Electric automobile cold start system based on eddy current heating

A technology of eddy current heating and electric vehicles, applied in electric vehicles, circuits, electrical components, etc., can solve the problems of thermal stress, weight reduction, and low reliability of batteries

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The specific implementation manners of the present invention will be further described below in conjunction with the accompanying drawings and technical solutions.

[0036] In order to facilitate the understanding of the present invention, the present invention will be described more fully below with reference to the associated drawings. However, it should be understood that these descriptions are only for further illustrating the features and advantages of the present invention, rather than limiting the claims of the present invention.

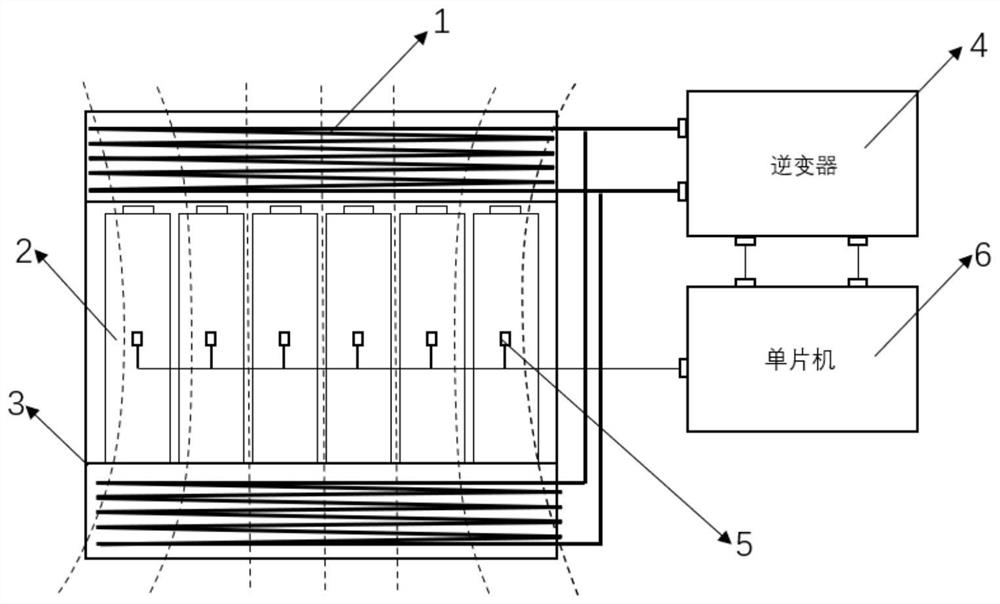

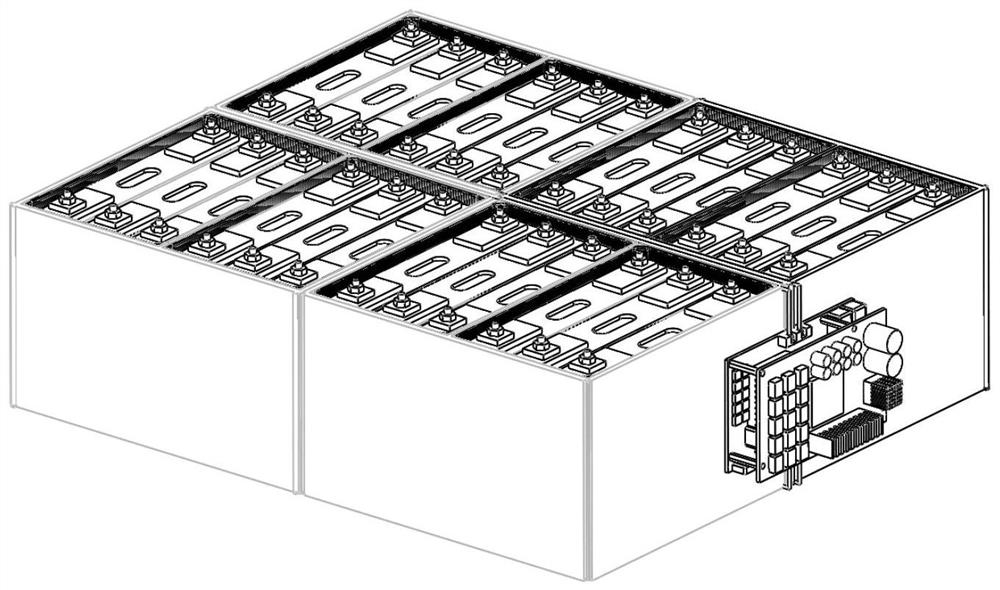

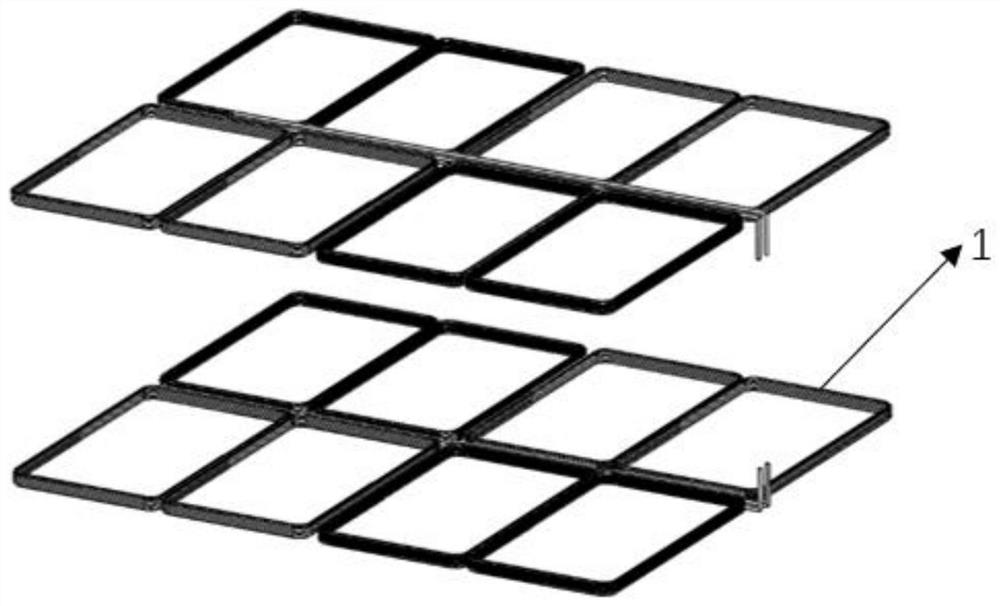

[0037] The invention discloses an electric vehicle cold start system based on eddy current heating, comprising: an eddy current coil 1, a square battery 2, a square battery support 3, an inverter 4, a temperature sensor 5, and a single-chip microcomputer 6;

[0038] The eddy current coil 1 is fixed by the slots at the upper and lower ends of the square battery support 3, which is convenient for maintenance.

[0039] The eddy current c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com