Patents

Literature

486results about How to "Wash evenly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

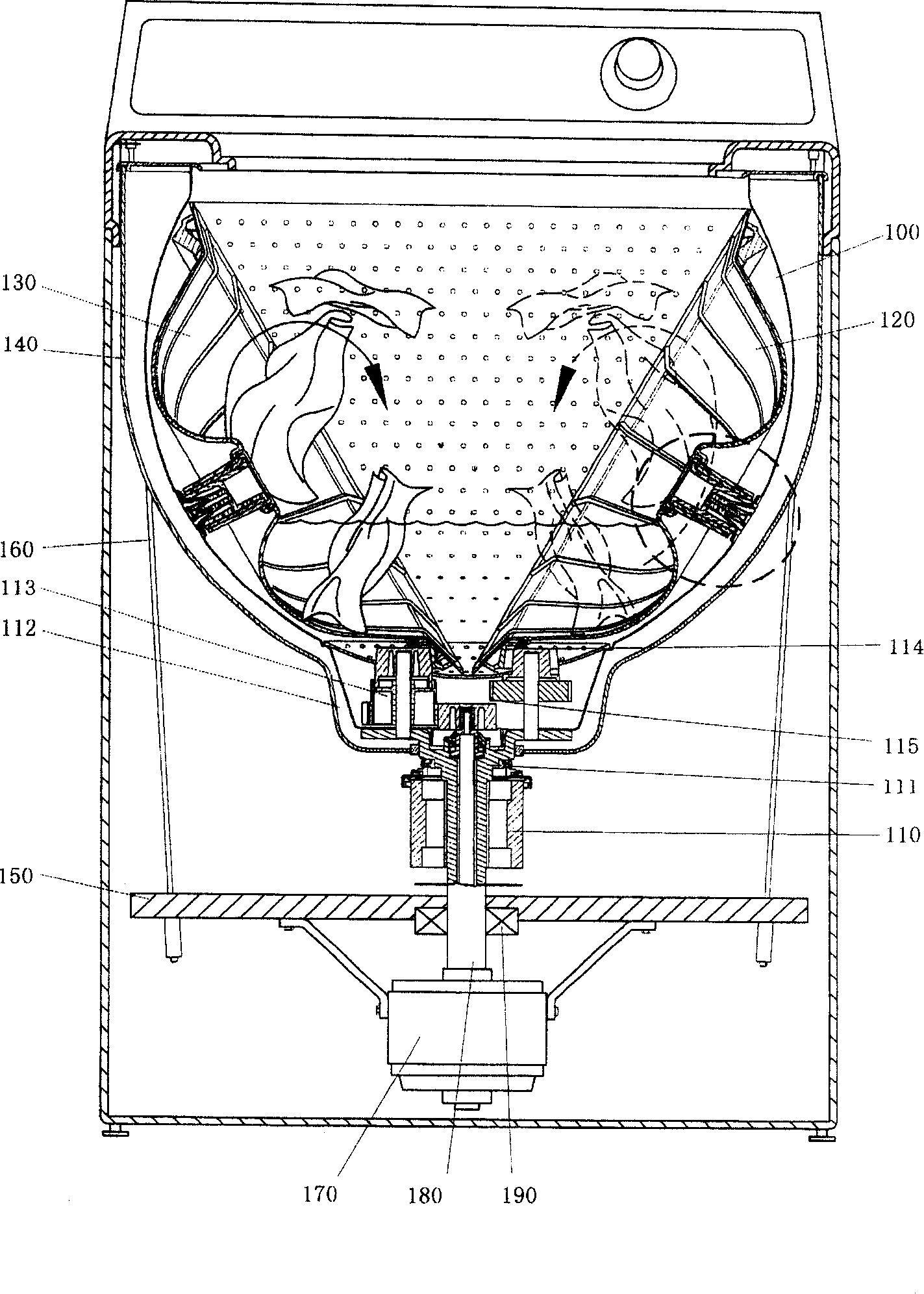

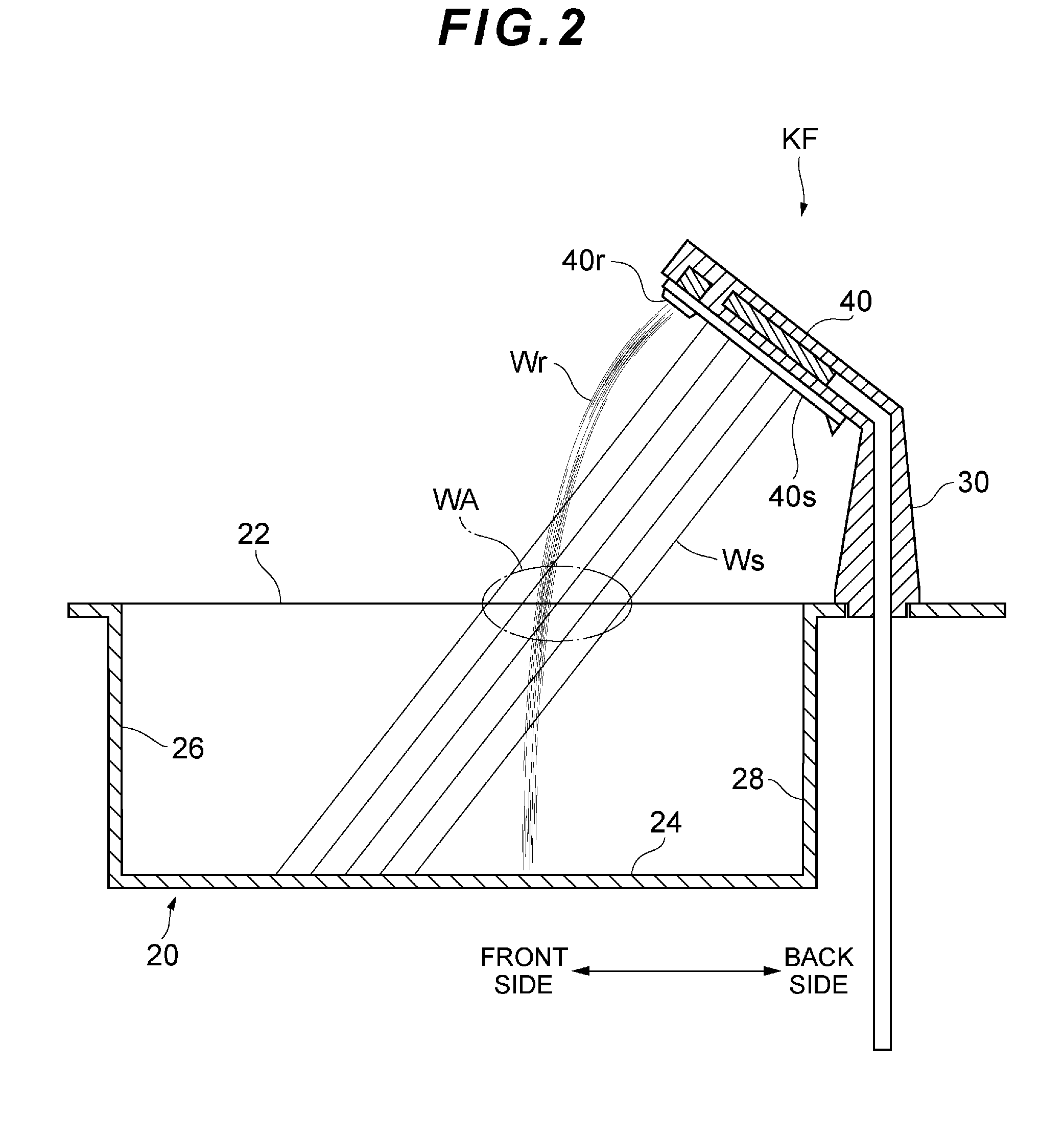

Washing machine

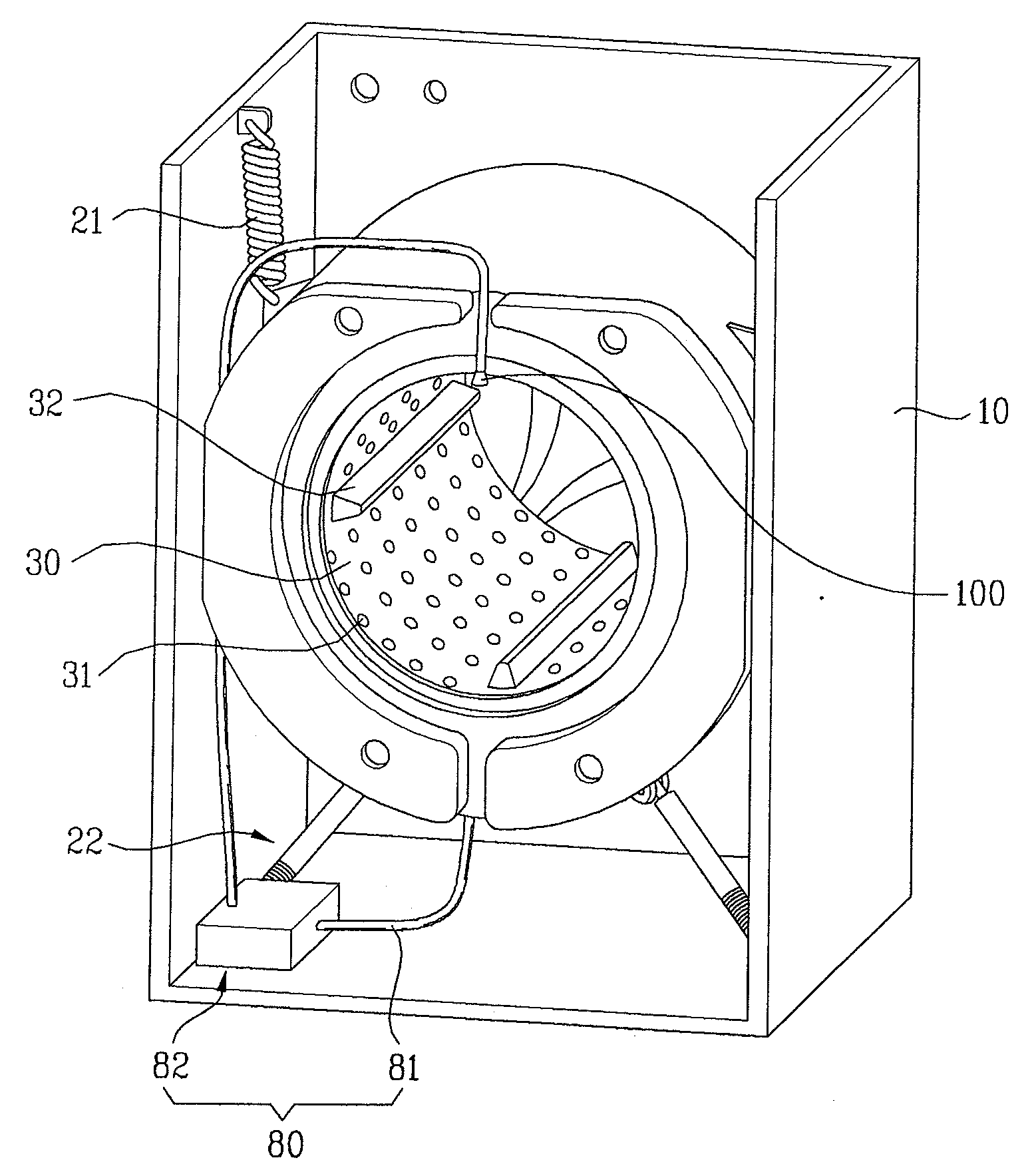

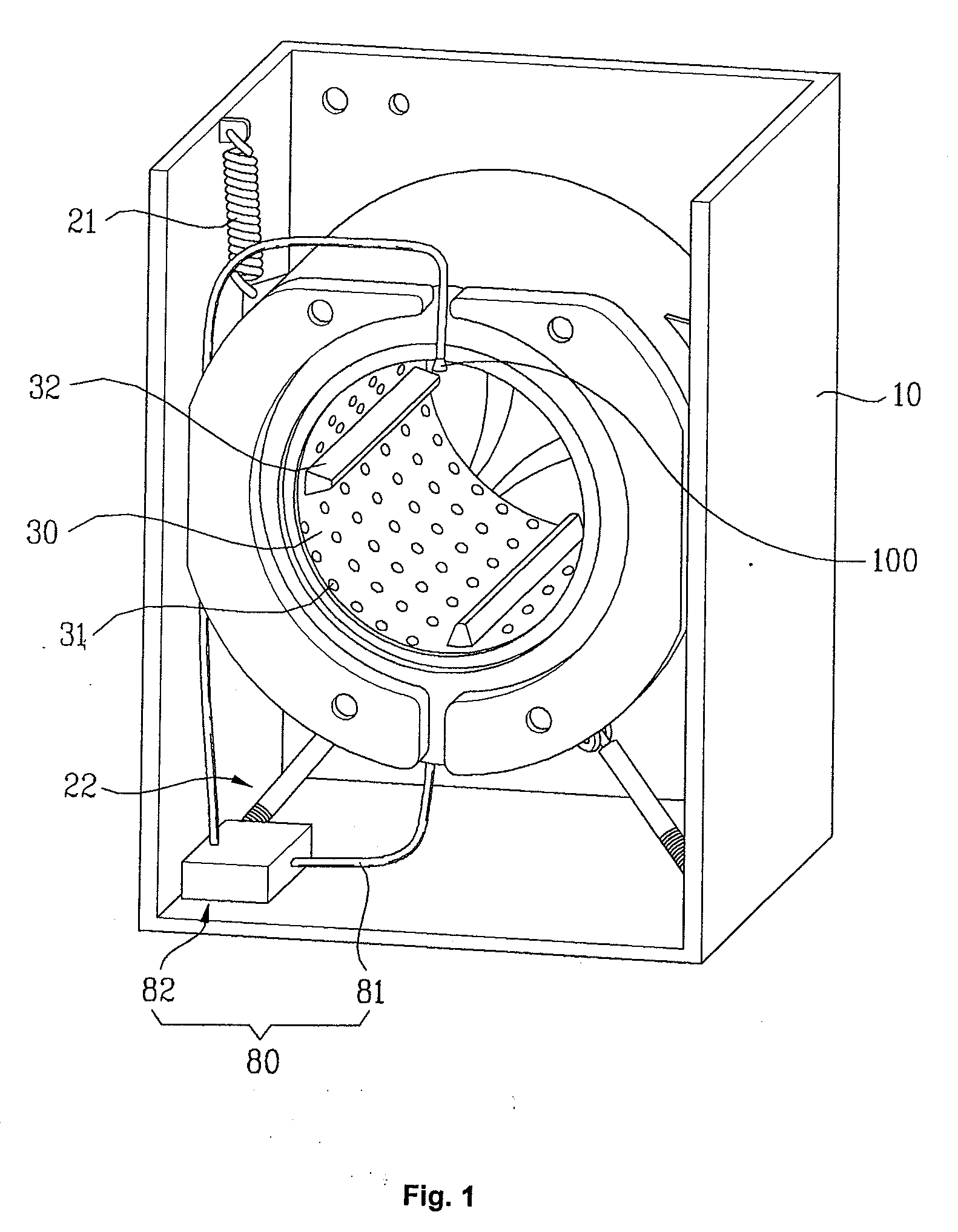

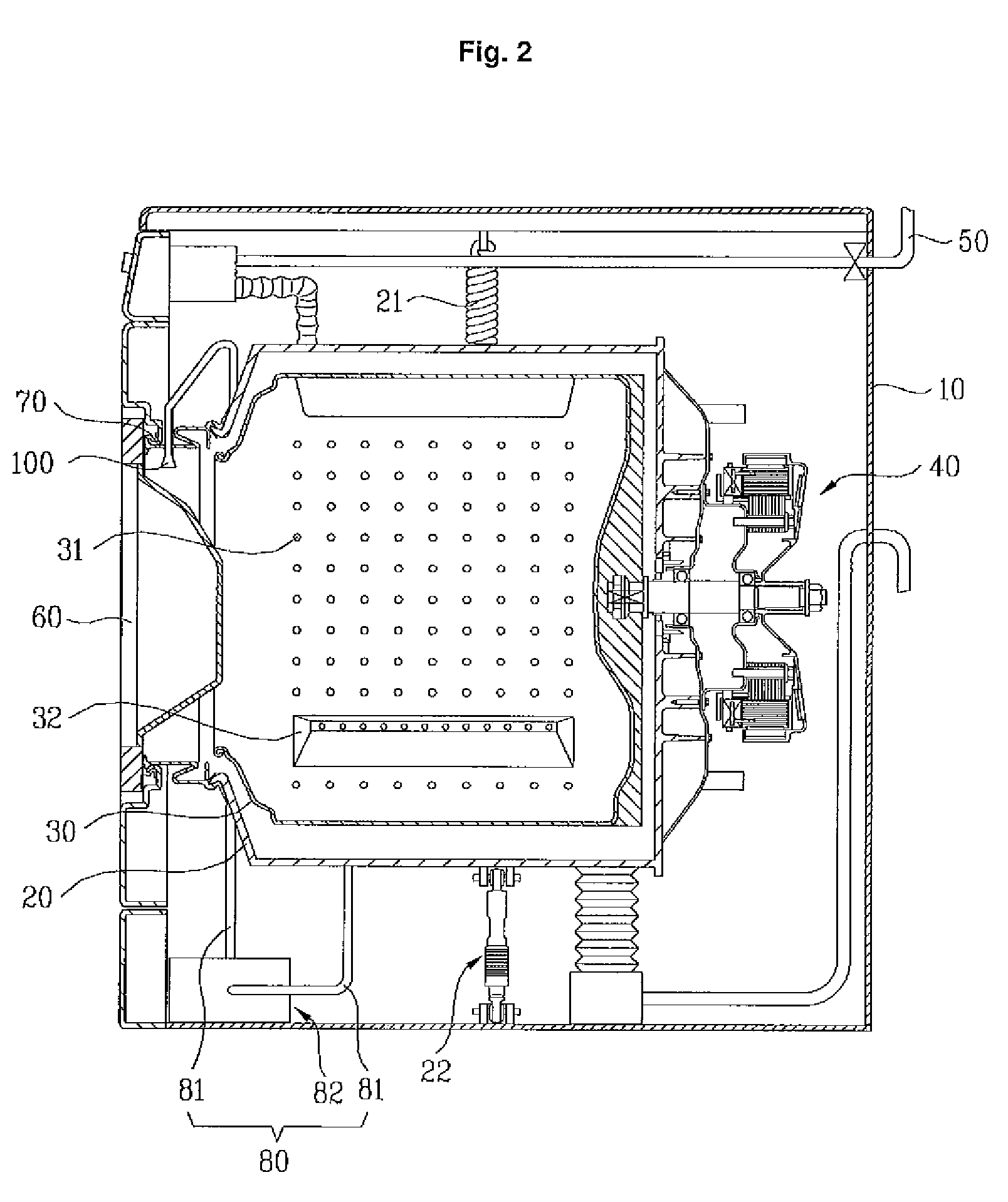

InactiveUS20090249838A1Uniform supplyWash evenlyOther washing machinesWashing machine with receptaclesSpray nozzleEngineering

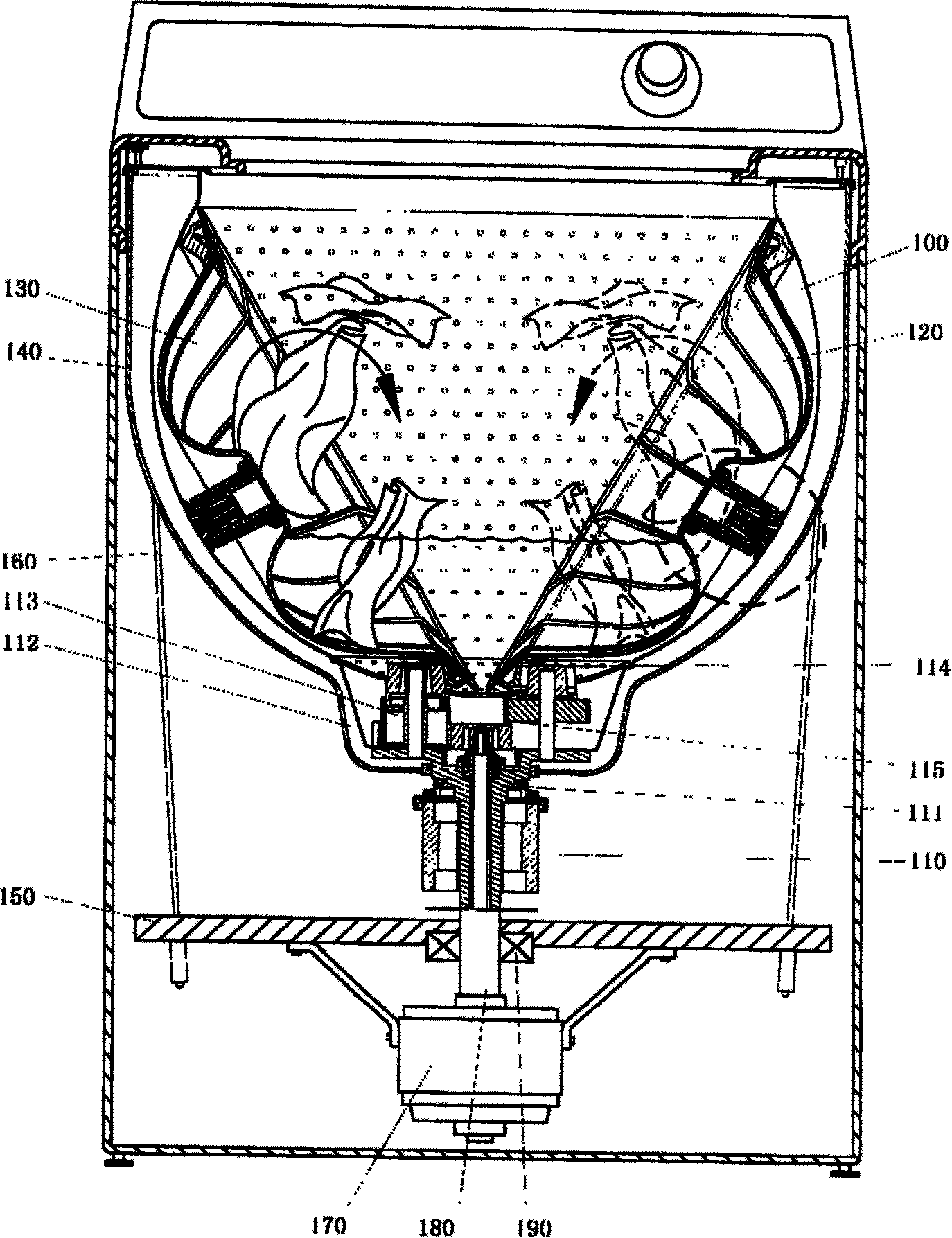

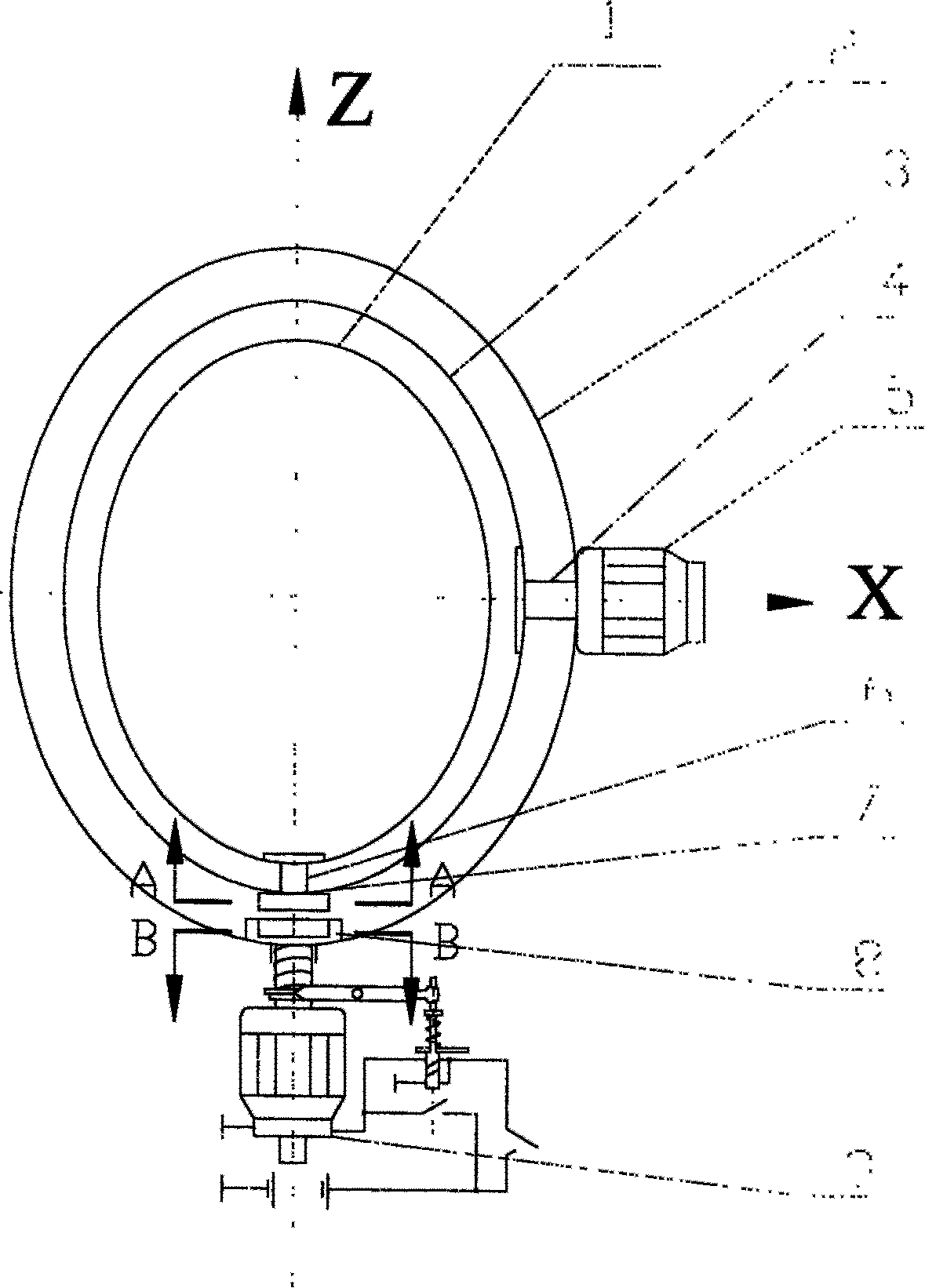

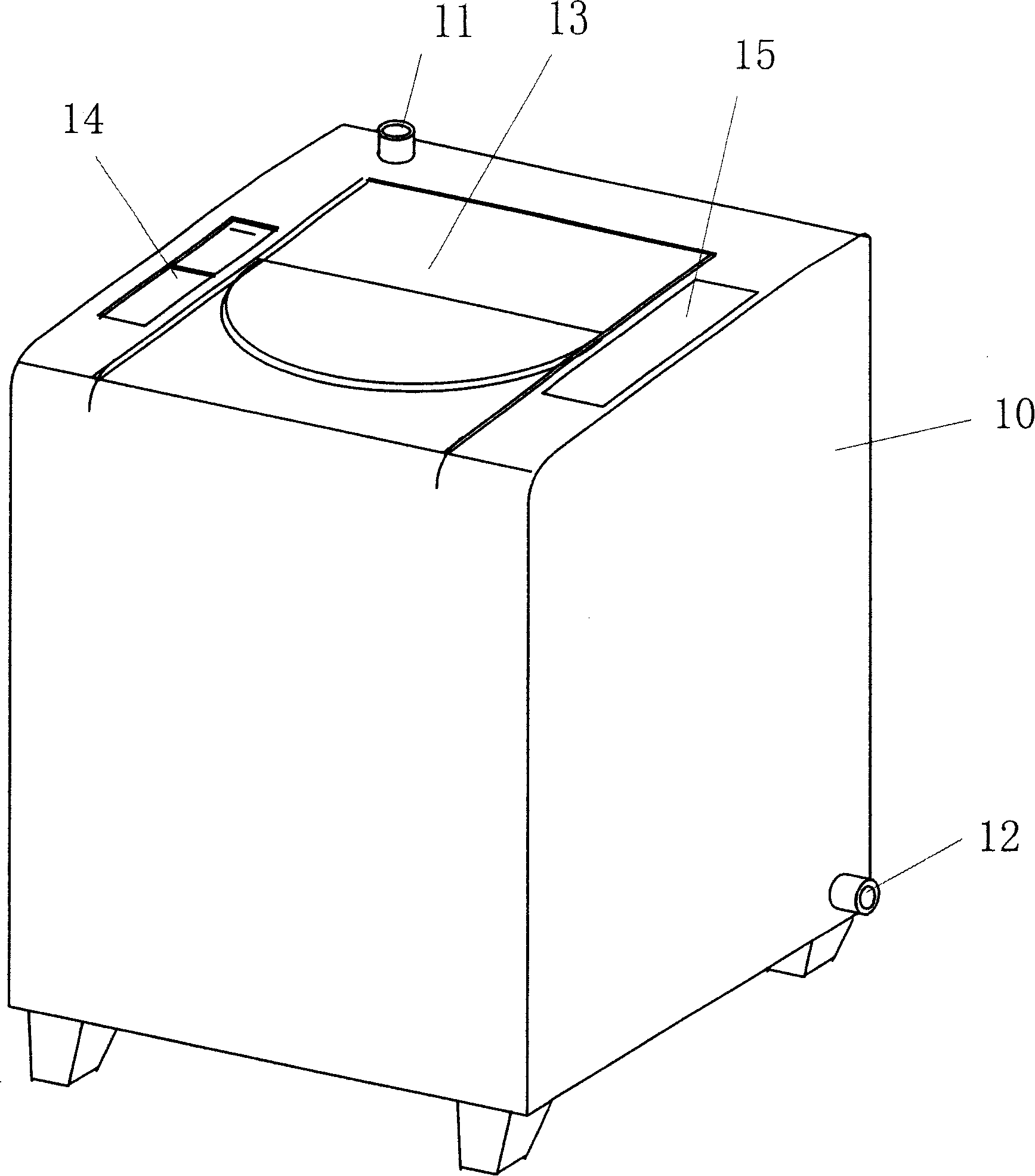

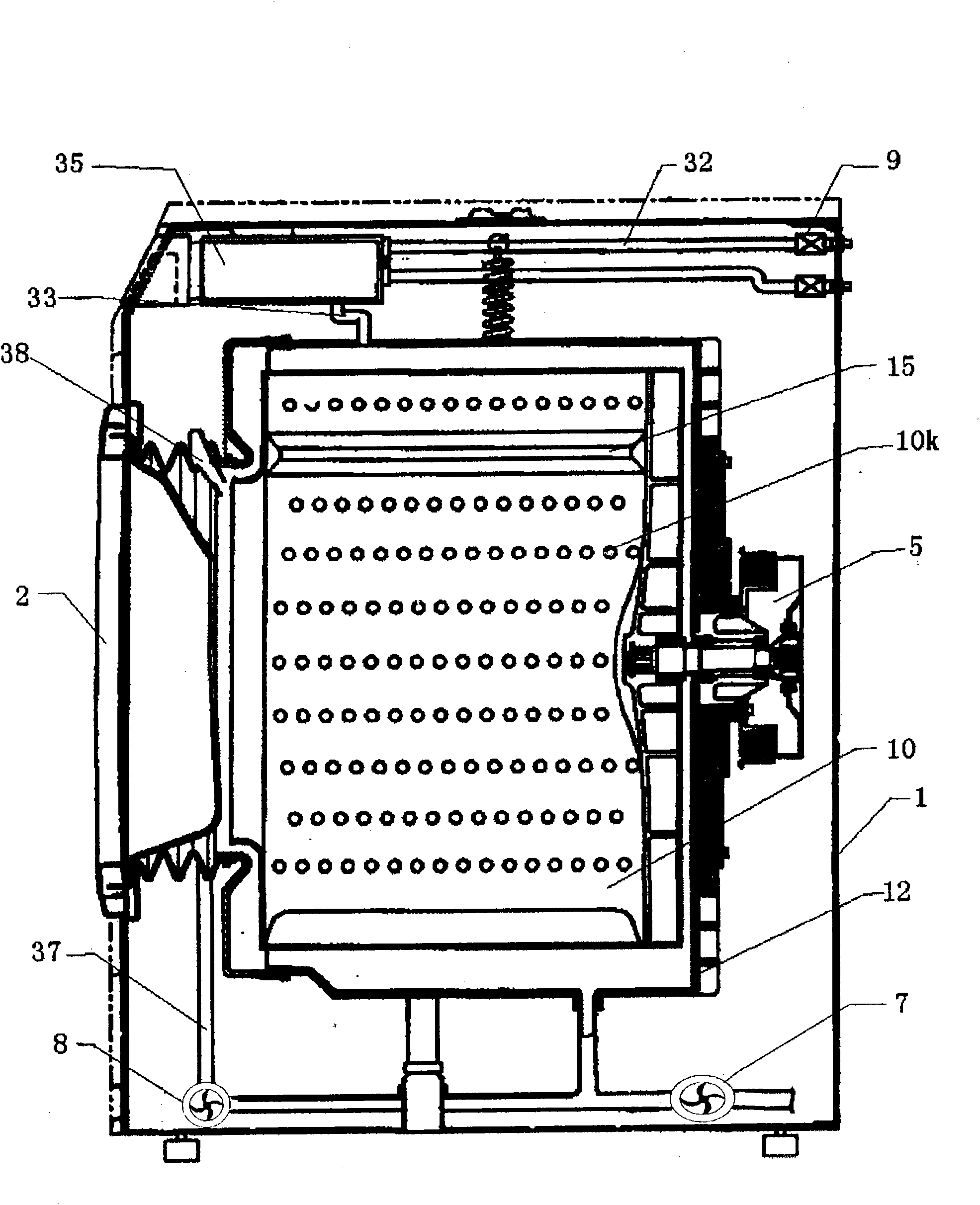

A circulatory washing machine, in which water stored in the bottom of a tub is circulated and supplied to a drum. The washing machine includes a tub for containing washing water; a drum rotatably installed in the tub; a circulation unit for circulating the washing water stored in the tub to the upper portion of the drum; and a spray nozzle for spraying the washing water, circulated by the circulation unit, to the rear portion of the inside of the drum.

Owner:LG ELECTRONICS INC

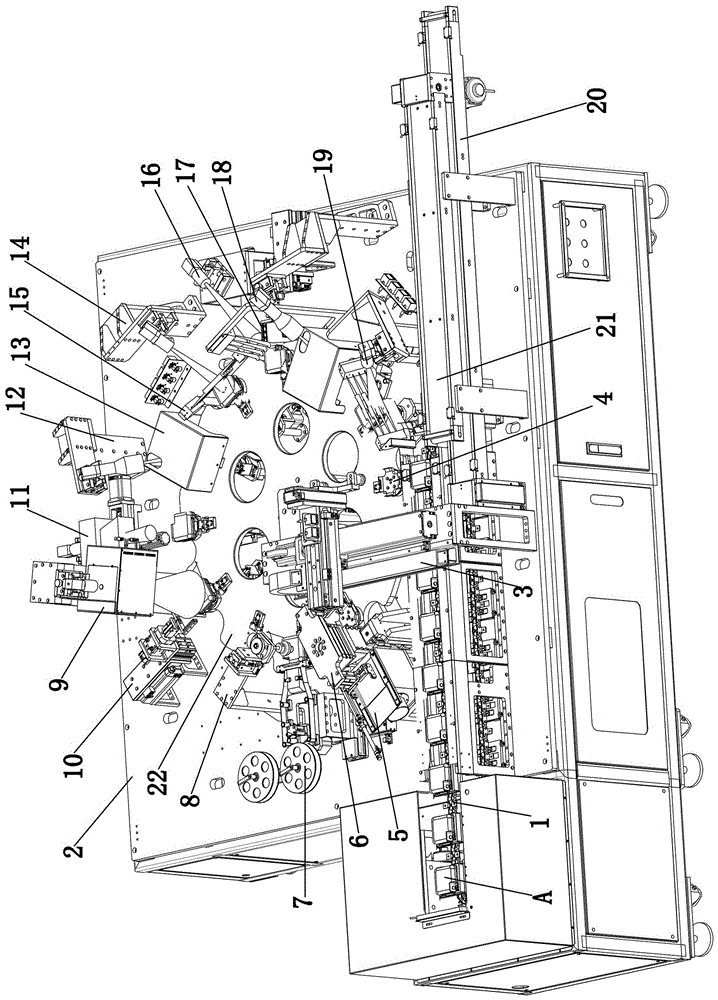

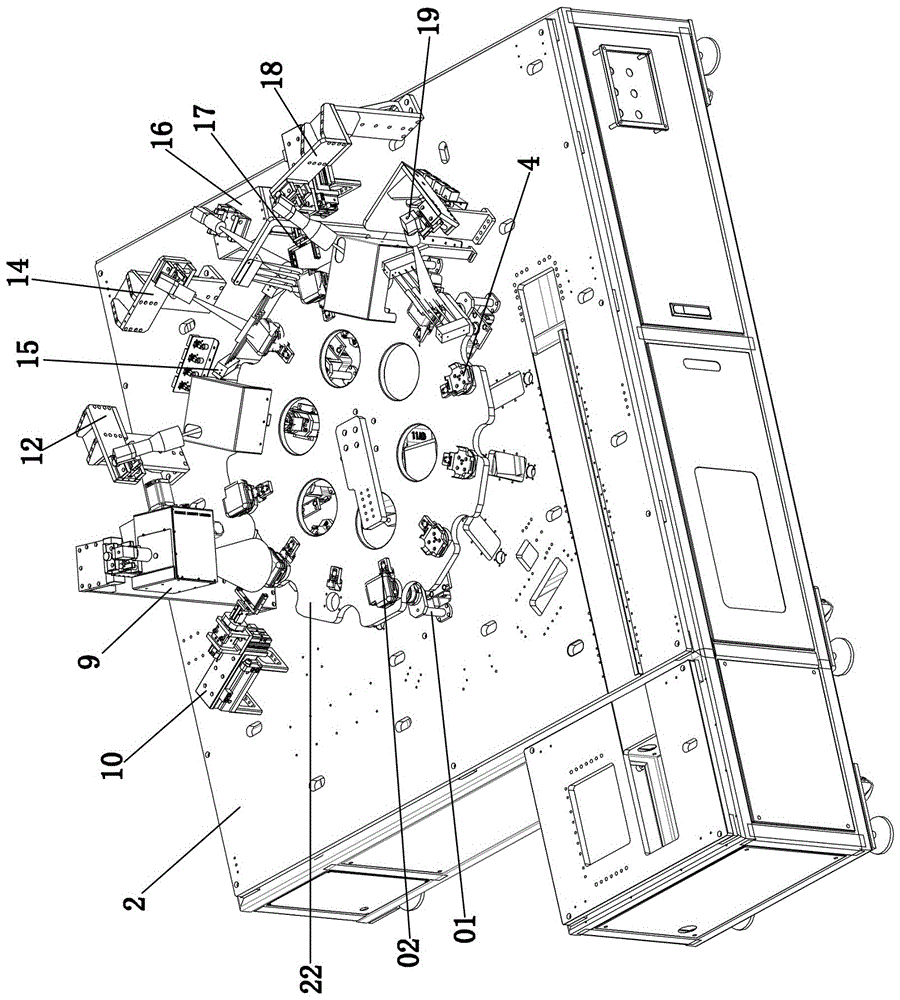

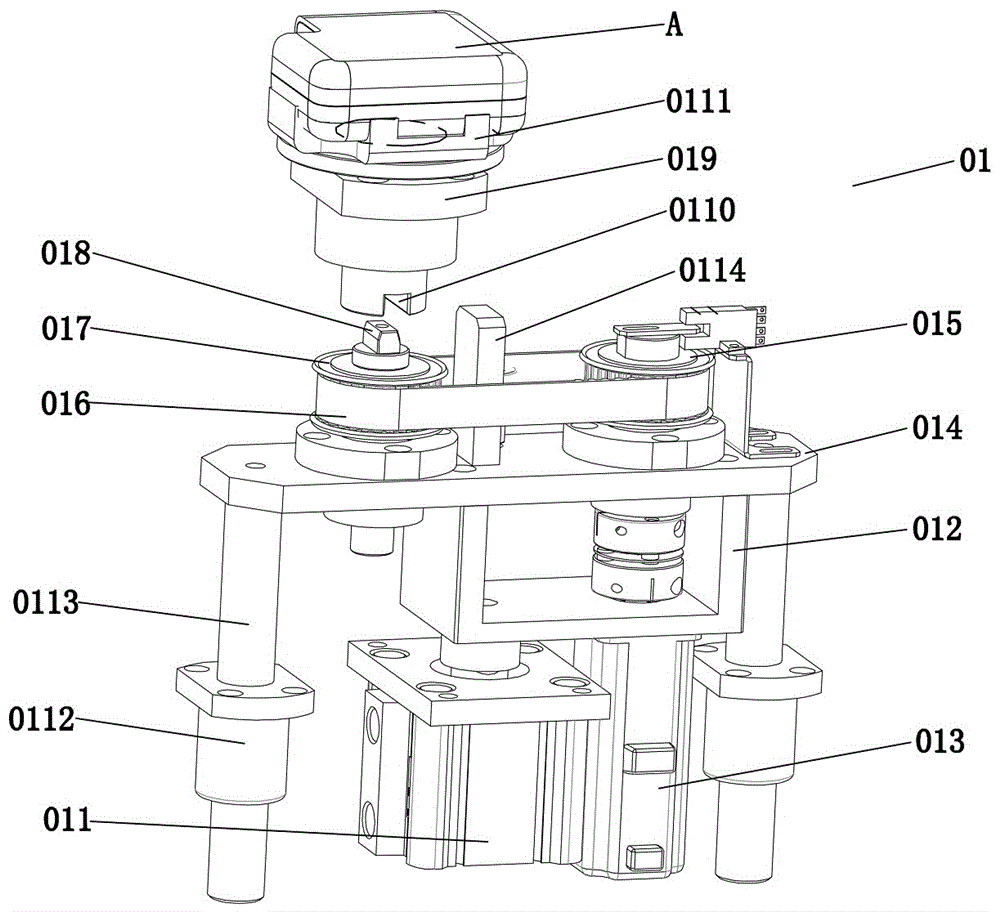

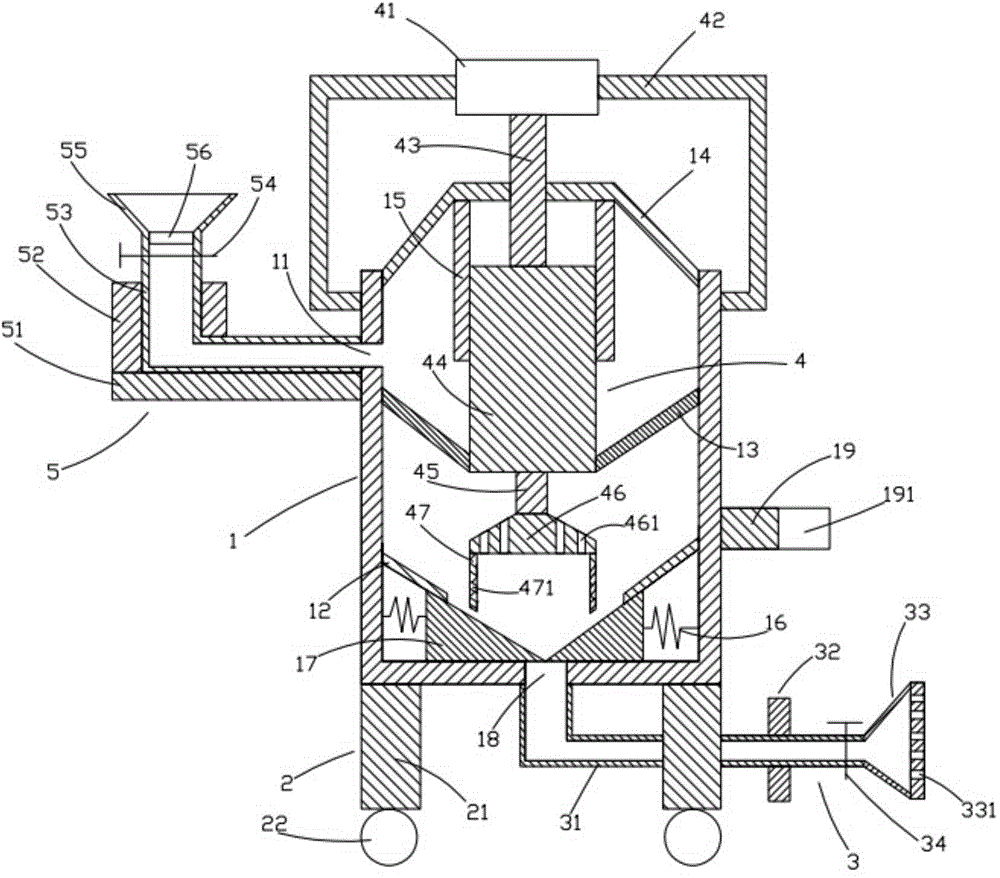

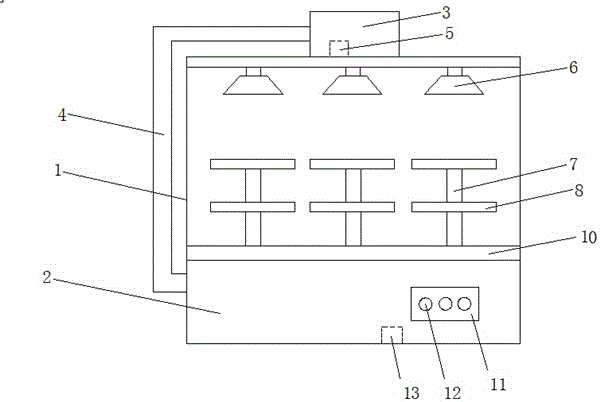

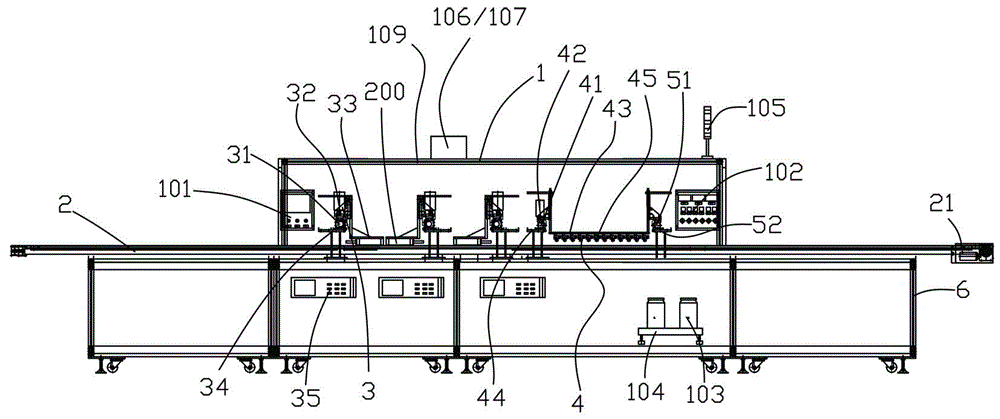

Cleaning and appearance detecting machine and detecting technology thereof

InactiveCN106000934ARealize classified storageAvoid interferenceOptically investigating flaws/contaminationCleaning using toolsIn degreeAutomation

The invention discloses a cleaning and appearance detecting machine and a detecting technology thereof. The cleaning and appearance detecting machine comprises a material belt, a feed-discharge carrying mechanism, a rotary table, a feed-discharge station, a working station, a jig rotation driving mechanism, a jig clamping limiting mechanism, a product cleaning mechanism, a product wiping mechanism and a product appearance detecting mechanism, wherein the material belt is arranged at the outer side part of a rack; at least two products are placed on the material belt at intervals; the rotary table is arranged on the rack; the feed-discharge station and the working station are arranged in the periphery of the rotary table at an interval; product jigs are arranged on the feed-discharge station and the working station; the feed-discharge carrying mechanism is arranged on the outer side of the feed-discharge station; the jig rotation driving mechanism and the jig clamping limiting mechanism are arranged on the working station; the product cleaning mechanism, the product wiping mechanism and the product appearance detecting mechanism are arranged on the working station. The cleaning and appearance detecting machine detects the surface and appearance of a product in a full-automatic manner, and is compact in structural design and high in degree of automation, detecting efficiency and quality.

Owner:宾兴

Method for purifying polyether ketone/polyether sulfone polymers

The invention discloses a method for purifying polyether ketone / polyether sulfone polymers, which comprises: grinding polymers containing impurities, sieving, and filling in a container together with deionized water, treating in ultrasound at 20 to 95 DEG C for 20 to 60 minutes, filtering the material mixed liquid treated in ultrasound in a centrifuge to remove water, drying at 130 DEG C and under vacuum till constant weight, and thus obtaining the purified polymers, wherein in the ultrasonic treatment process, acid solution can be added to improve a purifying effect. The purified product contains less sodium, potassium, aluminum, calcium, iron, phosphorus, sulfur and the like. The method can quickly and efficiently purify polyether ketone / polyether sulfone polymers, adopt simple equipment, lower polymer purification temperature and pressure, greatly save energy, reduce production cost, easily apply to large-scale production line and meet requirements of industrial large-scale production. The polyether ketone / polyether sulfone polymers purified by the invention can be used for processing parts of electronic and electrical parts and manufacturing medical appliances.

Owner:KINGFA SCI & TECH CO LTD +1

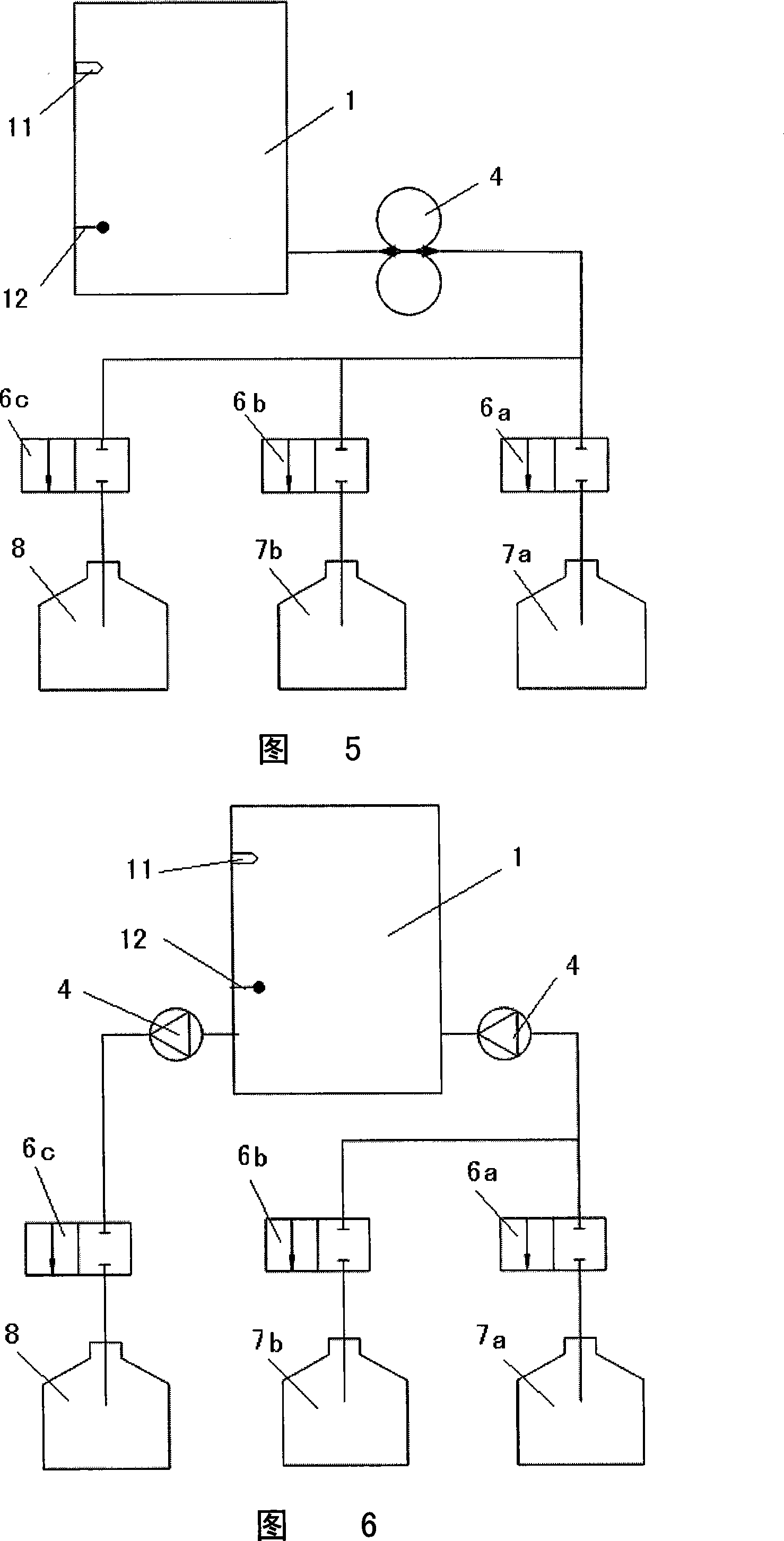

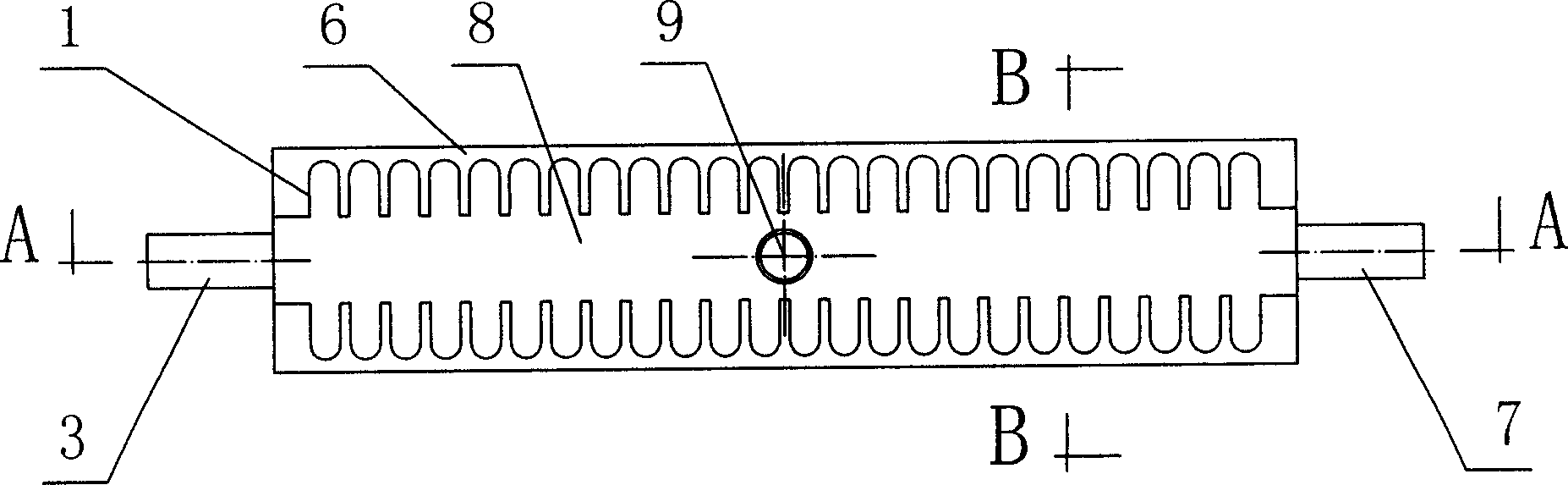

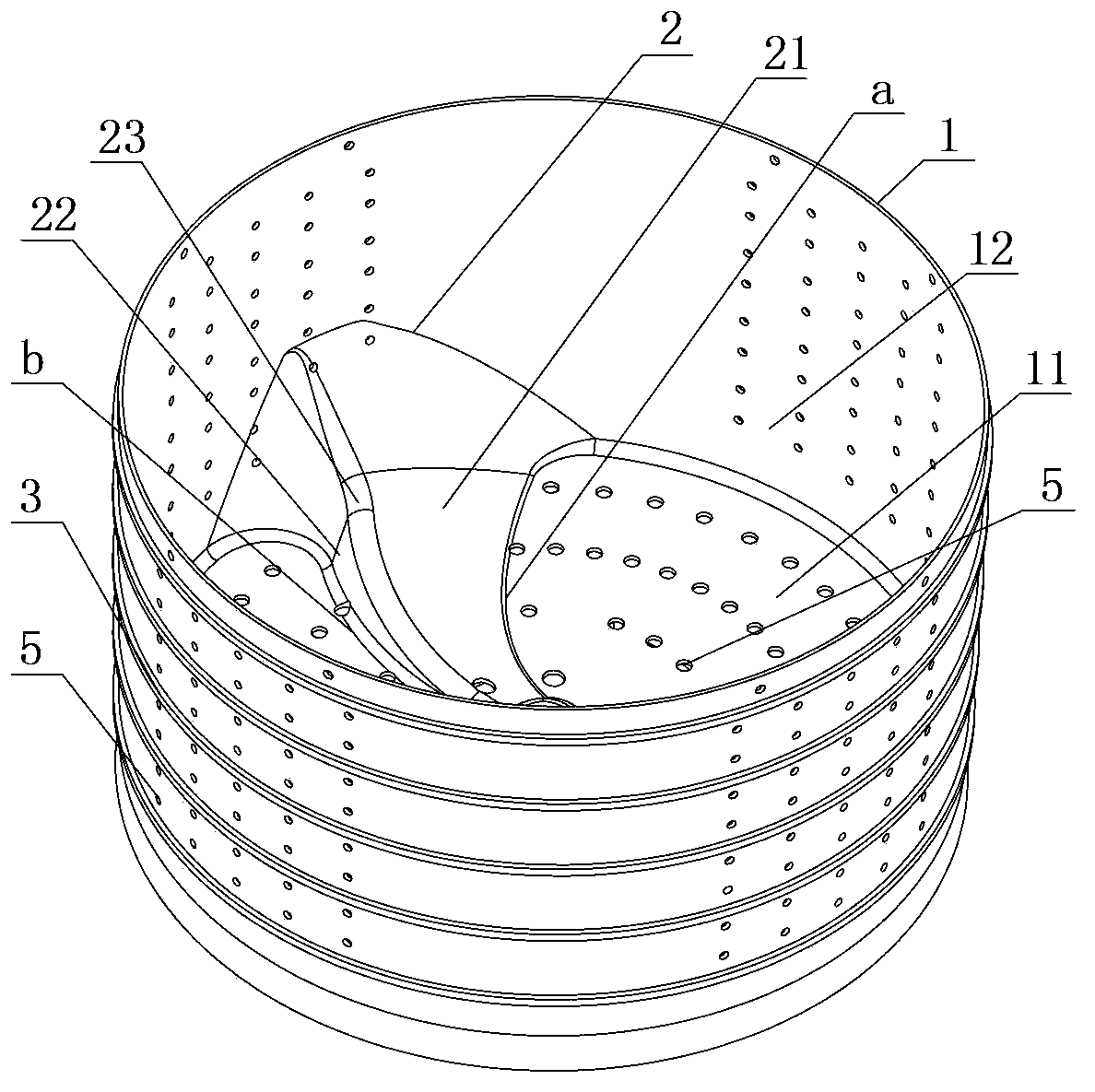

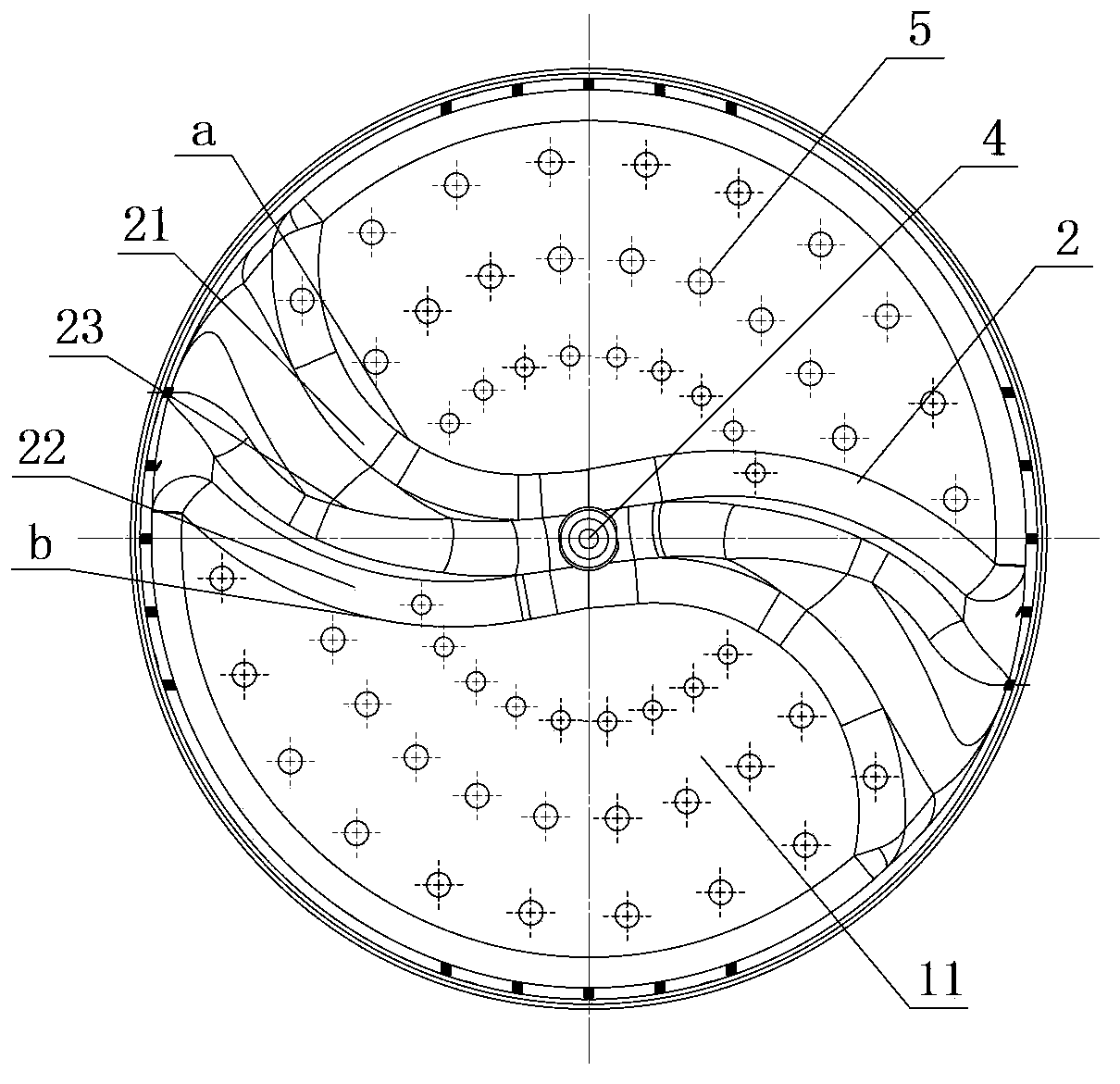

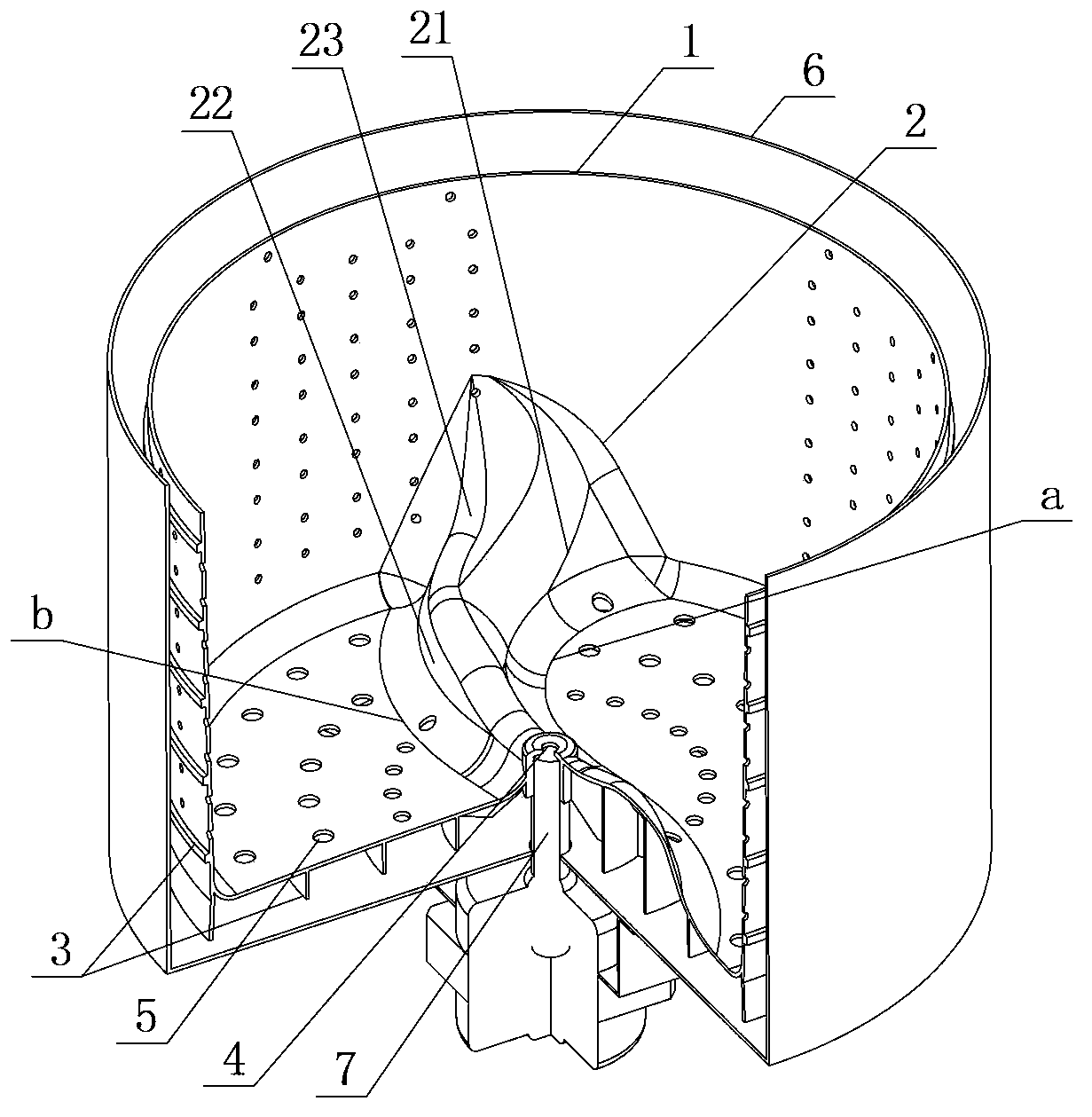

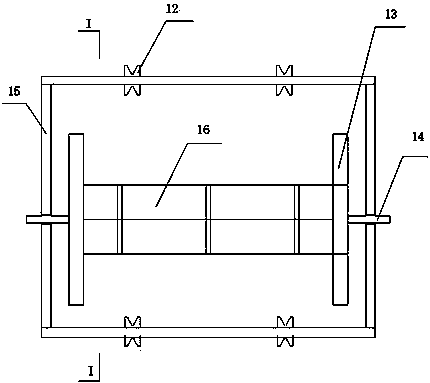

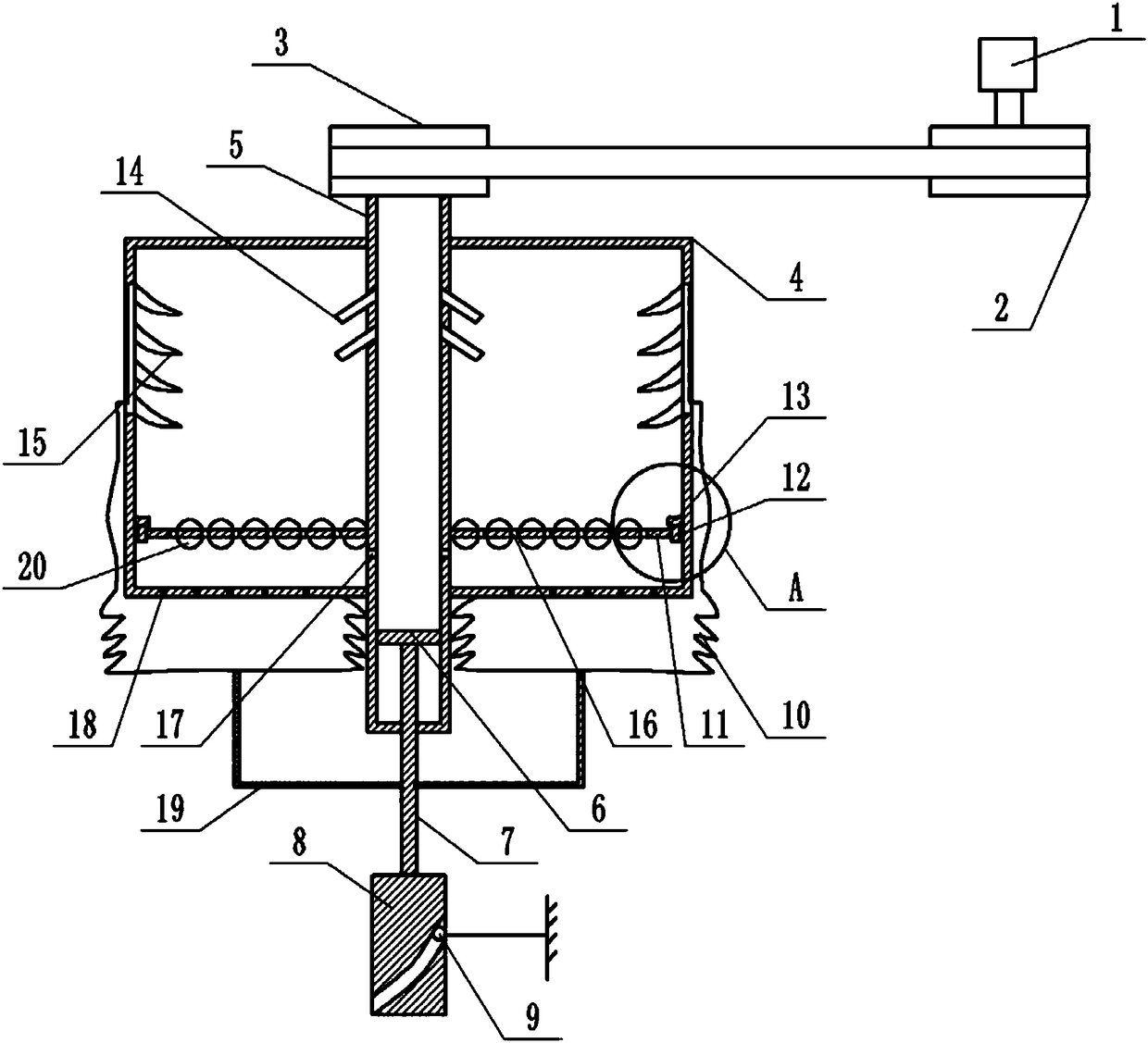

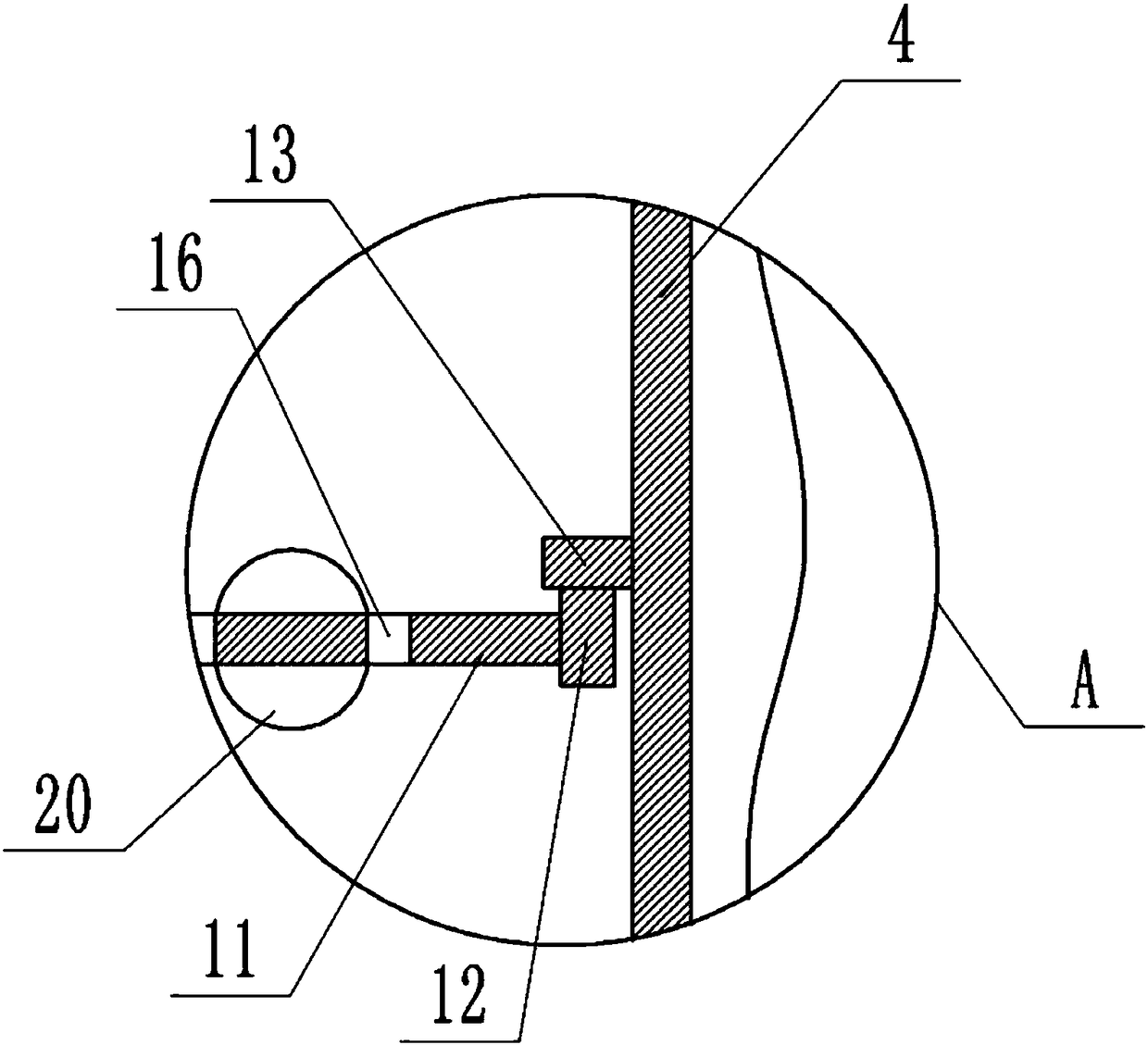

Washing barrel for double-mode washing machine

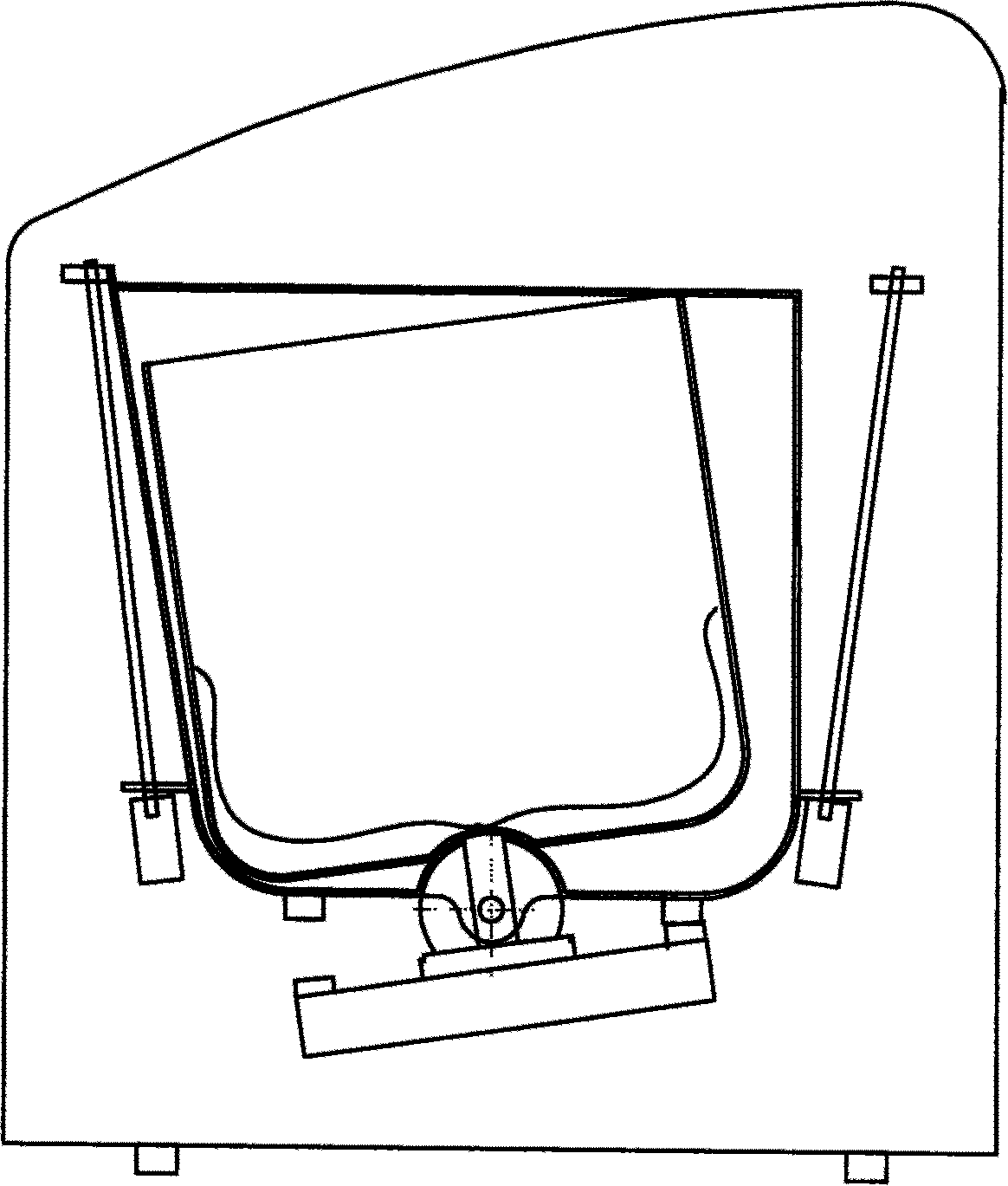

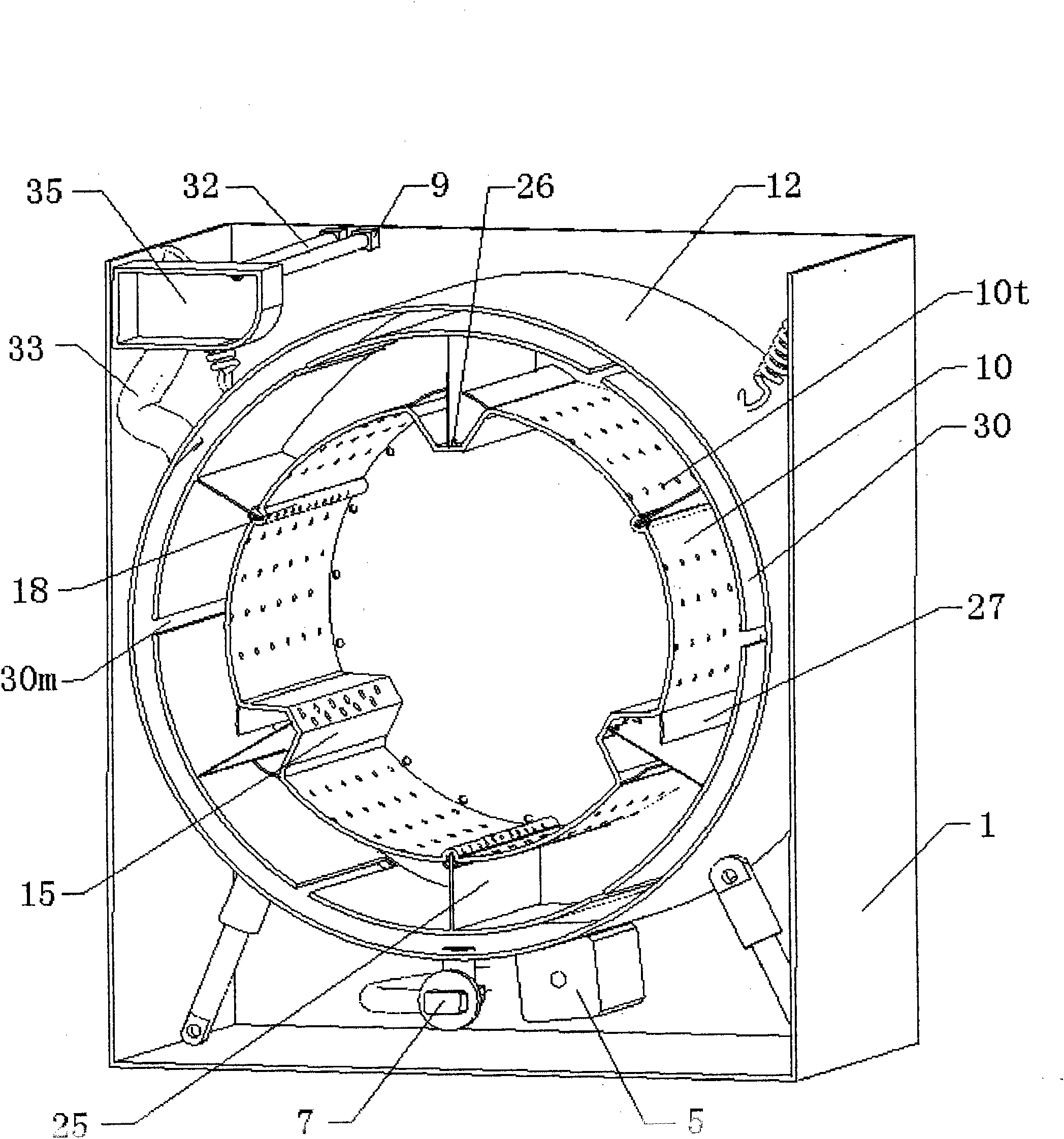

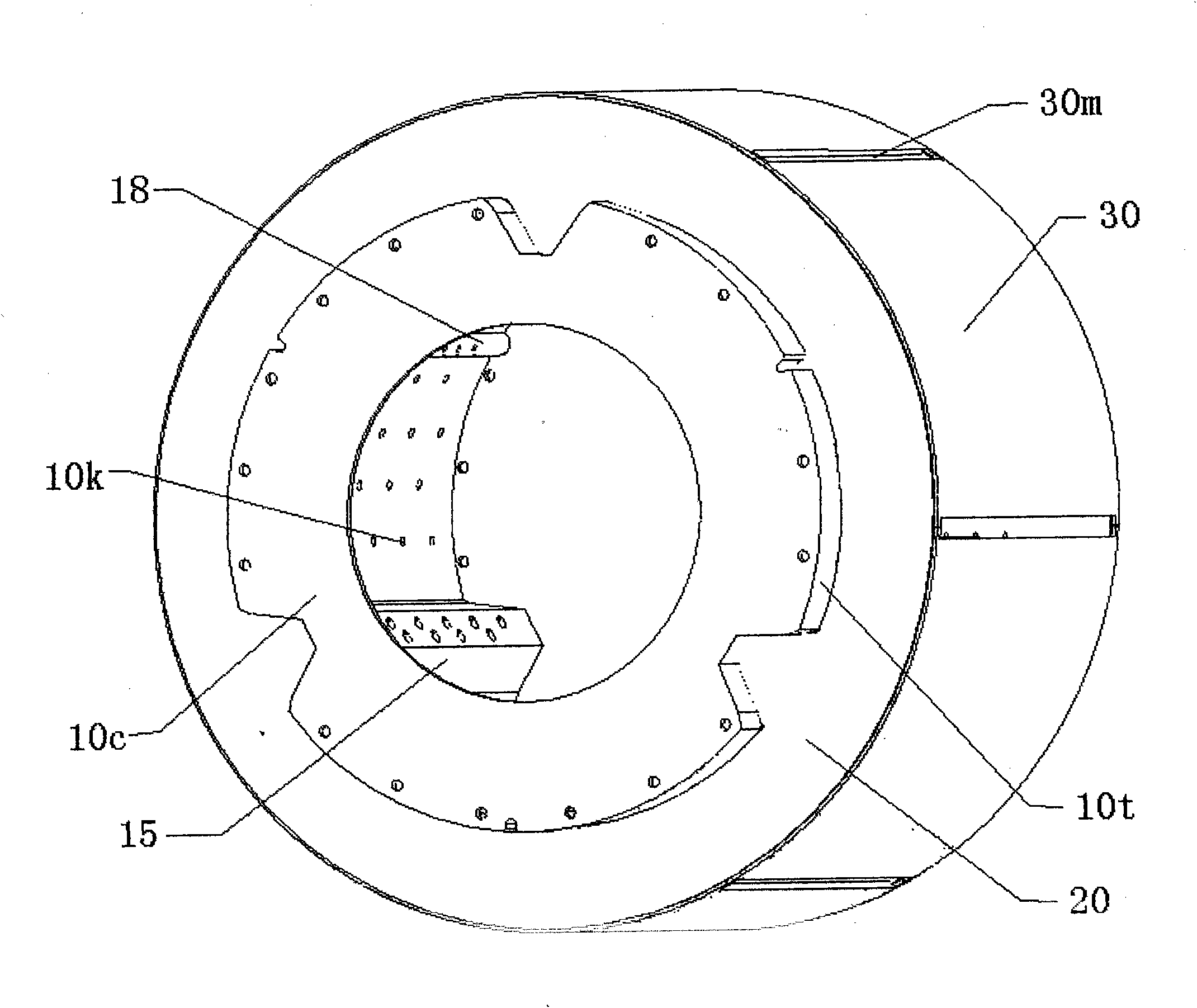

ActiveCN101191297AWash evenlyReduce wearOther washing machinesTextiles and paperImpellerHorizontal axis

The invention belongs to the washing machine field, in particular to a wash bucket for a double-mode washing machine, comprising a water holding bucket, a rotary drum and a clutch, wherein, the rotary drum consists of an inner rotary drum and an outer rotary drum; horizontal rotary shafts of the inner rotary drum and the outer rotary drum are coaxial; a vertical rotary shaft is arranged on the bottom center of the inner rotary drum; a horizontal rotary shaft is arranged on a horizontal axis of rotation of the outer rotary drum; a bearing is arranged at the bottom of the outer rotary drum; the inner rotary drum is pivotally arranged inside the bearing at the bottom of the outer rotary drum through the vertical rotary shaft on the bottom center of the inner rotary drum and combined with the outer rotary drums; water-sealed bearings are arranged on the side face and the bottom part of the water holding bucket; the horizontal rotary shaft of the outer rotary drum is pivotally arranged inside the water-sealed bearing on the side face of the water holding bucket; the clutch passes through the water-sealed bearing at the bottom of the water holding bucket and connected with the vertical rotary shaft of the inner rotary drum which is arranged inside the inner rotary drum and extended out of the bottom part of the outer rotary drum. During the washing process, the inner rotary drum and the outer rotary drum simultaneously rotate along the horizontal rotary shaft on the outer rotary drum, thereby washing mode of a drum-type washing machine is realized; during the wringing process, the inner rotary drum rotates at high speed along a shaft which is perpendicular to the ground, thereby wringing of an impeller washing machine is realized.

Owner:HAIER GRP CORP +1

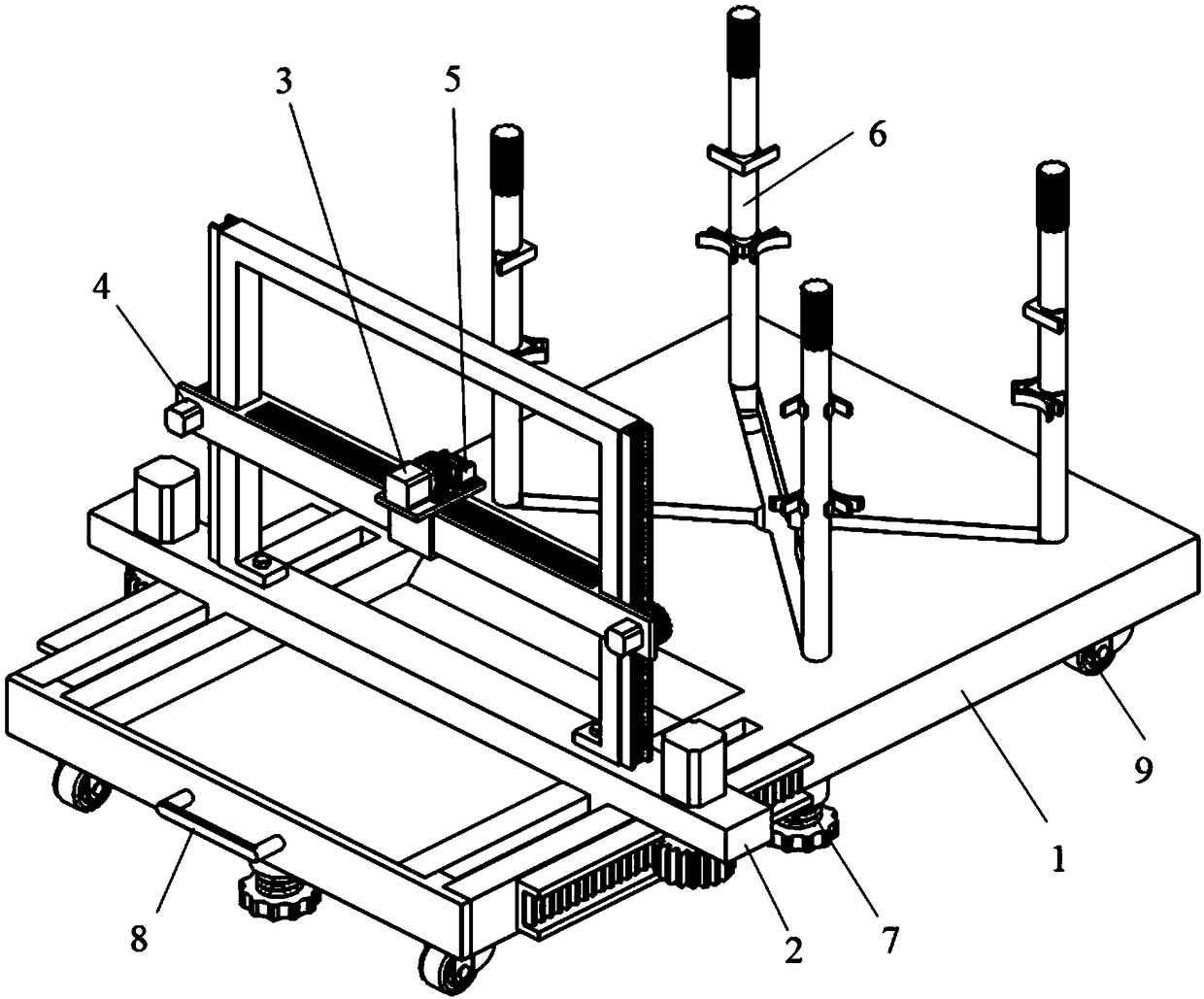

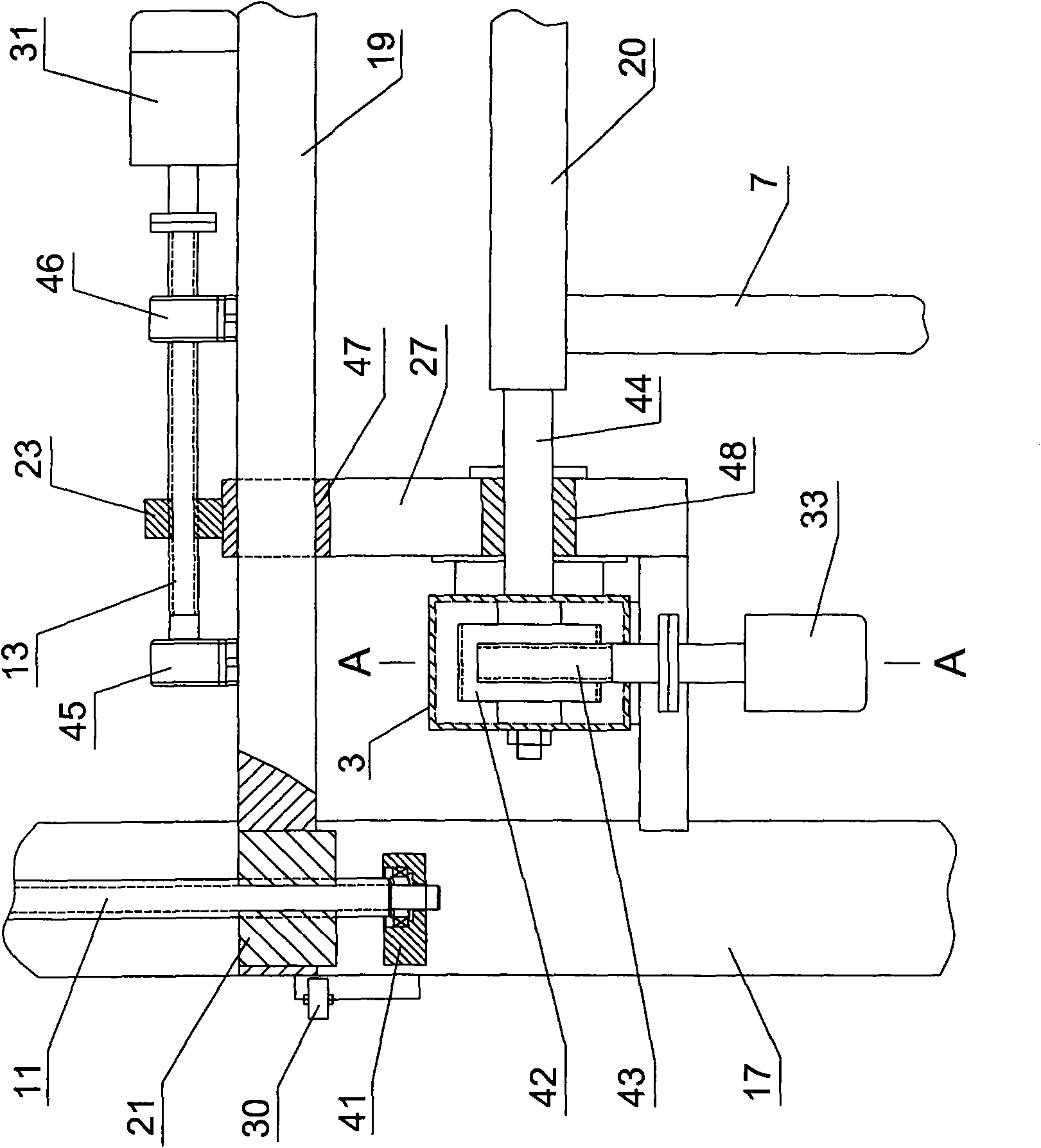

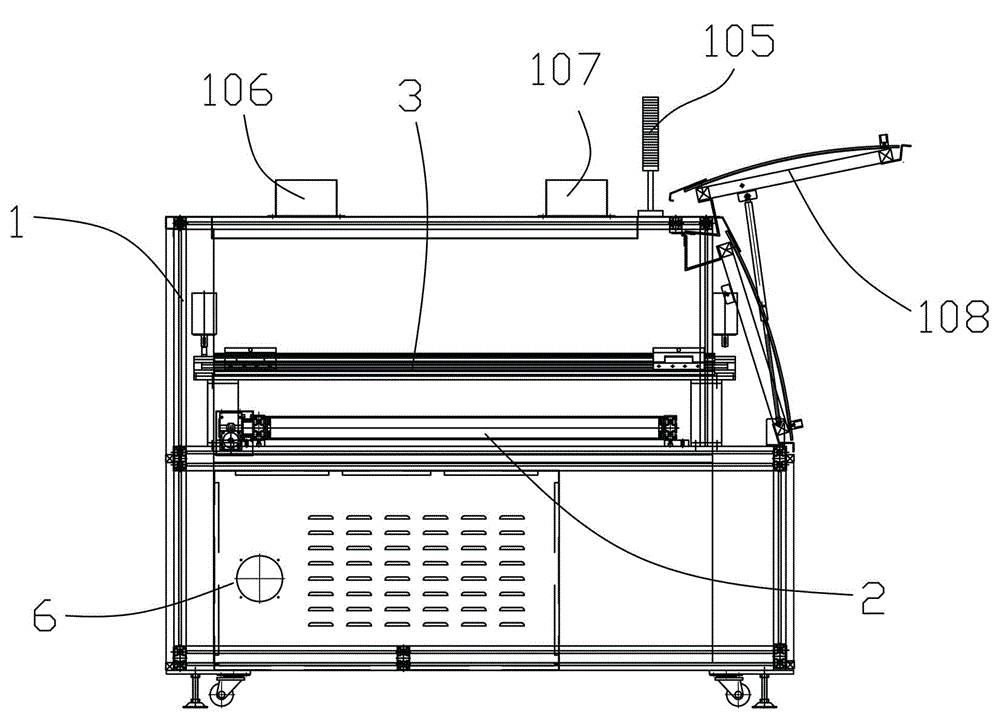

Easy-to-move laser cleaning device

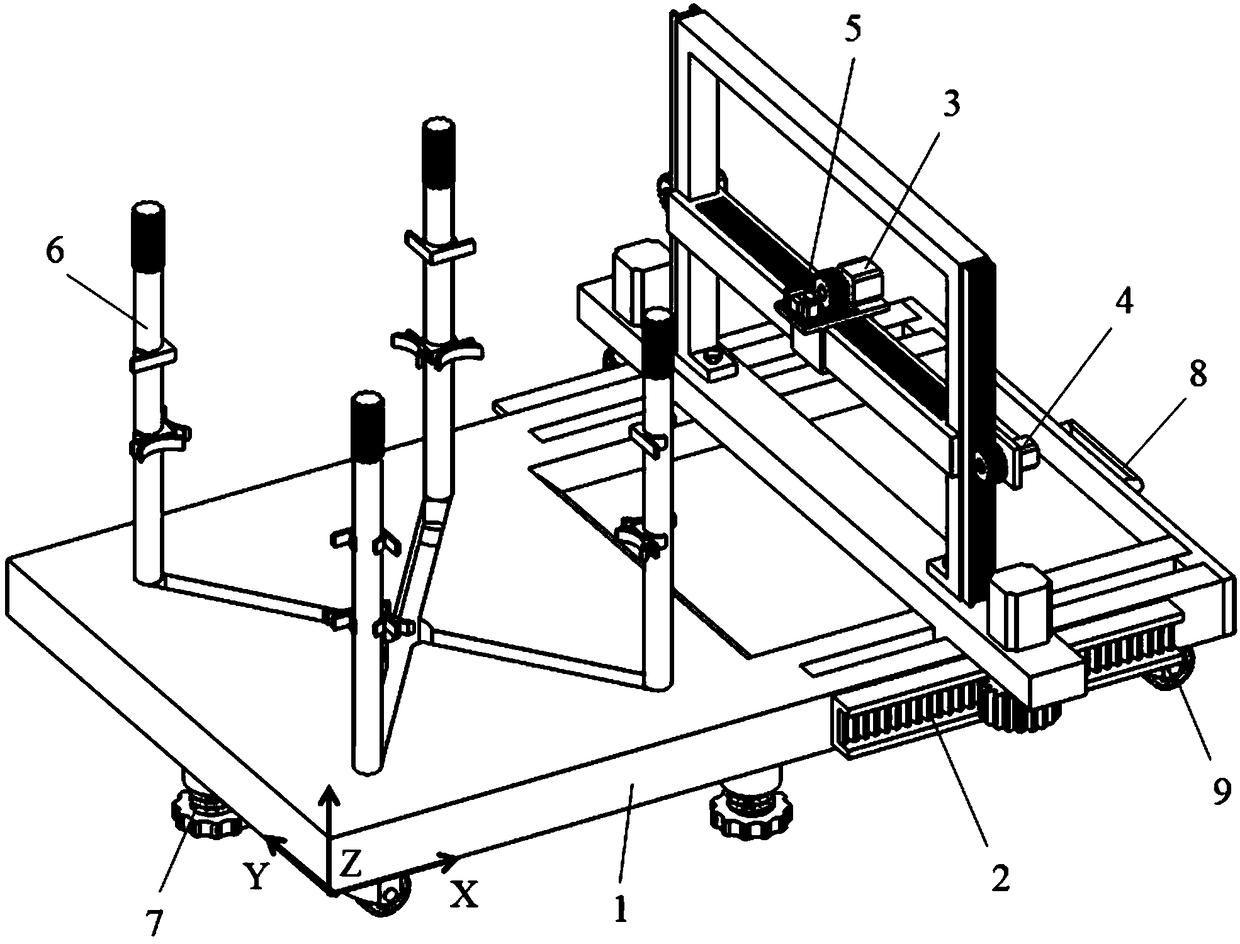

InactiveCN109048068AEasy to moveAchieve fixationWelding/cutting auxillary devicesAuxillary welding devicesLinear motionAutomatic control

The invention relates to a laser cleaning device, in particular to an easy-to-move laser cleaning device, and belongs to the technical field of laser cleaning. The easy-to-move laser cleaning device comprises a supporting mechanism, an X-axis motion mechanism, a Y-axis motion mechanism, a Z-axis motion mechanism, a laser cleaner, gripping mechanisms, adjustment mechanisms, a blocking plate and swivel wheels. A control system of the easy-to-move laser cleaning device automatically determines a cleaning path by analyzing images before laser cleaning, and can effectively improve the working efficiency. A cleaning result is judged through the analysis on images after laser cleaning; if the cleaning result is unsatisfactory, the cleaning task is performed once again until the cleaning result issatisfactory so as to ensure a satisfactory cleaning effect; and the cleaning effect is good. The control system automatically controls the coordinated motion of a first driving motor, a second driving motor and a third driving motor according to the cleaning path to separately drive the linear motion of the X-axis motion mechanism, the Y-axis motion mechanism and the Z-axis motion mechanism so as to drive a laser cleaning head of the laser cleaner to complete the cleaning task.

Owner:孟凡森

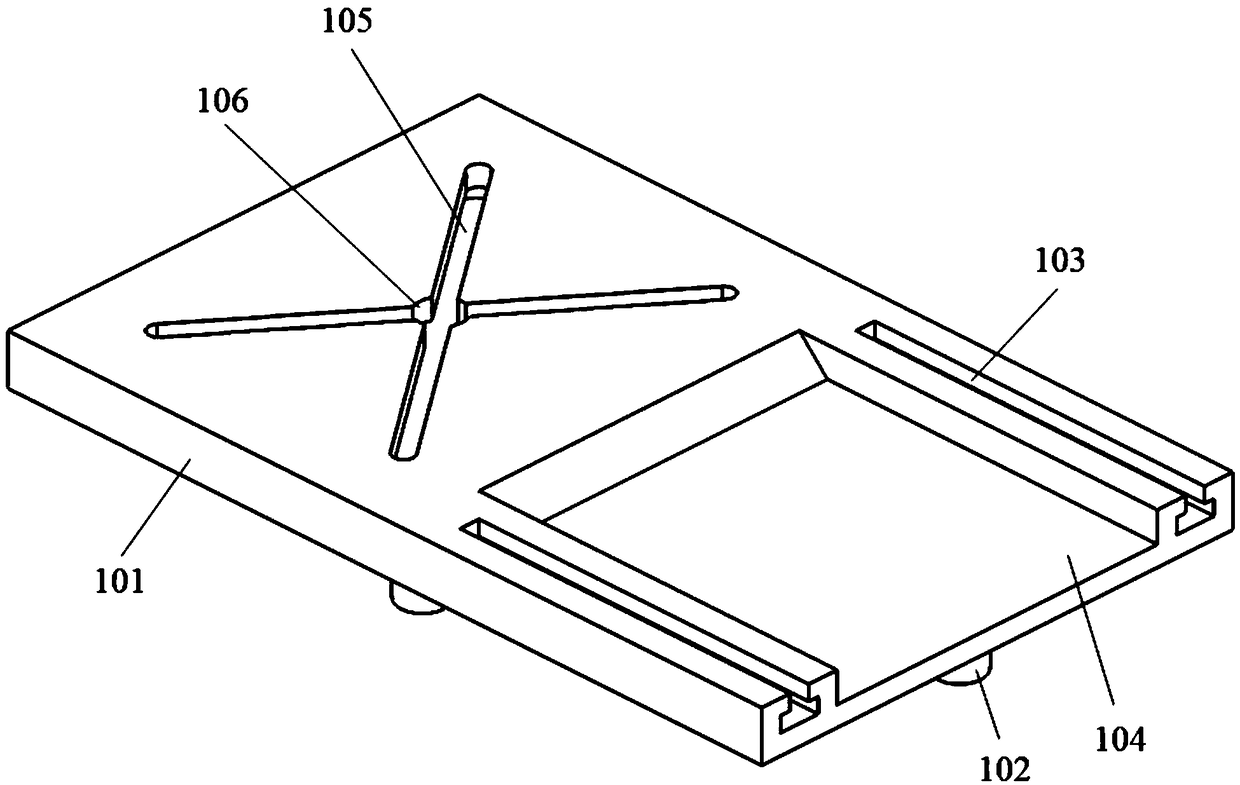

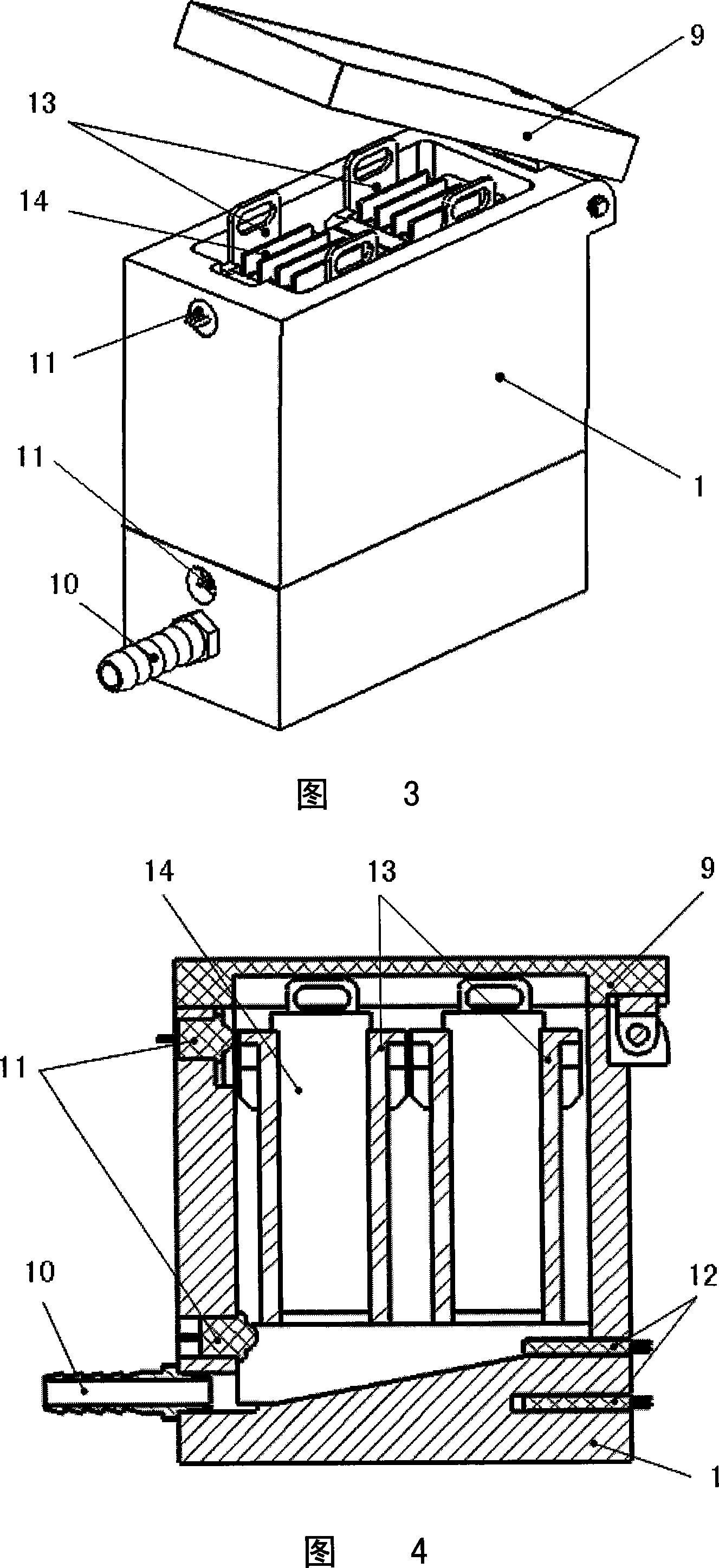

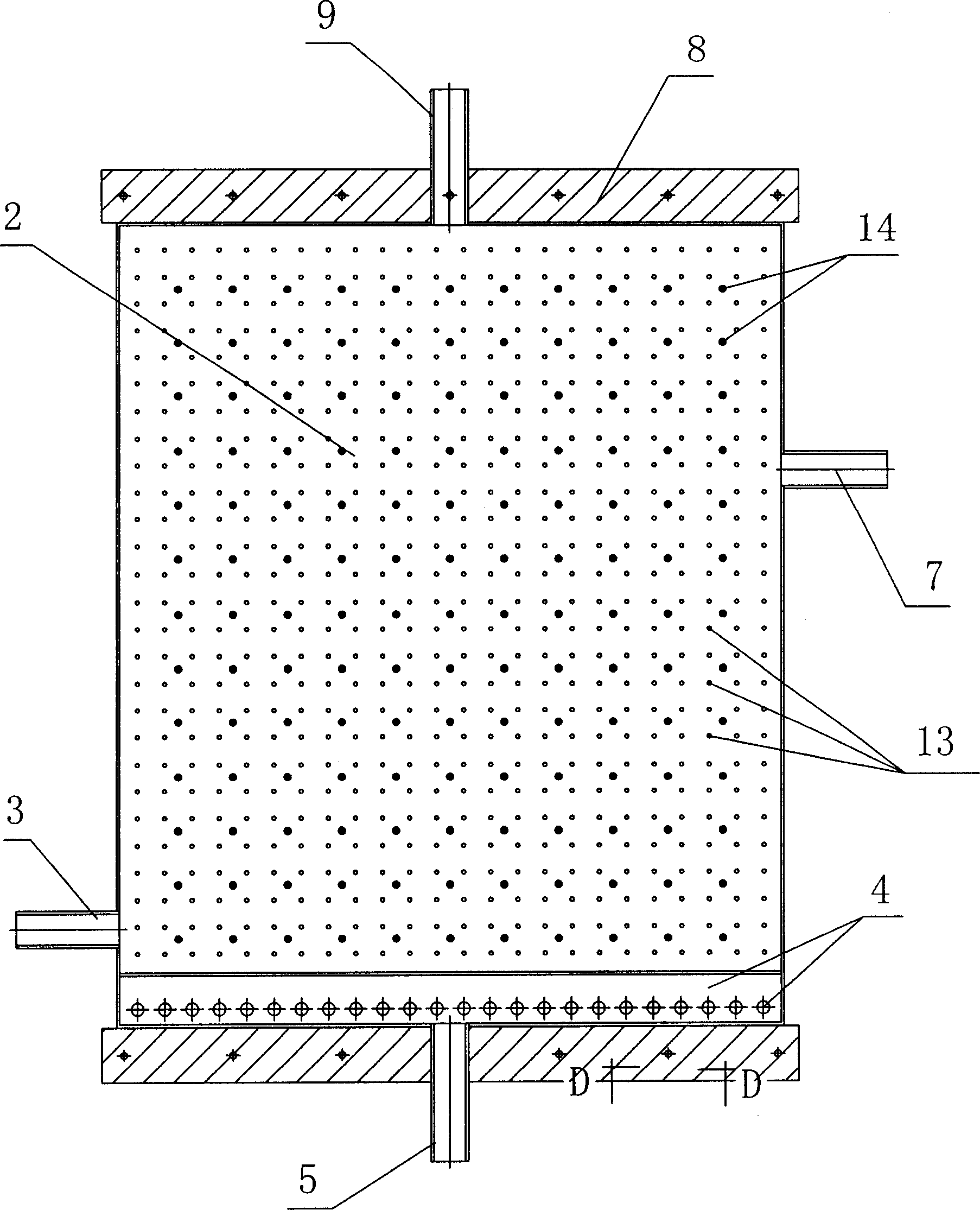

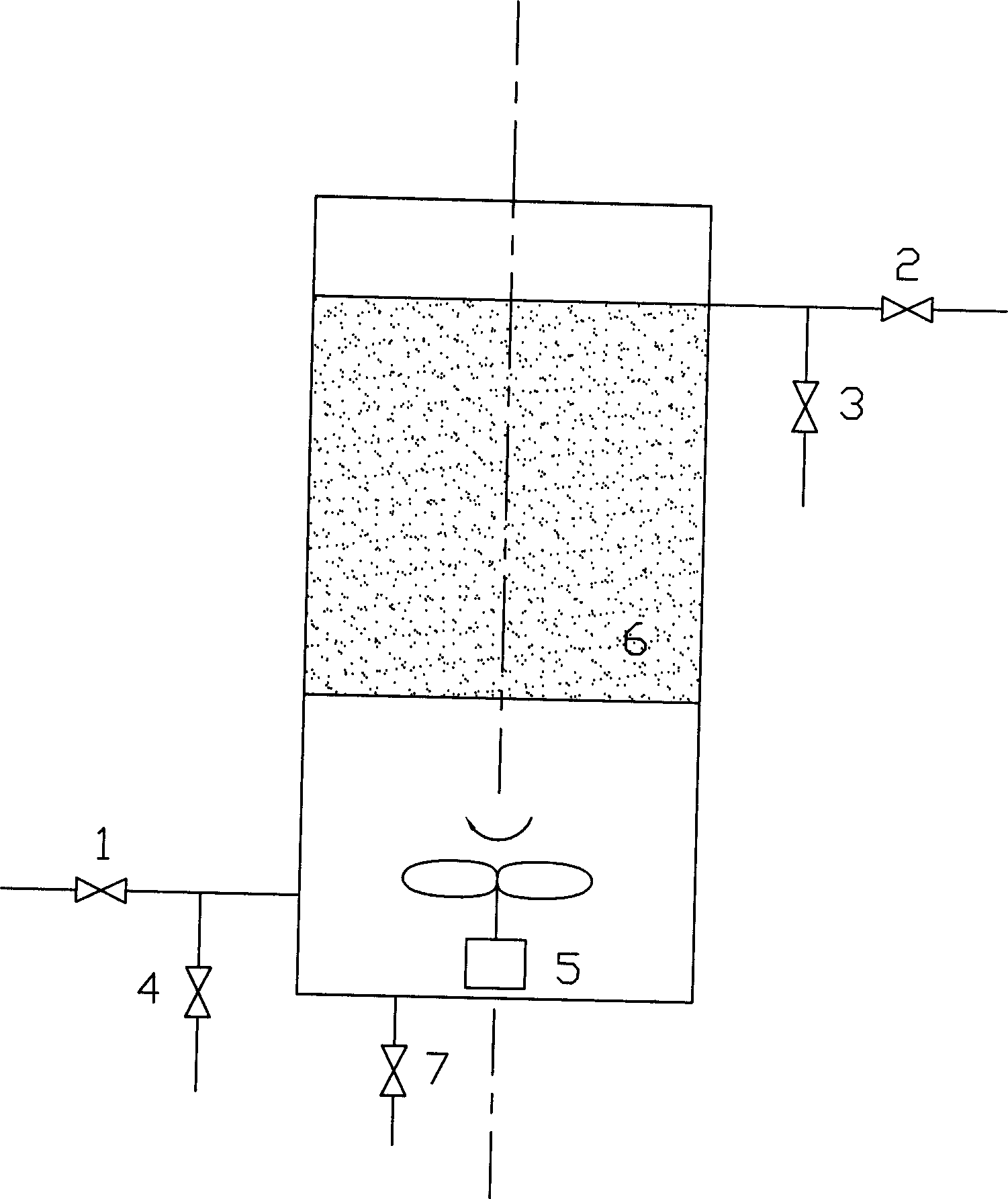

Washing method and device for biological chip

ActiveCN101196447AMeet cleaning needsImprove cleaning efficiencyPreparing sample for investigationBiological testingBiochipBottle

The invention relates to a cleaning method of biochip and device, which comprises the following procedures: firstly, a plurality of fixing grooves fixed with a biochip are arranged in a cleaning chamber; secondly, at least a pipeline to a liquid cleaning bottle and a pipeline to a waste liquid bottle are connected under the cleaning chamber, a liquid pump and a valve are arranged on the pipeline; thirdly, the valve to the waste liquid bottle is closed, the valve to the cleaning liquid is opened, through liquid pump, make the cleaning liquid pump in the cleaning chamber; fourthly, the valve to the cleaning liquid is closed and the valve to the waste liquid bottle is opened. Starts the liquid pump for / backward frequently, and makes the cleaning liquid pump in the cleaning chamber enter into the waste liquid bottle by pump. The invention has simple structure and lower cost, which realizes the automatic cleaning to biochip, avoids the error caused by manual operation, and is easier to realize automatic controlling and integrating.

Owner:BOAO BIOLOGICAL CO LTD +1

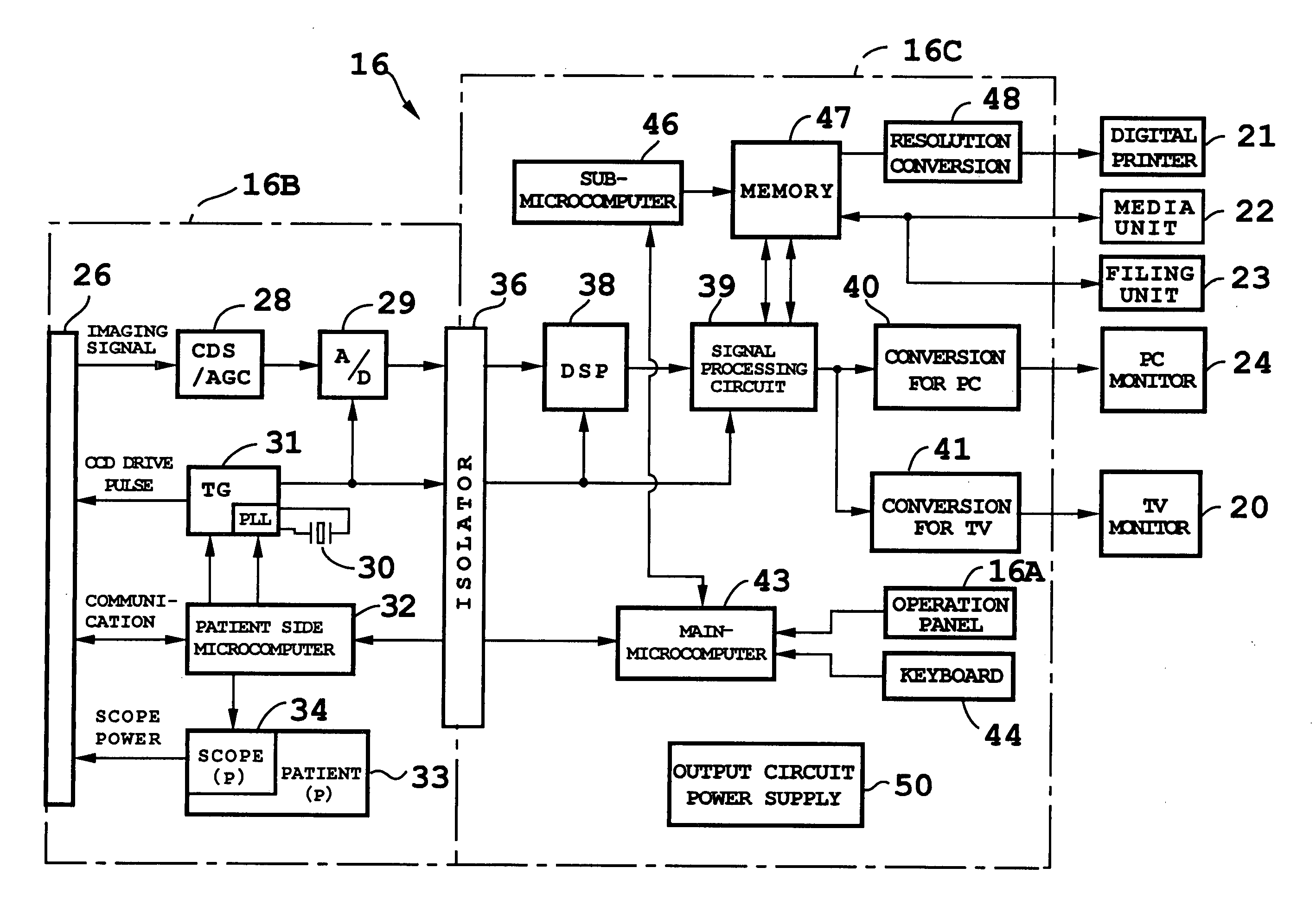

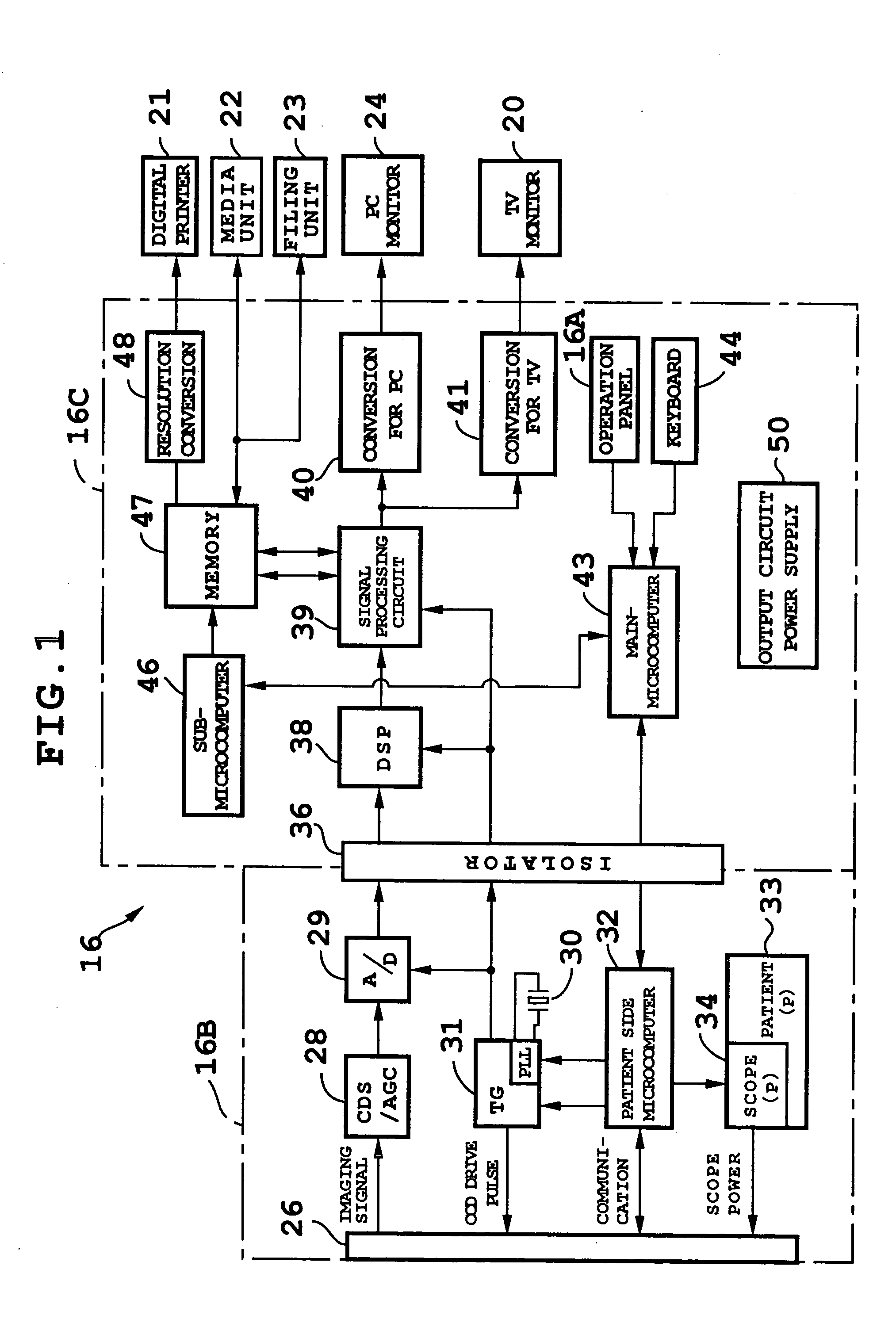

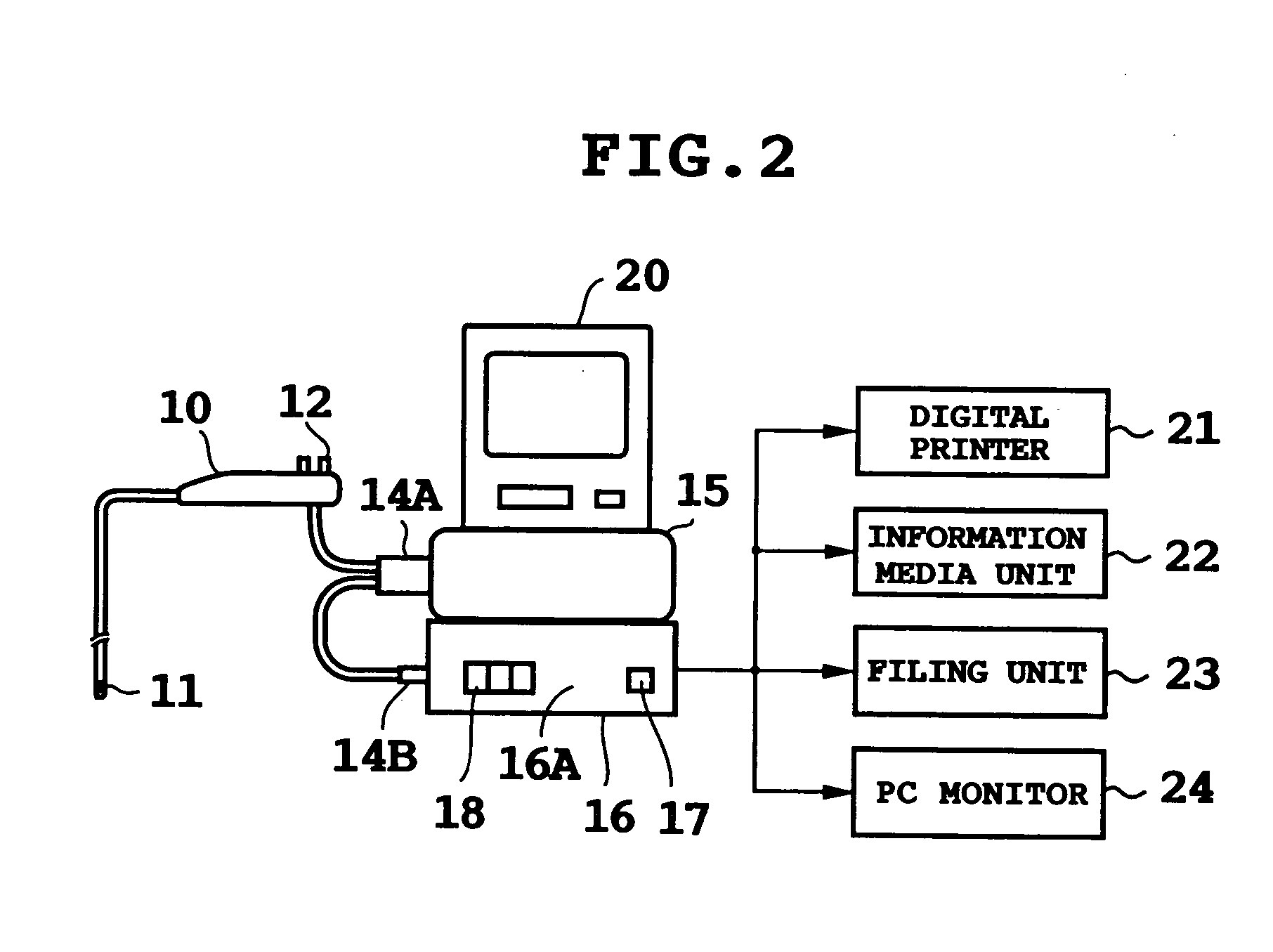

Electronic endoscope apparatus

InactiveUS20050070761A1Smoothly washSafely disconnectSurgeryEndoscopesImage storageSignal processing circuits

An electronic endoscope apparatus has the structure that an electronic scope is detachably connected to a processor unit. This processor unit comprises image storage memory which stores an object image imaged by a CCD, a signal processing circuit for outputting this image to external equipment, a scope power-off operation switch located separately from a main-power switch are provided. Only a scope power supply unit which supplies power to the electronic scope is turned off by this scope power-off switch. At this time, when a CCD drive pulse is being outputted or when communication between with the electronic scope is being performed, the outputting of this CCD drive pulse or the communication is stopped, and thereafter,the scope power supply unit is turned off. Thereby, the electronic scope can be removed from the processor unit which is outputting an image signal.

Owner:FUJI PHOTO OPTICAL CO LTD

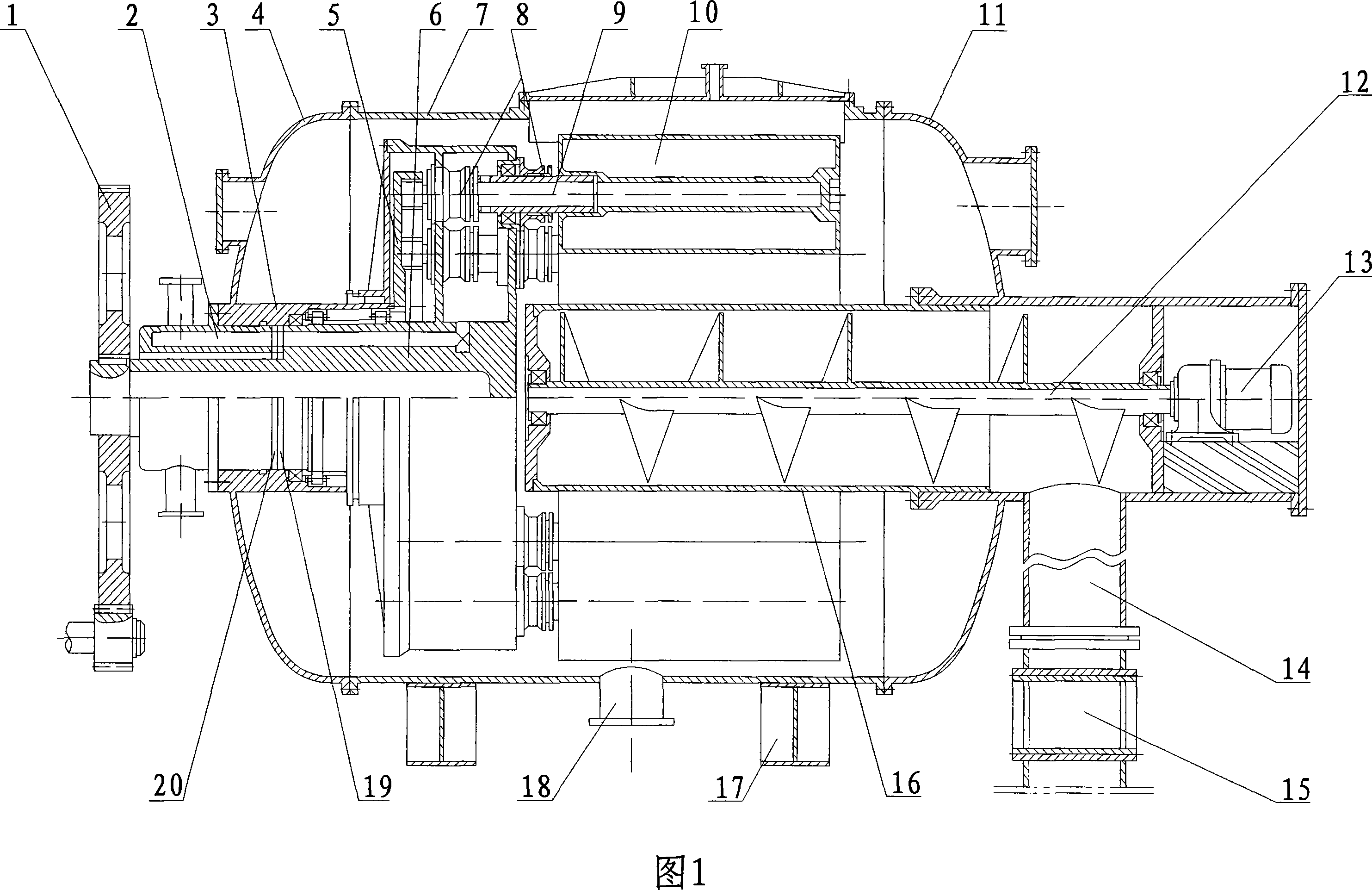

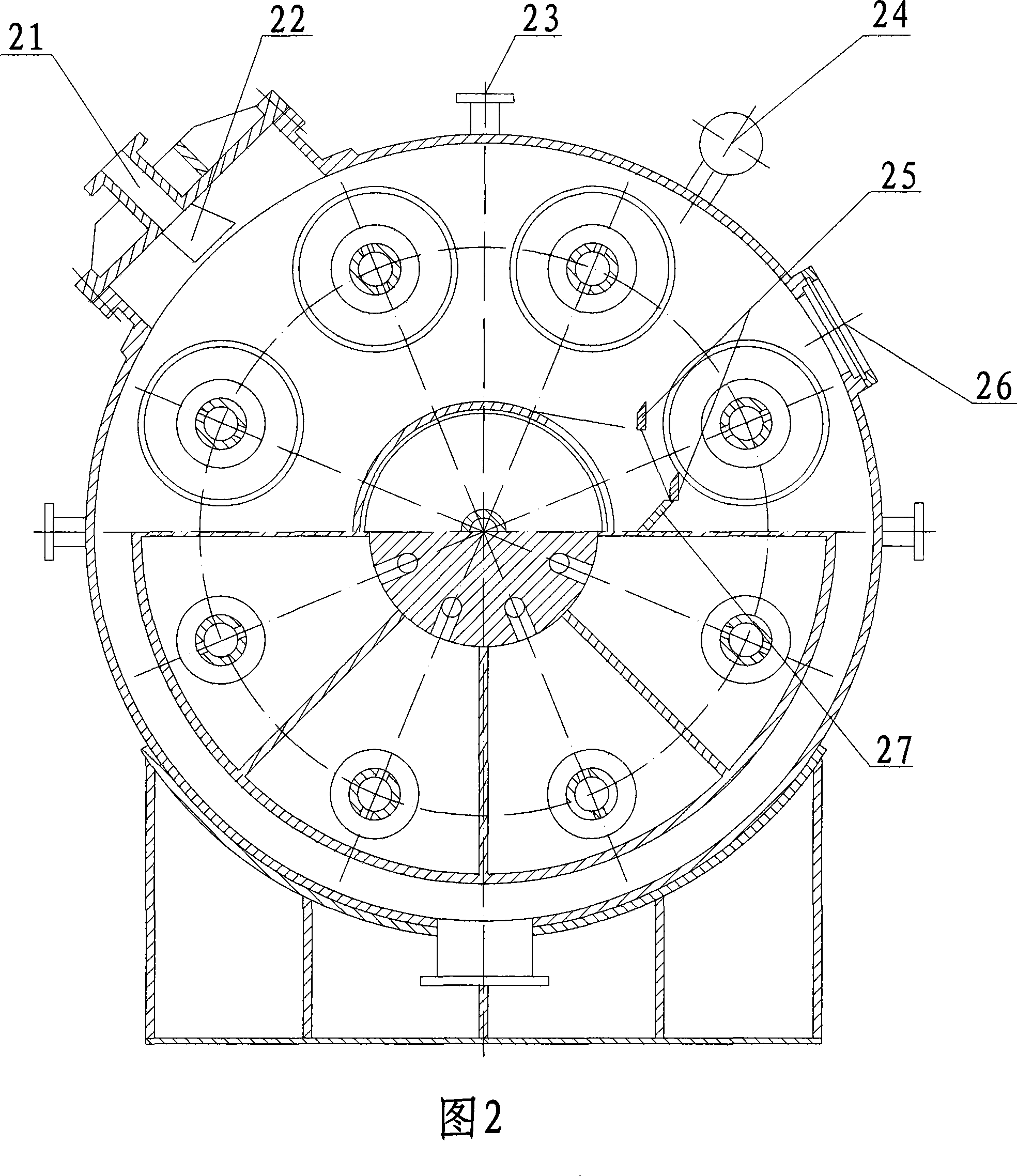

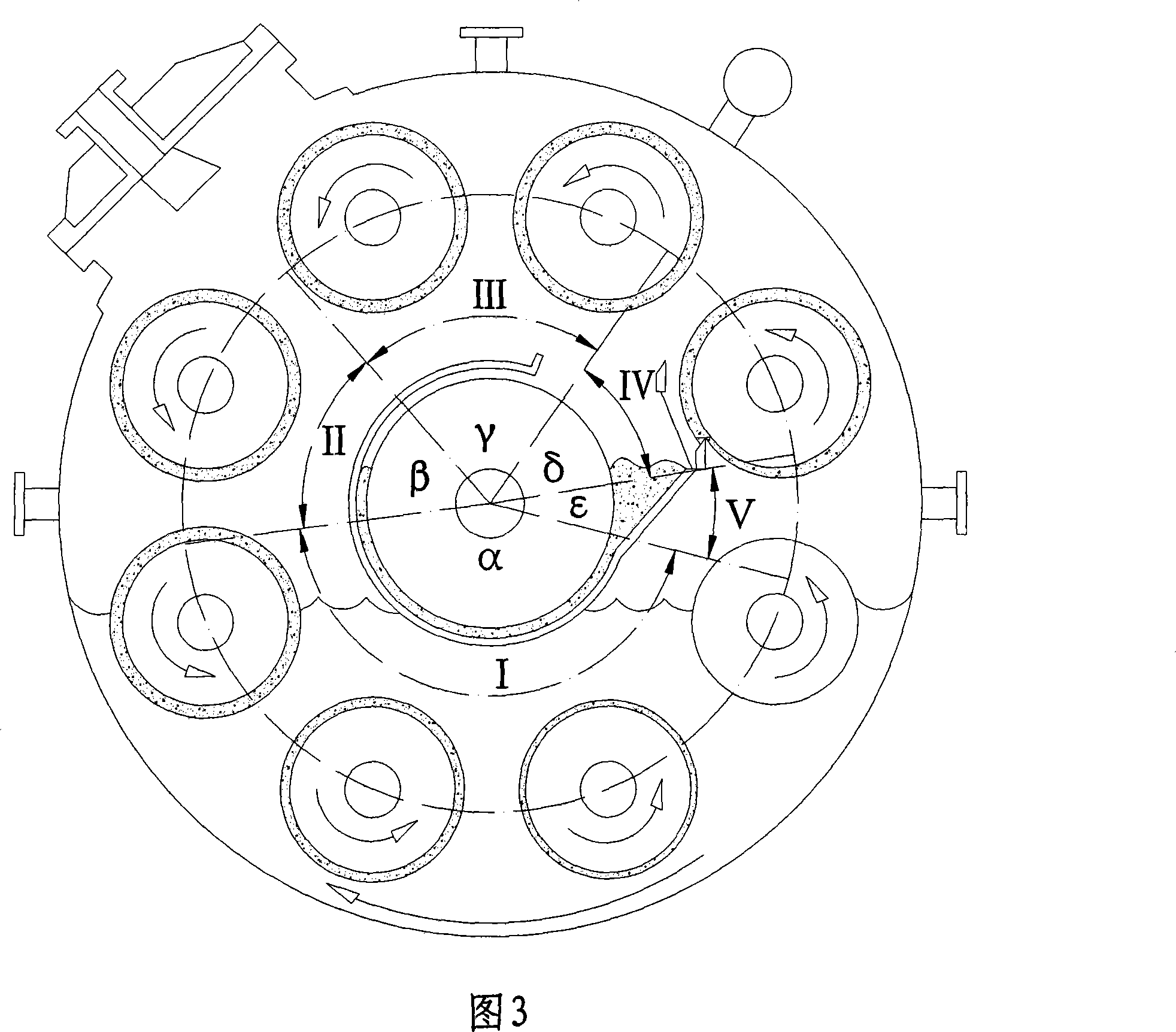

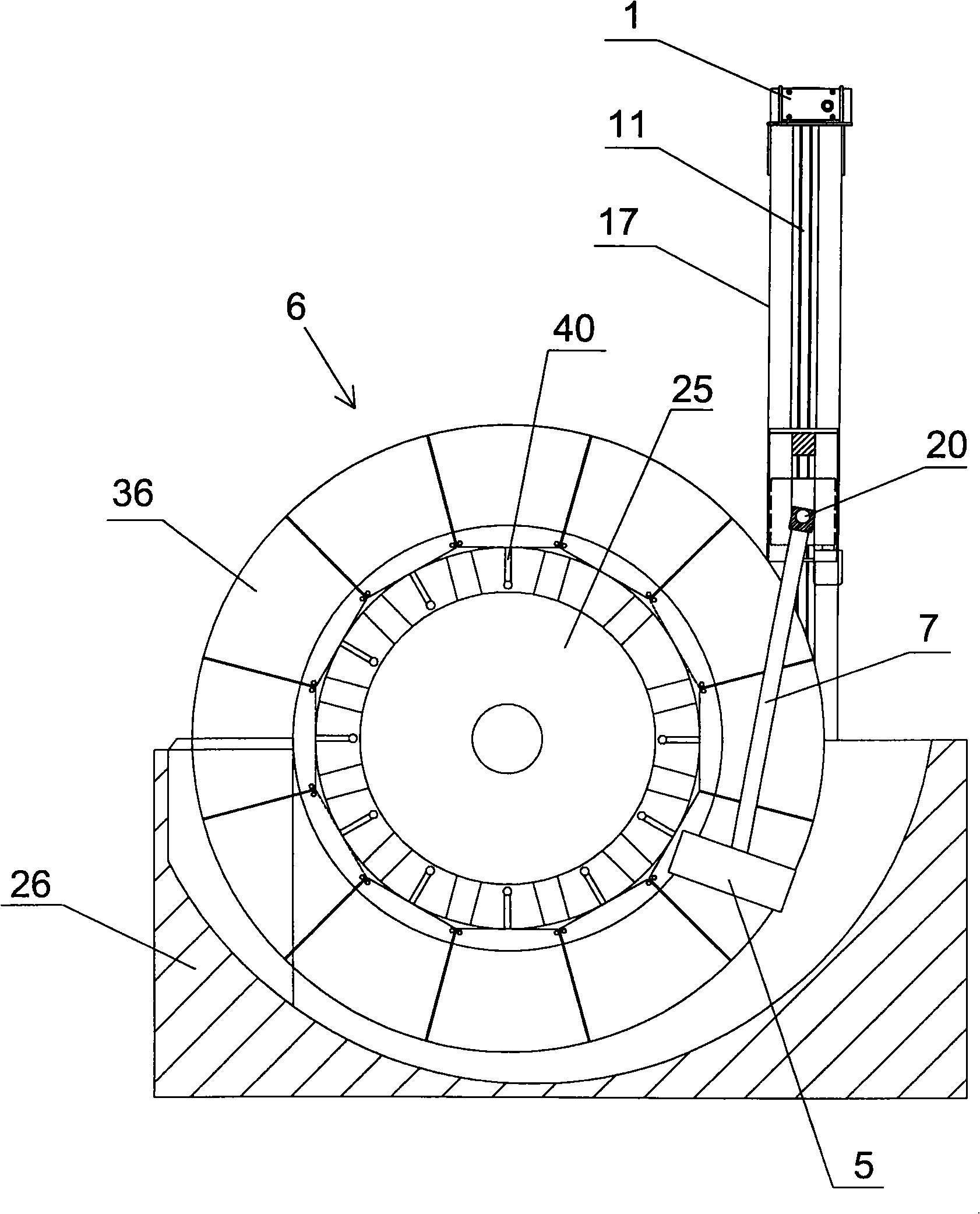

Planet gyration small circular cylinder continuous pressure filtration machine

InactiveCN101234269APrevent precipitationReliable filtration operationMoving filtering element filtersGyrationFilter cake

The invention relates to a continuous pressure filter used for filtering suspension, the main technical characteristics of which is that a plurality of filtering units are arranged in the direction of the inner circumference inside a shell body of the filter; each filtering unit consists of a filter cylinder, a filter axis and an inner channel of a planet carrier communicated with the filter axis. The filter cylinder used as a filter element is fixed and supported on the planet carrier by the filter axis, which executes a planetary motion when working; fluid is collected inside the filter cylinder after going through a filter medium on the filter cylinder, which enters the channel of the planet carrier through a hollow filter axis and is discharged after being switched through a distributing head. The continuous pressure filter of the invention has the main characteristics of high-efficiency filtration dehydration, effectively wash and dry a filter cake, reliable material-discharging way, a blowback regeneration function of the filter medium, and the operating steps are carried out sequentially.

Owner:SICHUAN UNIV

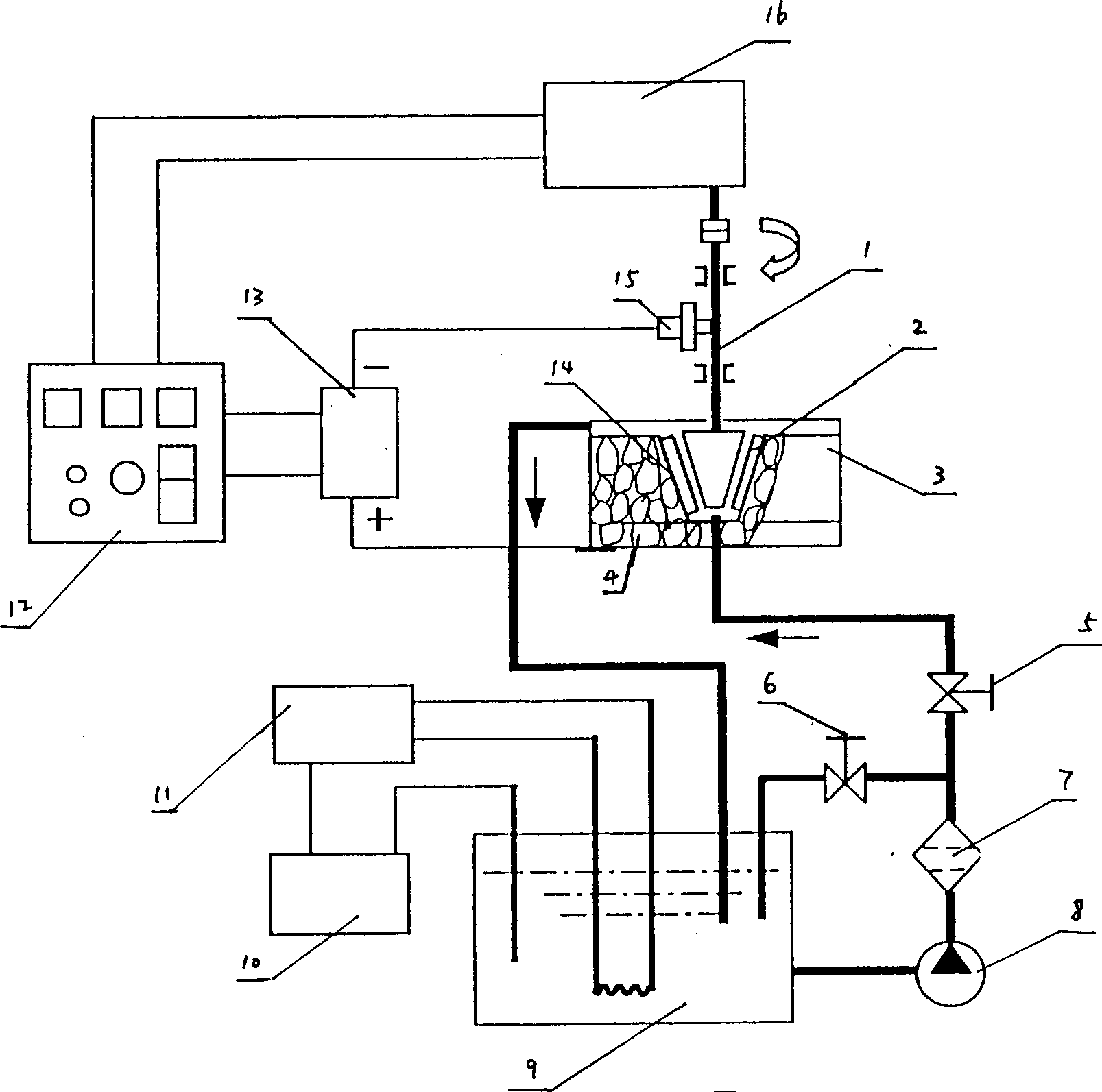

Medicine type cover electroforming manufacturing process and equipment

With core mould of the gunpowder typed cup being rotated, the feed flow of the electroforming fluid carries out from bottom part of the core mould. The anode with shape similar to the shape of the core mould of the medicine-typed cover is made with insulation material. The anode combines with the blocky electroform material of the anode to constitute the anode cavity as the anode unit. The rolling depression or the friction and disturbance treatment is carried out for the core mould of the cathode in rotating electroform by using the rolling depression method or the insulation friction method. The device includes the stock solution tank, the magnetic drive pump, the filter, the ball valve etc. The equipment also includes the rotating cathode, the rolling depression set or friction set, the imitating anode etc constituted the device of the electroform procedure.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

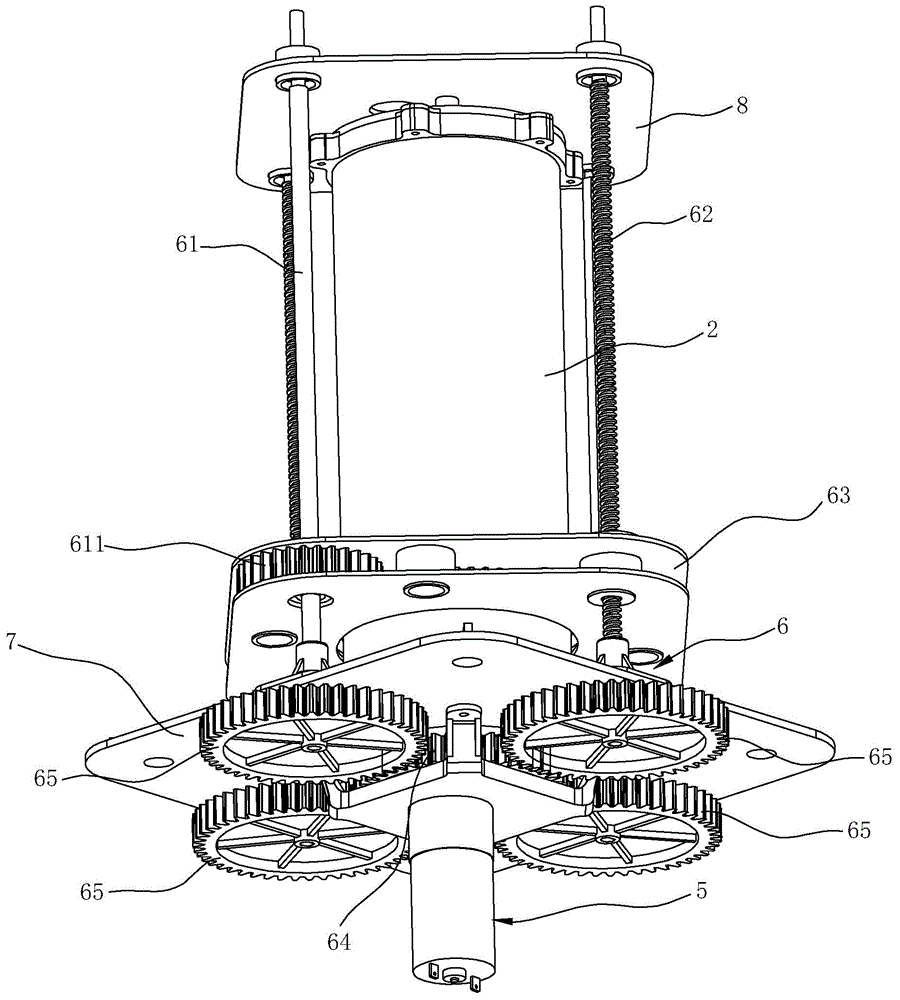

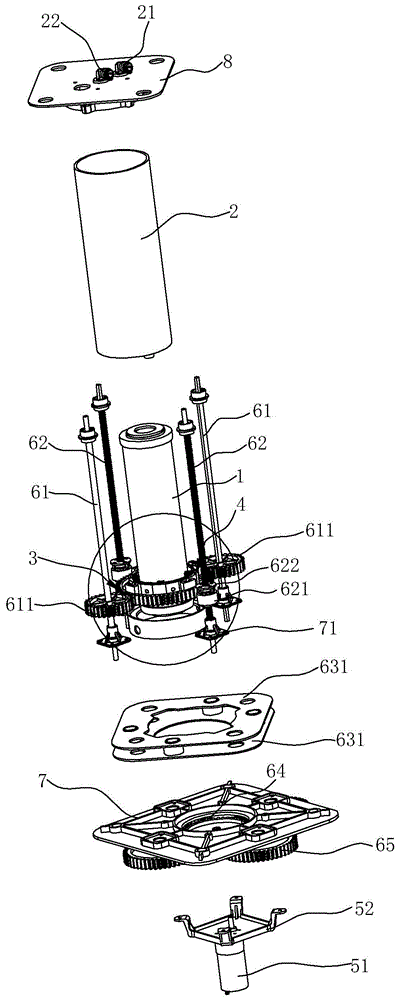

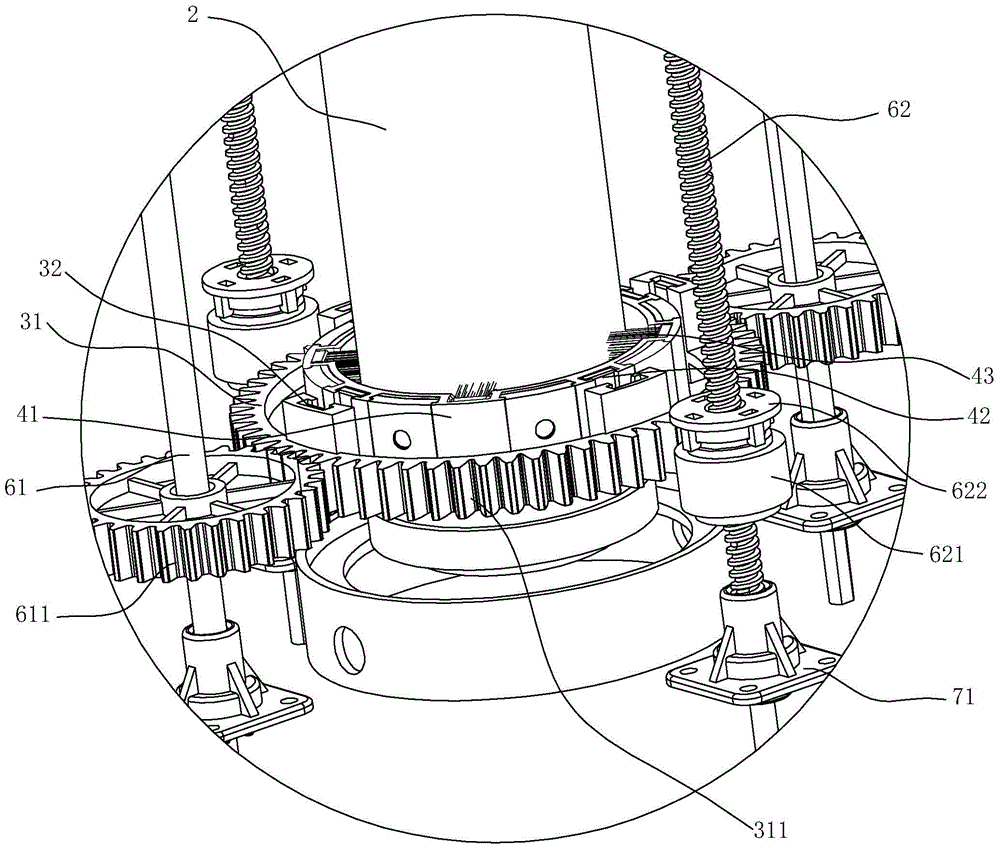

Ceramic filter element automatic cleaning device

ActiveCN104801093AImprove cleaning effectSave human effortStationary filtering element filtersEngineeringMechanical engineering

The invention discloses a ceramic filter element automatic cleaning device. A cylindrical filter element casing is arranged outside a ceramic filter element; the automatic cleaning device includes a driving outer ring component arranged on the outer periphery of the filter element casing, and a driven inner ring component arranged on the inner periphery of the filter element casing and linked with the driving outer ring component; brushes for brushing the ceramic filter element are arranged on the driven inner ring component; the automatic cleaning device also includes a driving mechanism and a transmission mechanism both enabling the driving outer ring component to rotate and move in the axial direction of the filter element casing; the transmission mechanism includes guide rods and screw rods all parallel to the filter element casing and driven by the driving mechanism to rotate, and a support base; the guide rods and the screw rods penetrate through the support base; the screw rods are in threaded connection with the support base to enable the support base to perform axial movement; the guide rods axially move along with the support base and drive a driving outer ring to rotate; the driving outer ring component is rotationally connected with the support base.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

High speed steel finishing roll of wire bar mill and manufacturing method of high speed steel finishing roll

ActiveCN104384193AEvenly distributedImprove bindingRollsMetal rolling arrangementsCrack resistanceChemical composition

The invention discloses a high speed steel finishing roll of a wire bar mill and a manufacturing method of the high speed steel finishing roll, belonging to the technical field of machining and casting. The finishing roll consists of a roll neck and a roll body comprising a working layer, a primary core and a core part; the working layer comprises the following chemical components: 1.50-2.50 percent of C, 0.40-1.00 percent of Si, 0.40-0.80 percent of Mn, less than or equal to 0.03 percent of P, less than or equal to 0.03 percent of S, 4.0-8.0 percent of Cr, 0.50-1.00 percent of Ni, 5.00-8.00 percent of Mo and 5.00-8.00 percent of V. In the casting process, the casting temperature and the rotating speed of a centrifuge can be controlled by adopting manners of high-temperature discharge from a furnace, low-temperature casting, high-speed mold filling and slow-down solidification. According to the high speed steel finishing roll and the manufacturing method of the high speed steel finishing roll, the adaptability of high speed steel materials on bar rolling can be effectively solved by reasonable design of alloy components and the processing technology, and the wear resistance and the millimeter rolling quantity of the roll are improved; in addition, the high speed steel finishing roll has favorable thermal crack resistance, and the working efficiency of a heavy and medium plate mill can be greatly improved.

Owner:SINOSTEEL XINGTAI MACHINERY & MILL ROLL

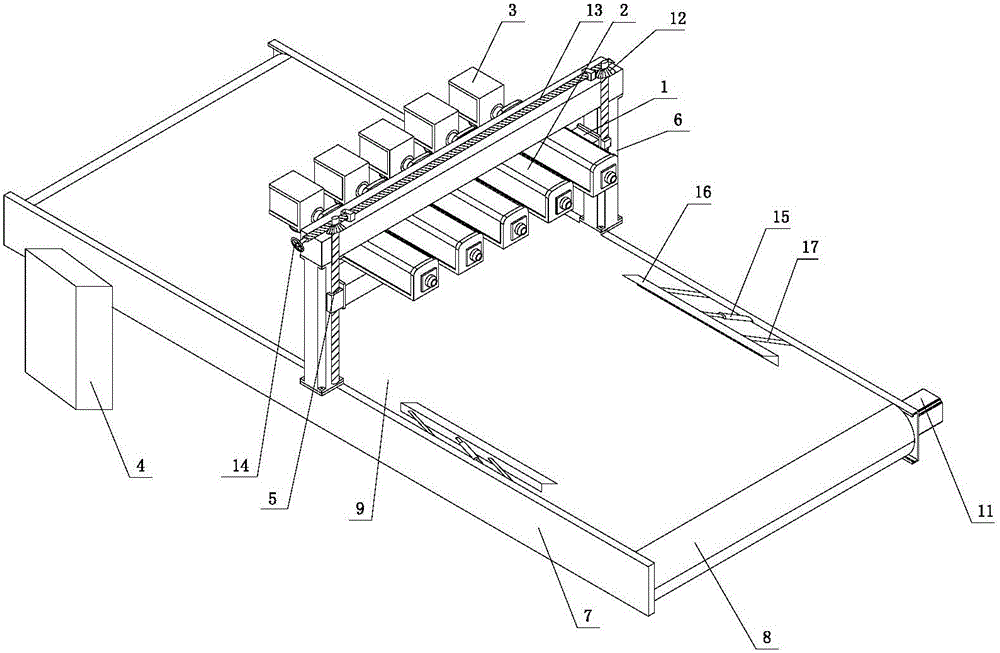

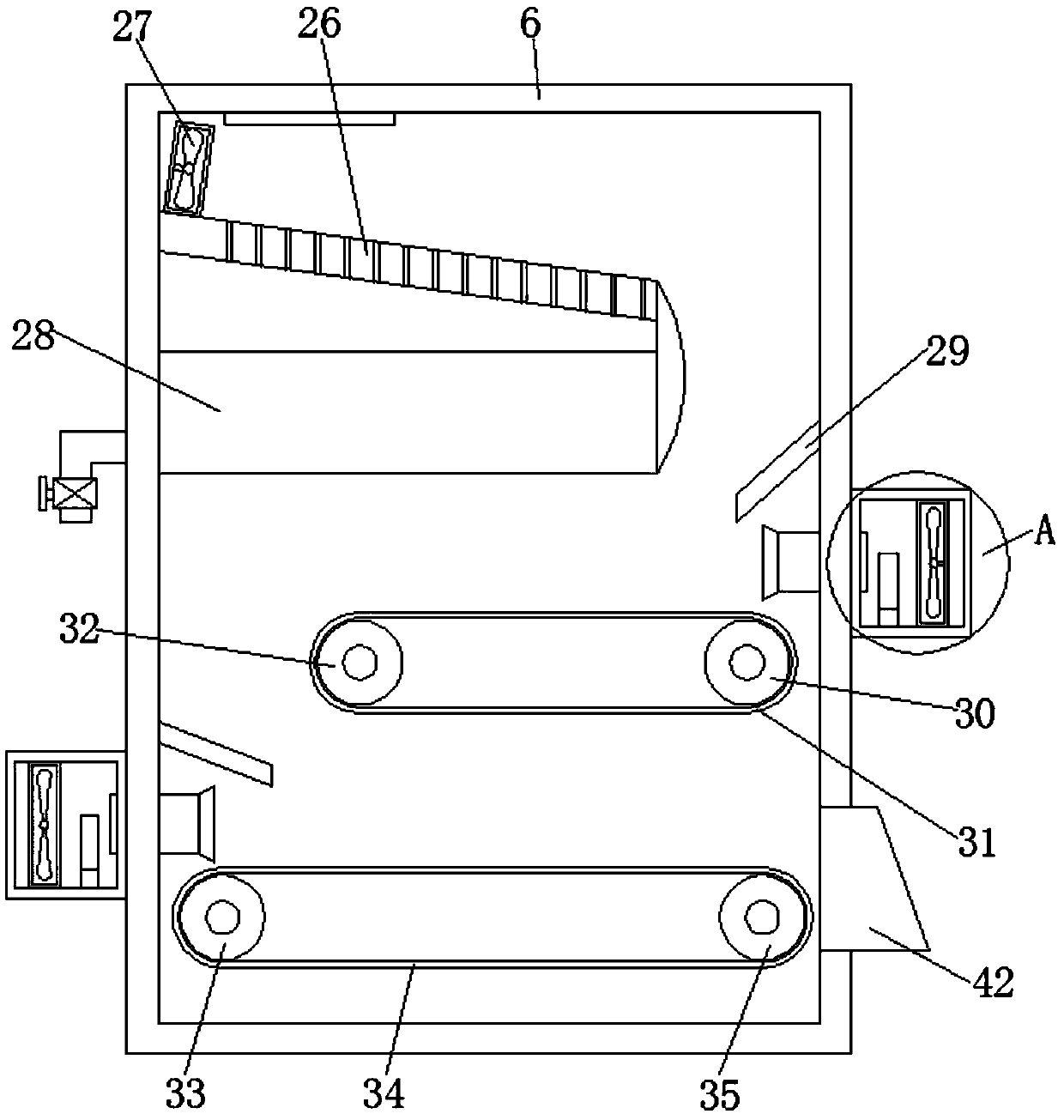

Large-breadth laser washing machine

InactiveCN105855245AHealth is not damagedNo pollution in the processCleaning processes and apparatusMetal sheetEngineering

The invention relates to a device for washing pollutants including rust spots, corrosion, oil stains and the like on surfaces of various types of metal sheet materials and particularly relates to a large-breadth laser washing machine. The large-breadth laser washing machine comprises a worktable, wherein a conveyor belt driven by a stepping motor is arranged on the worktable along the length direction of the worktable; the bottom of a supporting frame is mounted on the two sides of the worktable; a hoisting mechanism is arranged on the supporting frame; and the two ends of a hoisting transverse beam, which are arranged along the width direction of the worktable, are connected with the hoisting mechanism respectively. Therefore, the structure is reasonable and novel in design and has no grinding, non-contact and no heat effects in a washing process; in the washing process, no pollution to the environment is caused and body health of workers is not injured; a washing area is large, the efficiency is high and the washing cost is low; the distance between the device and a washing surface can be accurately controlled and the washing is uniform and has good effect.

Owner:济南高能清扬激光清洗有限公司

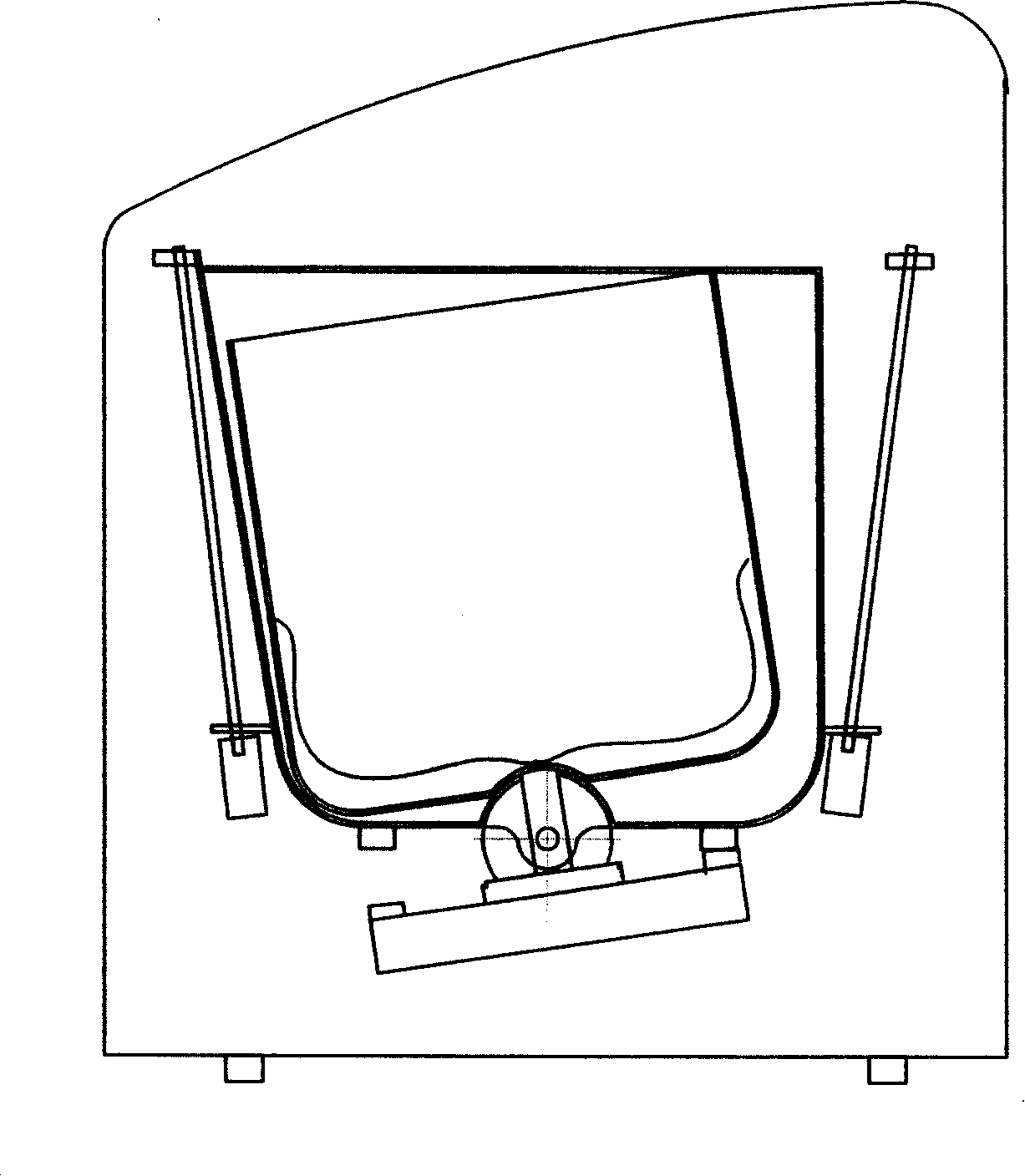

Double-mode washing machine and double-mode washing method

ActiveCN101191291AWash evenlyReduce wearOther washing machinesControl devices for washing apparatusEngineeringMoisture

The invention relates to a washing machine, in particular to a double-mode washing machine and a washing method, wherein, during the washing process, a rotary drum of the washing machine rotates along a horizontal rotary shaft, and clothes washed are driven by the rotary drum and continuously lifted and thrown in the rotary drum and lifted and thrown again, and then the clothes are thrown and washed repeatedly; during the wringing process, the rotary drum rotates at high speed along a shaft which is perpendicular to the ground and the clothes are dried. The washing process is designed by imitating the principle of a mallet striking the clothes, and the rotary drum is driven to rotate along a shaft in parallel with the ground and by utilization of mechanical power of a motor; the clothes are continuously lifted and thrown in the rotary drum and lifted and thrown again, and repeated motion is performed, thereby the invention has the advantages of non winding, even washing and small abrasion during the washing process. During the wringing process, the rotary drum rotates at high speed along the shaft which is perpendicular to the ground and moisture is made to be away from the clothes, thereby both noise and vibration are low. Moreover, due to removal of a damping block, the invention has the advantages of light weight and convenience in transportation and movement when users use the washing machine.

Owner:HAIER GRP CORP +1

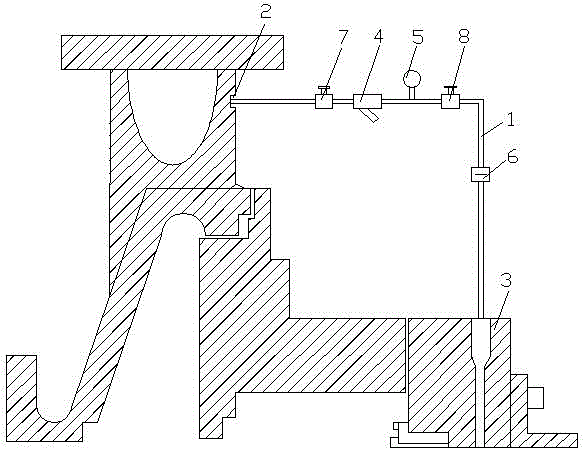

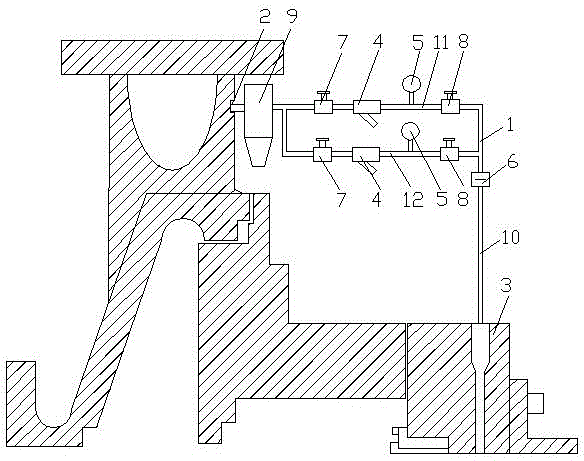

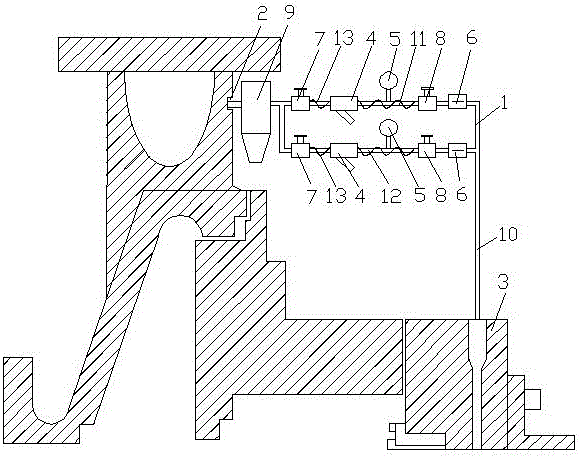

Flushing device for mechanical seal of centrifugal pump

ActiveCN106122108AFlow is stable and cleanPrevents deposition of particulate impuritiesPump componentsPumpsCentrifugal pumpOrifice plate

The invention discloses a flushing device for a mechanical seal of a centrifugal pump, and belongs to the technical field of centrifugal pumps. The flushing device comprises a flushing pipe connected to the centrifugal pump; the liquid feeding end of the flushing pipe is connected with the outlet end of the centrifugal pump; the liquid discharging end of the flushing pipe is connected with the mechanical seal of the centrifugal pump; the flushing device is characterized in that the flushing pipe is connected with a tubular filter, a pressure gauge and a throttling orifice plate; the tubular filter is close to the outlet end of the centrifugal pump; the throttling orifice plate is close to the mechanical seal of the centrifugal pump; a first stop valve and a second stop valve are arranged on the flushing pipe; the first stop valve is positioned between the outlet end of the centrifugal pump and the tubular filter; and the second stop valve is positioned between the pressure gauge and the throttling orifice plate. The flushing device can both achieve a good cooling effect on the mechanical seal and prevent particle impurities from being deposited on the sealing surfaces of movable and fixed rings, thus effectively protecting the sealing surfaces of the movable and fixed rings, relieving wear and enhancing the sealing effect; and therefore, normal and stable operation of the centrifugal pump is guaranteed.

Owner:CHINA PETROLEUM & CHEM CORP +1

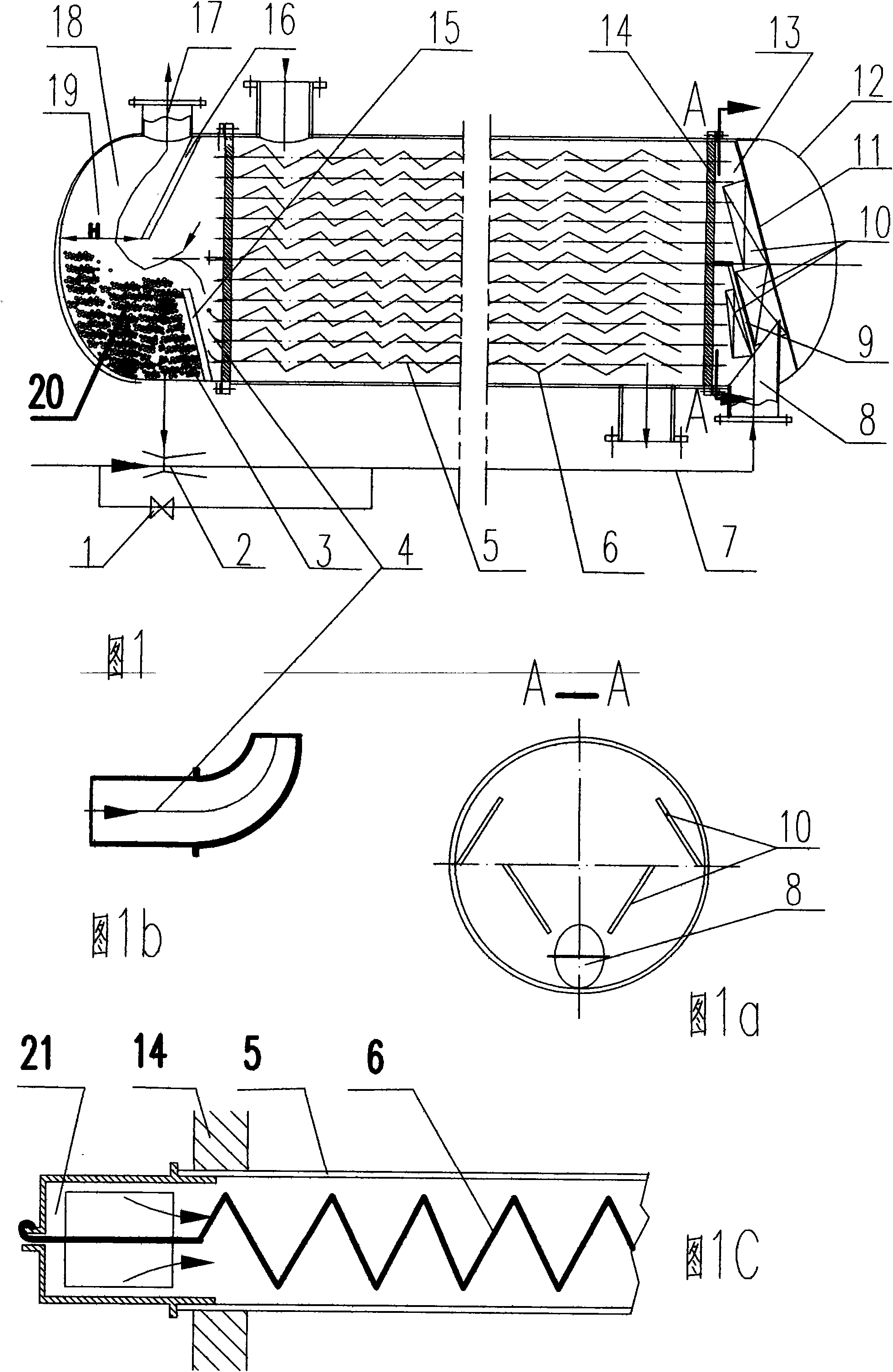

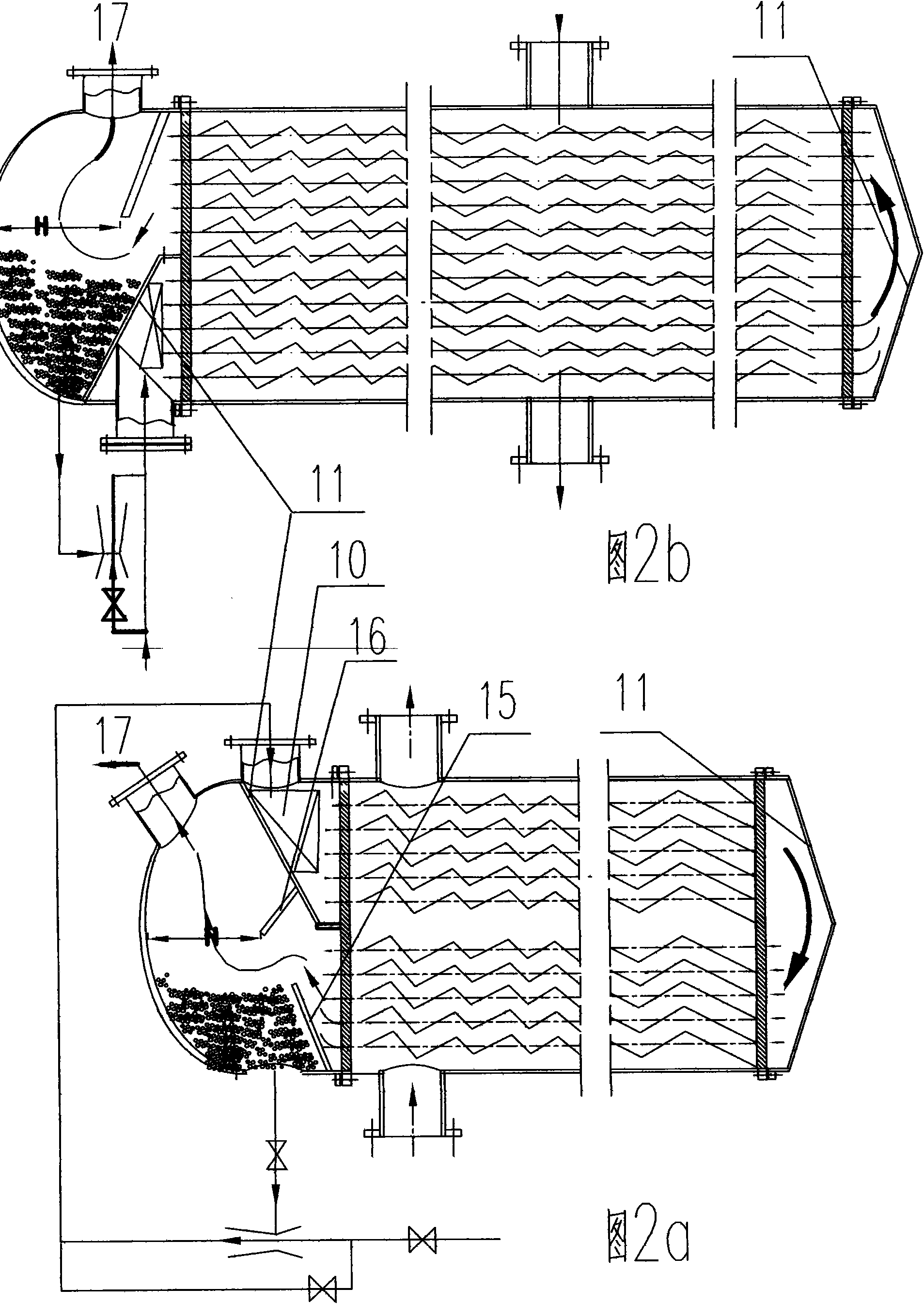

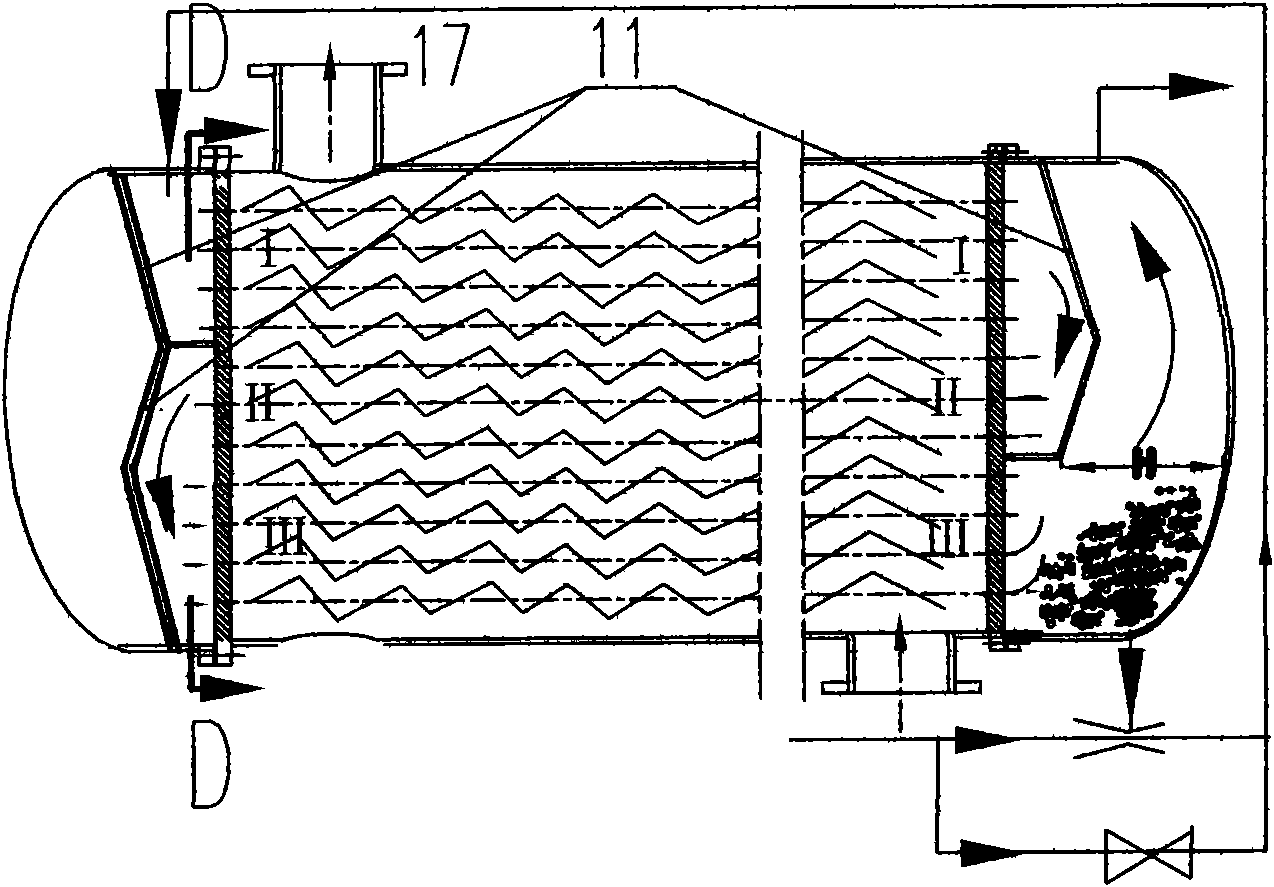

Vibratory spiral fluidized horizontal shell-and-tube heat exchanger

InactiveCN102645113AImprove uniformityEasy to cleanStationary tubular conduit assembliesHeat transfer modificationPlate heat exchangerShell and tube heat exchanger

The invention relates to a vibratory spiral fluidized horizontal shell-and-tube heat exchanger. Structures such as evenly distributed headers are used for improving the uniformity of fluidizing balls to enter heat exchange tubes. The clearance between the outer diameter of a steel wire spiral line and a pipe inner wall is more than two times of the diameter of the fluidizing ball. Dead zones during cleaning of fluidizing ball scale are eliminated. During operation, the fluidizing balls make spiral line motion under the push of a spiral flow, the centrifugal force of the fluidizing balls is naturally concentrated on the tube inner wall and pressure required for cleaning hard scale is produced. Sliding component velocity of the fluidizing balls on the tube inner wall takes an effect of automatically cleaning the hard scale. The fluidizing balls roll at high speed and violently and transversely agitate a boundary layer, the supersaturation degree of a stagnant layer is greatly reduced, the generation of hard scale is avoided or remarkably relieved and a more valuable antiscale effect is obtained. Since the inlet end of the steel wire spiral line which is arranged in each heat exchange tube is fixed and the tail end of the steel wire spiral line is free, the situation that the steel wire spiral line wears the tube inner wall is avoided. Therefore, the heat exchanger is suitable for all situations that hard scale is formed in horizontal shell-and-tube heat exchangers with all kinds of structures.

Owner:俞天翔

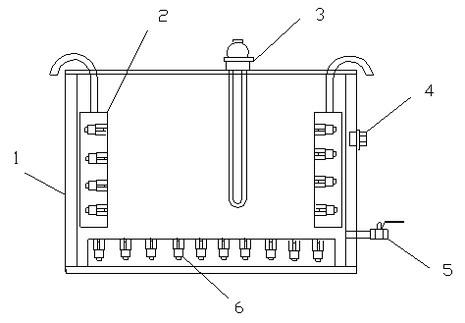

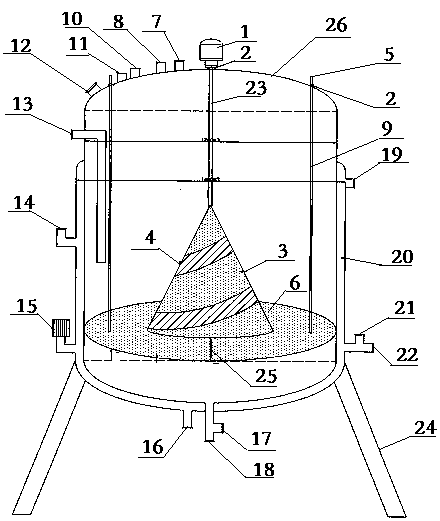

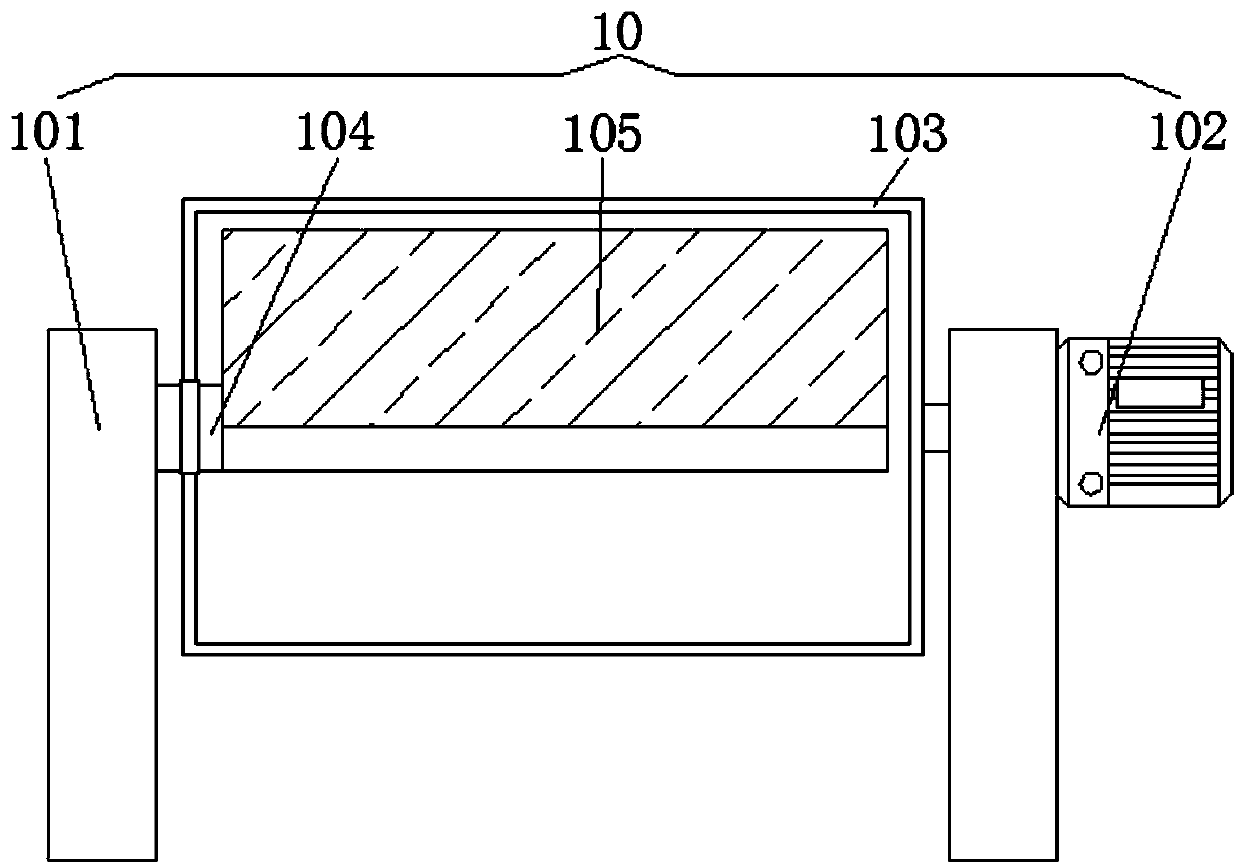

Multifunctional rice wind fermentation tank and process method thereof

InactiveCN108130256AReduce security risksLabor savingAlcoholic beverage preparationEngineeringEnergy consumption

The invention provides a multifunctional rice wind fermentation tank and a process method thereof. Semi-solid rice wine is prepared from sticky rice as a primary raw material. A cone-shaped stirrer and a round partition plate are arranged in the tank body, the round partition plate is arranged below the cone-shaped stirrer, spiral stirring blades are mounted on the cone-shaped surface of the cone-shaped stirrer, a connecting rod is mounted on the cone-shaped stirrer, penetrates through the top of the tank body and is driven by a motor, the round partition plate is composed of two semi-circularpartition plates which can turn around, and any one of the semi-circular partition plates can go up and down along with a tensile rod thereon to be horizontal or vertical to the other semi-circular partition plate. The multifunctional fermentation tank which integrates sticky rice soaking, steaming and cooling and separating steps before rice wine fermentation can finish all the work in th same container by a single person, so that the labor cost is lowered, the resources are saved, the work efficiency is improved, and the product quality is ensured. Multiple tanks are connected in series, sothat hot air and waste water are fully utilized, and the energy consumption cost is lowered.

Owner:湖北晶聚利精密组件有限公司

Tumbling barrel of high-efficiency washing machine

InactiveCN101988252AWash evenlyWide range of washingOther washing machinesTextiles and paperElectricityEngineering

The invention discloses a tumbling barrel of a high-efficiency tumbling barrel washing machine. The washing machine comprises a washing bucket for containing washing water, the tumbling barrel for containing clothes and a motor for supplying motive power to the rotation of the tumbling barrel, wherein multiple lifting cavities are distributed on the external side of the tumbling barrel and are used for lifting washing liquid; the lifting cavities lift part of the washing liquid out of the liquid surface when rotating along with the tumbling barrel; the lifted washing liquid passes through thethrough holes on the wall of the tumbling barrel to spray and wash the clothes in all directions so as to enhance the washing efficiency; and the tumbling barrel washing machine saves more water, electricity and time under the condition that the rolling mashing machine maintains the original advantages.

Owner:周围

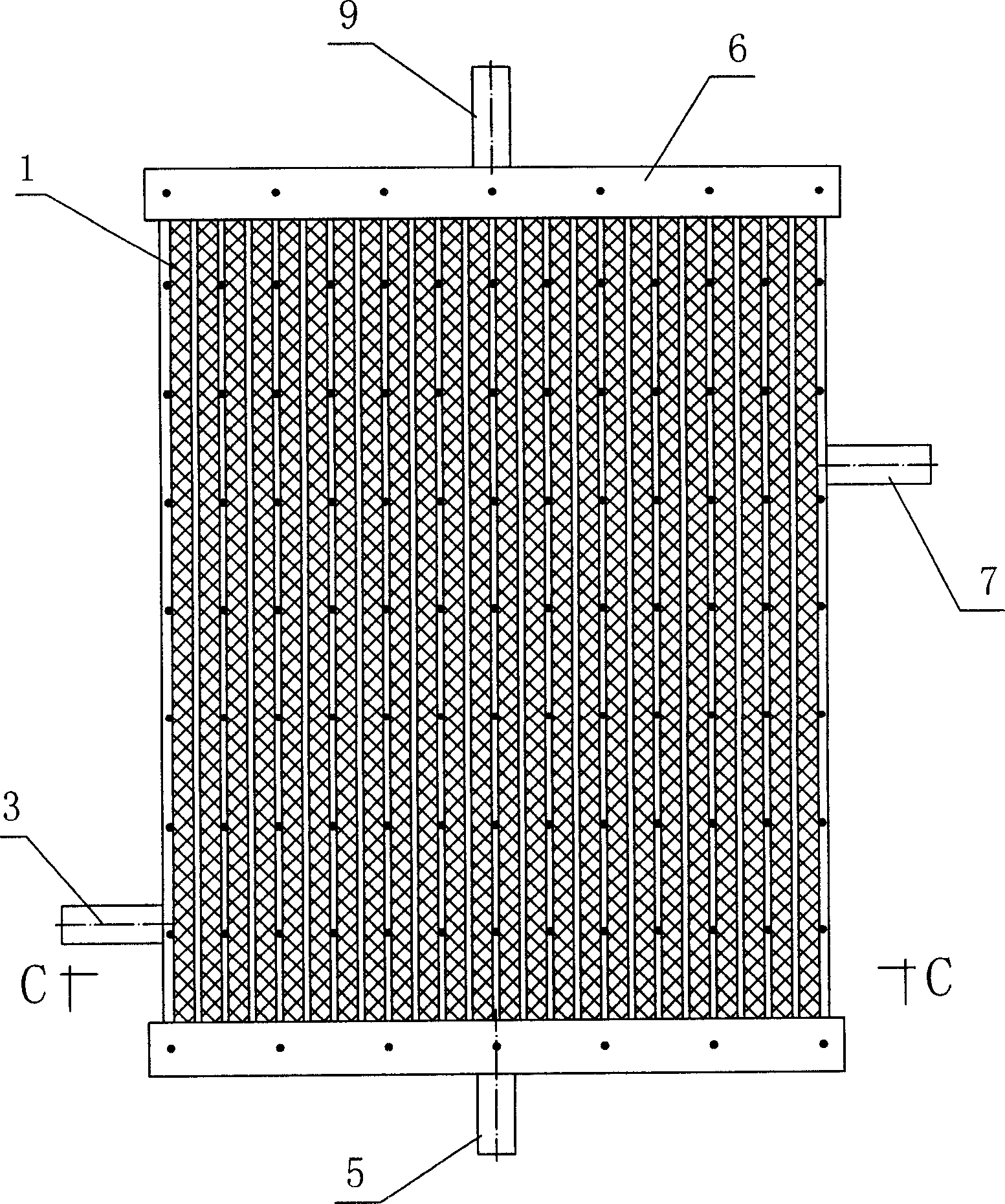

Dynamic micro filter membrane assembly and water treatment process method

InactiveCN1807275ASimple structureIncrease packing densityTreatment using aerobic processesSustainable biological treatmentDistribution systemEngineering

The invention discloses a dynamic microfiltration membrane module for water treatment technique, which comprises: a filter chamber contained a micropore on wall, a recoil inlet pipe and a filter outlet pipe both on side surface, and an air-exhaust pipe on top; and a filter network folded into a concave-convex curve to fix on the front and back walls of the filter chamber. Wherein, connecting the filter chamber lower end to a backwash gas-distribution system with an aeration header and a distributing pipe connected to the gas inlet pipe; connecting supporting parts with concave-convex surface on upper and lower ends of the filter chamber to lay the filter network, fixing the firmware for concave-convex surface on the network, and setting both the outside of supporting part and firmware inside with the opposite curves as the network. The opposite water treatment technique comprises: hanging the membrane, filtering, outputting water, and clearing the dynamic membrane. This invention enhances the membrane packing density, reduces cost, and prolongs membrane service lifetime.

Owner:于容朴

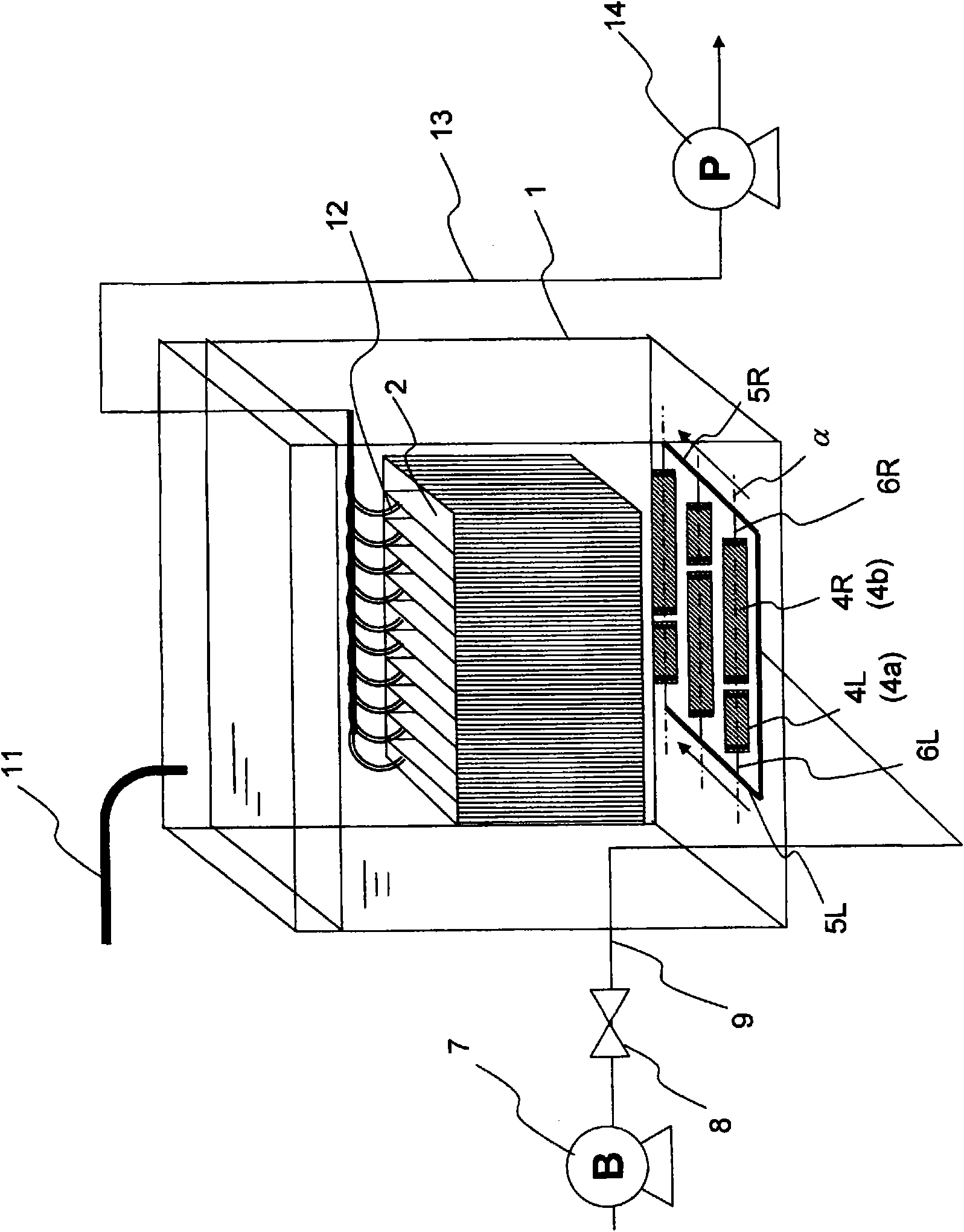

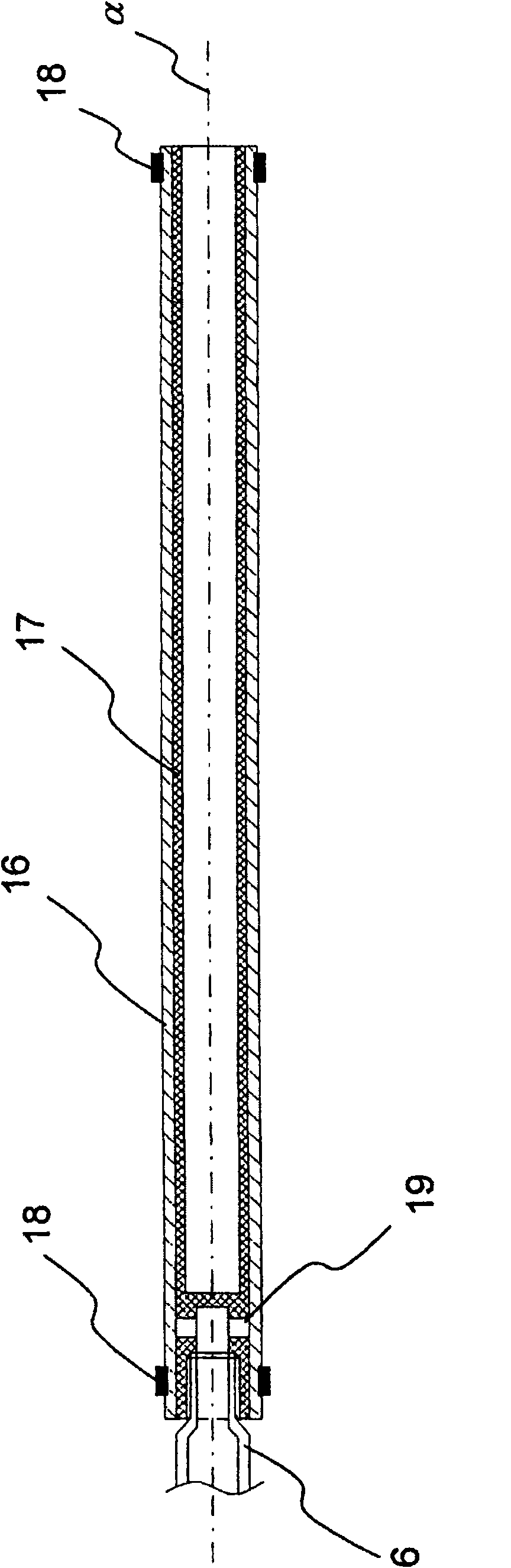

Immersion type membrane separation apparatus and method of operating the same

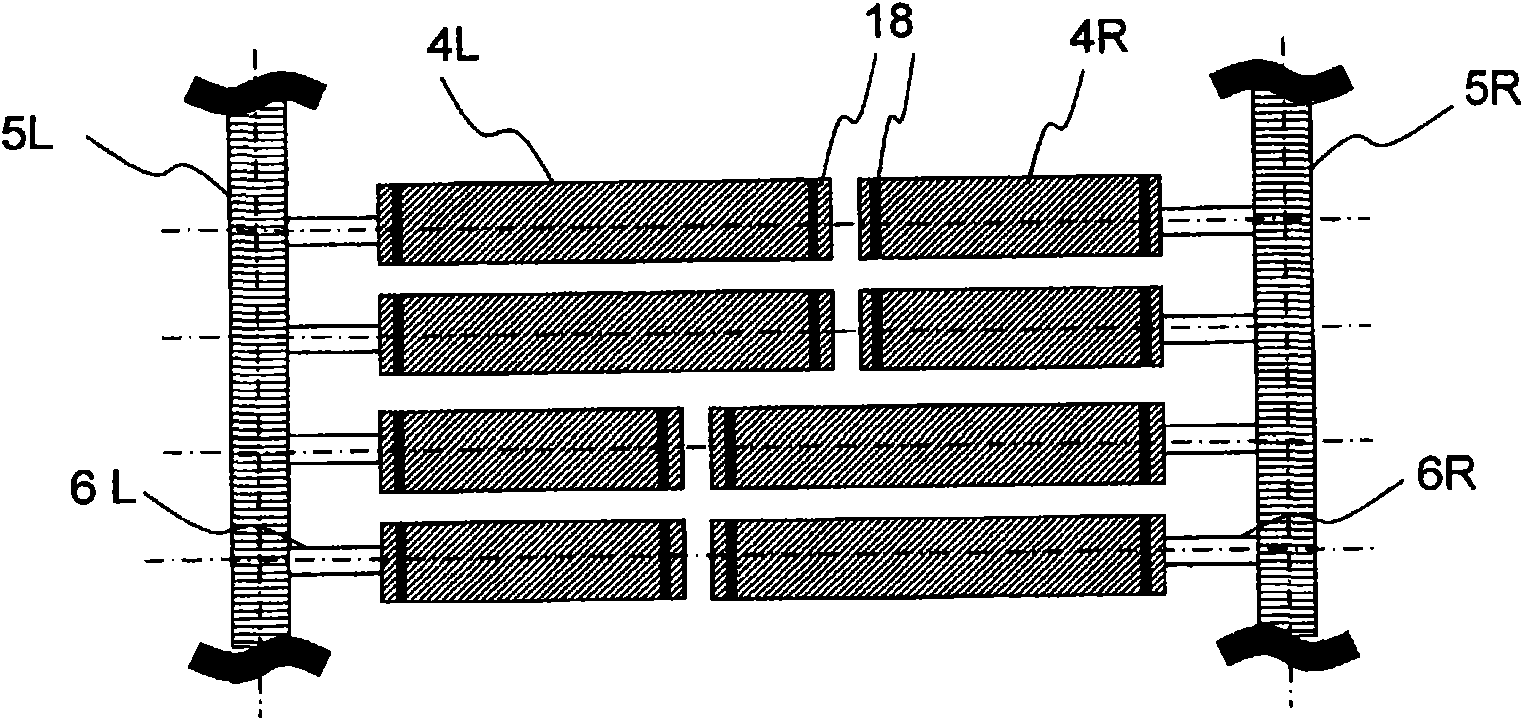

ActiveCN101678282ASeek long lifeWash evenlyMembranesTreatment using aerobic processesMicrobubblesLarge size

The invention provides an immersion type membrane separation apparatus having a microbubble dispersing tube placed vertically beneath a separation membrane module, in which even when the separation membrane module is of large size, there can be attained all-round uniform generation of microbubbles from an area vertically beneath the separation membrane module. The apparatus comprises a separation membrane module (2) having multiple separation membrane elements each using a flat membrane as a separation membrane disposed in parallel so that the membrane surfaces are parallel to each other; multiple microbubble dispersing tubes (4) placed vertically beneath the separation membrane module; and multiple gas supply tubes (5) for supplying a gas to the microbubble dispersing tubes. The multiple gas supply tubes (5) are arranged so as to be opposite to each other across an area vertically beneath the separation membrane module. The multiple microbubble dispersing tubes (4) connected in communicating relationship to the gas supply tubes are arranged so as to extend in a direction crossing a membrane surface of separation membrane element and so as to realize proximity to each other, or superposition on each other, of the distal ends of the opposite microbubble dispersing tubes.

Owner:TORAY IND INC

Medical cleaning and sterilizing device

InactiveCN104668229ASimple structurePrevent outflowCleaning using liquidsChemicalsRound tableEngineering

The invention discloses a medical cleaning and sterilizing device. The medical cleaning and sterilizing device comprises a frame body, a supporting device, an air cylinder device, a feeding device and a spraying device, wherein a first through hole, an oblique plate, a liquid collecting plate, a cover body, a positioning plate, a spring, a triangular block, a second through hole and an attaching rod are arranged on the frame body; the supporting device comprises a supporting rod and a universal wheel; the spraying device comprises a spraying pipe, a buckling rod, a first valve and a spraying head; the air cylinder device comprises an air cylinder, a bracket, a connecting rod, a rectangular block, a cylindrical rod, a material distributing block and a vertical plate; the feeding device comprises a horizontal plate, a supporting block, a feeding pipe, a feeding hopper, a filtering net and a second valve; the material distributing block comprises an upper end part and a lower end part; the upper end part is shaped like a round table; the lower surface of the cylindrical rod is fixedly connected with the upper surface of the upper end part; the lower end part is cylindrical; a first round hole is formed in the material distributing block and enables the side surface of the upper end part to be communicated with the lower surface of the lower end part; the lower surface of he vertical plate is oblique; the upper surface of he vertical plate is fixedly connected with the lower surface of the material distributing block.

Owner:任永恒

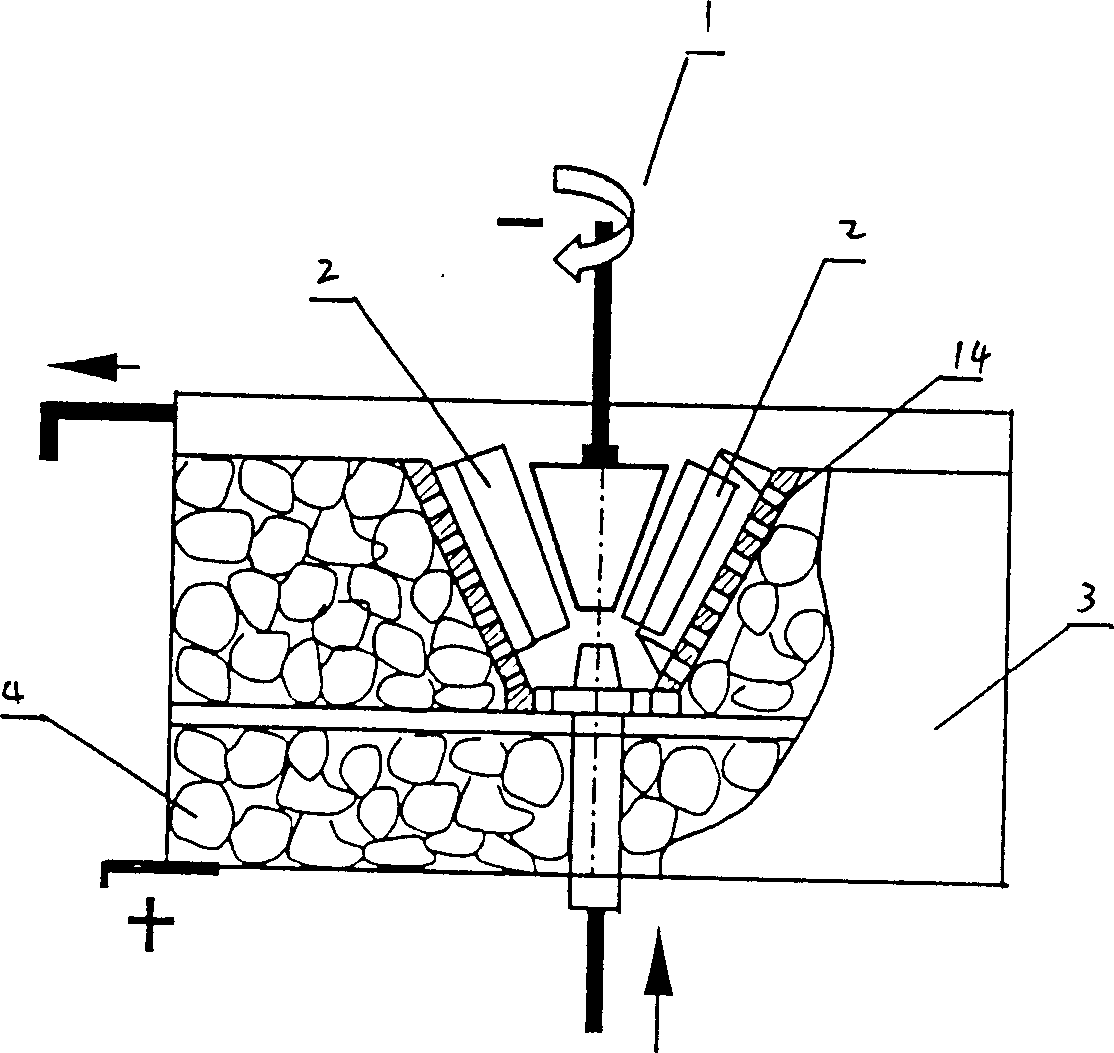

Rotary flow aeration biological filter

InactiveCN1640825AWash evenlySave washing waterTreatment using aerobic processesSustainable biological treatmentWater flowBiological filter

The rotary flow aerating and biologically filtering tank is circular or squared, adopts light suspended stuffing and has mechanical stirrer installed to make water and the stuffing rotate around the center of the tank. The aerating and biologically filtering tank runs in upstream mode. During processing sewage, the stirrer rotates slowly to rotate the bottom water flow for the homogeneous mixing and distribution of inflowing water. During washing the aerating and biologically filtering tank, the stirrer rotates quickly to rotate water and filtering material, the collision among filtering grains and the shearing force of water flow make the biological film on the stuffing fall down, and clear water is led in for rinsing to complete the washing process.

Owner:向连城

Showing stand for sale of fruits

The invention discloses a showing stand for sale of fruits. The showing stand for sale of fruits comprises a shield and a base, wherein a water tank is arranged on the top of the shield; a water leaking opening is formed in one end, which is close to the shield and away from a water feeding tube, of the upper surface of the base; a water stopping plate is mounted at the edge of the top of the base; a controller is arranged on the front surface of the base; a touch type power switch is arranged on the controller; a sleeve is arranged on the inner wall of the bottom of the base; a rotating bar is arranged in the sleeve, penetrates in the base and extends to a position above the base; and a tray is arranged on the rotating bar. By the showing stand for sale of the fruits, the fruits are placed in the tray, a controller controls a motor to rotate, the rotating bar is driven to rotate, meanwhile, a first water pump and a second water pump drive sprayers to begin to spray water, owing to distribution of the sprayers and rotation of the rotating bar, the fruits can be cleaned uniformly, and the effect of removing dust is achieved; and by a water purifying device, water resources can be recycled, and therefore, resources are saved.

Owner:无锡市阳山镇福寿水蜜桃专业合作社

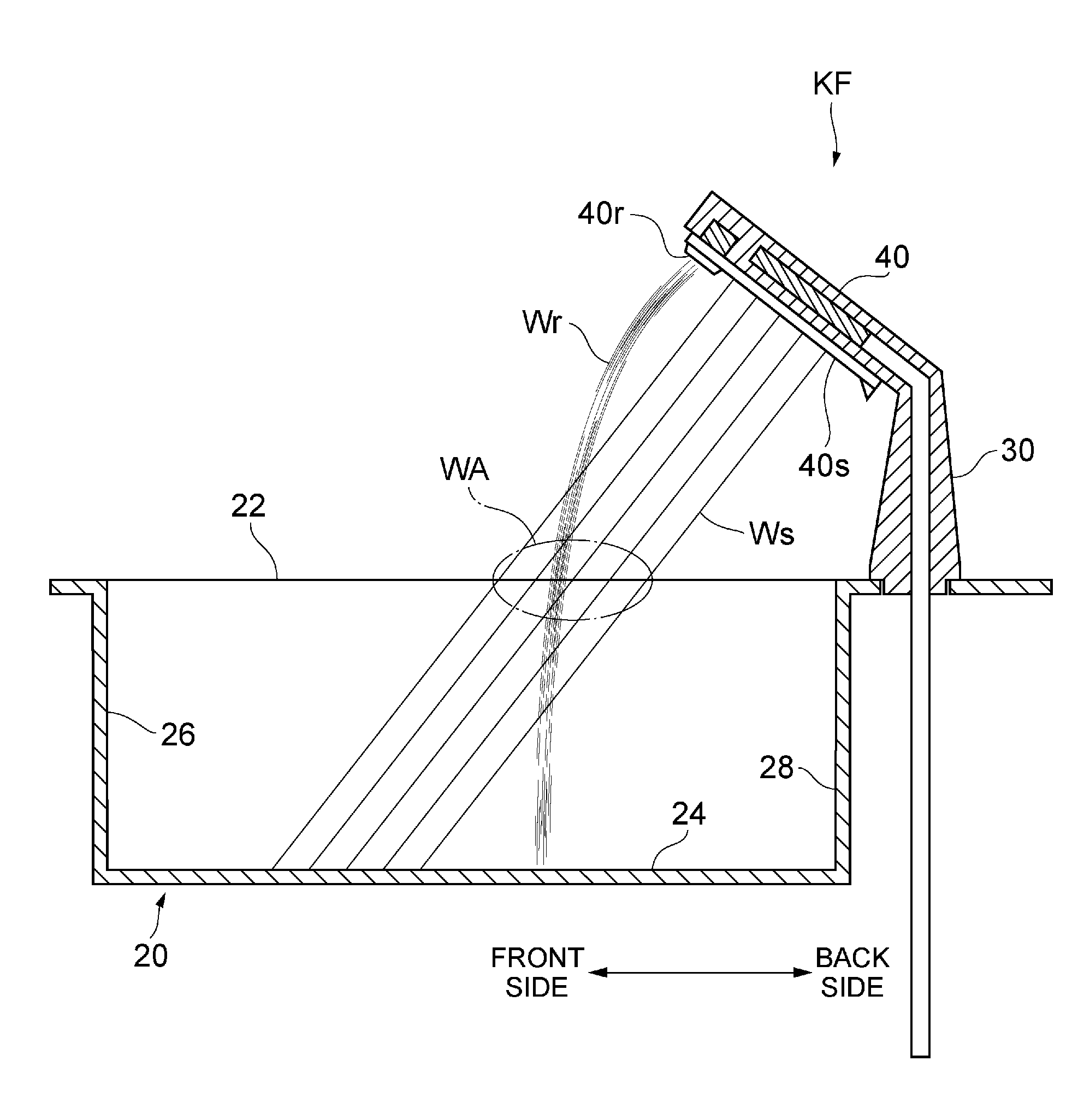

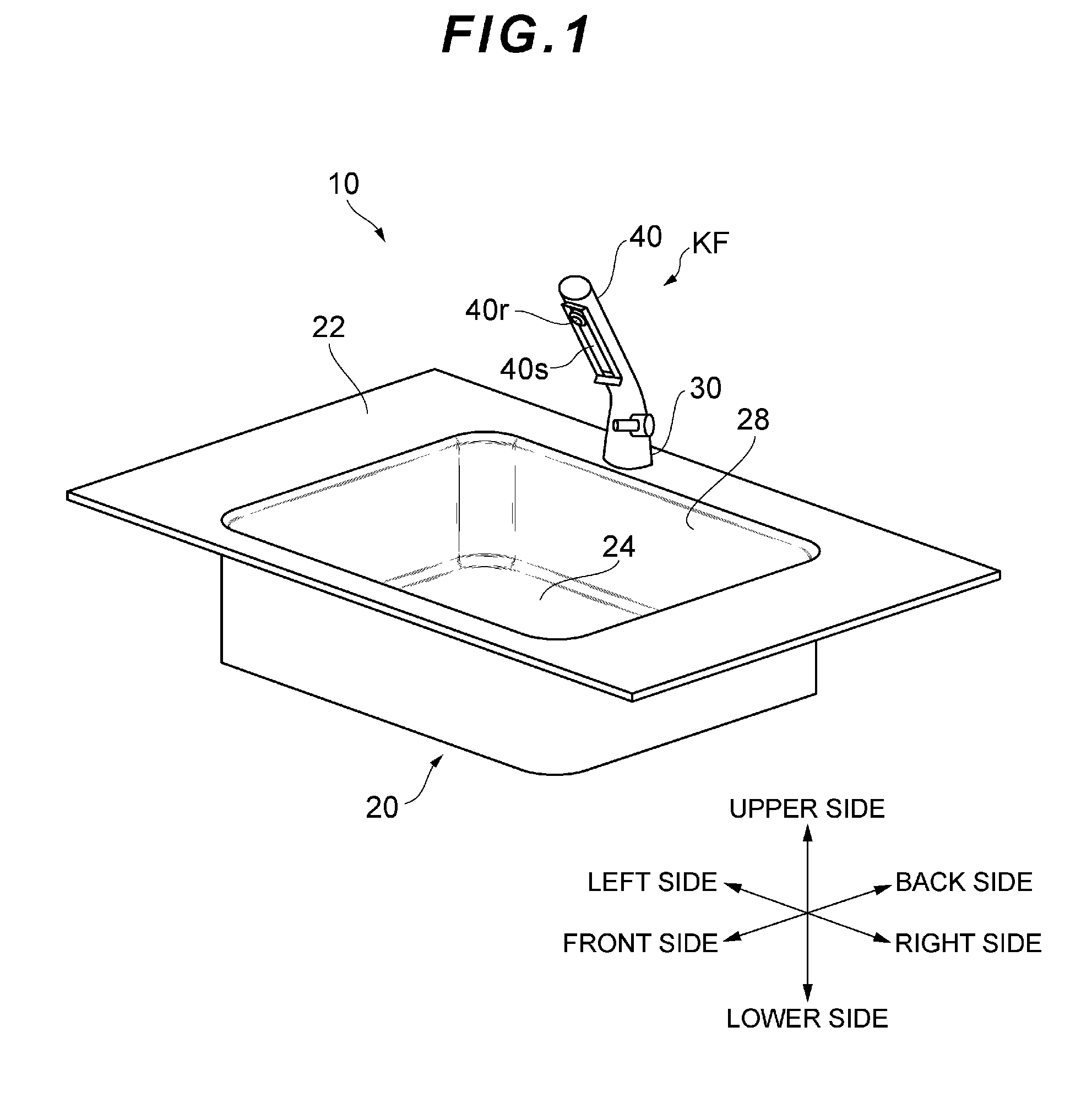

Water faucet

ActiveUS20150014447A1Reliably changed with timeReduce the cross-sectional areaDomestic plumbingSpray nozzlesWater flowEngineering

The present invention aims to provide a water faucet which allows a large space to be secured above the washing area and yet can deliver a high washing performance by landing streams or waterdrops having a large cross-sectional area evenly on a piece to wash. This water faucet includes a flow velocity changing part which changes the flow velocity of the stream discharged from each of multiple water spray holes such that the cross-sectional area of the stream changes with time. The multiple water spray holes are disposed at intervals such that, when the cross-sectional area of one stream discharged from one water spray hole exceeds a predetermined size, the one stream is merged with one of the other streams discharged from the multiple other water spray holes adjacent to the one water spray hole, and such that the one of the other streams with which the one stream merges changes with time.

Owner:TOTO LTD

Washing method and washing machine using same

ActiveCN104109962AReduce tanglingAvoid uneven washingOther washing machinesControl devices for washing apparatusEngineeringCentrifugal force

The invention relates to a washing method and a washing machine using the same. The washing machine is controlled to rotate forwardly and reversely in an intermittent manner to allow clothes to turn over in an inner barrel so as to complete washing, the angles of each forward rotation and each reverse rotation are different, and the angle of each forward rotation is unequal to that of each reverse rotation; by an impeller inner barrel integral structure, the clothes are pulled up and fall nearly vertically during forward rotation, in the periphery direction, of the inner barrel, and the clothes are impacted by nearly vertical faces in the periphery direction during reverse rotation of the inner barrel; during forward and reverse rotation, the clothes are turned over outwardly and upwardly and turned over inwardly and downwardly when reaching the wall of the inner barrel under the guide of centrifugal force generated by radial rotation and the bottom structure of the inner barrel; the clothes are turned over continuously in the inner barrel, clothes twining is reduced by the intermittent forward and reverse rotation, constant washing and friction of the same position of the clothes can be avoided due to the fact that the angles of forward rotation is unequal to that of the reverse rotation, washing unevenness is avoided, and the clothes can be washed comprehensively by the joint action of pulling up, falling, turning over by centrifugal force, impacting, friction and rubbing in washing.

Owner:QINGDAO JIAONAN HAIER WASHING MACHINE

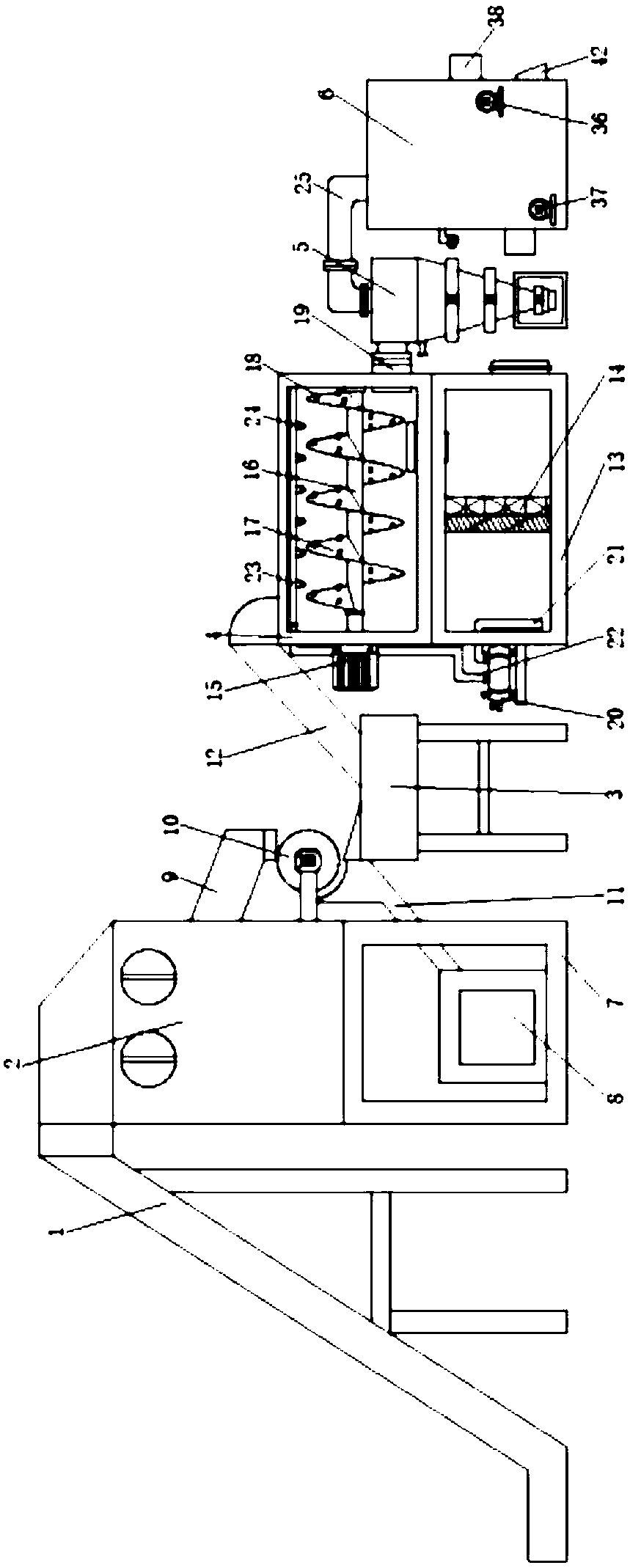

Swirling flow type waste plastic crushing sorting cleaning system

InactiveCN109551664AQuality improvementReduce metal magnetic impuritiesPlastic recyclingMechanical material recoveryWater resourcesPlastic recycling

The invention provides a swirling flow type waste plastic crushing sorting cleaning system. The swirling flow type waste plastic crushing sorting cleaning system includes a first transfer machine, a crushing machine, a transfer box, a cleaning device, a swirler, a box body and a fixing frame, and the top of the fixing frame is fixed to the bottom of the crushing machine. According to the swirlingflow type waste plastic crushing sorting cleaning system, metal magnetic impurities in waste plastic are reduced, the quality of waste plastic recycling is improved, meanwhile, the waste metal magnetic impurities are collected, post-processing and production of processing are convenient, multi-angle cleaning is realized, cleaning is more even, the efficiency and quality of cleaning are ensured, thus the recycling efficiency of the waste plastic is improved, reuse of water resources is improved, the cleanliness degree of the cleaning process is increased, thus the recycling quality of the wasteplastic is ensured, the water content of waste plastic recycling is decreased, and the quality of production is ensured, so that secondary processing is avoided.

Owner:开平市源成达塑胶制品有限公司

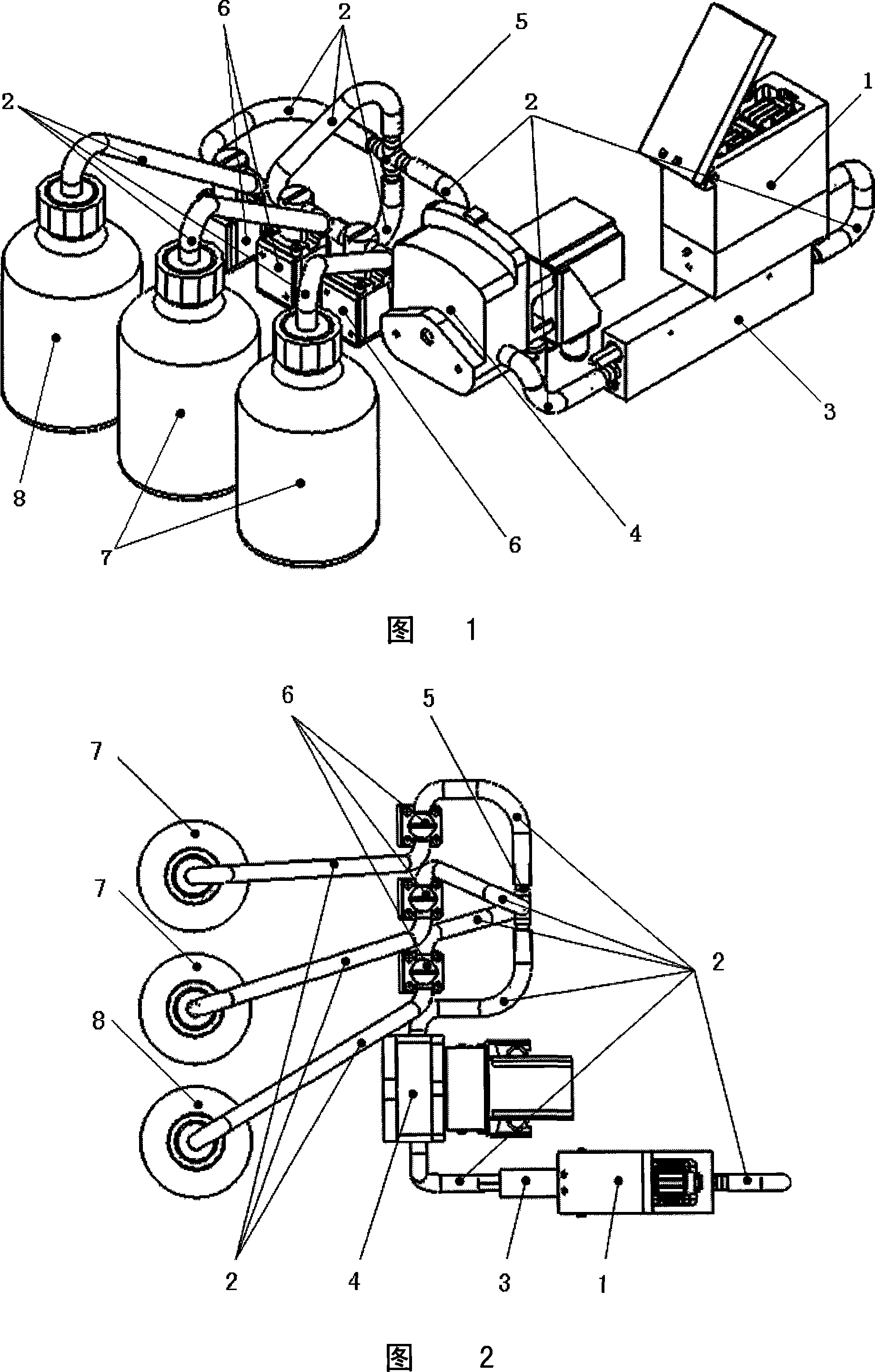

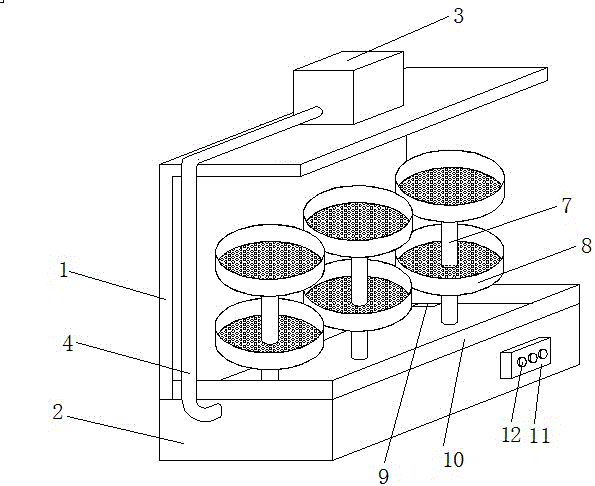

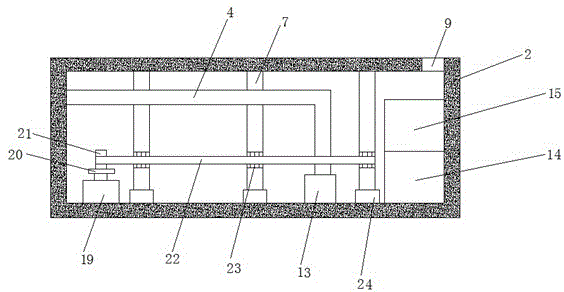

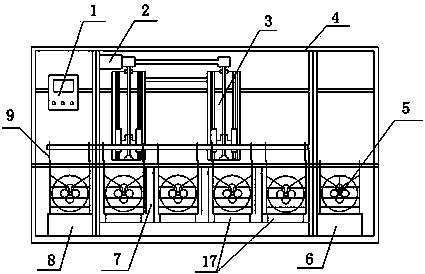

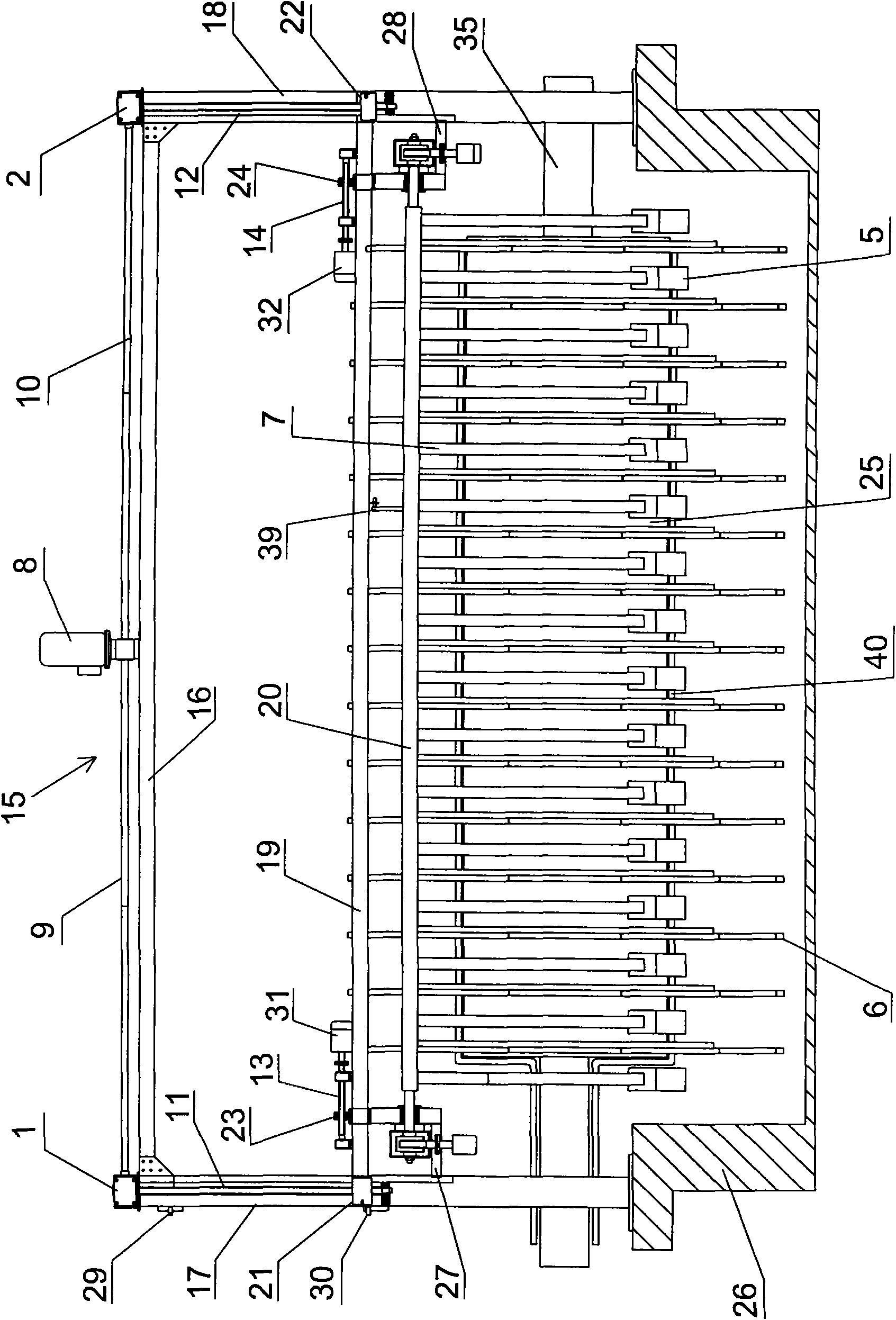

Wafer cleaning machine

ActiveCN103990614AReduce labor costsIncrease production capacityCleaning using liquidsManipulatorEngineering

The invention discloses a wafer cleaning machine which comprises a rack (4). A feeding workbench (6), a cleaning tank (7) and a discharging workbench (8) are arranged on the lower portion of the rack (4) from right to left in sequence, an ultrasonic vibrating plate (17) is arranged at the bottom of the cleaning tank (7), a rotary cleaning device (5) is arranged in the cleaning tank (7), a single-arm multi-hook mechanical arm (3), a gear motor B (10) driving the single-arm multi-hook mechanical arm (3) to horizontally move and a gear motor C (2) driving the single-arm multi-hook mechanical arm (3) to vertically move are arranged on the upper portion of the rack (4), a plurality of hooks (9) are arranged on an arm body of the single-arm multi-hook mechanical arm (3) and are used for lifting the rotary cleaning device (5), and a controller (1) is further arranged on the rack (4). The wafer cleaning machine has the advantages of being high in automation degree, high in product yield, high in product quality and low in manpower cost.

Owner:CHENGDU TIMEMAKER CRYSTAL TECH

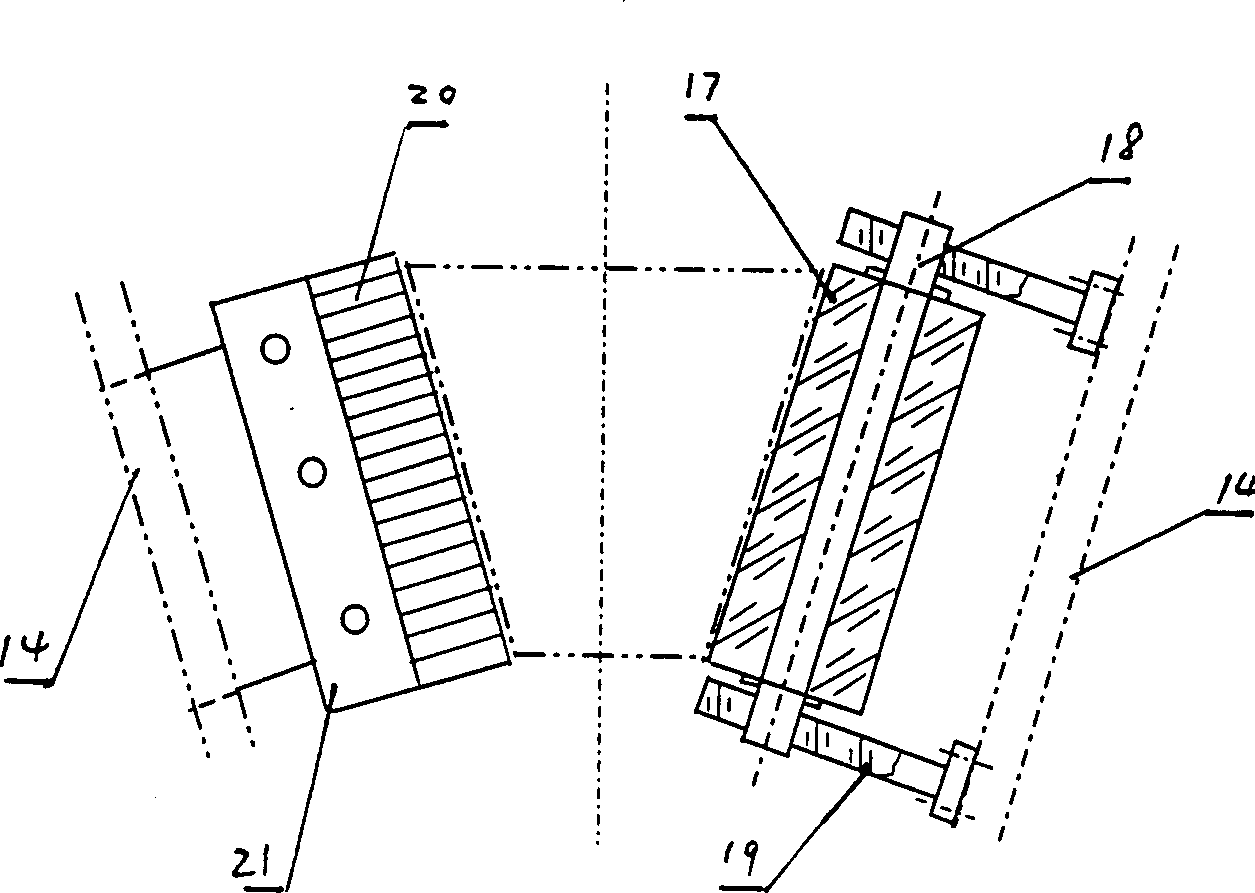

Multifunctional ceramic filterer ultrasonic washing system

ActiveCN101524607AWash evenlyPromote repairMoving filtering element filtersContinuous scanningUltrasonic sensor

The invention relates to a multifunctional ceramic filterer ultrasonic washing system, which comprise a plurality of vibrator boxes. Each vibrator box is provided with an ultrasonic transducer therein; the vibrator boxes are correspondingly arranged in clearances between filtering disks of a ceramic filterer; a stern bracket is connected to the upward side of each vibrator box and each stern bracket is connected with a swinging mechanism. The swinging mechanisms are connected with a shifting mechanism and the shifting mechanism is connected with a synchronous elevating mechanism. Inclinations, intervals and heights of the ultrasonic vibrator boxes of the system are adjustable, so that washing can be carried out in continuous scanning way, so as to eliminate ultrasonic washing blind area. The multifunctional ceramic filterer ultrasonic washing system has high washing efficiency, low energy consumption, convenient maintenance and replacement, and prolonged service life of vibrator box.

Owner:北京东方康明科技开发有限公司

Preliminary cleaning device for textile

ActiveCN108589118AEasy to cleanImprove efficiencyLiquid/gas/vapor fabric treatmentEngineeringWater circulation

The invention relates to the field of textile processing, in particular to a preliminary cleaning device for textile. The preliminary cleaning device comprises a rack, a motor arranged on the rack, adriving belt pulley driven by the motor, a driven belt pulley driven by the driving belt pulley and a cleaning mechanism connected with the driven belt pulley, wherein the cleaning mechanism comprisesa cleaning box arranged on the rack, a hollow rotating shaft fixedly connected to an axle of the driven belt pulley and vertically penetrating through the cleaning box, a piston glidingly connected to the lower end of the hollow rotating shaft, a cylindrical cam connected to the lower end of the piston rod of the piston, a slider arranged on the rack and sliding in a sliding chute of the cylindrical cam as well as an inflation air bag connected to the bottom of the cleaning box by surrounding the periphery of the hollow rotating shaft. According to the scheme, preliminary cleaning of the textile is completed through water circulation and stirring of the textile in the cleaning box, the cleaning effect is good and the efficiency is high.

Owner:NINGBO WENZE TEXTILE CO LTD

Anti-fingerprint spray coating method and equipment

The invention relates to an anti-fingerprint spray coating method and equipment. The equipment comprises a case, a plasma cleaning linear module and a spray gun linear module, wherein the case is arranged on a material conveying mechanism, the case is provided with a feed inlet and a discharge outlet, and the plasma cleaning linear module and the spray gun linear module are arranged in the case; the plasma cleaning linear module comprises a first guide rail arranged above the conveying trajectory of the material conveying mechanism, a first sliding block, a first motor and a plasma cleaning head connected with a plasma controller, wherein the plasma cleaning head is connected with the first sliding block; the spray gun linear module comprises a second guide rail arranged above the conveying trajectory, a second sliding block, a second motor and a coating feed device connected with a spray coating liquid storage device through a connecting pipe, wherein the coating feed device is provided with a spray gun head and the is connected with the second sliding block. The anti-fingerprint spray coating method and equipment have the advantages that the structure is simple, the production cost is low, the production efficiency is high, the cleaning is thorough, the quality of the produced product is high, the spray coating is uniform, the method and equipment can be widely popularized and the like.

Owner:SHENZHEN SHUNANHENG TECH DEV

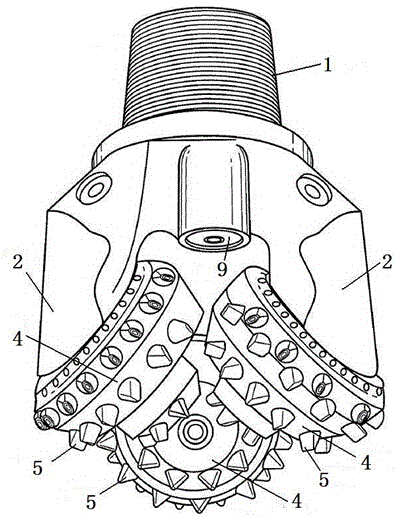

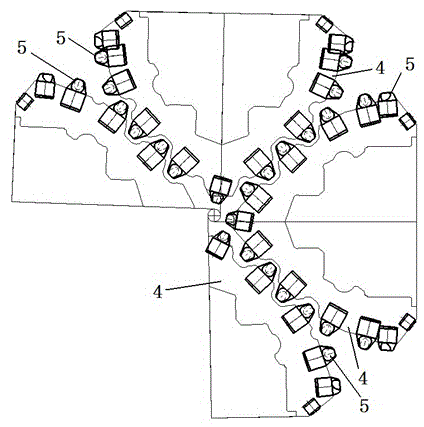

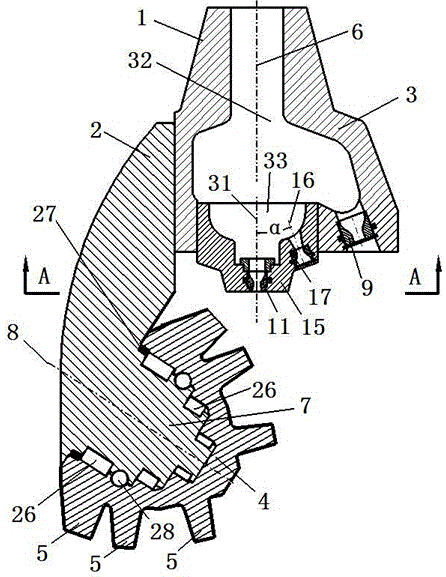

Multi-jetflow bodied tricone bit

The invention relates to a multi-jetflow bodied tricone bit. The multi-jetflow bodied tricone bit comprises a drill bit body, three cone palms and three cones. A drill bit handle is arranged at the top of the drill bit body, the middle of the drill bit body is provided with an inner flow passage, three side nozzles are peripherally arranged on the lower portion of the drill bit body and communicated with the inner flow passage, and lower portions of the cone palms are provided with journals with the cones. The multi-jetflow bodied tricone bit is characterized in that a central nozzle seat is arranged at the lower end of the middle of the drill bit body, a central nozzle is mounted in the middle of the lower end of the central nozzle seat, three middle nozzles are arranged at the lower end of the central nozzle seat surrounding the outer periphery of the central nozzle, and the central nozzle and the middle nozzles are communicated with the inner flow passage through a cavity. The multi-jetflow bodied tricone bit has the advantages that drilling fluid can be jetted to a mesh gap between each two adjacent cones, so that turbulence velocity and crossflow velocity of the drilling fluid at the bottom of a well can be increased to enable rock debris to be quickly taken away from the bottom of the well; the cones can be cleaned more uniformly to effectively avoid bit balling of the tricone bit, and accordingly increase of mechanical drilling rate of the bit and reduction of drilling cost are realized.

Owner:SINOPEC OILFIELD EQUIP CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com