Large-breadth laser washing machine

A laser cleaning, large-format technology, applied in cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems of low cleaning efficiency, small cleaning width, and high adjustment requirements, and achieve reasonable structural design, low cleaning cost, and cleaning. large area effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

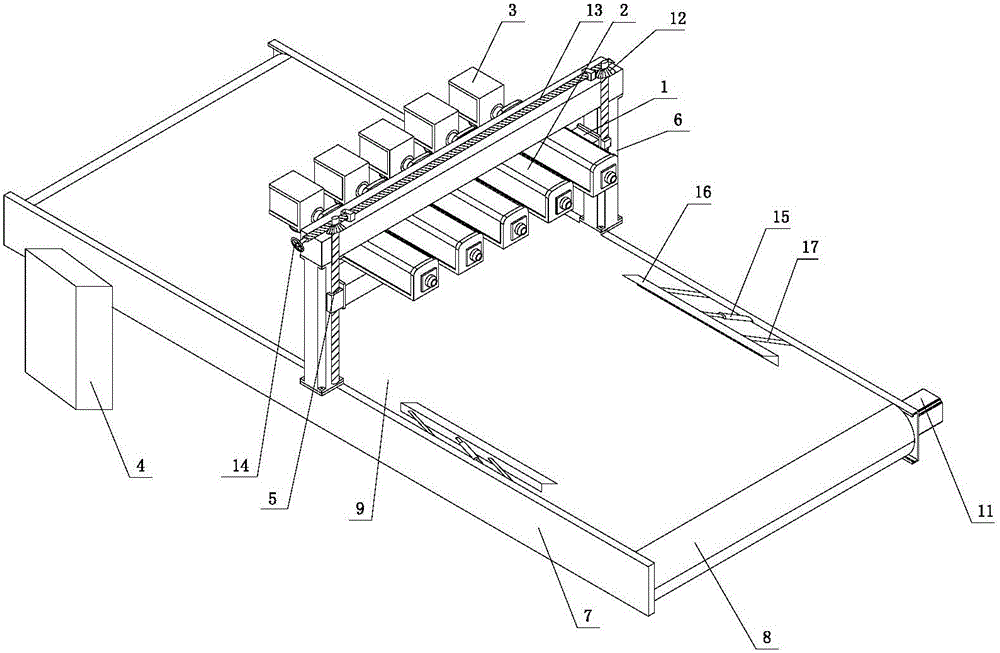

[0014] In order to clearly illustrate the technical features of this solution, the present invention will be described in detail below through specific implementation modes and in conjunction with the accompanying drawings.

[0015] Such as figure 1 As shown in , a large-format laser cleaning machine is characterized in that: it includes a workbench 1, and a conveyor belt 3 driven by a stepping motor 2 is arranged on the workbench 1 along the length direction of the workbench 1, and the bottom of a support frame is installed On both sides of the workbench 1, a lifting mechanism is provided on the support frame. The two ends of a lifting beam 4 arranged along the width direction of the workbench 1 are respectively connected with the lifting mechanism. 1. A laser cleaner arranged in parallel in the longitudinal direction. The laser cleaner includes a fiber laser 5. The output end of the fiber laser 5 is connected to a scanning vibrating mirror 6. The output end of the scanning v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com