Patents

Literature

68results about How to "No thermal effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method and device for cutting transparent material by using ultra-short pulse laser

ActiveCN102785031AAccelerateSmall kerfFine working devicesGlass severing apparatusMaterial consumptionTransfer procedure

The invention provides a method for cutting a transparent material by using ultra-short pulse laser. The ultra-short pulse laser output by an ultra-short pulse laser generating device is condensed by a condensation device so as to form a bunching laser beam; the bunching laser beam enters from the surface of the transparent material to be machined, so that the center refractive index at a laser application point is increased to form a waveguide structure along a laser emitting direction; the laser is transmitted to the inside of the transparent material along the waveguide structure, and continuously generates a waveguide structure along the laser emitting direction in a transmission process until the entire waveguide structure and the laser penetrate through the transparent material; and therefore, the laser moves in a direction which is vertical to the surface of the transparent material at uniform speed, so that a waveguide plane is formed in the transparent material. The invention further provides a device for cutting the transparent material by using the ultra-short pulse laser. The method and the device for cutting the transparent material by using the ultra-short pulse laser provided by the invention have the advantages of fast cutting speed, small cutting seam, no material consumption and no powder pollution. When the machined material bears a suitable external force, the material is cracked only along a stress fault surface; the broken surface nearly has no conical degree; and the roughness is good.

Owner:WUHAN JUNNO TECH

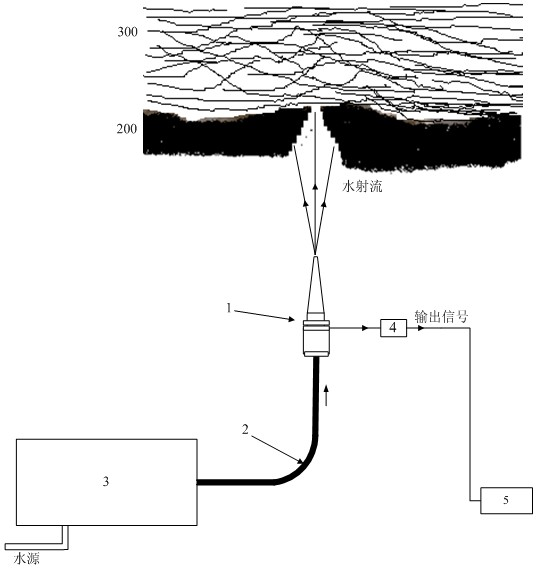

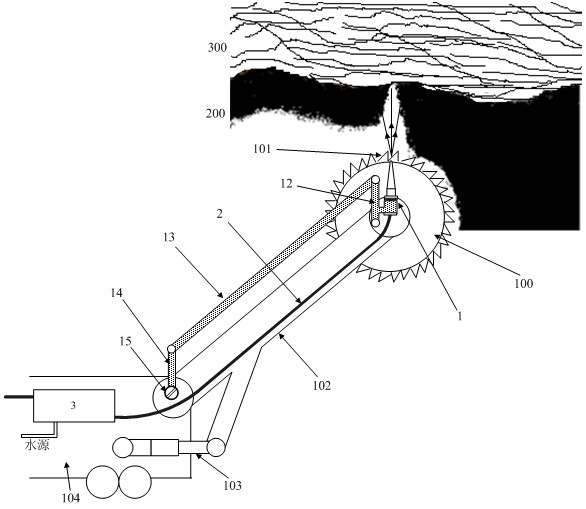

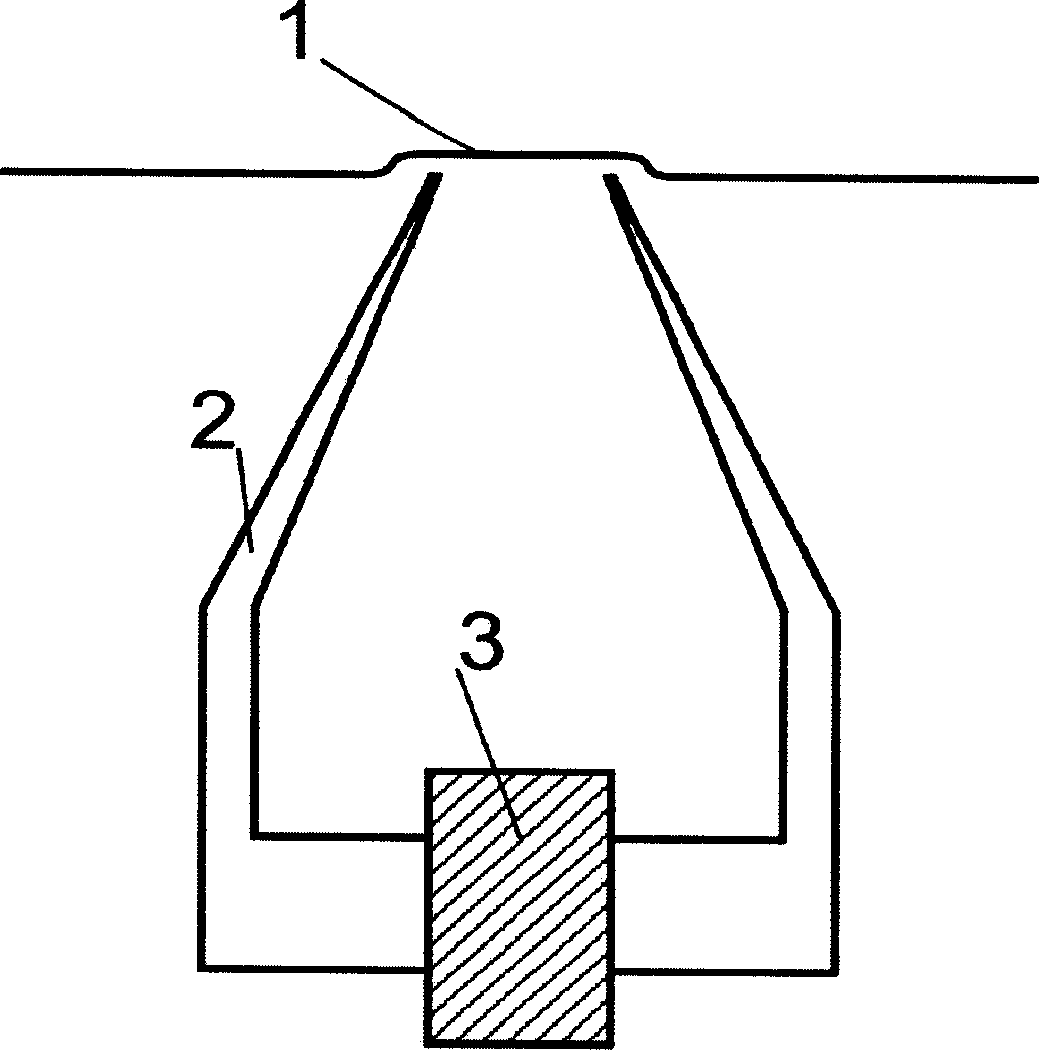

Coal-rock interface identification method, identification system and identification probe

ActiveCN101922290APromote recoveryImprove securityTesting machinesSlitting machinesMining engineeringHigh pressure water

In an underground exploitation process of a coal mine, the coal recovery rate needs improving, and a roller bit of a coal mining machine is prevented from cutting roof strata as far as possible so as not to damage equipment or even cause accidents, so an interface of a coal layer and a rock layer needs on-line identification. The invention provides a coal-rock interface identification method, a coal-rock interface identification system and a coal-rock interface identification probe. A specific energy-level high-pressure water jet which can penetrate the coal layer but cannot penetrate the rock layer is jetted to the coal layer above a tunnel, different acting forces of reflected flow reflected by the coal layer or the rock layer on a nozzle are sensed in real time, and a controller judges the distance between the upper end of the roller bit of the coal mining machine and the coal-rock interface to realize automatic heightening control of a rocker arm of the coal mining machine so that the coal exploitation process realizes the goals of high recovery rate, low mechanical abrasion rate, automatic operation and the like. The coal-rock interface identification method, the coal-rock interface identification system and the coal-rock interface identification probe provided by the invention have the advantages of low cost, high adaptability, high reliability, intrinsic safety and the like.

Owner:ZHEJIANG UNIV

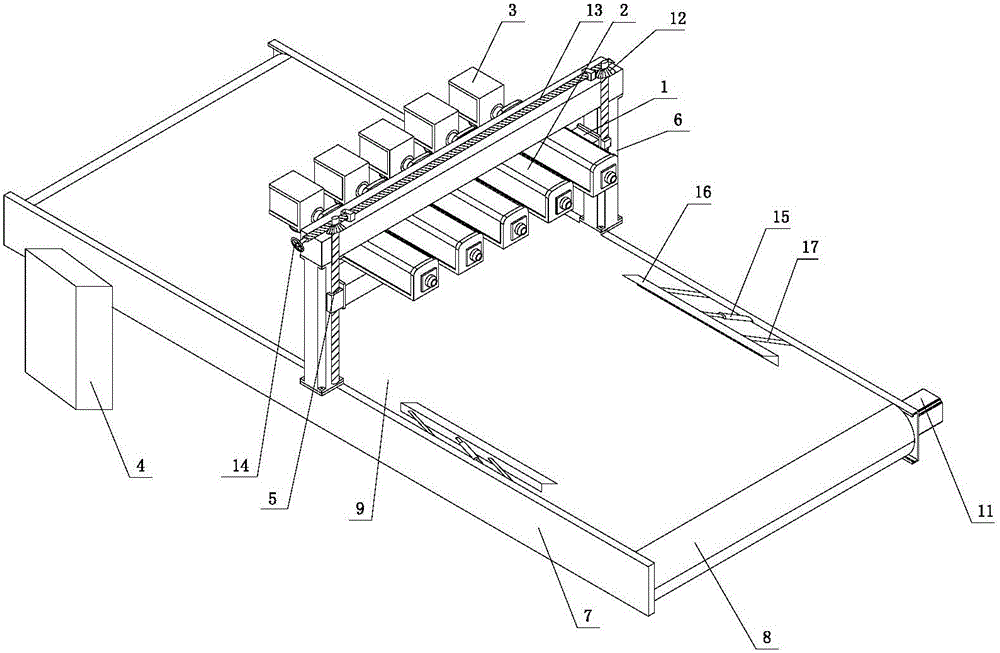

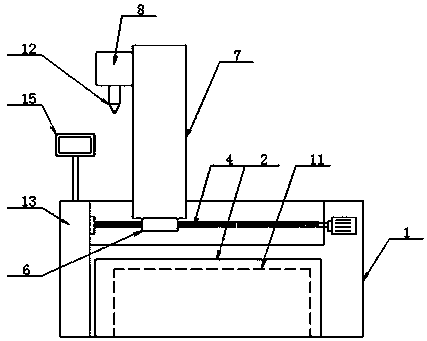

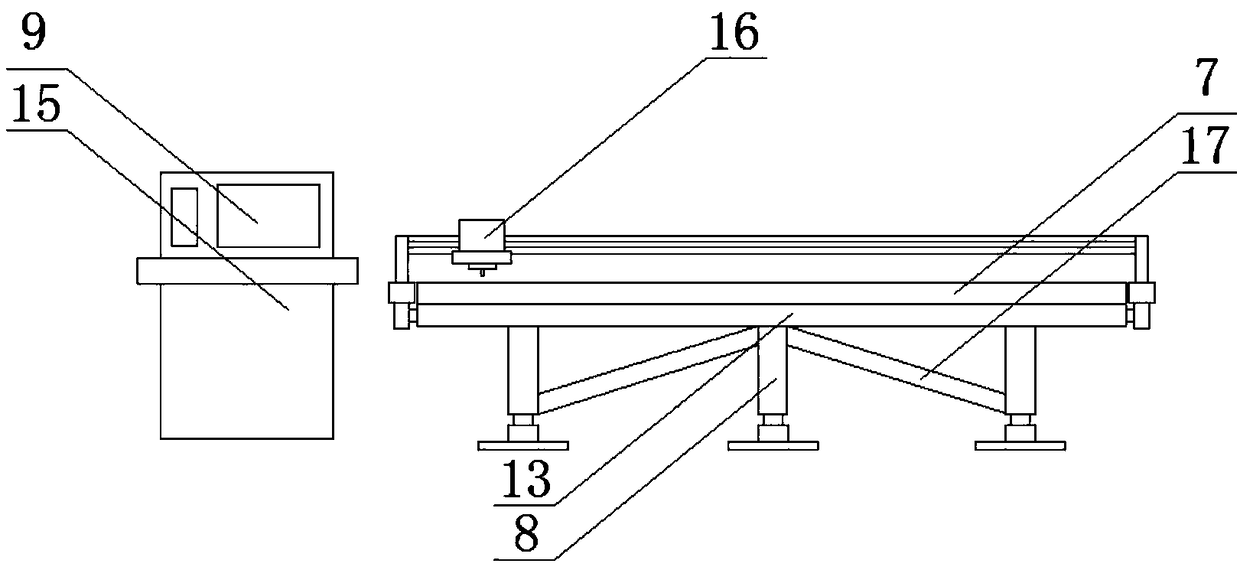

Large-breadth laser washing machine

InactiveCN105855245AHealth is not damagedNo pollution in the processCleaning processes and apparatusMetal sheetEngineering

The invention relates to a device for washing pollutants including rust spots, corrosion, oil stains and the like on surfaces of various types of metal sheet materials and particularly relates to a large-breadth laser washing machine. The large-breadth laser washing machine comprises a worktable, wherein a conveyor belt driven by a stepping motor is arranged on the worktable along the length direction of the worktable; the bottom of a supporting frame is mounted on the two sides of the worktable; a hoisting mechanism is arranged on the supporting frame; and the two ends of a hoisting transverse beam, which are arranged along the width direction of the worktable, are connected with the hoisting mechanism respectively. Therefore, the structure is reasonable and novel in design and has no grinding, non-contact and no heat effects in a washing process; in the washing process, no pollution to the environment is caused and body health of workers is not injured; a washing area is large, the efficiency is high and the washing cost is low; the distance between the device and a washing surface can be accurately controlled and the washing is uniform and has good effect.

Owner:济南高能清扬激光清洗有限公司

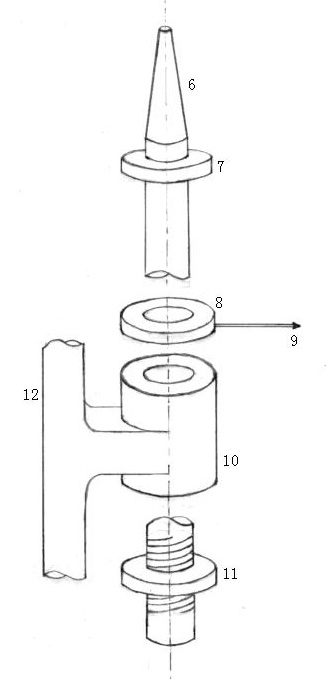

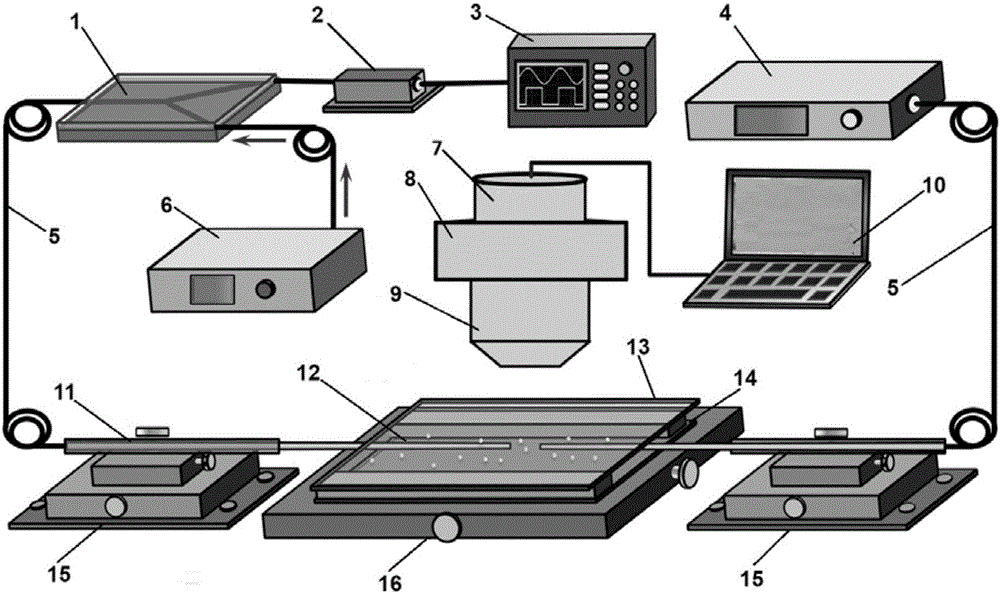

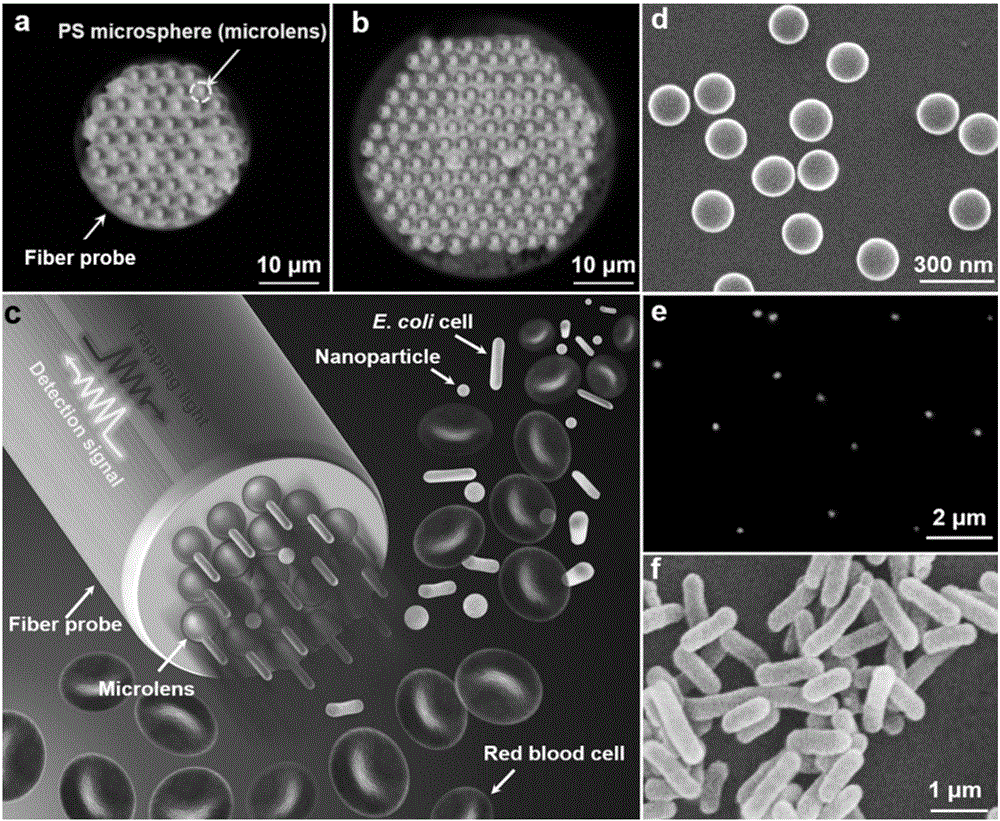

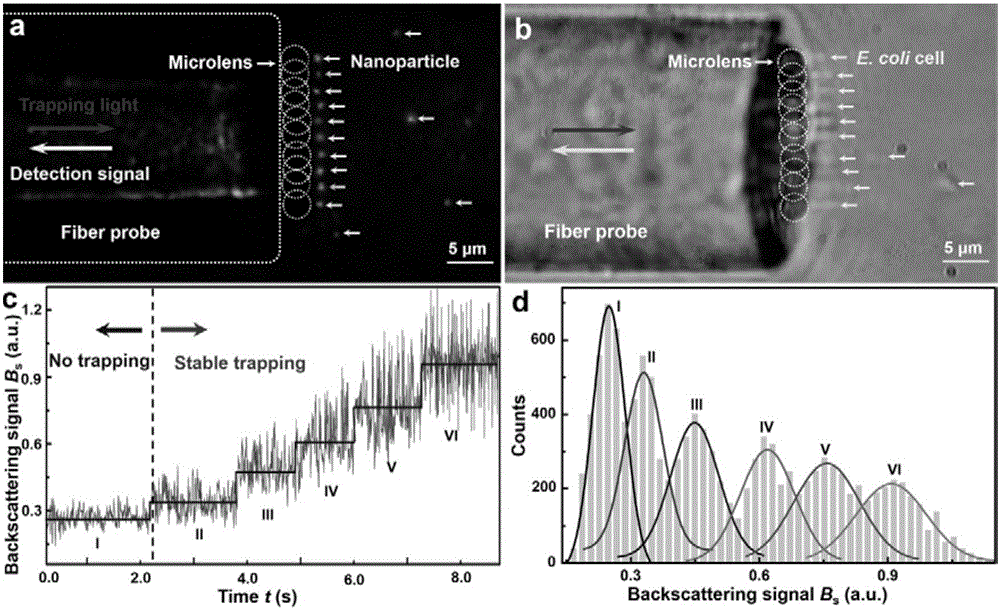

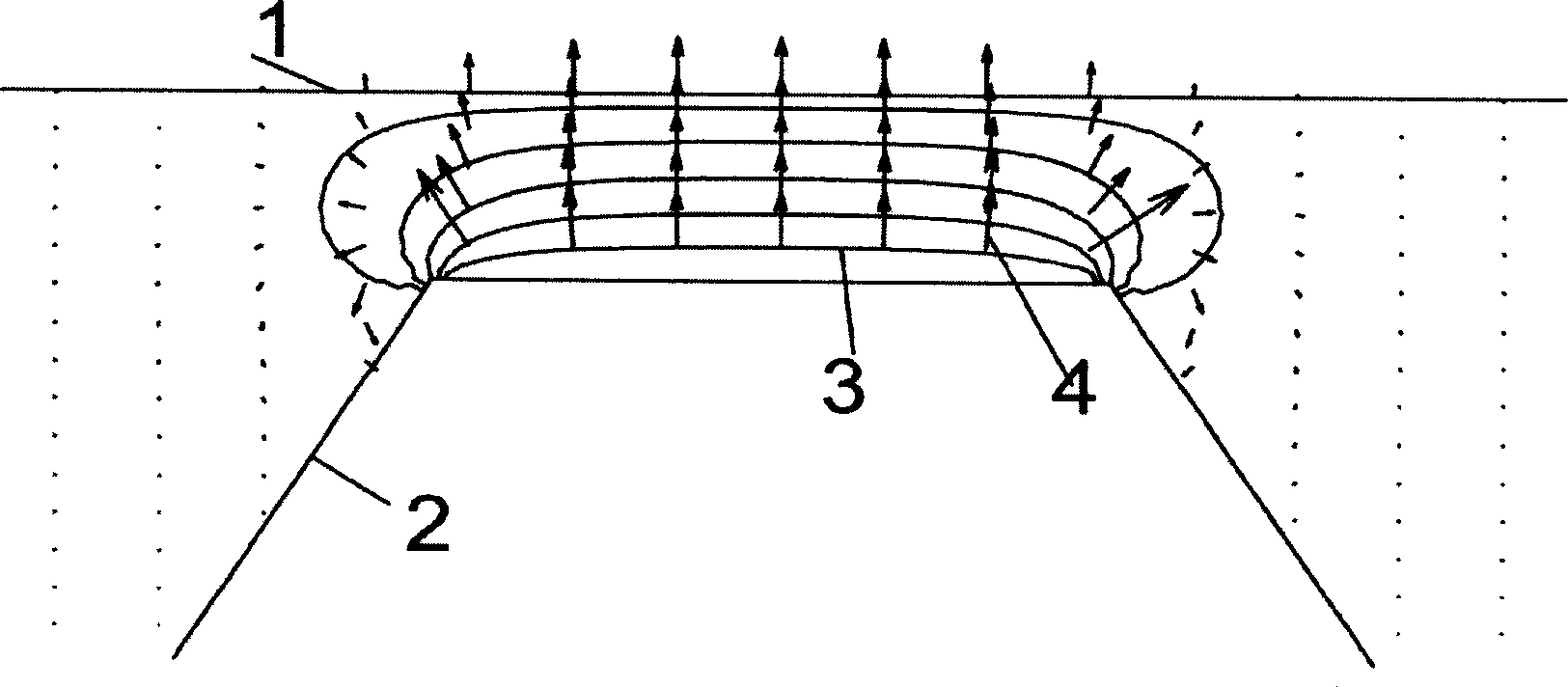

Optical capturing and detecting device and method based on quantum photon nano-jet array

InactiveCN106680985AHigh Efficiency Optical Capture and DetectionHigh precision optical capture and detectionMicroscopesIndividual particle analysisMicrofluidic channelCover glass

The invention discloses a device of optical capturing and detecting based on quantum photon Nano-jet array. The device comprises a microscope, a microfluidic channel is arranged on an microscopic objective table, the microfluidic channel consists of a cover glass and a glass slide, two optical fibers are placed inside the microfluidic channel, two optical fibers are respectively sleeved a glass capillary, the glass capillary is fixed on an adjustable light regulation frame, wherein end of one optical fiber is connected with a Y-tape optical fiber coupler,a photoelectric detector and a fiber laser, other end of the photoelectric detector is connected with an oscilloscope, other end of the other optical fiber is connected with a laser device. The invention further discloses a method of optical capturing and detecting based on quantum photon Nano-jet array, comprises the following steps: 1, preparing a mini-type optical fiber probe for capturing and detecting; 2, making a micro-lens array; 3, using the assemble micro-lens for capturing and detecting fluorescence Nano-particles; 4, using the assemble micro-lens for capturing and detecting colon bacillus.

Owner:JINAN UNIVERSITY

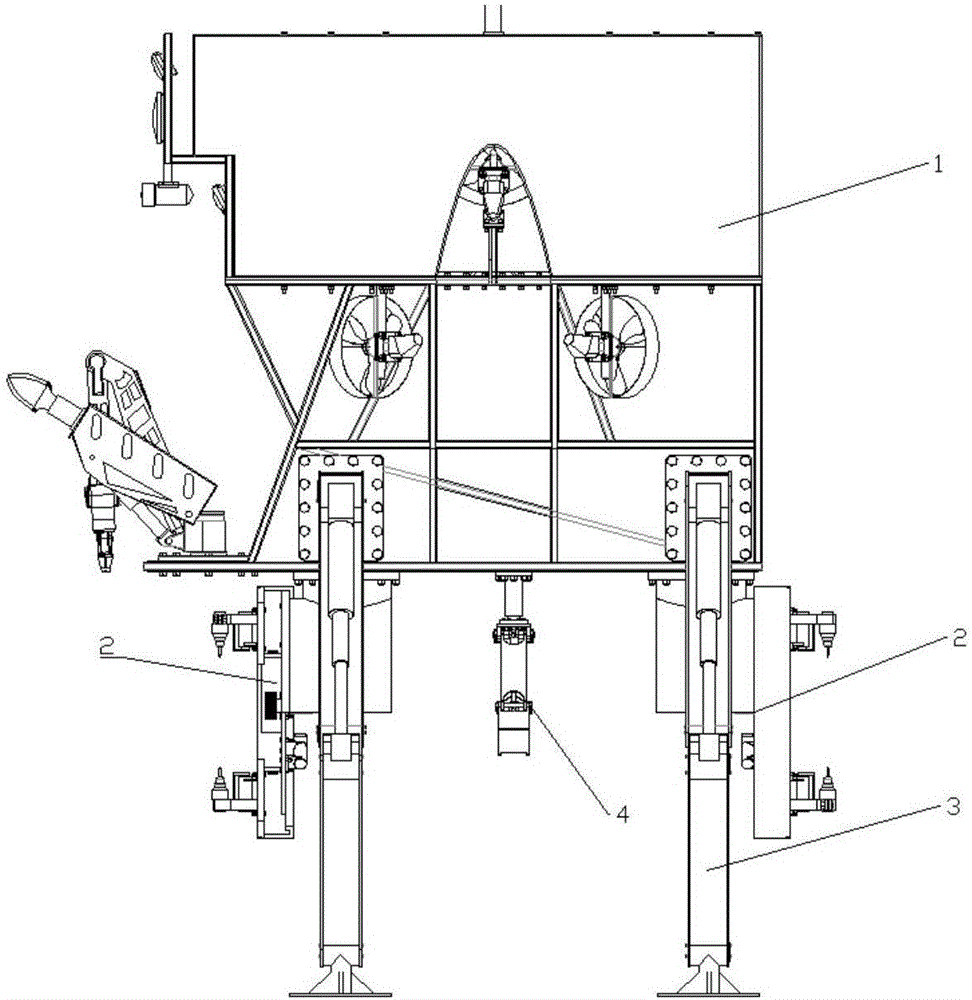

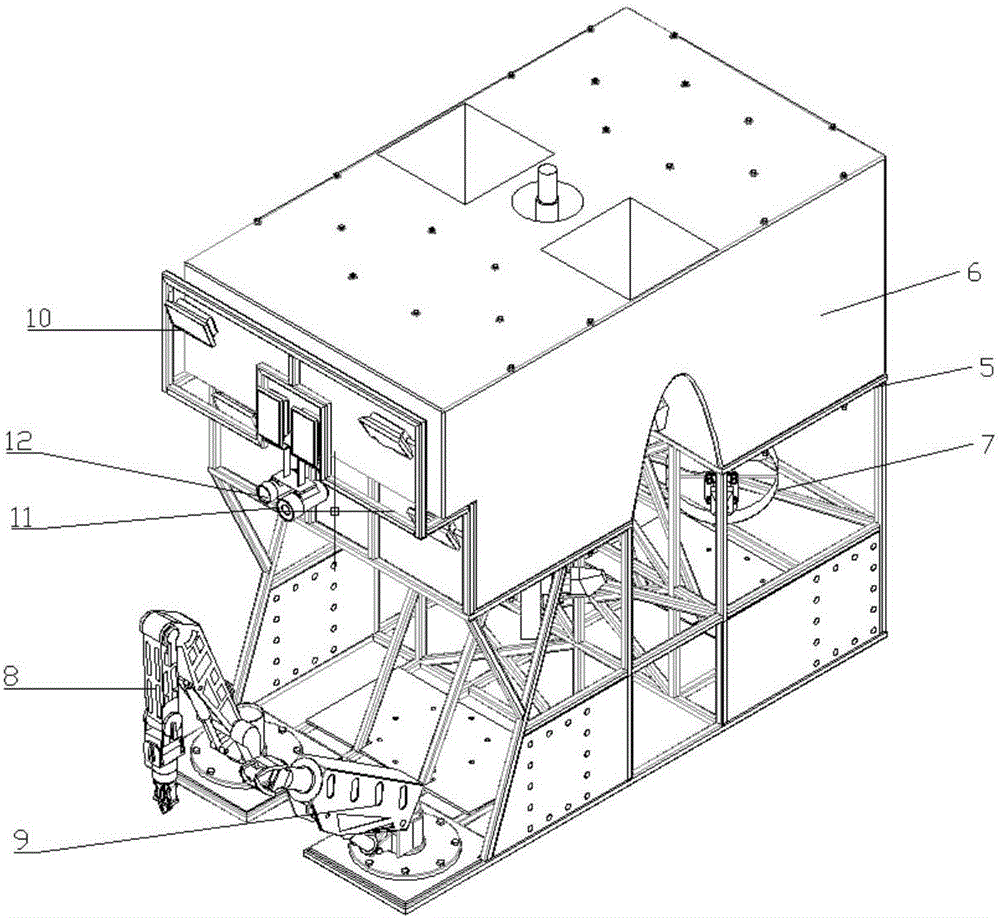

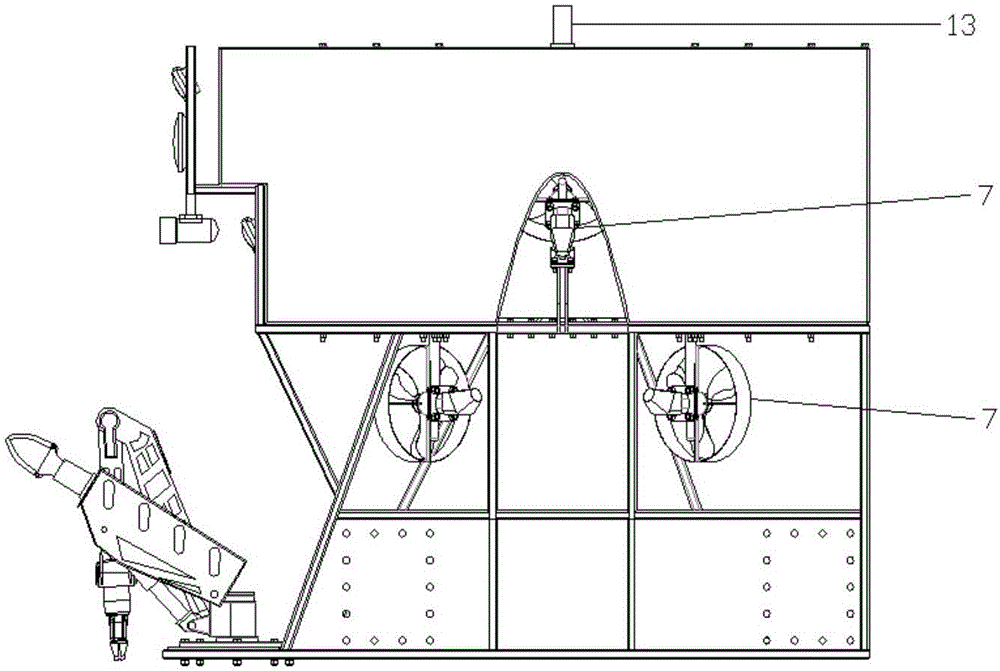

Underwater robot for submarine pipeline cutting

The invention discloses an underwater robot for submarine pipeline cutting. The underwater robot is mainly used for cutting submarine badly broken petroleum pipelines and comprises an ROV (remotely-operated vehicle) body, two cutting mechanisms, supporting legs and a small auxiliary manipulator, the ROV body comprises a frame, a buoyancy block, a propeller, a seven-degree-of-freedom manipulator, a five-degree-of-freedom manipulator, an underwater illumination device, a camera shooting device and a hydraulic electric control device, the supporting legs are uniformly distributed on two sides of the submarine pipeline cutting robot, a center line of the supporting legs is coincided with that of the cutting mechanisms, so that the ROV body is supported, the small auxiliary manipulator is connected below the submarine pipeline cutting robot through bolts and positioned in middle of the cutting mechanisms, the cutting mechanisms are fixed in the rearward front of the bottom of the submarine pipeline cutting robot through bolts, the cutting mechanisms and a pipeline are positioned by a positioning hydraulic cylinder, and the broken pipelines are cut by controlling rotation of a water cutter mechanism. The underwater robot can be automatically operated in deep water areas or special environments.

Owner:NORTHEAST GASOLINEEUM UNIV

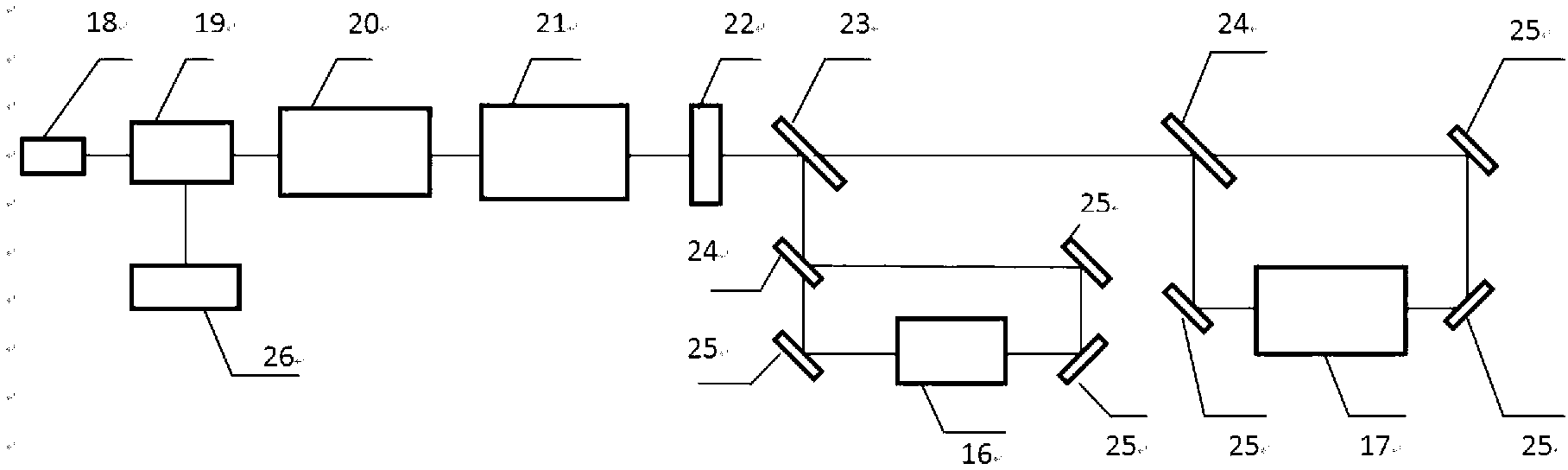

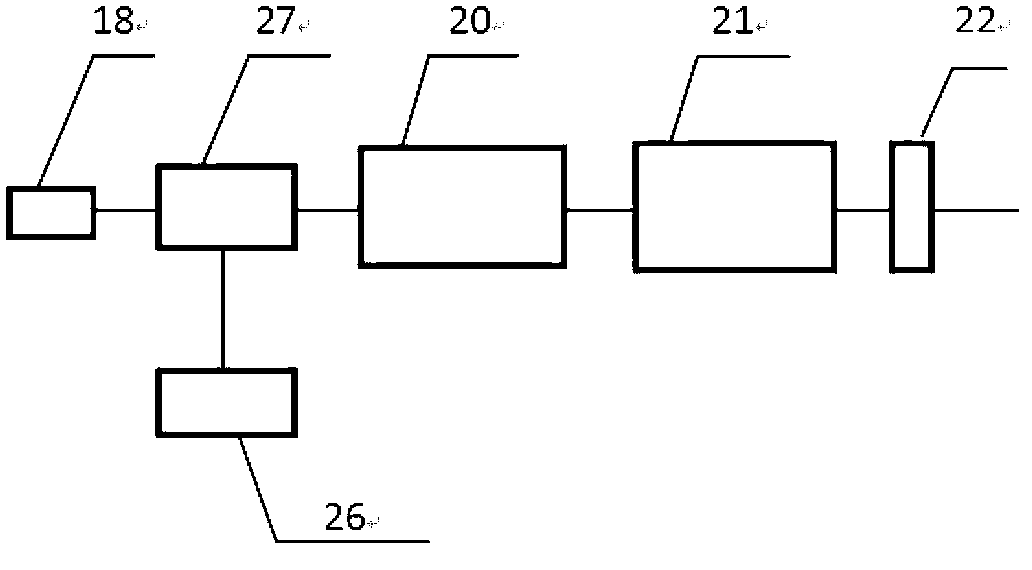

CPA and OPCPA mixed type ultra high power femtosecond laser system

InactiveCN103066484AImprove stabilityNo parasitic oscillationLaser detailsOptical modulatorMixed type

The invention provides a CPA and OPCPA mixed type ultra high power femtosecond laser system which comprises a Ti sapphire femtosecond locked mode impulse hunting device, a programmable acoustic optical modulator, a pulse broadening device, a CPA amplifer chain, an OPCPA terminal amplifier stage, an Nd:YAG pumping source, a CPA amplifier chain pumping source, an OPCPA terminal amplifier stage high-energy pumping source, a vacuum tube and a compressor, wherein pulse laser sequentially passes through the CPA amplifier chain and the OPCPA terminal amplifier stage by broadening of the pulse broadening device, and amplifier laser pulse is compressed by the compressor after transmitted by a vacuum tube image. The CPA and OPCPA mixed type ultra high power femtosecond laser system has the advantages of being high in stability, high in conversion efficiency, high in single-pass gain, free of heat effect, and free of parasitic oscillation, and achieving stable and high-efficiency IOPW stage high-power output, and even laser output of an ES (1018W) stage.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

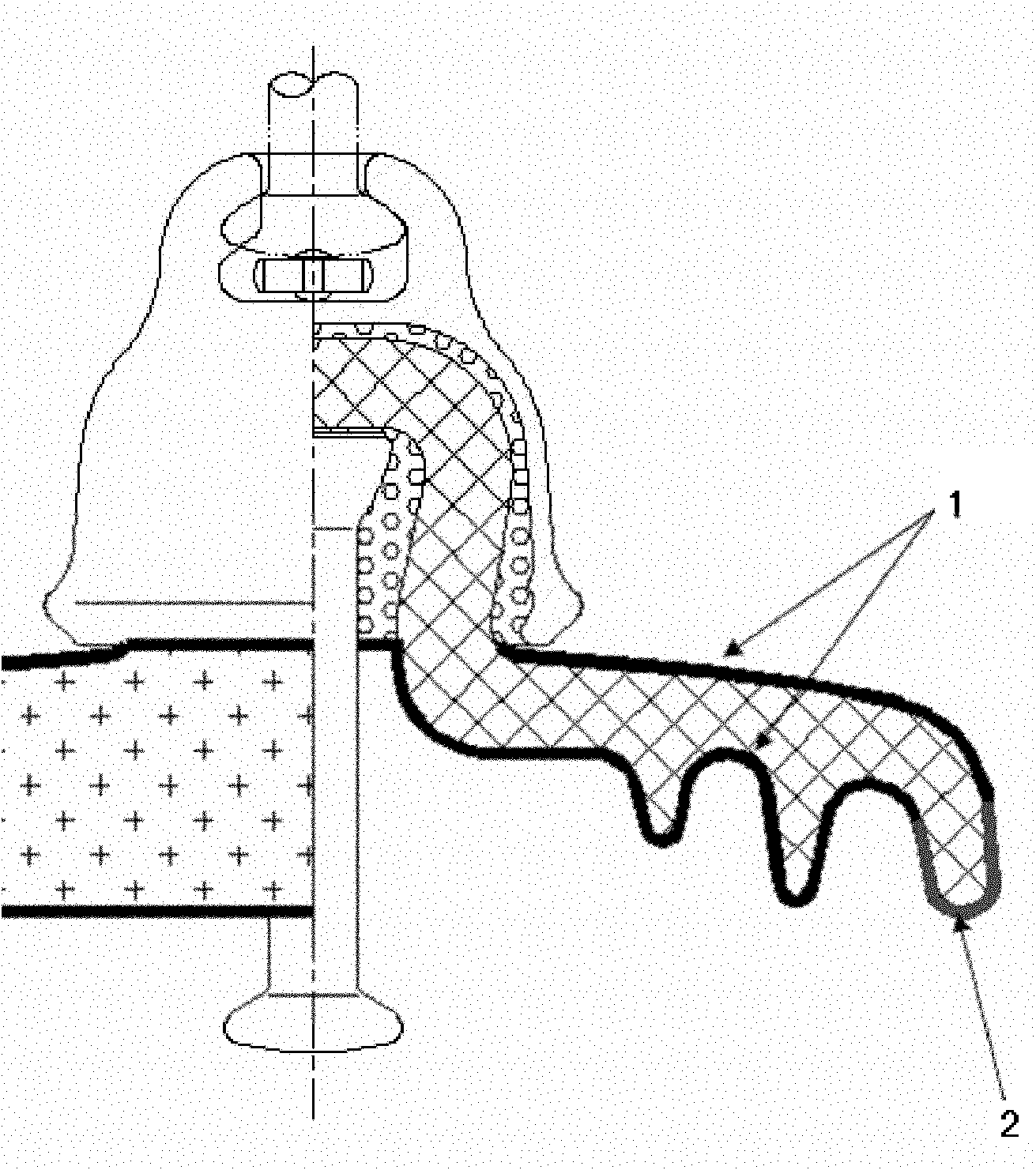

Anti-icing coating for insulator

InactiveCN102140310AHydrophobicIncrease pollution flashover voltageSuspension/strain insulatorsCoatingsMetallurgyHigh resistivity

The invention discloses an anti-icing coating for an insulator. The anti-icing coating consists of a high-resistivity coating and a low-resistivity coating. The high-resistivity coating consists of silicon rubber and carbon black, wherein the weight percentage content of the carbon black is lower than 1 percent; and the high-resistivity coating is coated at the outermost edge of the skirt of the insulator. The low-resistivity coating consists of silicon rubber and carbon black, wherein the weight percentage content of the carbon black is between 10 percent and 30 percent; and the low-resistivity coating is coated on the surface of the insulator except the outermost edge. Two coatings with high resistivity and low resistivity are prepared respectively by adding carbon black into the silicon rubber according to different proportions; the upper surface and the lower surface of the skirt of the insulator are coated with the low-resistivity coating; and the outermost edge of the skirt of the insulator is coated with the high-resistivity coating. By adopting the high-resistivity coating, ice is prevented from growing at the skirt edge by adopting the high-resistivity coating, the flashover voltage is prevented from being lowered by ice bridging, the working stability of the insulator is enhanced, and safe and reliable power transmission is ensured.

Owner:ELECTRIC POWER RES INST OF GUANGDONG POWER GRID +1

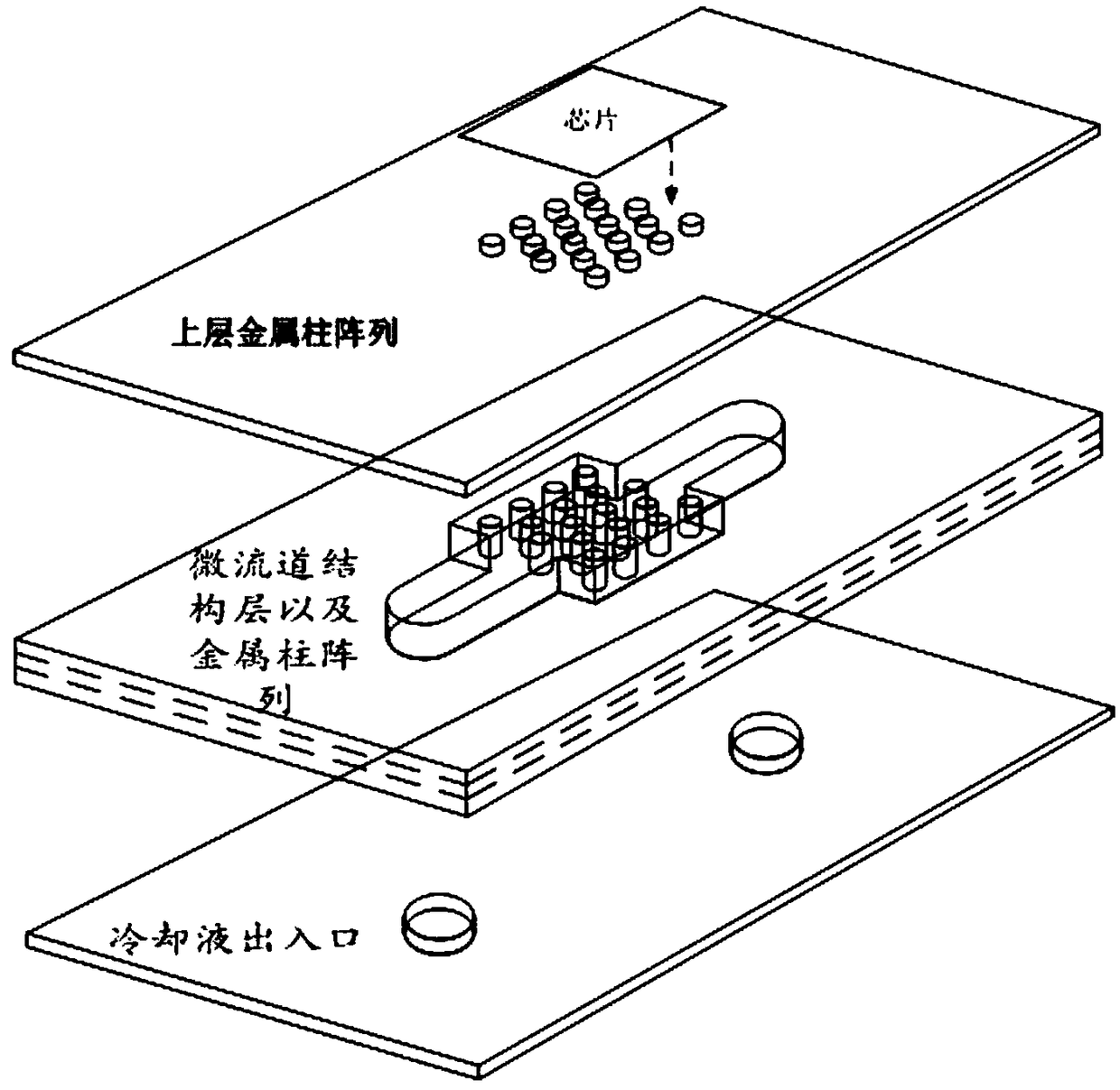

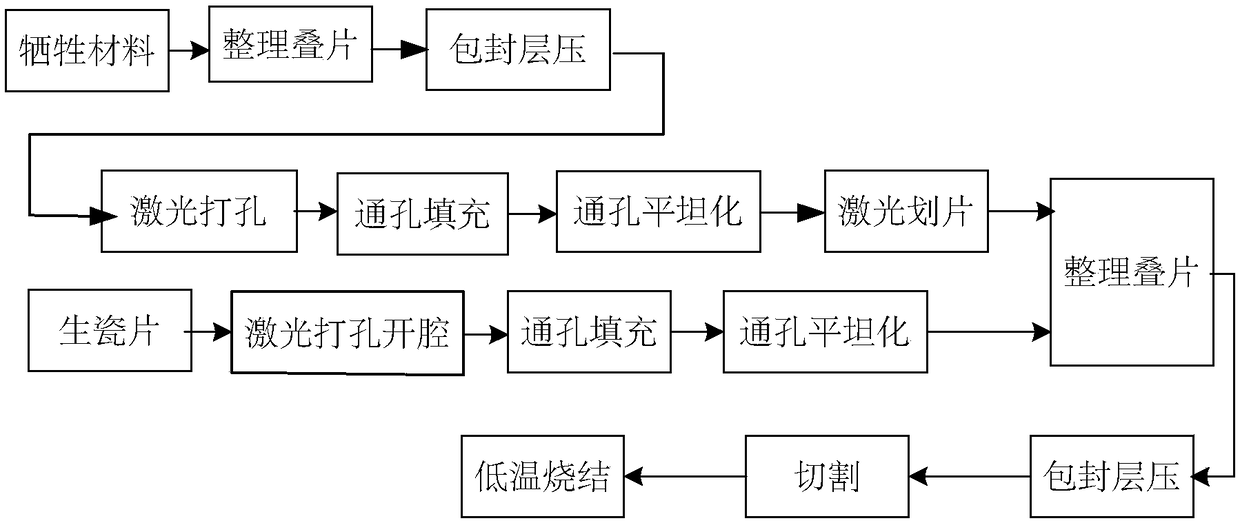

LTCC substrate with built-in microchannels and high heat dissipation performance as well as manufacturing method thereof

ActiveCN109449088AImprove cooling effectPrevent collapseSemiconductor/solid-state device detailsSolid-state devicesMetalGreen body

The invention provides an LTCC substrate with built-in microchannels and high heat dissipation performance as well as a manufacturing method thereof. The LTCC substrate comprises an upper layer part,a middle layer part and a lower layer part; the upper layer part is provided with a metal column array, the middle layer part is provided with a cavity formed by two microchannels and a hollow cavitywhich are communicated, the hollow cavity is internally provided with a metal column array, and metal columns of the upper layer part and metal columns of the middle layer part are in one-to-one correspondence; and the lower layer part is provided with a cooling liquid outlet / inlet hole. The manufacturing method comprises the following steps: preparing a carbon belt green body sample with a metalcolumn array and a pure carbon belt green body sample; preparing an upper layer green ceramic disc, a middle layer green ceramic disc and a lower layer green ceramic disc respectively corresponding tothe upper layer part, the middle layer part and the lower layer part; and laminating the carbon belt green body sample and the green ceramic discs in a corresponding manner, and sintering. The substrate provided by the invention is provided with the metal column arrays, the cavity and the microchannels, and the metal column array in an upper layer transfers heat produced by a chip to the metal column array in a middle layer; and the metal column array in the middle layer transfers heat to a heat dissipation medium inside the cavity by virtue of increased surface area, so that the heat dissipation performance of the substrate is improved.

Owner:XIAN MICROELECTRONICS TECH INST

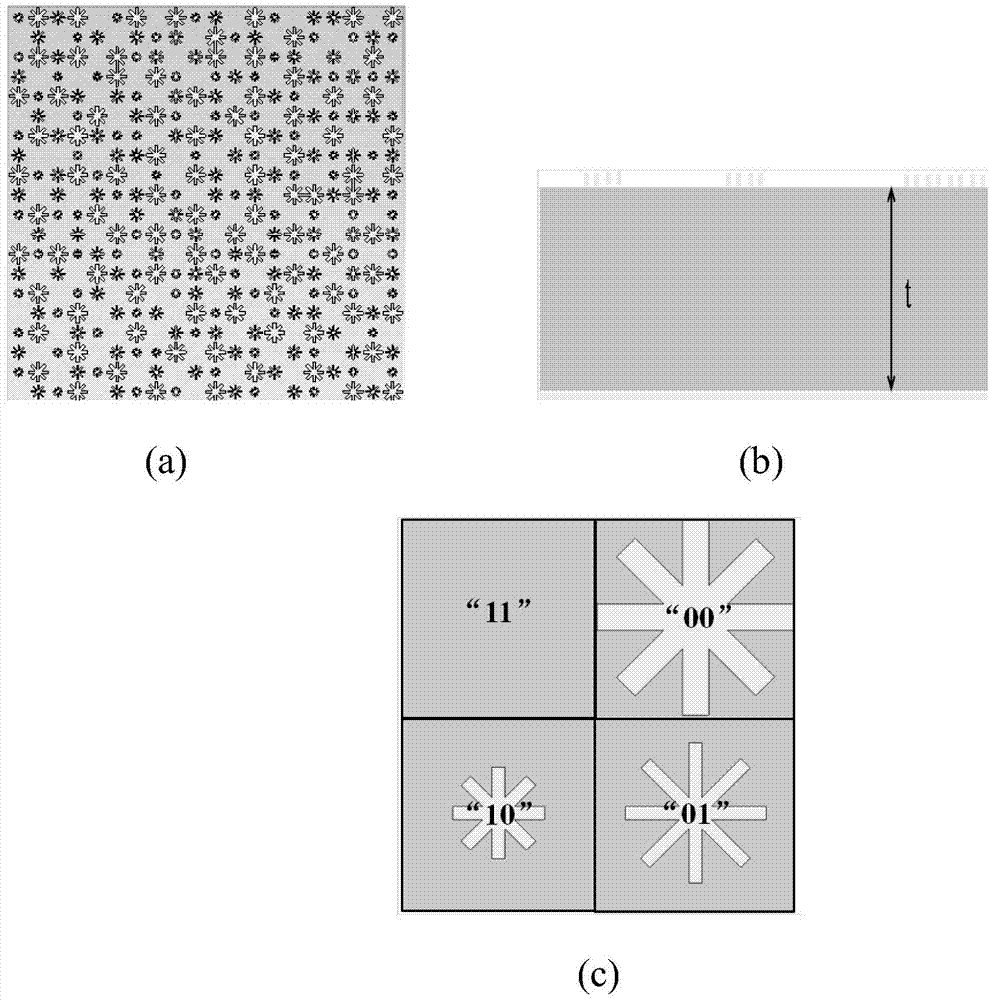

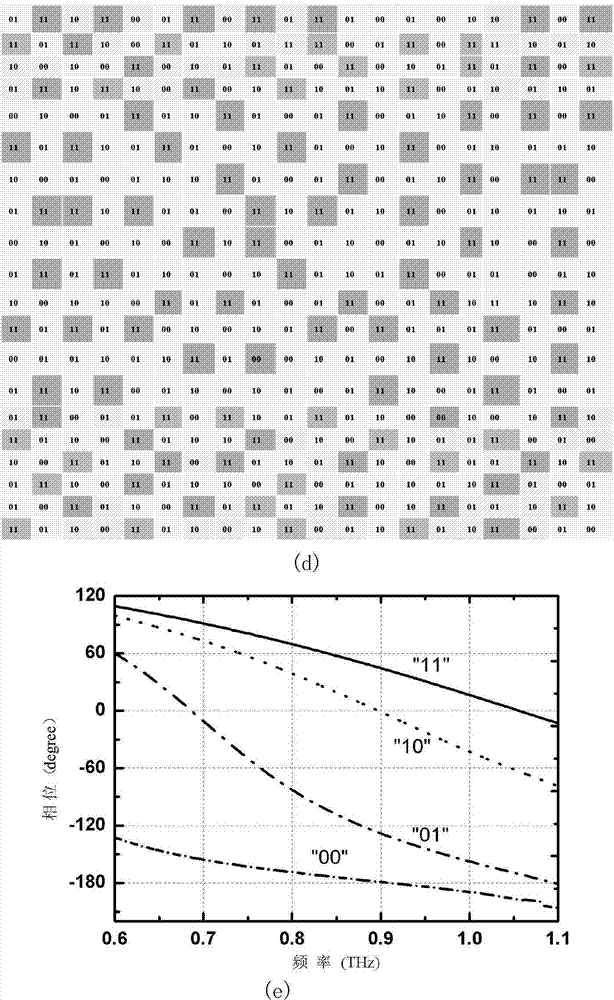

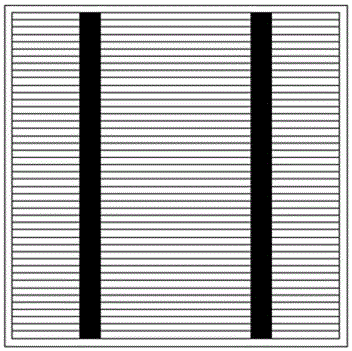

Terahertz code metasurface for wide-frequency-band radar scattering cross section reduction

The invention discloses a novel flexible terahertz 2bit code metasurface for wide-frequency-band radar scattering cross section reduction. The novel flexible terahertz 2bit code metasurface involves the following steps that electromagnetic field software is used for designing the structural shapes and parameters of four elements of '00', '01', '10' and '11' under optimization of the structural parameters, and the 2bit code metasurface achieving terahertz broadband nondirectional scattering, namely diffuse reflection, is optimized; on the basis of optimizing the 2bit code metasurface, a silicon wafer is coated with a polyimide film with a needed thickness; a needed code metasurface is prepared on the polyimide film through traditional micromachining technology, the silicon wafer is removed on the basis of the prepared 2bit code metasurface, and on the basis that the silicon wafer is removed, a gold film with a needed thickness is evaporated on the polyimide film on the other surface of a metal-free structure; terahertz broadband radar scattering cross section reduction is achieved, and simulation and experiment results show that the radar scattering cross section reduction can reach above 10 dBsm within the range from 0.66 THz to 1.26 THz.

Owner:ZAOZHUANG UNIV

Hericium erinaceus polysaccharide extraction and separation method

The invention discloses a hericium erinaceus polysaccharide extraction and separation method, which comprises the following steps: S1, obtaining hericium erinaceus powder; S2, freezing the hericium erinaceus powder with liquid nitrogen, unfreezing the hericium erinaceus powder with an unfreezing agent, and repeatedly freezing and thawing the hericium erinaceus powder for three times; S3, introducing inert gas until the pressure is 4000-5500kpa, and rapidly recovering to normal atmospheric pressure to obtain a hericium erinaceus cell suspension; S4, conducting centrifugal separation, and flocculating supernate through a flocculating agent, thus obtaining a hericium erinaceus polysaccharide extract. Hericium erinaceus polysaccharide is extracted evenly and thoroughly, the extraction speed ishigh, and the operation is easy and convenient. The structural integrity of polysaccharide is protected. The extraction rate is high, and pure physical extraction is achieved. The hericium erinaceuspolysaccharide extract is non-toxic, harmless and low in cost.

Owner:福州福德恩生物科技有限公司

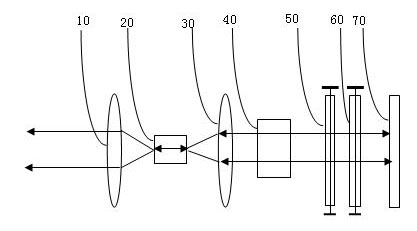

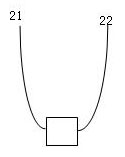

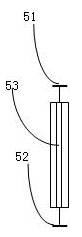

External cavity electro-optic tunable laser

ActiveCN102280809AGuaranteed normal outputImprove output stabilityLaser detailsEngineeringMechanical engineering

The invention provides an outer cavity type electrooptically tuned laser device, wherein an adopted electrooptically tuned filter adopts a liquid crystal Fabry-Perot cavity with very short cavity length and can ensure that only one mode of the fixed Fabry-Perot cavity of the filter is selected within one period interval, a broadband film is used for filtering periodic multiple waves generated by the fixed Fabry-Perot cavity and only reflecting wavelength of one peak to an optical resonant cavity, then one peak of a longitudinal mode of the optical resonant cavity can be adjusted to a main peak of the electrooptically tuned filter through an electrooptically tuned liquid crystal phase compensator, then single mold output of laser can be ensured, and the stability and reliability of the output of the laser can be improved.

Owner:瑞泰(威海)电子科技有限公司

Method and device for cutting transparent material by using ultra-short pulse laser

ActiveCN102785031BNo pollution in the processNo generationFine working devicesGlass severing apparatusTransfer procedureRefractive index

The invention provides a method for cutting a transparent material by using ultra-short pulse laser. The ultra-short pulse laser output by an ultra-short pulse laser generating device is condensed by a condensation device so as to form a bunching laser beam; the bunching laser beam enters from the surface of the transparent material to be machined, so that the center refractive index at a laser application point is increased to form a waveguide structure along a laser emitting direction; the laser is transmitted to the inside of the transparent material along the waveguide structure, and continuously generates a waveguide structure along the laser emitting direction in a transmission process until the entire waveguide structure and the laser penetrate through the transparent material; and therefore, the laser moves in a direction which is vertical to the surface of the transparent material at uniform speed, so that a waveguide plane is formed in the transparent material. The invention further provides a device for cutting the transparent material by using the ultra-short pulse laser. The method and the device for cutting the transparent material by using the ultra-short pulse laser provided by the invention have the advantages of fast cutting speed, small cutting seam, no material consumption and no powder pollution. When the machined material bears a suitable external force, the material is cracked only along a stress fault surface; the broken surface nearly has no conical degree; and the roughness is good.

Owner:WUHAN JUNNO TECH

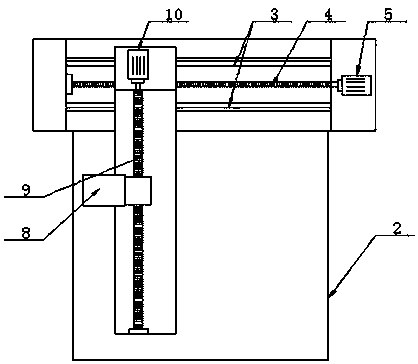

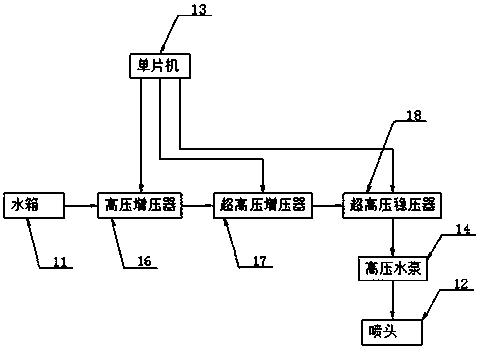

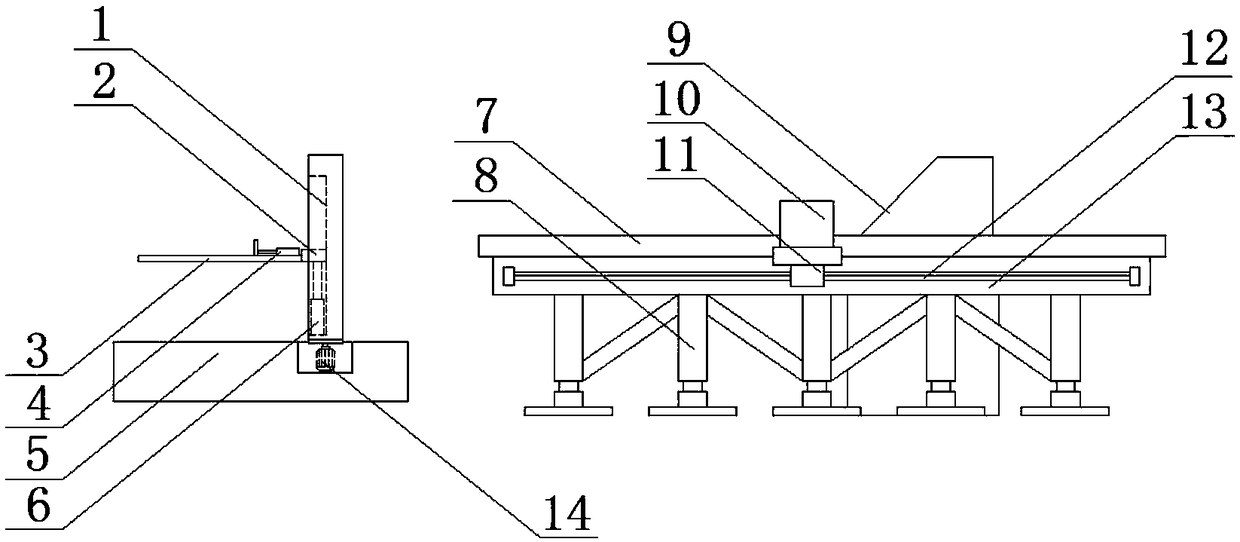

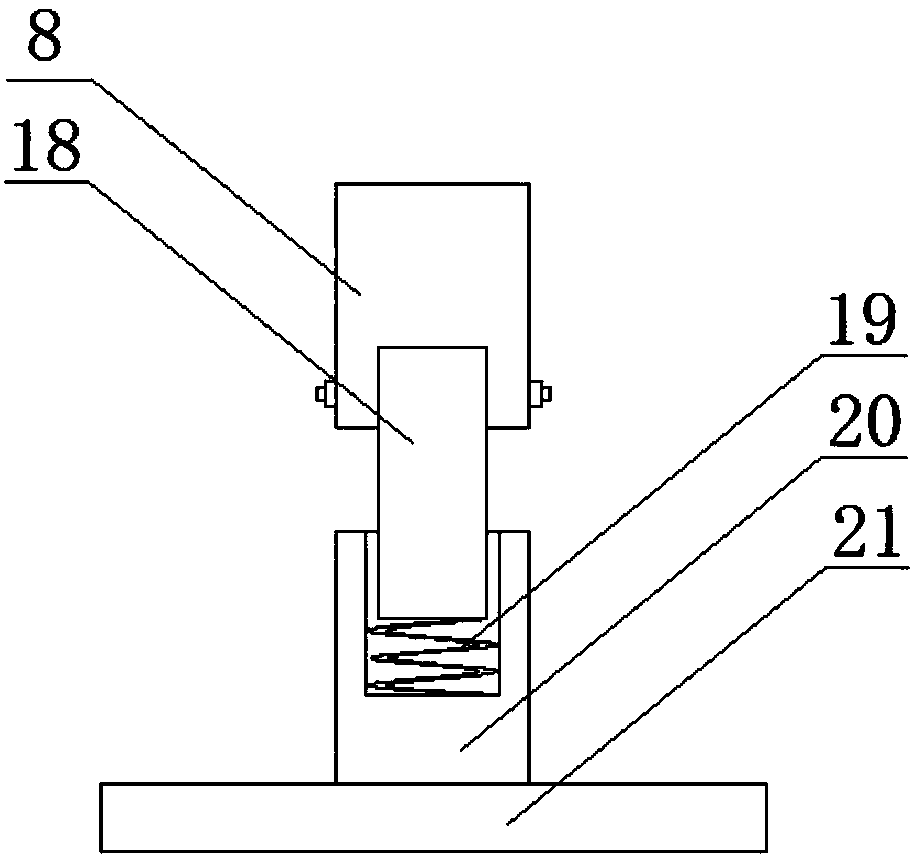

High-pressure water cutting machine

InactiveCN107756256ANo crackNo pollution in the processAbrasive machine appurtenancesAbrasive blasting machinesMicrocontrollerDrive motor

A high-pressure water cutting machine relates to the technical field of metal cutting equipment; one side of the frame is provided with a workbench, and a slide rail and a horizontal screw are arranged on the frame, and the horizontal movement motor is connected to the screw drive, and the screw is screwed with a Nut, the nut is connected with a moving frame, the moving frame is provided with a slide rail and a longitudinal screw rod, the longitudinal moving motor is driven and connected with the longitudinal screw rod, the longitudinal screw rod is connected with the longitudinal slider through the nut, and the lower end of the slider is fixed with a nozzle; The water tank is connected to the nozzle through a high-pressure water pump; the single-chip microcomputer is respectively connected to the horizontal movement motor, the longitudinal movement motor and the high-pressure water pump. The high-pressure water cutting machine of the present invention has no cracks, no burrs, and no dross on the cutting workpiece, and the incision is small and smooth, without thermal effects, work hardening and stress, and does not require secondary processing, which reduces processing time and improves production. Efficiency, no environmental pollution.

Owner:泰兴市金鳌机械制造有限公司

Preparation method of hericium erinaceus polysaccharide protein extract

ActiveCN110903408APreserve integrityNo thermal effectPeptide preparation methodsAlcoholPolysaccharide

The invention discloses a preparation method of a hericium erinaceus polysaccharide protein extract. The preparation method comprises the following steps: S1, obtaining hericium erinaceus powder; s2,performing ultrasonic wall breaking, and soaking in an extracting solution; s3, introducing an inert gas until the pressure is 4000-5500 kpa, and rapidly recovering to normal atmospheric pressure to obtain hericium erinaceus cell suspension; and s4, conducting centrifugal separation, and precipitating supernate through ethyl alcohol to obtain the hericium erinaceus polysaccharide protein extract;the hericium erinaceus polysaccharide protein is extracted evenly and thoroughly, the extraction speed is high, operation is easy and convenient, the structural integrity of the polysaccharide proteinis protected, the extraction rate is high, pure physical extraction is achieved, and the hericium erinaceus polysaccharide protein extract is non-toxic, harmless and low in cost.

Owner:福州福德恩生物科技有限公司

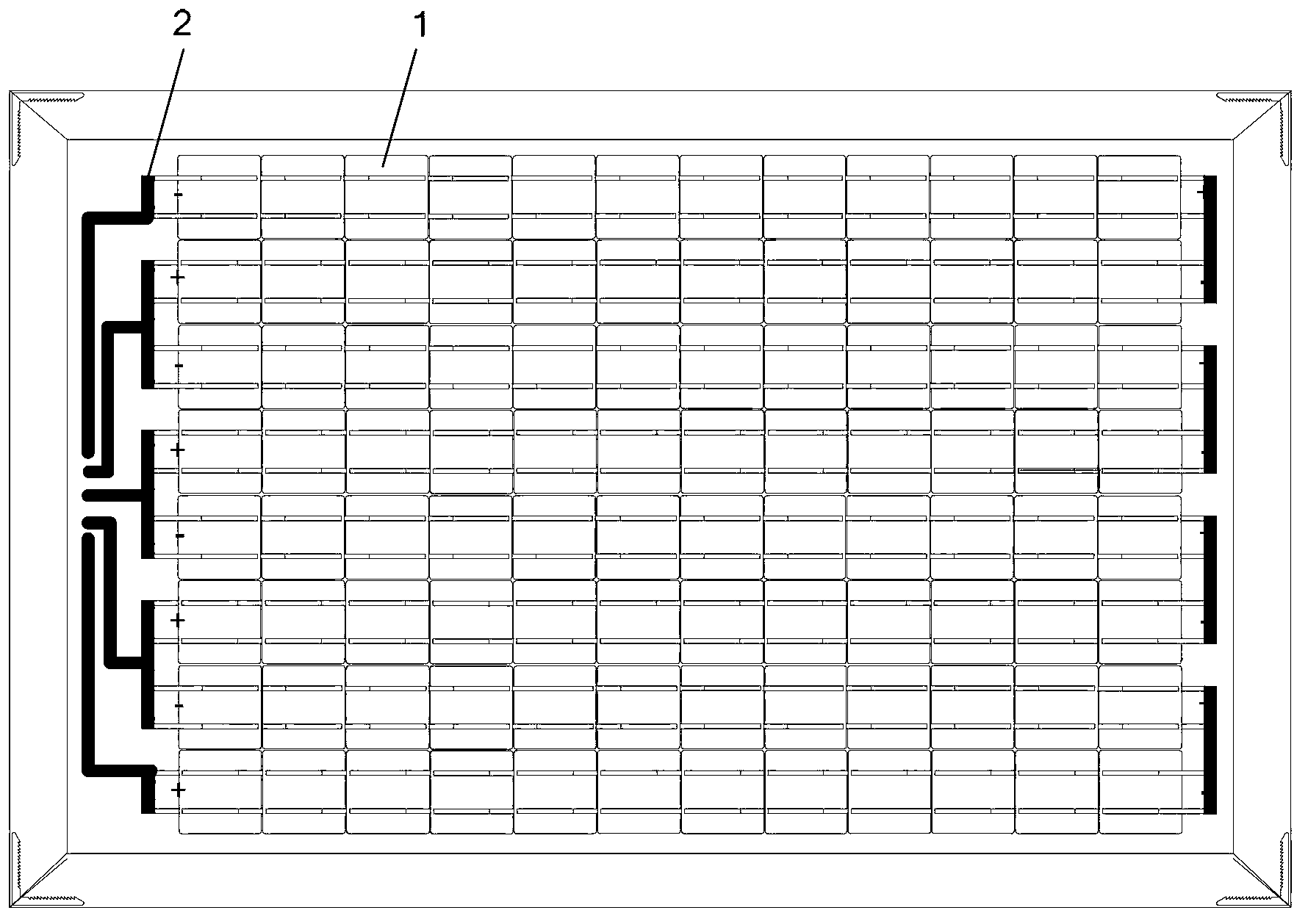

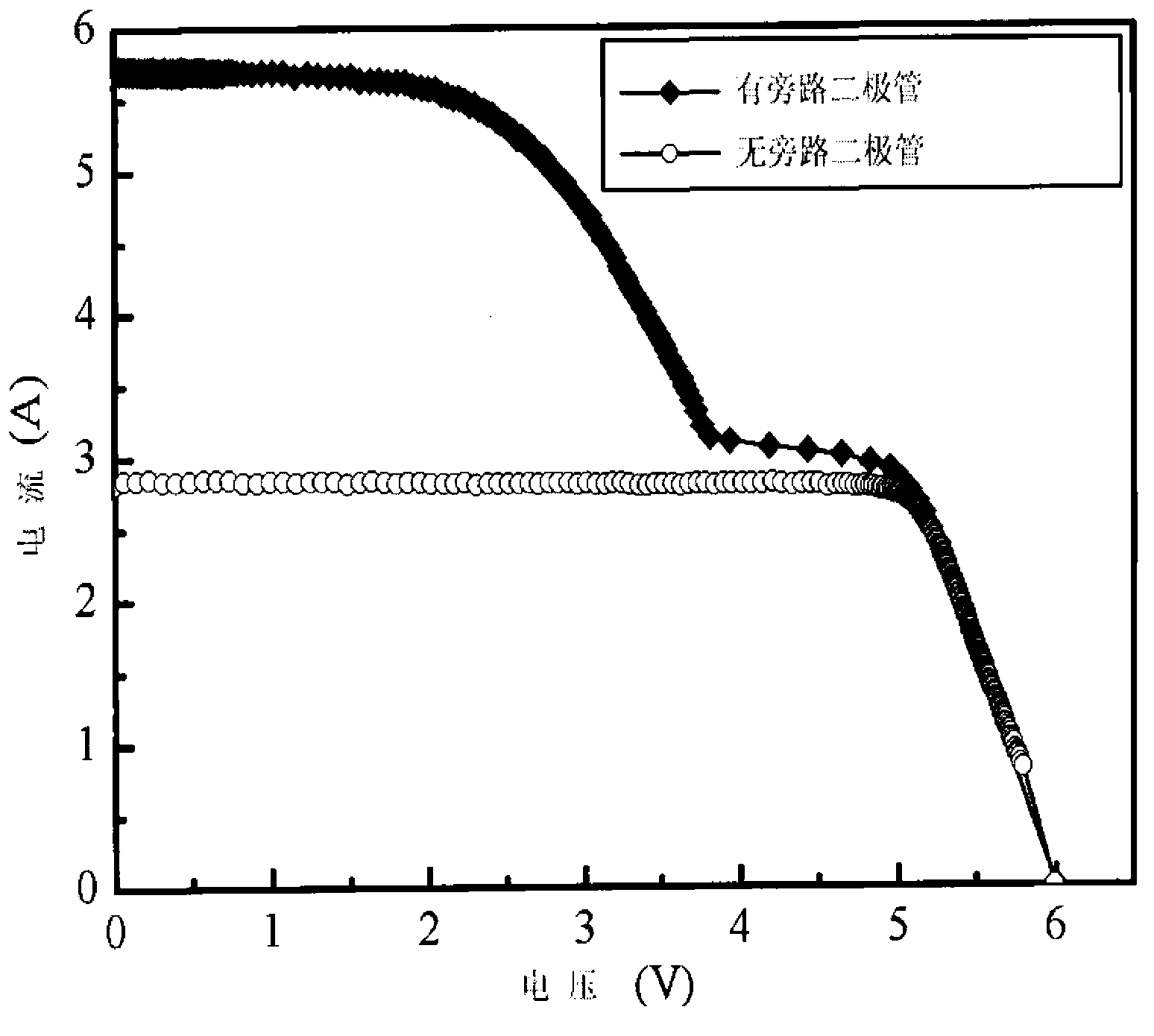

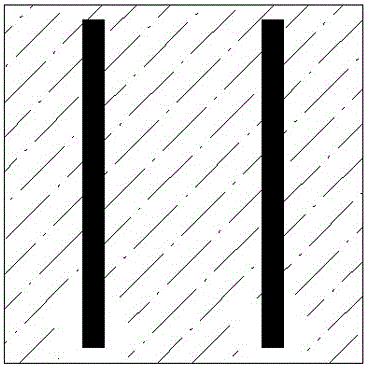

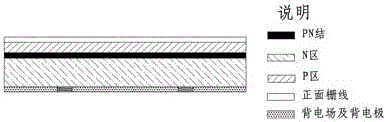

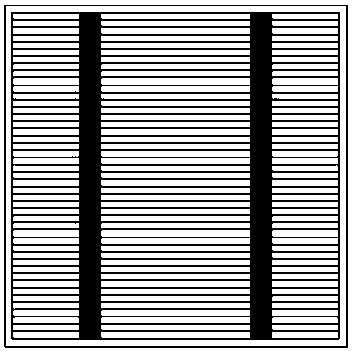

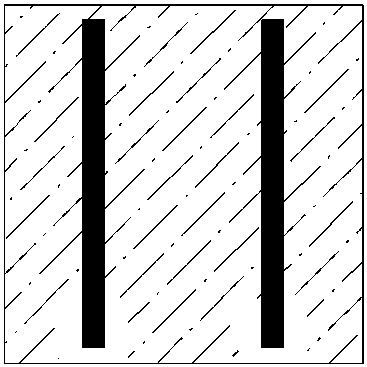

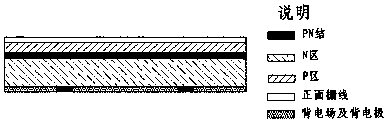

Production process for integrated solar cell with diodes and manufacturing method for photovoltaic assembly

ActiveCN102800759AAvoid hot spotsDoes not affect the light receiving areaFinal product manufactureSemiconductor devicesElectrical batteryEngineering

The invention discloses a production process for an integrated solar cell with diodes and a manufacturing method for a photovoltaic assembly. The production process comprises the following steps of: generating completely-isolated diodes on part of the back surface of the cell by virtue of the design concept of integrated circuits, a photoetching technology and an etching process; printing the same paste on the back surfaces of cell slices by virtue of a printing silk screen, and connecting the negative poles of the diodes with the positive pole of the cell (or connecting the positive poles of the diodes with the negative pole of the cell); and forming the integrated solar cell which is characterized in that the front surface is provided with the cell while the back surface is partially provided with the diodes. One end of the cell is connected with the diodes, and the other end of the cell is independent. During a process of producing an assembly by using the cell, the cell is connected with the electrodes of the diodes by virtue of a welding strip welding process, so as to form the photovoltaic assembly without a need to be externally connected with bypass diodes.

Owner:HENGSHUI YINGLI NEW ENERGY

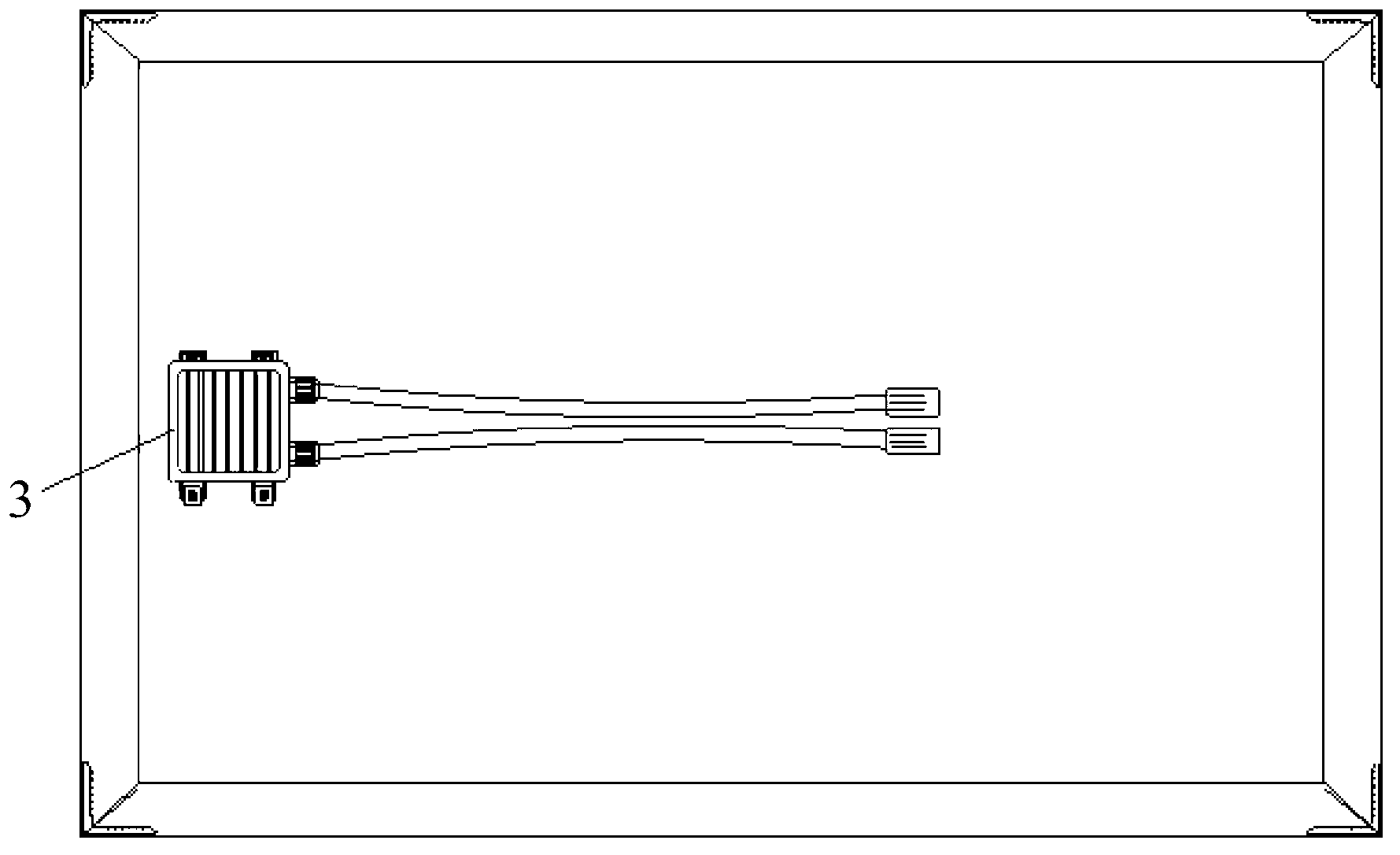

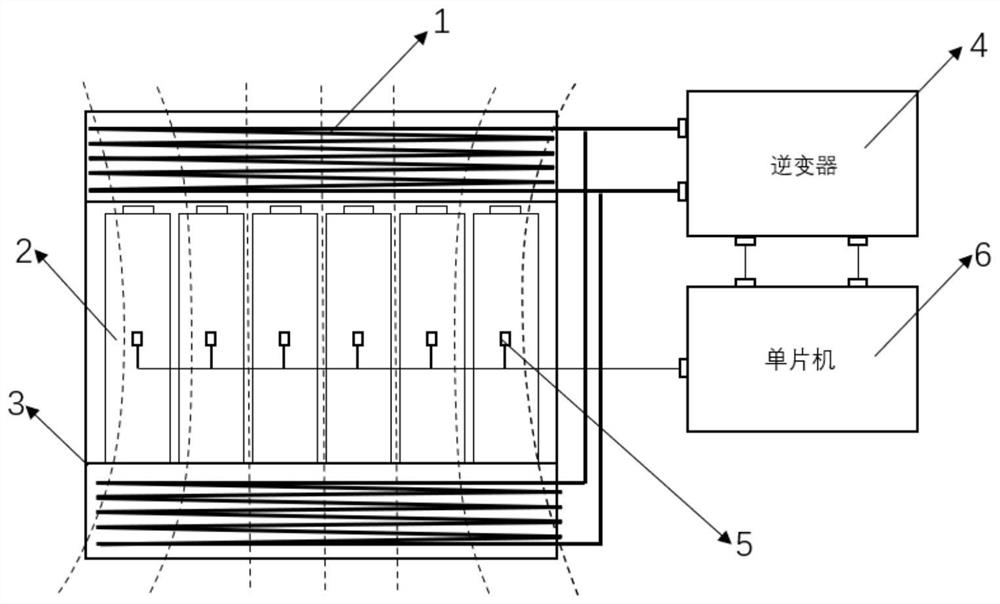

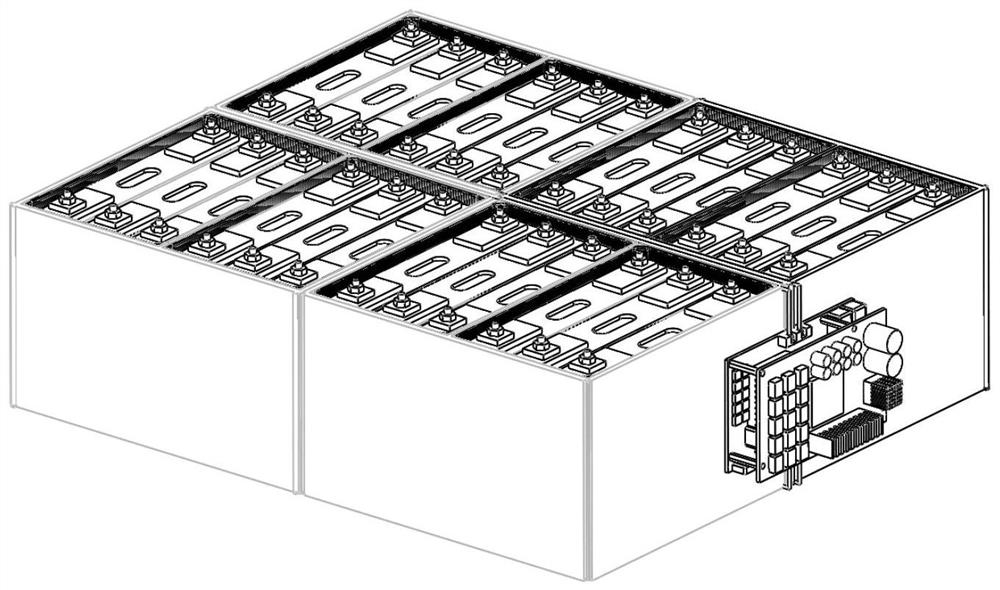

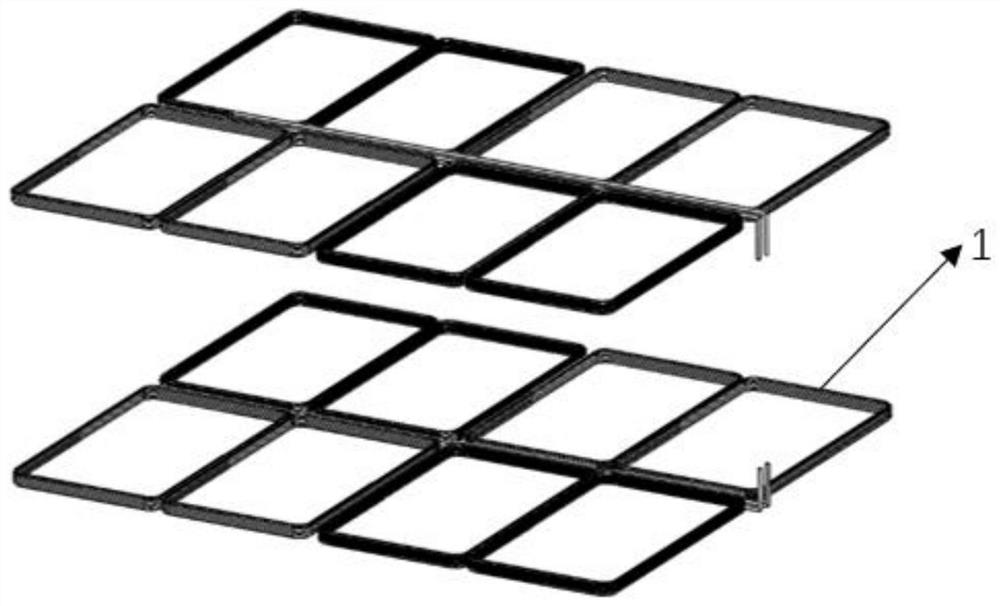

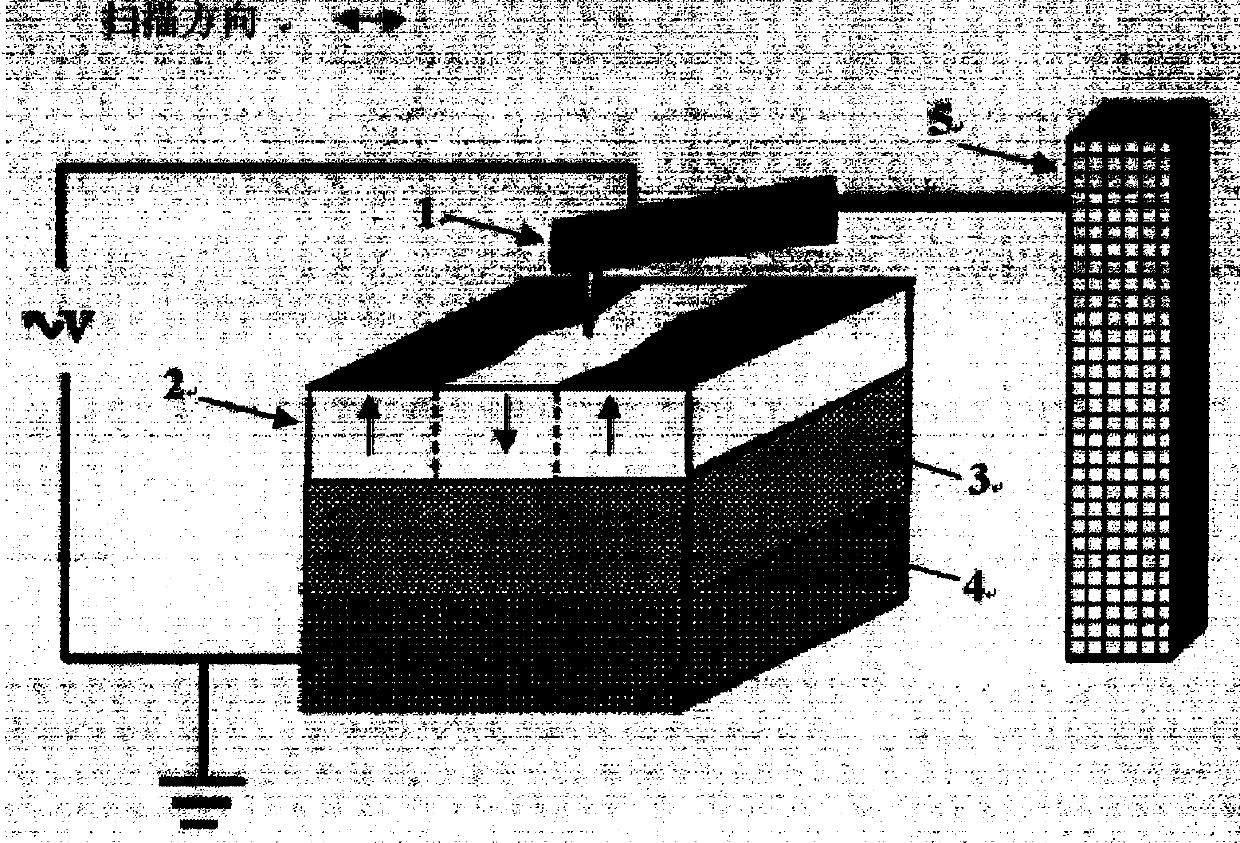

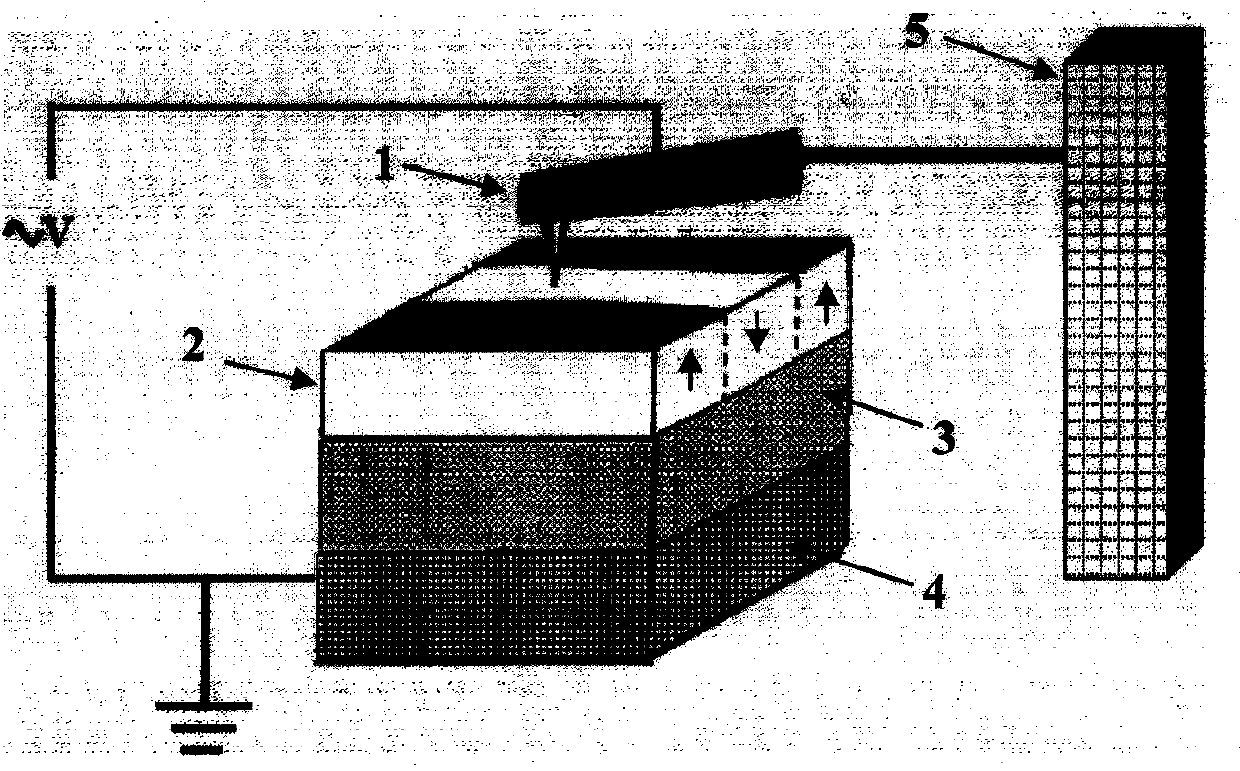

Electric automobile cold start system based on eddy current heating

PendingCN113363621AUniform distribution of temperature fieldNo thermal effectSecondary cellsVehicular energy storageAutomotive engineeringElectrical battery

The invention belongs to the technical field of electric vehicle application, and provides an electric vehicle cold start system based on eddy current heating. A high-frequency alternating current is introduced into eddy current coils arranged at the upper position and the lower position of the square battery, an eddy current is generated on a metal pole plate of the square battery through the electromagnetic induction effect, and the square battery is evenly heated through the heat effect of the eddy current. Temperature sensors are distributed on the surfaces of the square batteries, temperature signals of the surfaces of the batteries are transmitted to a single chip microcomputer, and the single chip microcomputer controls an inverter so as to control the heating process. Compared with a traditional electric automobile cold start system, the electric automobile cold start system has the advantages that the square batteries are heated in a spaced mode through the electromagnetic induction effect, the uniformity of the temperature of the single batteries is guaranteed, and the influence of heat conduction on other parts in an automobile body is reduced. Compared with a traditional heating mode, the efficiency of eddy current heating is as high as 95%. The eddy current heating speed is high and the response time is short. The system can directly utilize a direct-current power supply provided by a square battery, and the direct-current power supply is converted into a high-frequency alternating-current power supply through an inverter.

Owner:DALIAN UNIV OF TECH

Pork preserving method with irradiation

InactiveCN107094856AMaintain nutrientsMaintain sensory indicatorsMeat/fish preservation by freezing/coolingMeat/fish preservation using chemicalsShielding gasOxygen

The invention discloses a pork preserving method with irradiation, and the method comprises the following steps: rapidly freezing fresh pork at -20 to -10 DEG C for 1-2 hours, then cooling the pork at -2 to 6 DEG C for 5-10 hours, and cutting the pork into chilled meat blocks of 100-500 grams; treating the chilled meat with antioxidants at -2 to 6 DEG C, wherein the antioxidants comprise tea polyphenols; carrying out controlled atmosphere packaging on the chilled meat after antioxidation treatment, wherein in the controlled atmosphere shielding gas used for controlled atmosphere packaging, the gas ratio of oxygen to carbon dioxide to nitrogen gas equals to 70:20:10, or the gas ratio of oxygen to carbon dioxide equals to 75:25; and carrying out irradiation on the chilled meat after controlled atmosphere packaging. The pork preserving method with irradiation combines a controlled atmosphere technique with an irradiation preservation technique, has good sterilizing effect and broad-spectrum sterilization, and can effectively avoid bacterial breeding, prolong the preservation time of meat and keep the meat fresh red, and the irradiation is cold treatment which hardly generates heat effect.

Owner:合肥岭牧农产品有限公司

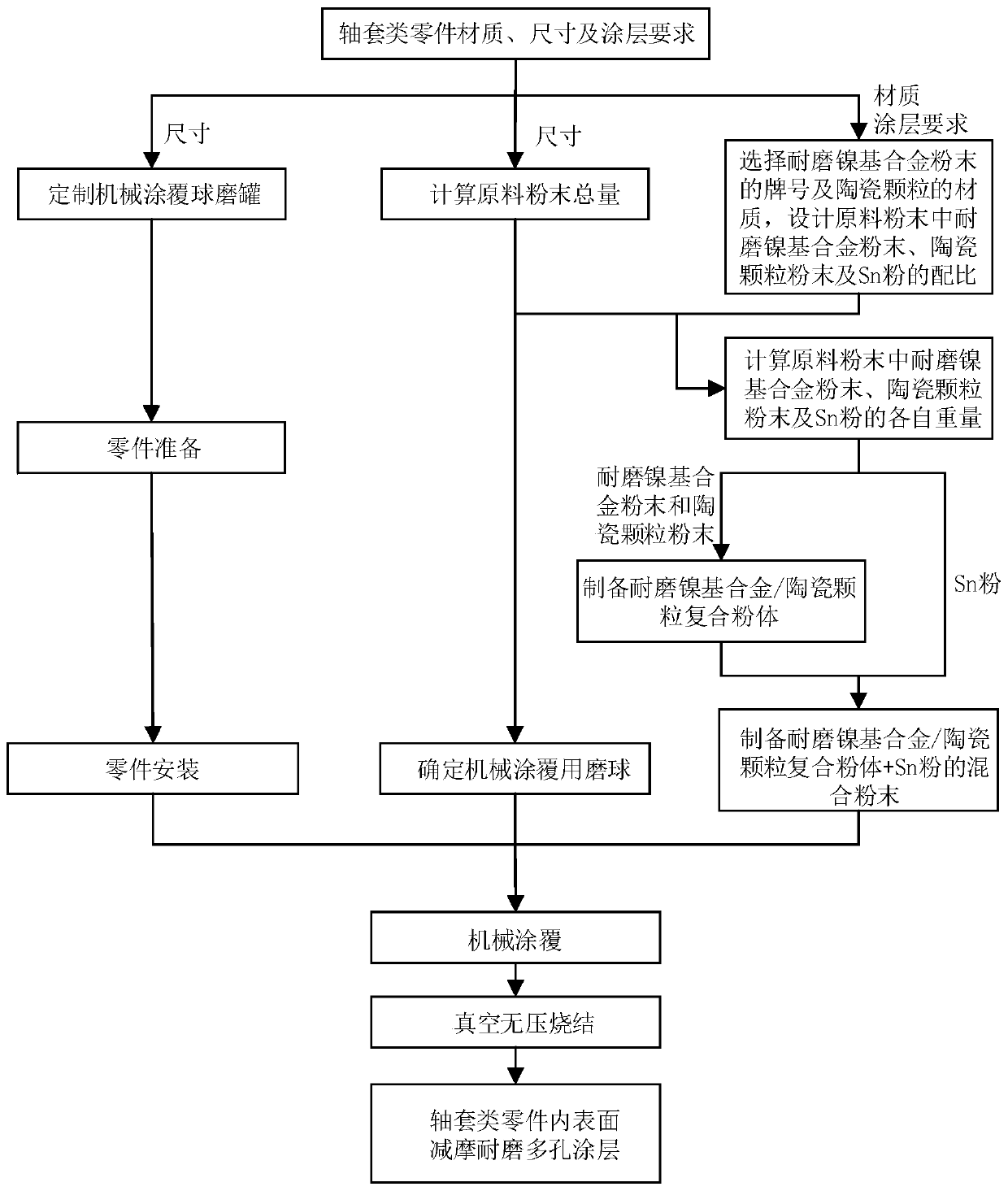

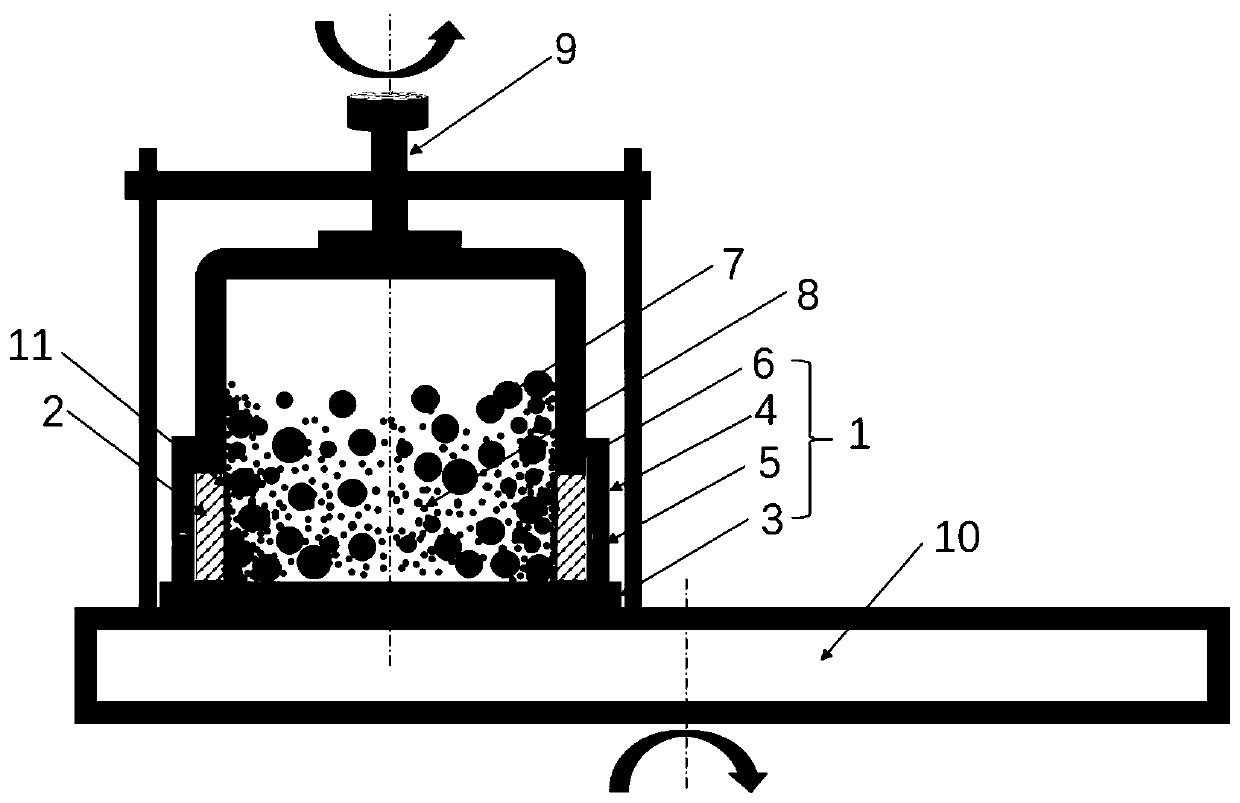

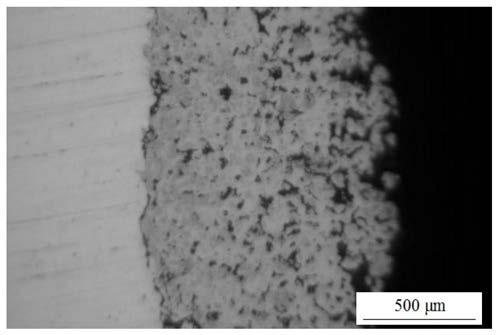

Method for preparing friction-reducing and wear-resistant porous coating on inner surface of shaft sleeve type part

ActiveCN110484915AIncrease profitLess investmentMetallic material coating processesWear resistantAlloy

The invention discloses a method for preparing a friction-reducing and wear-resistant porous coating on the inner surface of a shaft sleeve type part. The method comprises the following steps of: polishing the inner surface of the part, washing and drying the part; installing the part in a mechanically coating ball-milling tank; putting a certain amount of mixed powder and several hard alloy grinding balls in a ball grinding tank, wherein the mixed powder comprises nickel-based alloy powder, ceramic particle powder and Sn powder; closing the ball-milling tank, and carrying out ball milling under the protection of an inert gas to achieve mechanical coating of the inner surface of the part; and putting the coated part in a vacuum furnace, and carrying out vacuum pressureless sintering to form the friction-reducing and wear-resistant porous coating with the thickness of 1.2mm and the porosity of 5 to 25%. The prepared coating is tightly bonded to the inner surface of the part, and has small residual stress, connected and uniformly distributed pores, and excellent mechanical properties and tribological properties under oil lubrication. The method is suitable for shaft sleeve type partsmade from various materials including non-ferrous metals, is simple in process and low in cost and has no environmental pollution.

Owner:NANJING INST OF TECH

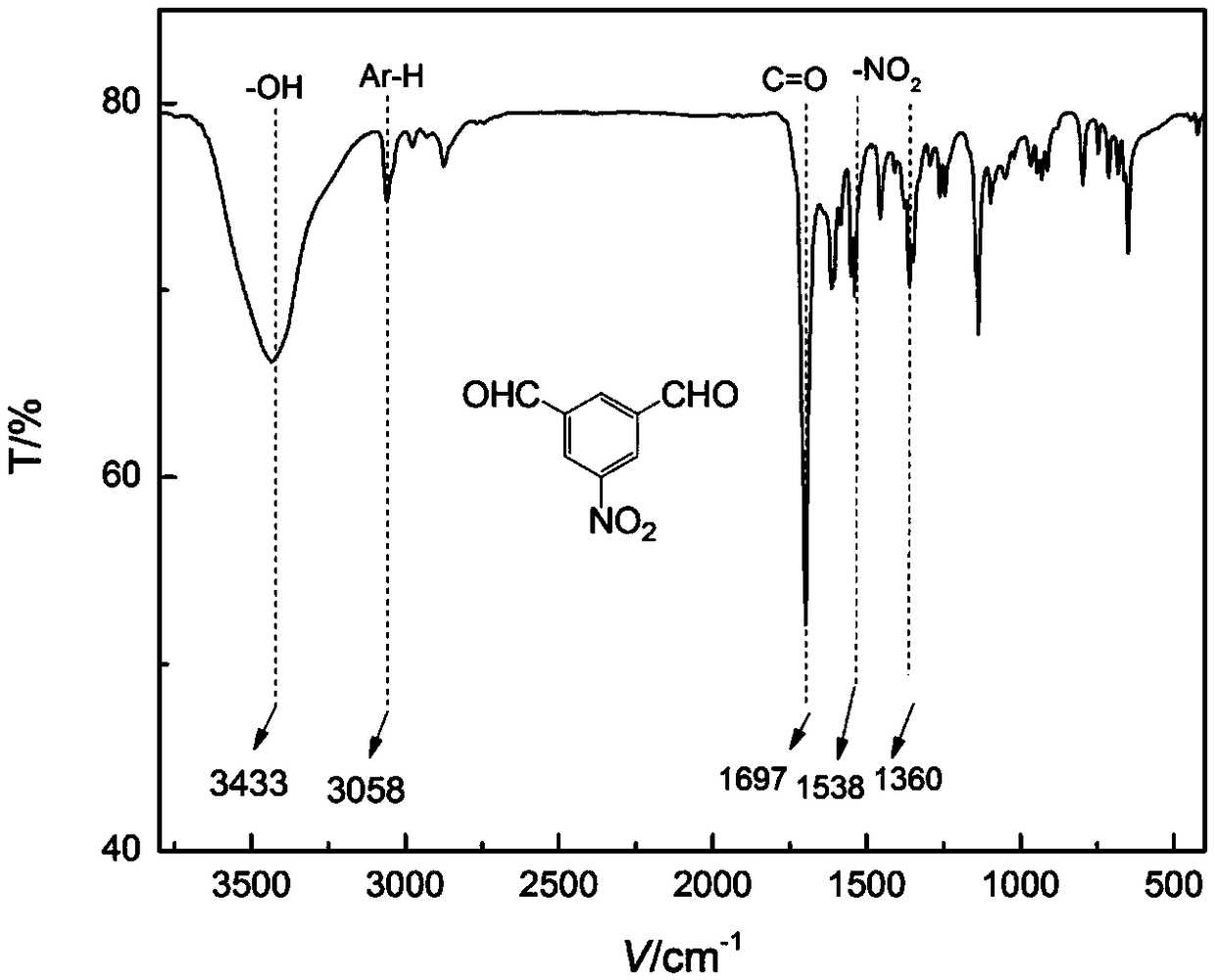

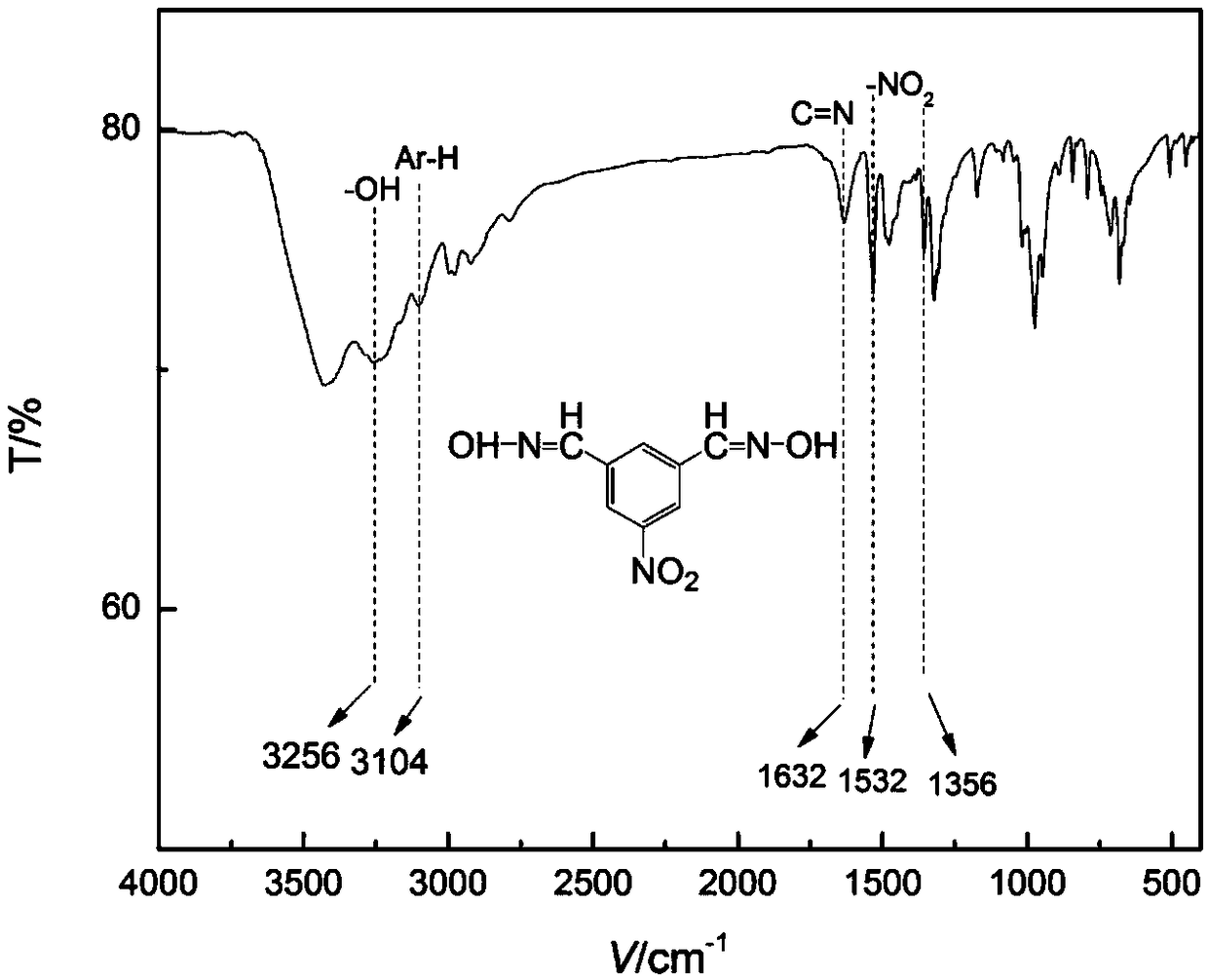

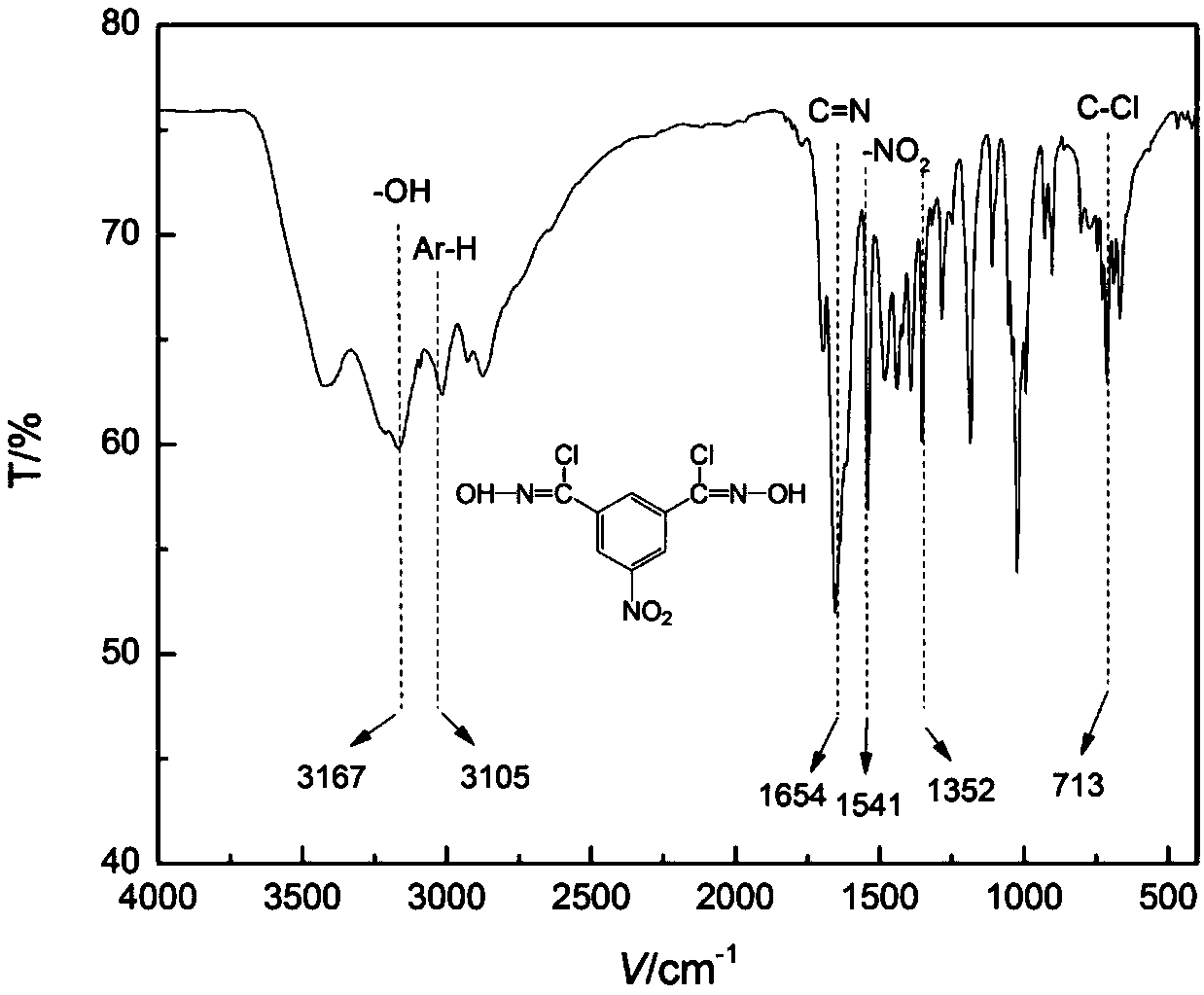

Energetic room-temperature curing agent based on hydroxyl-terminated polybutadiene bonding system and solidified body thereof and preparation method thereof

InactiveCN109096147ANo generationAvoid many defects caused by curingNon-macromolecular adhesive additivesCarboxylic acid nitrile preparationAdhesiveNitrobenzene

The invention discloses an energetic room-temperature curing agent based on a hydroxyl-terminated polybutadiene bonding system, namely, 5-nitrobenzene-1, 3-dinitrile oxide. According to a preparationmethod of the energetic room-temperature curing agent based on the hydroxyl-terminated polybutadiene bonding system, with 1, 3-phthalic aldehyde as an initial raw material, the 5-nitrobenzene-1, 3-dinitrile oxide is synthesized through four steps of reactions of nitrification, oximation, halogenation and dehydrohalogenation. The invention further discloses a solidified body, which is formed by mixing hydroxyl-terminated polybutadiene and the 5-nitrobenzene-1, 3-dinitrile oxide, of the energetic room-temperature curing agent based on the hydroxyl-terminated polybutadiene bonding system. The prepared energetic room-temperature curing agent based on the hydroxyl-terminated polybutadiene bonding system, disclosed by the invention, has the advantages of good product quality, high yield and simple separation, is suitable for large-scale industrial production, is suitable for room temperature curing and forming of hydroxyl-terminated polybutadiene type cast composite propellent in a solid rocket engine and room temperature curing and forming of a HTPB type explosive mixture and can also be used for room temperature curing of other HTPB type adhesives, sealing materials and coatings.

Owner:SOUTHWEAT UNIV OF SCI & TECH

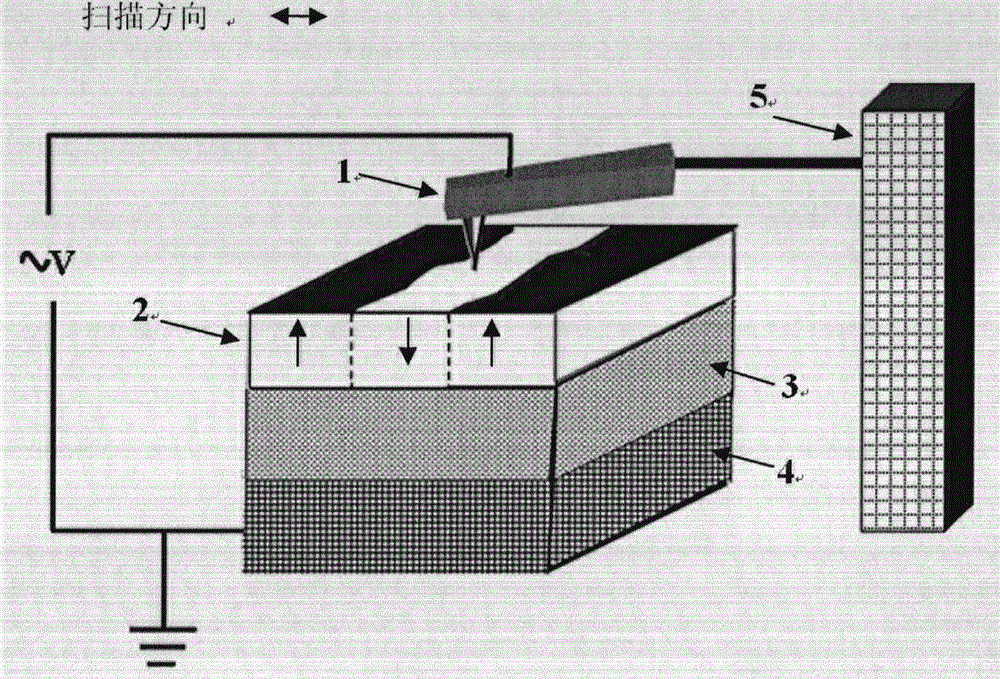

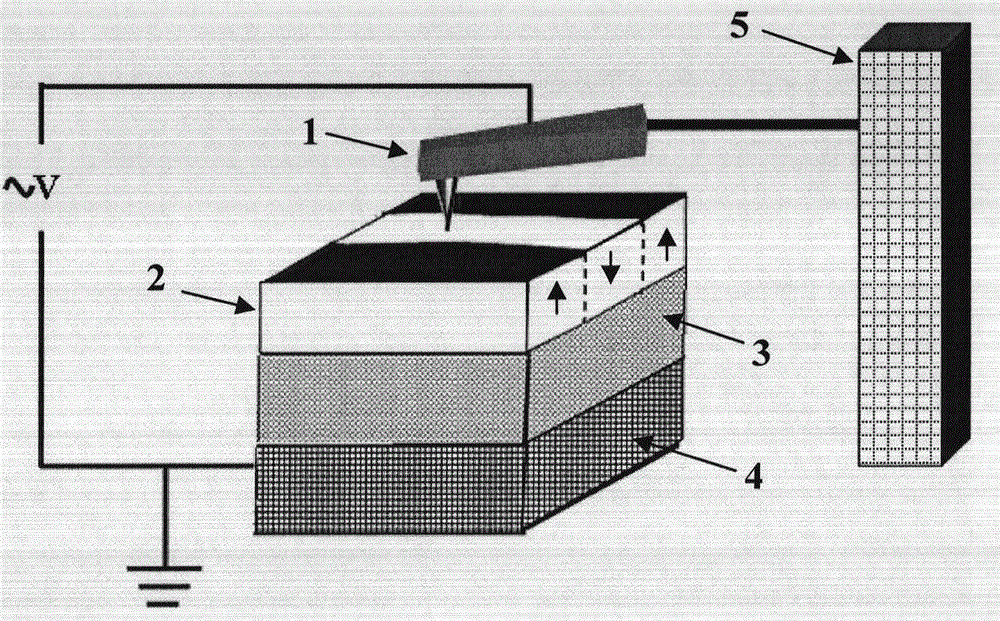

Device with manganese oxide film adjustable and controllable in magnetic domain wall and magnetic domain wall adjusting and controlling method

InactiveCN103427018AEasy flipRealize regulationMagnetic-field-controlled resistorsGalvano-magnetic material selectionVoltage amplitudeLow voltage

The invention provides a device with a manganese oxide film adjustable and controllable in a magnetic domain wall. The device comprises a manganese oxide core unit and a magnetic domain wall adjusting and controlling unit. The manganese oxide core unit comprises three layers of structures, namely the conductive manganese oxide film, an insulating substrate and a metallic conductive base arranged sequentially from top to bottom. The magnetic domain wall adjusting and controlling unit is a magnetic conductive needle point, a magnetization direction of the magnetic conductive needle point is perpendicular to the surface of the manganese oxide film, and the magnetic conductive needle point closely contacts with a top film surface and can move along the same. The invention further provides a magnetic domain wall adjusting and controlling method of the manganese oxide film. The method includes moving the magnetic domain wall on the basis of a low-voltage alternating-current electric field effect of the needle point. Based on the device and the method, the invention provides a magnetic memory and a writing method thereof. Since the adopted voltage amplitude is low and no thermal effect is produced, power consumption is reduced.

Owner:BEIJING NORMAL UNIVERSITY

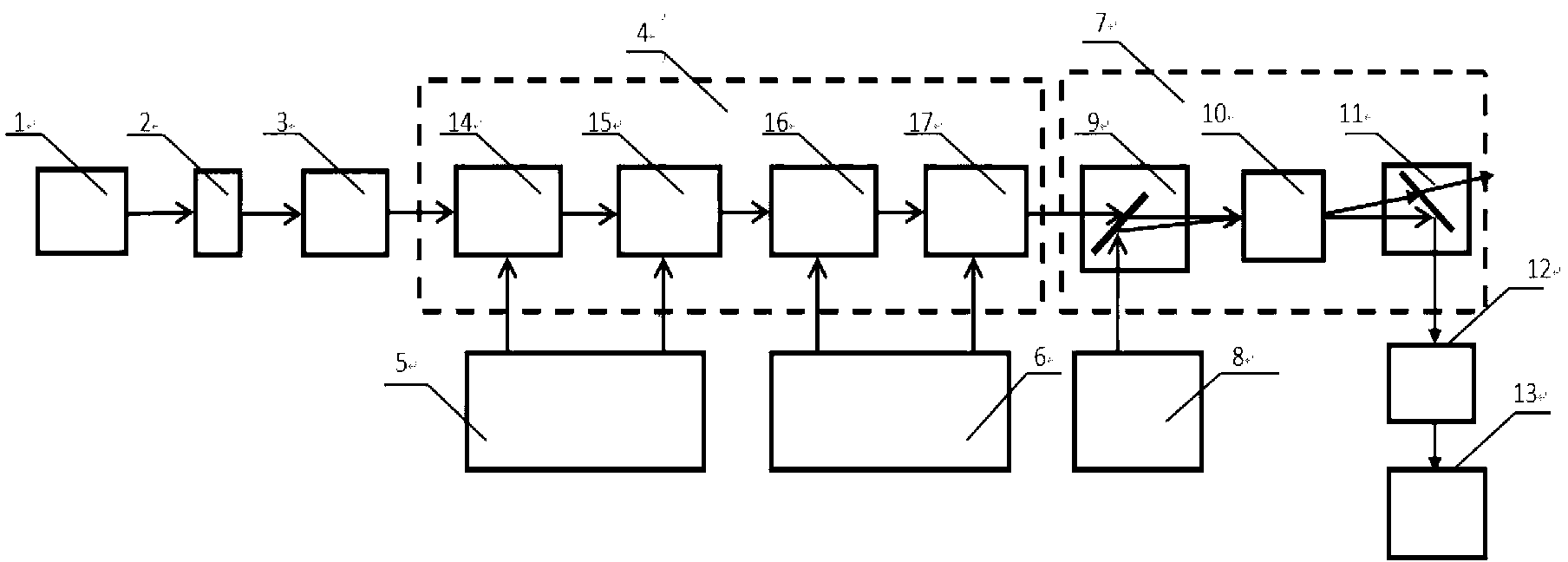

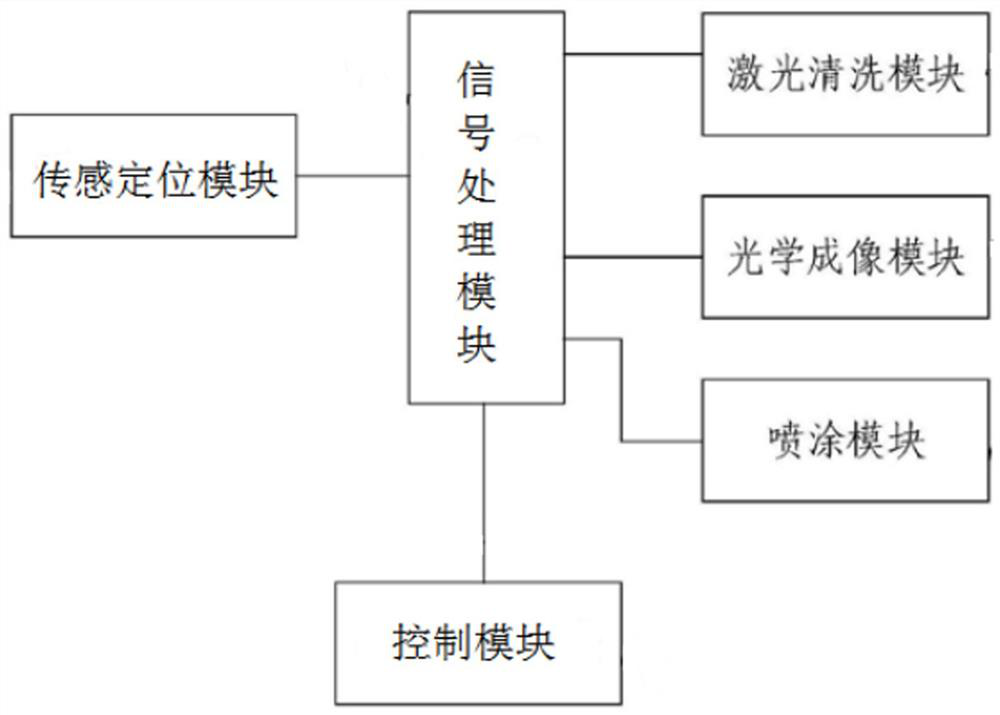

Laser cleaning equipment suitable for ships

InactiveCN111992542ANo thermal effectHigh degree of intelligenceVessel cleaningHullsComputer hardwareControl cell

The invention discloses laser multifunctional cleaning equipment suitable for ships. The equipment comprises a sensing positioning unit, a signal processing unit, a control unit, a laser cleaning unitand an optical imaging unit. The sensing positioning unit, the signal processing unit and the control unit are connected with the laser cleaning unit and the optical imaging unit correspondingly. Thesensing positioning unit is used for acquiring orientation information about a cleaning part of the laser cleaning unit and sending the orientation information to the control unit, the signal processing unit and the control unit control the cleaning action of an image sensing positioning device according to the orientation information, and the optical imaging unit is used for acquiring image information about the cleaning part and sending the image information to the control unit; and the control unit determines cleaning parameters according to the image information and controls the laser cleaning unit to emit laser for cleaning.

Owner:苏州禾焮烜智能科技有限公司

Metal shaping method based on local constrained electrochemistry

InactiveCN1785565ALimit hardnessNo hardnessElectric circuitsElectrochemical machining apparatusMetallic materialsHardness

An electrochemical metal shaping method based on local constraint features that a movable constraint part is used to constrain the region where electrochemical processing is conducted for directly forming the high-accuracy complex shape on metal material and treating its surface. Its advantages are no overheat and annealing phenomena and no need of casting.

Owner:高丹

Solar cell preparation method

ActiveCN106784163AImprove securityArea resistance decreasesFinal product manufactureSemiconductor devicesBoron diffusionSunlight

The invention discloses a solar cell preparation method, and belongs to the technical field of solar cell preparation. The method mainly comprises the following steps that cleaning is conducted; texturing is conducted; boron diffusion is conducted; regional ion implantation is conducted, wherein the back is divided into a comb-shaped N type region and a comb-shaped P type region; annealing is conducted; laser etching is conducted, wherein PN junctions around a silicon wafer are removed, so that PN junctions of the front and the back are separated, the front adopts the main cell PN junction, and the back adopts the secondary cell or protection diode PN junction; by means of PECVD, the two sides of the silicon wafer are coated with films, and anti-reflection films are formed; silk-screen printing is conducted on the front and the back of the silicon wafer, and a front electrode, a first back electrode and a second back electrode are formed through sintering. Accordingly, the influence caused by a bypass diode on the solar cell and component sunlight area is avoided; meanwhile, the solar cell shot spot effect problem can be solved, the generating efficiency is improved, the power generation loss is lowered, and the component operating life is prolonged.

Owner:YINGLI ENERGY CHINA

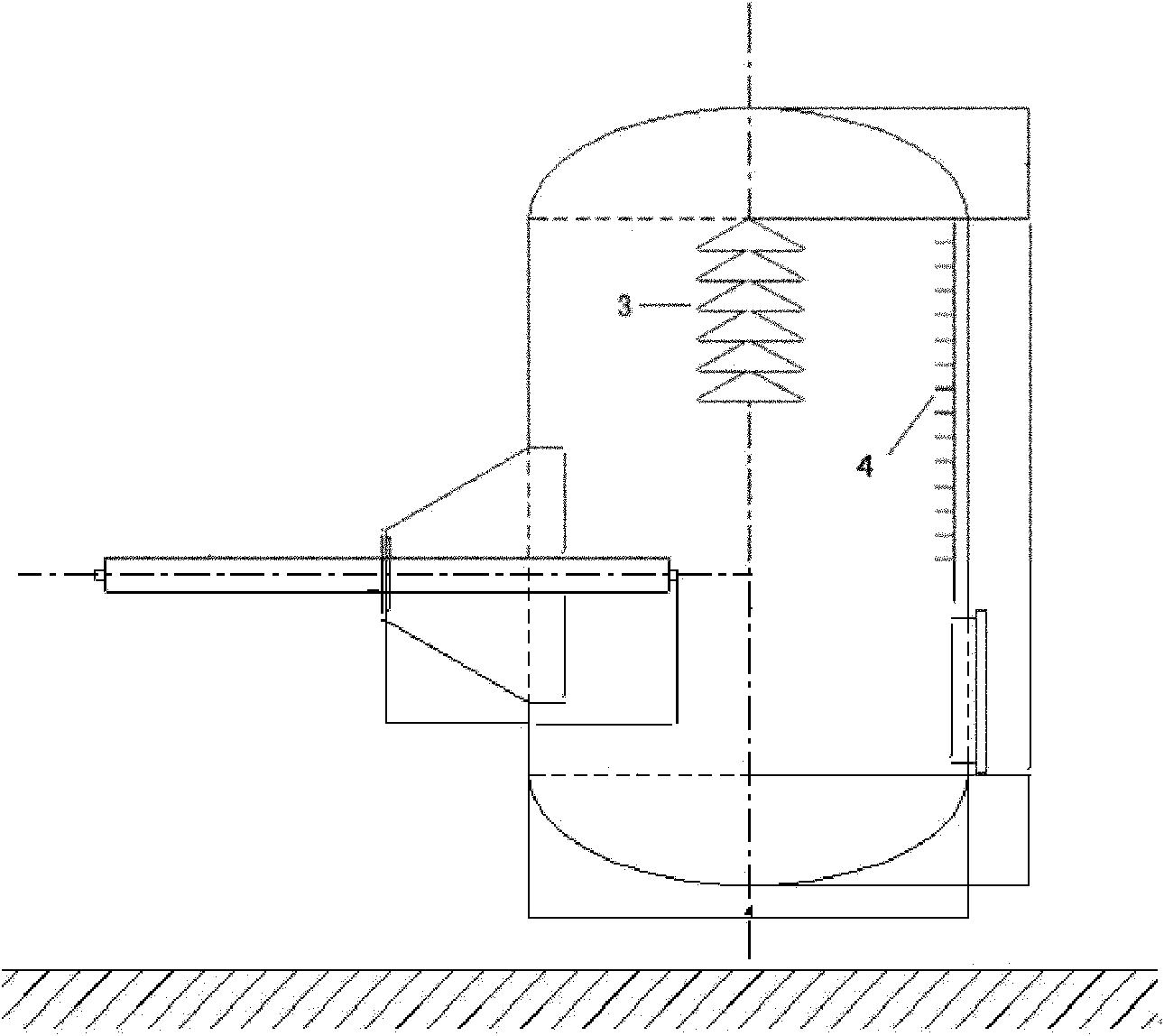

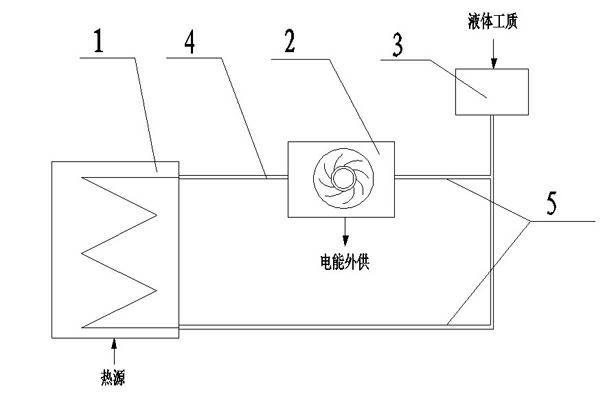

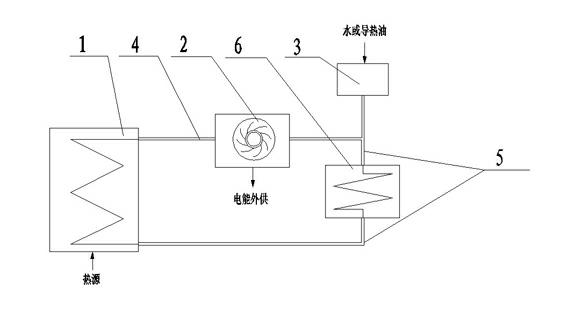

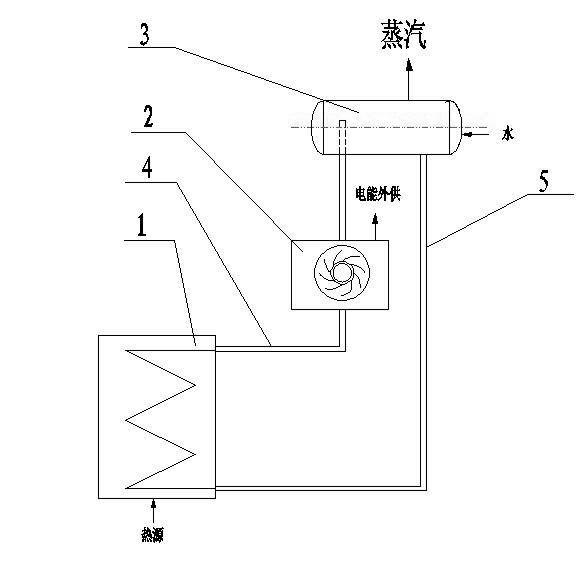

Liquid working medium temperature change self circulation power generation device and power generation method

InactiveCN102434358APrevent backflowNo thermal effectHydro energy generationMachines/enginesElectric energyElectric generator

The invention relates to a liquid working medium temperature change self circulation power generation device and power generation method, which belong to the technical field of comprehensive utilization of energy. The technical scheme is that: a liquid working medium heating device is arranged in a heater; the liquid working medium is rose in temperature, reduced in density and increased in volume after being heated in the heater; the liquid working medium is driven by buoyancy lift to automatically flow to a water wheel generator along an outlet pipeline on the upper part of the heater to push the water wheel generator to apply work; the decompressed liquid working medium automatically flows back to an inlet on the lower part of the heater from a liquid return pipeline to form a natural circulation loop; and the water wheel generator applies work continuously to generate power. The water wheel generator is introduced to a liquid working medium temperature change self circulation system to convert kinetic energy of the self circulation system into electric energy, so that the power generation method is safe, environment-friendly, energy-saving, water-saving, low-cost, high in power generation efficiency, without cold and heat effects and consumption of cooling water and cooling air, and is a novel power generation method.

Owner:文安县天澜新能源有限公司

Preparation method of solar cell

ActiveCN106784163BImprove securityImprove reliabilityFinal product manufactureSemiconductor devicesSolar cellIon implantation

Owner:YINGLI ENERGY CHINA

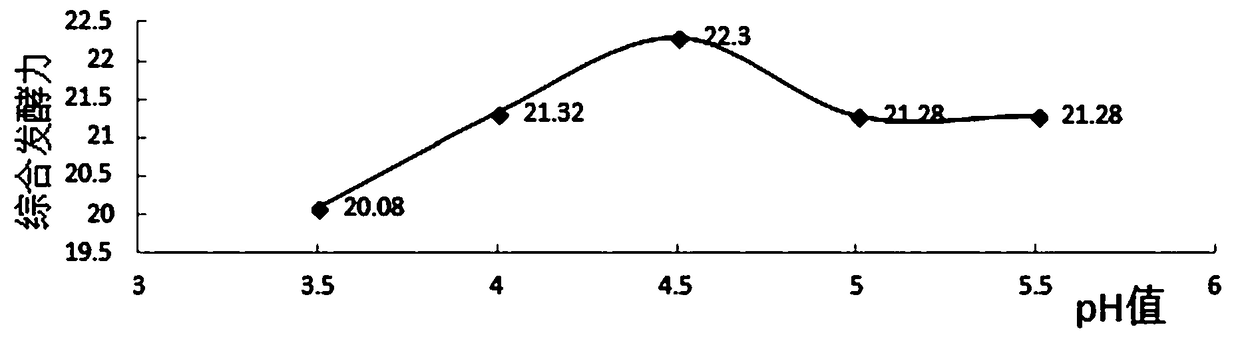

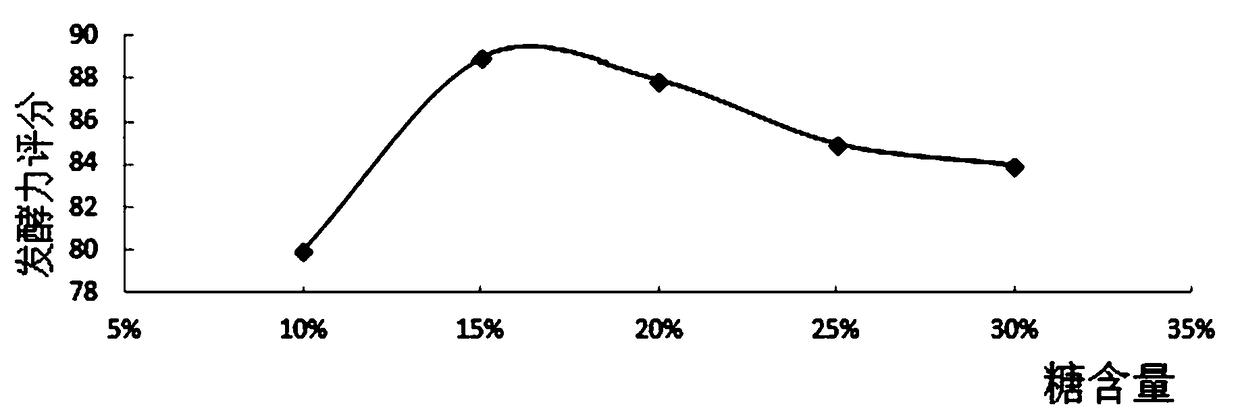

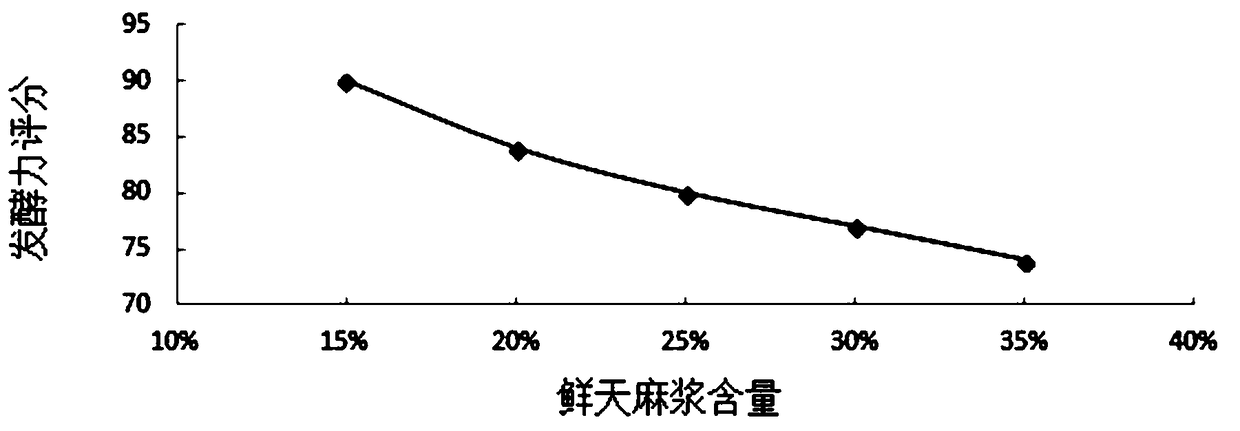

Gastrodiaelata wine

InactiveCN108841482AShorten the fermentation cycleReduce bacterial contaminationAlcoholic beverage preparationGastrodiaChemistry

The invention discloses gastrodiaelata wine and a preparation method thereof, and belongs to the technical field of health wine. The gastrodiaelata wine is prepared by the following steps: with freshgastrodiaelata as a raw material, treating the raw material, adjusting juice, saccharifying and inoculating with bacteria, performing primary fermentation, performing post-fermentation, aging and thelike. From raw material treatment to fermentation into the finished gastrodiaelata wine, all the steps are performed at low temperature, and UV pulse sterilization is adopted to avoid heat effect, sothat heat-sensitive components and volatile components are greatly protected, and destruction and loss of effective components of the gastrodiaelata are avoided. The gastrodiaelata wine prepared by the preparation method provided by the invention has the alcoholic strength of 14.9%vol (20 DEG C) and the gastrodin content of 106.65mg / L, the wine liquid has strong complex Baijiu aroma and special tianma aroma, the wine body is coordinated, mellow and palatable, and the gastrodiaelata wine has a unique flavor.

Owner:GUIZHOU UNIV

Ultraviolet light curing adhesive for 3D printing powder and preparation method of ultraviolet light curing adhesive

InactiveCN107245314ASimple conditions of useImprove performanceAdditive manufacturing apparatusNon-macromolecular adhesive additivesWhole bodyUltraviolet lights

The invention belongs to the field of adhesives and particularly relates to an ultraviolet light curing adhesive for 3D printing powder and a preparation method of the ultraviolet light curing adhesive. The ultraviolet light curing adhesive for the 3D printing powder is characterized in that the adhesive is a resin adhesive, is used for rapid forming of the 3D printing powder, is quickly cured under ultraviolet light irradiation, is adhered onto powder particles to form a whole body, does not need post-treatment and comprises the following components in parts by weight: 30-50 parts of acrylate, 1-5 parts of a photo-initiator, 3-5 parts of a toughening agent, 5-15 parts of a filling agent, 1-3 parts of a coupling agent, 0.5-2 parts of a stabilizing agent and the balance of a diluting agent. The adhesive prepared by the preparation method provided by the invention is simple in use condition, green and environment-friendly, good in product performance, high in precision and high in adhering speed; selected resin has no thermal effect during curing, smaller contraction force is generated in the curing process, and the adhesive force is strong; raw materials are widely available, and the preparation method is simple and easy to implement, low in cost and beneficial to market popularization.

Owner:苏州汉力新材料有限公司

Method for destroying waste airbag gas generator

ActiveCN110281165ALarge areaHigh construction and operating costsBlast gunsAbrasive machine appurtenancesSmall footprintMetal

The invention relates to a method for destroying a waste automobile airbag gas generator. The method adopts a water knife cutting process, namely by using high-pressure water jet flow to carry out cold-state cutting so as to destroy the airbag gas generator, and involves a water knife cutting machine, wherein the water knife cutting machine is mainly composed of a high-pressure pump, a numerical control machining platform, an injection cutting head, a sand supply system and a cooling system; and meanwhile, a waste water pretreatment system is also provided. The airbag gas generator is divided into two halves after being cut by a water knife, wherein sodium azide (NaN3 ) and potassium nitrate (KNO3) and the like of the airbag gas generator are completely dissolved in water, and an igniter is completely destroyed to lose the detonation function, so that only a metal shell capable of being recycled of the whole gas generator remains, and the metal shell is separately treated after being collected. Compared with the prior art, the method for destroying a waste airbag gas generator has the advantages of being safe and reliable in process, clean and environment-friendly, small in occupied area, low in operation cost, high in treatment efficiency and capable of running for 24 hours continuously; and meanwhile, the recycling application of the gas generator outer shell after treatment is wide.

Owner:SHANGHAI EMPEROR OF CLEANING HI TECH

An ultra-fast femtosecond laser cutting machine

The invention discloses an ultrafast femtosecond laser cutting machine. The ultrafast femtosecond laser cutting machine comprises a bearing platform, wherein multiple support rods are arranged at the lower end of the bearing platform at equal intervals; damping devices are arranged at the lower ends of the support rods, and a connecting rod is connected between every two adjacent support rods; a bearing plate is arranged at the upper end of the bearing platform, first electric sliding rails are arranged on two sides of the bearing platform, second sliders are mounted on the first electric sliding rails, mounting blocks are arranged at the upper ends of the second sliders, first vertical plates are fixed at the upper ends of the mounting blocks, and a mounting plate is arranged between the two first vertical plates. The ultrafast femtosecond laser cutting machine had the remarkable advantages of being high in machining speeds, high in accuracy, simple in parameter setting and the like through femtosecond laser cutting; a product obtained through femtosecond laser cutting does not have the problems of microcracks, breaking or fragments in the aspect of appearance quality; no contamination or edge breakage are caused, and the edge breakage resistance is very high; washing and polishing are not required, the manufacturing cost is reduced and the ultrafast femtosecond laser cutting machine is suitable for popularization.

Owner:WUHAN HONGLEI LASER EQUIP

A device with a magnetic domain wall adjustable manganese oxide film and a magnetic domain wall adjustment method

InactiveCN103427018BEasy flipRealize regulationMagnetic-field-controlled resistorsGalvano-magnetic material selectionVoltage amplitudeLow voltage

The invention proposes a device with a manganese oxide film with a controllable magnetic domain wall, including a manganese oxide core unit and a magnetic domain wall control unit; the manganese oxide core unit includes a three-layer structure, which are sequentially from top to bottom. A conductive manganese oxide film, an insulating substrate, and a metal conductive base are provided; the magnetic domain wall control unit is a magnetic conductive tip, the magnetization direction of the magnetic conductive tip is perpendicular to the surface of the above-mentioned manganese oxide film, and the tip is in contact with the above-mentioned manganese oxide The top film surface of the film is in close contact and can move along the top film surface; in addition, the present invention also proposes a method for regulating the magnetic domain wall of the manganese oxide film, which moves the magnetic domain based on the AC electric field effect of low voltage at the tip. The position of the wall; based on the above devices and methods, the present invention proposes a magnetic memory and a writing method of the magnetic memory. Since the voltage amplitude used is small, there is no thermal effect, thus reducing power consumption.

Owner:BEIJING NORMAL UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com