Planet gyration small circular cylinder continuous pressure filtration machine

A pressure filter, planetary technology, applied in the direction of filtration separation, moving filter element filter, separation method, etc., can solve the problems of affecting the filtration effect, single discharge method, small filter area, etc., to achieve flexible and diverse discharge methods , Solve the tendency of anti-humidity, and the effect of reliable filtering operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

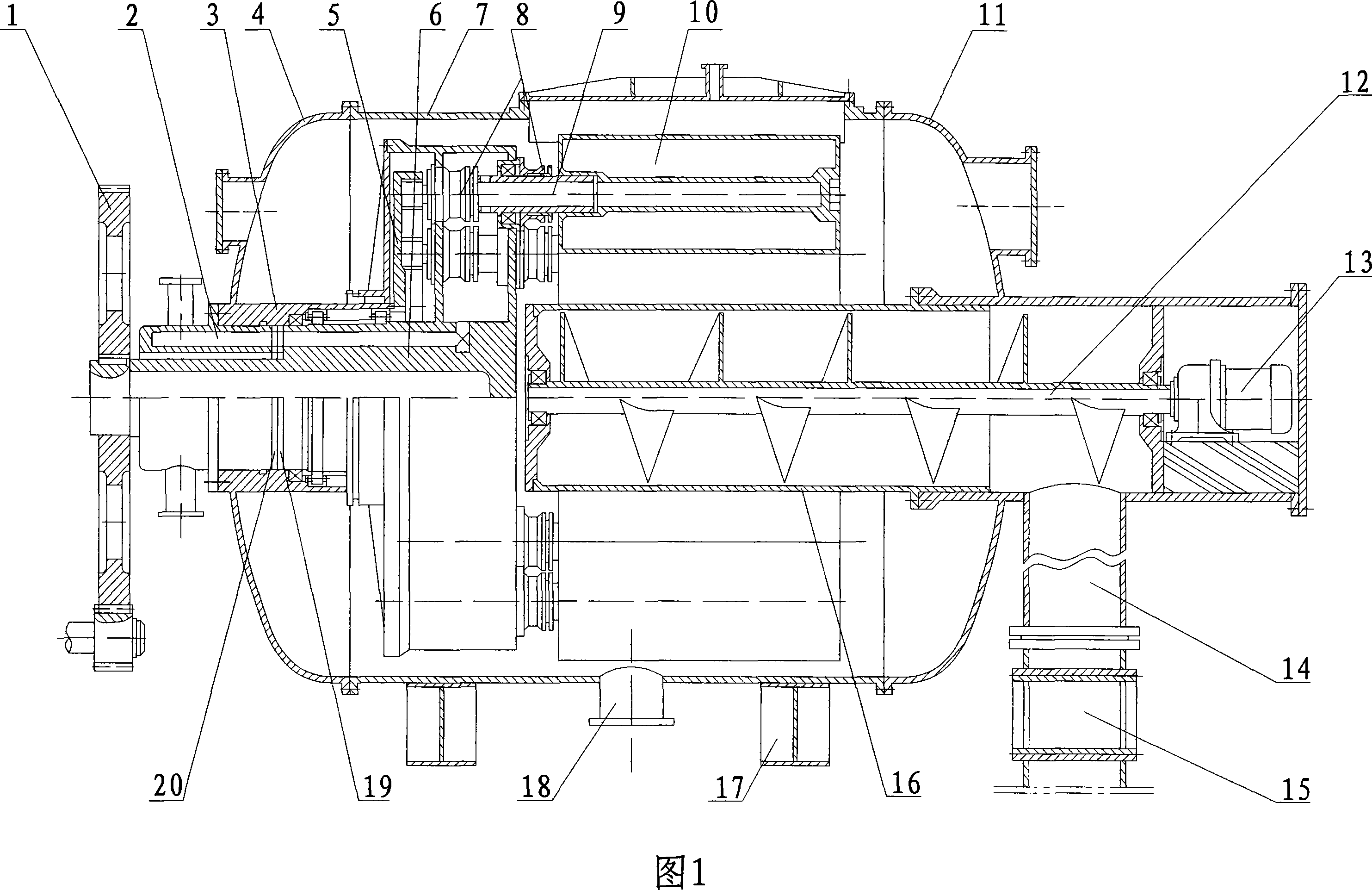

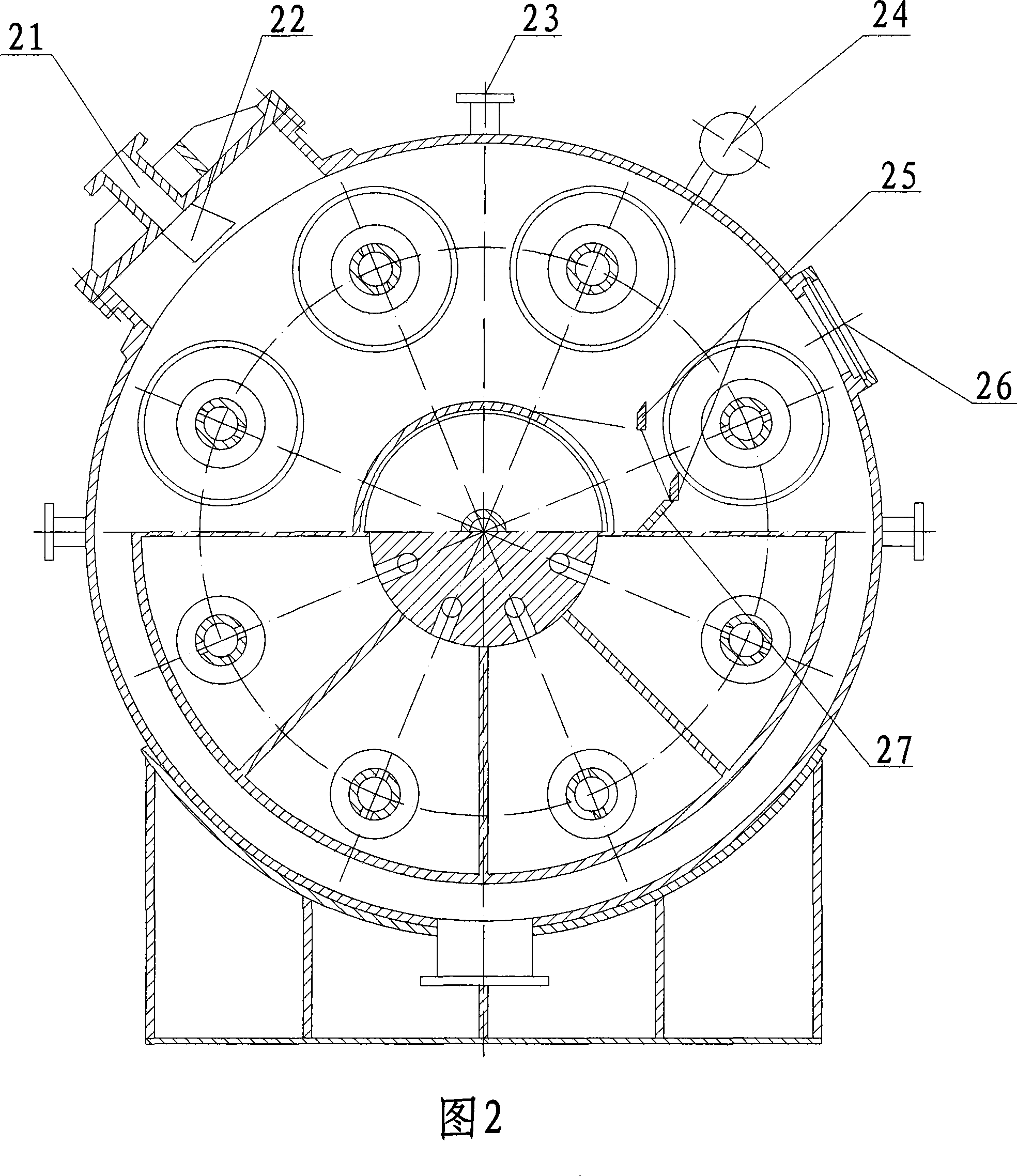

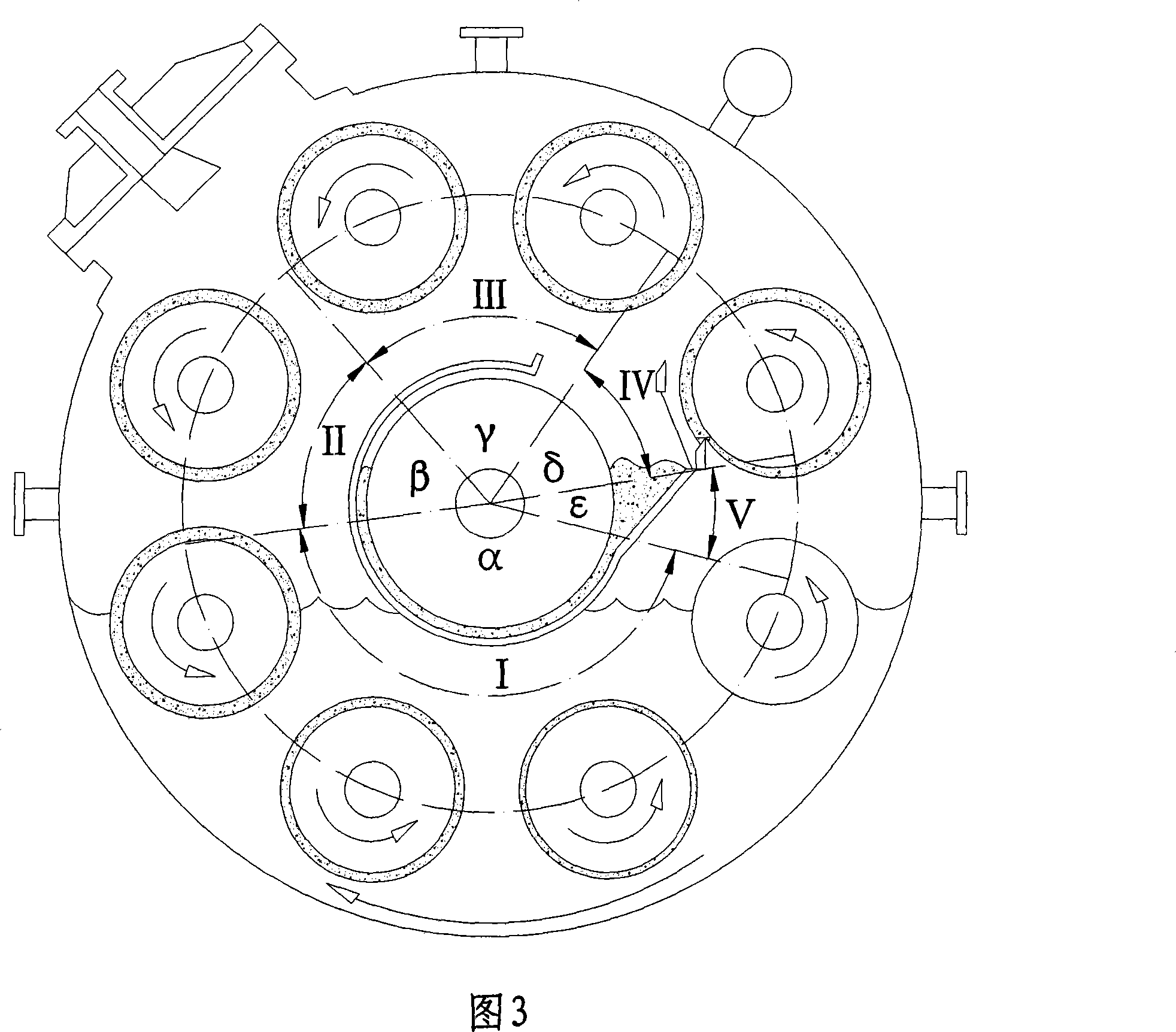

[0072] The planetary rotary small cylinder continuous pressure filter is used for the filtration and separation of PTA (purified terephthalic acid). The planetary rotary small cylinder continuous pressure filter has a pressure shell consisting of a head 4, a cylinder body 7 and a head 11, and is fixedly supported on the base by a support 17. Inside the pressure shell, the main rotary body and the unloading and slag discharge mechanism are arranged. Among them, after the filter cartridge 10 is connected with the filter shaft 9, it is installed on the grid drum 32 of the planet carrier 6 to form a filter unit; the filter cartridge is 1m long, and the filtering area of a single filter cartridge is 1m 2 , with a total filter area of 10m 2 There are 10 groups of such filter units in the whole pressure shell, which are jointly installed on the grid drum 32 to form the main rotary body, which is the main core component of the filter work. The main revolving body is driven by a ...

Embodiment approach 2

[0076]The planetary rotary small cylinder continuous pressure filter is used for the filtration and separation of heavy alkali in the production of soda ash. The shell of the planetary rotary small cylinder continuous pressurized filter is supported by the saddle 17 and fixed on the machine base. A bearing seat 3 is installed in the center of the left head 4, and the static distribution head 2 is fixedly placed in the bearing seat 3. At the same time, the planet carrier 6 is placed in the bearing seat 3 through two pairs of bearings, and the left end shoulder of the planet carrier 6 is used as the dynamic distribution head 29. , and opposite to the static distribution head 2, the dynamic distribution head 29 and the static distribution head 2 respectively have a dynamic dislocation gas disc 19 and a static dislocation gas disc 20 fixedly connected with them, and the end faces of the two dislocation gas discs are tightly combined to realize sealing, and at the same time achieve ...

Embodiment approach 3

[0080] The planetary rotary small cylinder continuous pressure filter is used for the filtration and separation of PVC, and the filter cake does not need to be washed during the process of filtering and separating PVC. The whole body of the planetary rotary small cylinder continuous pressure filter is supported and fixed on the machine base by the support 17 through the shell, and the filter shell is composed of three parts, including the head 4, 11 and the cylinder 7. There are main rotary body and unloader conveying mechanism inside the shell. Wherein the main rotating body is composed of a planet carrier 6 and multiple sets of filter assemblies installed thereon. There is a divisional drum 32 with a short axial length on the planet carrier 6. The interior of the divisional drum 32 is divided into 12 independent sections by partitions, and each independent divisional section has a filtrate channel 30 communicating with it. . Each group of filter assemblies is composed of a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com