Assembling system for explosive-surface light and thin part of igniter

A technology for assembling system and igniter, which is applied to devices for coating liquid on the surface, connecting components, material gluing, etc., and can solve the problems of manual assembly and manual gluing of light and thin parts of igniter medicine surface.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0064] In order to understand the purpose, technical solutions and beneficial effects of the present invention more clearly, the present invention will be further described below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the following embodiments.

[0065] The assembly method of the light and thin parts of the igniter powder mainly includes the following steps: 1. Loading the igniter charge shell assembly to be assembled and coated with glue; 2. Assembling the light and thin parts into the hole of the igniter charge shell assembly 3. Coating glue on the inner wall of the igniter charge shell; 4. Unloading the igniter charge shell assembly that has been assembled and coated with glue.

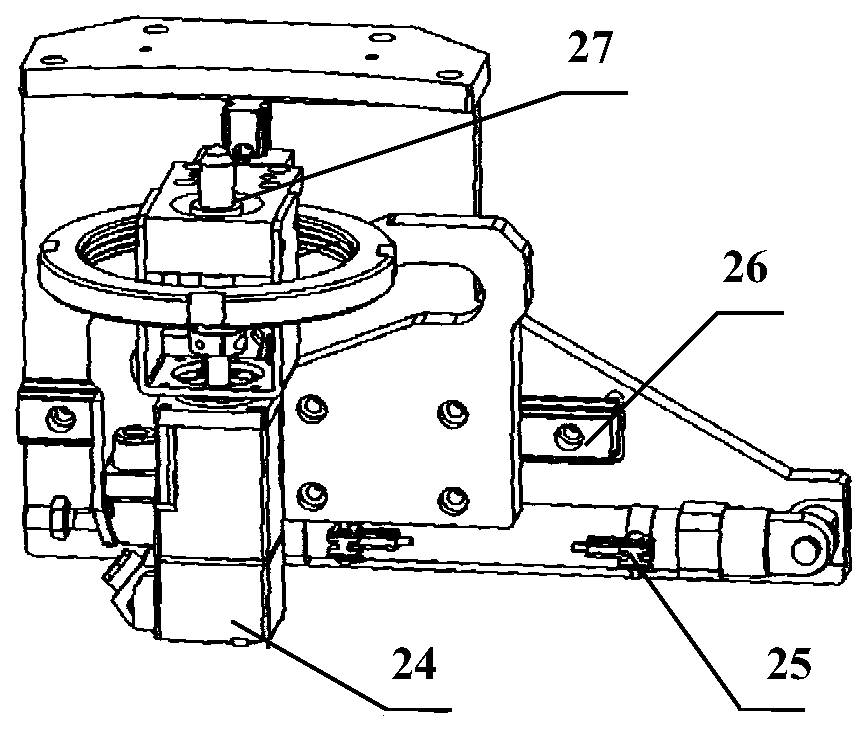

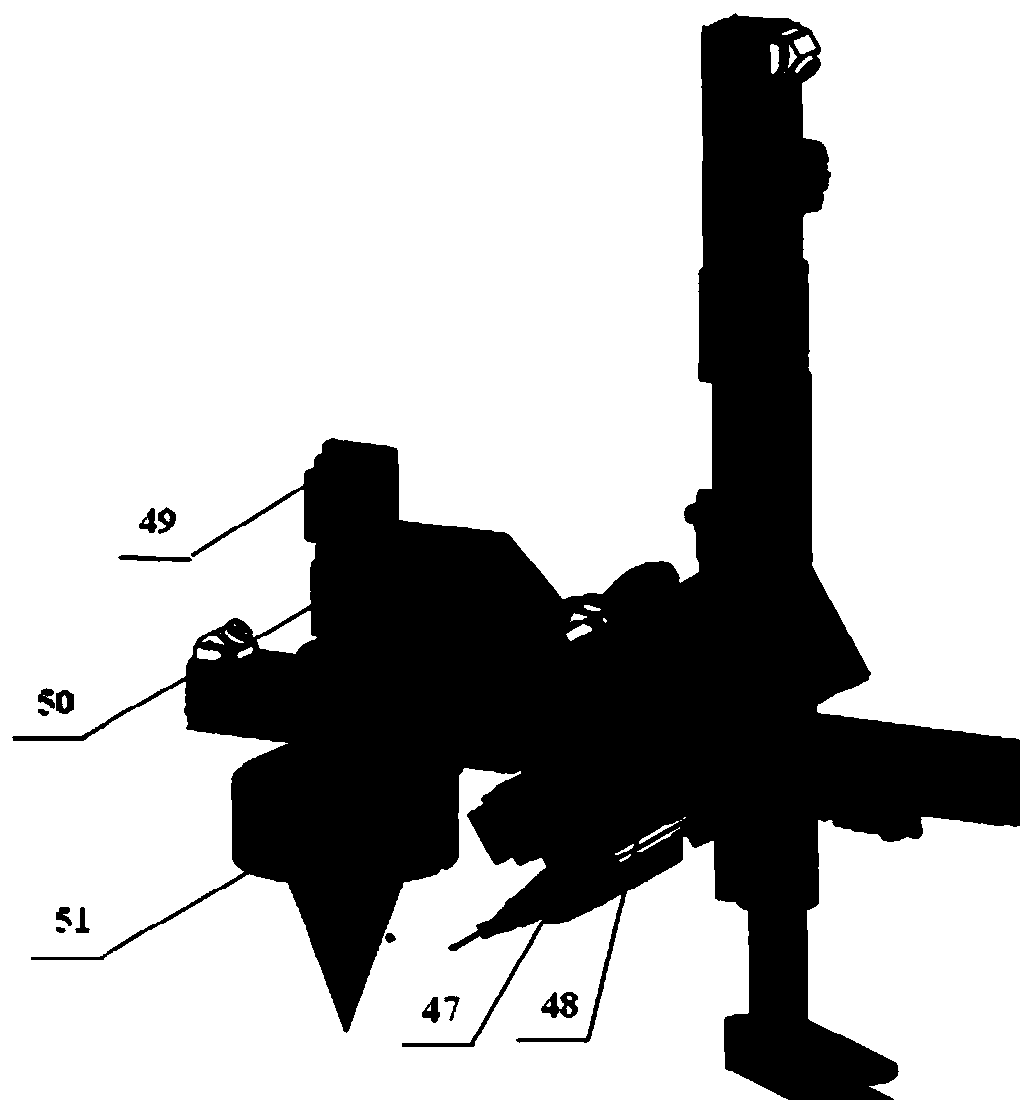

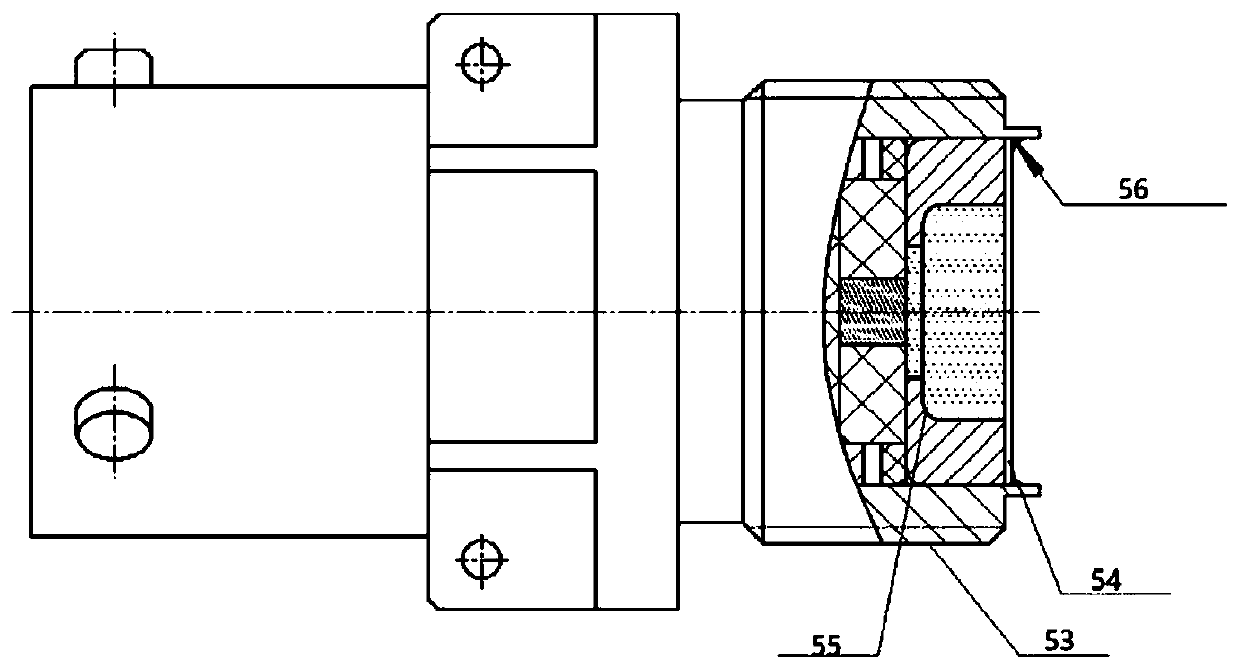

[0066] Based on the above-mentioned assembling method for the light and thin parts of the igniter powder, the present invention designs an assembly system for the light and thin parts of the igniter powder, such as figure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com