Automatic assembling device for assembly and detection of wiring terminal

A technology for connecting terminals and assembling devices, which is applied in the direction of testing dielectric strength, metal processing, metal processing equipment, etc., to save human resources and improve production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

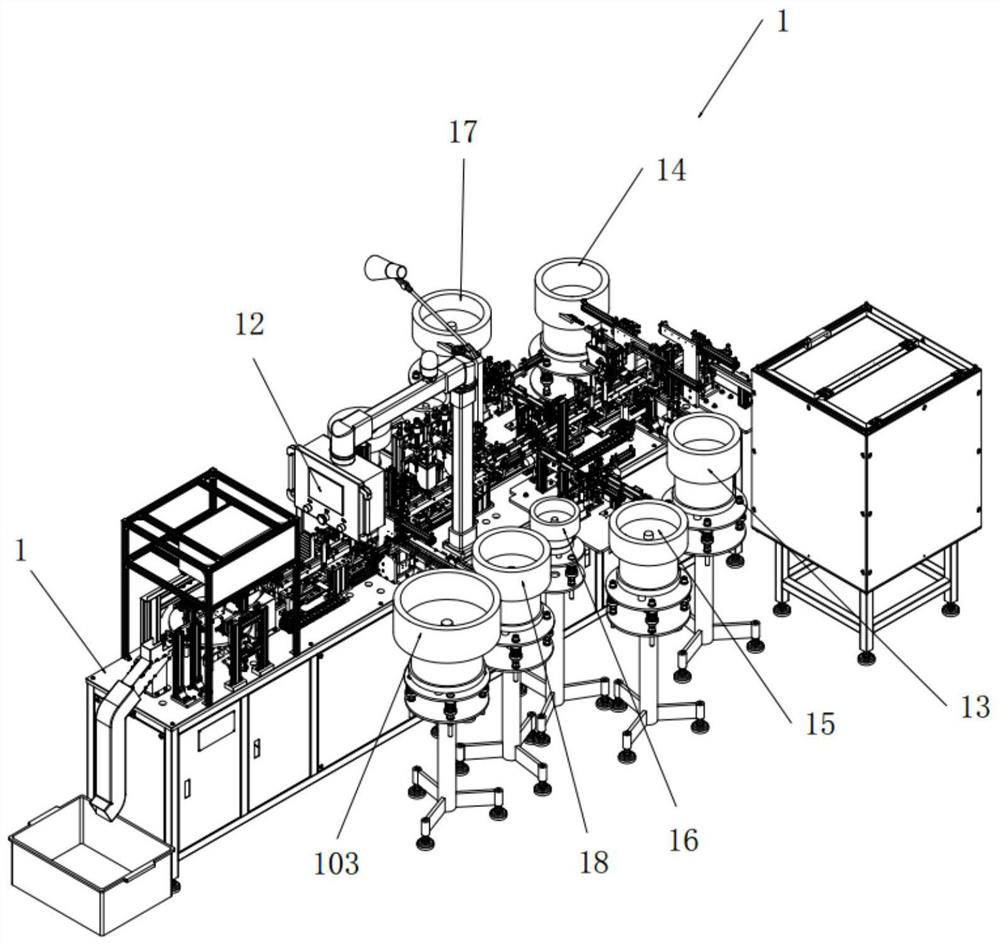

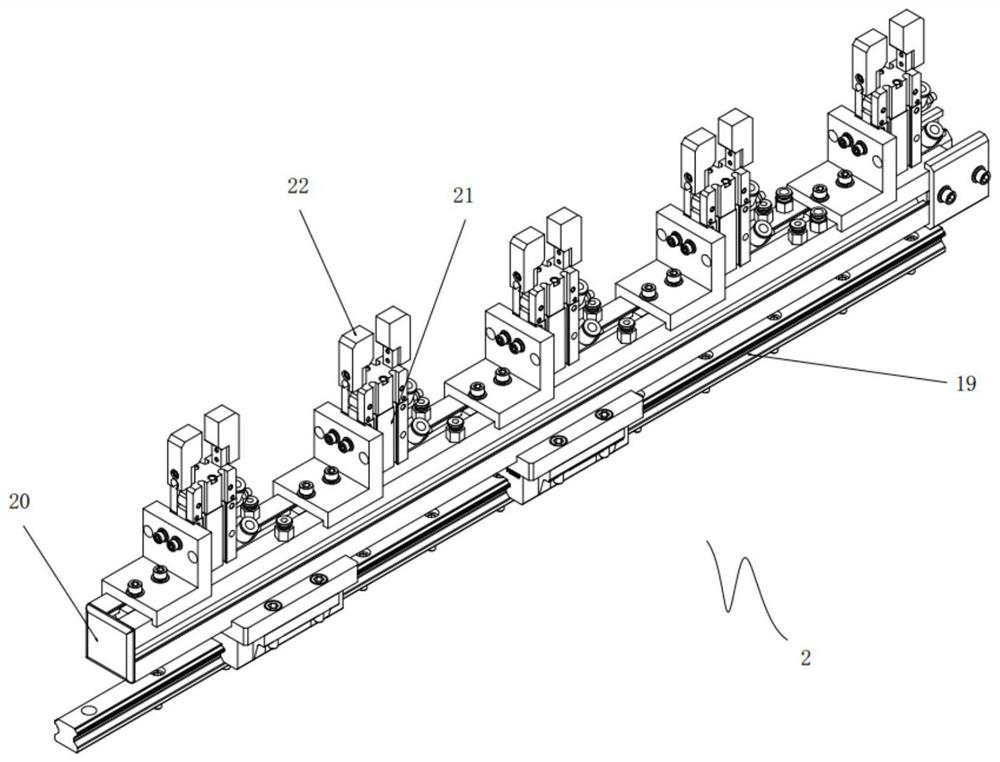

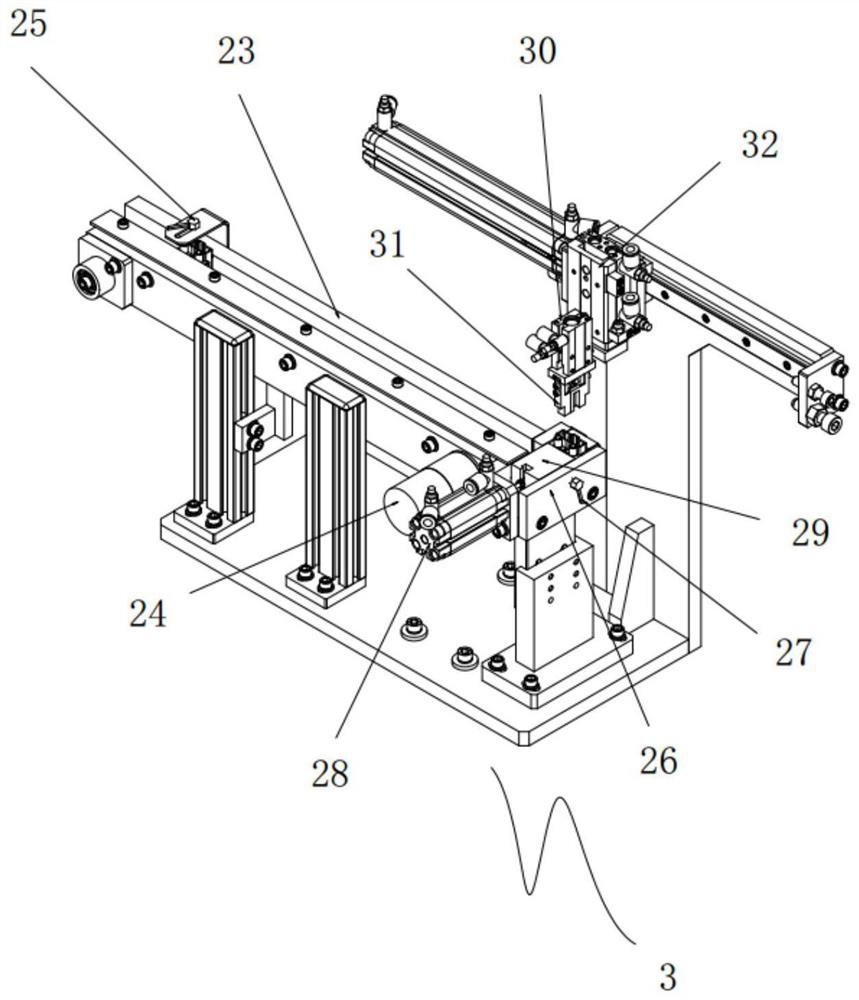

[0053] An automatic assembly device for terminal assembly and detection described in Embodiment 1, such as figure 1 As shown, it includes a workbench 1, and also includes a positioning jaw mechanism 2 installed on the workbench for positioning, clamping and transporting the column type insurance terminal shell, a shell installation mechanism 3 for installing the column type insurance terminal shell, and a safety tube The fixing piece is installed into the safety tube fixing piece installation mechanism in the column type insurance terminal shell 4. The fuse fixing piece correction mechanism is used to correct the fuse fixing piece 5. The fuse tube terminal wiring copper post and shrapnel are assembled and installed into the Assembling mechanism in the column-type safety terminal housing 6, screw-distributing mechanism for distributing screws 7, screw installation mechanism for installing screws into the column-type safety terminal housing 8, servo locking mechanism for screw i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com