Self-locking bottom opening trough

A trough and self-locking technology, applied in the field of metallurgy, achieves the effect of simple structure and reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

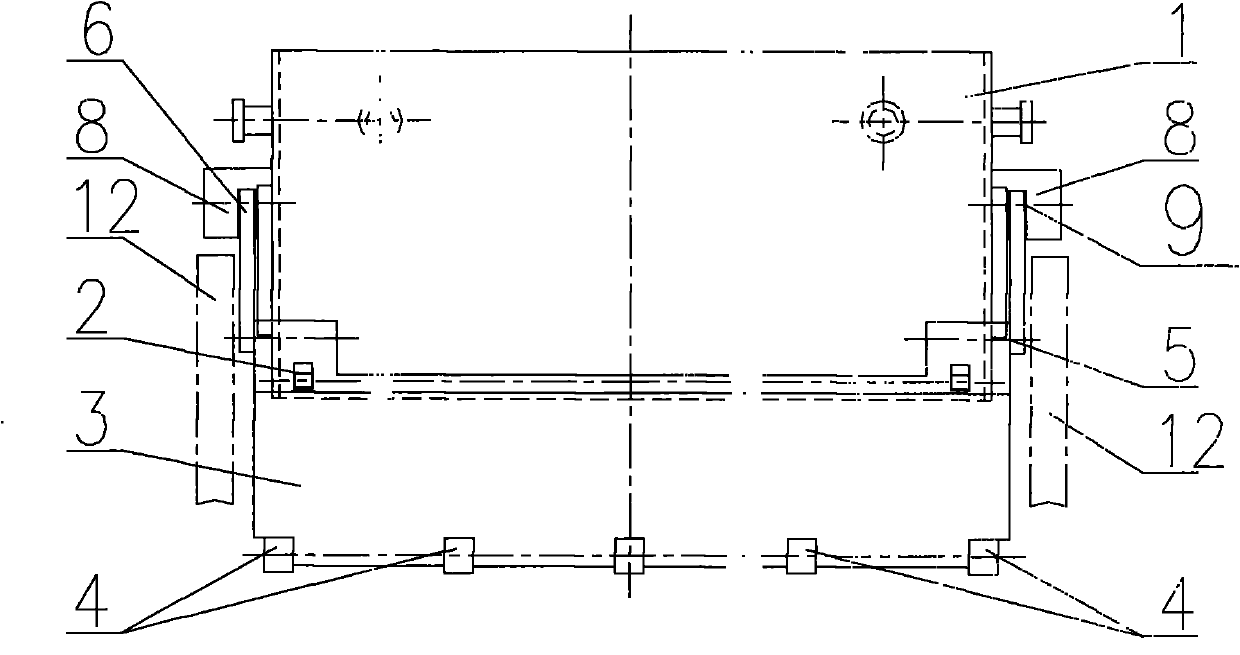

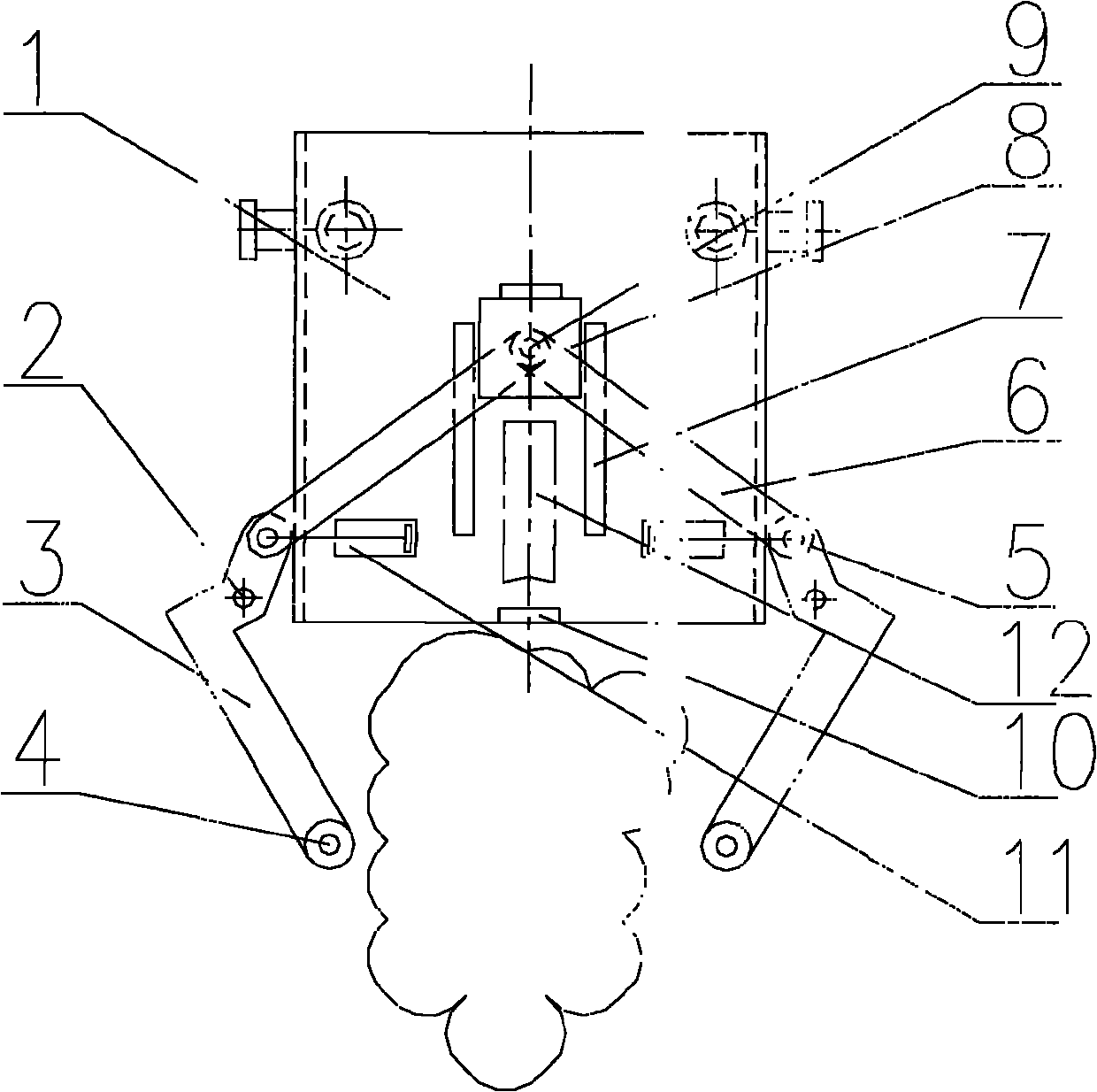

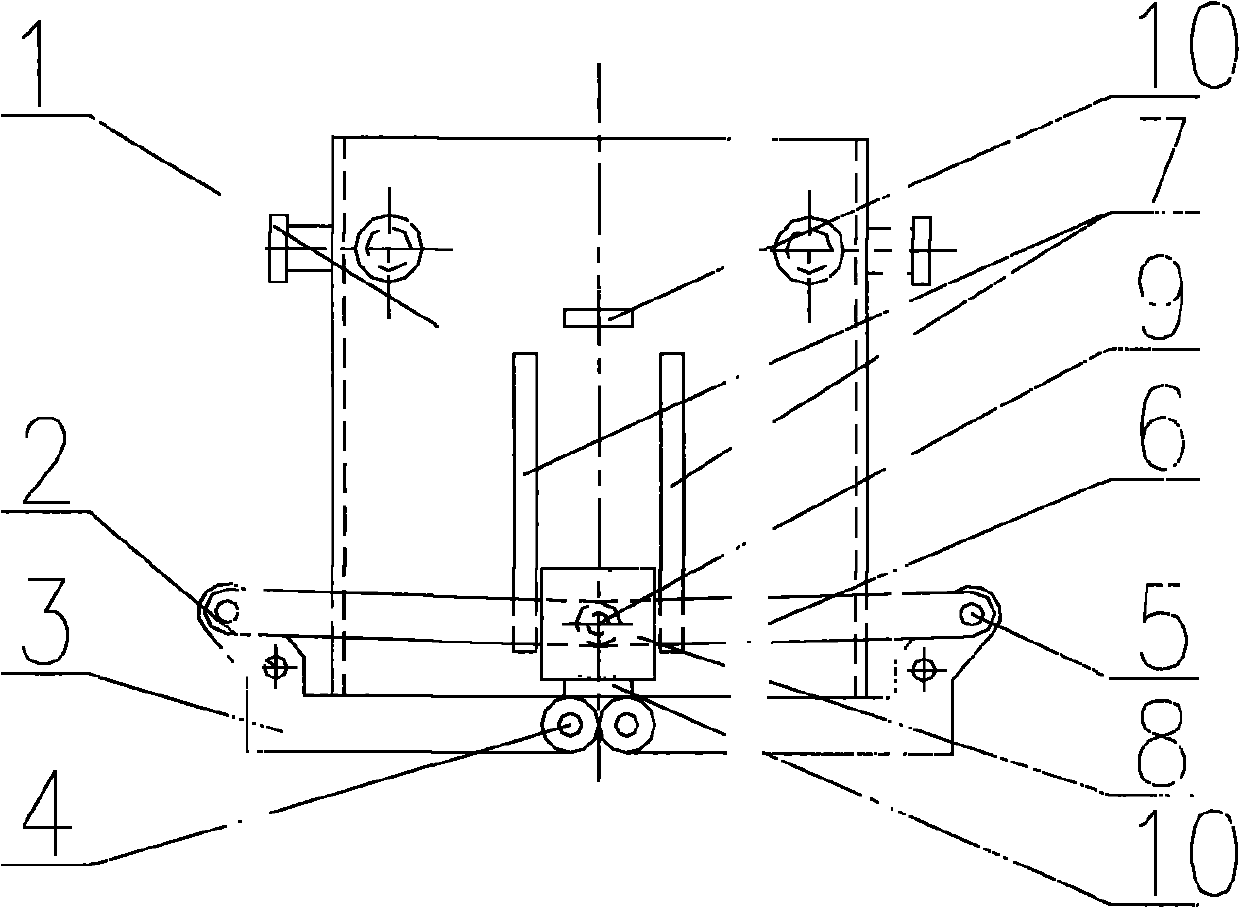

[0019] An embodiment, a self-locking bottom opening chute, including a chute 1, two swing doors 3 are arranged at the bottom of the chute 1, and the swing door 3 is connected to the chute 1 through the hinge axis A2 and can swing around the hinge axis A2 , the two sides of the trough 1 are provided with a weight slider 8, the weight slider 8 is connected with the swing door 3 through the connecting rod 6 and an external support 12 is arranged below;

[0020] The connecting rod 6 is hinged with the swing door 3 through the hinge shaft B5, and is hinged with the weight slider 8 through the hinge shaft C9;

[0021] A guide rail 7 is provided on the side wall of the trough 1, and the weight slider 8 moves up and down along the guide rail 7;

[0022] A limit block 10 is provided below the guide rail 7;

[0023] Dampers 11 are arranged on both sides of the trough 1;

[0024] The lower edge of the swing door 3 is provided with a roller 4;

[0025] The trough 1 is a cube, and can a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com