High-heat-capacity SiCp/Al composite material wheel-mounted brake disc bodies

A composite material and high heat capacity technology, applied in the direction of brake discs, brake types, brake components, etc., can solve the problems of aluminum-based composite materials such as difficulty in forming, shrinkage cavity shrinkage, and casting pores, and achieve good ventilation effect. Good molding quality and less constraint effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Combine below Attached picture The patent of the present invention is further described.

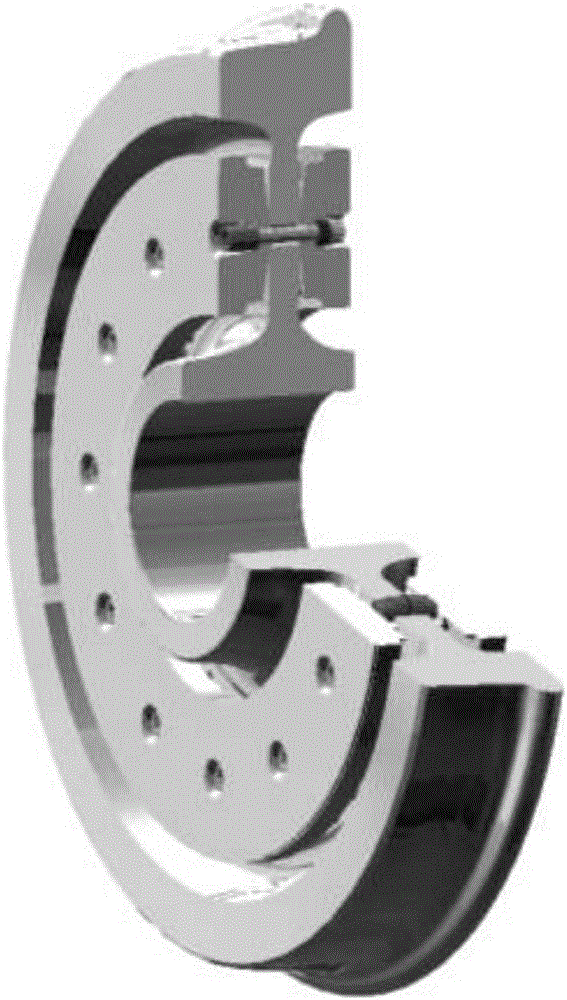

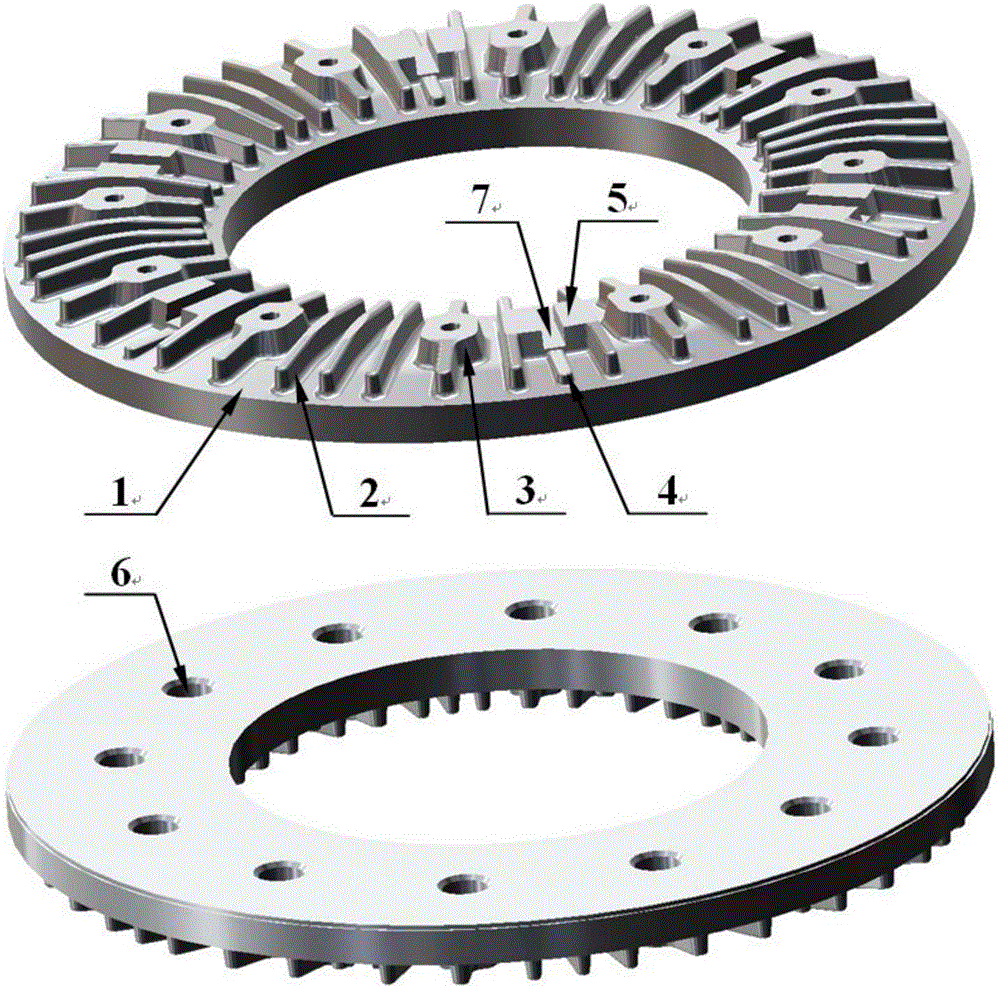

[0022] A high heat capacity SiCp / A356 composite wheel-mounted brake disc, Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 shown.

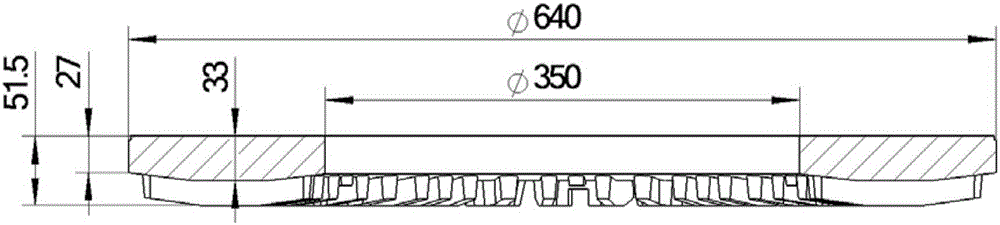

[0023] The total height of the disc body is 51.5 mm, the outer diameter of the friction ring 1 is Ф640 mm, and the inner diameter is Ф350 mm. The thickness of the inner and outer diameters of the disc body friction ring 1 is smaller at 27 mm, and the thickness at the middle diameter is larger at 33 mm. Such as figure 2 shown.

[0024] The high ribs 2 are radially arranged, 3 high ribs 2 form a group, a total of 6 groups are evenly distributed along the circumferential direction, and the angle between two adjacent high ribs 2 is 6°, Such as figure 2 shown. The top thickness of the high rib 2 is 8mm, the root length of the high rib 2 is 125mm, and the end face and side slope of the high rib 2 are 5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com