Patents

Literature

308results about How to "Achieve continuous operation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

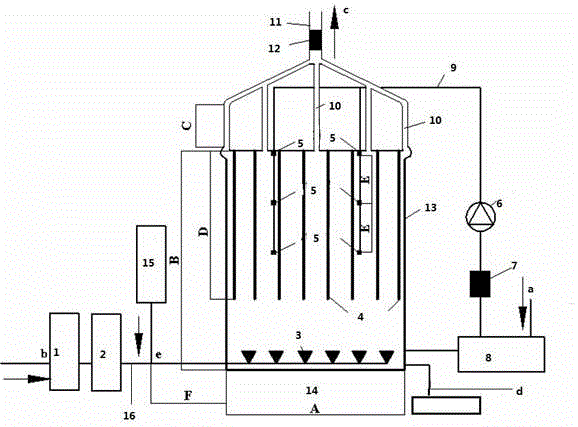

Industrial Wastewater Microwave Electrodeless UV Photocatalysis-Double Membrane Separation Coupling Treatment Device

InactiveCN102260003AAchieve coolingShort wavelengthWater/sewage treatment by irradiationWaste water treatment from animal husbandryIndustrial waste waterDecomposition

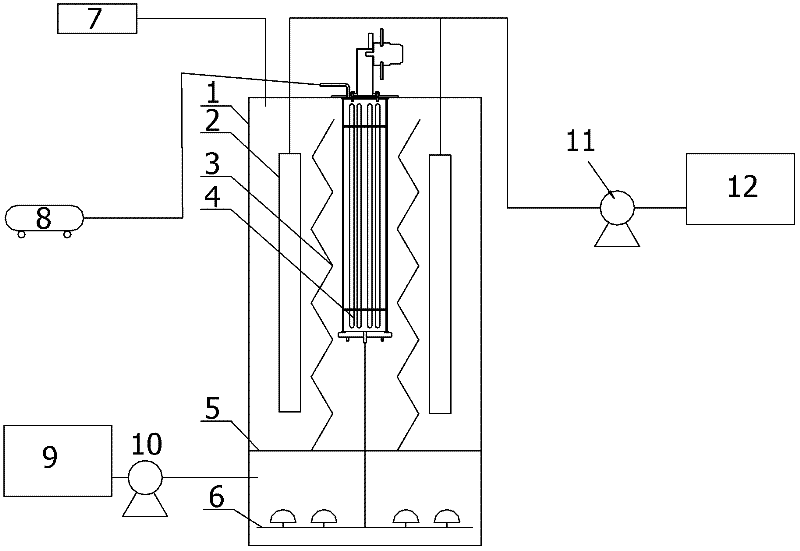

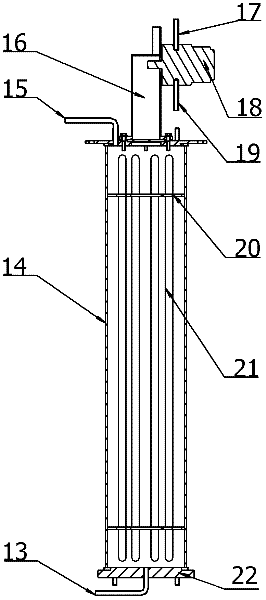

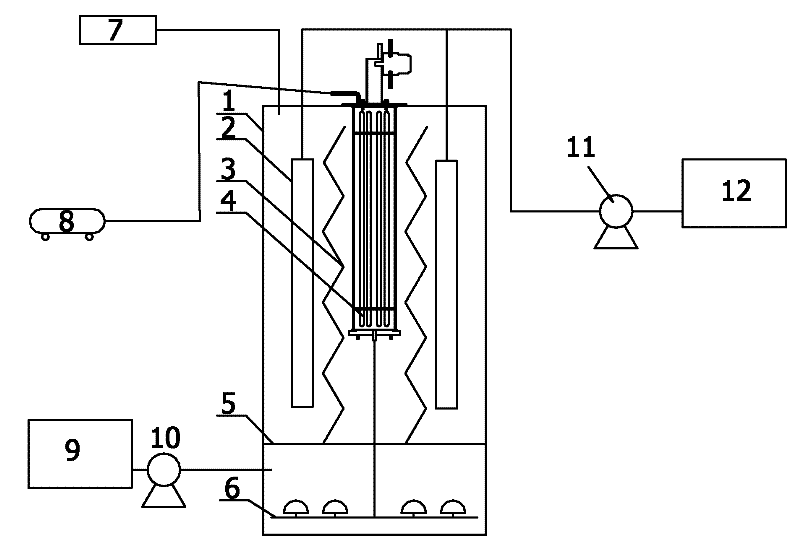

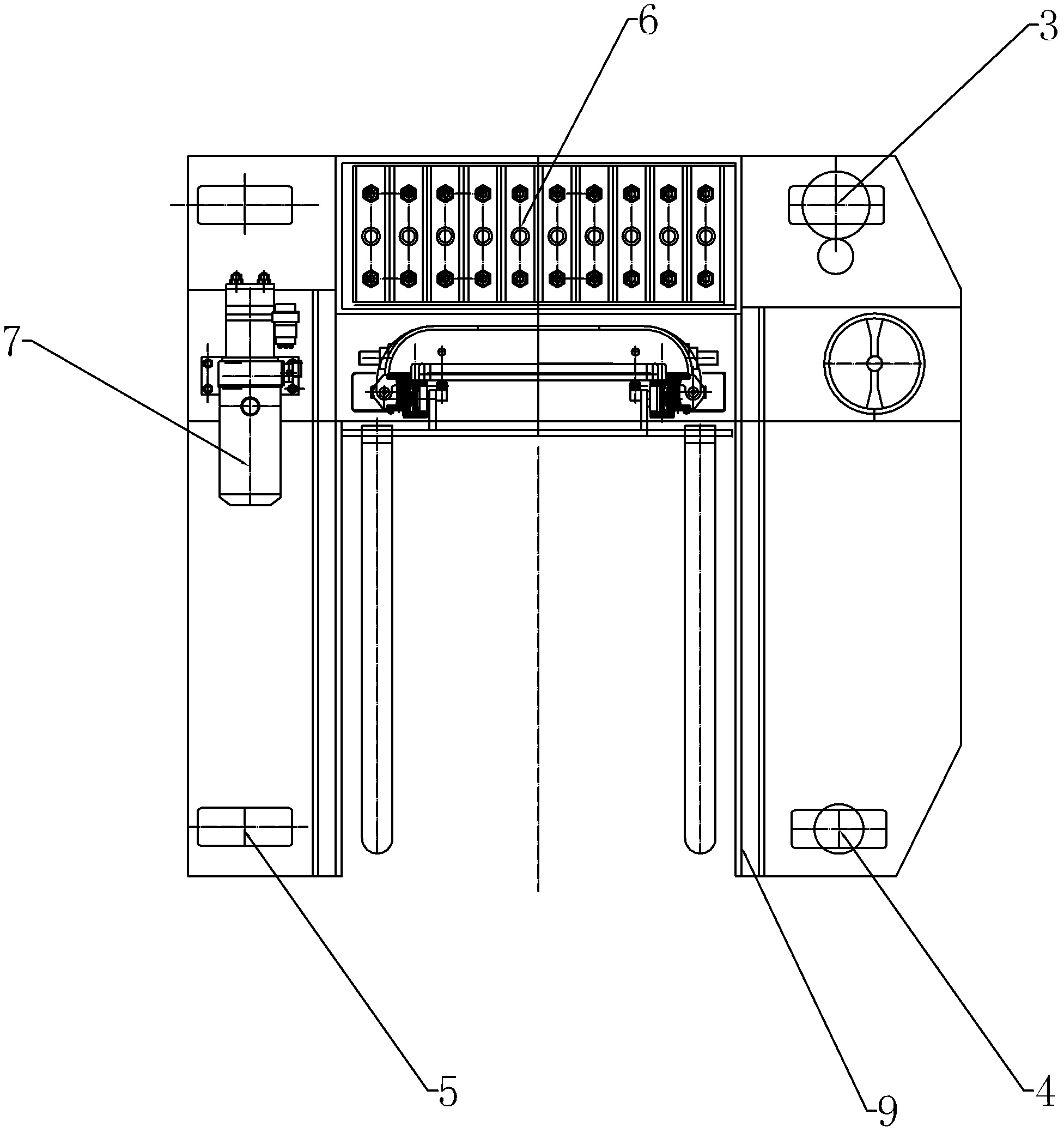

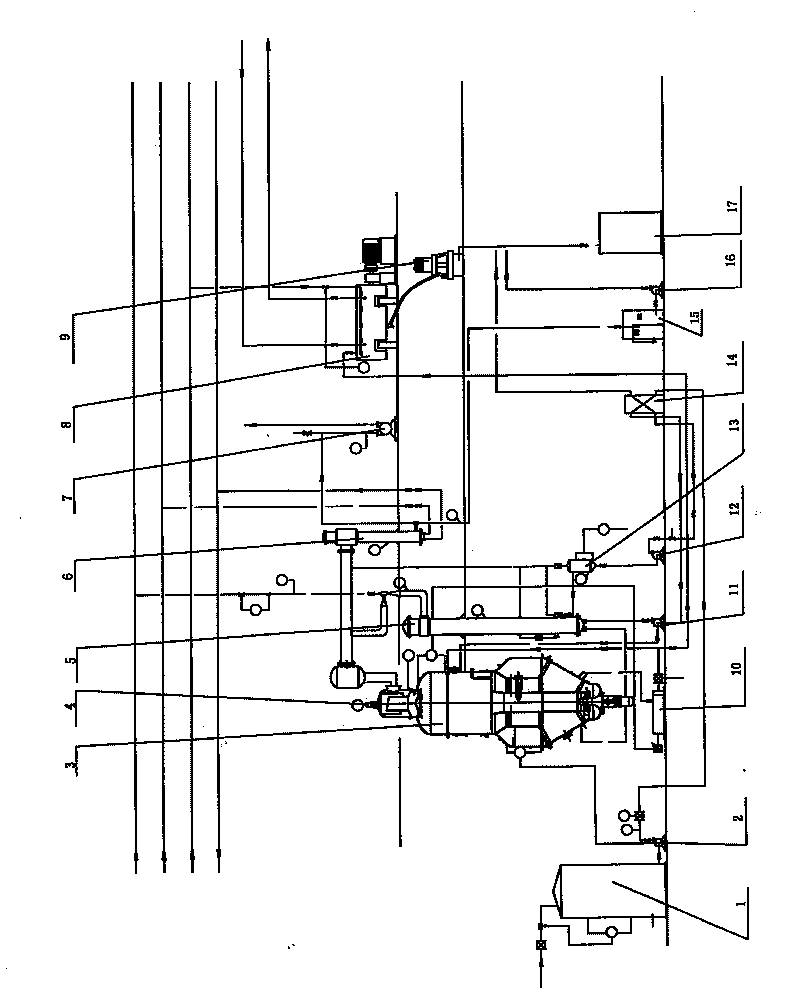

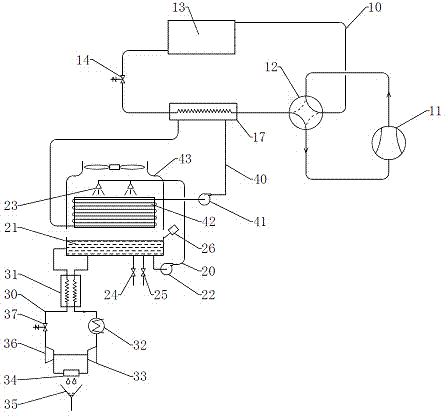

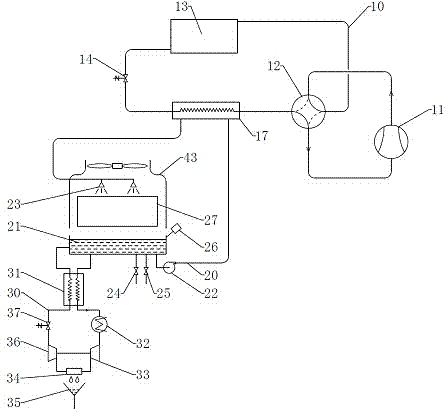

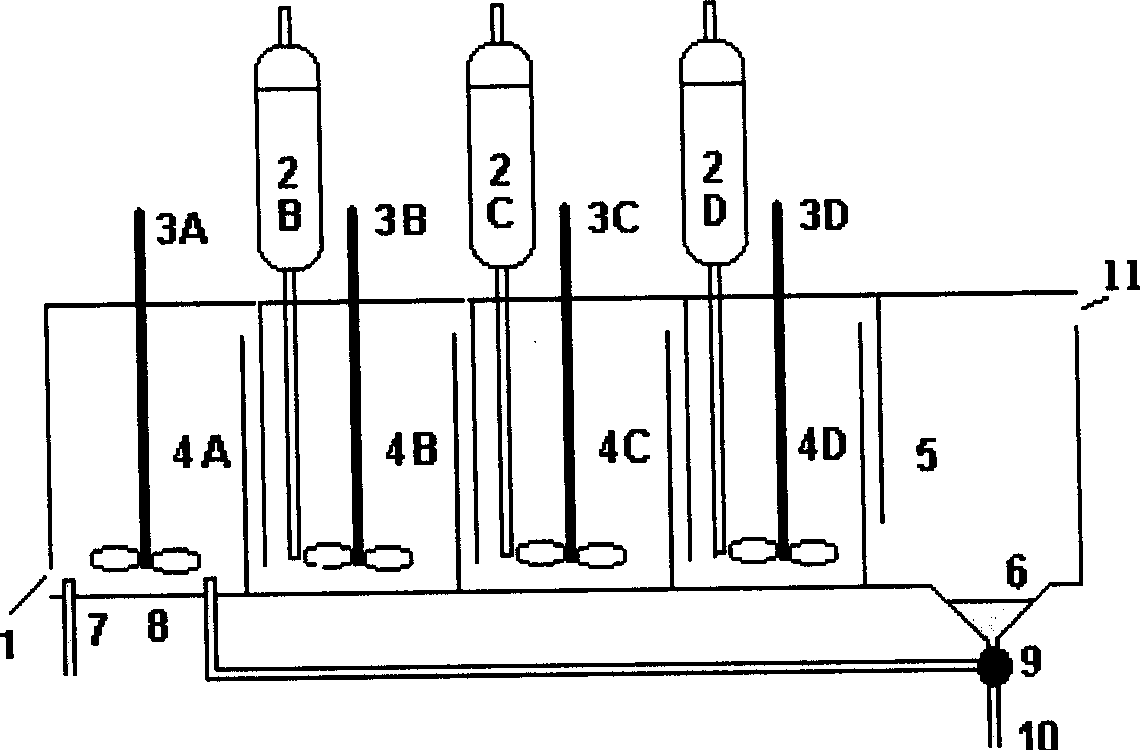

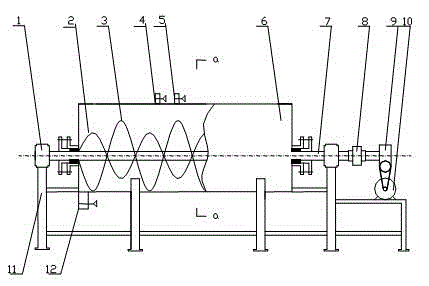

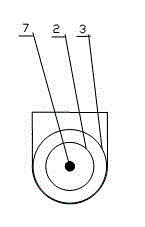

The present invention is an industrial waste water microwave electrodeless ultraviolet photocatalysis-dual membrane separation coupling treatment device, the device mainly consists of a reactor (1), a membrane separation system (2), a microwave electrodeless ultraviolet light source system (4), an aeration system, and an ozone tail gas decomposition device (7) connected to the reactor, and an inlet and outlet water system, wherein: the upper and lower parts of the reactor are respectively the reaction zone and the aeration zone, which are separated by a water distribution plate (5); the membrane separation system The microwave electrodeless ultraviolet light source system is located in the reaction zone and is separated by a corrugated partition (3); the aeration system is composed of a microporous aeration head (6) and a blower (8), and the microporous aeration head is located in the aeration At the bottom of the zone, the blower sends air to the aeration zone through the air duct. The invention has the characteristics of high reaction rate, complete degradation of organic matter, long-term operation and the like, and has strong operability and high safety. It is suitable for the treatment of refractory organic industrial wastewater, and it is also suitable for sterilization and disinfection in the field of water supply.

Owner:WUHAN TEXTILE UNIV

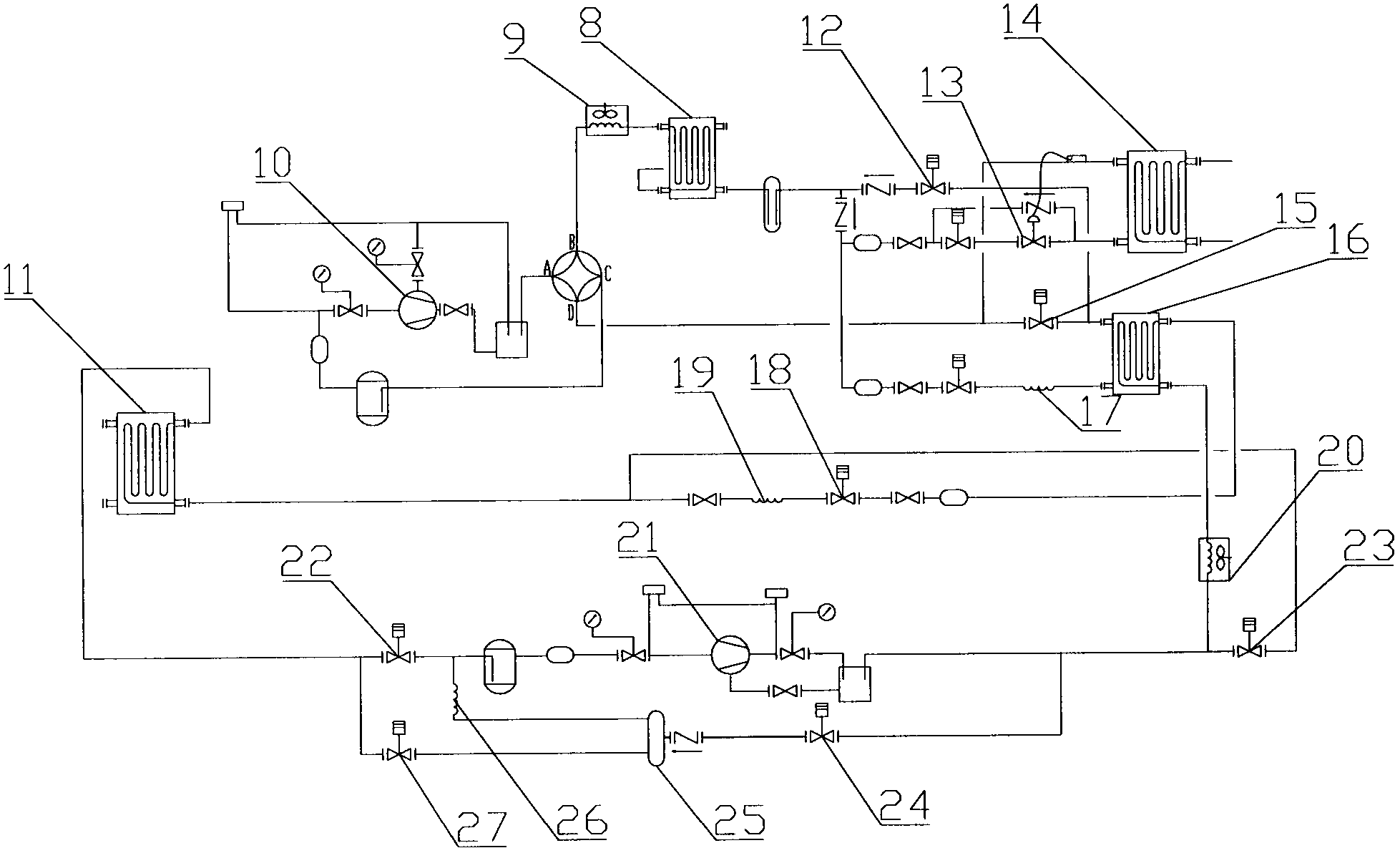

Stepped refrigerating system and method for recovering oil gas and defrosting method

ActiveCN102706024AImprove energy efficiency ratioFast heat transferCorrosion preventionCompression machines with cascade operationBusiness efficiencyProcess engineering

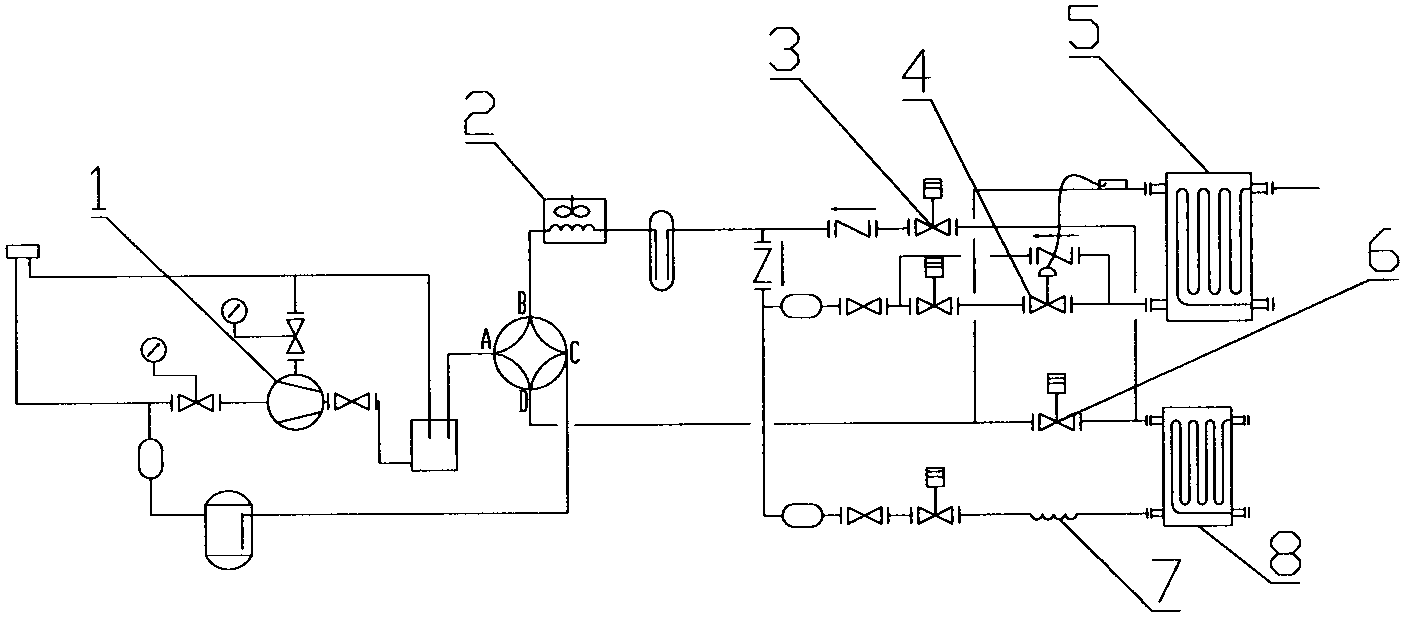

The invention relates to a stepped refrigerating system for recovering oil gas, which comprises a primary refrigerating system, a secondary refrigerating system and a tertiary refrigerating system, wherein the primary refrigerating system is connected with the secondary refrigerating system connected with the tertiary refrigerating system. The invention has the benefits that a refrigerant in a hot steam manner is directly used for performing the phase change defrosting (hot freon defrosting), and the energy efficiency ratio is high. Since the hot freon defrosting is carried out in a heat exchanger, so that the heat transfer speed and the defrosting speed are high, the defrosting time of a primary oil gas condenser and a secondary oil gas condenser is within 15 minutes, and the defrosting time of a tertiary oil gas condenser can also be within 30 minutes. The defrosting time is saved greatly.

Owner:上海森鑫新能源科技有限公司

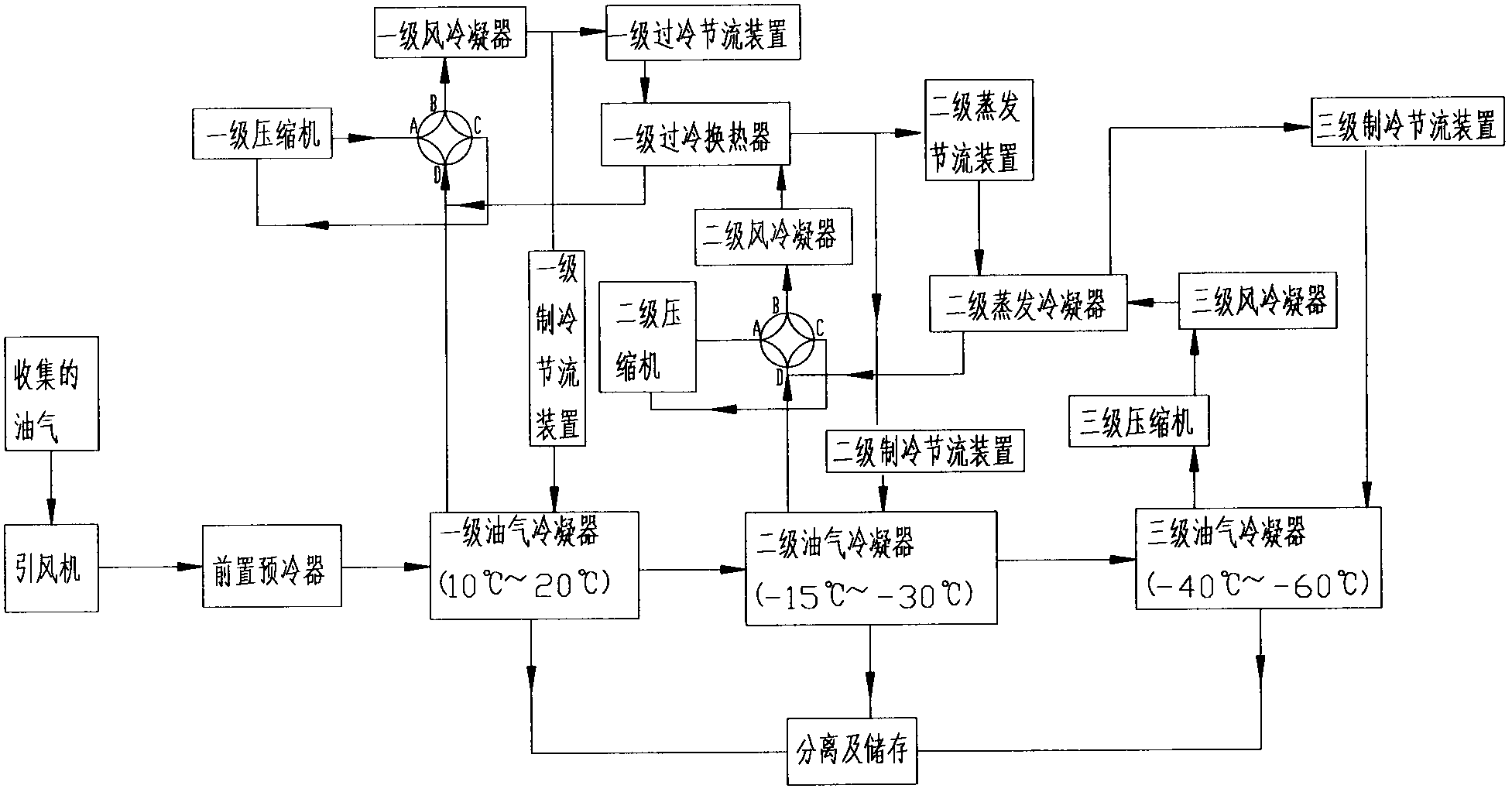

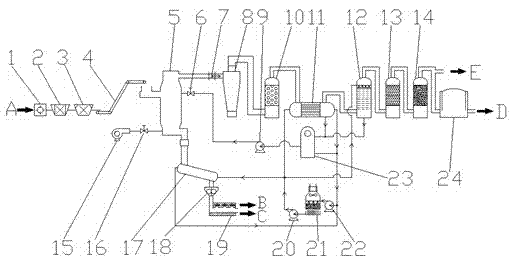

Energy-saving recycling treatment disposal system and energy-saving recycling treatment disposal process for organic solid waste

InactiveCN104944732AImproved anaerobic biodegradabilityImprove the efficiency of anaerobic digestionSludge treatment by de-watering/drying/thickeningSolid waste disposalExternal energyWaste treatment

The invention relates to an energy-saving recycling treatment disposal system and an energy-saving recycling treatment disposal process for an organic solid waste. The energy-saving recycling treatment disposal process mainly comprises a continuous sludge pyrohydrolysis anaerobic digestion section, a sludge dehydration heat drying section and a dry sludge, domestic garbage and biogas mixing incineration section. Due to the energy-saving recycling treatment disposal system and process disclosed by the invention, the innocent treatment of kitchen garbage, municipal sludge and the domestic garbage can be thoroughly realized by combining a high-temperature sludge anaerobic digestion technology with the high-organic matter characteristic of the kitchen garbage by utilizing respective characteristics of three solid wastes, applying a solid waste high-temperature incineration technology of mixed biogas, adopting a reasonable energy resource integrated means and applying an advanced high-temperature continuous pyrohydrolysis pretreatment technology. In addition, the energy-saving recycling treatment disposal process disclosed by the invention can also be used for realizing the recycling of the three solid wastes, improving the energy resource utilization efficiency of an integrated system, effectively reducing the input of external energy resources and reducing the operation cost. The energy-saving recycling treatment disposal process disclosed by the invention is capable of realizing the continuous operation of solid waste treatment, simple and reliable, simple in equipment, small in initial investment and has good environmental and economic benefits.

Owner:TONGJI UNIV

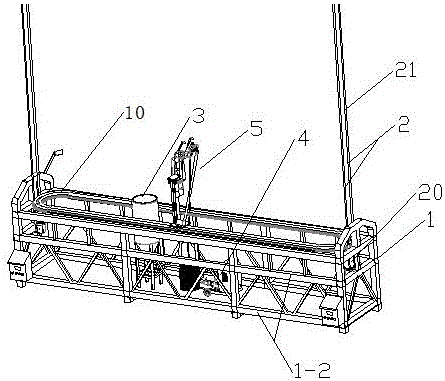

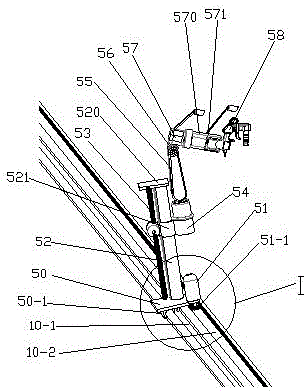

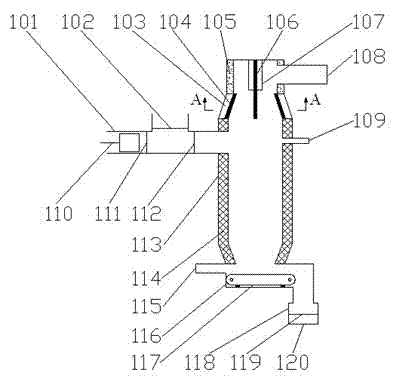

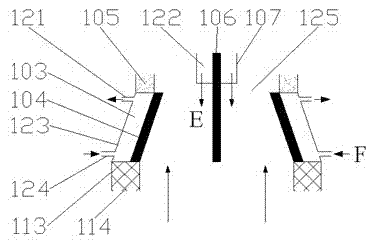

Intelligent robot for spraying outer wall of high-rise building

ActiveCN106695830ARealize intelligent controlEasy to controlProgramme-controlled manipulatorBuilding constructionsElectric machineHigh rise

The invention provides an intelligent robot for spraying the outer wall of a high-rise building and belongs to the technical field of high-rise building outer wall spraying equipment. The intelligent robot has the beneficial effects that the perpendicular movement of an automatic spraying mechanical arm can be adjusted; a supporting rod is inlaid in a fixing sleeve A; a rotating shaft A is hinged to the top of the supporting rod; one end portion of the rotating shaft A is connected with an output shaft of a servo motor A; the other end of the rotating shaft A is connected with a rotating seat; a fixing sleeve B of the rotating seat is connected with an output shaft of a servo motor B; an aerial fog spray gun is arranged at the tail end of the fixing sleeve B; the servo motor A and the servo motor B drive the rotating shaft A to rotate; and the rotating seat rotates so that the aerial fog spray gun can rotate by 360 degrees for spraying; The whole device is reasonable in layout, fast in action speed, capable of conducting continuous work and capable of achieving the effects that spraying is conducted in an all-dimensional manner without dead corners, and flatness and evenness are achieved.

Owner:JUYE QICAI SHELL E COMMERCE CO LTD

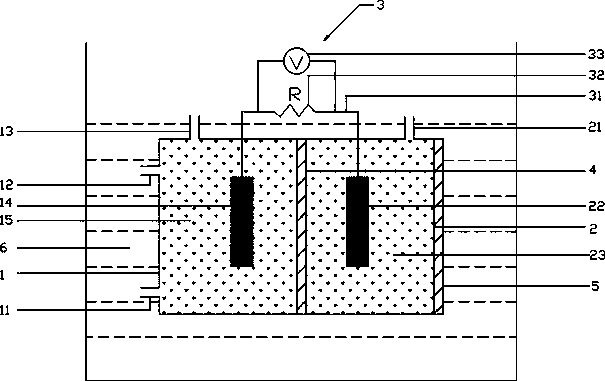

Microbial fuel cell capable of repairing nitrate polluted underground water in situ

InactiveCN104064794ACompact structureLow running costTreatment by combined electrochemical biological processesFinal product manufactureIon-exchange membranesWater pipe

The invention provides a microbial fuel cell capable of repairing nitrate polluted underground water in situ. The microbial fuel cell comprises an anode chamber, a cathode chamber, anion exchange membranes at the two sides of the cathode chamber and an external circuit system, wherein the anode chamber is provided with a water inlet pipe, a water outlet pipe and an exhaust pipe and is internally provided with a biological anode, and anaerobic electro-microorganisms are attached to the biological anode; the anode chamber is fully filled with anode liquor, and efficient anaerobic digestion sludge is inoculated in the anode chamber; the cathode chamber is provided with an exhaust pipe and is internally provided with a biological cathode, and electroactive denitrifying microorganisms are attached to the biological cathode; the cathode chamber is fully filled with cathode liquor, and denitrifying sludge is inoculated in the cathode chamber; the external circuit system comprises an external resistor, a lead and an electrical signal acquisition recorder. The microbial fuel cell has three functions of organic waste water treatment, biological electricity production and in-situ repair of nitrate polluted underground water, solves the problem of secondary pollution, caused by organic matter, microorganisms and the like, on underground water in the in-situ repair process and is compact in structure and low in running cost as well as economic and efficient.

Owner:OCEAN UNIV OF CHINA

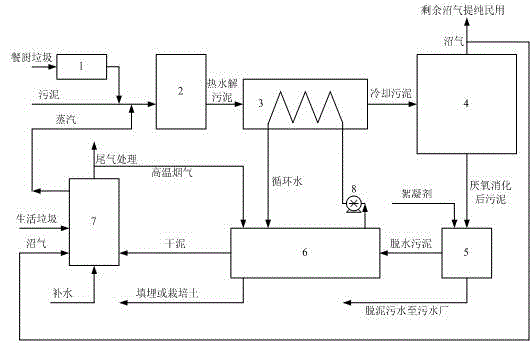

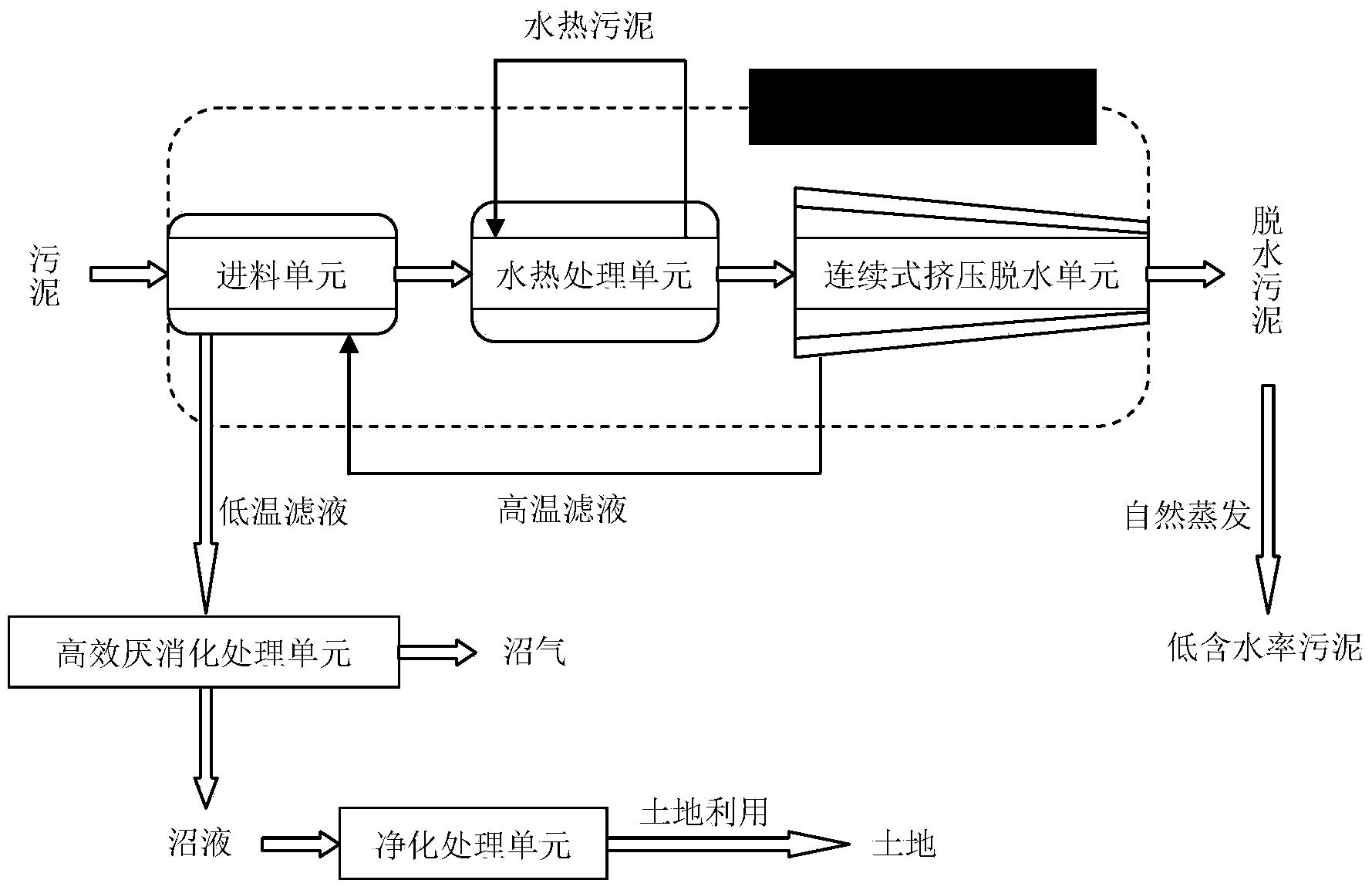

Continuous sludge dewatering method based on hydro-thermal treatment

ActiveCN103964662AAvoid heat consumptionHigh calorific valueSludge treatment by de-watering/drying/thickeningSludge treatment by thermal conditioningThermal treatmentThermal reaction

The invention relates to a continuous sludge dewatering method based on hydro-thermal treatment, and belongs to the field of sludge treatment. An external heat exchanger of a feeding unit is filled with high temperature filtrate, sludge is continuously introduced in the feeding unit, and the high temperature filtrate is used for preheating the sludge; the sludge after preheating enters a hydro-thermal treatment unit under the pushing of the feeding unit, and is heated to above 150 DEG C for a hydro-thermal reaction through a heating device arranged on the outside of the hydro-thermal treatment unit; the standing time of the sludge inside the hydro-thermal treatment unit is controlled by an accelerator arranged at the interior of the hydro-thermal treatment unit; partial sludge after hydro-thermal treatment is flown back to the hydro-thermal treatment unit; the sludge passing through the hydro-thermal treatment unit is introduced in a continuous extrusion dewatering unit to realize continuous dewatering of the hydro-thermal sludge, and a cavity in the dewatering process is at a sealed state. According to the dewatering method, based on the hydro-thermal treatment for improving the sludge structure and physicochemical characteristics, the energy sources are fully utilized and recycled while the energy consumption input is saved, and the sludge dewatering in a liquid form is realized continuously.

Owner:DALIAN UNIV OF TECH

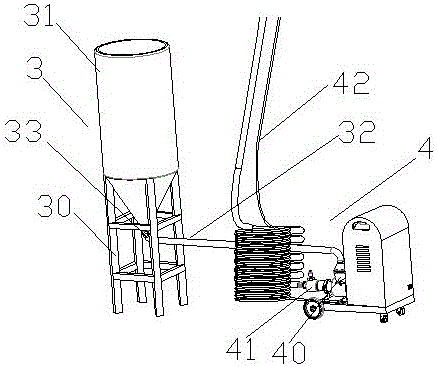

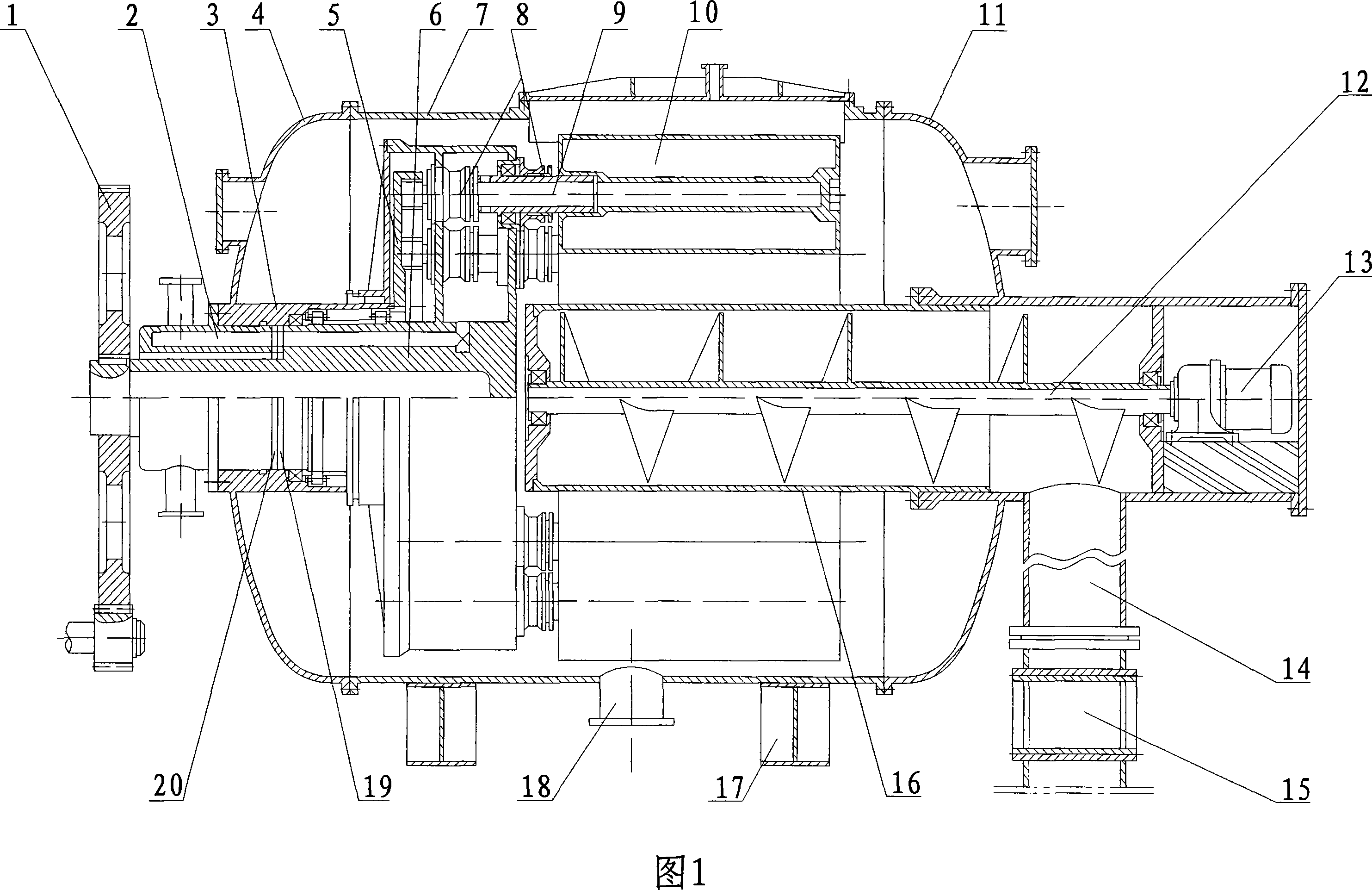

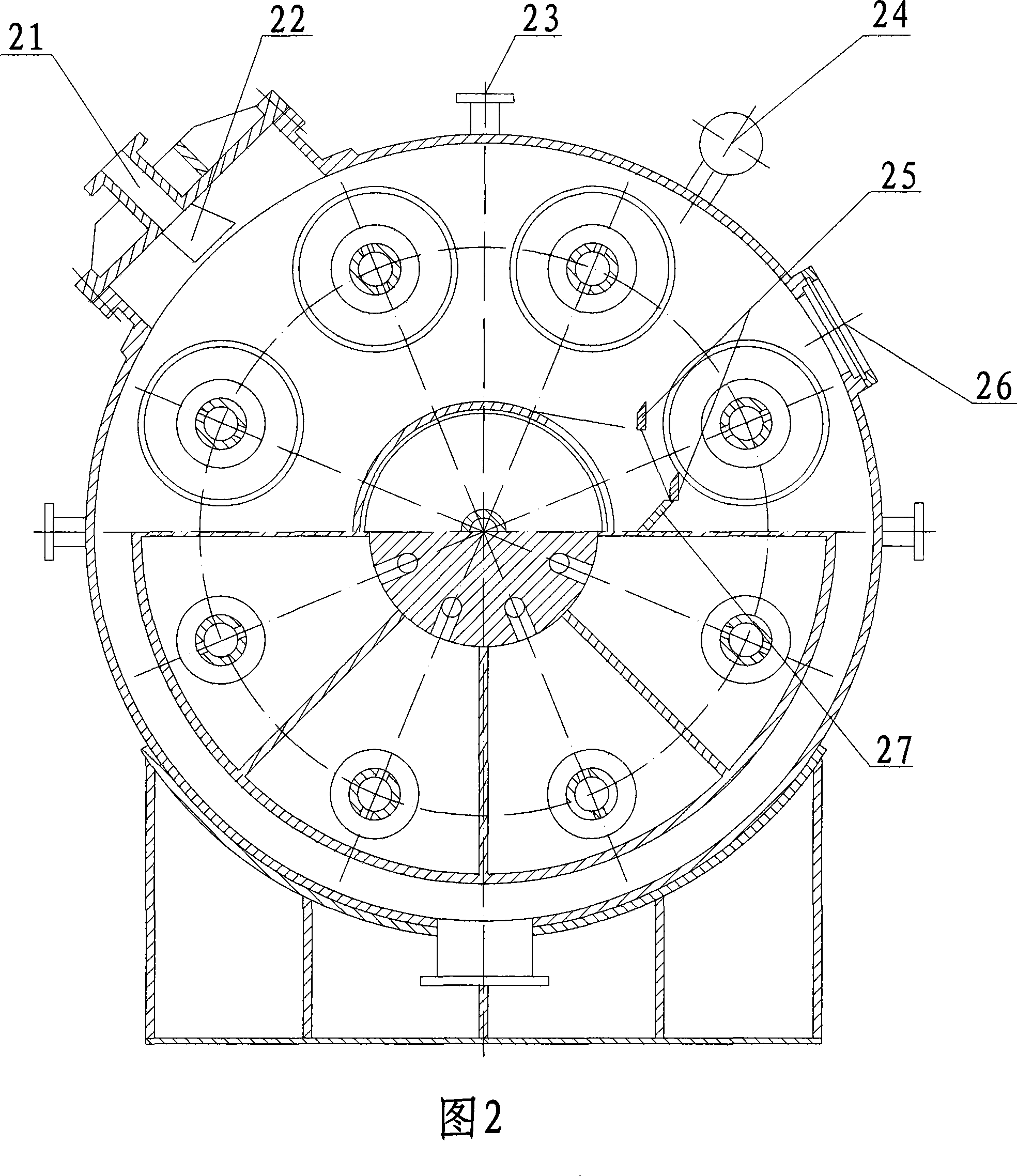

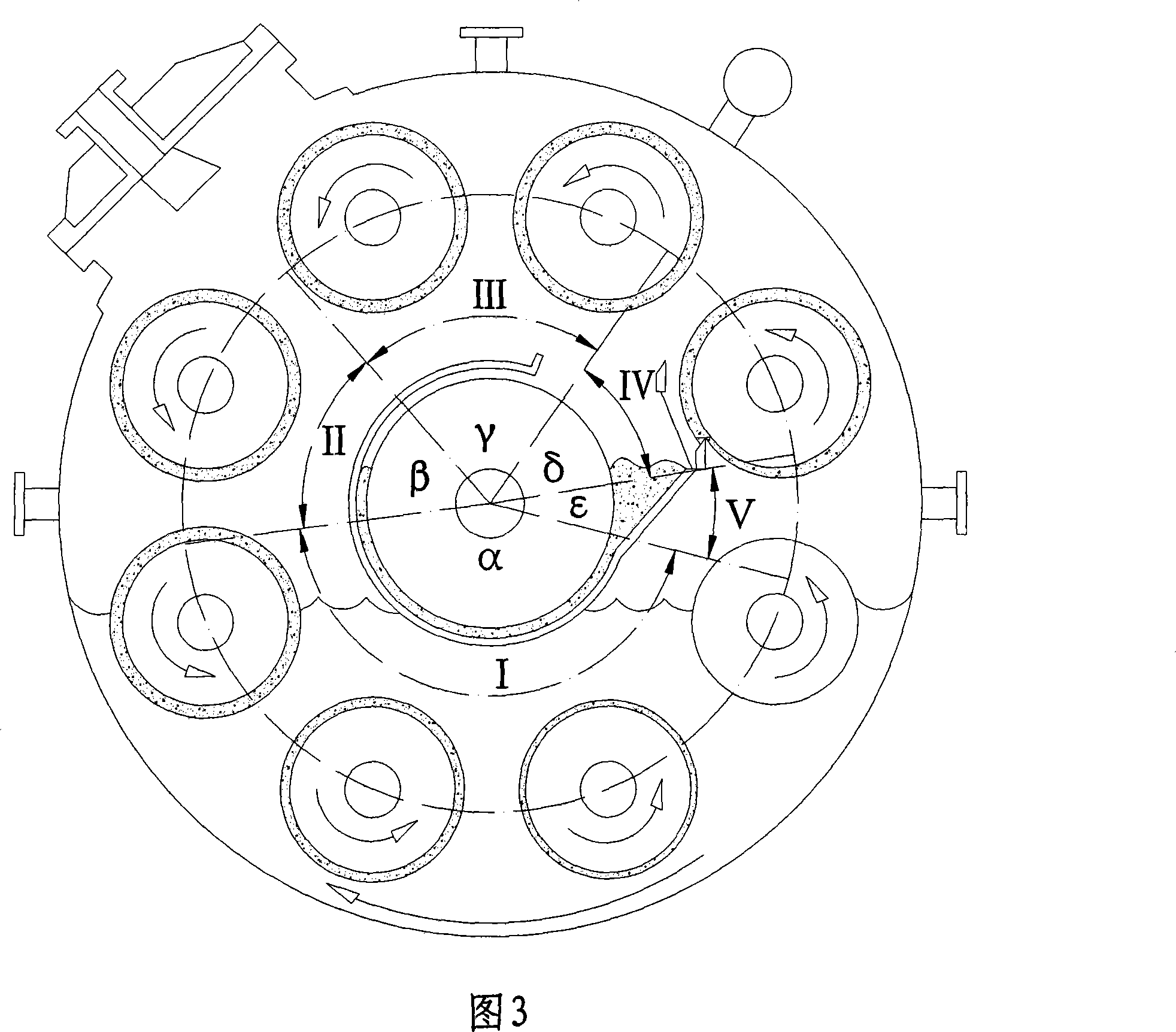

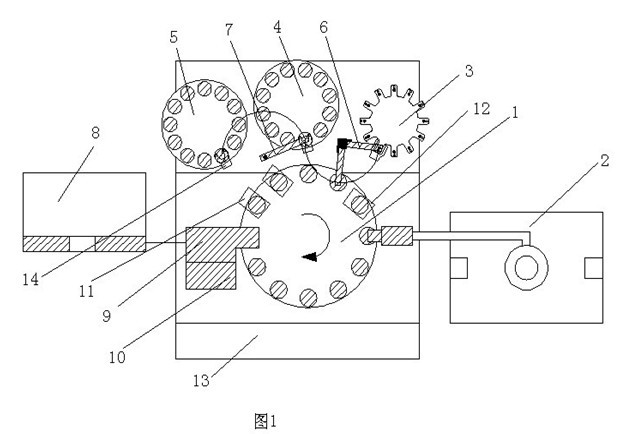

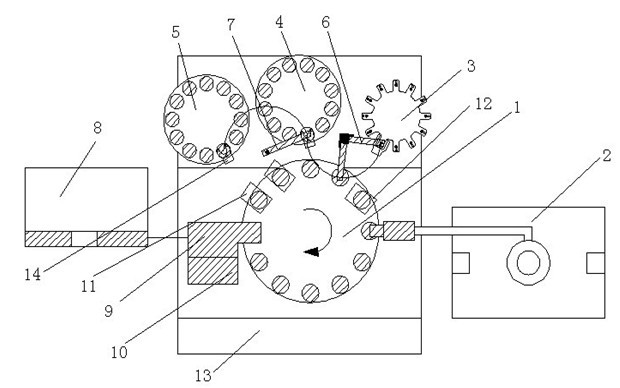

Planet gyration small circular cylinder continuous pressure filtration machine

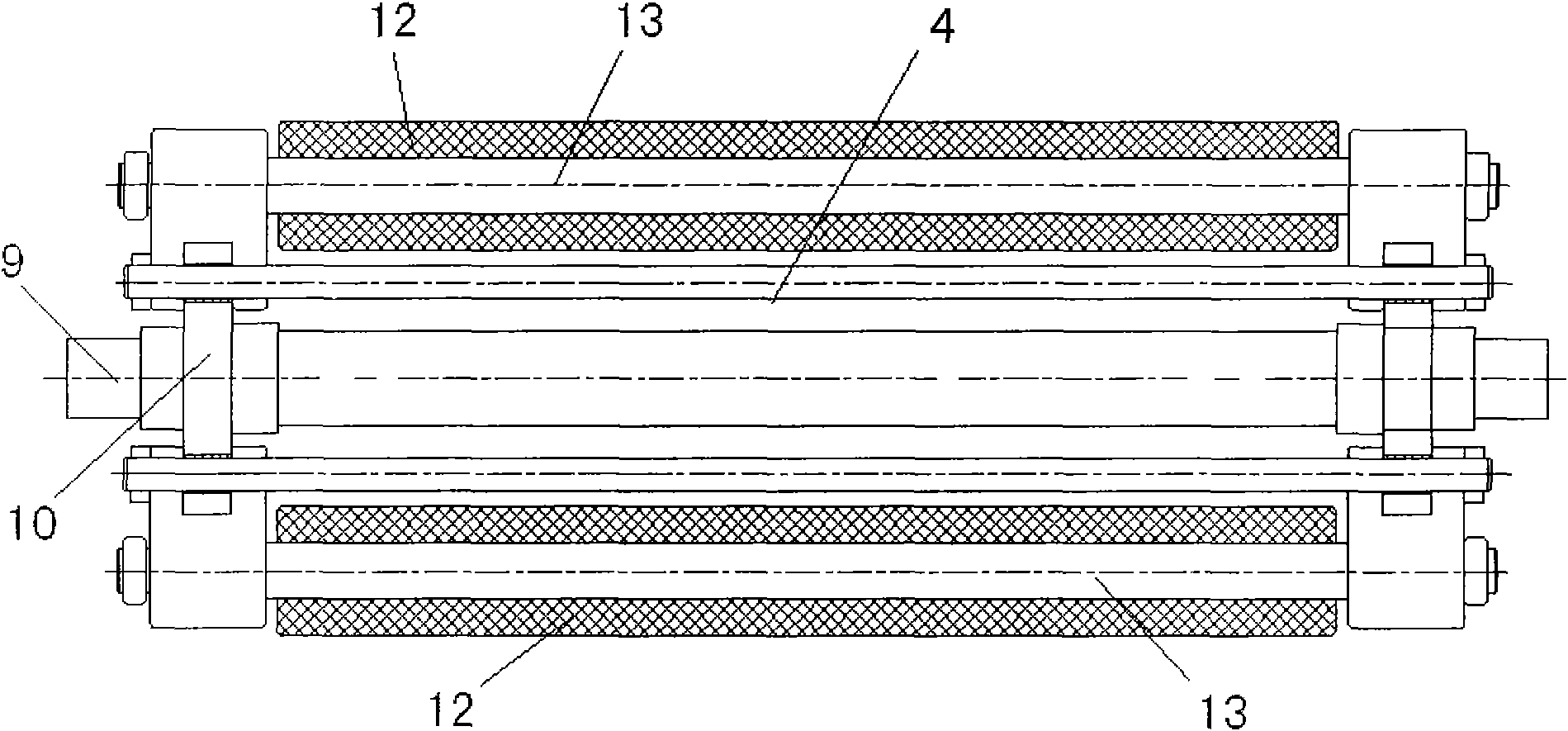

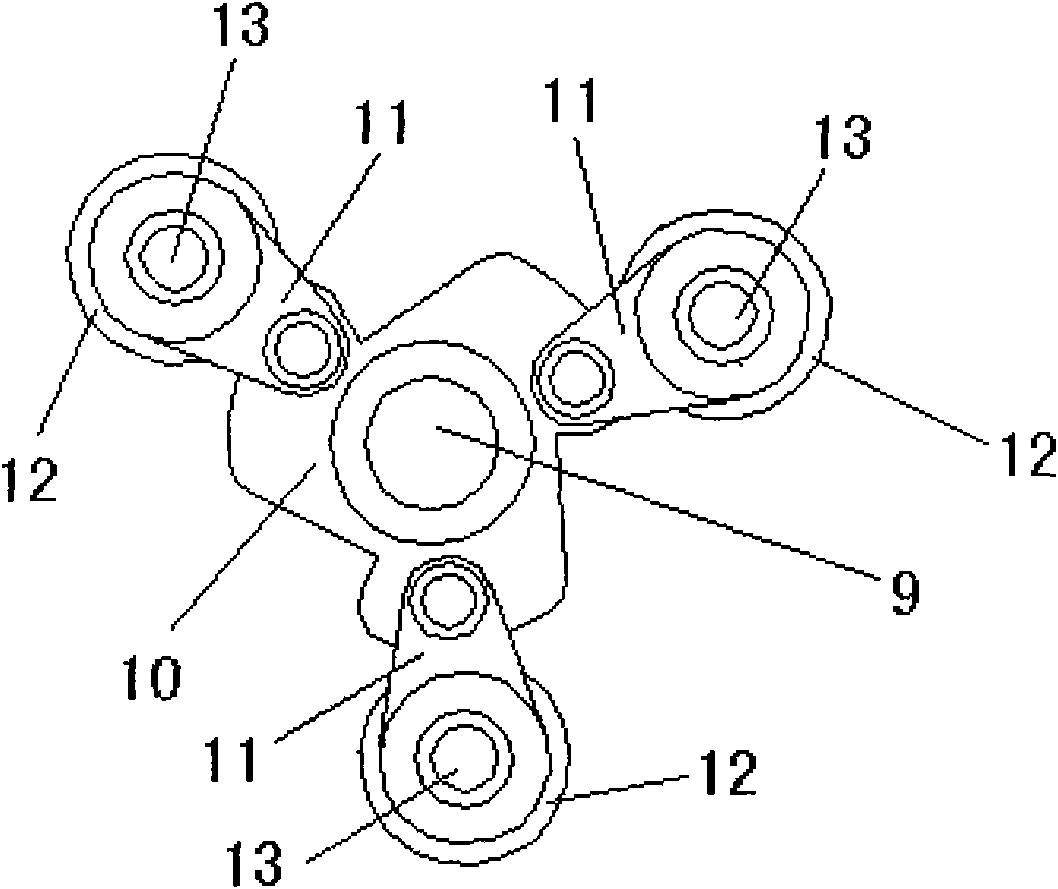

InactiveCN101234269APrevent precipitationReliable filtration operationMoving filtering element filtersGyrationFilter cake

The invention relates to a continuous pressure filter used for filtering suspension, the main technical characteristics of which is that a plurality of filtering units are arranged in the direction of the inner circumference inside a shell body of the filter; each filtering unit consists of a filter cylinder, a filter axis and an inner channel of a planet carrier communicated with the filter axis. The filter cylinder used as a filter element is fixed and supported on the planet carrier by the filter axis, which executes a planetary motion when working; fluid is collected inside the filter cylinder after going through a filter medium on the filter cylinder, which enters the channel of the planet carrier through a hollow filter axis and is discharged after being switched through a distributing head. The continuous pressure filter of the invention has the main characteristics of high-efficiency filtration dehydration, effectively wash and dry a filter cake, reliable material-discharging way, a blowback regeneration function of the filter medium, and the operating steps are carried out sequentially.

Owner:SICHUAN UNIV

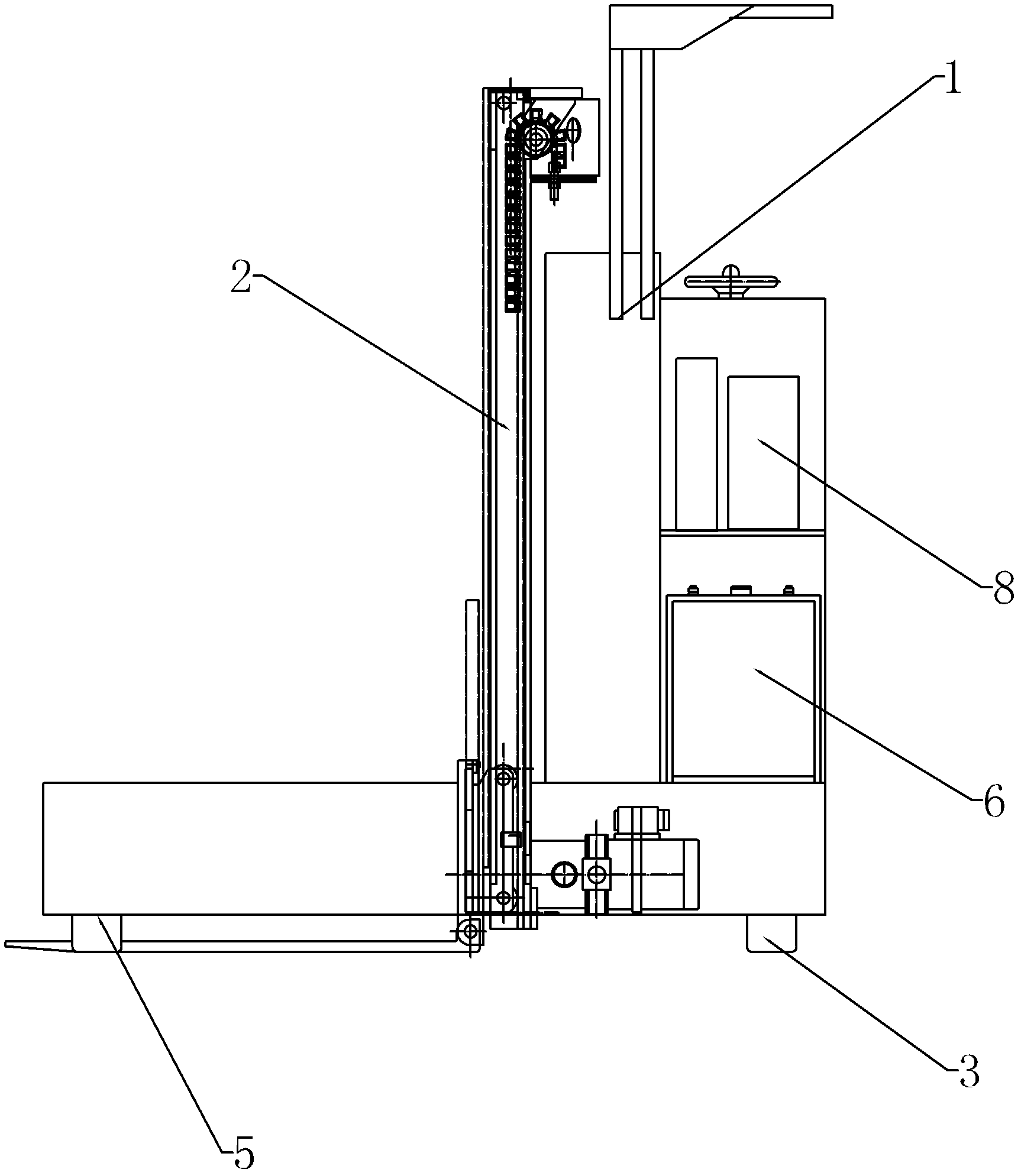

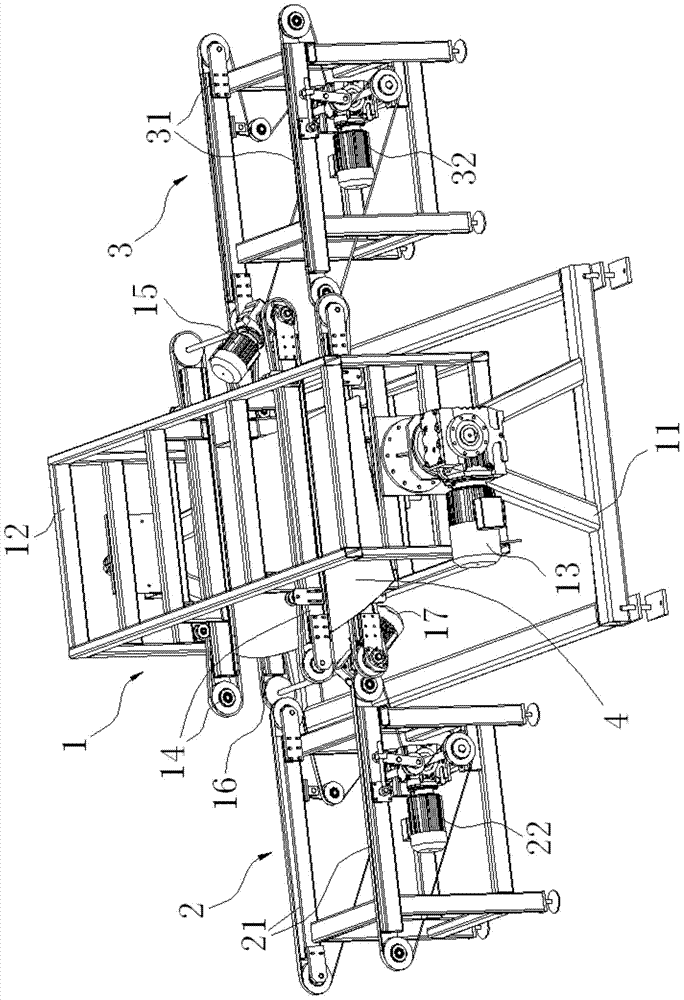

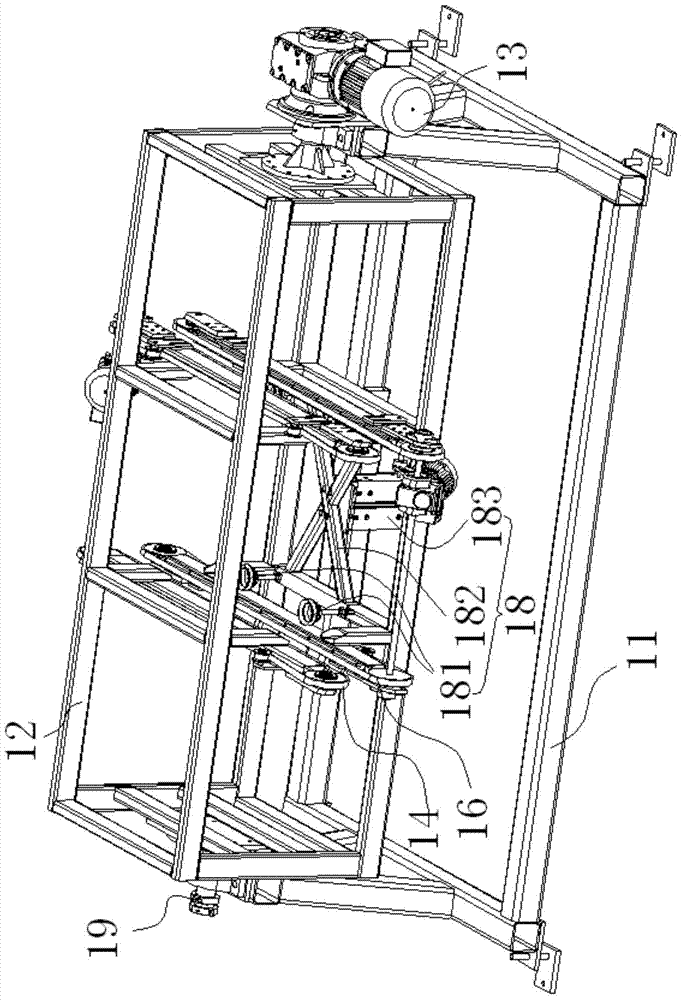

Track-free intelligent moving device of goods shelf warehouse

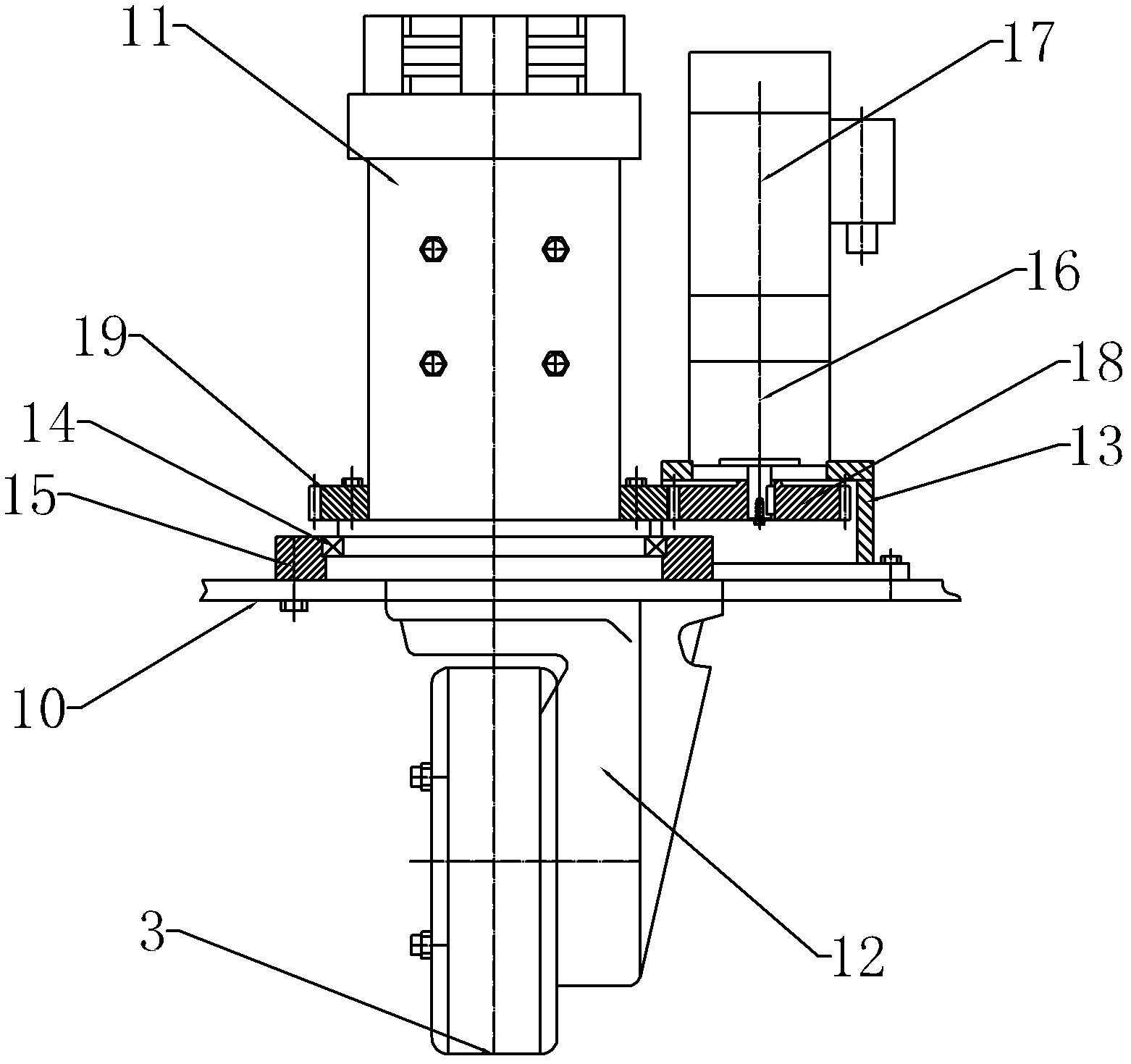

ActiveCN102616703ARealize intelligent accessAchieve continuous operationLifting devicesElectrical steeringLogistics managementDrive wheel

The invention relates to a track-free intelligent moving device of a goods shelf warehouse, which is particularly used for moving work of goods in the goods shelf warehouse and belongs to the technical field of logistics. The track-free intelligent moving device comprises a car body and a door frame, and the door frame is arranged in the front of the car body. A storage battery, a hydraulic power pack and a master controller are arranged in the car body. Four corners of the lower end of the car body are sequentially connected with a driving wheel, a steering wheel and a two follower wheel. The door frame comprises a front moving support, an outer door frame, an inner door frame and a sliding support. A push-out oil cylinder is connected with the car body, and a piston rod of the push-out oil cylinder is connected with the front moving support. A guide track is further arranged in the front of the car body, the front moving support is pushed by the push-out oil cylinder and slides in the guide track through a roller arranged at the lower end of the front moving support. The track-free intelligent moving is simple, compact and reasonable in structure, intelligent access of the goods shelf warehouse is achieved, cost is low, and working efficiency is greatly improved. Working burden of work staff is reduced, and continuous operation of the goods shelf warehouse is achieved.

Owner:梁溪区惠浩智能科技中心

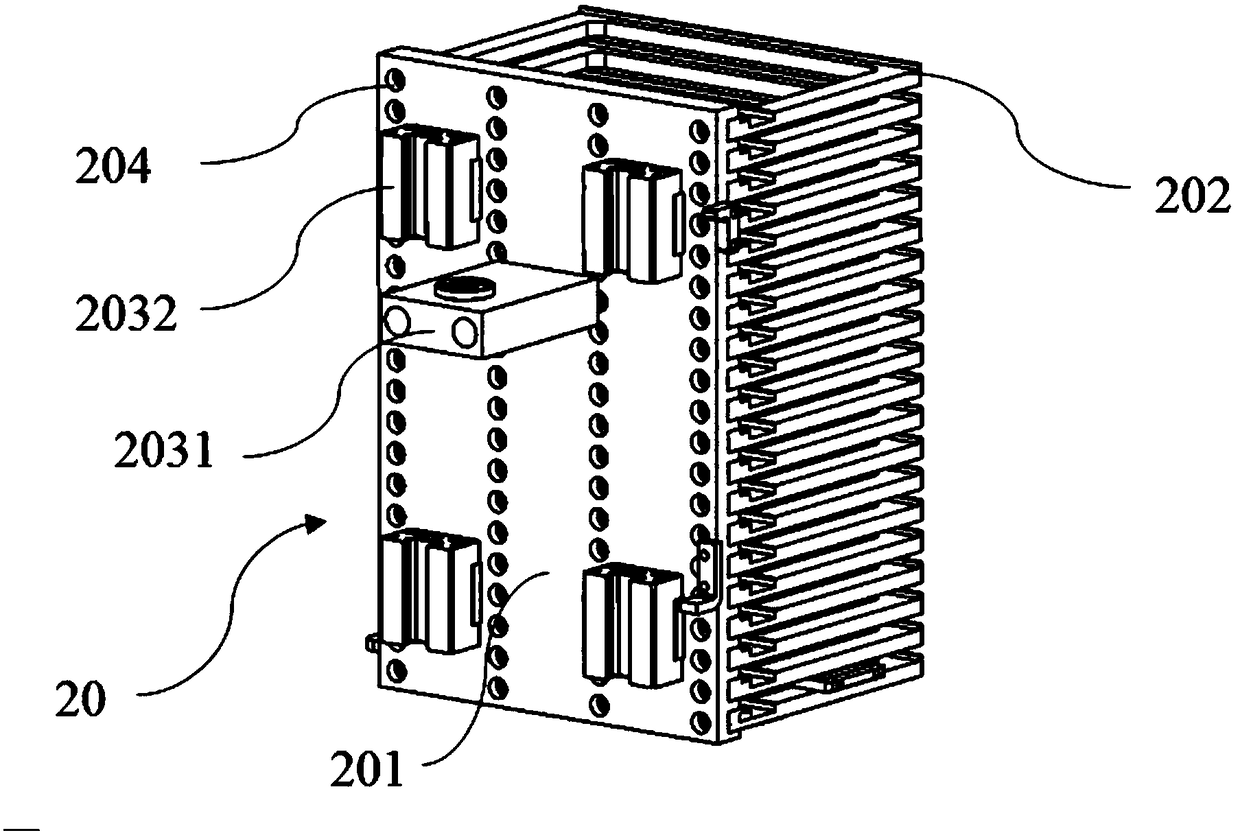

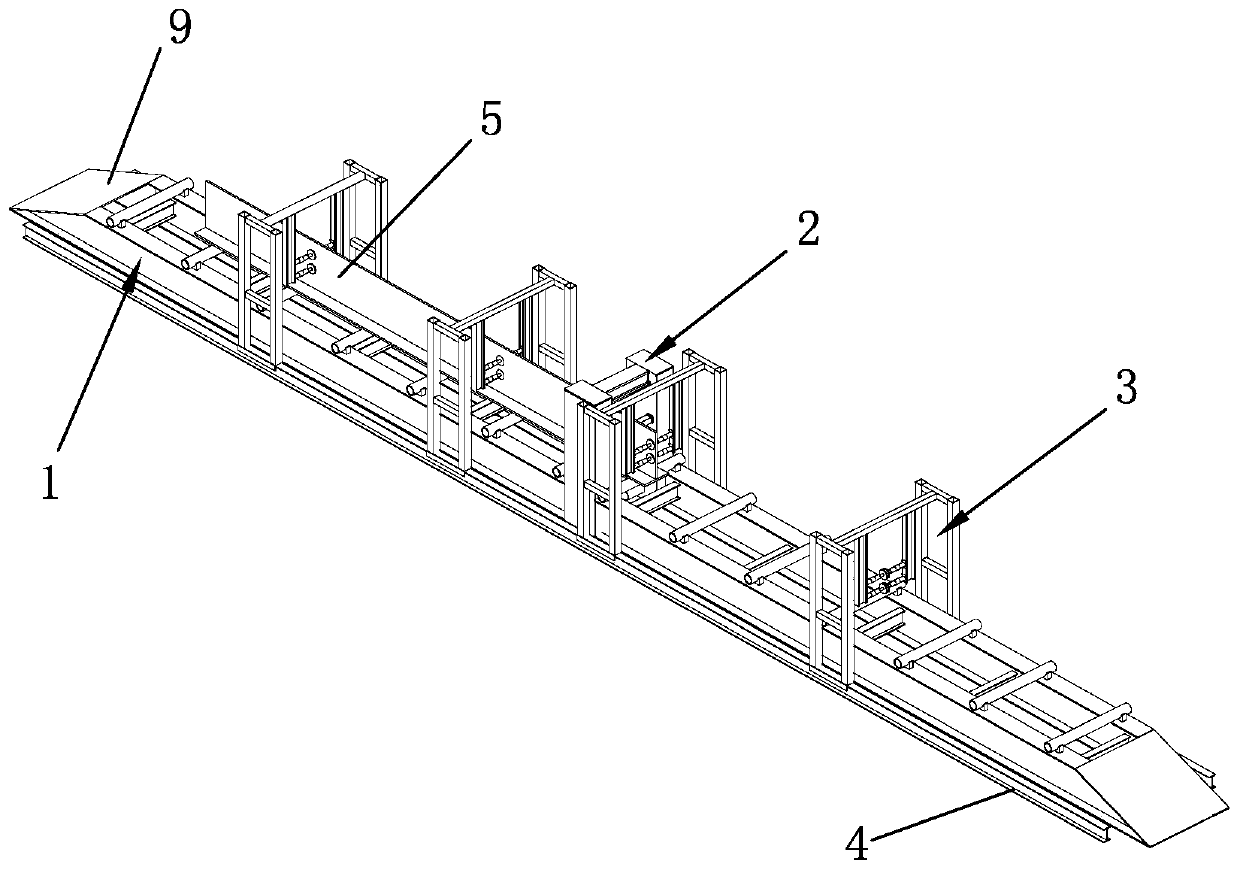

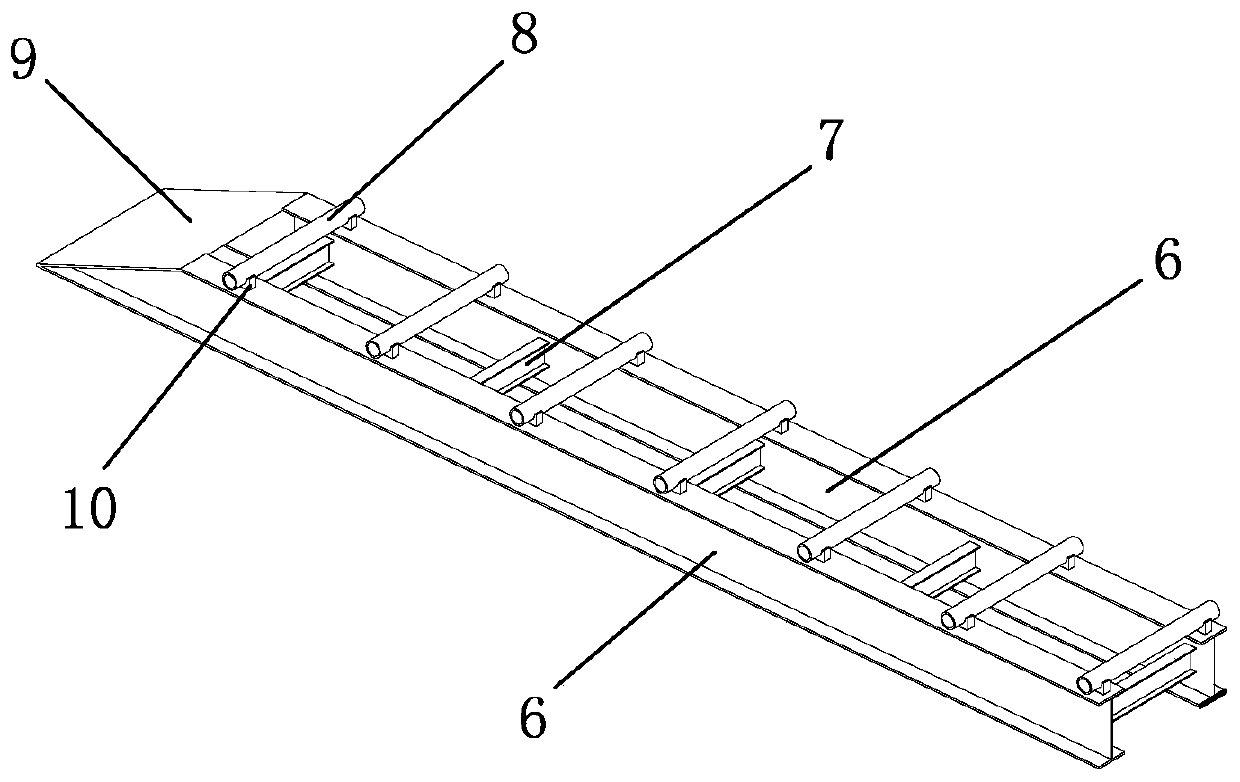

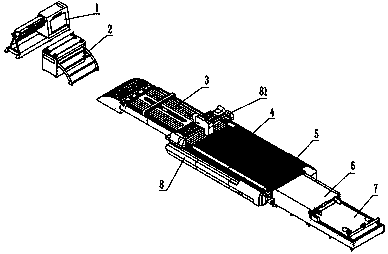

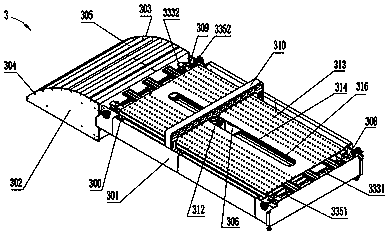

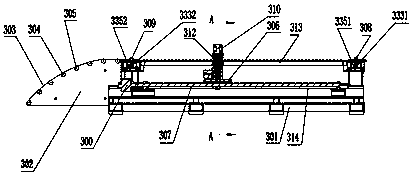

Automatic slice scanning device and slice scanner

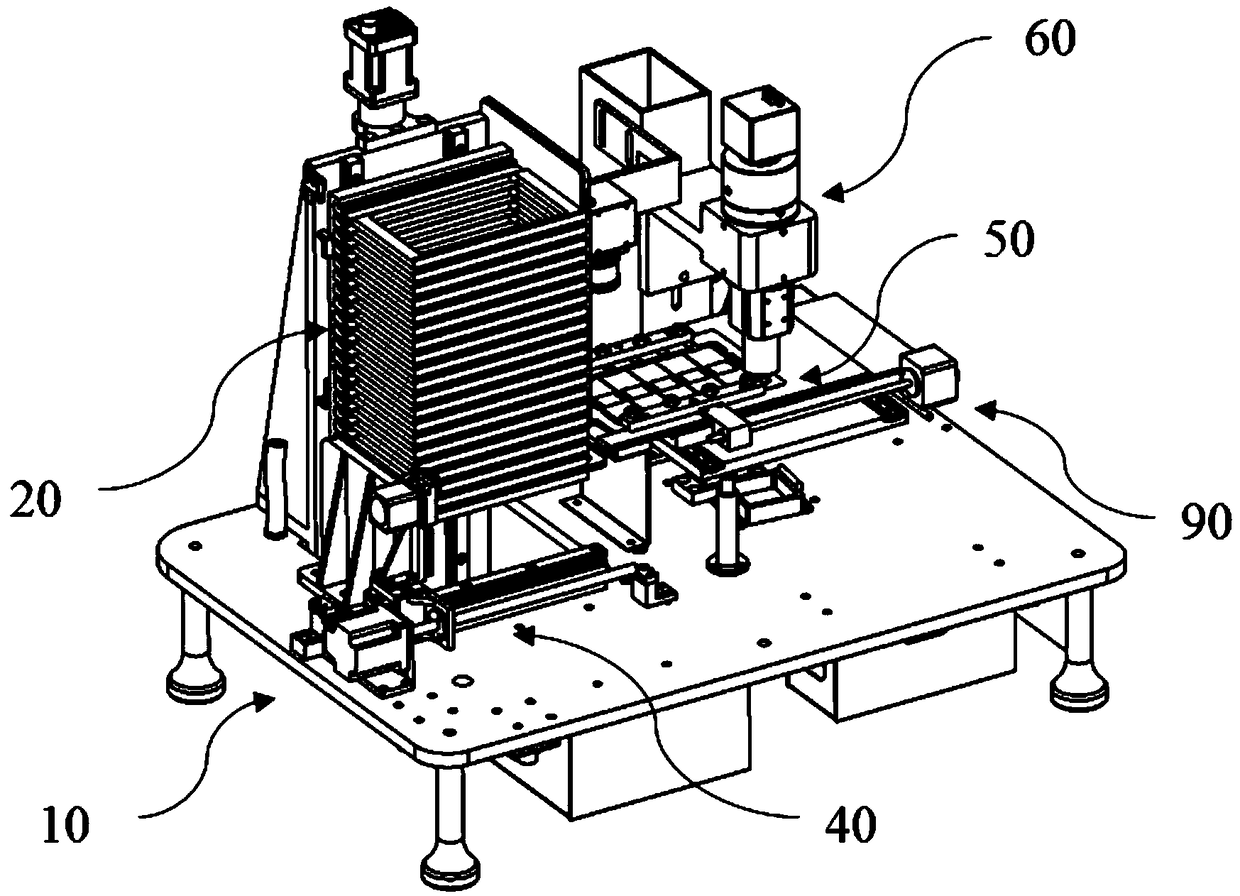

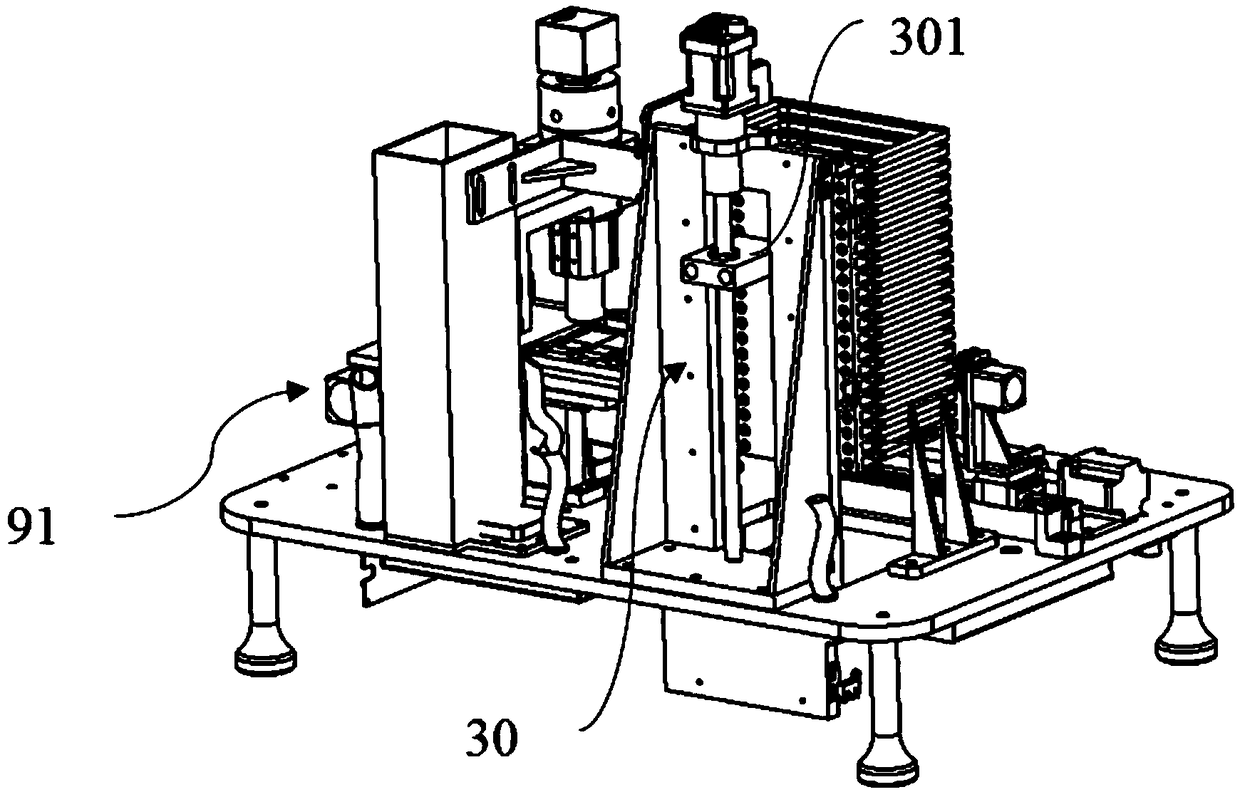

PendingCN109030371AReduce work intensityAchieve continuous operationMaterial analysis by optical meansMedical deviceComputer science

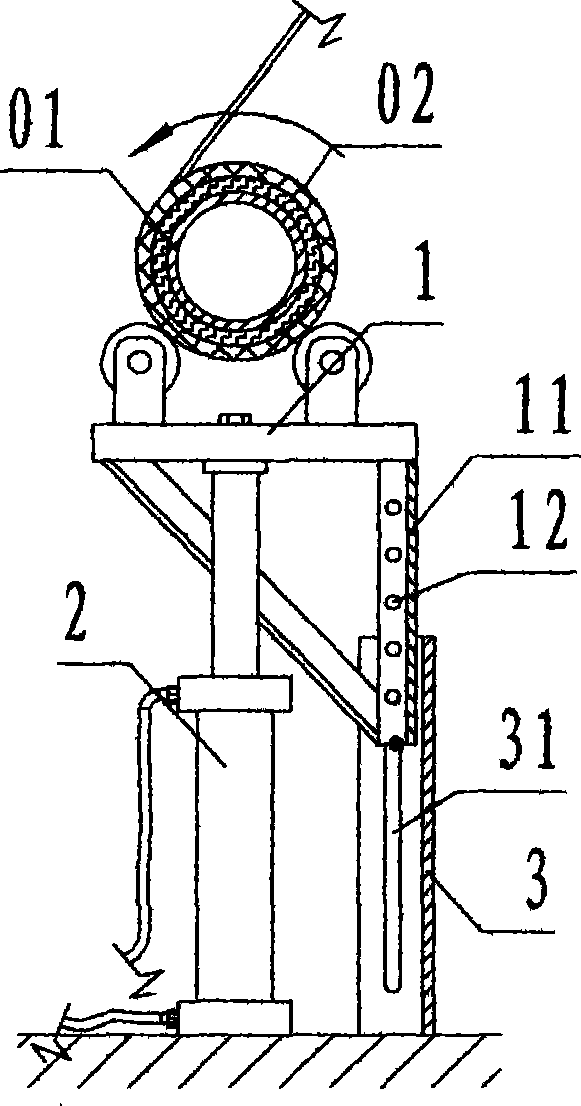

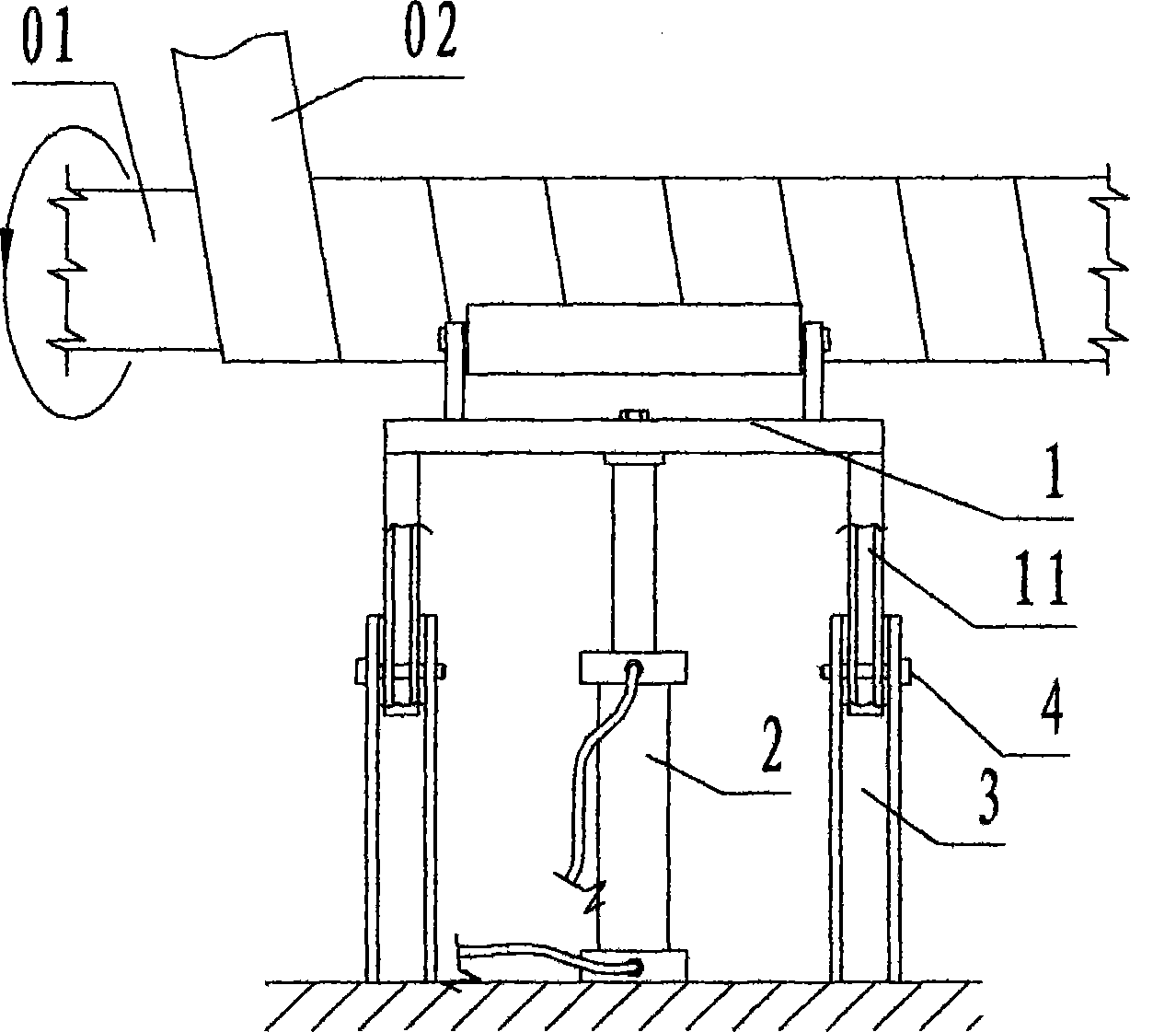

The invention provides an automatic slice scanning device and a slice scanner, and relates to the field of biological medical devices. The automatic slice scanning device comprises a base, a luggage carrier, a lifting device, a first translation device and a slice carrier platform, wherein the luggage carrier, the lifting device, the first translation device and the slice carrier platform are installed on the base. The automatic slice scanning device and the slice scanner provided by the invention can achieve automatic focusing scanning, so that the operation is simple. Furthermore, in the device, a plurality of glass slides can be placed on the luggage carrier at the same time, after the pathological scanning of the previous slice is finished, the working procedure of the next slice is continued, batch scanning can be automatically performed, the scanning result is reliable, errors caused by human operation are reduced, the work efficiency is high, and unmanned operation and automaticscanning can be realized, so that the work intensity of workers is reduced, the comprehensive cost performance is high, and the automatic slice scanning device and the slice scanner can be promoted in large scale and are suitable for routine inspection projects.

Owner:赛恩斯科学仪器(广州)有限公司 +1

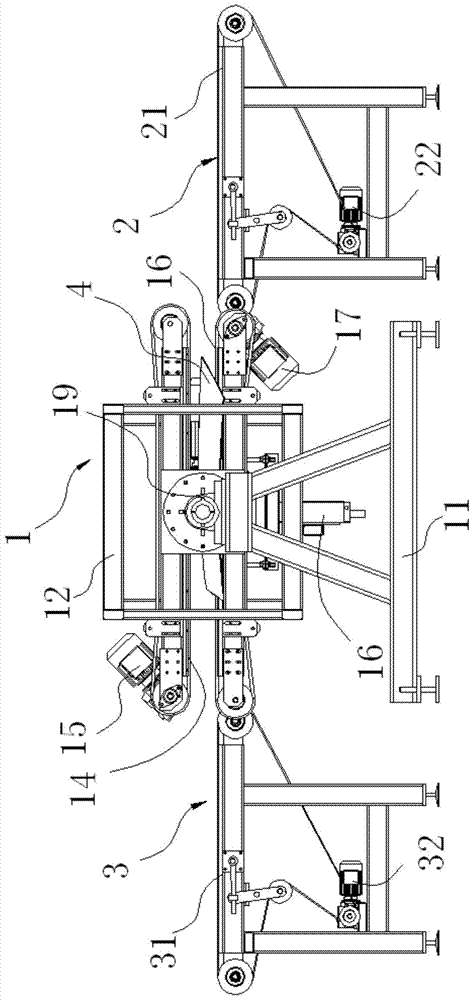

Glass overturning device

ActiveCN103754608ACompact structureLow costCharge manipulationConveyor partsProduction lineEngineering

The invention relates to the technical field of glass processing equipment, in particular to a glass overturning device used for performing glass overturning operation on a conveying belt. The glass overturning device comprises a front conveying mechanism, a rear conveying mechanism and an overturning mechanism. The glass overturning device is characterized in that the overturning mechanism comprises a support, an overturning frame, an overturning motor, adsorption units, a first conveying passage, a first conveying motor, a second conveying passage and a second conveying motor, the overturning motor and the adsorption units are fixed on the support, the overturning frame is rotatably mounted on the support, a motor shaft of the overturning motor is connected with a rotating shaft of the overturning frame, the first conveying motor, the first conveying passage, the second conveying motor and the second conveying passage are mounted on the overturning frame, and a glass conveying face of the first conveying passage is up-down opposite to a glass conveying face of the second conveying passage. The glass overturning device has the advantage of being simple and compact in structure, low in cost, stable in running and capable of guaranteeing continuous running of a production line, and production efficiency is improved.

Owner:FUYAO GROUP FUJIAN MACHINERY MFG

Method for preparing furfural and co-producing lignin and cellulosic ethanol via plant material

ActiveCN103193737AAchieve recyclingRealize comprehensive utilizationOrganic chemistryBiofuelsFiberSlag

The invention discloses a method for preparing furfural and co-producing lignin and cellulosic ethanol via a plant material. The method disclosed by the invention comprises the following steps of: (1) hydrolyzing hemicelluloses to prepare pentose; (2) preheating a pentose solution; (3) ejecting and heating; (4) dewatering and cyclizing; (5) flash-evaporating aldehyde steam to release pressure; (6) distilling; (7) rectifying in a manner of rectifying under vacuum and controlling the temperature at 98-120 DEG C to obtain a main fraction furfural; and (8) eluting lignin in pentose slag acquired in the step (1) by using an alkali liquor, acquiring delignification slag and a lignin solution, neutralizing the lignin solution to acquire the lignin, and carrying out enzymolysis on the delignification slag via cellulase to prepare the cellulosic ethanol. The method disclosed by the invention can be used for realizing cyclic utilization and comprehensive utilization of the plant materials, improving the utilization rate of raw materials, reducing the consumption of auxiliary materials and reducing the emission of wastes and reducing environmental protection pressure; and the method disclosed by the invention is a clean production and preparation process.

Owner:SHANDONG LONGLIVE BIO TECH CO LTD

Combined method for producing abrasive cloth flap disc automatically

ActiveCN102152251AIncrease productivityLower requirementGrinding devicesControl systemCombined method

The invention relates to a combined method for producing an abrasive cloth flap disc automatically, aiming at overcoming the defects of low production efficiency and unstable product quality in the prior art. The technical scheme is as follows: an adopted device comprises a main rotating disc, a glue applying system, a pallet loading rotating disc, an abrasive cloth flap disc loading rotating disc, a supporting cover loading rotating disc, a manipulator I, a manipulator II, a material conveying mechanism, a piece planting device, a cutting device, a shaping device, a thickness measuring mechanism and a control system for controlling the operation of all the devices; when workers install a supporting cover and a pallet on the supporting cover loading rotating disc and the pallet loading rotating disc, the pallet is grabbed by the manipulator I and the manipulator II and is placed on the corresponding work station on the main rotating disc; and after thickness measurement, glue applying, piece planting, primary shaping and secondary shaping of the pallet are finished in sequence on the main rotating disc, the pallet is grabbed by the manipulators and is placed on the abrasive cloth flap disc loading rotating disc, so that rod penetration is finished. The combined method is mainly applied in automatic production of the abrasive cloth flap disc.

Owner:谢泽

Anti-sidewise-bending deformation control device of H-shaped steel component and welding method

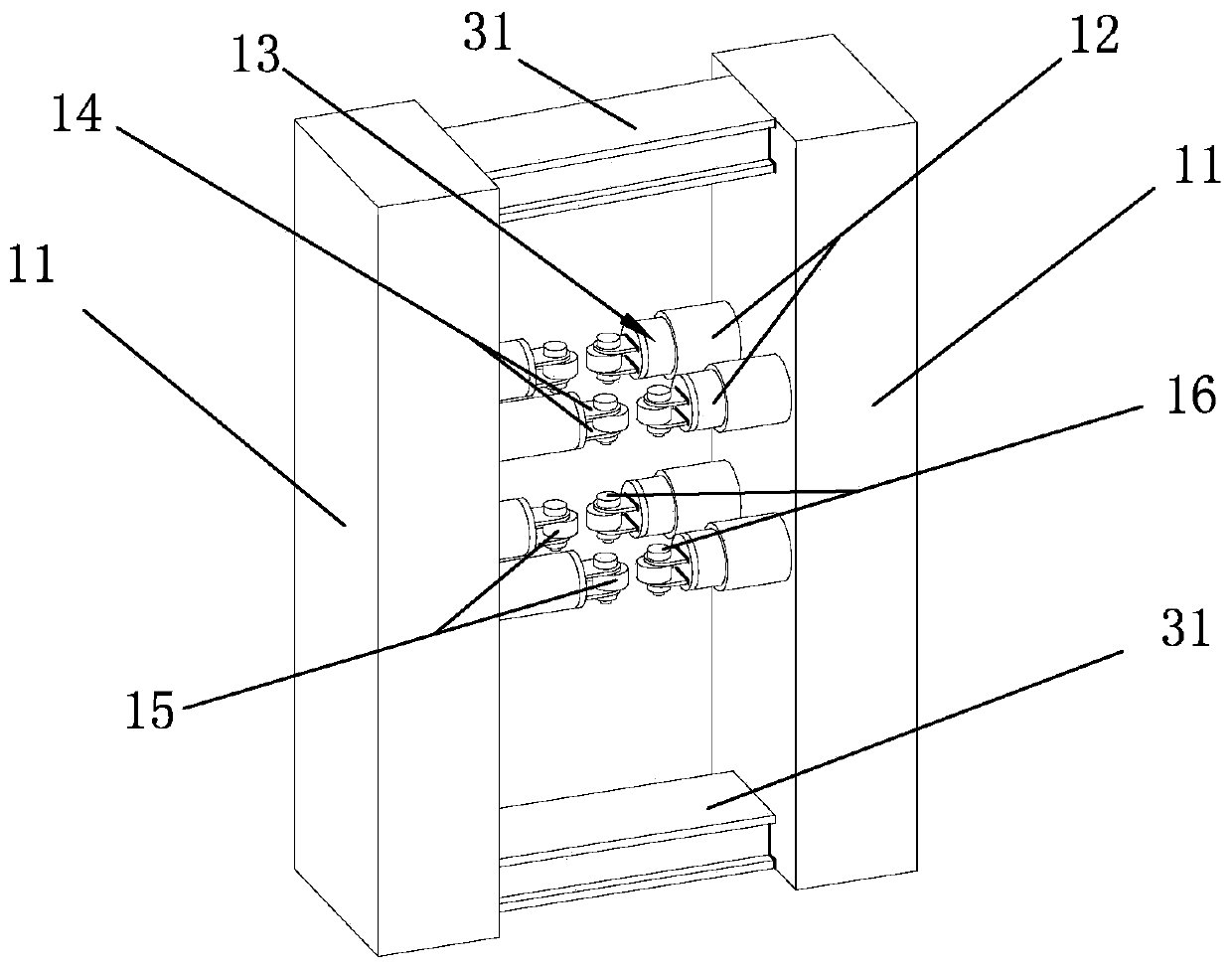

ActiveCN110102862AGuaranteed structural strengthEnsure structural stabilityWelding/cutting auxillary devicesAuxillary welding devicesCompression deviceEngineering

The invention discloses an anti-sidewise-bending deformation control device of an H-shaped steel component. The anti-sidewise-bending deformation control device comprises an assembly jig, an anti-sidewise-bending device, compression devices, a sliding rail and the to-be-welded component; the anti-sidewise-bending device is located in the middle of the assembly jig; the compression devices with thesame number are arranged on the left side and the right side of the anti-sidewise-bending device; and the compression devices are distributed in the direction of the assembly jig. A welding method comprises the steps: (1) the compression devices are adjusted; (2) a lower flange plate and a web are welded; and (3) an upper flange plate and the web are welded. During welding, the web at a welding point is compressed through the anti-sidewise-bending device, thus deformation and bending of the web in the welding process are avoided, two welding heads are symmetrically arranged on the welding positions of the flange plates and the web, the compression devices work to drive the to-be-welded component to move, the two sides of contact points of the web and the flange plates are synchronously welded through the two welding heads, in the process, the to-be-welded component can be semi-automatically welded, the machining efficiency of the H-shaped component can be improved, and the welding quality of the H-shaped component is guaranteed.

Owner:浙江中南绿建科技集团有限公司

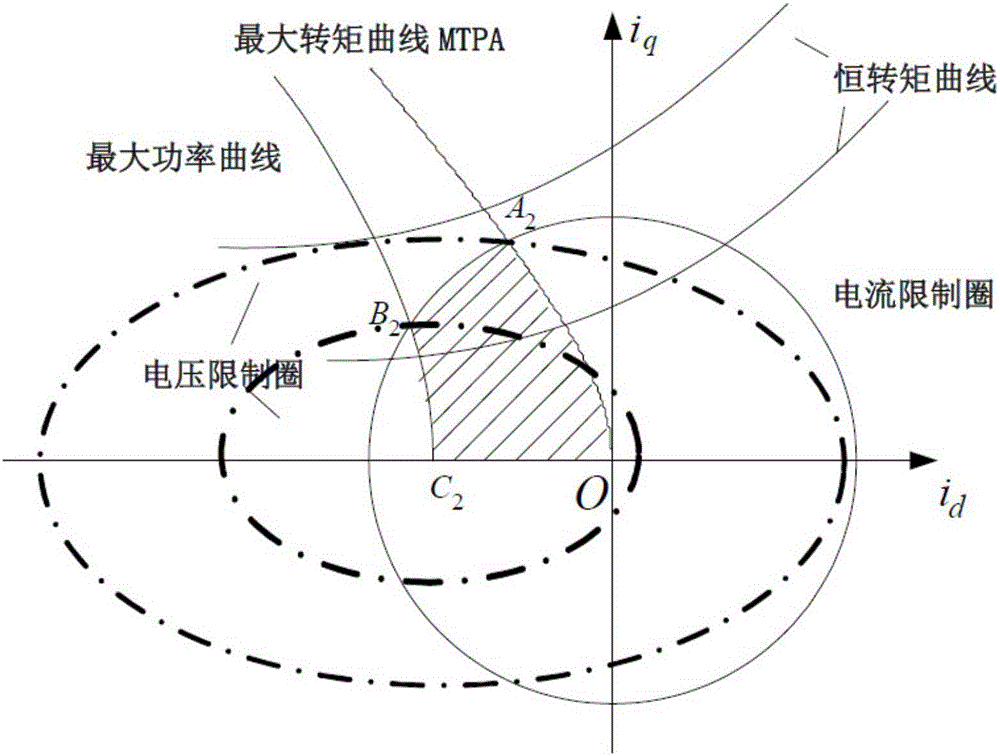

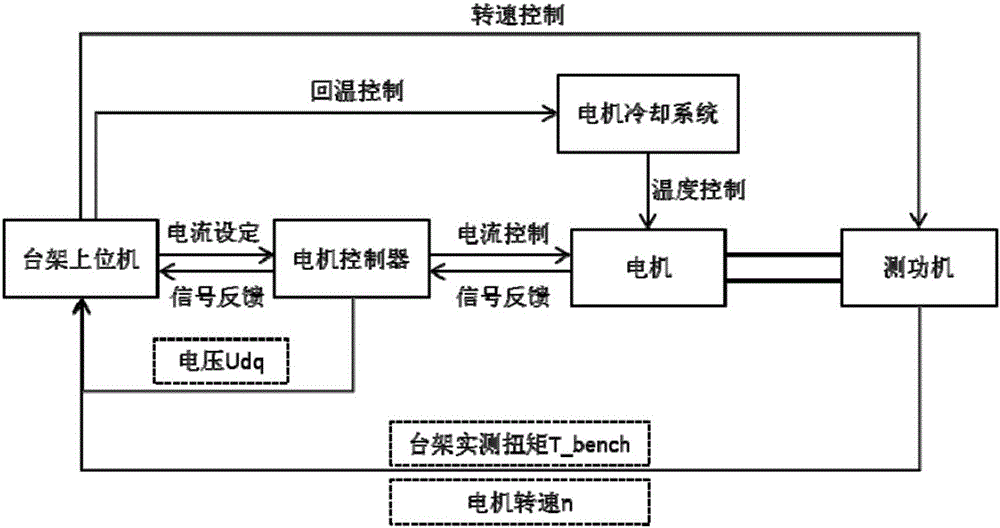

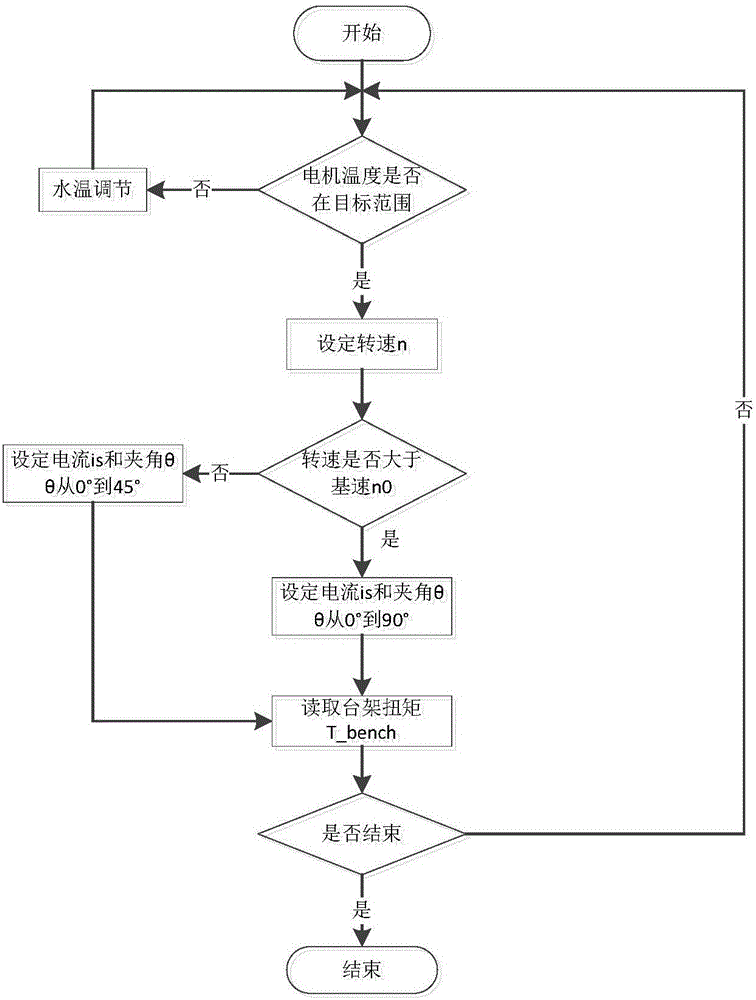

Automatic calibration method for driving motor rack of new energy automobile

ActiveCN105717917AHigh precisionImprove work efficiencyEngine testingElectric testing/monitoringAutomatic Data ProcessingElectric machine

The invention discloses an automatic calibration method for a driving motor rack of a new energy automobile, which improves the rack calibration efficiency, enhances the calibration precision and reduces the labor intensity of a calibration engineer. According to the technical scheme, during matching of the rack of a driving motor of the new energy automobile, system resources of the rack are integrated; by automatic temperature returning control, automatic current setting and automatic data processing, motor control current can be automatically set, so that the precision of calibrating the motor rack is improved, and the motor rack calibration working efficiency is greatly improved. Particularly, the fluctuation of a magnetic chain of a rotor is reduced by controlling the temperature of the motor, a reading error is eliminated, and the precision of calibrating the motor control current is improved; therefore, an automatic procedure replaces frequent manual operation and visual inspection of the engineer, to realize continuous running and unattended operation, so that the working efficiency of motor rack calibration is greatly improved, and precious engineer resources are saved.

Owner:SAIC VOLKSWAGEN AUTOMOTIVE CO LTD

Method for treating waste water in production of para-hydroxyphenyl hydantoin

InactiveCN1884144AGood environmental benefitsThe principle is simpleWater/sewage treatment by ion-exchangeMultistage water/sewage treatmentHydantoin derivativesSalt-wasting

The invention discloses a disposing method of waste water in the p-hydroxybenzene hydantoin manufacturing course, which comprises the following steps: salting waste water with phenol mother liquid through soluble salt; stewing to divide water-phase; blending salted water phase and waste water according to 1:1-8; adsorbing the composite liquid in the resin adsorbing column under normal temperature at 0.1-2 BV per h flow; desorbing the adsorbed saturated resin; preparing for next adsorbing disposal. The invention removes p-phenolsulfonate by over 99 percent, which doesn't pollute environment.

Owner:NANJING UNIV

Laser cutting device

PendingCN110170752APrecise cutting and automatic unloadingReduce biasLaser beam welding apparatusStops deviceLaser cutting

The invention belongs to the technical field of metal plate production equipment, and particularly relates to a laser cutting device. The laser cutting device is provided with a main lathe bed (8), afeeding machine (3), a clean material cutting area (4) and a rotary workbench (5), wherein the feeding machine (3), the clean material cutting area (4) and the rotary workbench (5) are arranged from back to front; the feeding machine (3) is provided with a feeding rail (314), a feeding crossbeam (310) and a floating clamp (312); the clean material cutting area (4) is provided with a clean materialcutting support bar (41), a clean material cutting servo motor (42) and a stop device; and the rotary workbench (5) is provided with a rotary support bar (51), a rotary servo motor (52), a chain support rail (53) and a supporting bracket (54). According to the laser cutting machine, the feeding machine can achieve high-precision positioning and automatic deviation rectifying through plate limiting and can achieve automatic feeding; a plate is accurately positioned by the clean material cutting area so to be cleaned and cut and is then conveyed to the rotary workbench to be cut into a workpiece; and laser cutting based on automatic feeding and discharging is achieved, and the production efficiency is improved.

Owner:河南力锋科技有限公司 +1

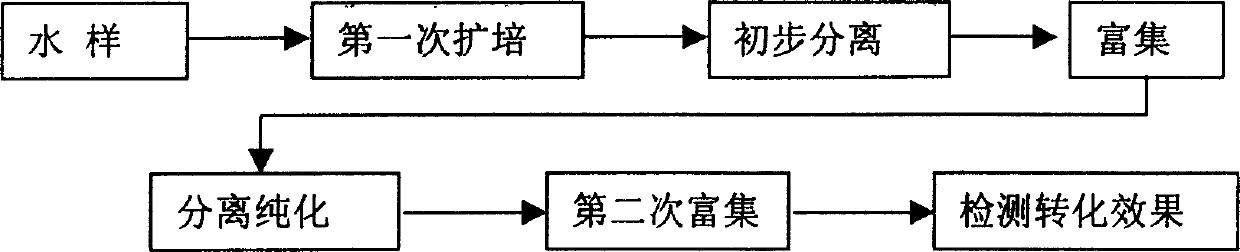

High efficiency nitrogen circulating bacteria artificial screening and application in aquatic state sepairing and water treatment

InactiveCN1693449AImprove nitrogen removal effectImprove toleranceBacteriaBiological water/sewage treatmentEcological environmentNitrifying bacteria

A process for effectively screening the nitrogen cycling bacteria used to repair the ecological environment of water and treat water includes such steps as acquiring the water sample containing local nitrogen cycling bacteria, respectively preparing the culture media for ammonifying bacteria, nitrosifying bacteria, nitrifying bacteria and denitrifying bacteria, culturing, separating, purifying and using the bacterium with high conversion rate as the preferable one.

Owner:NANJING UNIV

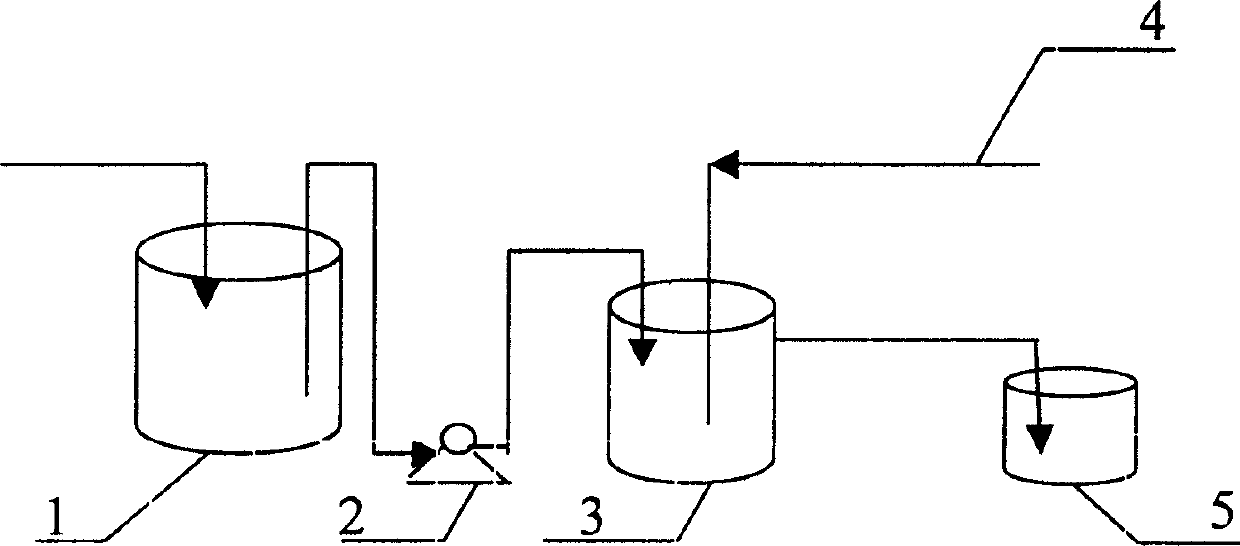

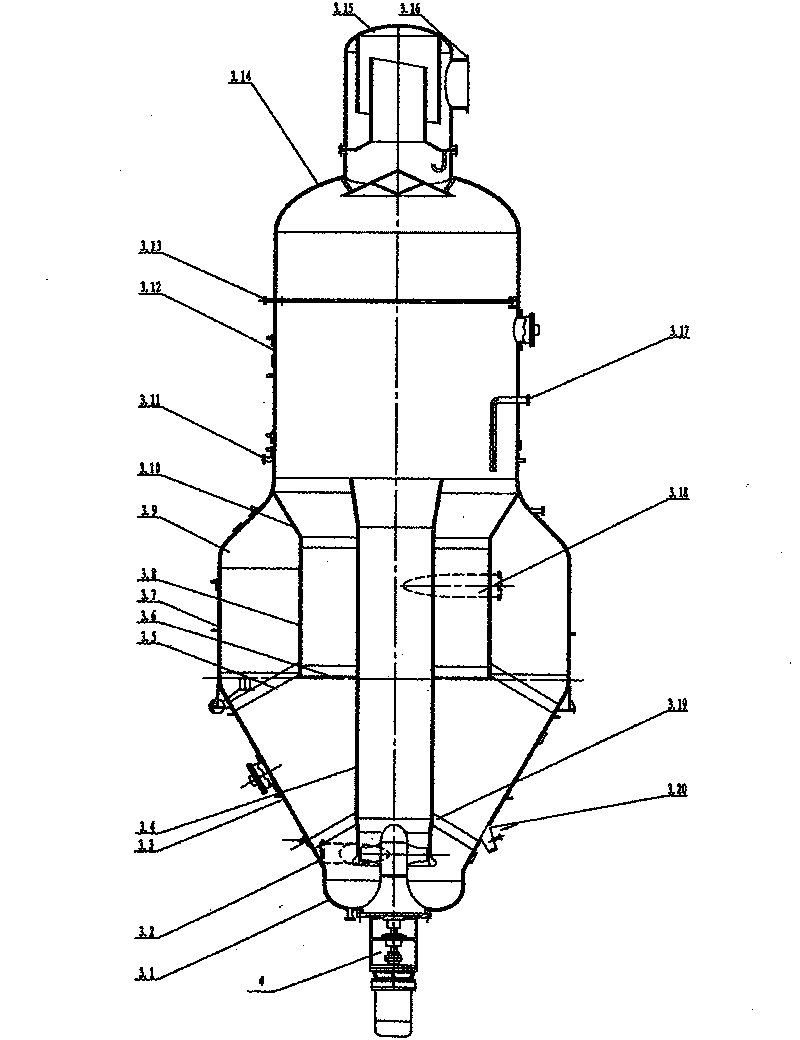

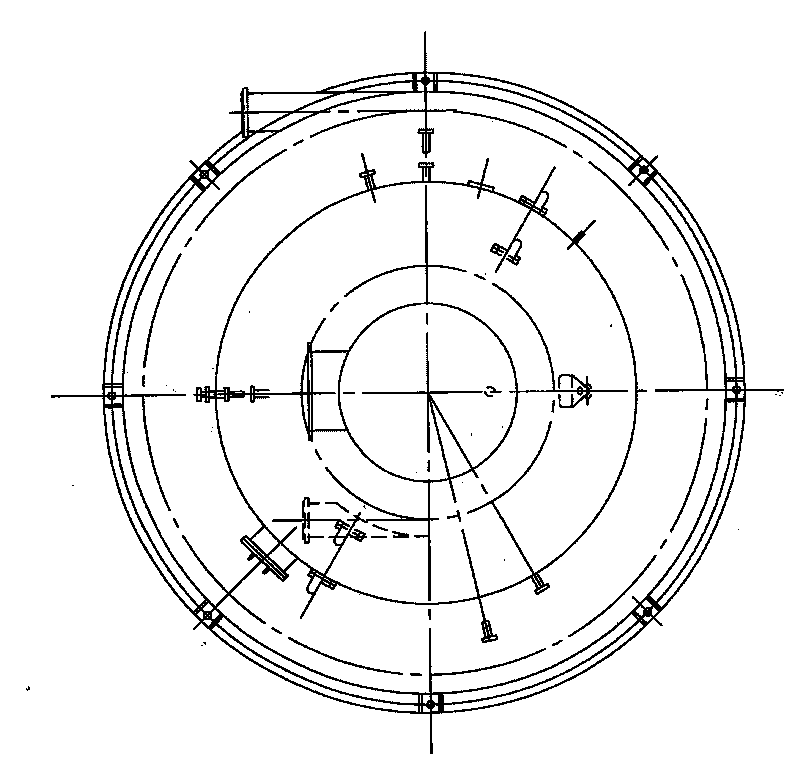

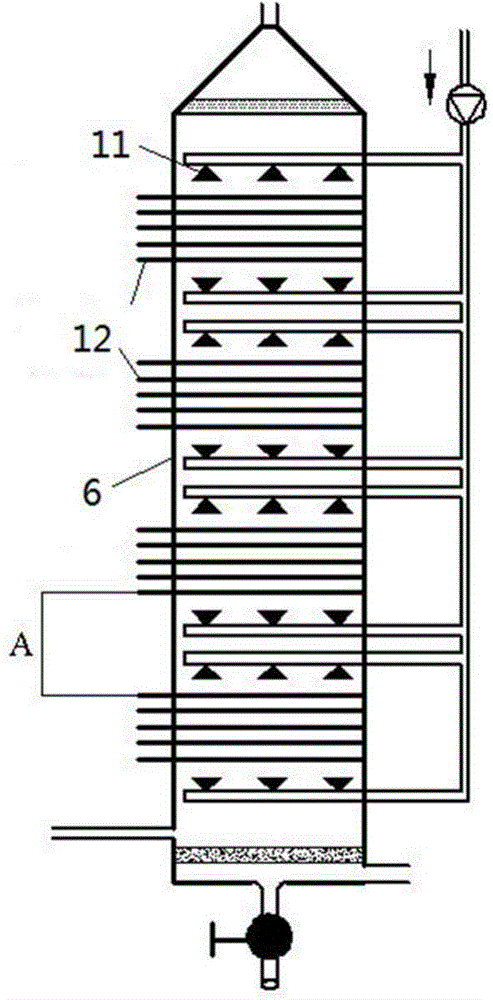

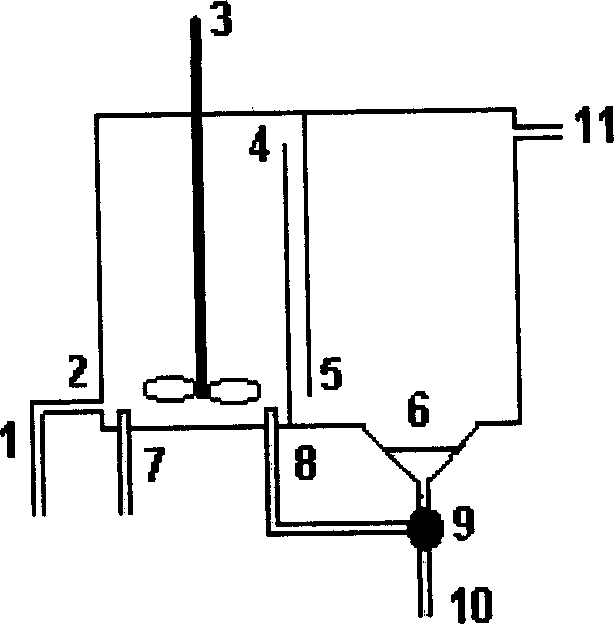

Continuous crystallizer

InactiveCN101732885AIncrease production capacityContinuous operationSolution crystallizationCirculating pumpMixing tank

The invention relates to a continuous crystallizer mainly used for concentrative crystallization in monosidum glutamate production of food industry, which comprises a crystallizer (3), a raw liquid and mother liquid mixing tank (1), a feeding pump (2), a plate type heater (14), an outer circulating pump (11), a heater (5), an inner circulating pump (4) and a discharging pump (10), wherein the raw liquid and mother liquid mixing tank (1) is connected with the feeding pump (2) connected with the plate type heater (14) which is communicated with the outer circulating pump (11), the outer circulating pump (11) is connected with the heater (5) communicated with a circulated flow returning port (3.2) of the crystallizer (3), and an circulated discharging port (3.18) of the crystallizer (3) is communicated with the outer circulating pump (11); the inner circulating pump (4) is arranged at the bottom of the crystallizer (3); and an outlet of the discharging pump (10) is respectively connected with a crystal paste circulating port (3.11) of the crystallizer (3) and a crystallization-assistant slot (8). The continuous crystallizer has the characteristics of low steam consumption, high equipment yield, high degree of the automation and the like.

Owner:江阴丰力生化工程装备有限公司

Fiber bundle dividing and washing method and device

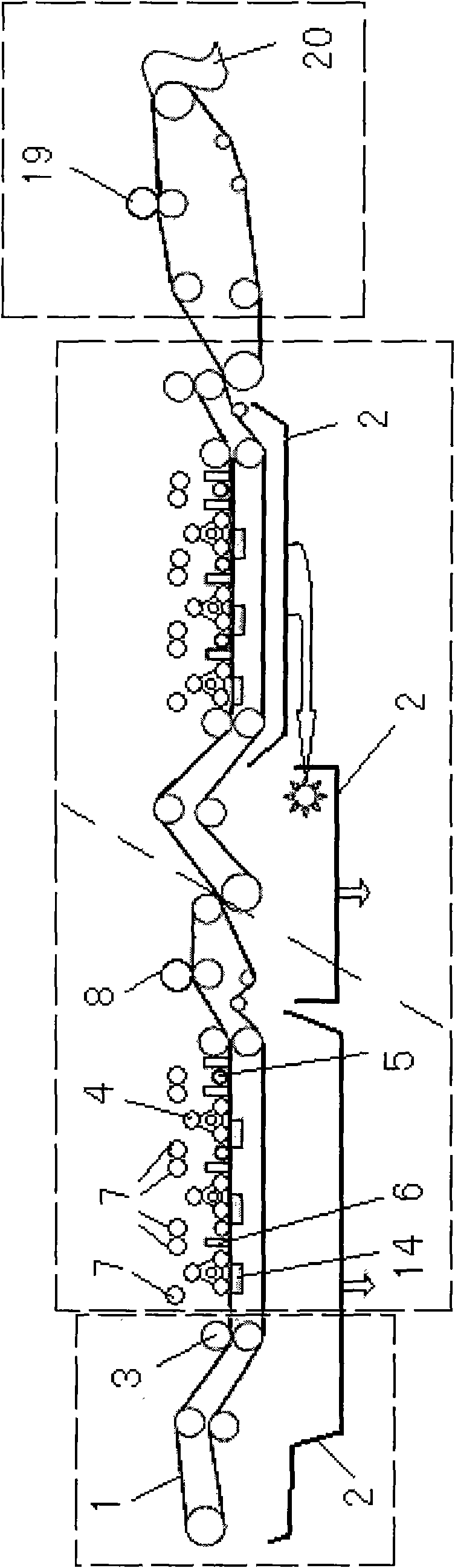

ActiveCN101851789AGuaranteed cleanlinessHit evenlyMechanical treatmentFibre treatment to obtain bast fibreCardingFiber bundle

The invention relates to a fiber bundle dividing and washing method and a fiber bundle dividing and washing device. The method comprises the following steps of: 1) arranging a plurality of groups of fiber dividing and washing units and a fiber output unit on a frame, wherein each unit is provided with a running rotating crawler; 2) passing a feeding roller through a crawler input end of each fiber dividing and washing unit so as to convey the fiber bundle forward, making the fiber bundle enter a fiber dividing and washing area which is provided with a beater and a fiber dividing roller at intervals, simultaneously opening a high pressure water pipe which is arranged above the beater and the fiber dividing roller, and performing washing soaking, beating, carding and fiber dividing on the fiber bundle edges; 3) feeding the fiber treated by the previous fiber dividing and washing unit to the next fiber dividing and washing unit for continuous fiber dividing and washing; and 4) feeding the fiber treated by the last fiber dividing and washing unit into a fiber dividing input area, performing water squeezing operation through a squeezing roll, feeding the fiber into a cloth arrangement mechanism, arranging and folding the strip-shaped fiber through the cloth arrangement mechanism, and feeding the fiber into a fiber storage box. The fiber bundle dividing and washing method and the fiber bundle dividing and washing device can be widely applied to fiber dividing and washing treatment for various bast fibers, leaf fibers, and grass family fibers.

Owner:WUHAN HEMP BIOLOGICAL TECH CO LTD +3

Waste tyre fixed-bed gasification furnace and gasification method

InactiveCN103205279ACost savingsSave process costPlastic recyclingCombustible gas purificationProcess equipmentResource utilization

The invention relates to a waste tyre fixed-bed gasification furnace and a gasification method. The fixed-bed gasification furnace mainly consists of a charging system, a discharging system, an electric-arc type tar decomposer and a furnace body; the gasification method mainly comprises the following steps of: enabling tyre material blocks to react with gasification agent in the fixed-bed gasification furnace to generate a combustible gas; guiding the combustible gas out of the gasification furnace after most of tar in the combustible gas is primarily purified and removed by the electric-arc type tar decomposer on the inner top of the gasification furnace; and converting the combustible gas into the combustible gas with a medium heat value after the subsequent purifying and treating processes including dust-removing, condensing, spraying, sulfur-removing, drying, pressure-stabilizing and the like, wherein the tar separated in the subsequent purifying process is re-introduced to the gasification furnace for being secondarily decomposed. The gasification method is free of an extra heat source, so that the whole system is operated under micro-negative pressure, and no harmful gas is leaked in the process; and the whole process equipment can be continuously operated by virtue of the unique charging structure design and the discharging structure design of the fixed-bed gasification furnace, and therefore, the gasification method is an efficient waste tyre resource utilization method.

Owner:ZHONGSHAN SAIKE ENVIRONMENTAL PROTECTION TECH CO LTD

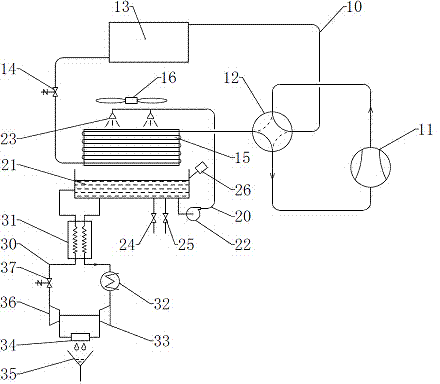

Heat pump type cold and heat source unit capable of achieving frost-free and evaporative cooling

InactiveCN104713266AIncreased sustained average effective heating capacity and efficiencyImprove heating service qualityCompression machines with reversible cycleRefrigeration componentsRefrigerantEngineering

A heat pump type cold and heat source unit capable of achieving frost-free evaporative cooling comprises a refrigerant circulation loop, a spraying water or water solution circulation loop and a water solution regeneration system circulation loop, wherein the refrigerant circulation loop comprises a compressor, a four-way reversing valve, a user-side heat exchanger, a throttle valve, an environment-side heat exchanger and a communication pipe I, a water or water solution pool, a circulating pump and a sprayer are arranged in the spraying water or water solution circulation loop, an inlet of the circulating pump is communicated with the water or water solution pool through a connecting pipe, an outlet of the circulating pump is communicated with the sprayer through a connecting pipe, water or a water solution is sprayed in the environment-side heat exchanger of the refrigerant circulation loop or a cooling tower communicated with the environment-side heat exchanger through the sprayer, and a solution heater, a high-pressure pump, a reverse osmosis device and a reverse osmosis pressure regulating valve are arranged in the water solution regeneration system circulation loop. The heat pump type cold and heat source unit is high in refrigerating / heating capacity and efficiency and has very important significance on energy saving and environmental protection.

Owner:HUNAN UNIV

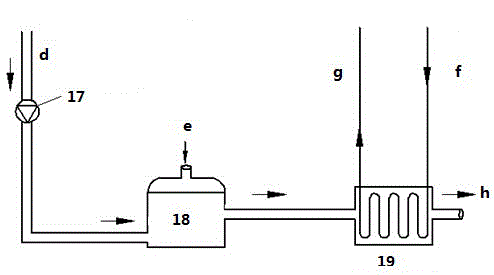

Thermal energy comprehensive utilization device for supplying hot water and generating power through solar energy

ActiveCN102418954AIncrease profitShorten heating timeFrom solar energyLighting and heating apparatusWater sourceSolar water heating system

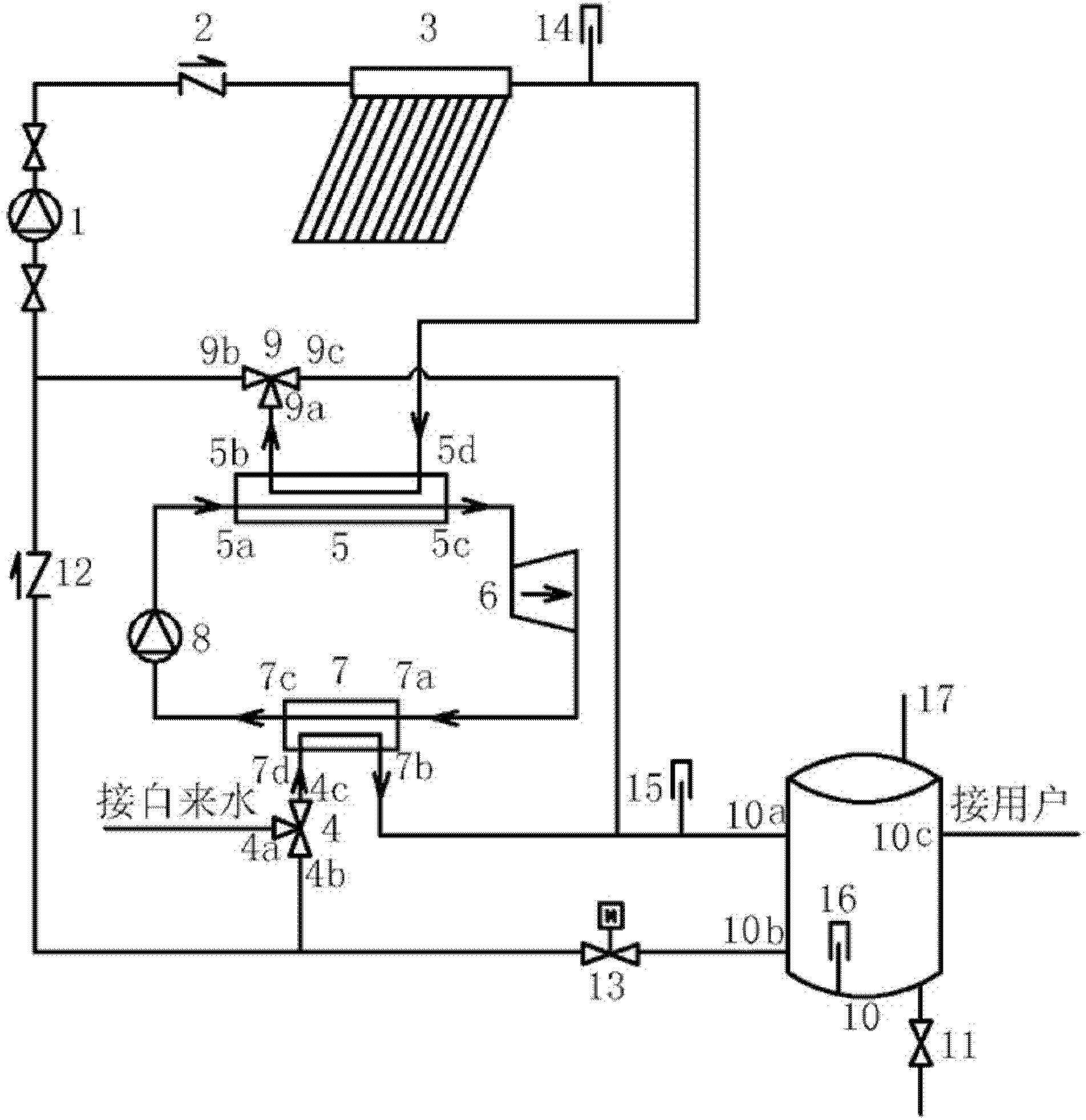

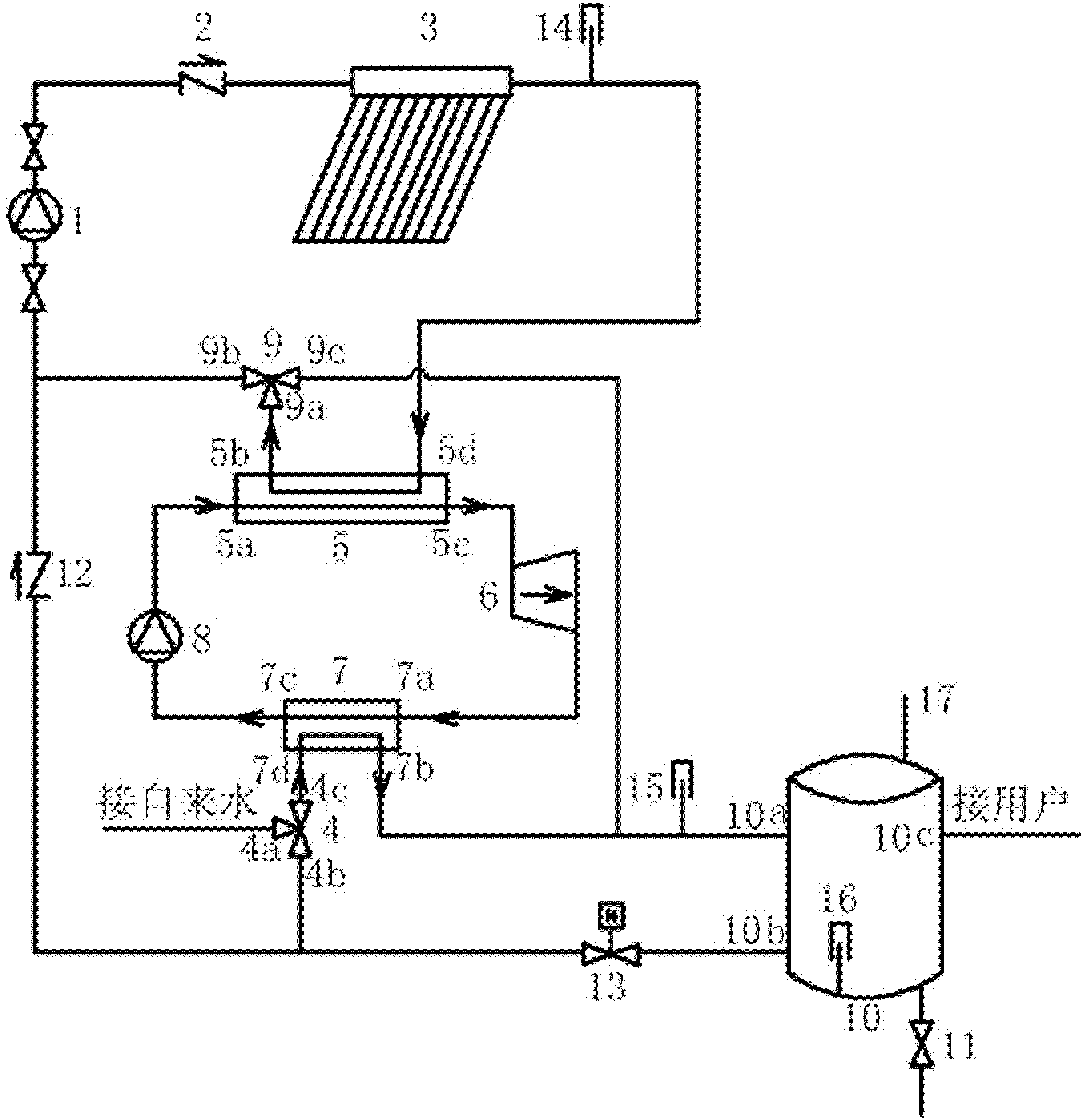

The invention discloses a thermal energy comprehensive utilization device for supplying comfortable hot water and generating power through solar energy. The device mainly comprises two parts, namely a solar hot water system and a Rankine cycle system. The device can be adjusted according to a water supply temperature set by a user, water is heated by a solar thermal collector, and effluent of thethermal collector is subjected to thermal energy recovery or cyclic heating. If the temperature of the effluent of the thermal collector is higher than the set water supply temperature, the Rankine cycle system is started to convert high-temperature thermal energy into electric energy; and if a water supply temperature of a water tank on a user side is lower than the set temperature, the water tank of the user is heated through the solar thermal collector, so that the condition that the water tank of the user provides comfortable hot water all the time is ensured. By the device, utilization amount and utilization efficiency of solar energy can be improved, the comfort level of domestic hot water is improved, the solar energy can be comprehensively used for supplying the domestic hot waterand generating the power, and evaporation waste of a water source caused by excessive heat energy is prevented; and the device is suitable for technical upgrade and technical transformation of civil and industrial solar thermal collectors.

Owner:宝莲华新能源技术(上海)股份有限公司 +1

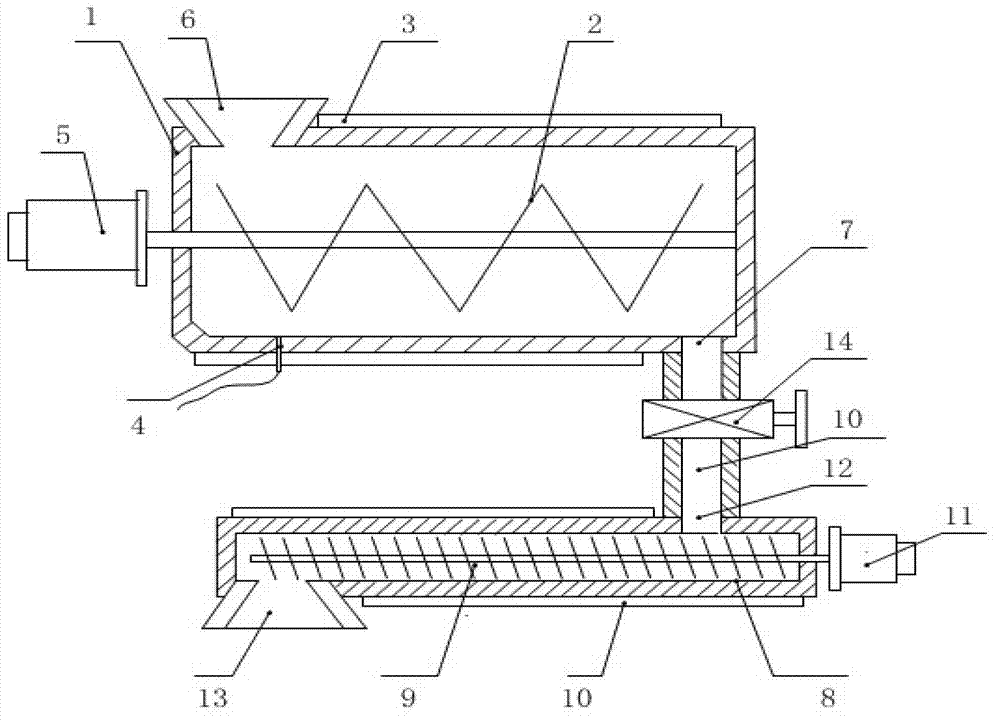

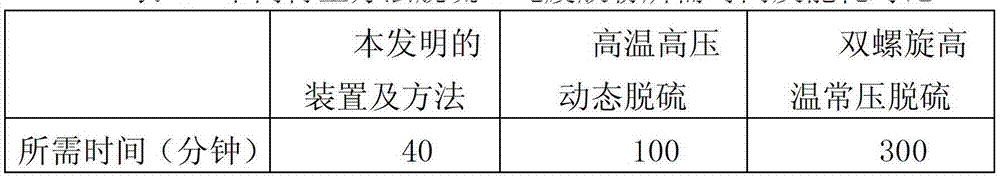

Device and method for regenerating waste rubber at normal pressure, medium temperature and low consumption

InactiveCN103205016ARecycling, environmental protection, energy saving and high efficiencyLow costChemical industryPlastic recyclingWaste rubberDrive motor

The invention relates to a device and a method for regenerating waste rubber at normal pressure, medium temperature and low consumption, and belongs to the field of reutilization of the waste rubber. The device comprises two parts, wherein the first part is a heating reaction kettle which comprises a tank body, a stirring paddle, a heater, a temperature sensor, a paddle driving motor, a first material inlet and a first material outlet; the second part is a cooler which comprises a cylinder body, a spiral, a cooling flow channel, a spiral driving motor, a second material inlet and a second material outlet; and the material outlet of the heating reaction kettle is connected with the material inlet of the cooler. The regeneration process flow which utilizes the device comprises the following steps of: simultaneously adding metered waste rubber, softening agents and activating agents to the heating reaction kettle; reacting at 160-250 DEG C for 15-40 minutes, and then opening a connecting valve to enter the cooler; conveying for 8-15 minutes through the spiral, and cooling materials to be lower than 80 DEG C. The device and method which are disclosed by the invention have the advantages of low manufacturing cost and environmental protection and energy saving in a production process, effectively solve the problem of wall adhesion of rubber powder in a regeneration process and are stable in product quality.

Owner:QINGWEI RUBBER SUQIAN +1

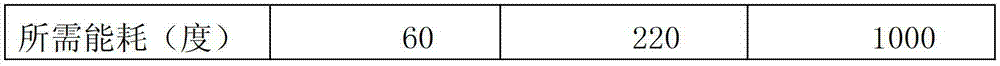

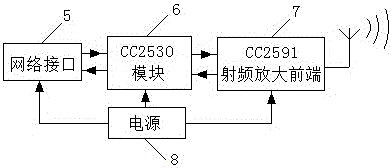

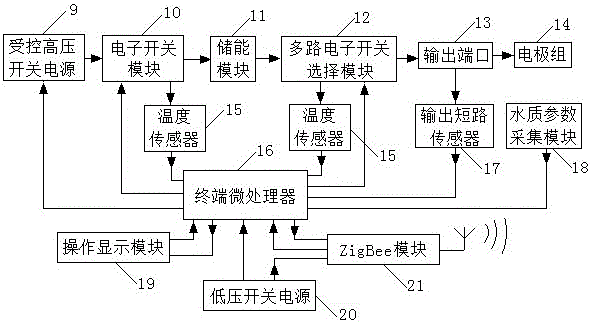

Zigbee-based wireless fish blocking system

InactiveCN105116849ALess investmentStrong networking abilityTotal factory controlProgramme total factory controlTerrainWireless transmission

The invention discloses a zigbee-based wireless fish blocking system. The system comprises a PC upper computer, a coordinator, routers and a plurality of terminal controllers for blocking fishes; the PC upper computer is used in display and control of working states of the terminal controllers; the coordinator is in serial port communication with the upper computer and in communication with the routers through wireless transmission; the routers are connected with the terminal controllers through wireless transmission; and the terminal controllers are used in fish blocking control. An existing fish blocking control system is implemented through wired connection, is high in cost and cannot achieve remote control, and the control system achieves remote control through the wireless transmission and does not need to build a system control station in complex terrain, so fish blocking cost is greatly reduced, unified monitoring of large-scale adaptive water area fish blocking can be achieved, the zigbee-based wireless fish blocking system has the advantages of the good anti-interference capability, the continuous running capability, simple maintenance and the good fish blocking effect, and the system can be widely popularized and applied.

Owner:SOUTHWEST UNIV

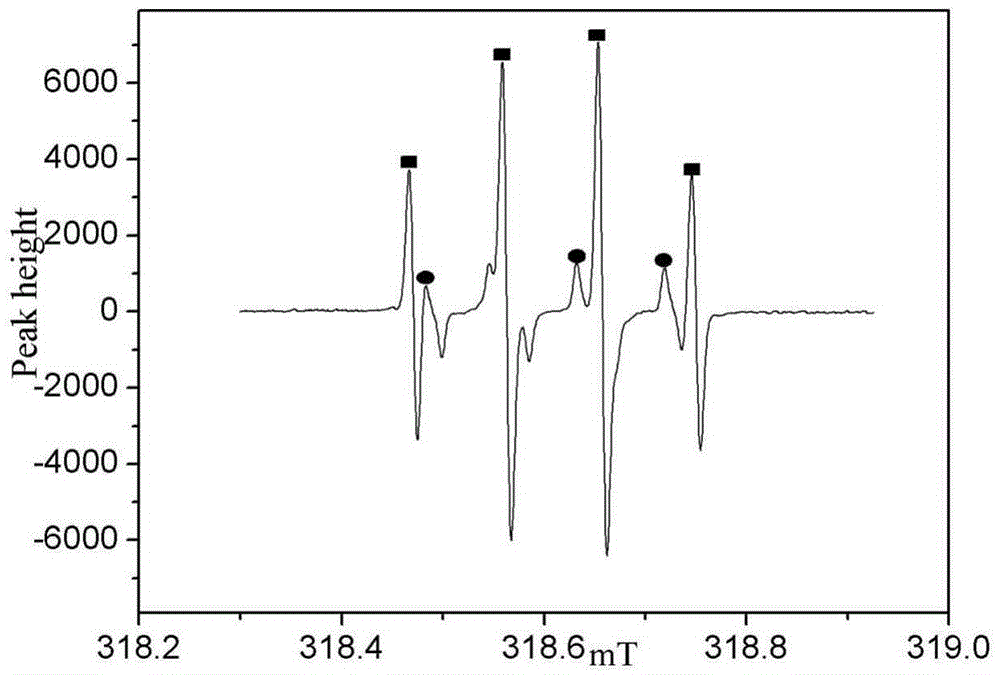

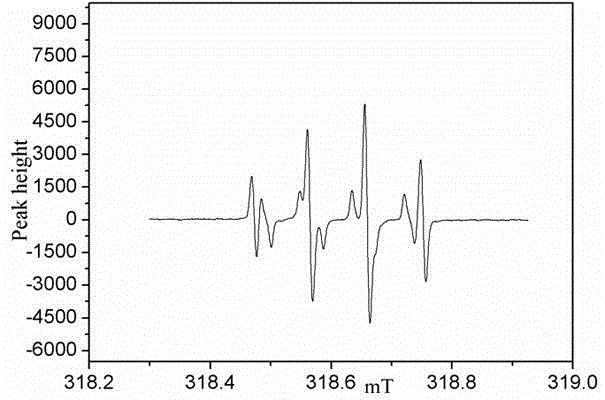

Method for removing VOCs (volatile organic chemicals) by ozone and photolytic peroxide

ActiveCN104815537ANo secondary pollutionEfficient removalDispersed particle separationAir quality improvementSulfate radicalsDecomposition

The invention relates to a method for removing VOCs (volatile organic chemicals) by ozone and photolytic peroxide. According to the method, the VOCs from a discharging source are firstly pre-oxidized into organic intermediate by the ozone in a flue, ultraviolet light excites the peroxide to generate sulfate radical and hydroxyl free radical, so that the VOCs and the organic intermediate generated by oxidization of the ozone are further oxidized, and final decomposition products are harmless CO2 and harmless H2O. The VOCs in flue gas can be efficiently removed, secondary pollution is avoided in the removing process, and a novel VOCs purification system has a wide application prospect.

Owner:CHANGSHU YONGXIN PRINTING & DYEING CO LTD

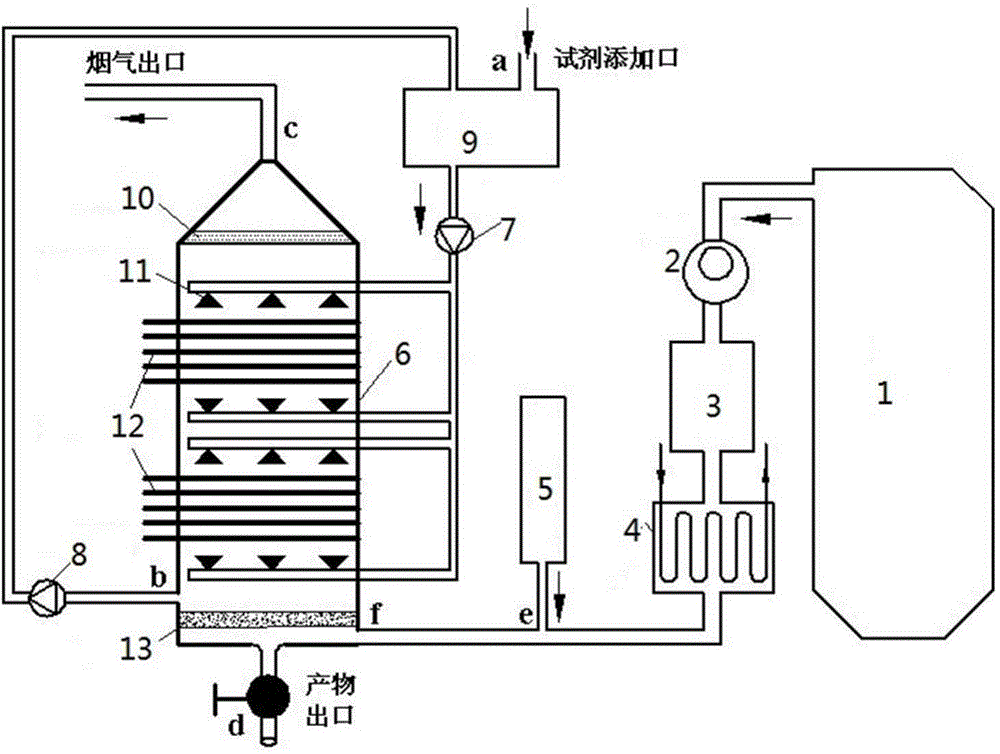

Ozone combined photo-excited peroxide VOCs (volatile organic chemicals) purification system and method

ActiveCN104815534ALow application costEasy to removeDispersed particle separationParticulatesSulfate radicals

The invention relates to an ozone combined photo-excited peroxide VOCs (volatile organic chemicals) purification system and method, and belongs to the field of atmospheric pollutant control. The purification system mainly comprises a dust collector, a cooler, a photochemical atomization bed reactor, a gas distribution nozzle, a circulating pump, a particulate matter filtering device, a charging tower, a spray pipeline, a main flue, a demister and a product post-processing system. VOCs from a discharging source are firstly pre-oxidized into organic intermediate by the ozone in a flue, ultraviolet light excites peroxide to generate sulfate radical and hydroxyl free radical, so that the VOCs and the organic intermediate generated by oxidization of the ozone are further oxidized, and final decomposition products are harmless CO2 and harmless H2O. The VOCs in flue gas can be efficiently removed, secondary pollution is avoided in the removing process, and the novel VOCs purification system has a wide application prospect.

Owner:JIANGSU UNIV

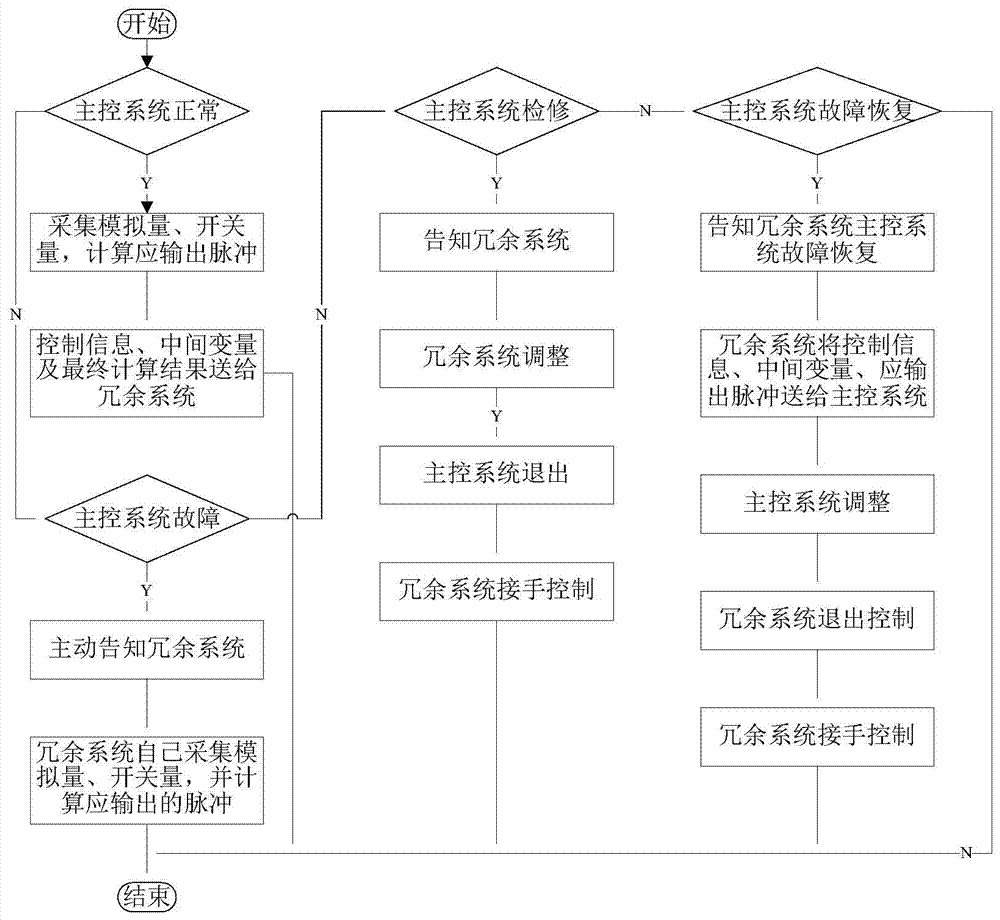

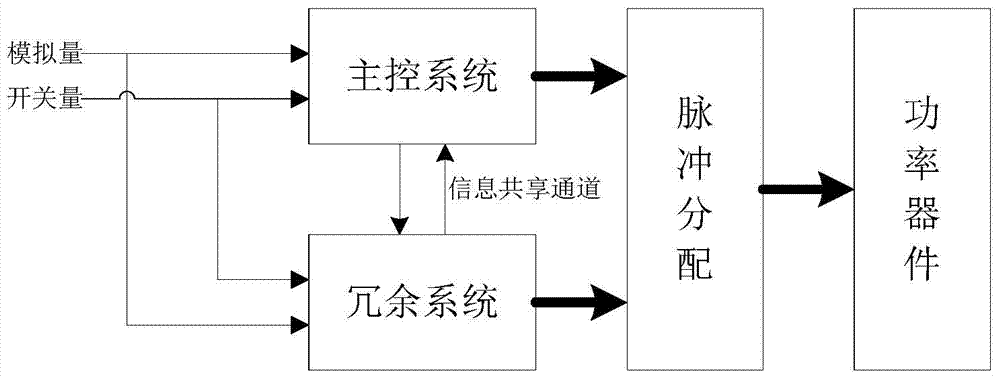

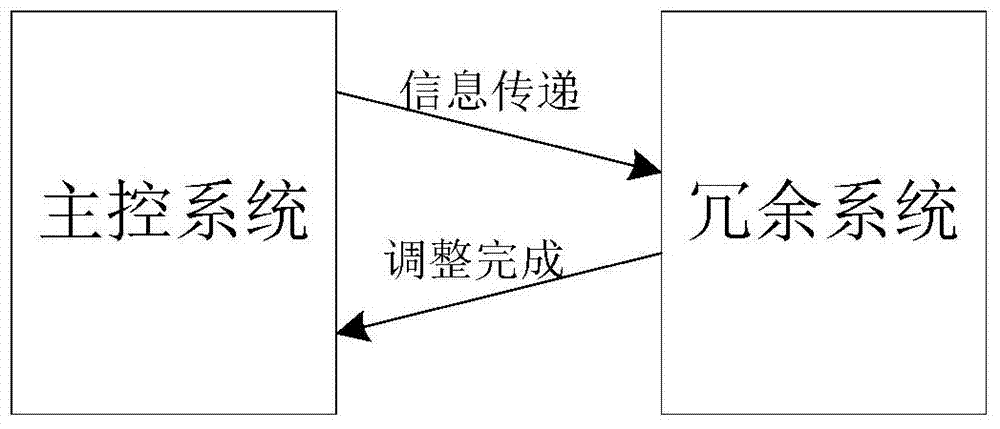

Redundancy control method for flexible direct current transmission system

ActiveCN104852372AAchieve continuous operationLow failure rateDc network circuit arrangementsFailure rateElectric power system

The invention relates to a redundancy control method for a flexible direct current transmission system, and belongs to the field of an electric power system. The method adopts two control systems which are a main control system and a redundancy control system, wherein the two control systems are identical in function and can control operations of the whole direct current transmission system independently at specific conditions. The main control system carries out control on a flexible direct current system and transmits operation control information to a redundant system through a high-speed optical fiber at the same time, and the redundant system stays at a hot standby state. When the main control system is abnormal, the redundant system identifies automatically and completes control for the flexible direct current system automatically according to the received operation control information before the abnormity, the redundant system turns into the main control system, and the original main control system is notified to turn into the redundant system. According to the method provided by the invention, the redundant system automatically completes control for the flexible direct current system when the main control system is abnormal, the failure rate of the system is reduced, and the operation reliability of the system is improved.

Owner:CHINA SOUTHERN POWER GRID COMPANY +1

Continuous reactor suitable for ion liquid catalyst and its use

ActiveCN1676207AAchieve continuous operationAchieve recyclingOrganic-compounds/hydrides/coordination-complexes catalystsHydrocarbonsIonChemistry

The present invention relates to a continuous type reactor for ion liquid catalyst, including reaction section and settling section. The reaction section includes 1-8 series-connected reaction tanks, and the settling section includes a settling tank, in which reaction tank includes raw material inlet, new catalyst inlet, circulating catalyst inlet and material outlet, and the settling tank includes material inlet, material outlet and catalyst collector, said catalyst collector is positioned in the bottom portion of settling tank, and the outlet of the collector is connected with circulating catalyst inlet of reaction tank by means of pipeline, and the pipe line is set a valve for controlling circulating quantity of the catalyst. Said invention also provides its concrete application method.

Owner:CHINA PETROLEUM & CHEM CORP

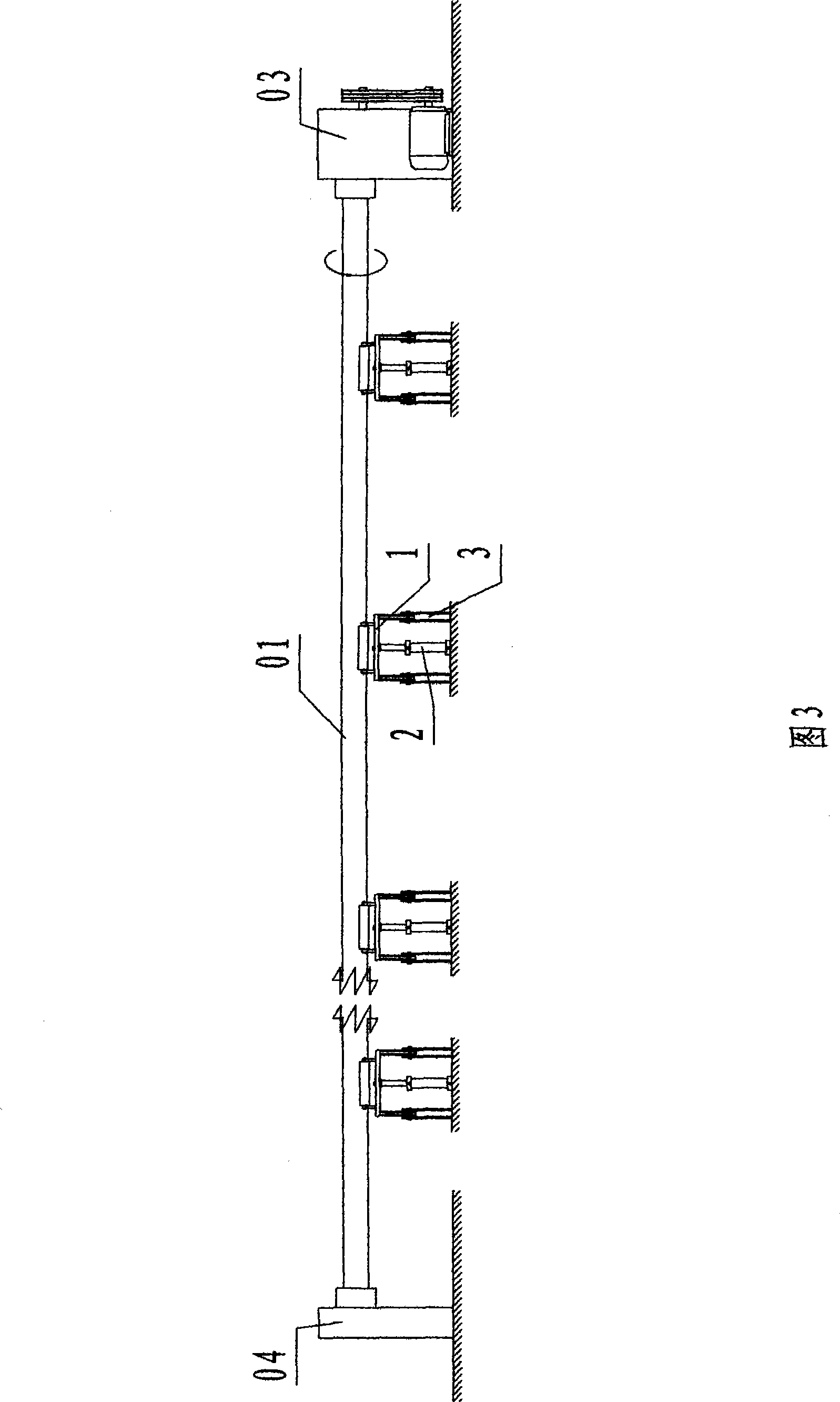

Pneumatic supporting device for producing ultralong large caliber rubber hose

InactiveCN101457857AMeet production requirementsOvercoming production inefficienciesFlexible pipesEngineeringContinuous operation

The invention discloses a pneumatic supporting device for producing hosepipe with an overlong heavy caliber, which comprises a double-roll supporting bracket (1), an air cylinder (2), a slide grooved rail (3) and a spacing pin (4). The invention adopts the technical scheme of supporting and stabilizing a core bar by the pneumatic supporting device, and overcomes the problem and defect of low production efficiency of the prior art. The pneumatic supporting device for producing hosepipe with an overlong heavy caliber supplied by the invention utilizes the elasticity and the damping characteristic of compressed air to automatically adjust the supporting height and eliminate vibration by a double-roll support with the increased thickness of a winding adhesive layer of the core bar under the condition of given supporting force, and therefore, the production of hosepipe with an overlong heavy caliber achieves the goals of continuous operation and higher production efficiency.

Owner:宁波大洋实业发展有限公司

Slurrying and visbreaking method for improving liquidity of dewatered sludge

The invention relates to the field of solid waste treatment, in particular to a slurrying and visbreaking method for improving liquidity of dewatered sludge. The method includes: placing the dewatered sludge into a container with a shearing and stirring function, closing a feeding port to enable the container to be hermetic, and enabling the dewatered sludge to be in an anoxic or anaerobic environment; setting the rotation speed of a stirrer to be 10-40r / min; continuously stirring the dewatered sludge, and adding inorganic salts or / and alkaline substances for catalysis, wherein stirring time is in inverse proportion to the set rotation speed at the stage, and the minimum stirring time is 2.5h; and when material viscosity is lowered by more than 40%, lowering the stirring rotation speed to10-30r / min, setting a 'stirring / stopping' time proportion of the stirrer to be 1 / 5-1 / 1, wherein the stirring time is in inverse proportion to the set rotation speed, and materials can be slurried after 15-30h. By controlling the stirring speed, the anoxic environment and stirring modes to enable physical slurrying and biological slurrying to play a synergetic role, slurrying efficiency of the dewatered sludge is improved, and viscosity of the dewatered sludge can be lowered by 70-80% within 20-35h, so that the slurrying and visbreaking method for improving liquidity of the dewatered sludge isefficient, low in consumption, simple in device and operation and suitable for amplification and popularization in projects.

Owner:TONGJI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com