Solar cell preparation method

A solar cell and battery technology, applied in the manufacture of circuits, electrical components, final products, etc., to achieve the effects of easy ohmic contact, reduced area resistance, and improved power generation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

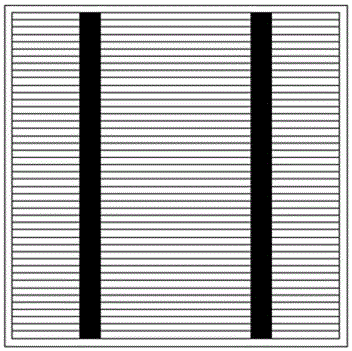

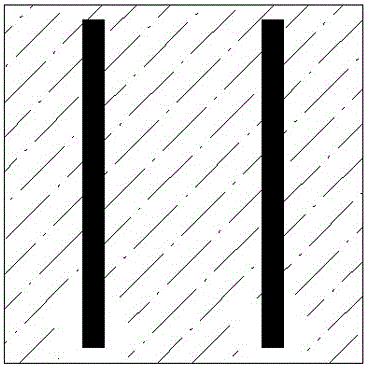

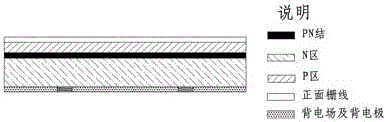

[0060] see Figure 5 , Figure 6 , first, the principle of the method for preparing a solar cell provided by the embodiment of the present invention is described as follows:

[0061] Battery positive electrode 1: the positive pole of the main battery;

[0062] The first electrode 2 on the back: according to different applications, the electrical principle is different; when the battery is applied to double-sided glass components, it is the positive electrode of the secondary battery; when the battery is applied to single-sided glass components, it is the positive electrode of the protection diode;

[0063] The second electrode 3 on the back side: the common output electrode of the negative pole of the main battery and the negative pole of the secondary battery or the negative pole of the protection diode.

[0064] The preparation m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com