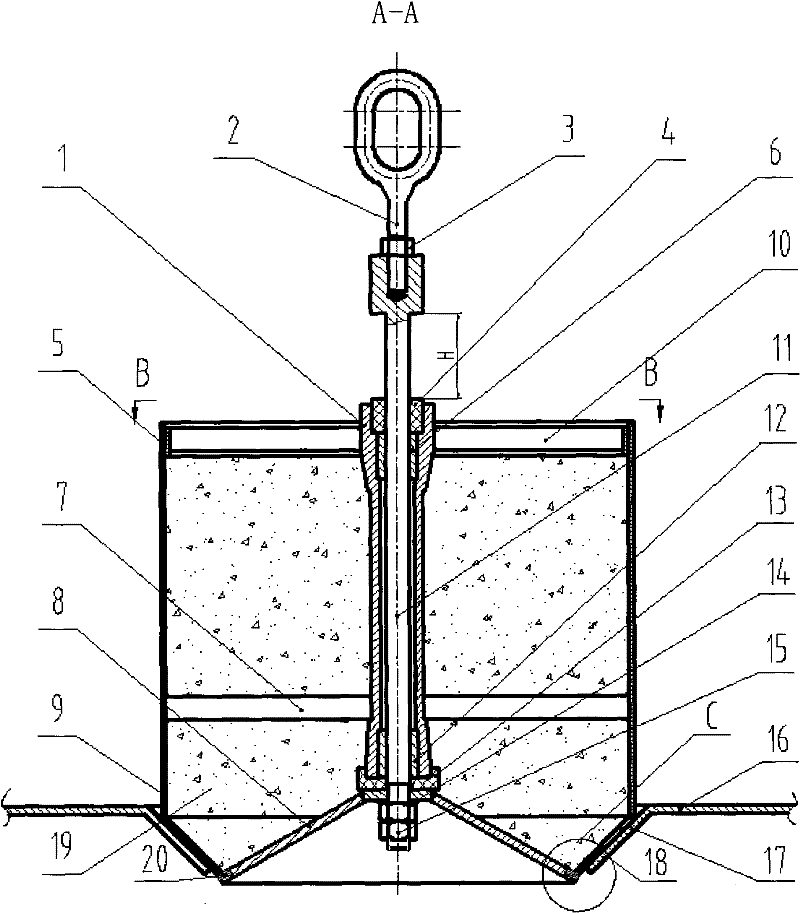

Open-bottom automatic discharging tank device

An automatic unloading and material tank technology, used in packaging, wrapping paper, transportation and packaging, etc., can solve the problems of inconvenient operation and low loading and unloading efficiency, and achieve the effect of avoiding manual operation, improving production efficiency and reducing friction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

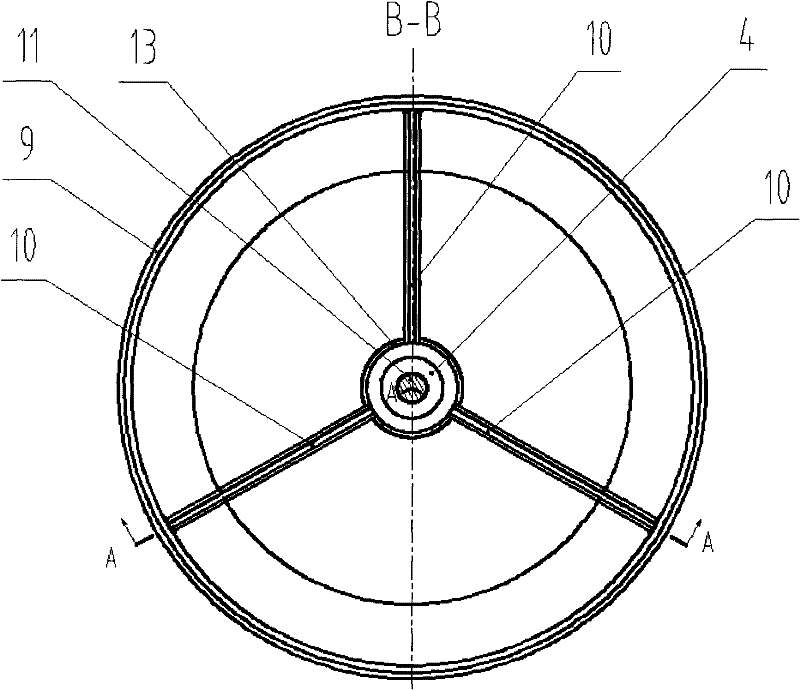

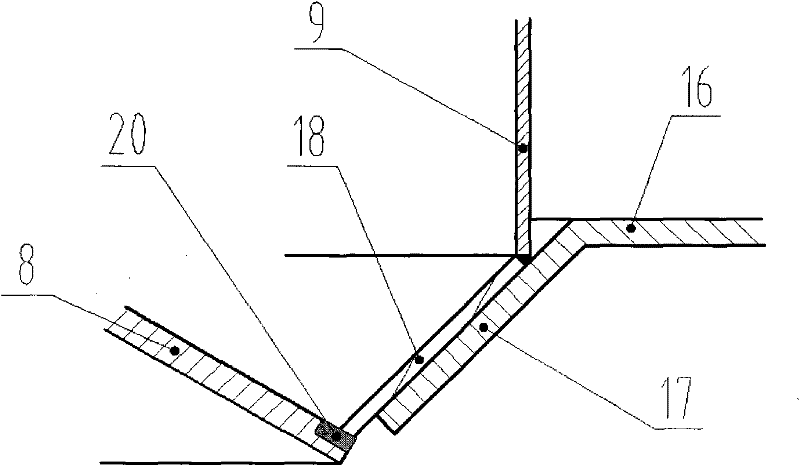

[0010] Such as figure 1 As shown, when the hoisting equipment lifts the material tank 9 by the suspension ring 2, the material bell 8 will automatically close the cone-shaped discharge port 18 below the material tank 9, and the material can be loaded in the material tank 9 at this moment, when the hoisting equipment will be filled with When the feed tank 9 of the bulk material 19 is hoisted above the feed bin 16 and the center of the feed tank 9 is aligned with the center of the trumpet-shaped opening 17 above the feed bin 16, it can be lowered to make the following cone-shaped discharge of the feed tank 9 Mouth 18 is aligned with the trumpet-shaped opening 17 above the material bin 16 and fits together, and the material bell 8, boom 11, lock nut 3 and suspension ring 2 can continue to descend. Under the action of the weight of the shape material 19, the suspension rod 11 descends the H distance, and the bulk material 19 is automatically discharged into the feed bin 16, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com