vehicle exists or not on the predetermined position; an instruction of opening is sent to a discharging controlling apparatus when the determine conclusion is that the conveying vehicle exists on the predetermined position; the discharge port can be opened by the discharging controlling apparatus according to the instruction of opening. An automatic discharging process can be realized according to the control system provided in the invention. The fault caused by manual misoperation can be minimized or avoided, labor strength of operators can be also reduced; the image information collected by the image acquisition apparatus through automatically processing determines whether the conveying vehicle arrives or not on the predetermined position without depending on the images displayed by a display apparatus, so that at least one display apparatus can be omitted, thereby the system provided inthe invention provides convenience for arrangement of each part of the control chamber and reduces the cost of control chamber of the mixing station.

Owner:益阳市科技成果转化服务中心 +1

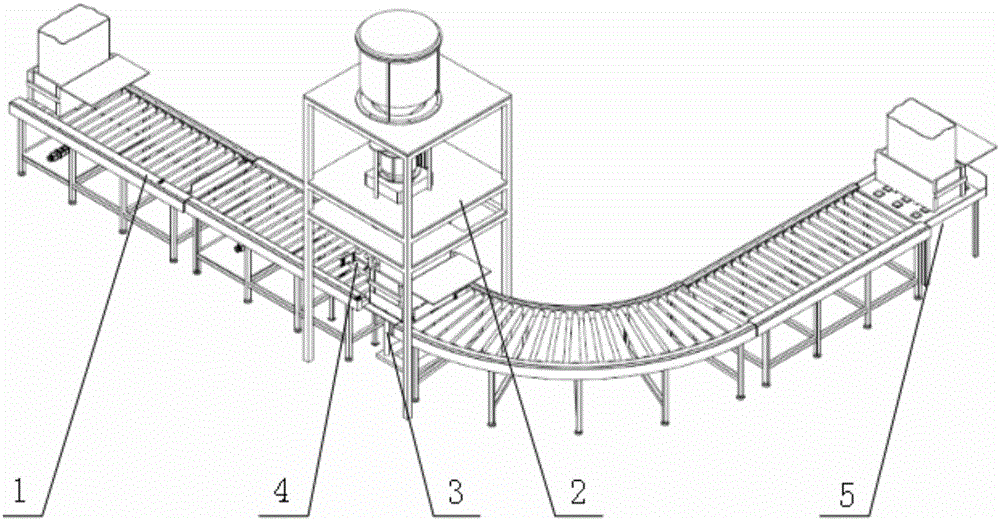

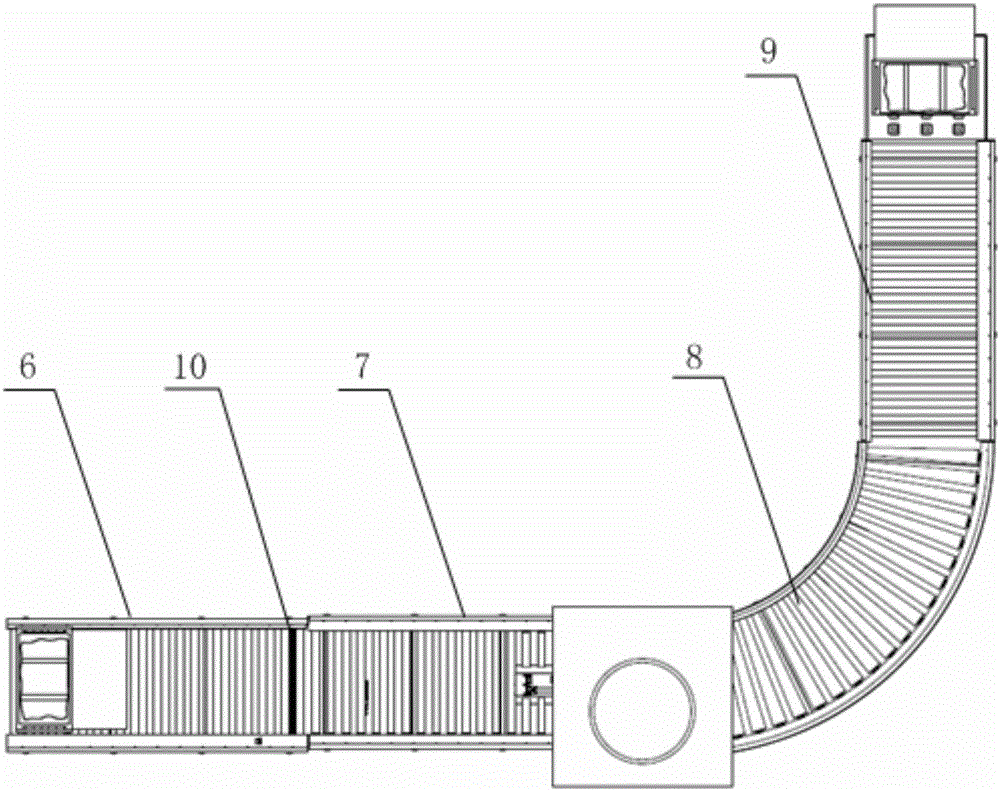

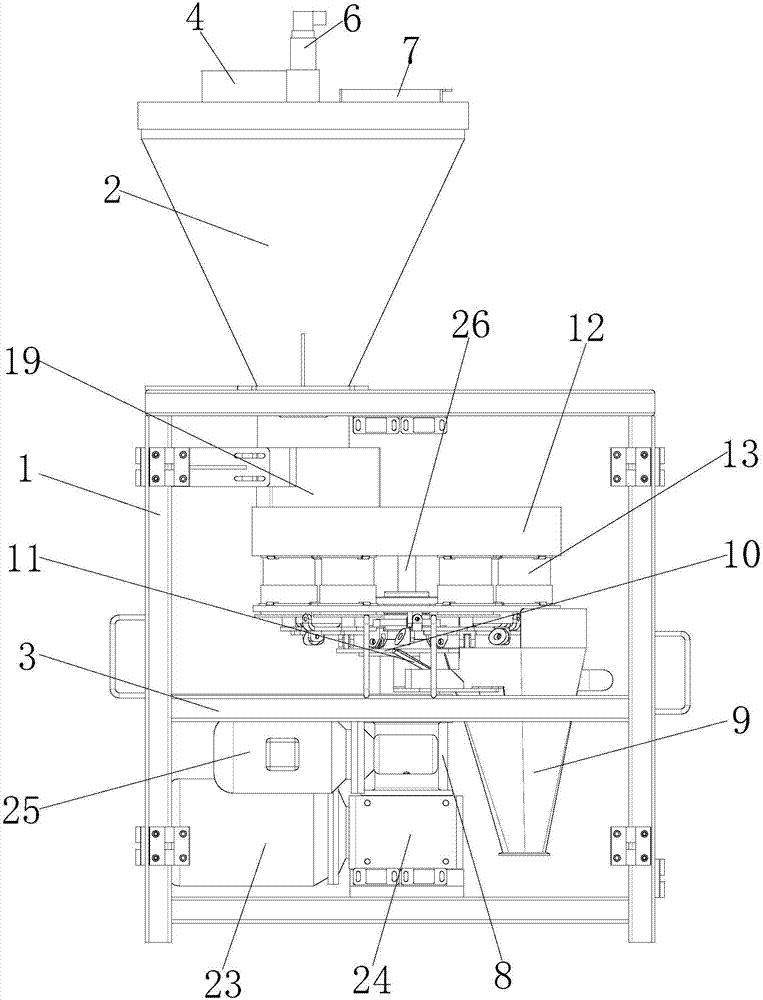

Automatic weighing and boxing device for powder blasting supplies

InactiveCN105857756ARealization of automatic weighingRealize automatic unloadingSolid materialMechanical engineeringAutomatic testing

The invention discloses an automatic weighing and boxing device for powder blasting supplies. The automatic weighing and boxing device is composed of a roller conveying line, a feeding and weighing device, a vibration platform, an auxiliary device and a finished product packaging table. Part of the roller conveying line and the finished product packaging table are installed outside a semi-closed workshop. The roller conveying line is formed by sequentially connecting a plurality of roller conveyors in the conveying sequence. An explosion-proof motor and power chain wheel type rollers are adopted by the roller conveyors, and the roller conveyors are subjected to dust-proof treatment, so that automatic conveying of products is achieved. Weighing of materials and automatic filling of the materials are completed by the feeding and weighing device. The vibration platform is used for jolt-ramming of the materials, the number of gaps between the materials is reduced, and the materials are prevented from being piled up. The auxiliary device is used for pushing material boxes onto the vibration platform and pushing the material boxes off the vibration platform after the material boxes are filled with the materials. The finished product packaging table is used for product packaging. The automatic weighing and boxing device is provided with pneumatic elements, the explosion-proof structure design is adopted, and unmanned operation is achieved; and the automatic weighing and boxing device has the characteristics of being simple in structure, high in weighing precision and convenient and fast to operate.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

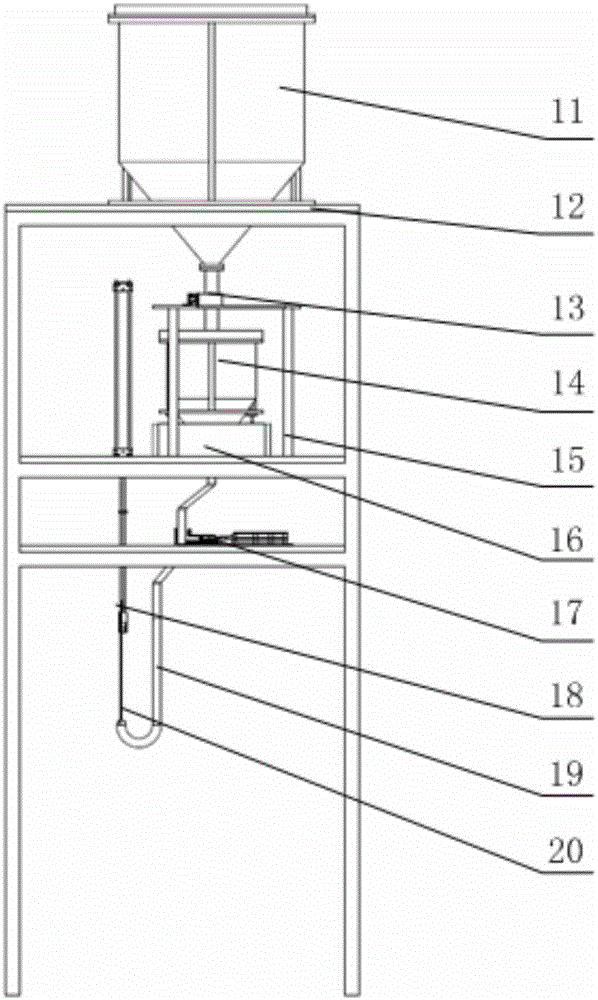

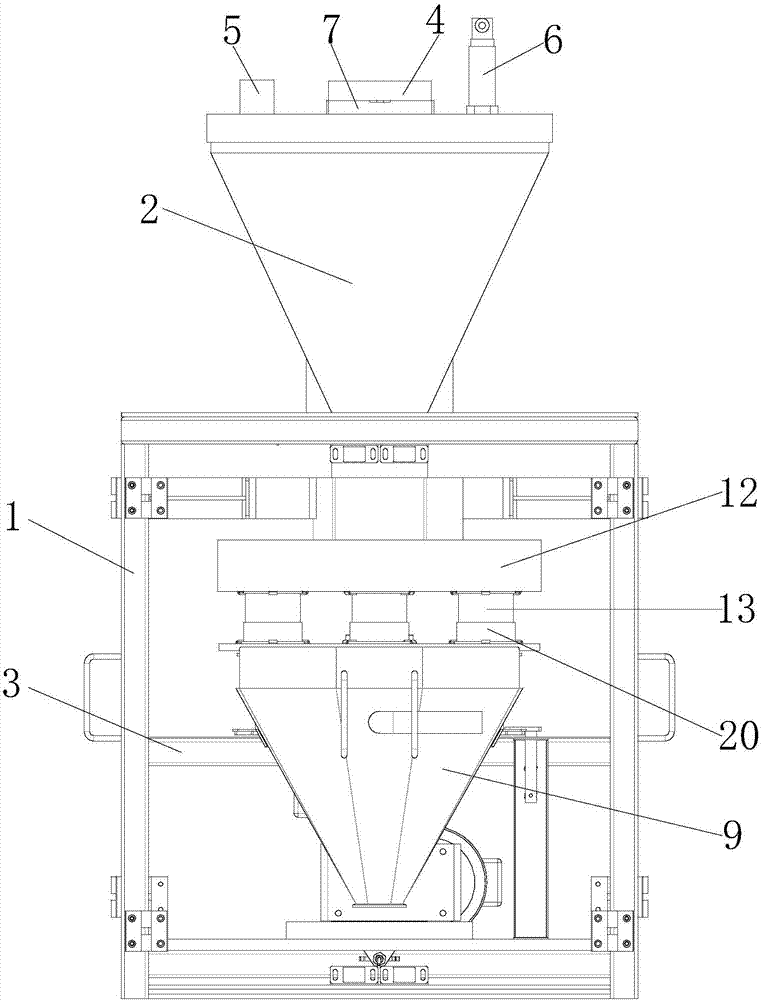

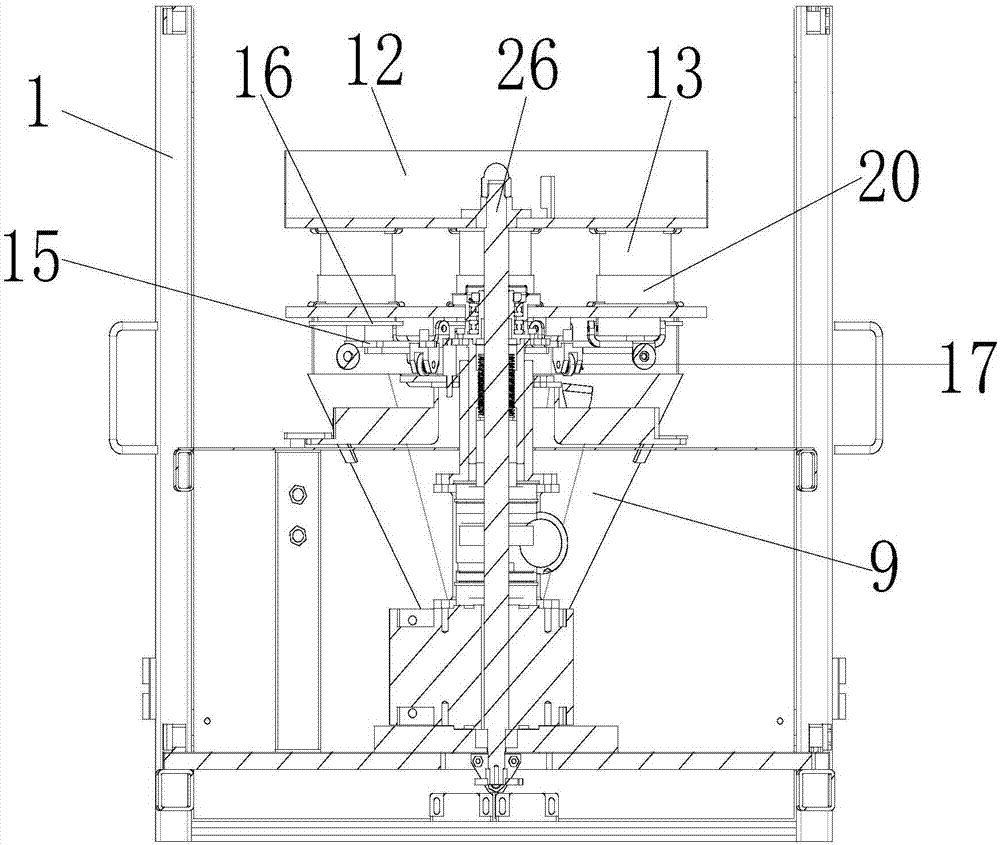

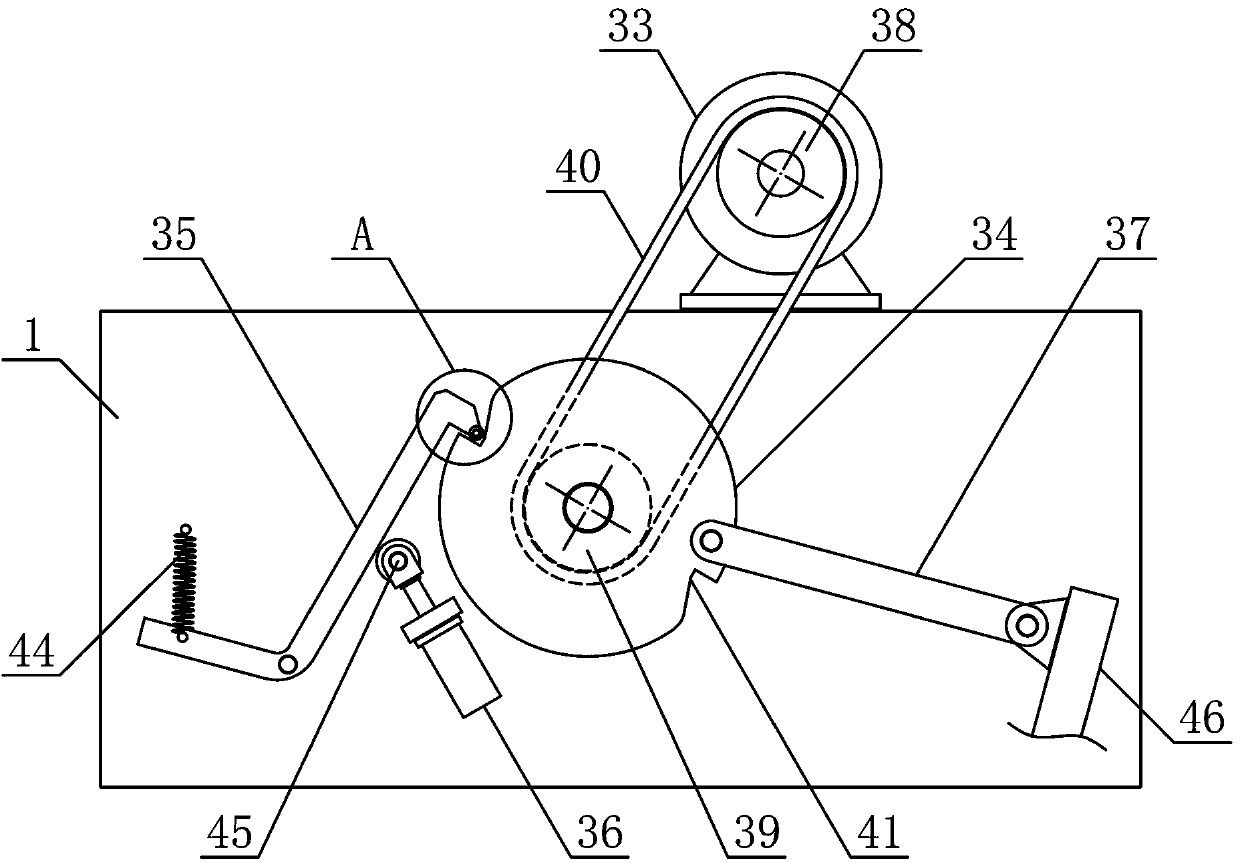

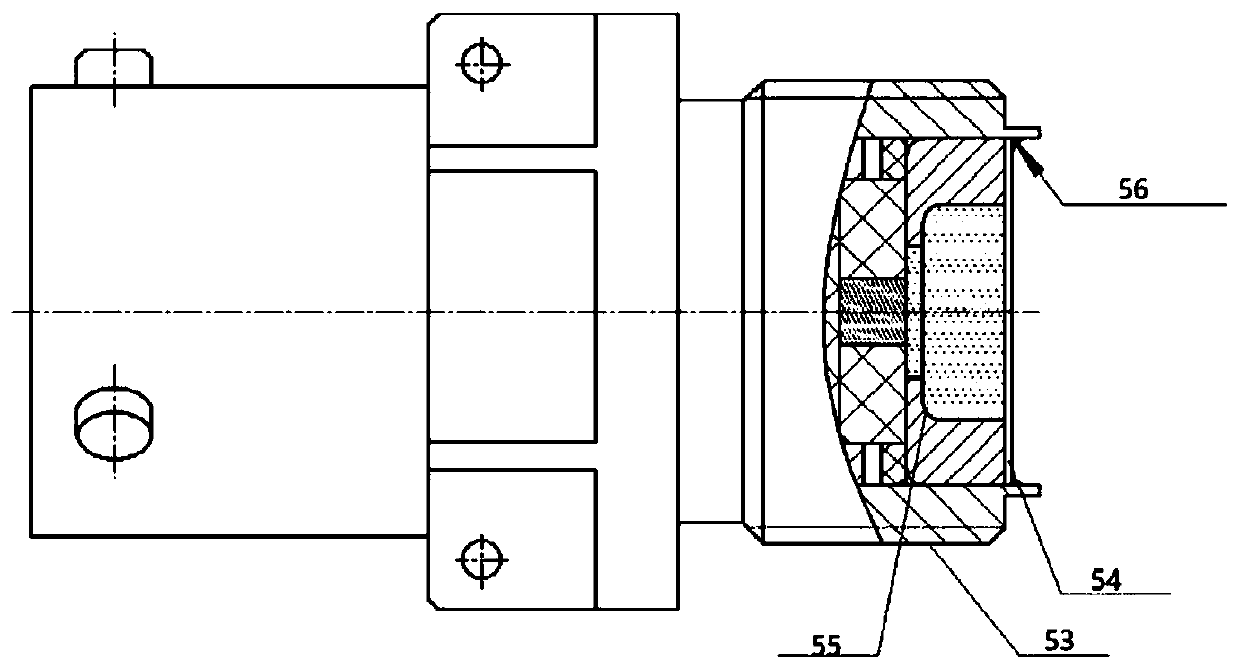

Volume type metering device of salt packaging machine

InactiveCN107187620AHigh measurement accuracyGuaranteed measurement accuracySolid materialEngineeringPackaging machine

The invention discloses a volume type metering device of a salt packaging machine. The volume type metering device comprises a metering cabinet body. A feeding hopper is arranged at the top of the metering cabinet body, and a support plate is fixedly arranged inside the metering cabinet body. A metering portion is mounted on the upper portion of a transmission sleeve, a guide rail disc is mounted in the middle of the transmission sleeve, and a power device is mounted on the lower portion of the transmission sleeve, wherein the metering portion is located above the support plate; the guide rail disc is located below the metering portion; and the power device is located below the support plate. The volume type metering device of the salt packaging machine is provided with an ascending-and-descending disc and a metering disc, so that the volume of each metering cup is changed, materials can be metered in a quantitative manner, and metering precision is high; material scraping can be conducted on the interior of the metering disc through a material disc and a material scraping plate which are arranged, friction occurring between residual materials and the metering disc is effectively reduced, and metering precision of the metering cups is guaranteed; by means of the guide rail disc which is arranged, a bottom disc of the metering cups can fall under the effect of gravity, automatic unloading of the materials is achieved, and operation is easy and convenient to conduct; and the device is provided with multiple metering cup holes, continuous metering is achieved, and work efficiency of quantitative metering is improved.

Owner:ANHUI XINYUAN PACKING TECH

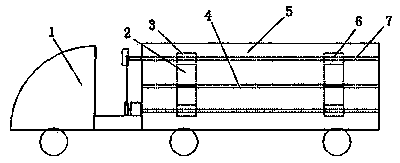

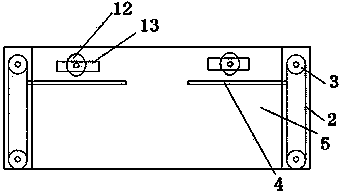

Variable-capacity compressible easily unloading transport vehicle and transport method

InactiveCN104260793AEasy to operateStrong ventilationAir-treating devicesVehicle heating/cooling devicesSprocketEngineering

The invention relates to the field of transport logistics, in particular to a variable-capacity compressible easily unloading transport vehicle and a transport method. The transport vehicle comprises a carriage and is characterized in that two horizontal chain wheel shafts are arranged on the carriage wall, the ends of the chain wheel shafts are rotatably mounted on a carriage body through bearings, holes are formed in the carriage body, the bearings are arranged in the holes, the chain wheel shafts penetrate the bearings, a belt is mounted on the chain wheel shafts after the chain wheel shafts penetrate the bearings and connected with a power output shaft of a power system by the aid of power, chain wheels are mounted on the chain wheel shafts, a chain is arranged on the vertically distributed chain wheels, a lifting plate is welded outside the chain and can rise and fall inside the carriage, and the power system is a forward and reversely rotating motor and a speed reducer of the motor. The transport vehicle has the advantages that internal capacity can be distributed, the transport vehicle is high in operability, automation degree and ventilation or gas orientation capability, various cargoes can be simultaneously transported and can be automatically unloaded, and separation intervals are formed.

Owner:LUDONG UNIVERSITY

Metal round pipe continuous conveying machining device

InactiveCN111229923AStable processingAutomatic and stable processingPerforating toolsMetal-working feeding devicesStructural engineeringMachining

The invention discloses a metal round pipe continuous conveying machining device, and belongs to the field of mechanical workpiece machining equipment. A round pipe guide storage pipe and a guide pipeinclined table plate are sequentially and fixedly mounted on the upper side of a round pipe conveying support in the inclined direction, a guide pipe driving mechanism and a round pipe guide conveying mechanism are sequentially mounted at the position, on the upper side of the guide pipe inclined table plate, of the round pipe conveying support from top to bottom, a round pipe machining mechanismis fixedly mounted at the position, above the lower end of the guide pipe inclined table plate, of the round pipe conveying support, a round pipe positioning mechanism is horizontally and fixedly mounted on the lower side of the end of the guide pipe inclined table plate, and a round pipe falling mechanism is fixedly and vertically mounted at the position, on the lower side of the round pipe machining mechanism, of the round pipe conveying support. Structural design is reasonable, a metal round pipe can be efficiently and stably guided and conveyed continuously to be punched, the machined round pipe can be conveniently, rapidly and smoothly conveyed and discharged, automatic and accurate machining of the metal round pipe can be achieved, machining efficiency and machining quality of the metal round pipe can be improved, and needs of production use can be met.

Owner:黄薇婷

Agricultural rotary soybean screening device

ActiveCN108405298AReduce work intensityRealize automatic unloadingSievingScreeningScreening effectElectric machinery

The invention relates to a screening device, in particular to an agricultural rotary soybean screening device. The invention aims to solve the technical problem so as to provide the agricultural rotary soybean screening device which is convenient to operate, high in screening efficiency and good in screening effect. The invention provides the agricultural rotary soybean screening device which comprises a bottom plate, supports, annular slide rails and the like. The supports are left-and-right symmetrically arranged on the top part of the bottom plate; the annular slide rails are arranged on the top parts of the supports; first slide blocks are slidably connected onto the annular slide rails; the annular slide rails are matched with the first slide blocks; and placement rings are arranged on the top parts of the first slide blocks. According to the agricultural rotary soybean screening device provided by the invention, the effects of convenience in operation, high screening efficiency and good screening effect are achieved; a rotary electromotor rotates to control a first baffle plate to move, so that automatic blanking is realized; the rotary electromotor rotates to drive a screening frame to rotate, so that automatic screening is realized, the screening efficiency is improved, and a screening effect is improved; and the device is novel in structure and high in practicability.

Owner:沙洋县尹琦食品有限公司

Automatic tightening device for double-end studs and nuts

InactiveCN103495860AAutomatic tighteningRealize automatic hat recognitionMetal working apparatusCircular segmentElectrical and Electronics engineering

The invention discloses an automatic tightening device for double-end studs and nuts. The automatic tightening device comprises an arch-shaped support, a lead screw, transverse guide rails, a motor, longitudinal guide rails, a tightening air cylinder, lifting-up devices and supporting claws, the lead screw and the transverse guide rails are arranged on the upper portion of the support, the motor is connected with the lead screw, the longitudinal guide rails are distributed to be perpendicular to the transverse guide rails, the tightening air cylinder is arranged on the upper portion of the longitudinal guide rails, and the air cylinder shaft of the tightening air cylinder is connected with a tightening mechanism through a connecting piece. The drive rod of the tightening mechanism is connected with a tightening head. The automatic tightening device for the double-end studs and the nuts is used for automatically tightening batched double-end studs or nuts regularly distributed on a narrow workpiece, the reliability, the precision and the interference resisting capacity of a tightening system are ensured, and tightening consistency and tightening efficiency can be improved.

Owner:CHINA NTAIONAL NUCLEAR TIANJIN MACHINERY

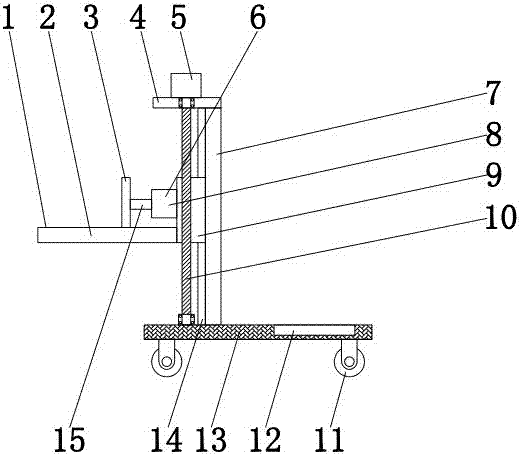

Building material lifting device for construction site

InactiveCN107572449ARealize automatic unloadingReduce work intensityLifting devicesHydraulic cylinderArchitectural engineering

The invention discloses a building material lifting device for a construction site. The building material lifting device comprises a base, universal wheels, a hydraulic cylinder, a motor and a supporting rod. The universal wheels are arranged at the bottom of the base, so that free movement of the building material lifting device is achieved, when building materials are lifted to a specified height, the hydraulic cylinder is utilized to drive the hydraulic rod to extend, further a push plate is pushed to move on a placing plate, so that automatic unloading of the building materials placed at the top of the placing plate is achieved, manual unloading of the building materials placed at the top of the placing plate is not needed, a lot of manpower is saved, the working intensity of construction workers is greatly relieved, and the efficiency of building construction is improved; and when the building materials on the high position needs to be conveyed to the low position, firstly the building materials are placed at the top of the placing plate, further a threaded rod is driven to rotate in the counter-clockwise direction by utilizing reversing rotation of the motor so that a slidingblock can move downwards on the threaded rod, and further the building materials placed at the top of the placing plate are driven to descend.

Owner:南京苏格信息技术有限公司

Fully automatic soymilk machine

The invention provides a fully automatic soymilk machine, which comprises a cup body, a machine head and a circuit control board. The machine head is arranged on the cup body and comprises an upper cover, a lower cover and a storage box, wherein the lower cover covers on the upper cover; the lower end of the storage box is provided with an unloading device; and the storage box is hung or clamped on the cup body. The machine head is also provided with a solenoid valve trigger switch of a transmission mechanism, wherein the transmission mechanism is connected with the circuit control board and can drive the unloading device of the storage box to work when the circuit control board sends a corresponding command. The fully automatic soymilk machine is provided with the automatic unloading device, has a reservation function, and is more convenient and humanized in use.

Owner:DONGGUAN BBK HOUSEHOLD ELECTRICAL APPLICANCES

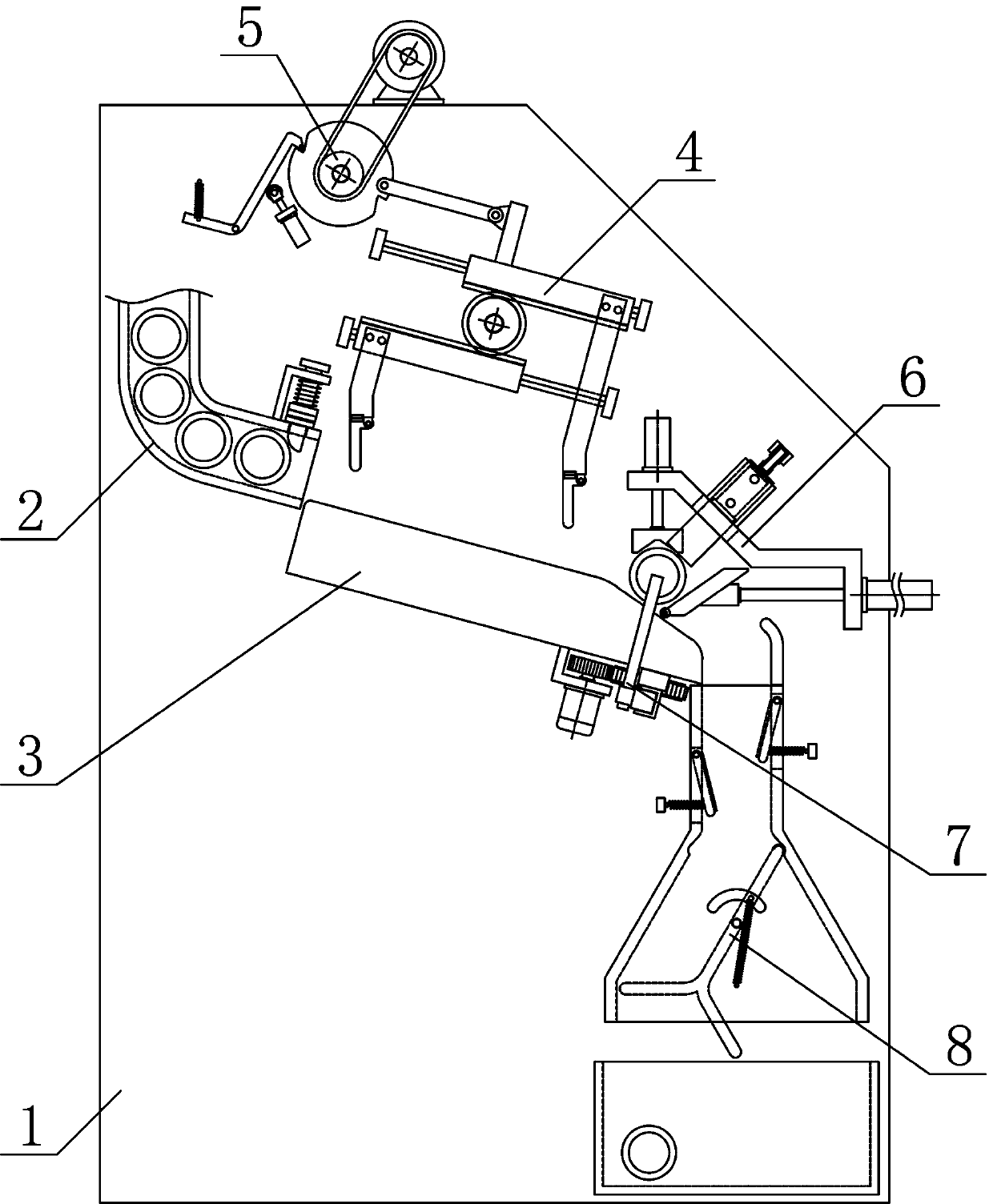

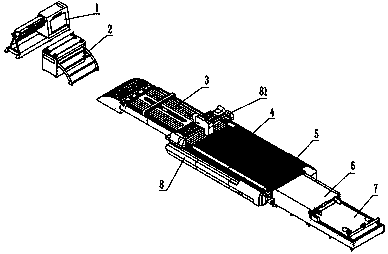

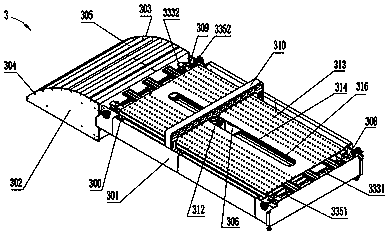

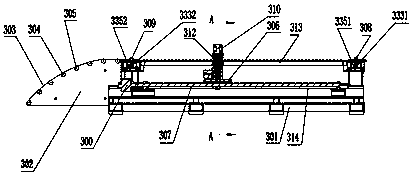

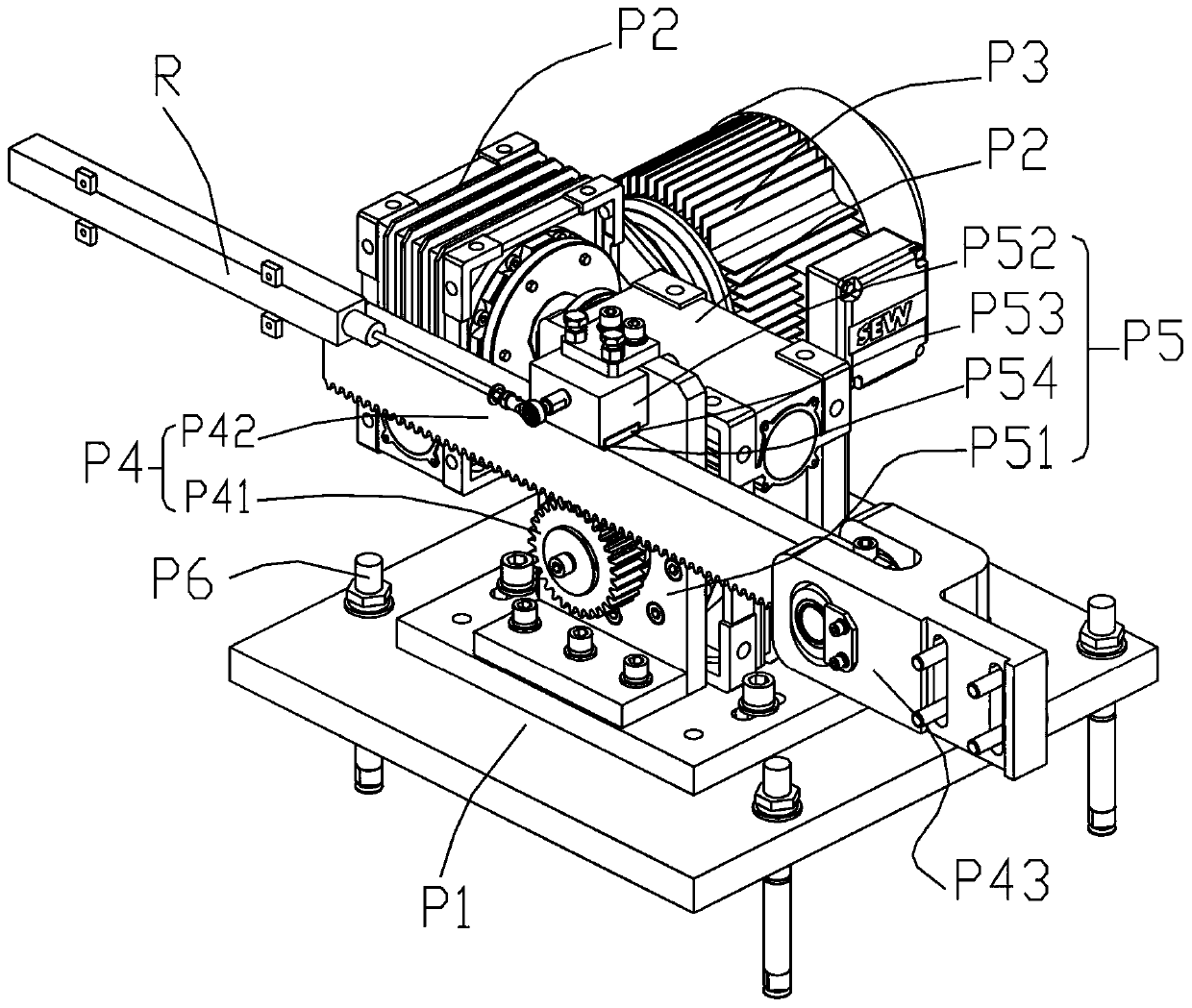

Laser cutting device

PendingCN110170752APrecise cutting and automatic unloadingReduce biasLaser beam welding apparatusStops deviceLaser cutting

The invention belongs to the technical field of metal plate production equipment, and particularly relates to a laser cutting device. The laser cutting device is provided with a main lathe bed (8), afeeding machine (3), a clean material cutting area (4) and a rotary workbench (5), wherein the feeding machine (3), the clean material cutting area (4) and the rotary workbench (5) are arranged from back to front; the feeding machine (3) is provided with a feeding rail (314), a feeding crossbeam (310) and a floating clamp (312); the clean material cutting area (4) is provided with a clean materialcutting support bar (41), a clean material cutting servo motor (42) and a stop device; and the rotary workbench (5) is provided with a rotary support bar (51), a rotary servo motor (52), a chain support rail (53) and a supporting bracket (54). According to the laser cutting machine, the feeding machine can achieve high-precision positioning and automatic deviation rectifying through plate limiting and can achieve automatic feeding; a plate is accurately positioned by the clean material cutting area so to be cleaned and cut and is then conveyed to the rotary workbench to be cut into a workpiece; and laser cutting based on automatic feeding and discharging is achieved, and the production efficiency is improved.

Owner:河南力锋科技有限公司 +1

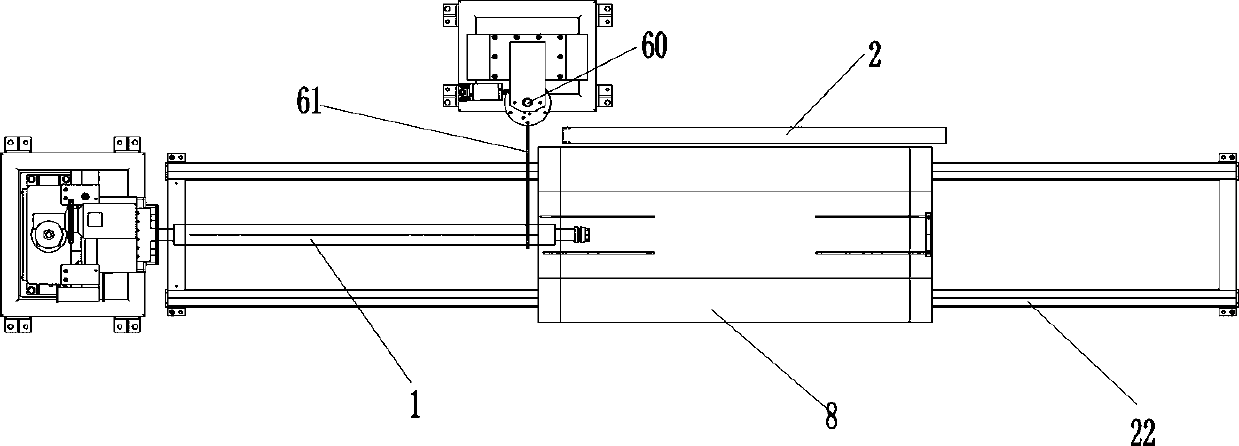

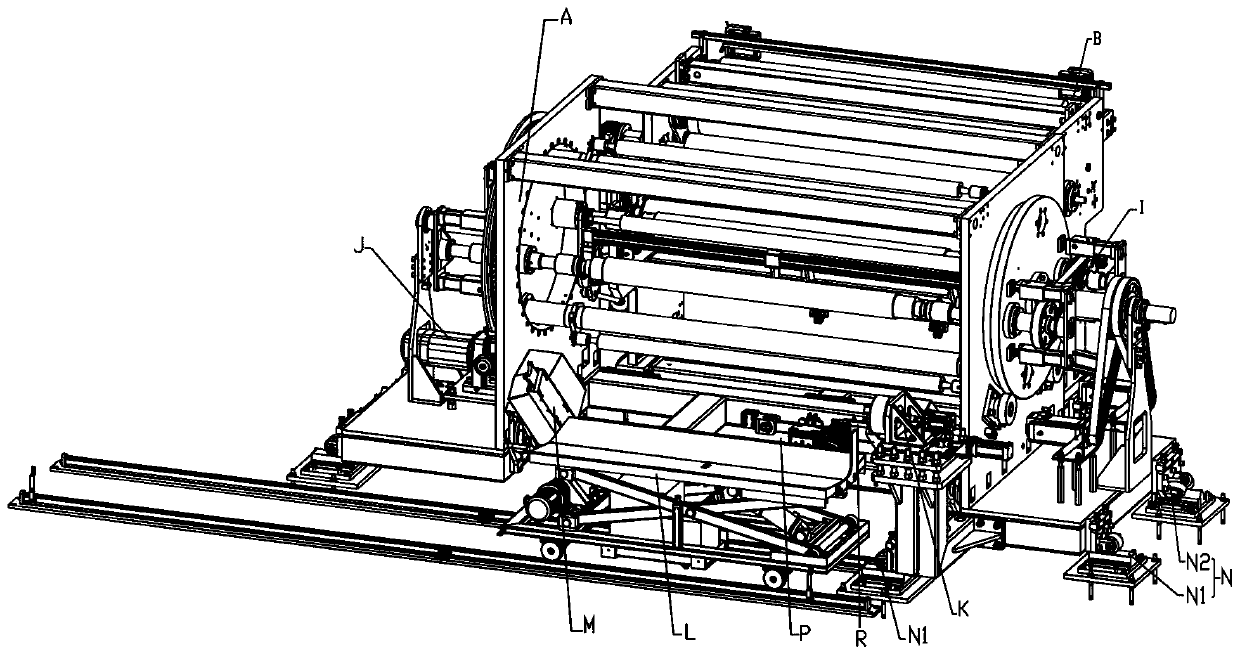

Automatic unwinding and winding device and automatic unwinding and winding method

ActiveCN109720916ARealize automatic unloadingHigh degree of automationWebs handlingEngineeringElectromagnetic valve

The invention provides an automatic unwinding and winding device. The automatic unwinding and winding device comprises a left winding shaft support and a right winding shaft support, wherein a clamping assembly is further arranged behind the left winding shaft support, a clamping plate support is further provided with an air nozzle connector and a proximity switch used for sensing the position ofthe winding shaft, the left end of a gas nozzle joint is connected with a two-way electromagnetic valve, a transverse guide rail which transversely extends is arranged on the right side of the clamping assembly, a carrying trolley is installed on the transverse guide rail, the carrying trolley is further provided with a left unwinding swing arm, a right unwinding swing arm, a left longitudinal lifting rail and the right longitudinal lifting rail, a vertical lifting arm can be installed on each longitudinal lifting rail in a sliding mode, and a mechanical clamping hand is installed at the lowerend of each vertical lifting arm; and a supporting arm assembly is further arranged beside the transverse guide rail. The invention further provides an automatic unwinding and winding method. The device has the advantages that the automation degree is high, a vehicle roof panel does not need to be lifted, and the structure is compact.

Owner:GUANGDONG JINMING MACHINERY

Medical-use tablet grinding equipment

ActiveCN111632718AEasy to addImprove grinding efficiencyGrain treatmentsEngineeringMedical treatment

The invention relates to grinding equipment, in particular to medical-use tablet grinding equipment. The technical problem to be solved is to provide the medical-use tablet grinding equipment that tablets can be added conveniently and the grinding efficiency can be improved. The technical scheme of the invention is that the medical-use tablet grinding equipment comprises a bottom plate, a grindingmechanism and fixed plates, wherein the bottom plate is provided with a vertical plate, the vertical plate is provided with a first sliding groove, the first sliding groove is internally and slidablyprovided with a first sliding block, and a first spring is connected between the first sliding block and the vertical plate; the grinding mechanism is arranged on the first sliding block; and the fixed plates are arranged two, are both installed on the side, away from the vertical plate, of the bottom plate and are rotatably provided with rotating rods, and a storing tray is arranged between thetwo rotating rods. According to the medical-use tablet grinding equipment, the grinding mechanism is moved downwards to contact the tablets, and the tablets can be ground by starting the grinding mechanism, the tablets can be added conveniently through the storing tray, and the grinding efficiency can be improved.

Owner:HEBI CITY PEOPLES HOSPITAL

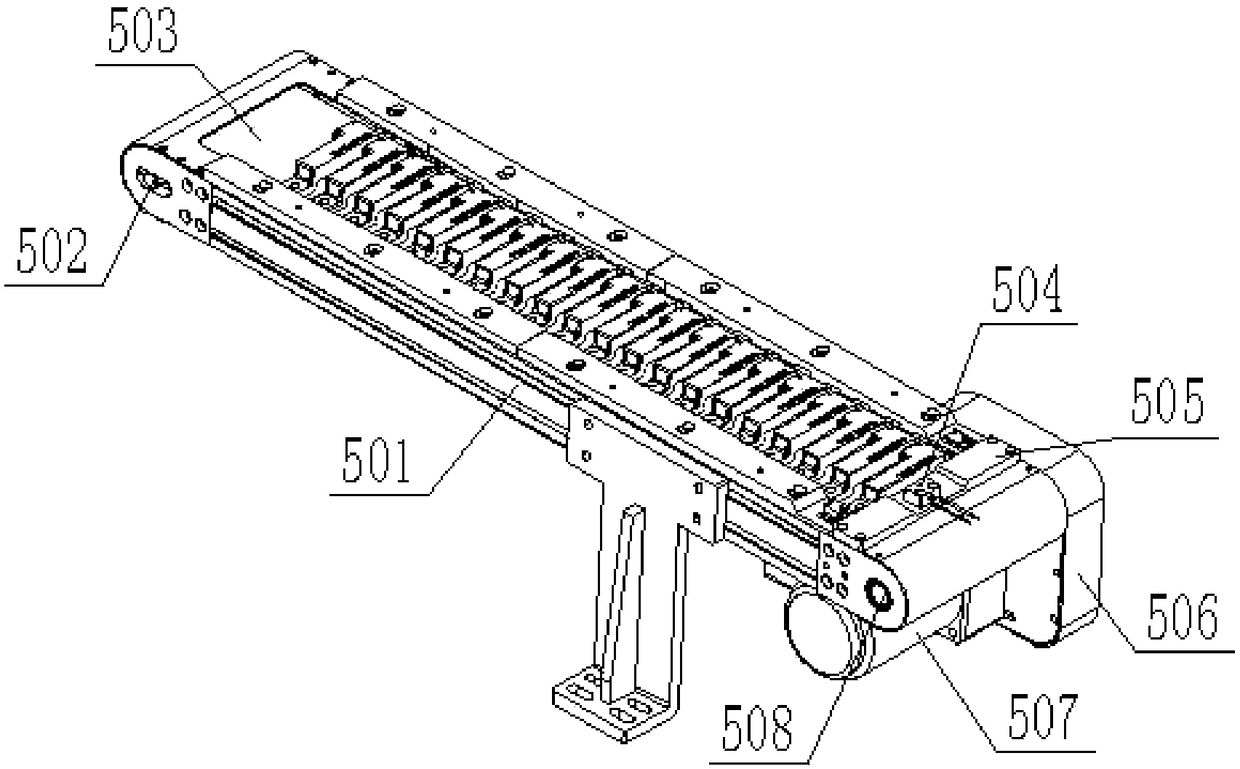

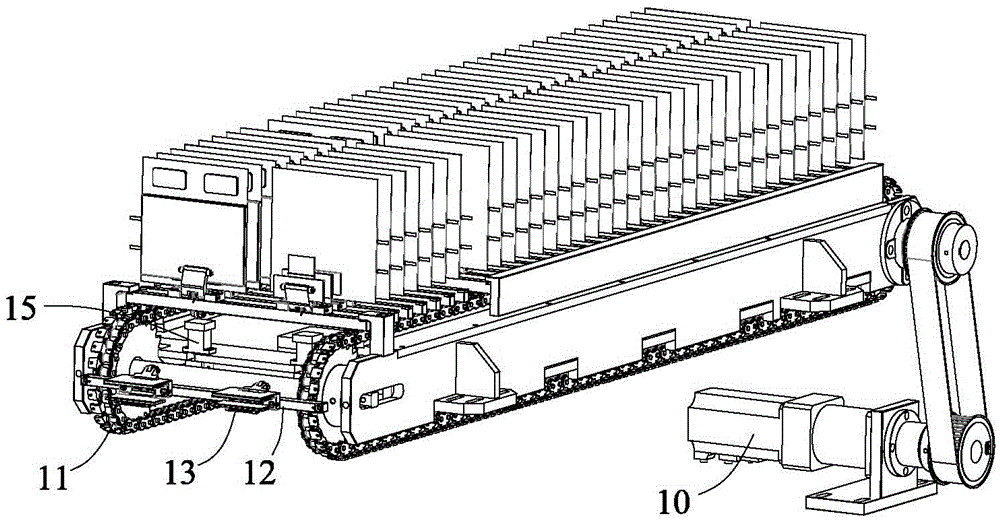

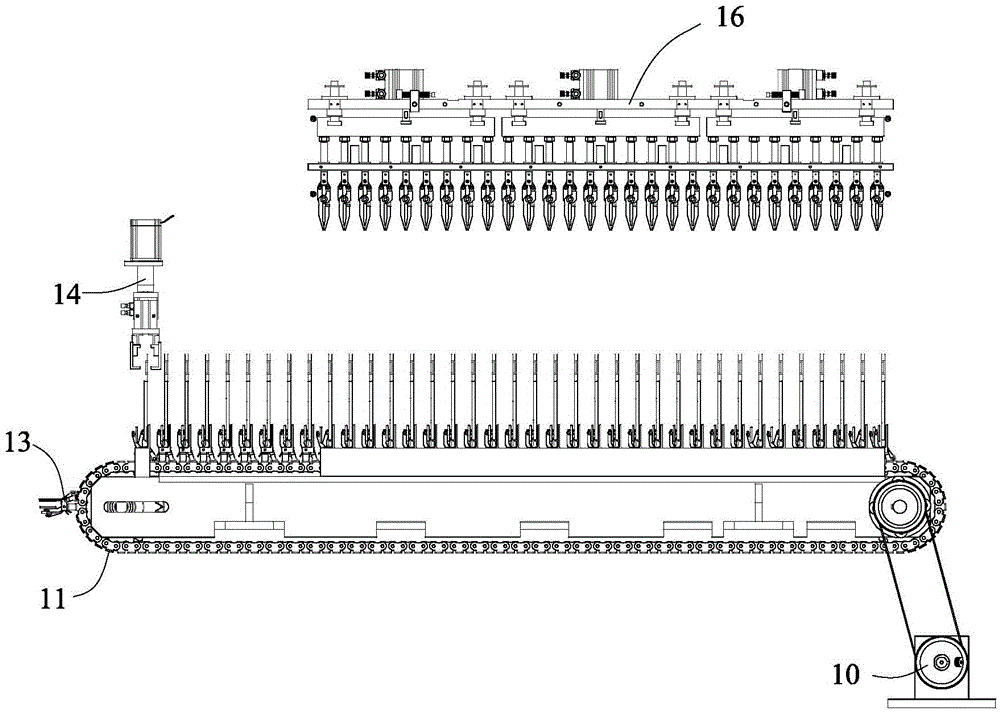

Automatic loading and unloading device for batteries

ActiveCN105540252AReduce battery loading and unloading timeIncrease productivityConveyorsConveyor partsManipulatorEngineering

The invention provides an automatic loading and unloading device for batteries. The automatic loading and unloading device for the batteries comprises a loading mechanism and an unloading mechanism; the loading mechanism is used for collecting multiple batteries and moving the batteries into external equipment to be processed, and the unloading mechanism is used for collecting the processed batteries. The loading mechanism comprises a first power mechanism, a loading and conveying mechanism, multiple battery fixing mechanisms, a loading manipulator and opening and clamping mechanisms; the loading and conveying mechanism is driven by the first power mechanism, the battery fixing mechanisms are arranged on the loading and conveying mechanism and driven by the loading and conveying mechanism, the loading manipulator moves the batteries to the corresponding battery fixing mechanisms, and the opening and clamping mechanisms control opening and closing of the corresponding battery fixing mechanisms, so that the corresponding battery fixing mechanisms are opened to receive the corresponding batteries to be loaded and closed to fix the corresponding batteries to be loaded. According to the automatic loading and unloading device for the batteries, automation of battery loading and unloading can be achieved, the battery loading and unloading time is shortened, and the production efficiency is improved.

Owner:NINGDE AMPEREX TECH

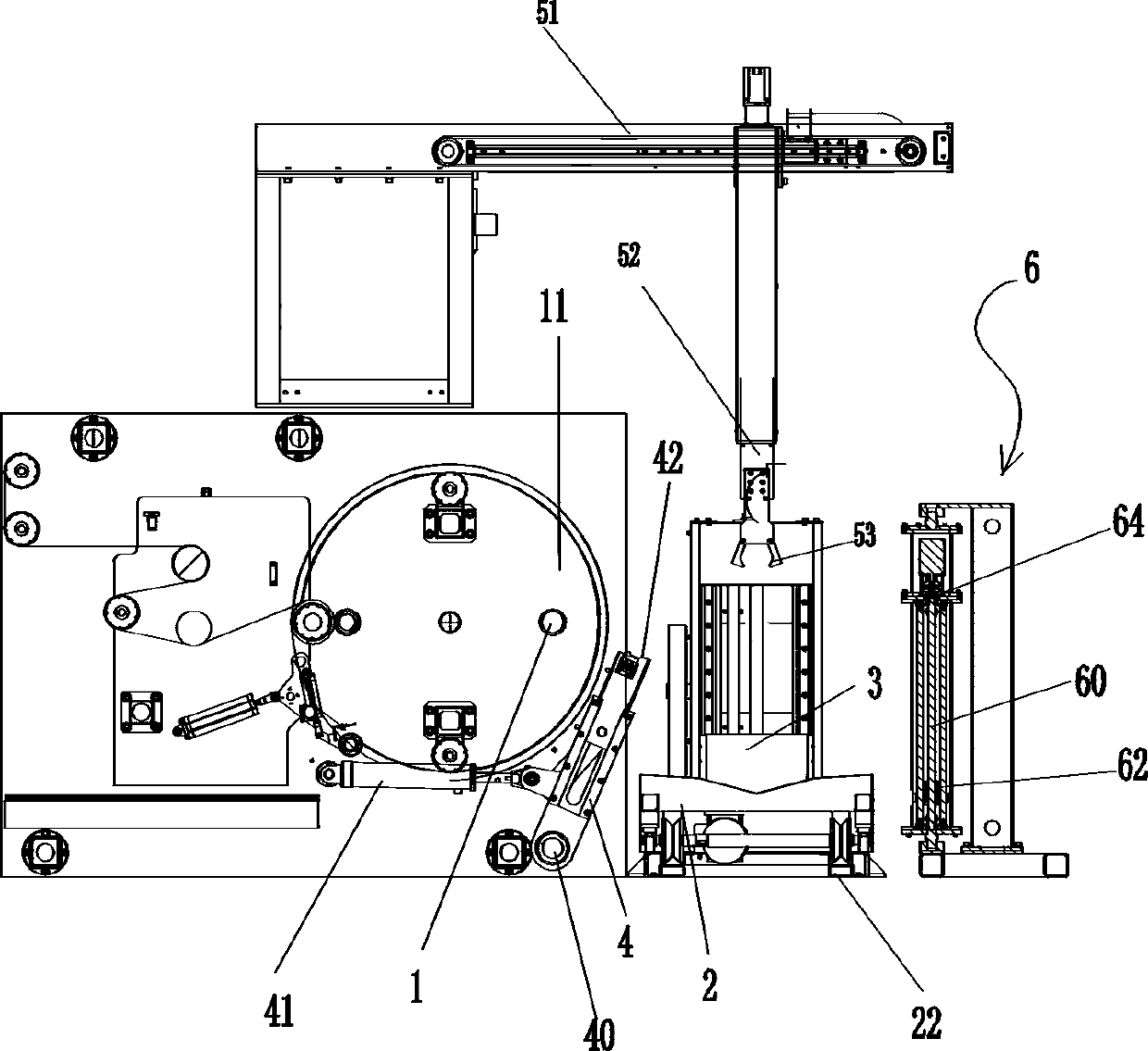

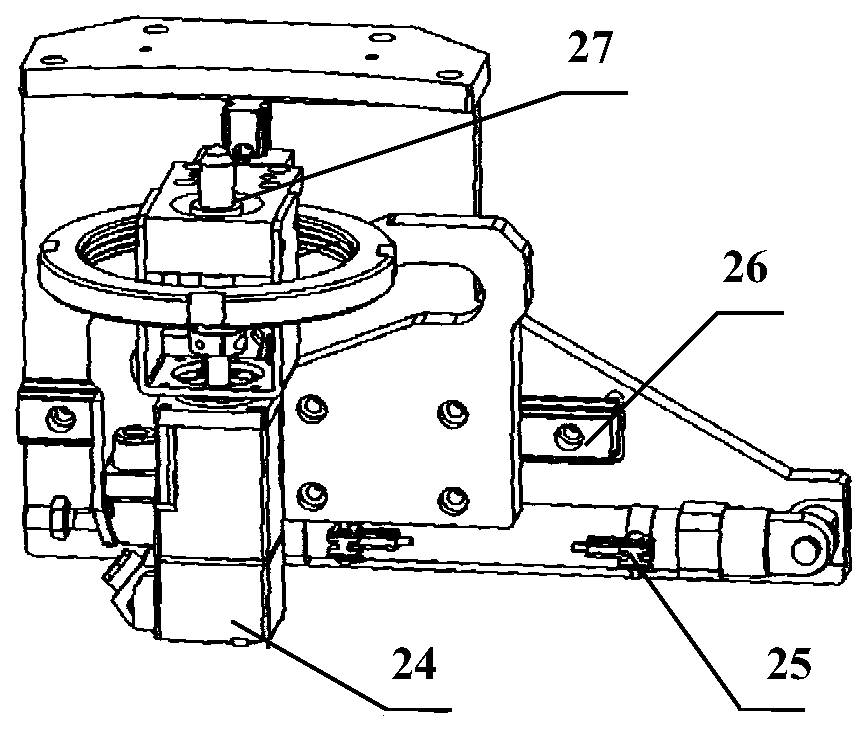

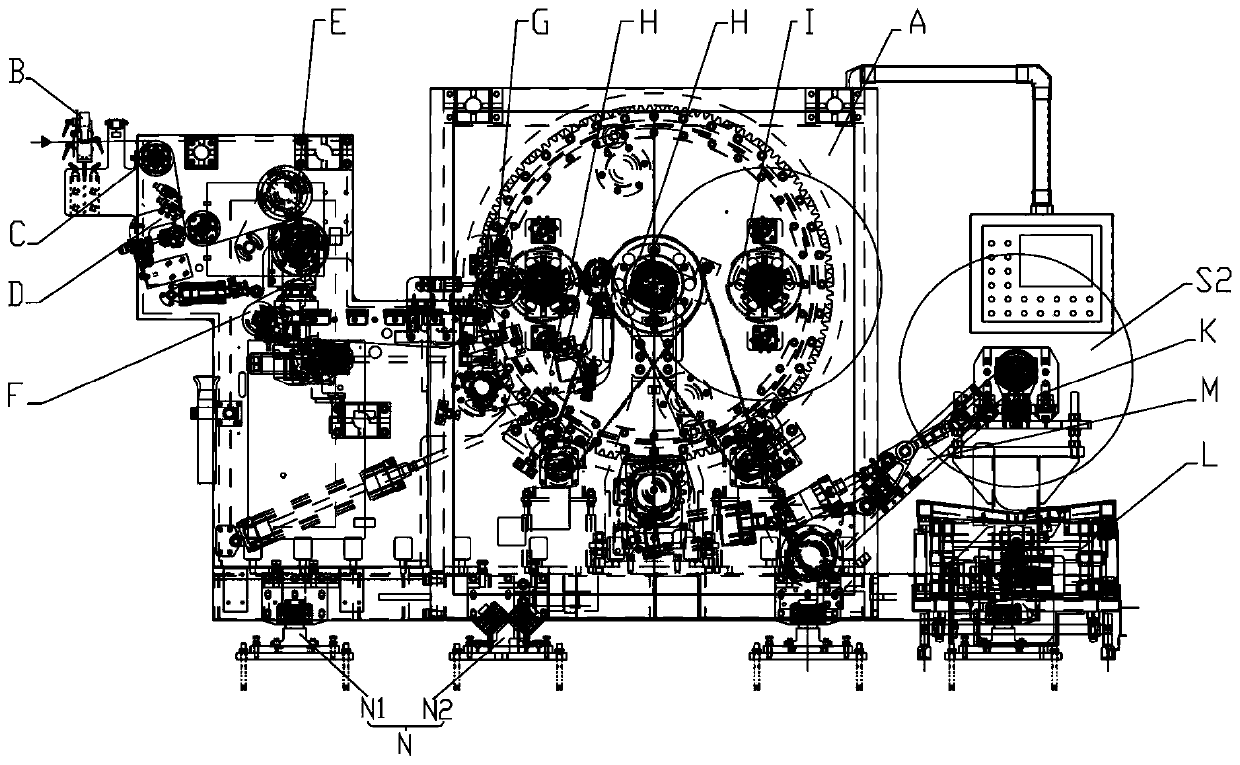

Assembling system for explosive-surface light and thin part of igniter

ActiveCN110821928ASolve the problem of manual assemblyDraw reliableLiquid surface applicatorsMaterial gluingRobot handEngineering

The invention discloses an assembling system for an explosive-surface light and thin part of an igniter, and belongs to the field of automatic assembling of igniters. The assembling system comprises afeeding and discharging module (1), a light and thin part assembling module (2), a glue solution coating module (3), a product circulation module (4), a product transferring module (5) and a module mounting base (6). According to the assembling system for the explosive-surface light and thin part of the igniter, automatic feeding and discharging are achieved through a feeding and discharging mechanical arm in the feeding and discharging module (1), and rapid and accurate assembling of the light and thin part is achieved through reliable negative-pressure suction and grab and positive-pressurepushing and placement by an anti-static suction head of the light and thin part assembling module (2); a multi-axis motion module in the glue solution coating module (3) is adopted to control the direction of a glue gun to complete glue extrusion; through joint cooperation of the modules, the explosive-surface light and thin part of the igniter is automatically assembled and the inner wall of a shell is automatically coated with a glue solution and checked; and the problems in manual assembling of the light and thin part of an existing igniter and manual coating of the glue solution on the inner wall of the shell are solved.

Owner:CHUANNAN MACHINERY PLANT CHINA ASTRONAUTIC SCI &TECH GROUP CORP

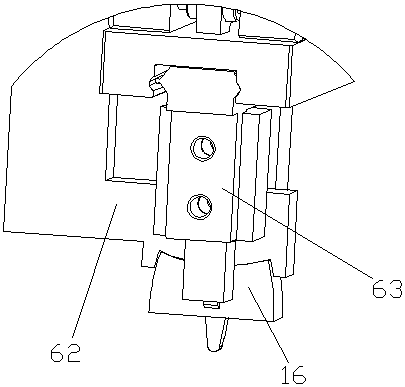

Automatic clamping and adsorbing mechanism

Owner:宁波镇海昕龙网络科技有限公司

Smashing and cleaning mechanism

InactiveCN108437282ANot easy to break awayReduce processing timePlastic recyclingMechanical material recoveryEngineeringSlide plate

The invention relates to the technical field of plastic processing, and particularly discloses a smashing and cleaning mechanism. The smashing and cleaning mechanism comprises a motor, a rotating drumand a storage bin, wherein the motor is connected with a rotating shaft, and the storage bin is connected with a discharge pipe. The rotating shaft is provided with a plurality of cutters for cuttingplastic, a plurality of rows of clapboards are connected with the inner wall of the rotating drum, the clapboards are provided with through grooves for the cutters to pass through, and openings are formed between the adjacent clapboards on the peripheral wall of the rotating drum. Rotating plates are hinged at the openings, torsion springs are installed at the hinging positions between the rotating plates and the rotating drum, and an arc-shaped baffle plate for abutting against the rotating plates is arranged beside the rotating drum. A plurality of first through holes are formed in the sidewall of the rotating drum, and a plurality of spray heads are installed at both ends of the rotating drum. The discharge pipe is slidingly connected with an inclined T-shaped sliding plate, the T-shaped sliding plate is provided with a second through hole, and a spring is connected between the T-shaped sliding plate and the outer wall of the discharge pipe. The rotating plates can abut against the T-shaped sliding plate, and a vertical rod capable of abutting against the rotating plates is connected to the outer wall of the discharge pipe. The smashing and cleaning mechanism can simultaneously clean and cut the plastic, the smashing and cleaning mechanism can work for a long time, and the efficiency is improved.

Owner:宁波隆锐机械制造有限公司

CPP film winding machine

PendingCN111137724ASmooth yaw movementYaw movement is reliableWebs handlingWinding machineControl theory

The invention discloses a CPP film winding machine. The CPP film winding machine comprises a swing frame, an edge clamping assembly, a guide roller assembly, an edge cutting assembly, a traction roller assembly, a tension roller assembly, a floating roller assembly used for controlling the winding flatness of a film, a fly-cutter assembly, a wind-up roll driving assembly, a roll changing assembly,an air expansion shaft clamping and exhausting device, a roll unloading trolley, an automatic film roll transferring device, rolling wheel devices, a swing frame driving device, a linear displacementsensor and a displacement detection device; and the linear displacement sensor feeds back a signal to the roll unloading trolley, so that the roll unloading trolley moves corresponding to the position of the swing frame during roll unloading to realize accurate positioning between the roll unloading trolley and an air expansion shaft. According to the CPP film winding machine, the swing frame issmooth and reliable in deflection movement, the film thickness deviation can be automatically adjusted, and the end face of a wound film is neat and free of wrinkling; and when the winding machine isused for winding, the swing frame and the roll unloading trolley can be accurately positioned, and automatic roll unloading by the swing frame in the swing period is achieved.

Owner:GUANGDONG SHICHENG PLASTIC MACHINERY

Plate automatic spraying equipment

InactiveCN107961930AHigh degree of automationImprove work efficiencySpraying apparatusMotor driveWork performance

The invention discloses a sheet metal automatic spraying equipment, which includes a material box, the material box is connected to a vertical screw rod through a lifting slider, and the vertical screw rod is fixedly connected to a first motor through a first bracket. One side of the large screw rod is provided with a large guide rod, and the large screw rod is connected to the unloading plate through a large slider, and the unloading plate is located above the spraying platform. The present invention has high degree of automation, easy operation, high work efficiency, and low energy consumption. The power source is provided by the first motor and the second motor, and the automatic feeding of the plate is realized by using the material box and the pushing plate as the execution parts, which saves labor costs. The third motor is used as the power source to drive the right screw rod and the left screw rod at the same time, and the spraying slider drives the nozzle to move along the surface of the plate. The working performance is stable and the spraying quality is high. The fourth motor drives the large screw rod to rotate, and then passes The large slider drives the unloading plate to translate along the surface of the spraying platform, and pushes the sprayed plate away from the spraying platform to realize automatic unloading.

Owner:董丽芳

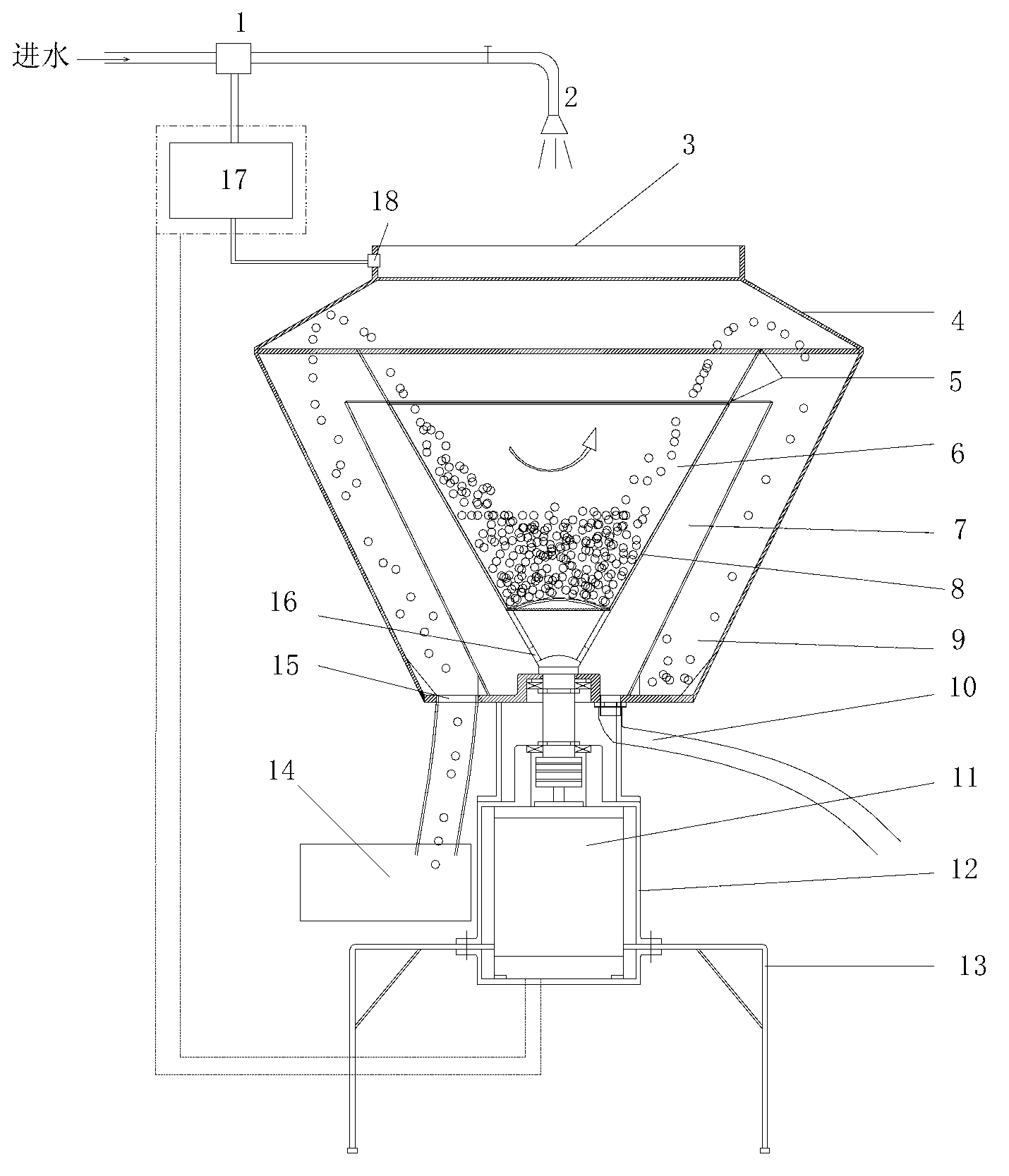

Full-automatic drill cutting cleaning machine and cleaning method thereof

The invention discloses a full-automatic drill cuttings cleaning machine, comprising a sand collecting cavity; a waste water holding cavity is arranged in the sand collecting cavity, a sand cleaning bucket is arranged in the waste water holding cavity, a motor is connected with the bottom of the sand cleaning bucket for driving the same to rotate, a water injection nozzle connected with a water intake pipe is arranged over the top of the sand cleaning bucket, a sensor is arranged on a sand conveying path, a high-pressure water pump is arranged on the water intake pipe, the output signal of the sensor is connected to a automatic controller. When in use, the cuttings to be cleaned is placed in the sand cleaning cavity; water is injected into the cuttings in the sand cleaning bucket; the motor drives the sand cleaning bucket to rotate so as to clean, dewater and throw the cuttings; the water released from the cuttings is drained from an outlet at the bottom of the waste water holding cavity; and the sand thrown out is collected after discharging from a sand outlet at the bottom of the sand collecting cavity. According to the cleaning method of the full-automatic drill cuttings cleaning machine, the cuttings are fully cleaned by combined effect of low-speed forward and reverse rotation and high-pressure water, the cleaning efficiency of the cuttings is improved, the automatic discharge of cuttings is realized, the cuttings is prevented from being secondarily damaged, the sand cleaning period is shortened, and the automatic sand cleaning process is realized.

Owner:XI'AN PETROLEUM UNIVERSITY

Open chain belt type barrel plating machine

ActiveCN102747410ASimple structureIncrease productivityElectrolysis componentsElectricityEngineering

The invention discloses an electro-plating device and specifically relates to an open chain belt type barrel plating machine. The open chain belt type barrel plating machine comprises an electro-plating slot, an anode plate, a cathode plate guide wire and a control device, wherein the control device is electrically connected with the anode plate and the cathode plate guide wire respectively; the open chain belt type barrel plating machine further comprises a chain belt, a transmission wheel for driving the chain belt to move left and right and a motor; the motor is electrically connected with the control device; the chain belt is arc-shaped and arranged in the electro-plating slot; the circle centre of the circular arc where the chain belt lies is arranged above the chain belt; a plurality of liquid through holes for passing bath solution are arranged on the chain belt; and an unloading mechanism is fixed at the left side of the electro-plating slot. The open chain belt type barrel plating machine is simple in structure, high in production efficiency, good in quality of the surface of a plated part and extensive in applicative component dimension range; moreover, the chain belt for bearing components is open so as to be capable of detecting the quality of plated work pieces at any time in a working status, thereby ensuring the product yield.

Owner:KUNSHAN DONGWEI MACHINERY CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com