Automatic loading and unloading device for batteries

An automatic loading and unloading, battery technology, applied in the direction of transportation and packaging, conveyors, conveyor objects, etc., can solve the problems of labor intensity, long time, slow feeding speed, etc., to reduce the time of battery loading and unloading. , the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

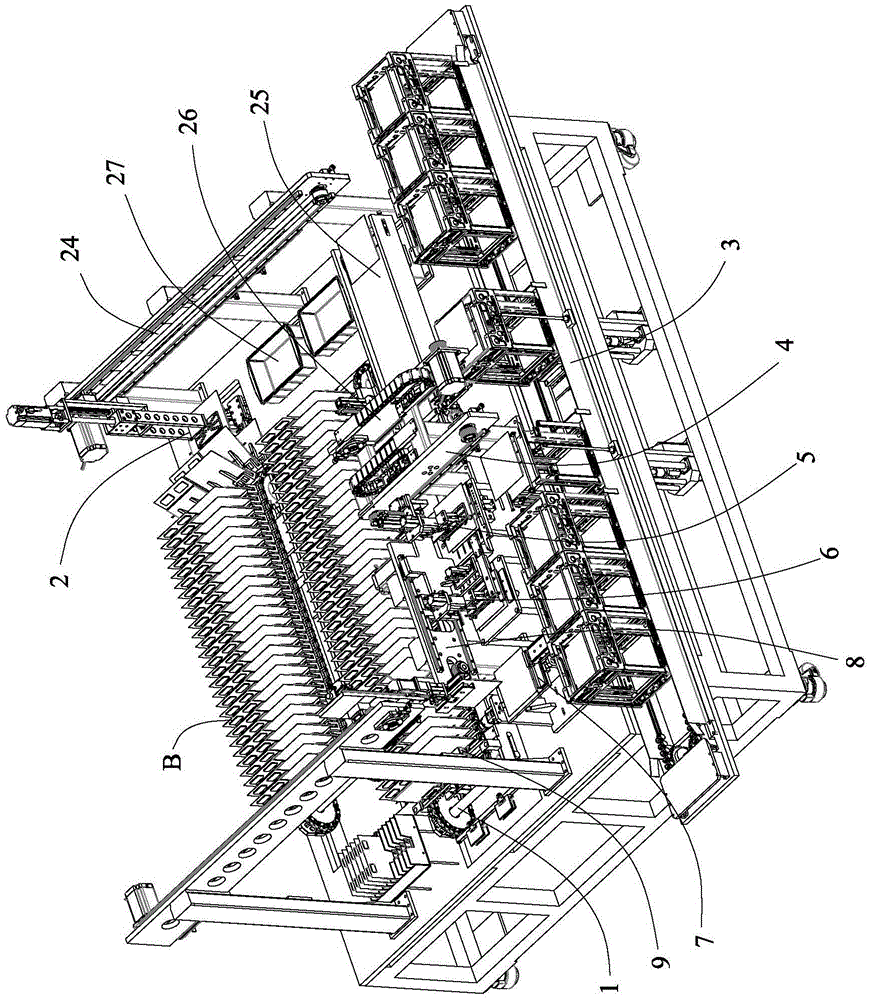

[0043] The battery automatic loading and unloading device of the present invention will be described in detail below with reference to the accompanying drawings.

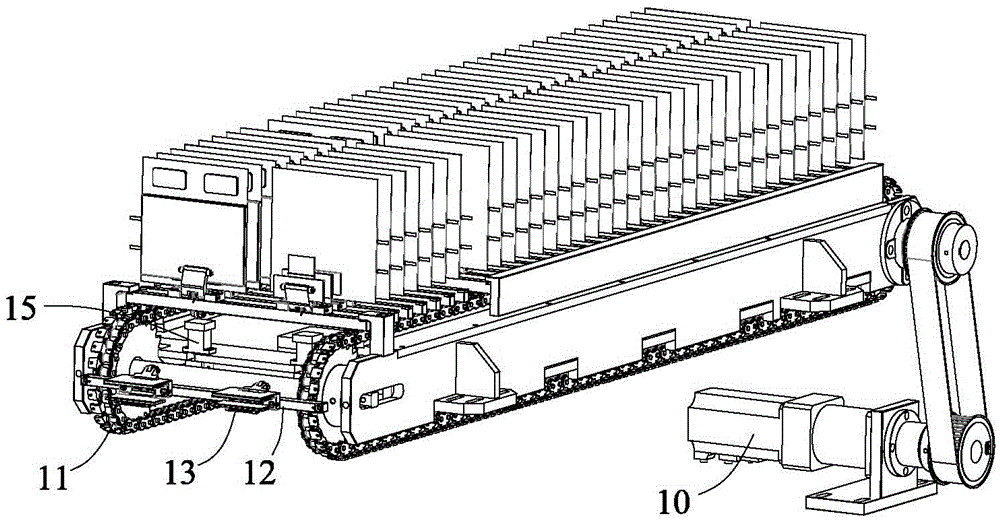

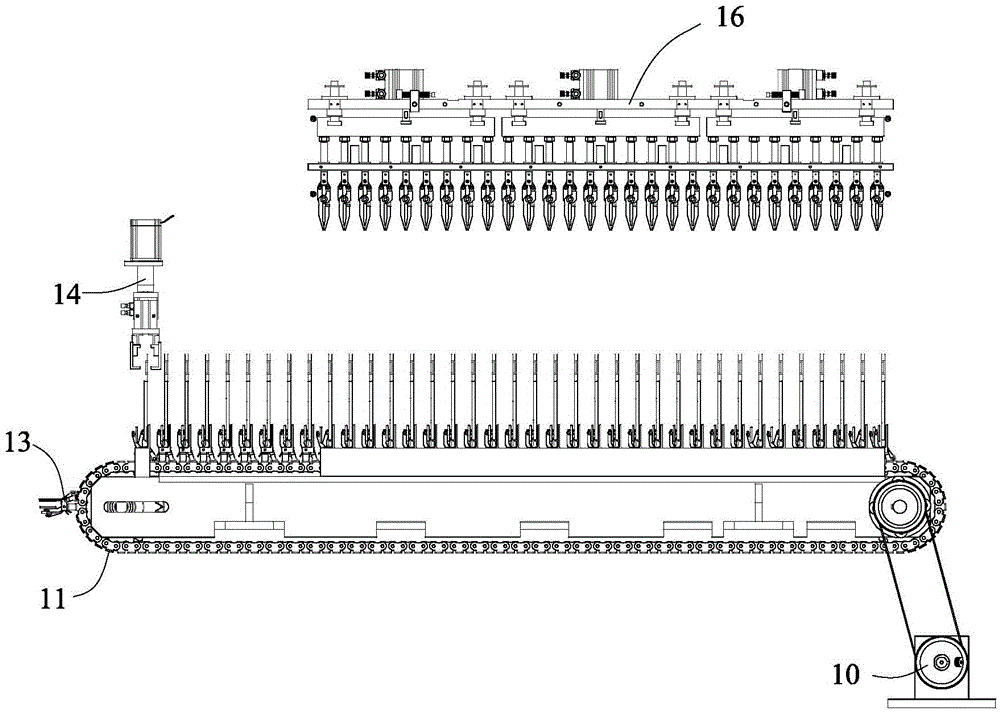

[0044] refer to Figure 1 to Figure 9 , according to the battery automatic loading and unloading device of the present invention, comprising: a feeding mechanism 1, which collects a plurality of batteries B and simultaneously moves them into external equipment for processing; and a feeding mechanism 2, which collects the processed batteries B.

[0045] Wherein, the feeding mechanism 1 comprises: a first power mechanism 10; a feeding transmission mechanism 11 driven by the first power mechanism 10 (such as a motor); a plurality of battery fixing mechanisms 13, each battery fixing mechanism 13 being arranged on the feeding transmission mechanism 11 and driven by the feeding transmission mechanism 11; the feeding manipulator 14 moves the battery B to the relative battery fixing mechanism 13; the opening mechanism 15 co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com