Laser cutting device

A technology of laser cutting and equipment, applied in laser welding equipment, welding equipment, metal processing equipment and other directions, can solve the problems of complex structure of sorting robot equipment, complex structure of laser cutting machine tools, inability to identify different finished parts well, etc. The effect of reducing deviation, precise cutting, automatic blanking, and precise cutting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

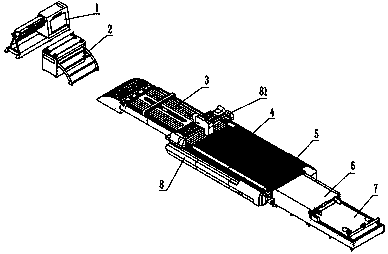

[0091] The overall structure of the laser cutting equipment of the present invention is as follows: figure 1 As shown, the laser cutting equipment is provided with a main bed 8 and is provided with the following working units from back to front, that is, a feeder 3, a clean material cutting area 4, a rotary table 5, a conveyor 6 and a stacker 7. The material cutting area 4 and the rotating worktable 5 are fixed together on the main bed 8, and the rest of the working units are fixed on the ground by anchor bolts; the main bed 8 is also provided with a laser cutting head assembly 81. Set above the clean material cutting area 4 and the rotary table 5. During specific implementation, a leveler 2 and a material rack 1 are also provided at the rear of the feeder 3, and the leveler 2 is provided with a leveler roller, which can roll the coiled sheet material flat, which is beneficial to feeding and laser cutting; The specific structures and usage methods of the material rack and the...

Embodiment approach 2

[0137] Figure 16 It shows the overall structure of another laser cutting equipment of the present invention. The laser cutting equipment is provided with a main bed 8 and is provided with the following working units from back to front, namely material rack 1, leveling machine 2, feeder 3, clean material cutting Area 4, rotating table 5, conveyor 6 and stacker 7, the clean material cutting area 4 and rotating table 5 are fixed on the main bed 8 together, and the rest of the working units are fixed on the ground by anchor bolts ; The main bed 8 is also provided with a laser cutting head assembly 81, and the laser cutting head assembly 81 is arranged above the clean material cutting area 4 and the rotating table 5;

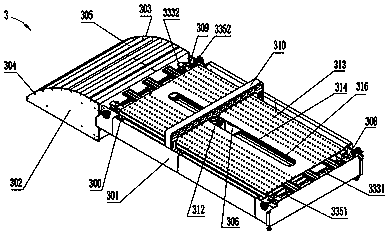

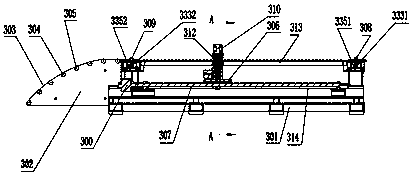

[0138] Feeder for laser cutting equipment 3 such as Figure 17-18 As shown, the feeding machine 3 is provided with a feeding machine body 301 and a feeding idler 302, and the feeding idler 301 is arranged at the rear end of the feeding machine body 301; the feeding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com