Mixing station or mixing building and system for controlling mixing station or mixing building

A control system and mixing plant technology, applied in mixing plants, control devices, mixing operation control, etc., can solve the problems of high cost of control room and mixing plant, material hurting people, misjudgment, etc., to reduce the number of display devices , reduce labor intensity and avoid the effect of manual intervention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The present invention will be described in detail below in conjunction with the accompanying drawings. The description in this part is only exemplary and explanatory, and should not be regarded as limiting the technical content disclosed in the present invention.

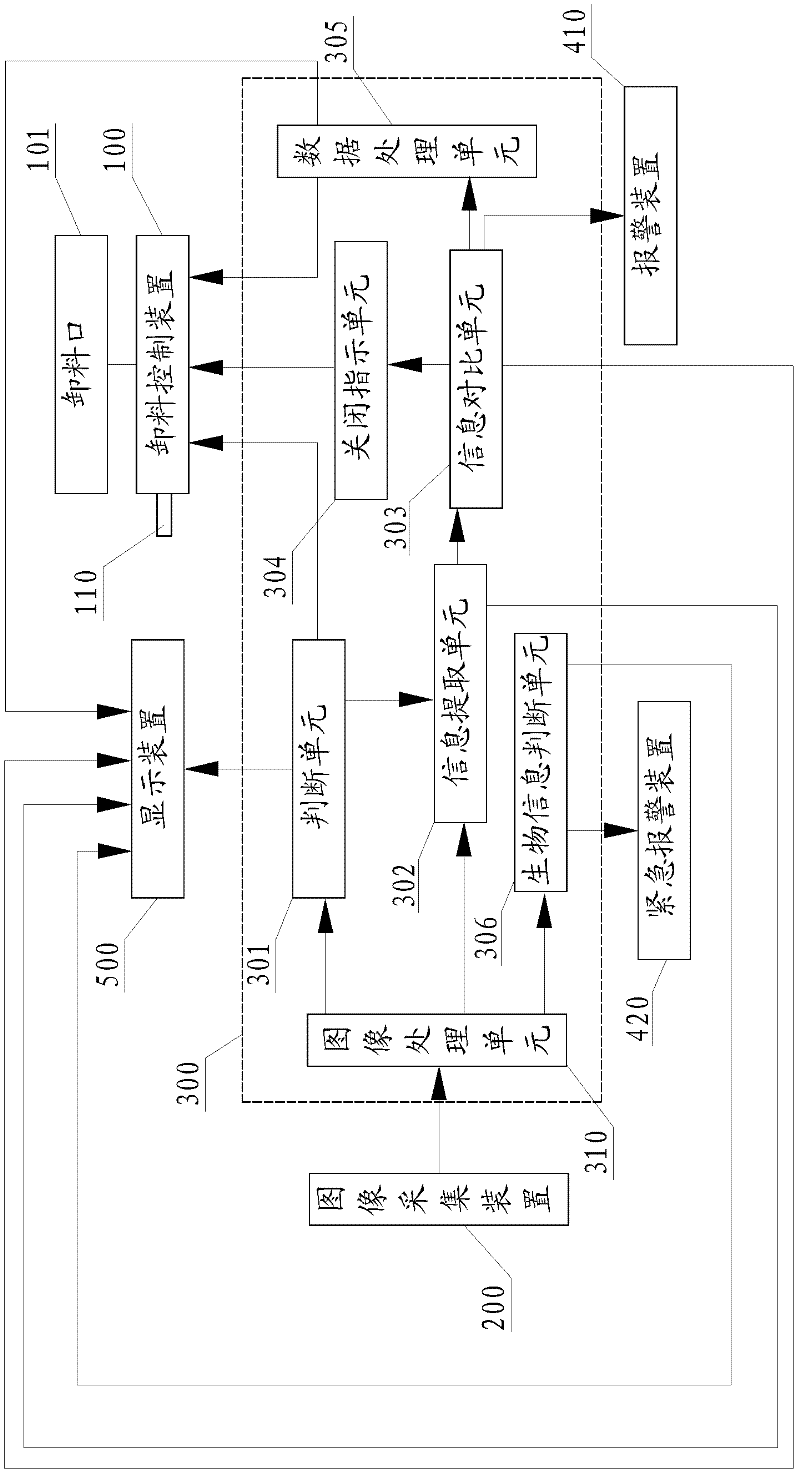

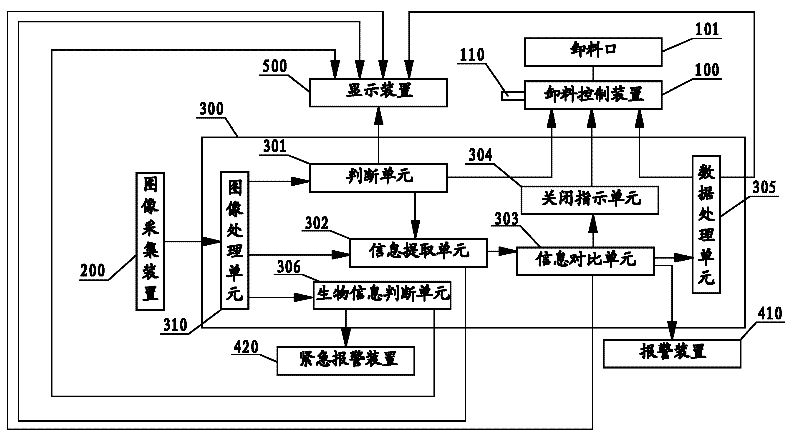

[0051] Please refer to figure 1 , which is a structural block diagram of the control system of the mixing station provided by the present invention; for the convenience of description, the figure also shows the discharge port of the mixing main engine.

[0052] The control system provided by the present invention includes a discharge control device 100 , an image acquisition device 200 , a display device 500 and a central processing device 300 . The central processing device 300 includes an image processing unit 310 and a judging unit 301 . Wherein, the output port of the image acquisition device 200 is connected to the input port of the image processing unit 310, the output port of the image processing unit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com