Patents

Literature

107results about How to "Address the degree of automation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Mobile ultrasonic anemoclinograph and method for measuring wind speed and direction

InactiveCN102175887ASolve the technical problems that cannot meet the wind speed and direction measurement in mobile situationsSolve the technical problem that the position data cannot be obtained accuratelyIndication/recording movementFluid speed measurementUltrasonic sensorEngineering

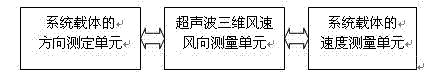

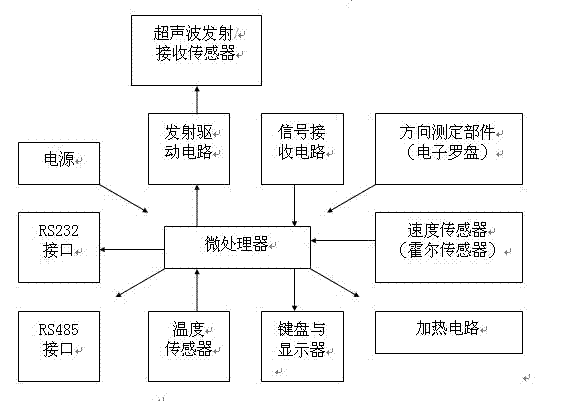

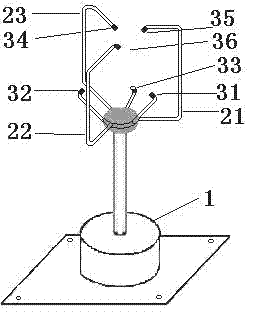

The invention provides a mobile ultrasonic anemoclinograph and a method for measuring wind speed and direction, wherein the device comprises an ultrasonic wind speed and direction measuring unit, a mobile system carrier speed measuring unit and a system direction measuring unit; the wind speed and direction measuring unit comprises a base, a control circuit board, six measuring arms and six ultrasonic transmitting / receiving sensors; the measuring arms are connected to the base and in an included angle at 60 degrees in turn; each measuring arm is provided with an ultrasonic sensor; the speed and direction measuring unit of the system carrier comprises a speed sensor and a direction measuring component; simultaneously, the invention further provides a method for measuring the wind speed anddirection in actual environment under a mobile condition by ultrasonic, wherein the method comprises the steps of: measuring the wind speed and direction parameters under the mobile condition by the ultrasonic wind speed and direction measuring unit; combining the measured moving speed and direction parameters of the system carrier; and calculating the measured wind speed and direction parametersin actual environment of the system under a mobile condition.

Owner:兴化市华伦达铸钢有限公司

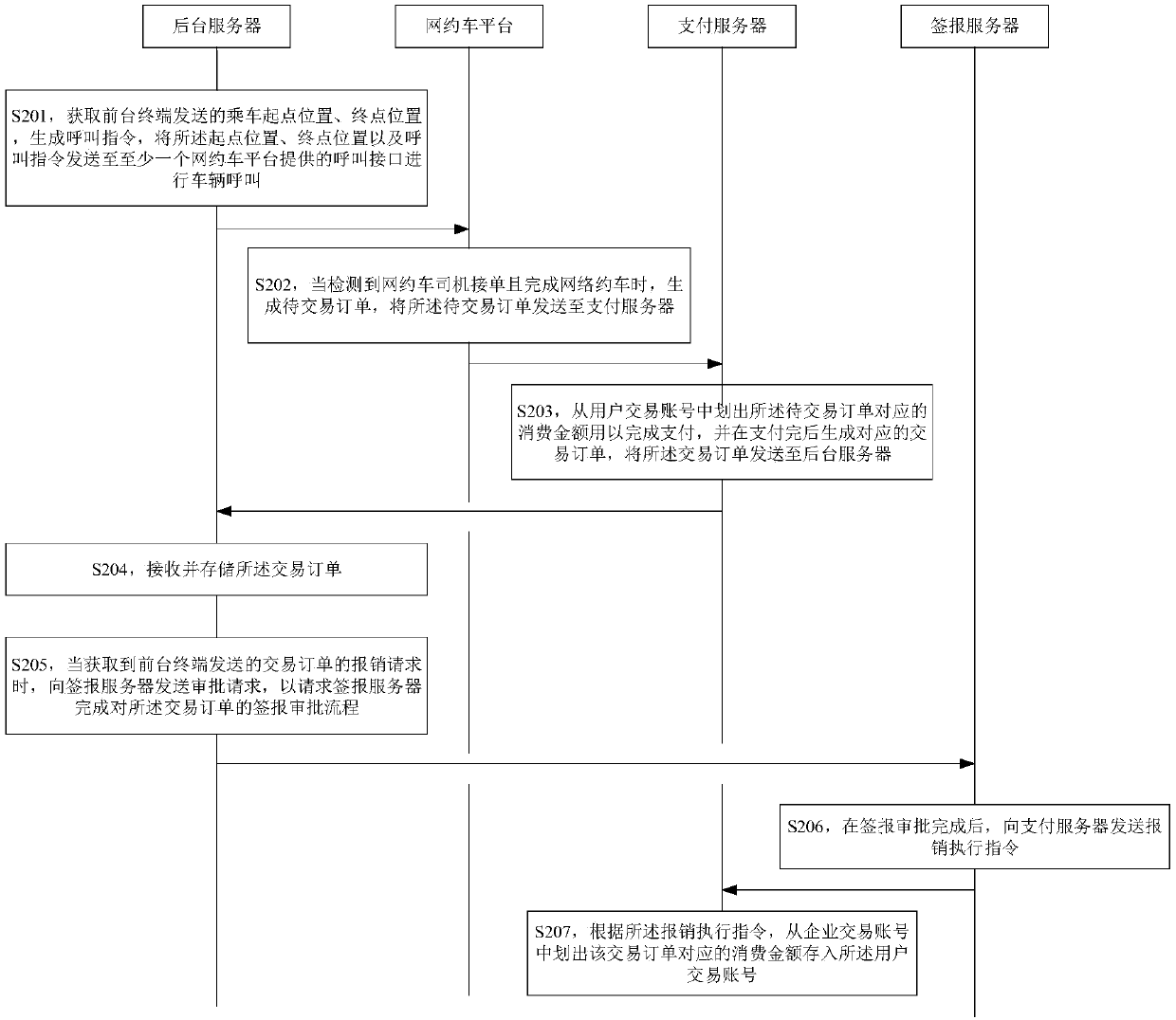

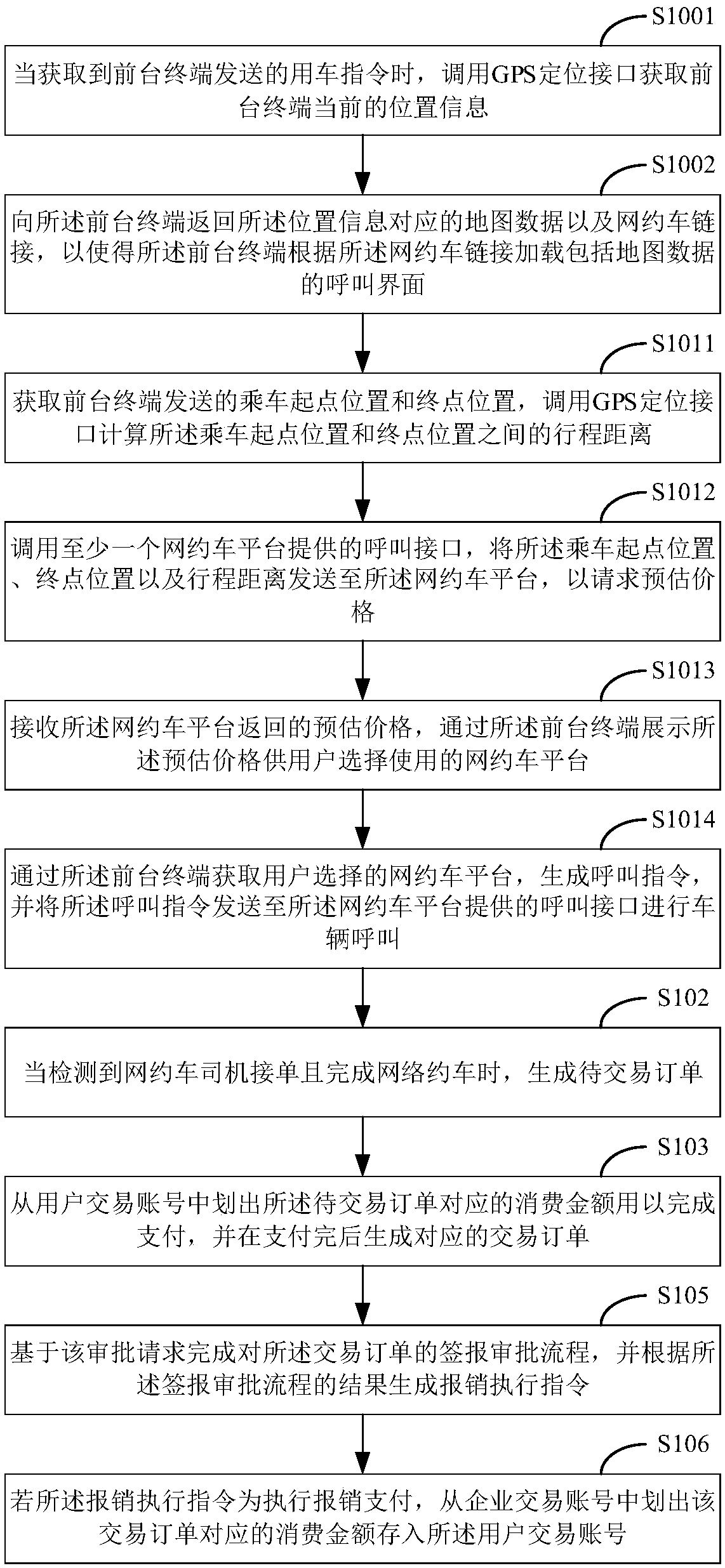

Online car-hailing settlement and reimbursement method, system and storage medium

InactiveCN108038774ASolve the cumbersome reimbursement processAddress the degree of automationFinanceReservationsComputer terminalComputer science

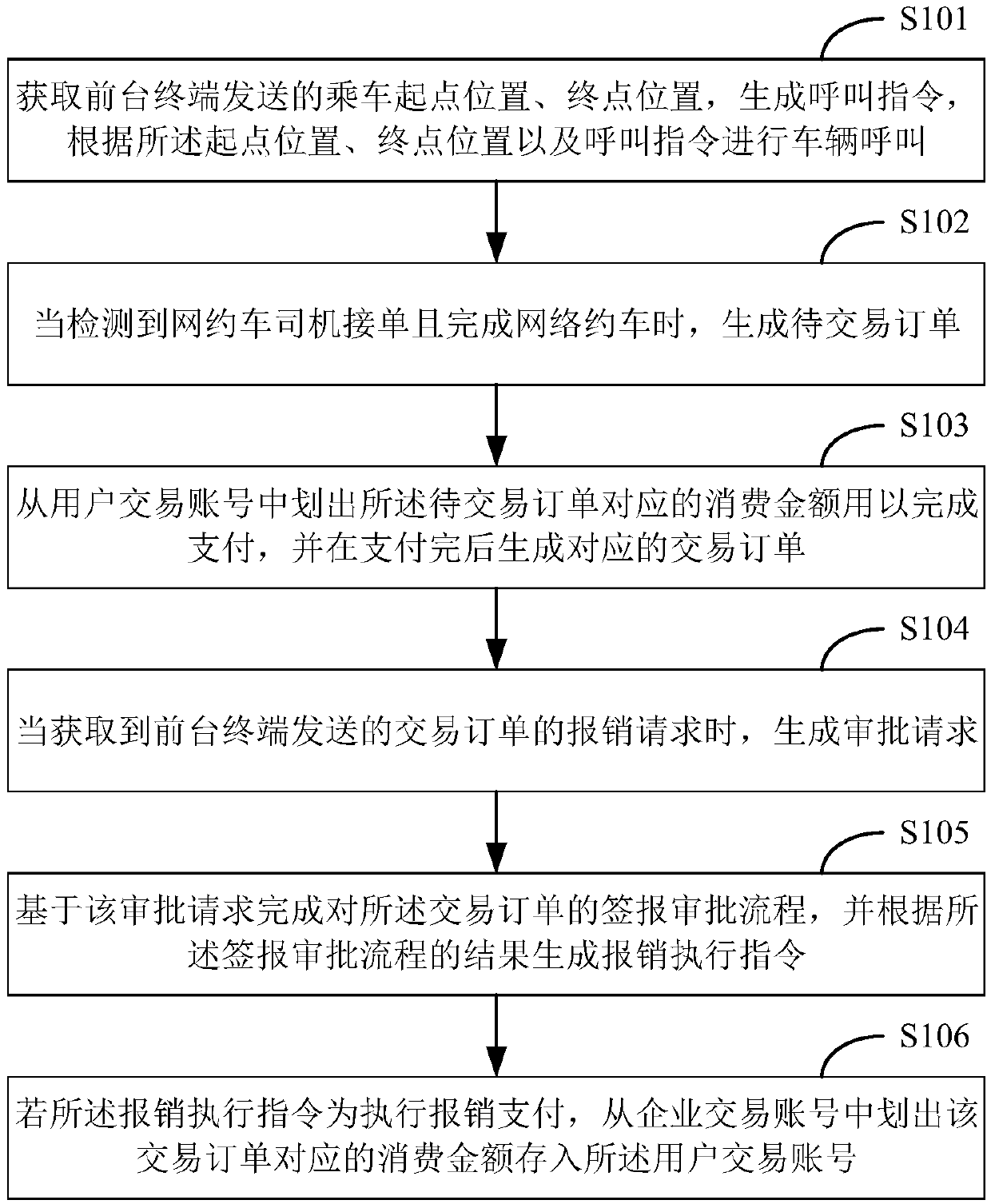

The invention belongs to the technical field of communication, and provides an online car-hailing settlement and reimbursement method. The method comprises the steps of acquiring a riding starting position and a riding ending position sent by a foreground terminal, generating a calling command and calling a car; upon detecting the order receiving state of an online car-hailing driver, completing the online car-hailing process and generating a to-be-transacted order; drawing a consumption amount corresponding to the to-be-transacted order from a user transaction account for completing the payment, and generating a transaction order; upon receiving a reimbursement request of the transaction order sent by the foreground terminal, generating an approval request; completing the signing and approving process of the transaction order the basis of the approval request, generating a reimbursement execution instruction, drawing the consumption amount corresponding to the to-be-transacted order from an enterprise transaction account, and storing the consumption amount in the user transaction account. The online settlement and online reimbursement of the online car-hailing process are realized, so that the problems of complex process and low efficiency during the car-hailing reimbursement process are solved. The risk management level of an enterprise on the car-hailing reimbursement process is improved.

Owner:PING AN TECH (SHENZHEN) CO LTD

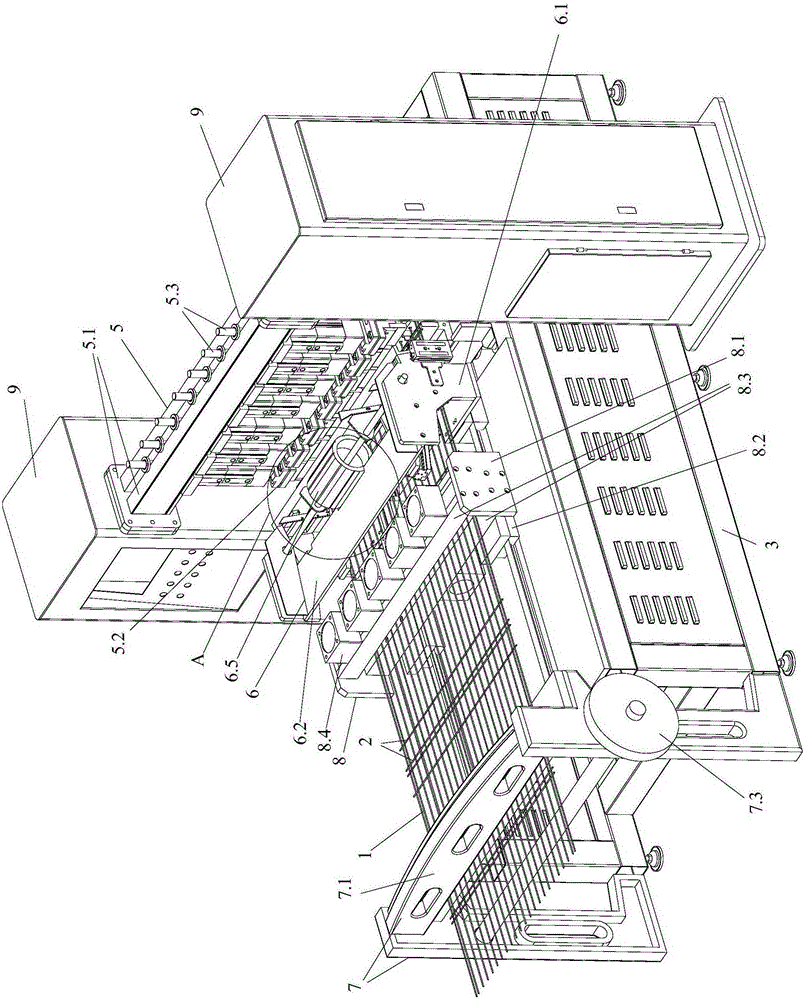

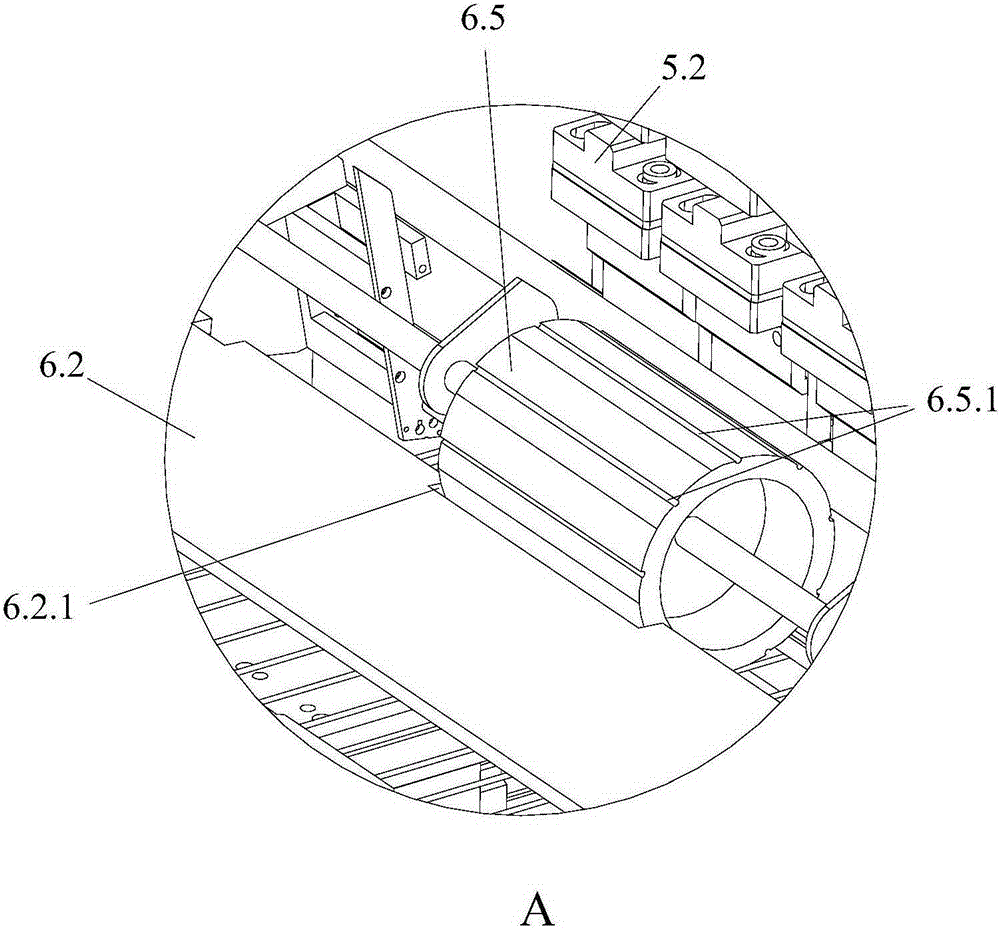

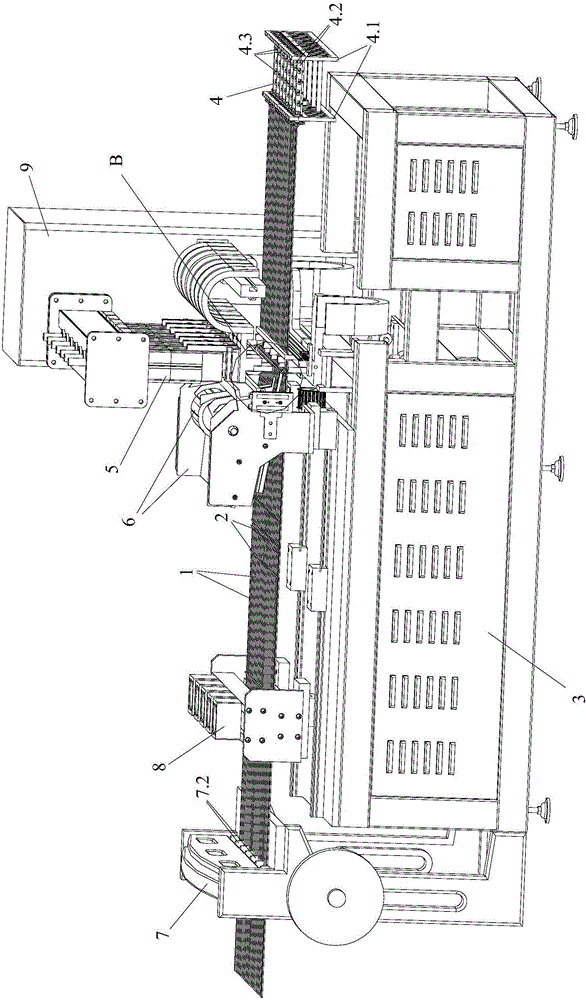

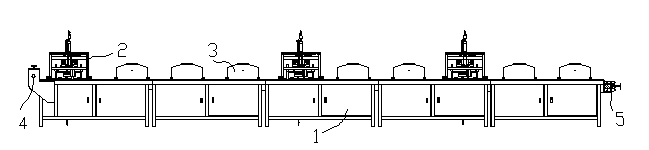

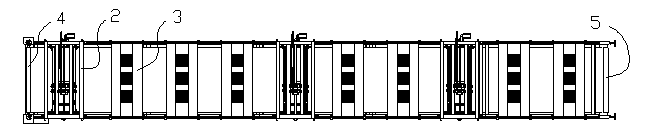

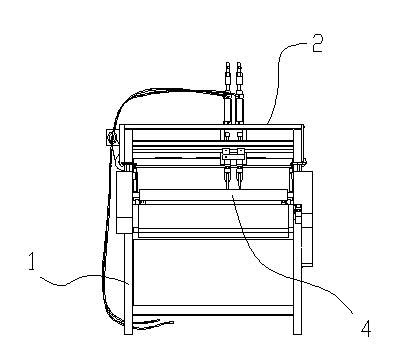

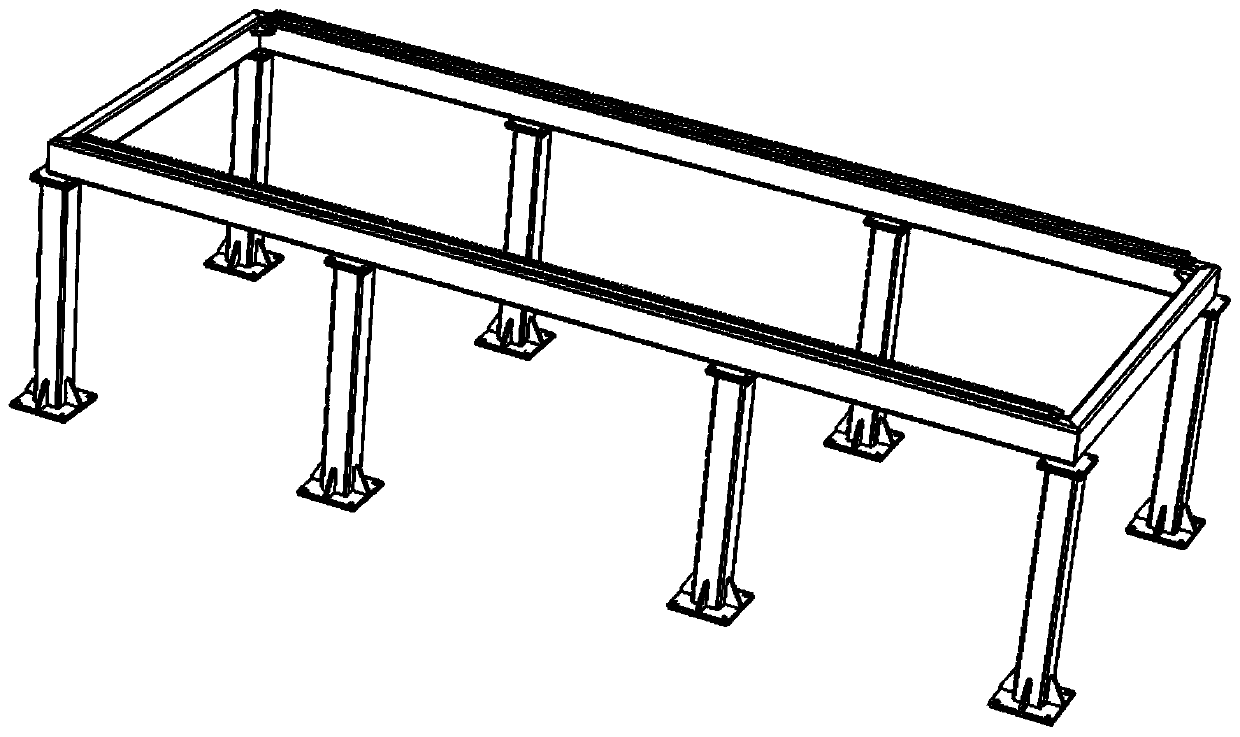

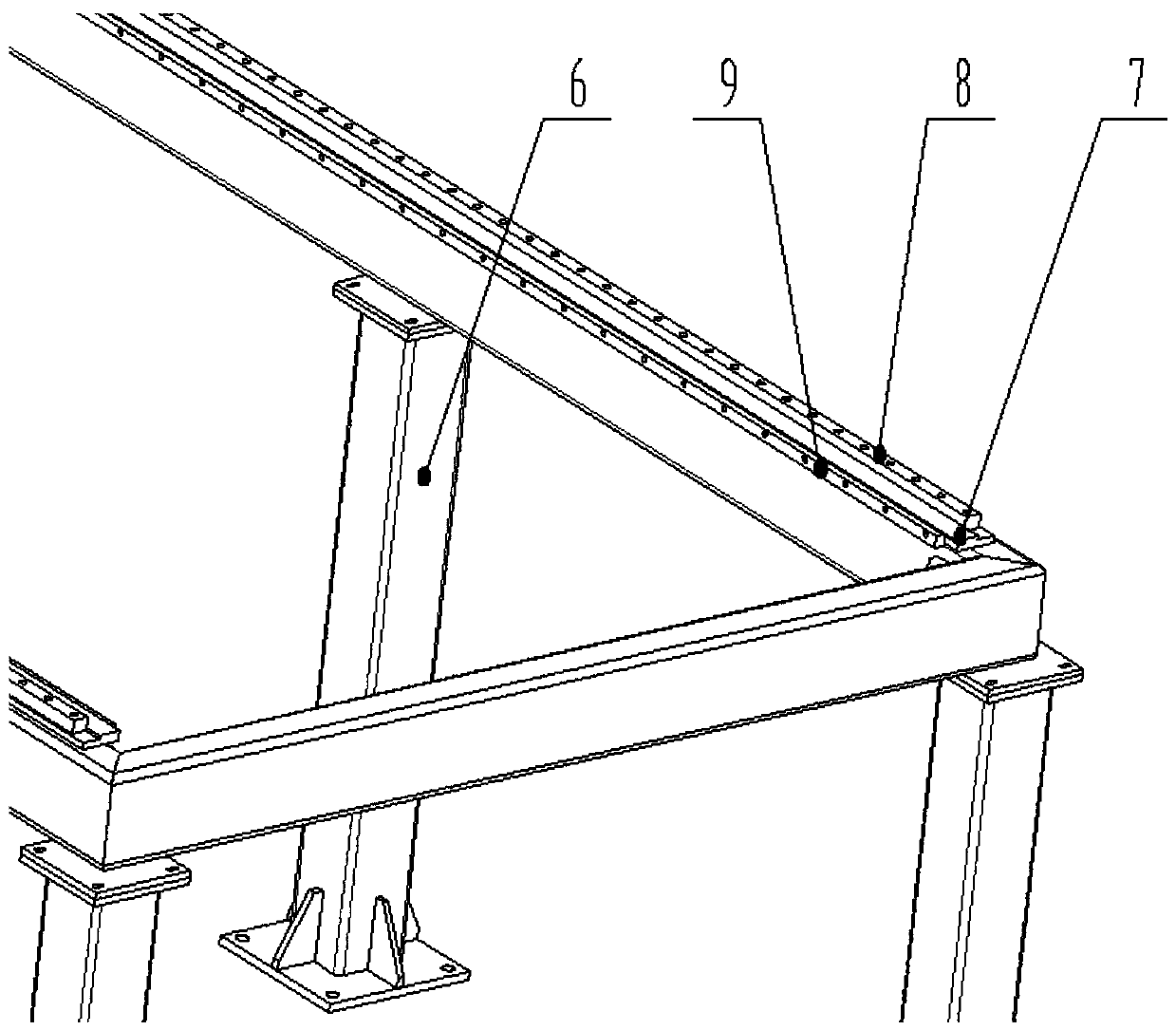

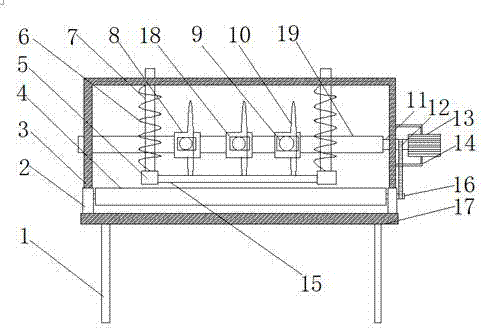

Automatic network-arranging welding equipment

ActiveCN105171263ASimple structureFast welding speedWelding/cutting auxillary devicesWire networkEngineeringWire mesh

The invention provides automatic network-arranging welding equipment which comprises the components of a frame; a longitudinal network wire arranging mechanism which is arranged at the front end of the frame and is used for straightening and arranging longitudinal network wires; a welding mechanism which bestrides the frame; a transverse network wire blanking mechanism which bestrides the frame and is arranged at one side of the welding mechanism and is used for conveying transverse network wires to the welding mechanism and performing positioning; a cutting mechanism which is arranged at the tail end of the frame and is used for cutting a metal wire network that is formed through welding; a wire drawing mechanism which is movably connected with the frame and is used for clamping the network wire and pushes the network wires to penetrate the welding mechanism and the transverse network wire blanking mechanism to the cutting mechanism; and control mechanisms which are arranged at two sides of the frame. The network-arranging welding equipment can realize full-automatic network-arranging welding of the metal wire network according to a production requirement, thereby replacing a traditional manual network-arranging welding process, improving production efficiency and settling the problems of low automatic degree and low production efficiency in an existing welding machinery industry.

Owner:佛山煜宁智能科技有限公司

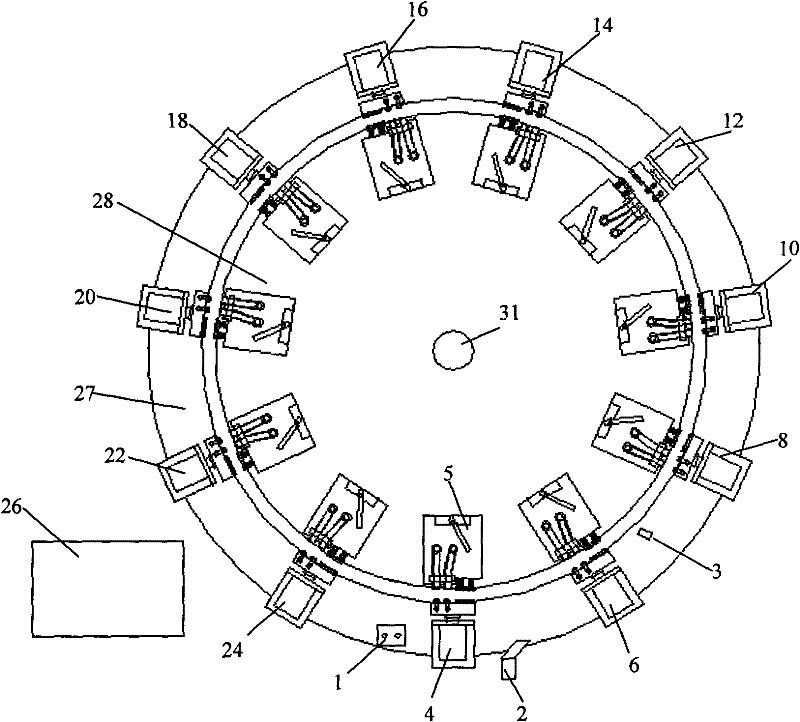

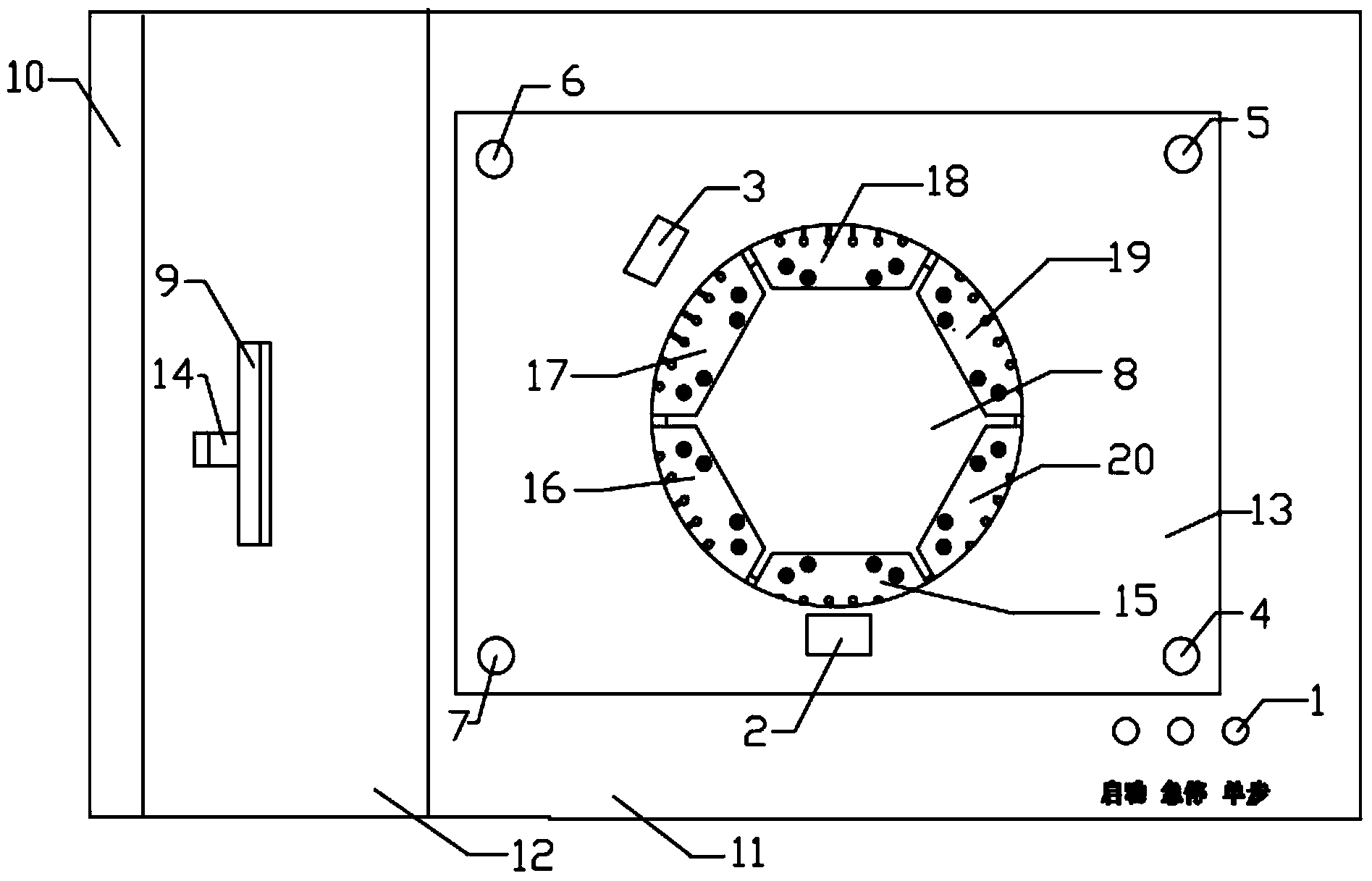

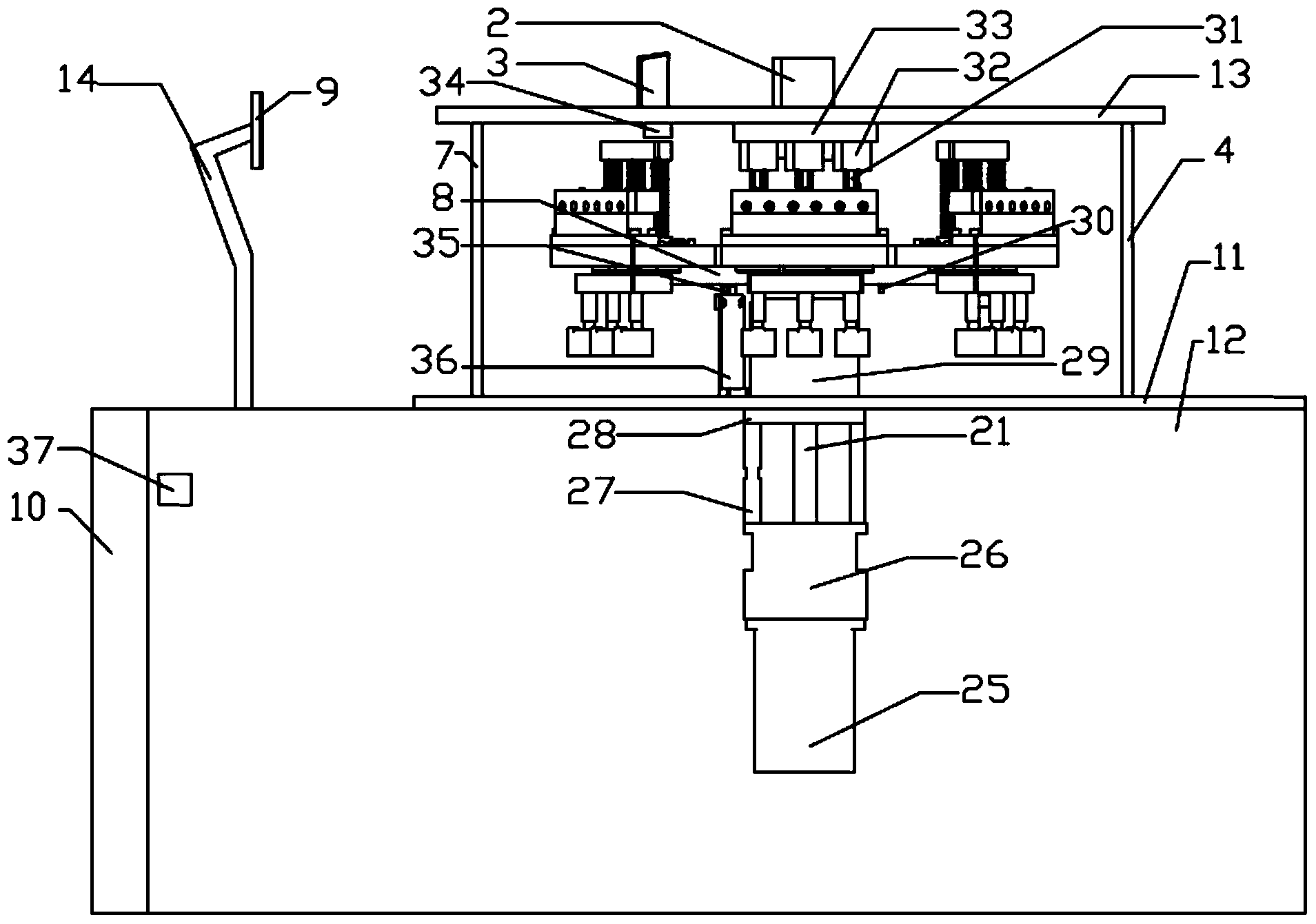

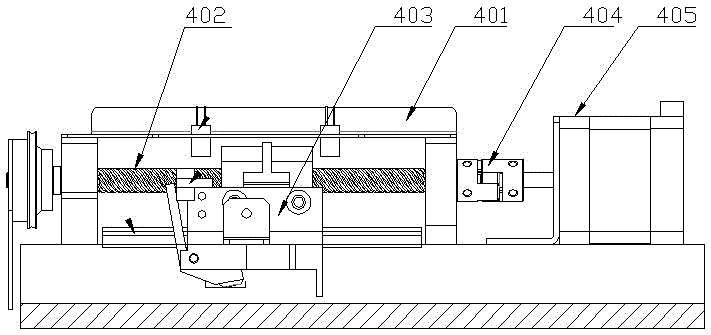

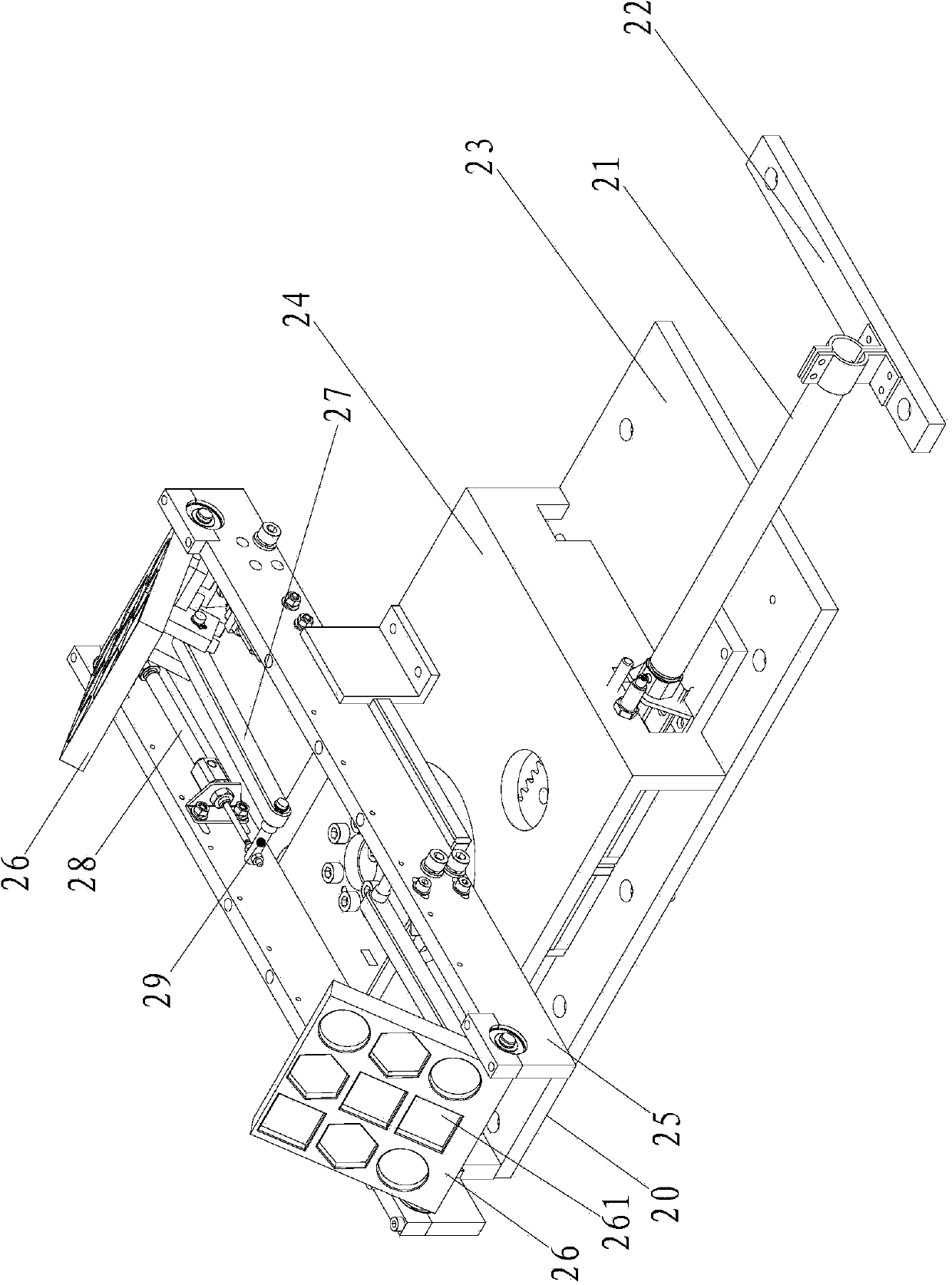

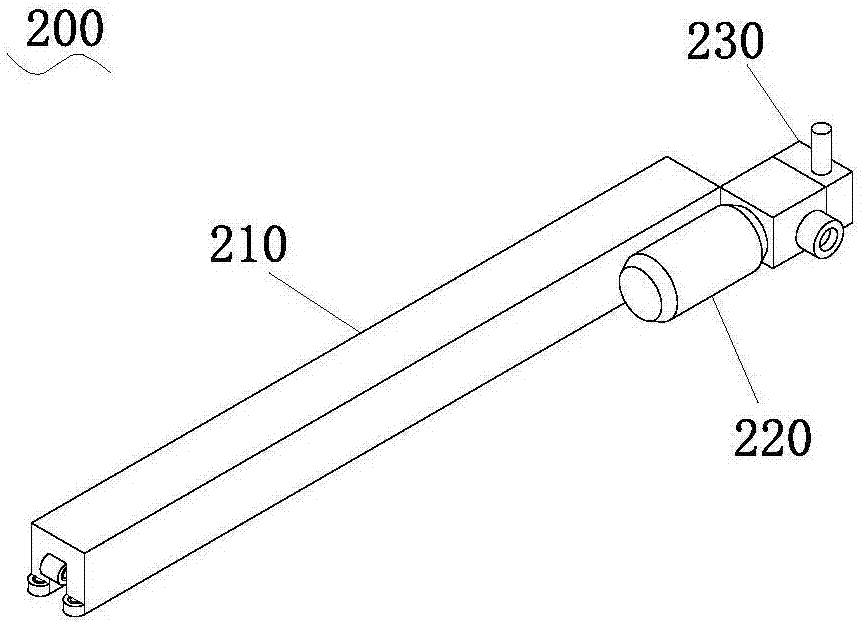

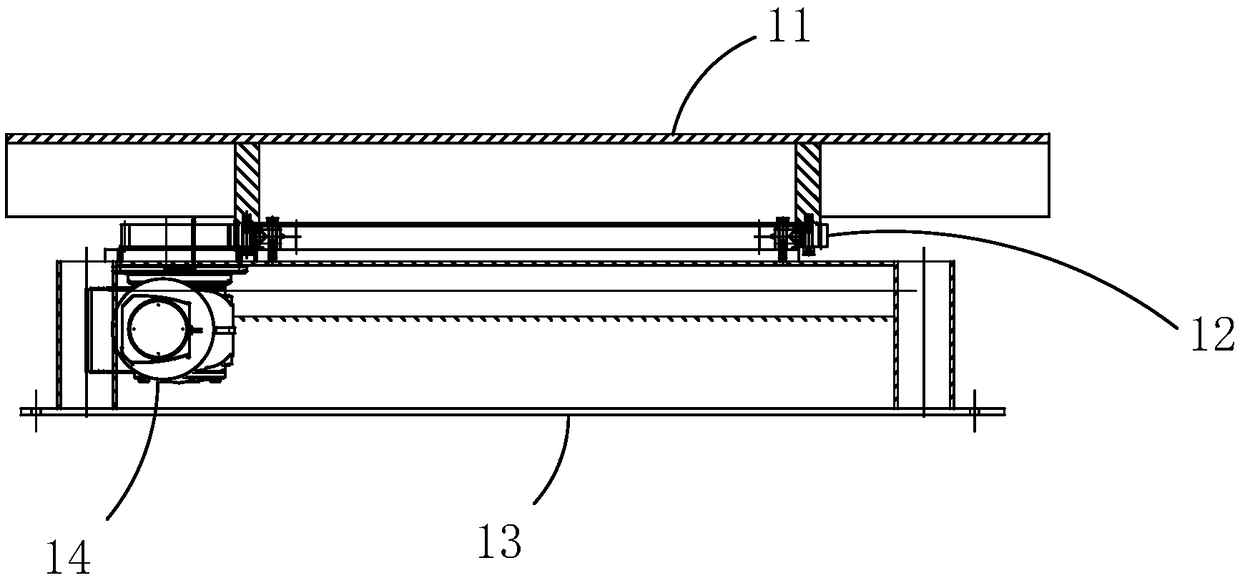

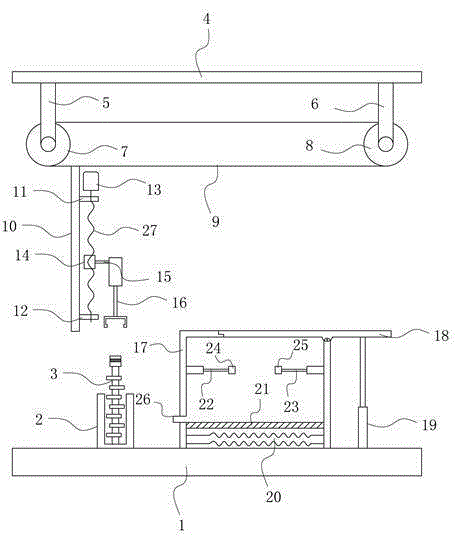

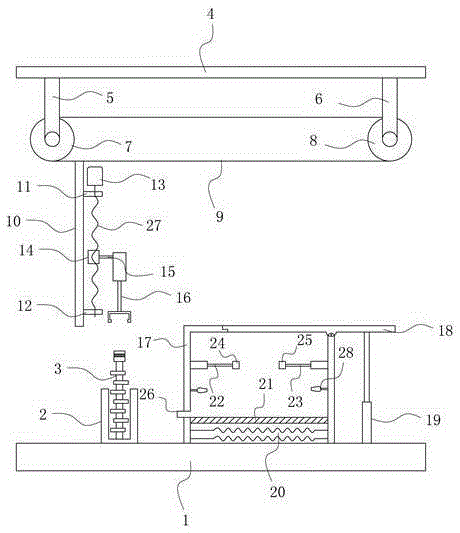

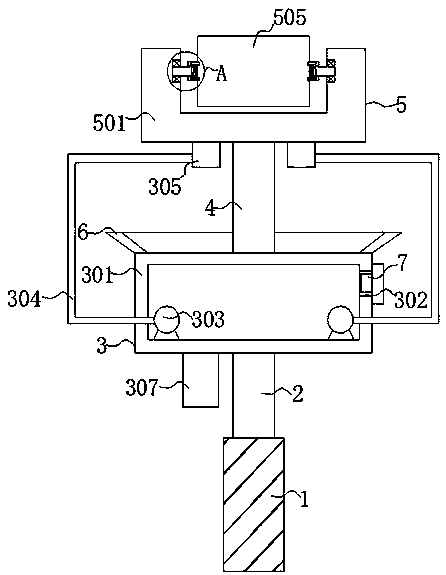

Electronic expansion valve rotary type multiple stations integration testing device

InactiveCN102230846AAddress the degree of automationSolve the disadvantage of re-clamping every time an index is measuredMachine part testingCombined testDifferential pressure

The invention discloses an electronic expansion valve rotary type multiple stations integration testing device. The device comprises a valve loading station, a valve closing station, a valve closing flow determination station, a valve opening point determination station 1, a valve opening point determination station 2, a zeroload flow determination station, a high pressure valve opening station, a loading flow determination station, a low flow determination station, a high flow determination station, a pulse setting station, a stationary work table, a swivelling angular table, an index dial, a control system and the like. During an operation, an operation worker takes down a measured valve from the valve loading station and put a valve to be measured in place after scanning. The valve to be measured is conveyed to each appointed station to realize operations of valve closing flow determination, valve opening point determination, maximal valve opening differential pressure, multi-pointflow determination, factory pulse setting and the like. In a present electronic expansion valve testing device, automation degree is low, a new clamp needs to be installed after testing each index, and a device can only test a performance index. According to the testing device in the invention, the above disadvantages are overcome, working time is saved and automation degree of testing is raised.

Owner:CHINA JILIANG UNIV

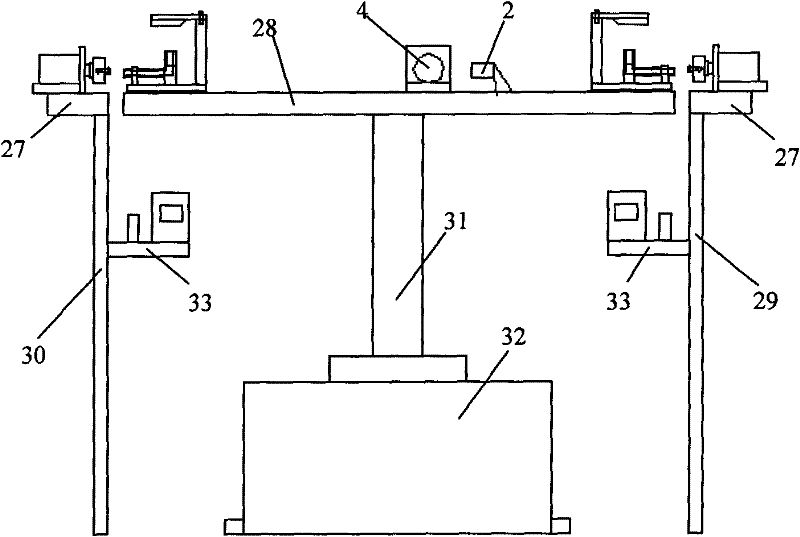

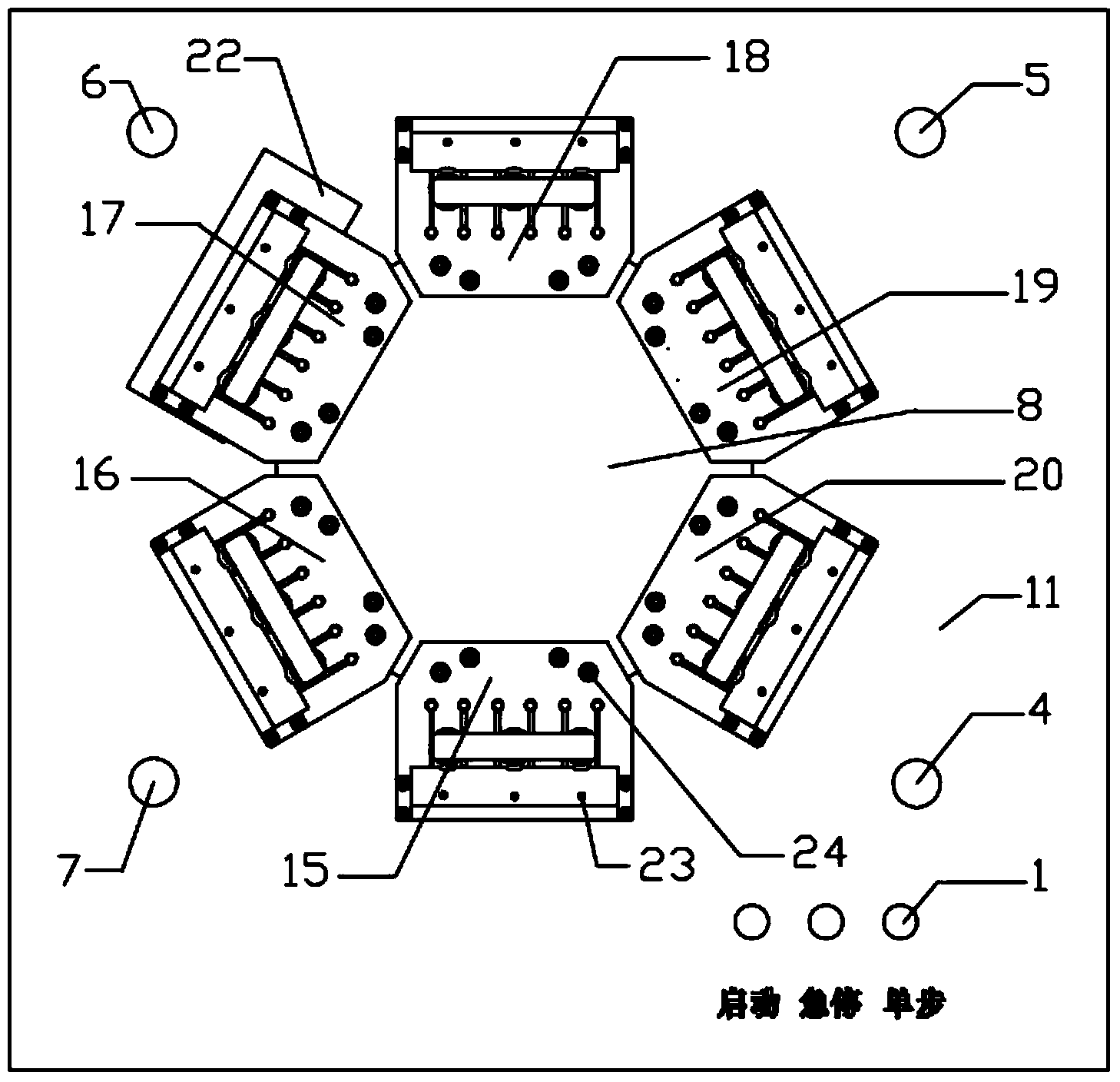

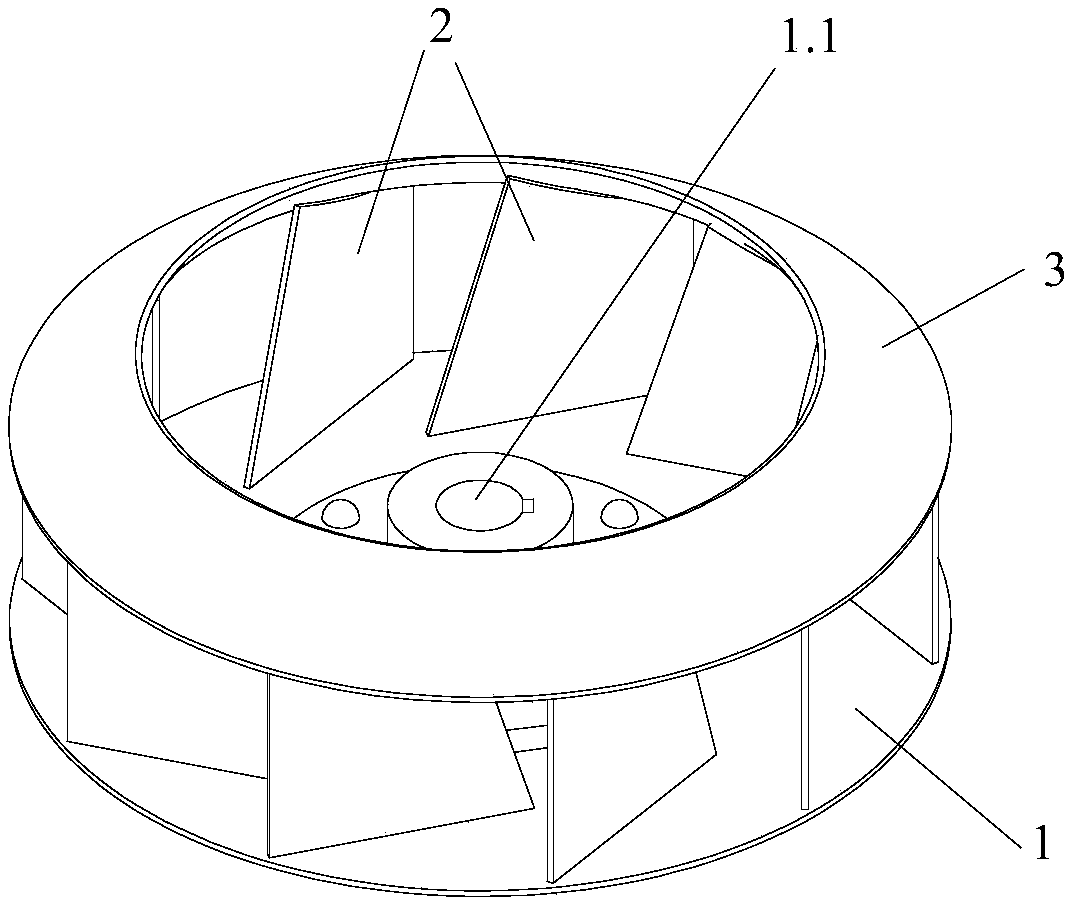

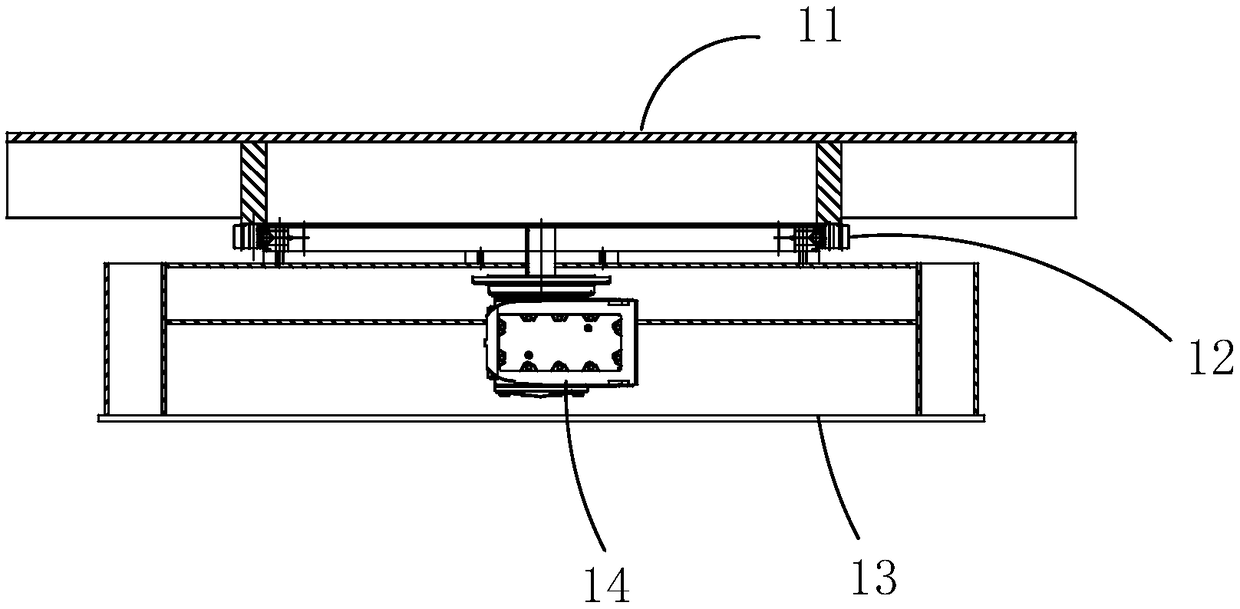

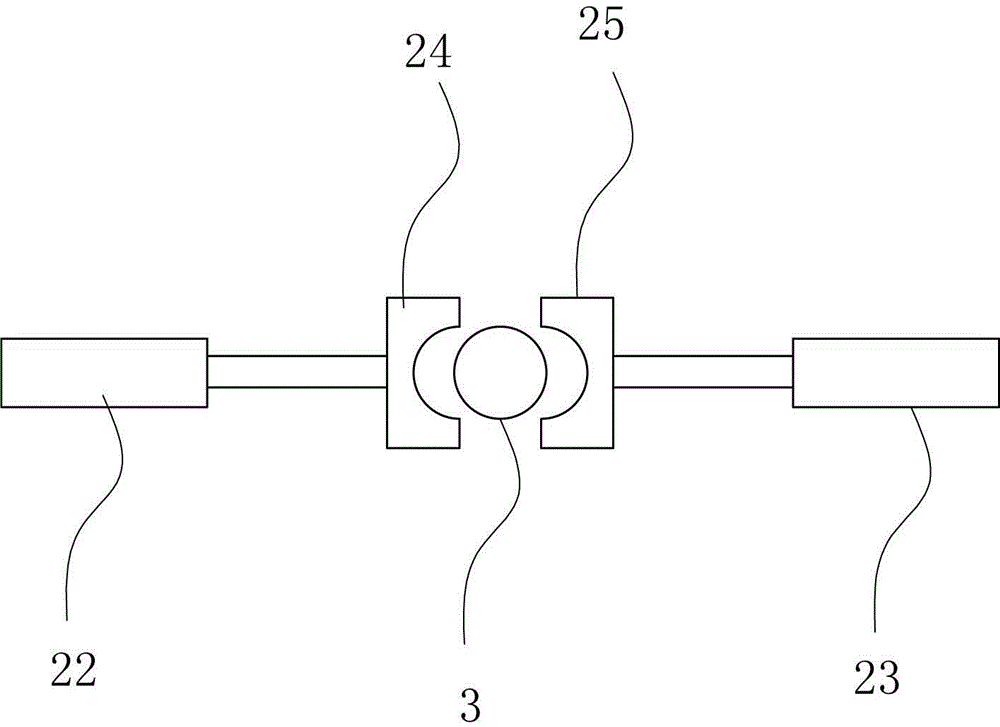

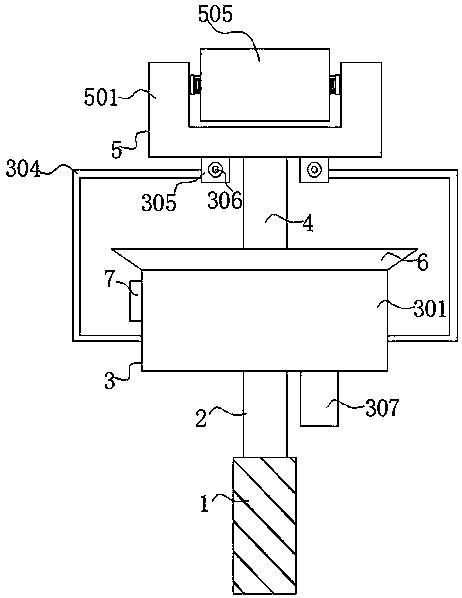

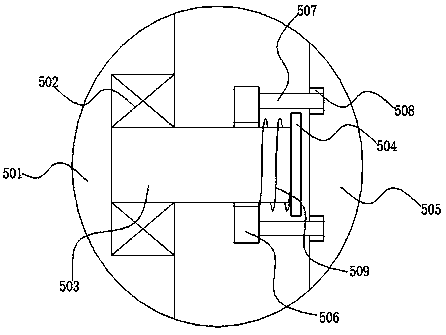

Rotation type multi-station combination property auxiliary testing device of solenoid valve coil

InactiveCN103472334AAddress the degree of automationSolve the disadvantage of re-clamping every time an index is measuredElectrical testingSolenoid valveEngineering

The invention discloses a rotation type multi-station combination property auxiliary testing device of a solenoid valve coil. A fixing bottom plate is arranged on a machine cabinet, a top plate is connected with the fixing bottom plate, a first connecting block is fixedly connected to the fixing bottom plate and connected with a stepping motor through a reduction gear, and a rotating shaft of the reduction gear is fixedly connected with a rotating working table. The rotating working table is installed on the fixing bottom plate through a rotating supporting column, the rotating working table, the rotating supporting column and the rotating shaft are coaxial, and an optoelectronic switch is installed on the fixing bottom plate through a first fixing block. Six blocking pieces are evenly installed on the lower bottom surface of the rotating working table in the circumferential direction in a partitioning mode. Same six measuring tools are evenly installed on the rotating working table in the circumferential direction, and four periphery tools are fixed over the top plate. Flow line production is adopted for the rotation type multi-station combination property auxiliary testing device, kinds of auxiliary measurement are achieved through one-time disassembly, production efficiency is high, labor cost is low, working time is saved, a gas circuit is simple, mutual interference is small, and production tempos of each product meet requirements of enterprise production.

Owner:CHINA JILIANG UNIV

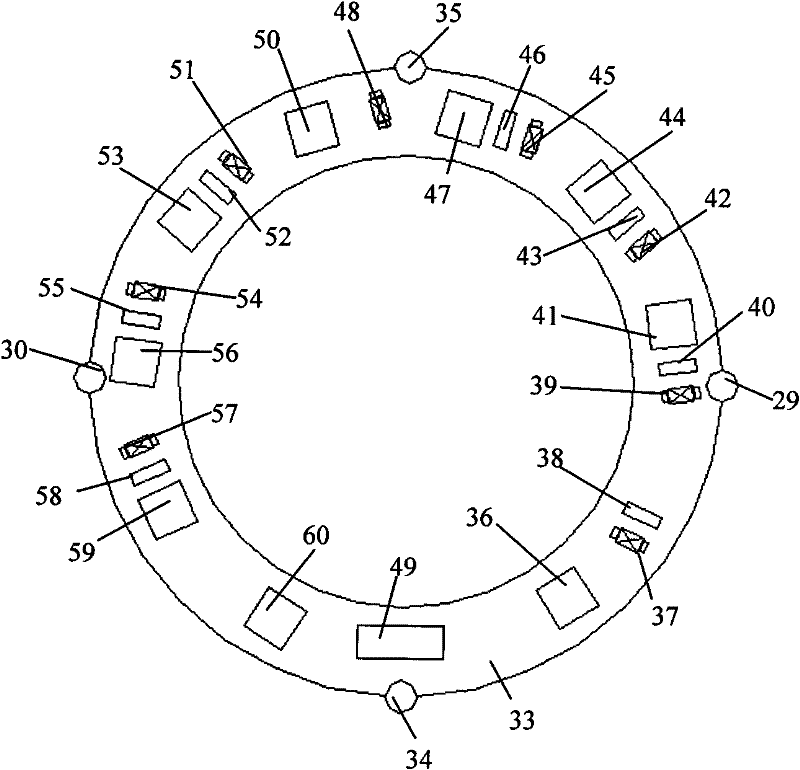

Full-automatic screen printer

The invention provides a full-automatic screen printer. The full-automatic screen printer comprises a control system, a workbench, a plurality of printing systems and a plurality of ovens, wherein the printing systems and the ovens are arranged on the workbench and used for multi-color printing. The control system is connected with the multiple printing systems to control the operation time sequence of the printing systems. Each printing system comprises a rack, a sliding rail, a scraper support, an air cylinder, a scraper, a stepping motor and a transmission belt, wherein the sliding rail is arranged on the rack; the scraper support is arranged on the sliding rail in a sliding mode; the air cylinder is perpendicularly arranged on the scraper support; the scraper is arranged at the outer end of a piston rod of the air cylinder; the stepping motor is arranged on the rack; the transmission belt is connected with an output shaft of the stepping motor, and the scraper support is fixed to the transmission belt. The full-automatic screen printer not only can achieve automation of the screen printing technology, but also is simple in structure and low in cost and well solves the problem that in the prior art, the high automation degree and the low cost can not be achieved at the same time.

Owner:XIAMEN DAILISHI AUTOMATION EQUIP

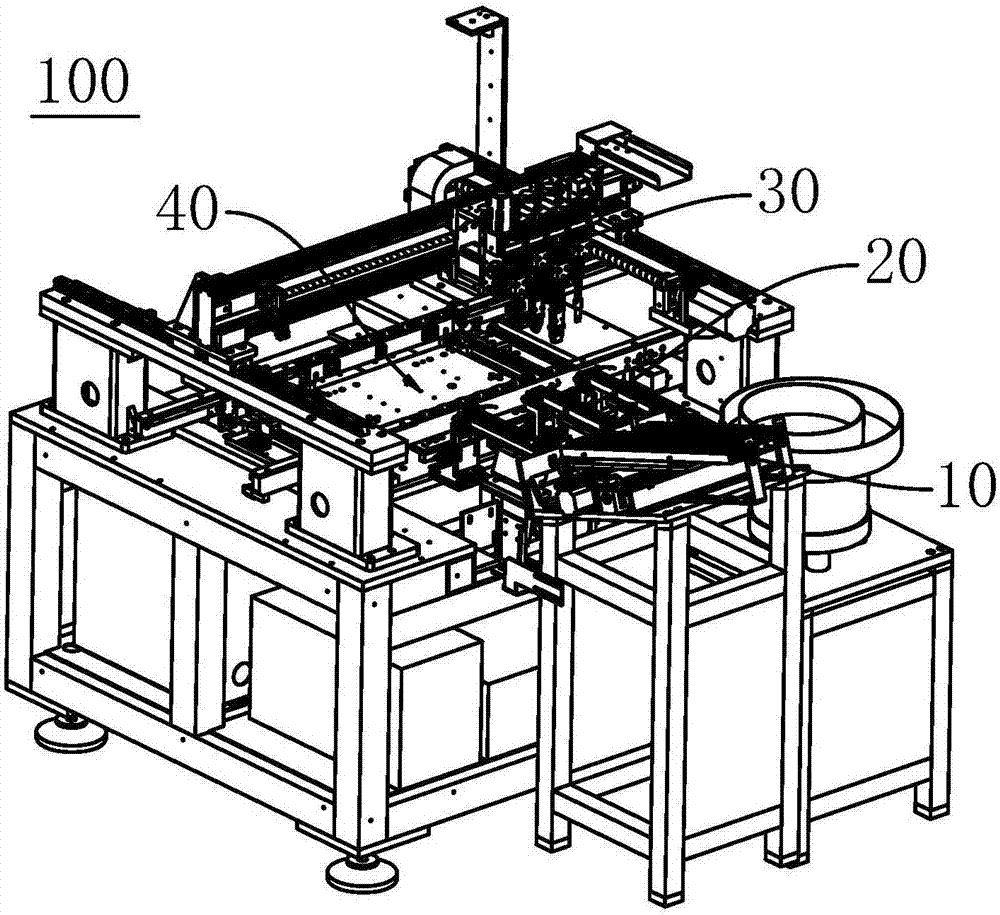

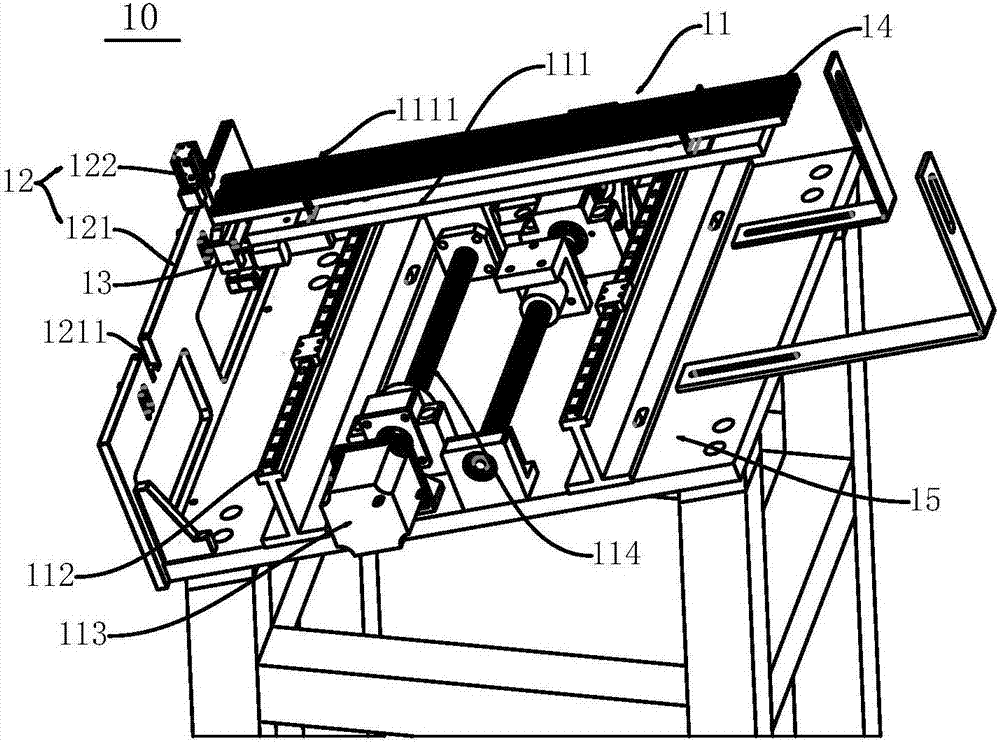

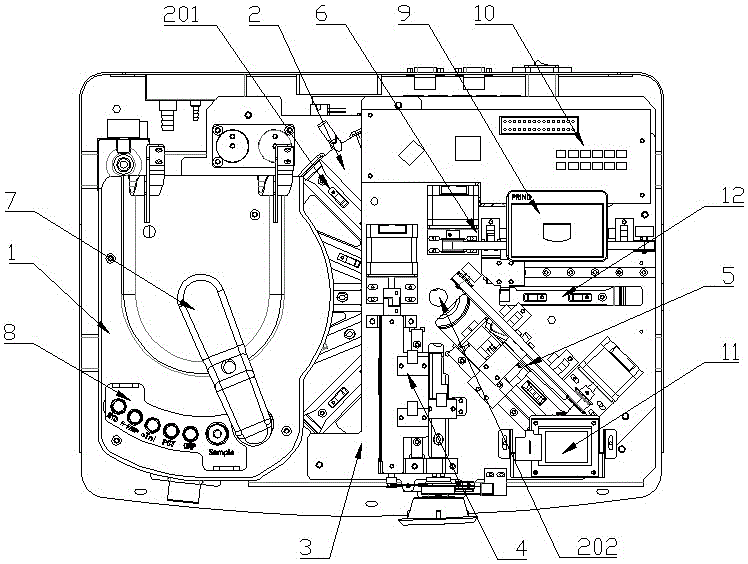

Automatic component insertion machine

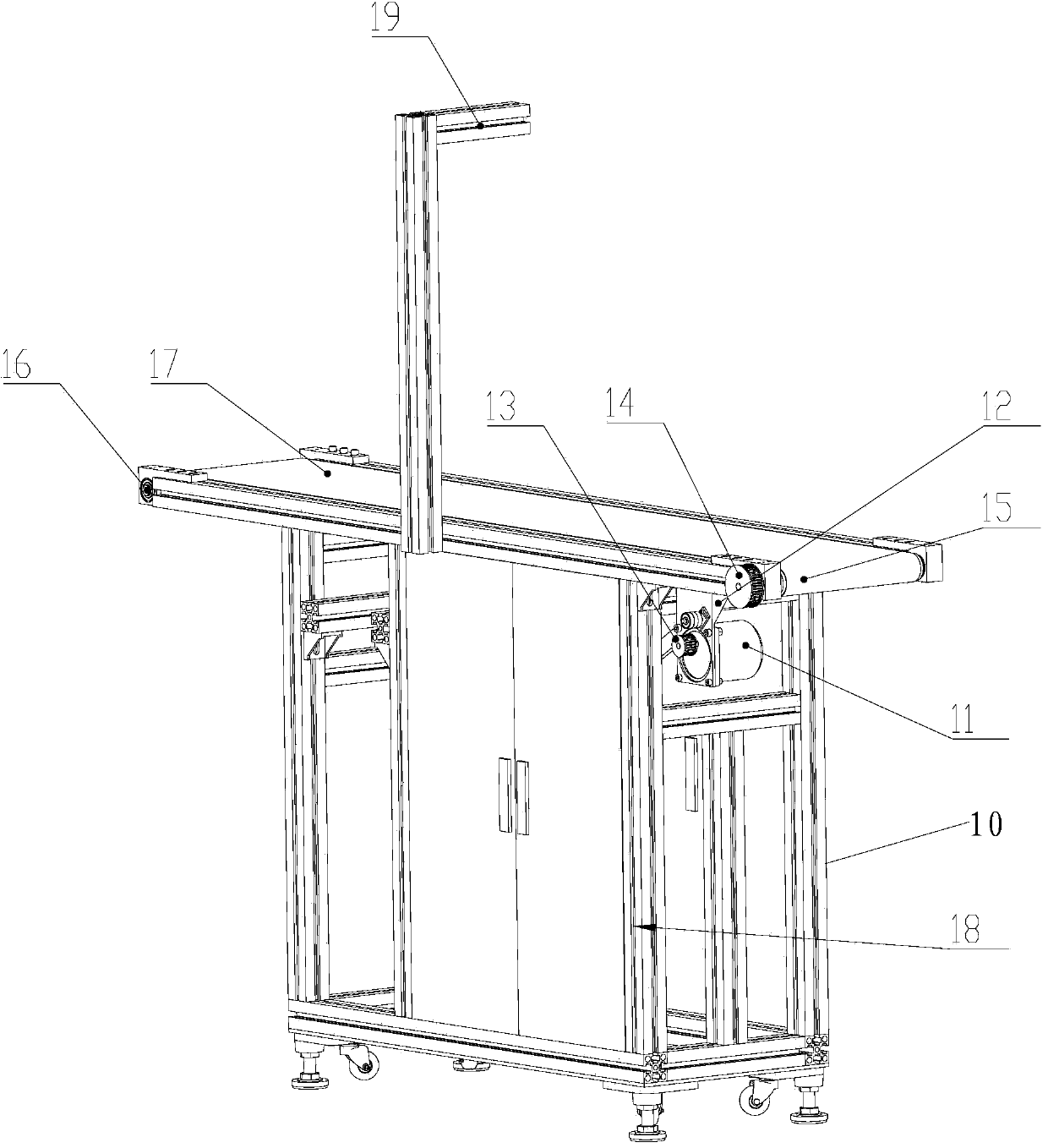

ActiveCN106879248AAddressing Structural ComplexityAddress the degree of automationPrinted circuit assemblingElectrical componentsEngineeringMaterial supply

The invention provides an automatic component insertion machine. The automatic component insertion machine comprises a material supplying apparatus, a material conveying apparatus, a PCB conveying apparatus and a component insertion mechanical arm apparatus; the material conveying apparatus is provided with a capturing station for allowing the component insertion mechanical arm apparatus to capture a material; the material conveying apparatus is connected to the tail end of the material supplying apparatus; the PCB conveying apparatus is provided with an operation region for allowing the component insertion mechanical arm apparatus to perform material insertion and connection, and is used for conveying the PCB; the PCB conveying apparatus is arranged on one side, back to the material supplying apparatus, of the capturing station; the PCB conveying apparatus comprises a PCB conveying mechanism and a PCB fixing driving mechanism; the component insertion mechanical arm apparatus is used for performing material insertion and connection on the PCB; and the component insertion mechanical arm apparatus is arranged above the PCB conveying apparatus. By virtue of the setting of the material supplying apparatus, the material conveying apparatus, the component insertion mechanical arm apparatus and the PCB conveying apparatus, the structure of the automatic component insertion machine is simplified, the cost is lowered and working efficiency is improved.

Owner:SHENZHEN TECHWIN PRECISION MACHINERY

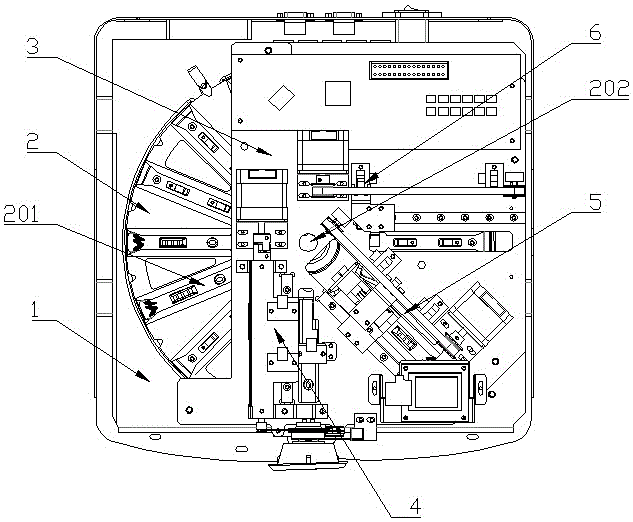

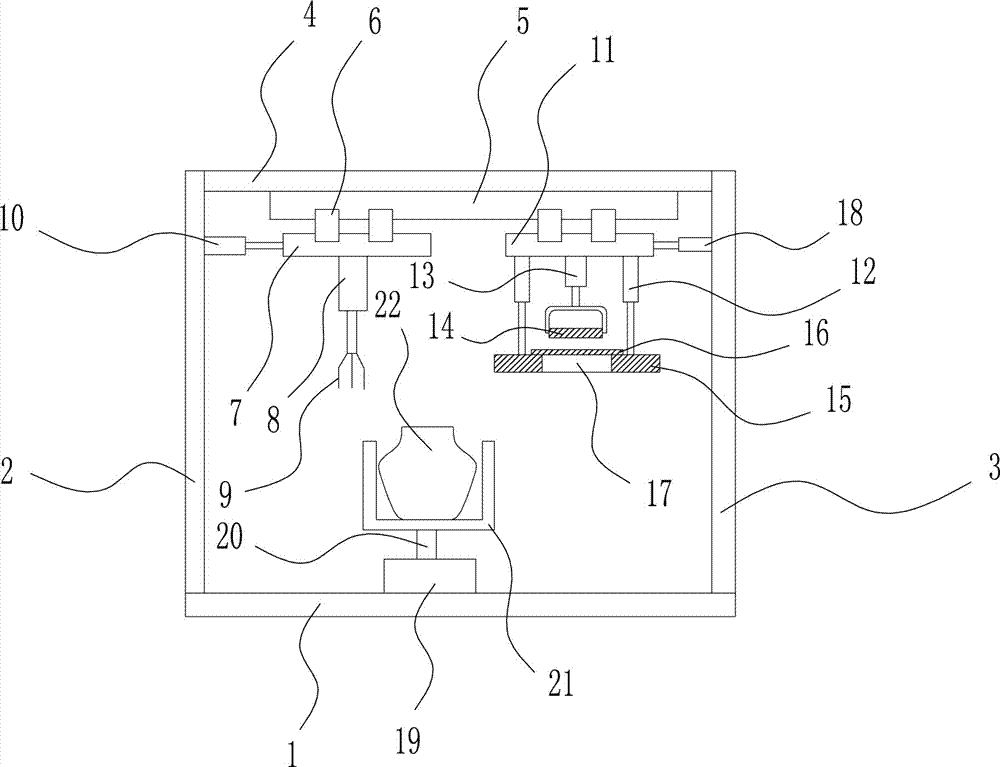

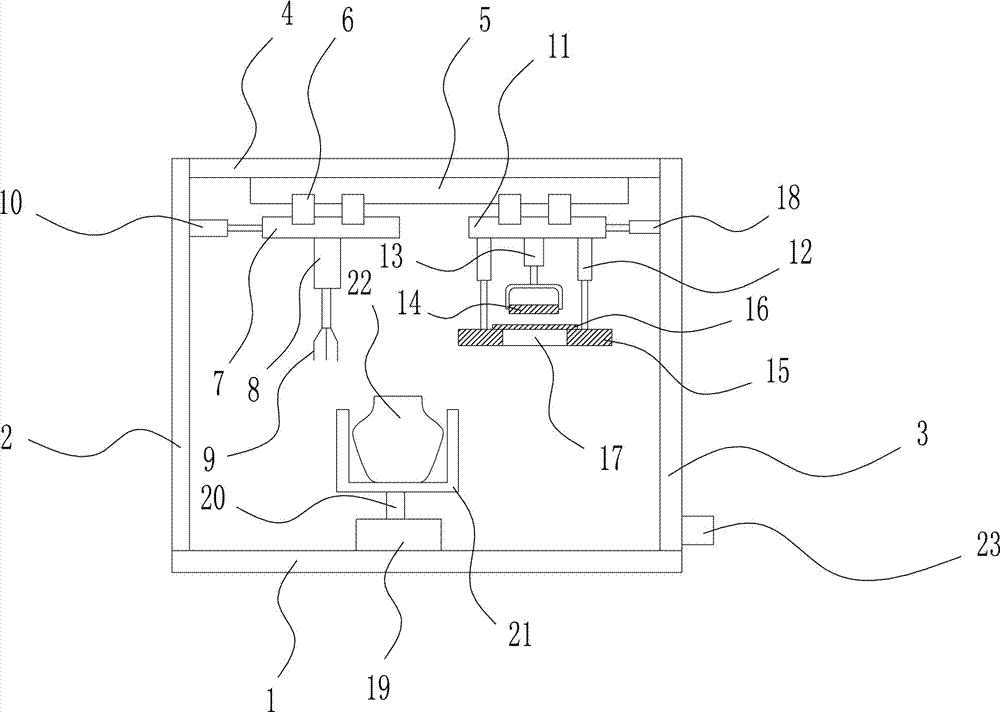

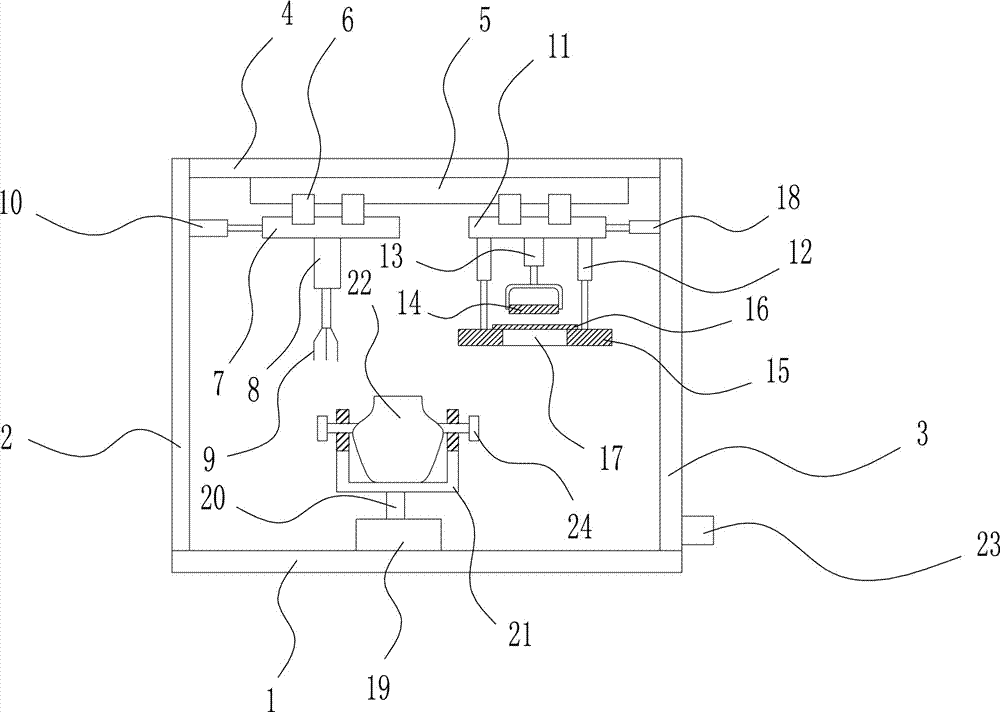

Multi-channel dry type immunofluorescence detector

InactiveCN105866452ARealize automatic continuous detection and analysisSolve the speed problemMaterial analysisImmunofluorescenceEngineering

The invention relates to a multi-channel dry type immunofluorescence detector which comprises a mounting platform. An incubation rotary disc, an automatic card inlet unit, an automatic measuring unit and an automatic card outlet unit are mounted on the right side of the mounting platform. A mounting plate is mounted above the incubation rotary disc. The automatic card inlet unit, the automatic measuring unit and the automatic card outlet unit are mounted on the mounting plate. A sample adding unit and a sample and reagent unit are arranged on the left side of the mounting platform. The multi-channel dry type immunofluorescence detector has the advantages of being high in speed, high in efficiency, capable of carrying out multi-channel mass detection and high in precision.

Owner:HUNAN DISAI BIOTECH CO LTD

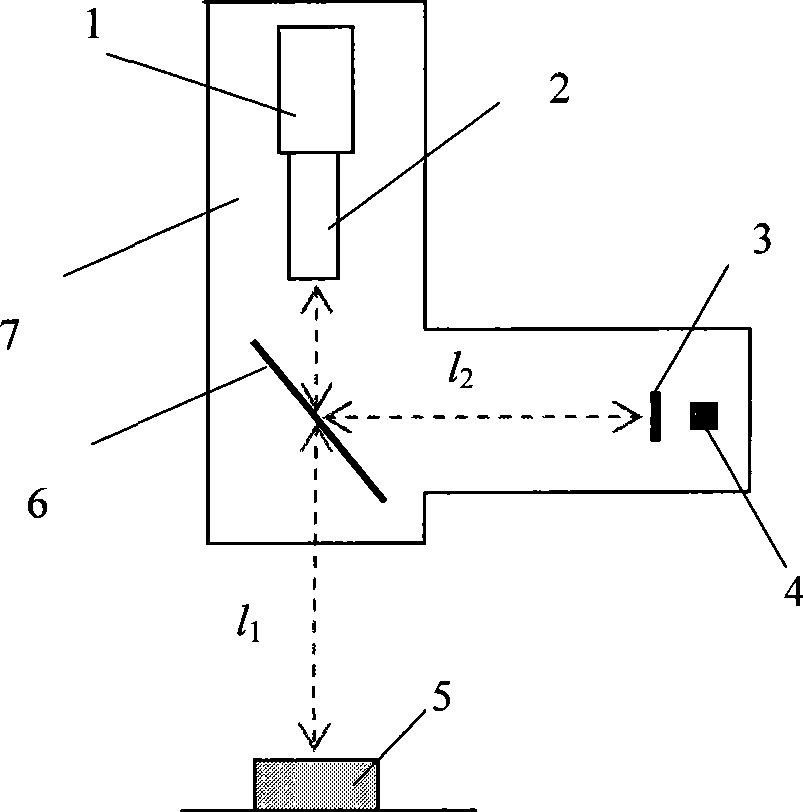

Self-demarcating system and method for vision detecting system

InactiveCN101509759ASolve efficiency problemsSolve operational problemsUsing optical meansCamera lensOptical axis

The invention relates to a self-calibration system used for a visual inspection system in the field of precise testing technology and a method. The self-calibration system comprises parts of a CCD camera, a lens, a standard component, a light source, a dichroic mirror, a shell and the like. The lens is directly connected with the camera, put right above a measured piece and directed at the measured piece. A dichroic mirror is arranged between the lens and the measured piece and keeps 45 degrees with the optical axis of the lens. The standard component and the light source are arranged at the side of the dichroic mirror, wherein the light source and the dichroic mirror are respectively arranged at the different sides of the standard component. A calibrated light path formed by the dichroic mirror, the standard piece and the light source is in orthogonal intersection with an original measurement light path. When an object to be measured is within the range of depth of field, the distance between the center of the dichroic mirror and the clear surface of the object to be measured has a unique definite corresponding relation with the distance between the center of the dichroic mirror and a calibration object. Therefore, the embedded standard component can be used for realizing the calibration of the visual inspection system without manual intervention.

Owner:上海砺晟光电技术有限公司

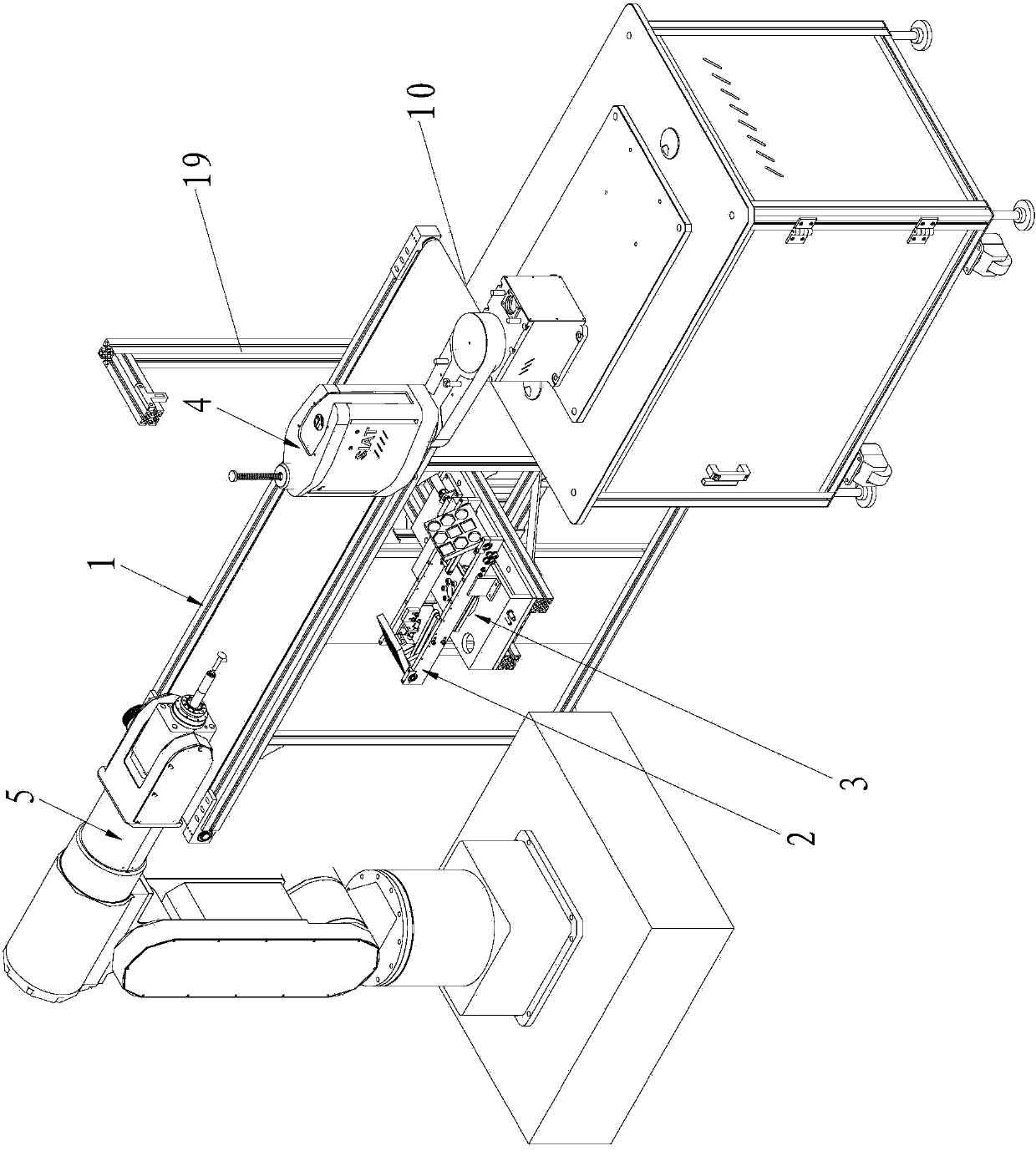

Automatic workpiece conveying and assembling production system and method

ActiveCN103625920AAddress usability issuesAddressing Structural ComplexityManipulatorConveyor partsEngineeringMaterial storage

The invention discloses an automatic workpiece conveying and assembling production system and method suitable for the technical field of automatic production systems. The production system comprises a transmission device, a material accommodating device, a rotating drive device, a first industrial robot and a second industrial robot. The material accommodating device is provided with at least two material storage discs; an image recognition device is arranged above the transmission device and / or the material accommodating device. The production method includes the following steps that photos of different teaching workpieces are taken through the image recognition device, and then the workpieces are alternatively taken out of the material accommodating device and conveyed to the transmission device through the first industry robot; photos of the teaching workpieces on the transmission device are taken through the image recognition device, and then the workpieces are clamped into the material accommodating device from the transmission device through the second industrial robot. The automatic workpiece conveying and assembling production system and method are perfect in adaptability, high in production efficiency and convenient to adopt.

Owner:SHENZHEN INST OF ADVANCED TECH CHINESE ACAD OF SCI

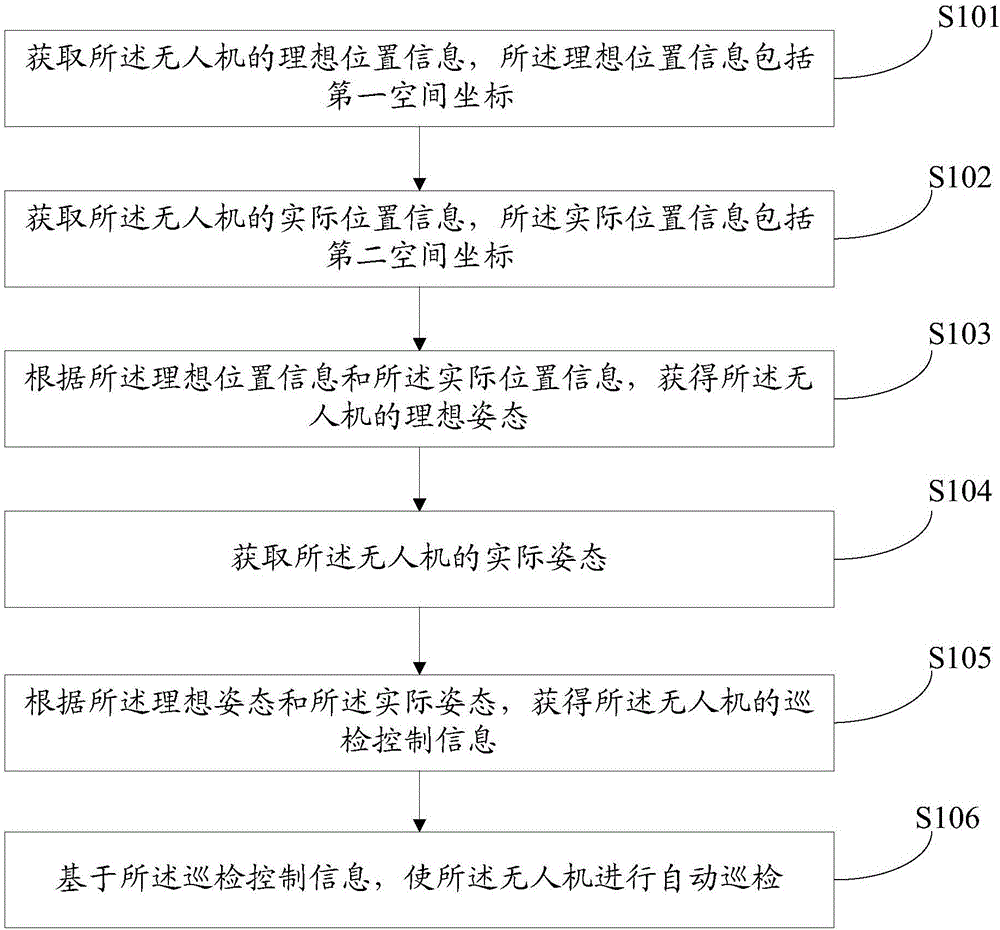

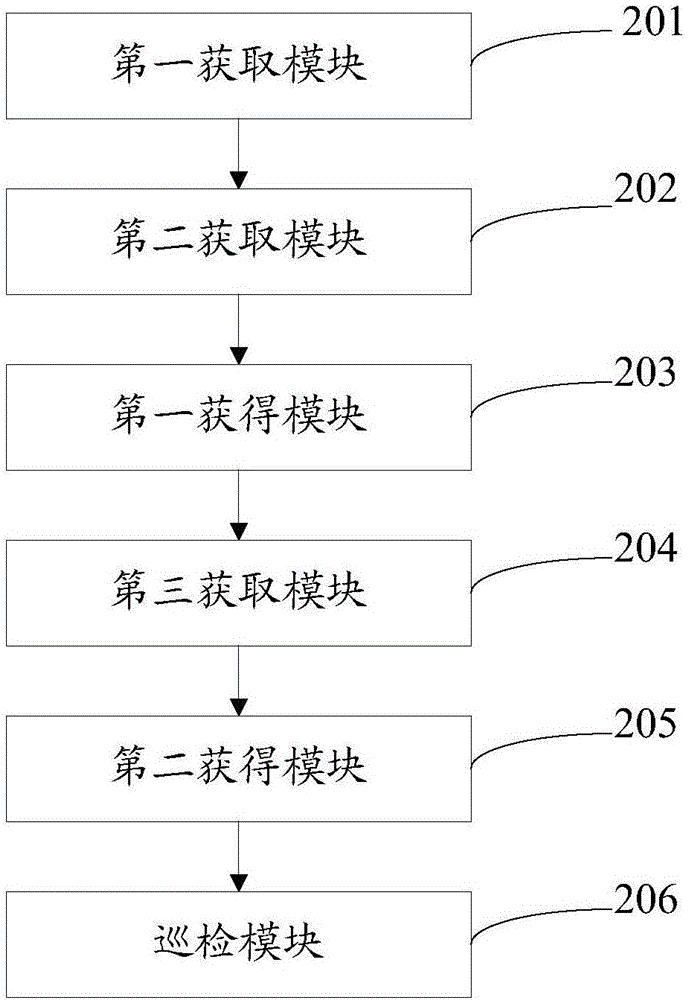

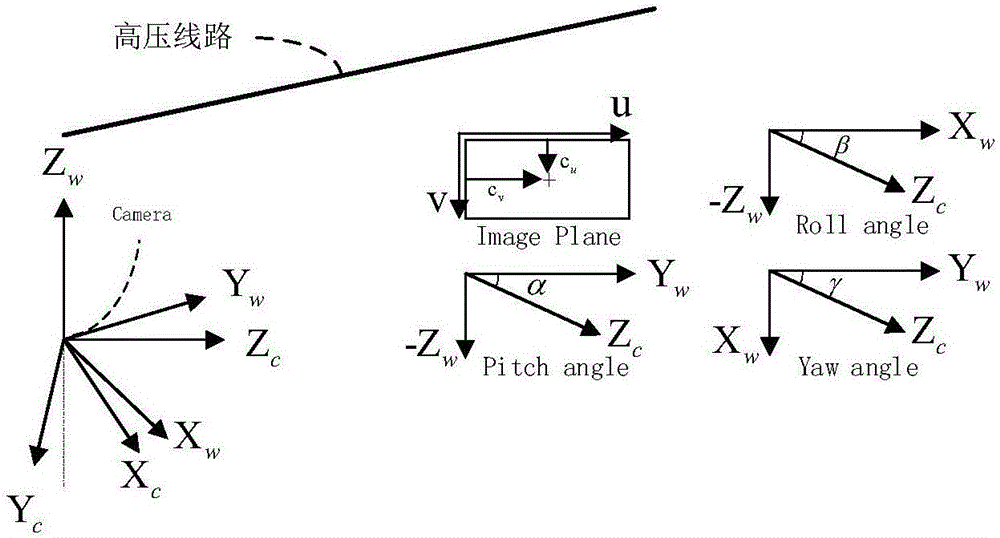

Drone automatic inspection method and system

InactiveCN106774374AImprove flight accuracySolve the accuracy problemAttitude controlSimulationAutonomation

The invention discloses a drone automatic inspection method and system. The method comprises the following steps: (1) obtaining the ideal position information of the drone, wherein the ideal position information comprises the first space coordinate, (2) obtaining the mathematics position information of the drone , wherein the mathematics position information comprises the second space coordinate, (3) obtaining the ideal posture of the drone according to the ideal and mathematics position information, (4) obtaining the practical posture of the drone, (5) obtaining the inspection and control information of the drone according to the ideal and practical posture and the drone implements the automatic inspection based on the inspection control information. Drone automatic inspection method and system are capable of solving the technical problem in prior art of low flight accuracy and automatic level in the automatic inspection process of the drone and realizing the technical effects of drone of full-automatic inspection and high flight accuracy.

Owner:WUHAN UNIV OF SCI & TECH

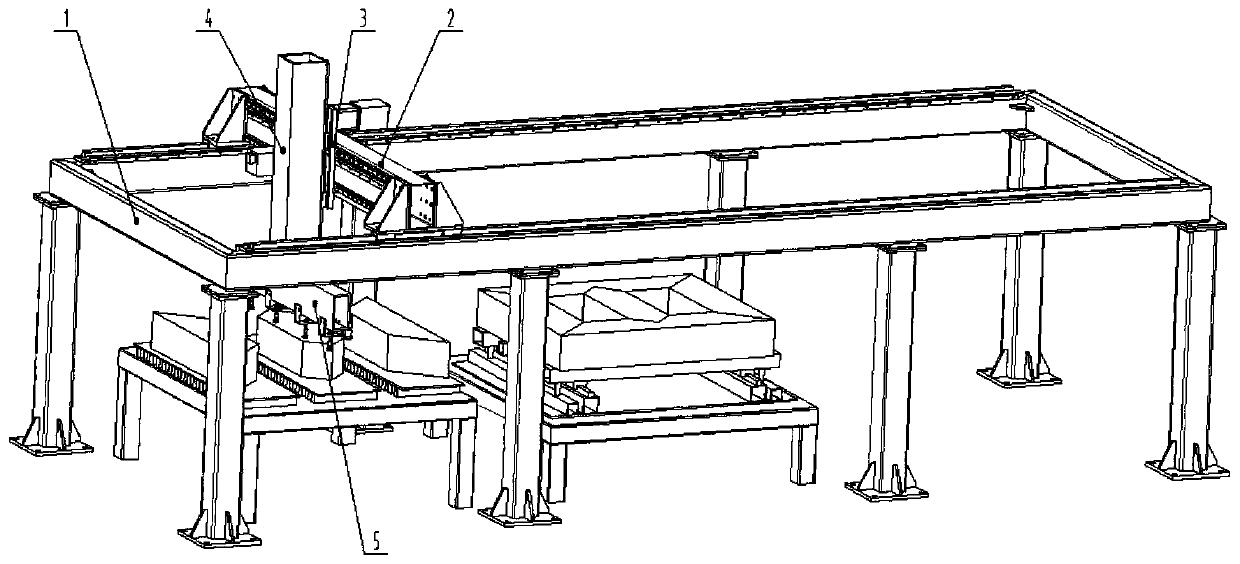

Automatic lamination robot for transformer iron core

PendingCN110534334ASolve efficiency problemsAddress the degree of automationProgramme-controlled manipulatorGripping headsImaging processingFree rotation

The invention discloses an automatic lamination robot for a transformer iron core and can solve technical problems of low efficiency, light labor and high intensity of the transformer iron core lamination process in the prior art. The robot comprises a main frame supporting large cross beam assembly, wherein the large cross beam assembly can move front and back on a main frame, a transverse movingassembly is installed on the large cross beam assembly and can move left and right, a longitudinal moving assembly is installed on the transverse moving assembly and can move up and down, and a rotating assembly is installed at a tail end of the longitudinal moving assembly and can rotate freely. An industrial camera installed at the tail end of the rotating assembly can shoot an overall pictureof a feeding area, the position of a silicon steel sheet to be sucked by a mechanical arm is determined through image processing and identification, the position of the mechanical arm is adjusted to just face the to-be-sucked silicon steel sheet, and thereby the truss mechanical arm is controlled for completing single-sheet suction of the silicon steel sheet. The robot is advantaged in that the required silicon steel sheet can be automatically identified in an image identification mode, the position of the mechanical arm is automatically corrected, the silicon steel sheet is grabbed and placedat the designated position of a lamination table, the lamination quality and efficiency are improved, and labor intensity of workers is reduced.

Owner:HEFEI YUANZHEN ELECTRIC POWER TECH +1

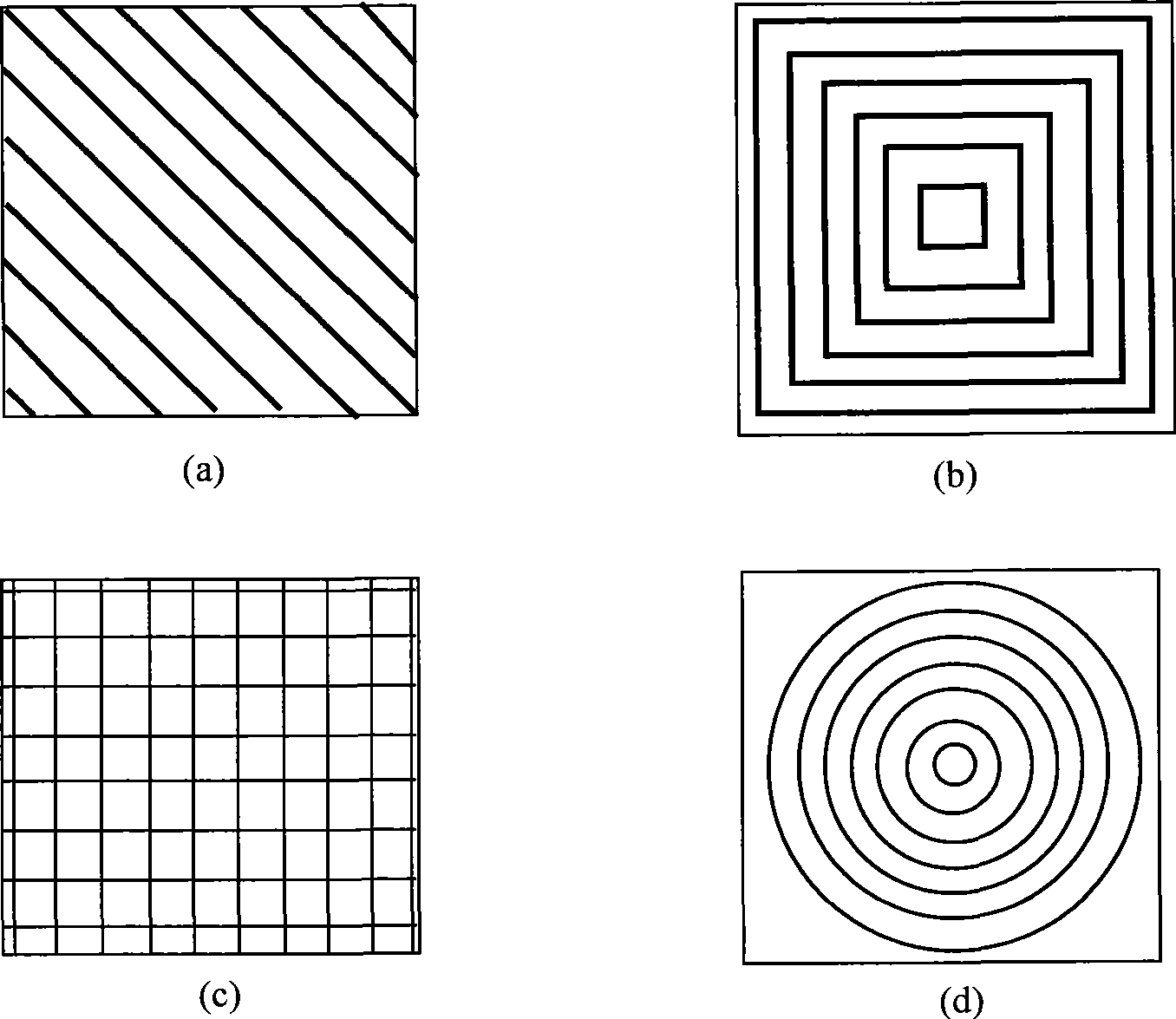

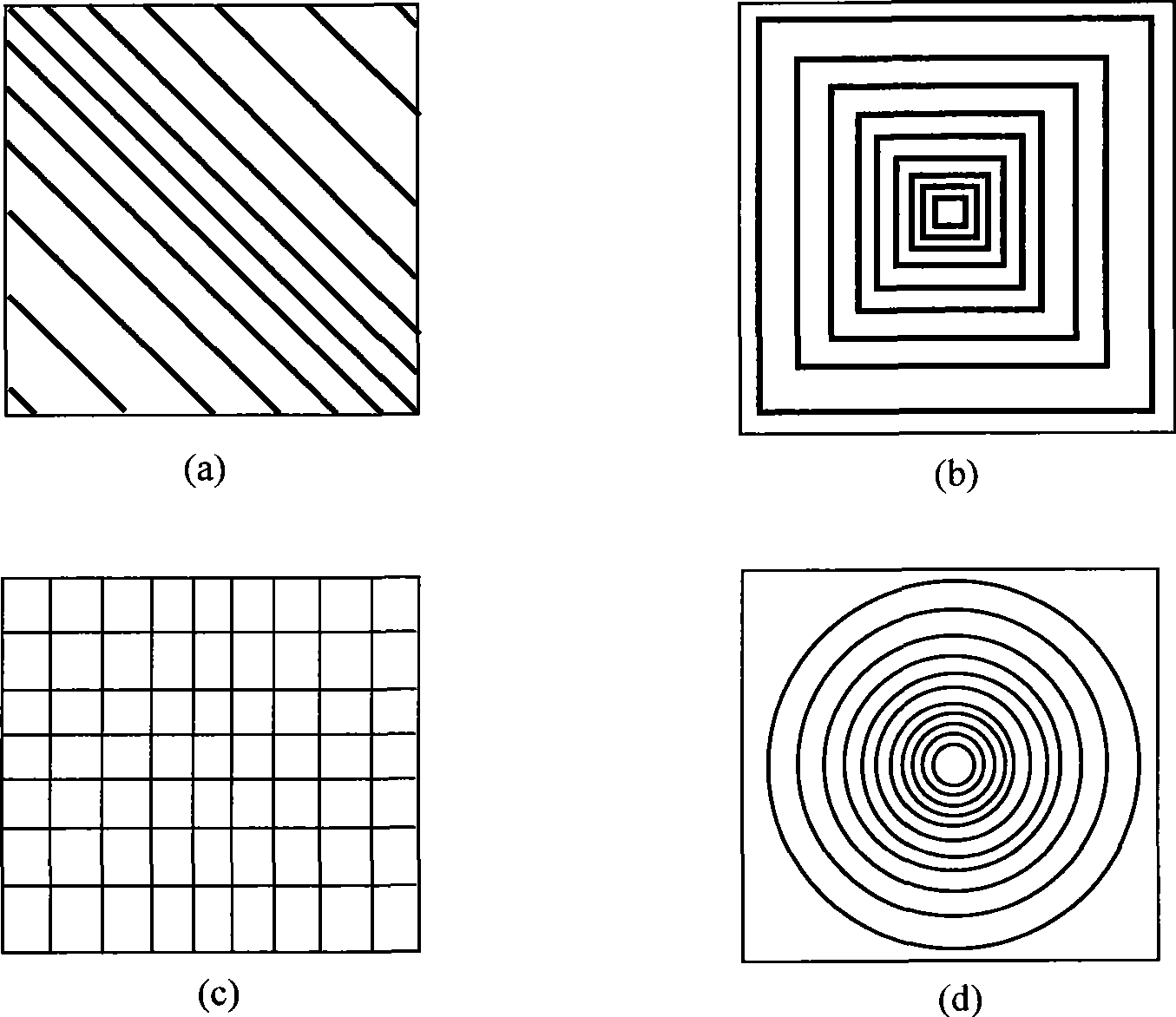

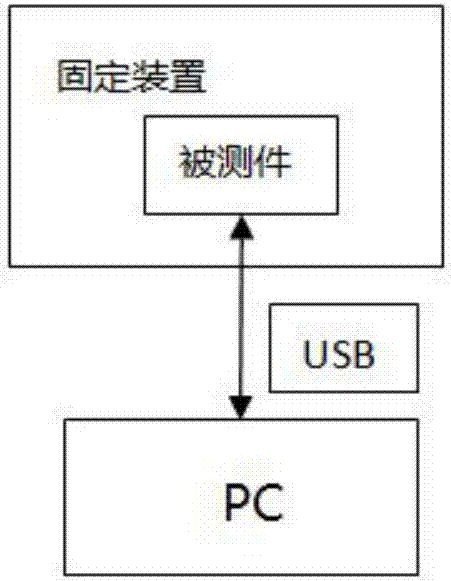

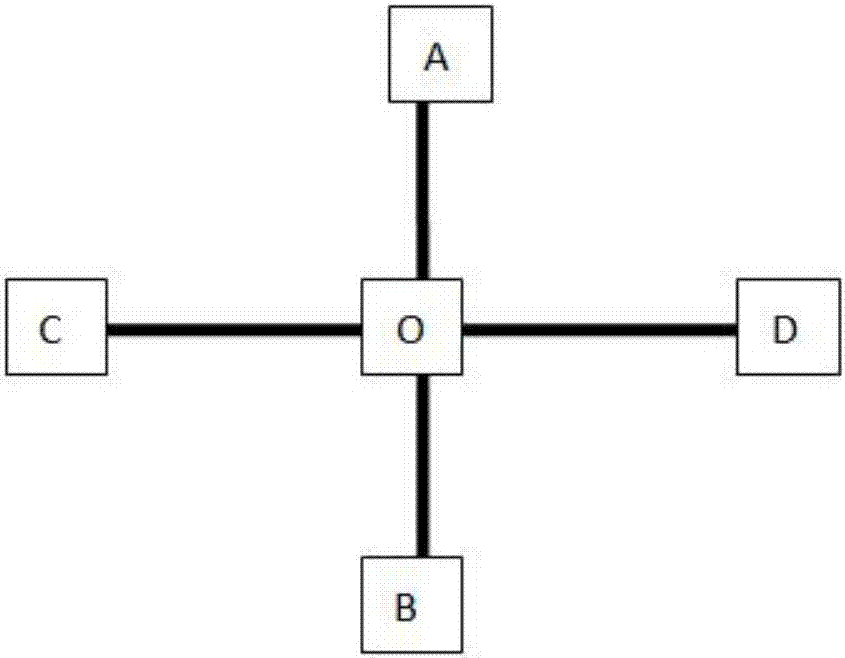

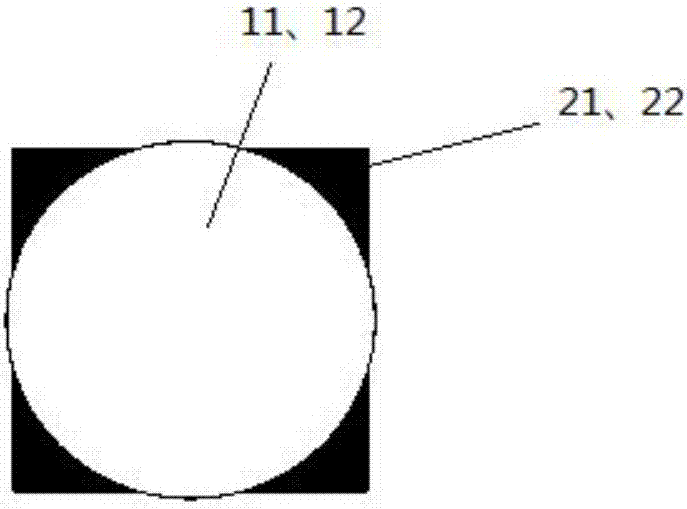

Back-to-back double-lens optical axis consistency test fixture and test method

ActiveCN107063640AAddressing Structural ComplexitySolve the cumbersome testingTesting optical propertiesCamera lensGraphics

The invention discloses a back-to-back double-lens optical axis consistency test fixture and test method. The test fixture comprises a fixture stage and graph cards; the graph cards and two lenses are arranged on the fixture stage; the graph cards are located at the object sides of the two lenses; each of the graph cards is provided with a rotary variable mark graph; the mark graph includes a center point mark and four end point marks; connecting lines between the non-adjacent end point marks of the mark graph are perpendicular to and equally divided by each other, and the center point mark of the mark graph is overlapped with perpendicular equal-division points; the lens surfaces of the two lenses are parallel with the graph card surfaces of the corresponding graph cards; connecting lines between the center point marks of the graph cards and the centers of the two lenses are perpendicular to the lens surfaces of the two lenses; the tested two lenses include a first lens and a second lens which are arranged in a back-to-back manner; the first lens and the second lens are arranged in a camera; and the camera is provided with a USB interface for communicating with a PC. With the back-to-back double-lens optical axis consistency test fixture and test method provided by the technical schemes of the invention adopted, the problem of judging the consistency of optical axes can be judged. The accuracy of test results of the test fixture and test method is highly.

Owner:GOERTEK OPTICAL TECH CO LTD

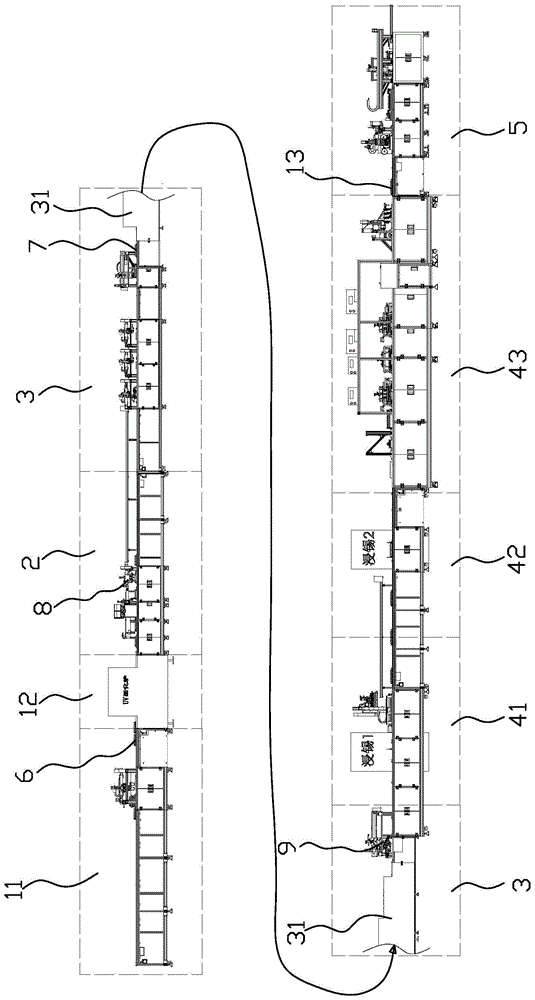

Automatic production line of transformer

ActiveCN105895348ARealize automated productionHigh degree of automationInductances/transformers/magnets manufactureCooking & bakingProduction line

The invention discloses an automatic production line of a transformer. The automatic production line comprises a dispensing mechanism, a glue solidifying mechanism, a trimming, peeling and unlocking mechanism, a dispensing reflux baking mechanism, a first tin dipping mechanism, a second tin dipping mechanism, a detection mechanism, a laminating combination mechanism, a magnetic ring jig, a transformer jig and a detection jig, wherein the magnetic ring jig, the transformer jig and the detection jig are applied in cooperation with the production line. The automatic production line of the transformer has the advantages, of high automatic degree, high production efficiency and the like, which the prior art does not have.

Owner:SHENZHEN HYMSON LASER INTELLIGENT EQUIP CO LTD

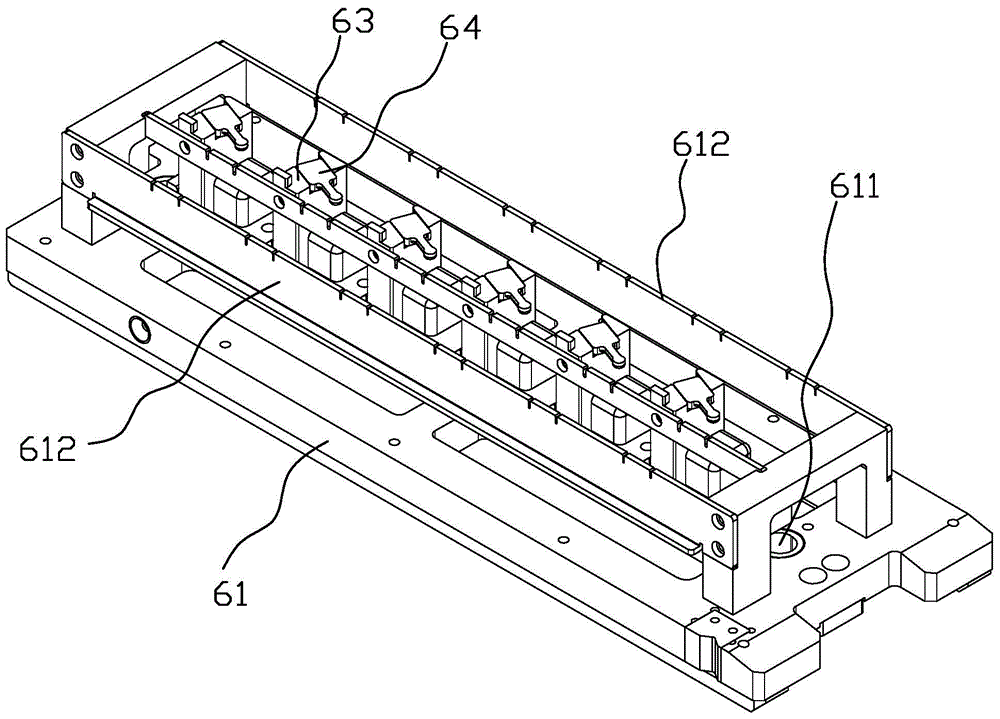

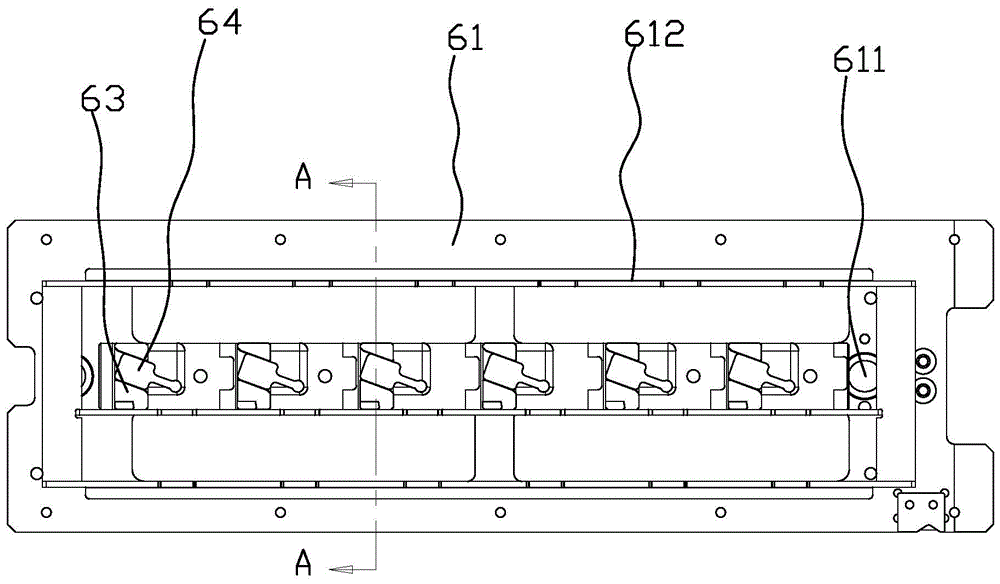

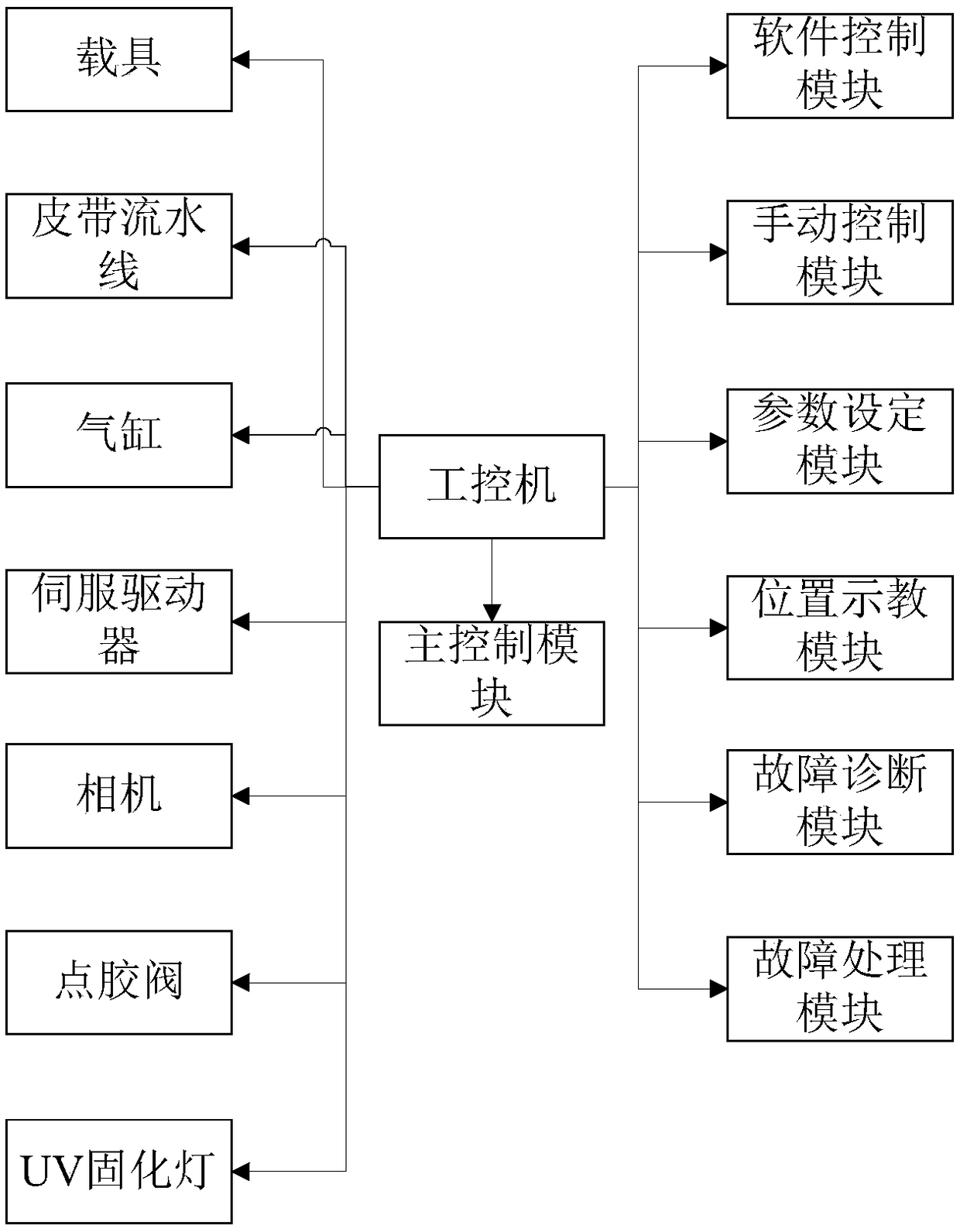

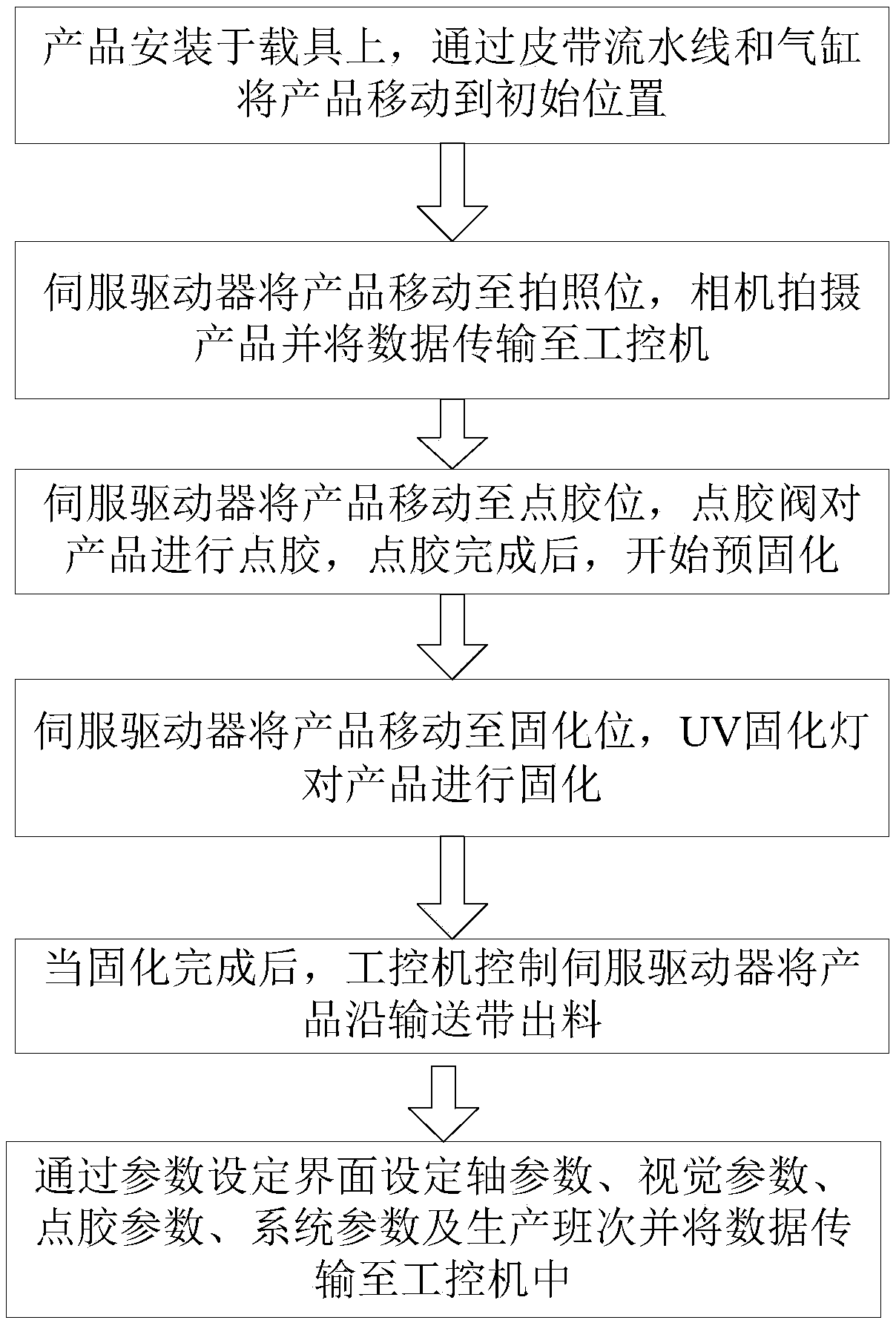

High-precision dispensing system based on upper computer integrated control and use method of high-precision dispensing system

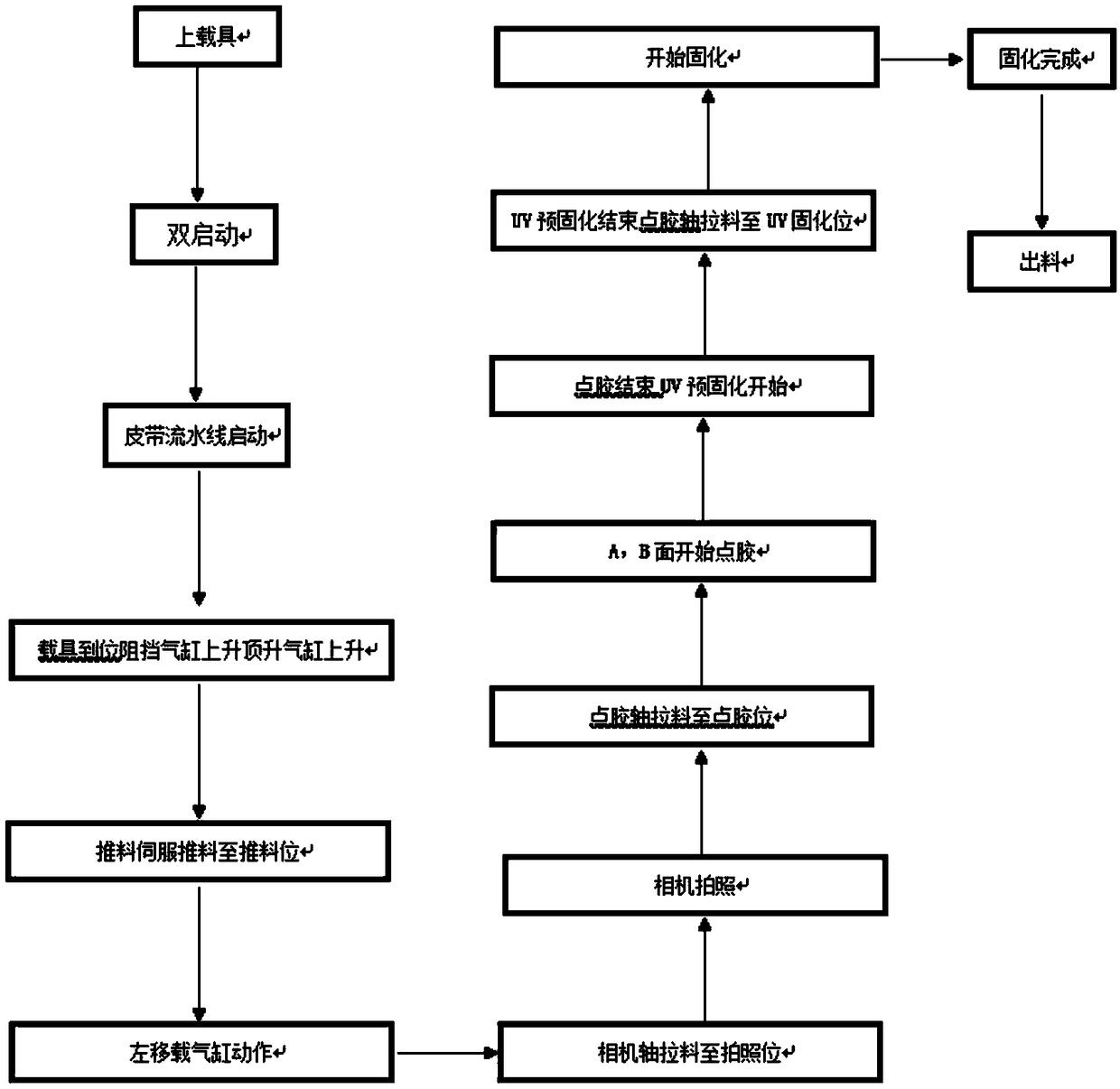

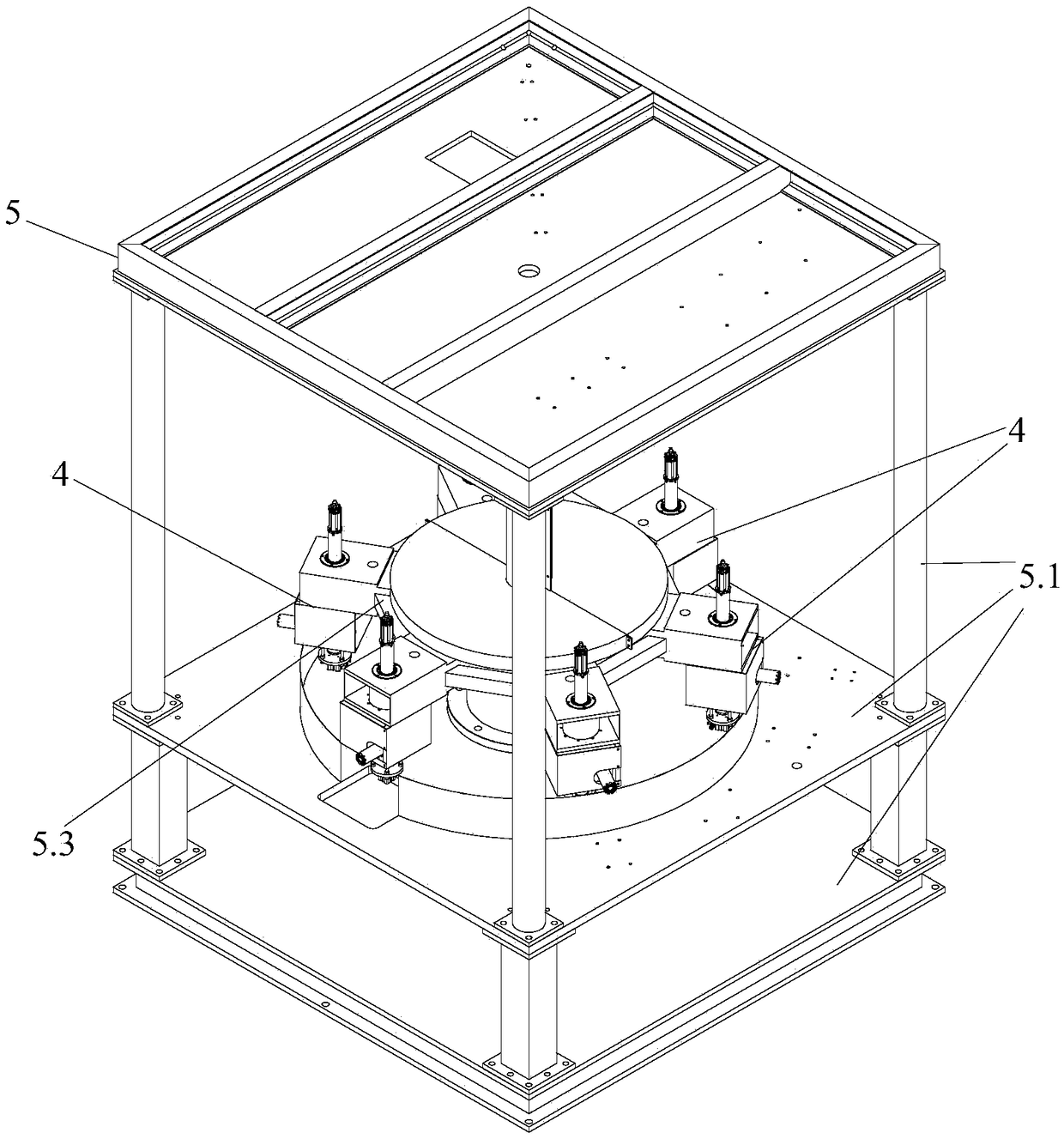

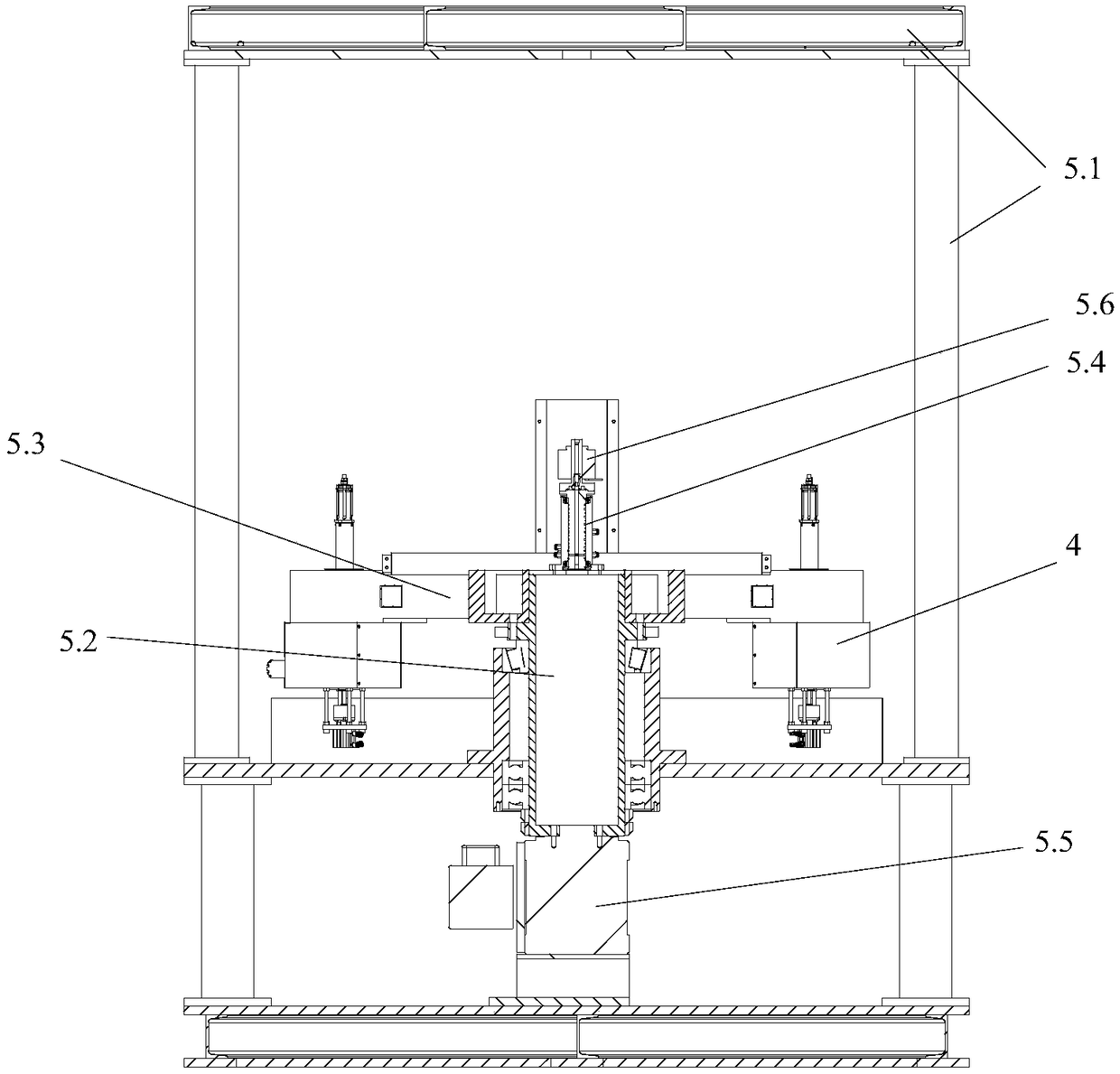

InactiveCN109013201ASolve efficiency problemsAddress the degree of automationPretreated surfacesCoatingsUV curingComputer module

The invention discloses a high-precision dispensing system based on upper computer integrated control. The high-precision dispensing system comprises an industrial personal computer, a main control module, a carrier, a belt assembly line, an air cylinder, a servo driver, a camera, a dispensing valve and a UV curing lamp. The industrial personal computer communicates with the main control module, aproduct is mounted on the carrier, the main control module drives the belt assembly line to convey the product, after the product is moved by the air cylinder, the servo driver moves the product to ashooting position, the servo driver moves the product to a dispensing position, the main control module drives the dispensing valve to carry out dispensing, pre-curing is carried out, the servo driver moves the product to a curing position, the product is cured through the UV curing lamp, and the main control module drives the product to be discharged along a conveying belt. The high-precision servo driver is controlled to move through corresponding software in the main control module, thus, automatic dispensing is controlled, highly-automatic integration is adopted, and the problems that thedispensing efficiency is low, and the automation degree is low are solved.

Owner:深圳市运泰利自动化设备有限公司

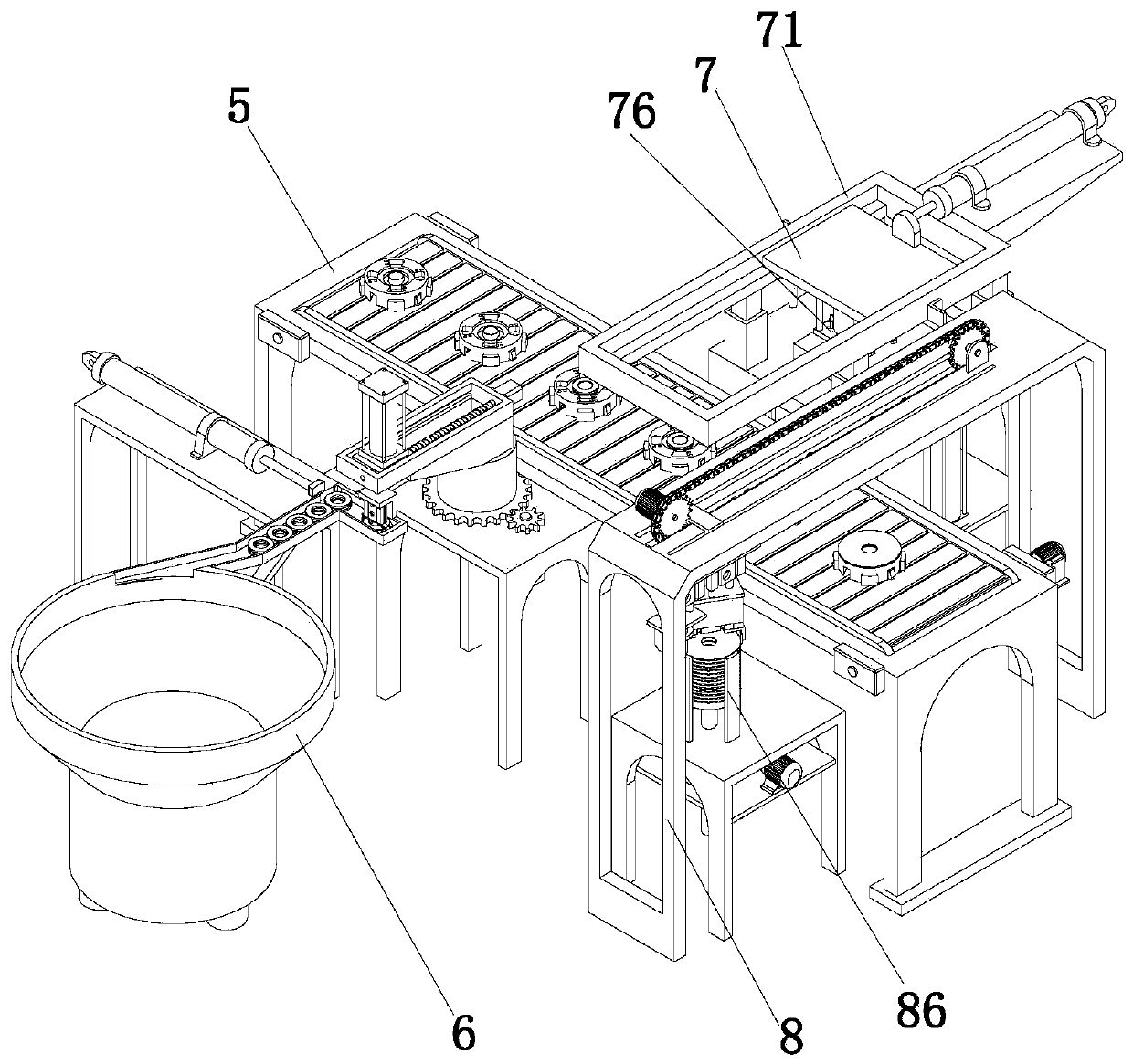

Multi-station full-automatic welding method for fan wheel processing

ActiveCN109249120AAddress the degree of automationSolve efficiency problemsWelding/cutting auxillary devicesAuxillary welding devicesWork in processSpot welding

The invention provides a multi-station full-automatic welding method for fan wheel processing, comprising the steps of baseplate positioning, baseplate alternating, blade and baseplate assembly, positioning and welding, top cover feeding, welding, tilting welding, and discharging, wherein the blade and baseplate assembly, positioning and welding step refers to clamping a baseplate, pushing blades,and correcting and positioning the blades on the baseplate for welding; the top cover feeding step refers to adjusting horizontalness of a top cover twice and conveying the top cover to a semi-finished blade and baseplate assembly; the welding step refers to performing spot welding on the top cover and blades on a third processing station; the tilting welding step refers to tilting and fully welding a semi-finished top cover and blade welded product subjected to spot welding; the discharging step refers to discharging the finished fan wheel. A fan wheel can be full-automatically welded according to production needs; the traditional welding technique is replaced; welding efficiency, welding quality and welding precision are improved.

Owner:FOSHAN GOOGOL AUTOMATION TECH

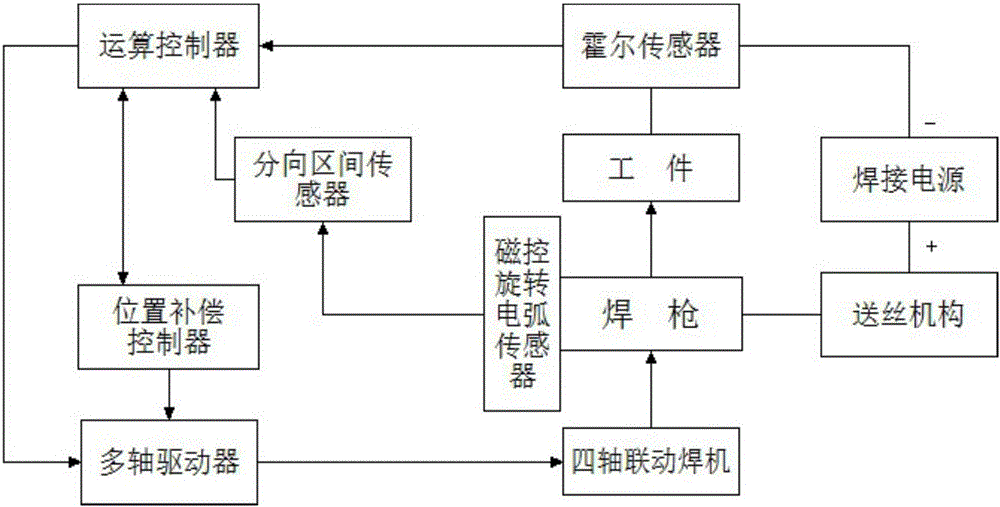

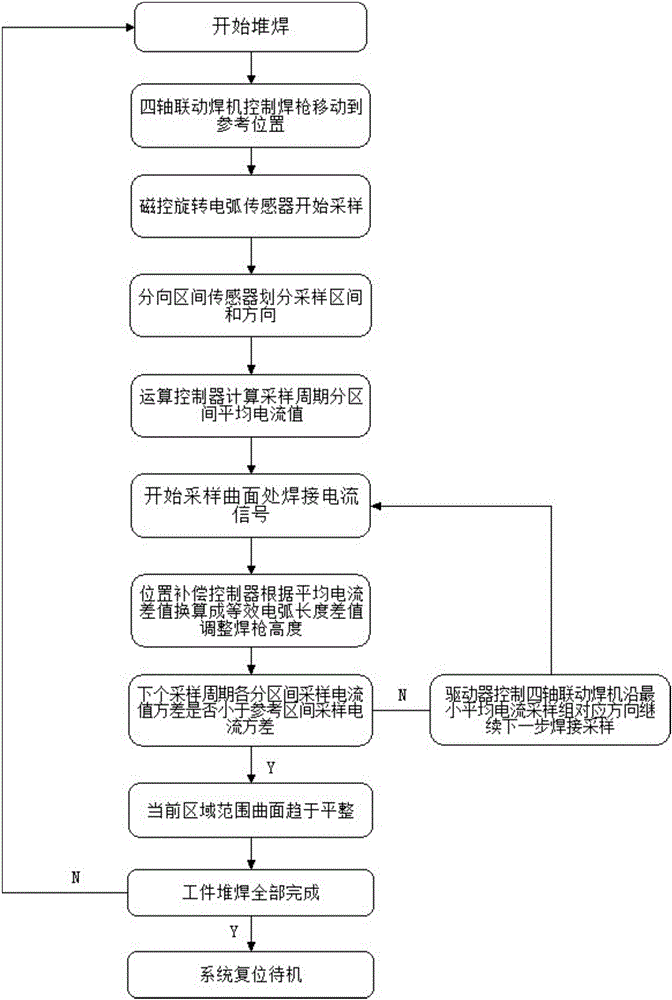

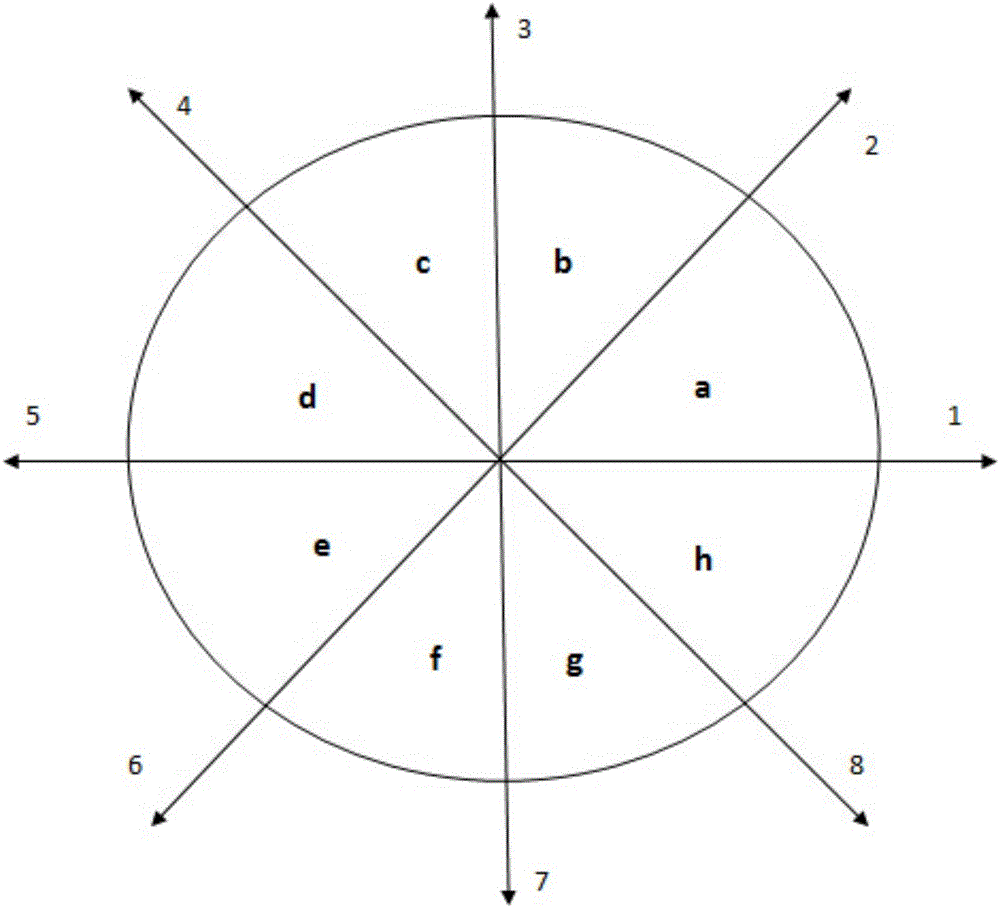

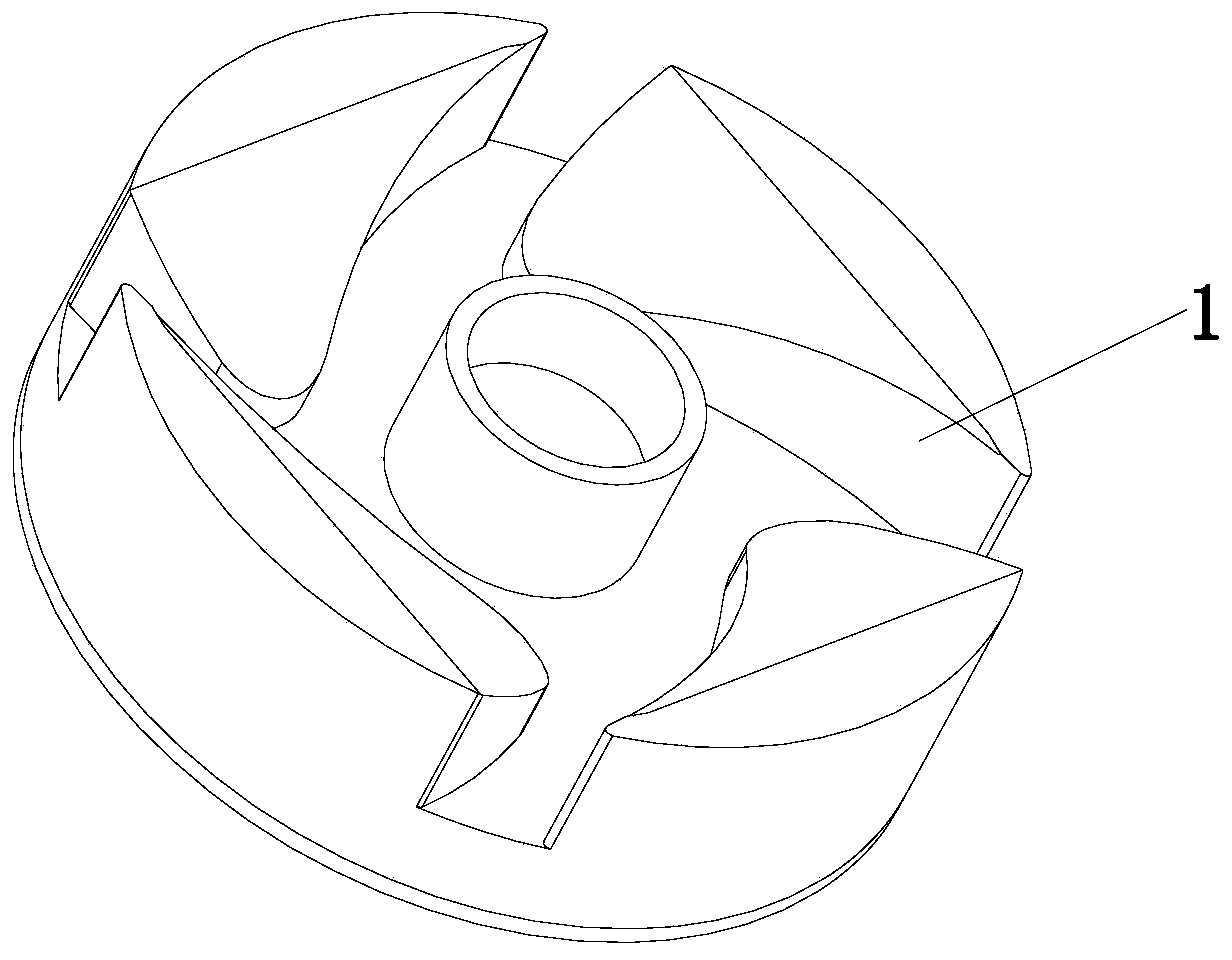

Route self-searching complex curved surface bead welding method based on magnetic control rotating arc sensing

ActiveCN105750694AAddress the degree of automationSolve efficiency problemsArc welding apparatusReference PeriodAverage current

The invention discloses a route self-searching complex curved surface bead welding method based on magnetic control rotating arc sensing. According to the main principle of the method, a curved surface is scanned through a magnetic control rotating arc sensor, a sampling point current signal is collected through a Hall sensor, an interval and direction dividing sensor conducts interval and direction dividing on a sampling point in each rotating period, an operation processor calculates the average current of each interval, conducts filtering processing, and then determines the direction of the minimum average current of a sampling period, a position compensation controller compares the average current value of the sampling period with the average current value of a reference period, the height of a welding gun is automatically adjusted, and arc breaking and gun colliding are stably avoided. A multi-axis driver controls a four-axis linkage welding machine, it is guaranteed that the welding direction faces the direction corresponding to a sampling set with the current minimum average current, welding is always conducted at the low horizontal height position of the curved surface, when the change fluctuation of average currents of all intervals of the sampling period is small, it is judged that the current curved surface tends to be smooth, and bead welding of the curved surface is completed.

Owner:XIANGTAN UNIV

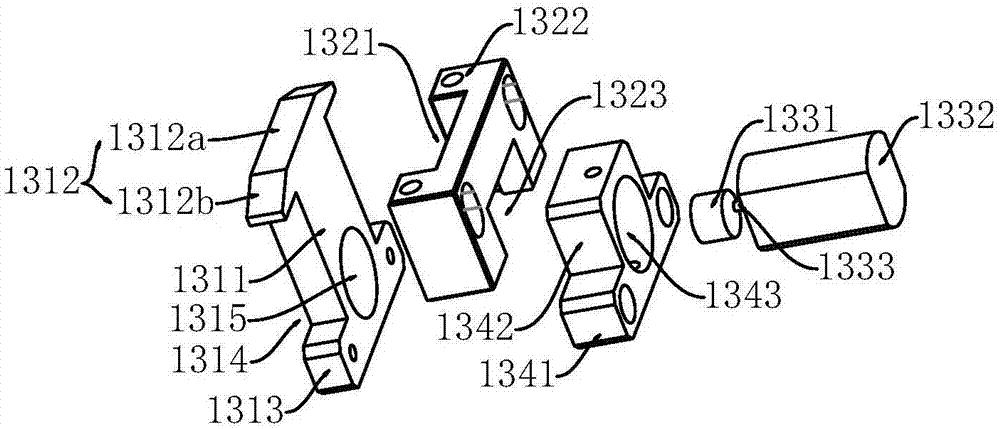

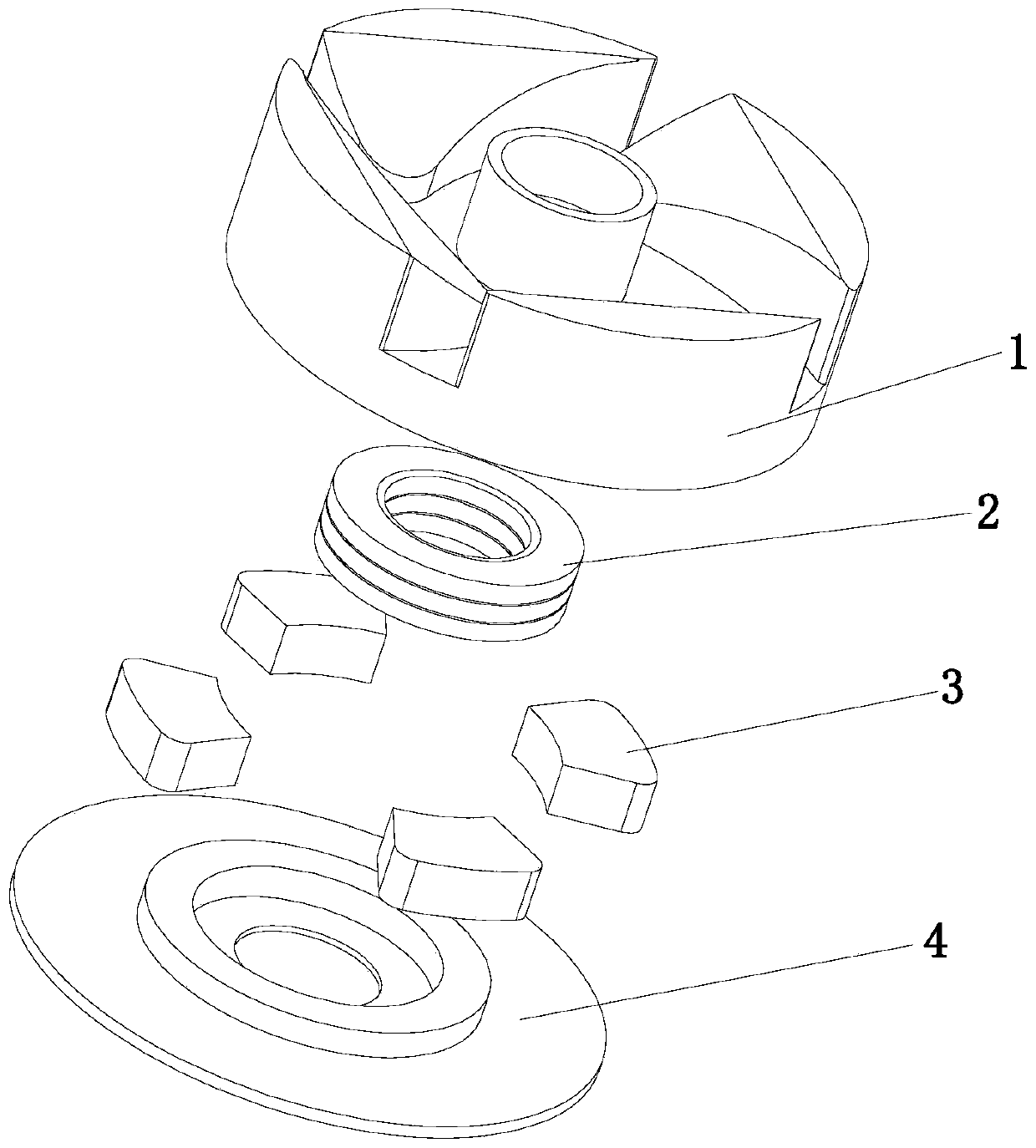

Assembly production line of centrifugal blood pump rotor

ActiveCN110900028ASolve efficiency problemsAddress the degree of automationMetal working apparatusWelding apparatusImpellerBlood pump

The invention discloses an assembly production line of a centrifugal blood pump rotor, and belongs to the technical field of assembling equipment. The assembly production line of the centrifugal bloodpump rotor involves a conveyor belt, a bearing magnetic stack press-fitting mechanism, a motor magnet installing mechanism and a base welding mechanism, wherein a plurality of limiting assemblies arearranged on the conveyor belt, the motor magnet installing mechanism comprises a sliding plate, a workbench, a material pushing assembly, a lifting assembly, a clamping assembly and a bearing frame,the clamping assembly comprises an installing plate, a four-jaw air cylinder and a limiting column arranged at the bottom of the installing plate, limiting plates are installed at the bottoms of clamping jaws of the four-jaw air cylinder, arc-shaped grooves are formed in the limiting plates, and four bearing rods are arranged between the installing plate and the sliding plate. According to the assembly production line, the bearing magnetic stack press fitting, the motor magnet installing and the base welding steps of the centrifugal blood pump rotor can be automatically completed, four motor magnets can be simultaneously installed in an impeller by the motor magnet installing mechanism, and a worker does not need to install the motor magnets one by one.

Owner:韶关市武江区冠启自动化设备设计有限公司

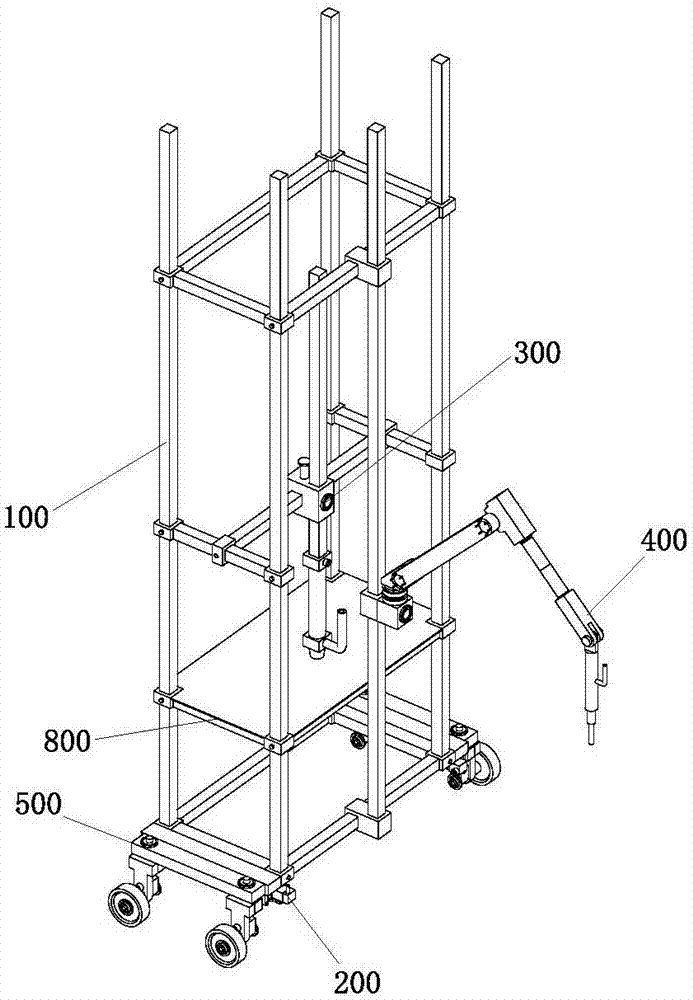

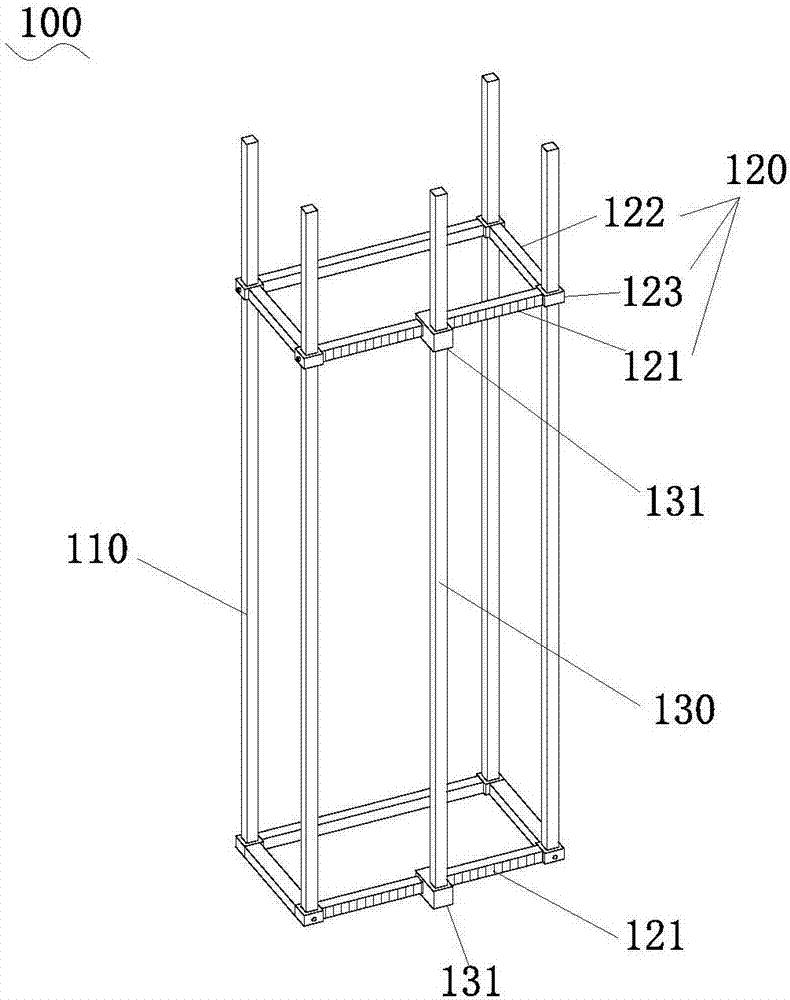

Bridge 3D printing with formwork collaboration and construction method thereof

ActiveCN107974950AFully automaticAchieve continuous printingBridge erection/assemblyEngineering3d printer

The invention relates to a bridge 3D printing with formwork collaboration and a construction method thereof and belongs to the technical field of building construction. The bridge 3D printing device comprises a guide frame, a guide rail travelling mechanism, a bridge 3D printing mechanism, a rail 3D printing mechanism and a collaborating formwork; the guide frame provides supporting for the bridge3D printing mechanism, the rail 3D printing mechanism and the collaborating formwork; the rail 3D printing mechanism provides 3D printing for a rail support structure; the guide rail travelling mechanism supports the guide frame the rail support structure that is constructed; the bridge 3D printing mechanism can print a bridge body; the collaborating formwork can provide supporting for the bridgebody during printing. The bridge 3D printing with formwork collaboration and the construction method thereof have the advantages that complex formwork erection and removal operations during traditional bridge printing are avoided so that construction efficiency is improved; the bridge 3D printing with formwork collaboration can provide full-automatic continuous printing.

Owner:SHANGHAI CONSTRUCTION GROUP +1

Chinese sauerkraut seasoning sealing device

InactiveCN105438512AAddress the degree of automationResolutionLiquid materialPackaging fruits/vegetablesRobot handElectric machinery

The invention relates to a Chinese sauerkraut seasoning making technology, in particular to a Chinese sauerkraut seasoning sealing device. The technical aims that the Chinese sauerkraut seasoning sealing device is high in automation degree and good in sealing effect and saves manpower are achieved. To achieve the technical aims, the Chinese sauerkraut seasoning sealing device comprises a base, a left support, a right support, a top support, a slide rail, slide blocks, a fixed plate I, a lifting air cylinder I, an electric mechanical arm, a left horizontal air cylinder, a fixed plate II, lifting air cylinders II, a thumb air cylinder, a fixed plate III, a right horizontal air cylinder, a rotary motor, a connecting rod and a containing box. The left support is arranged at the left end of the top of the base, the right support is arranged at the right end of the top of the base, and the top support is arranged at the top of the left support and the top of the right support. The defects that the existing Chinese sauerkraut seasoning sealing process is completed mainly through manpower, the automation degree is low, manpower is small, and the sealing effect is poor are overcome.

Owner:CHONGQING YONGCHUAN DISTRICT ANJUN FOOD FACTORY

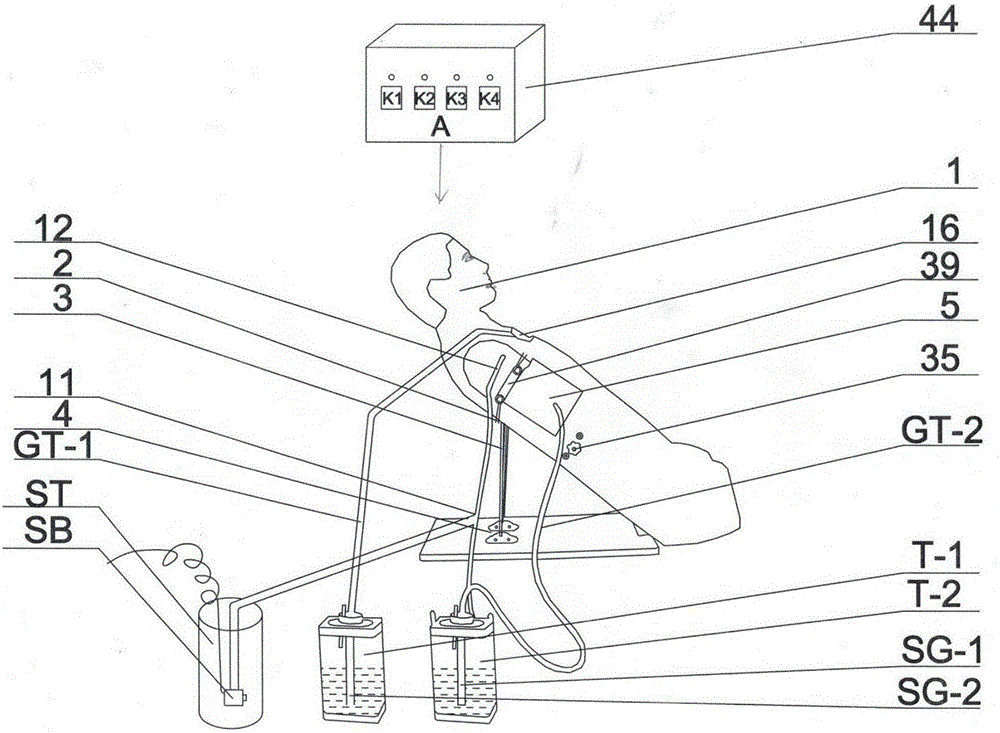

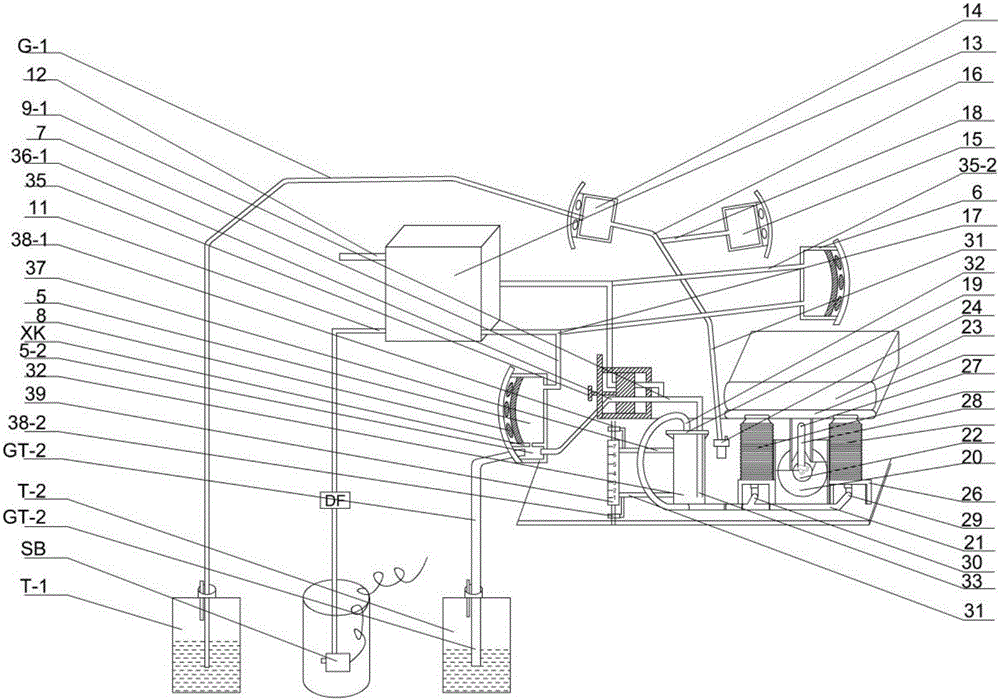

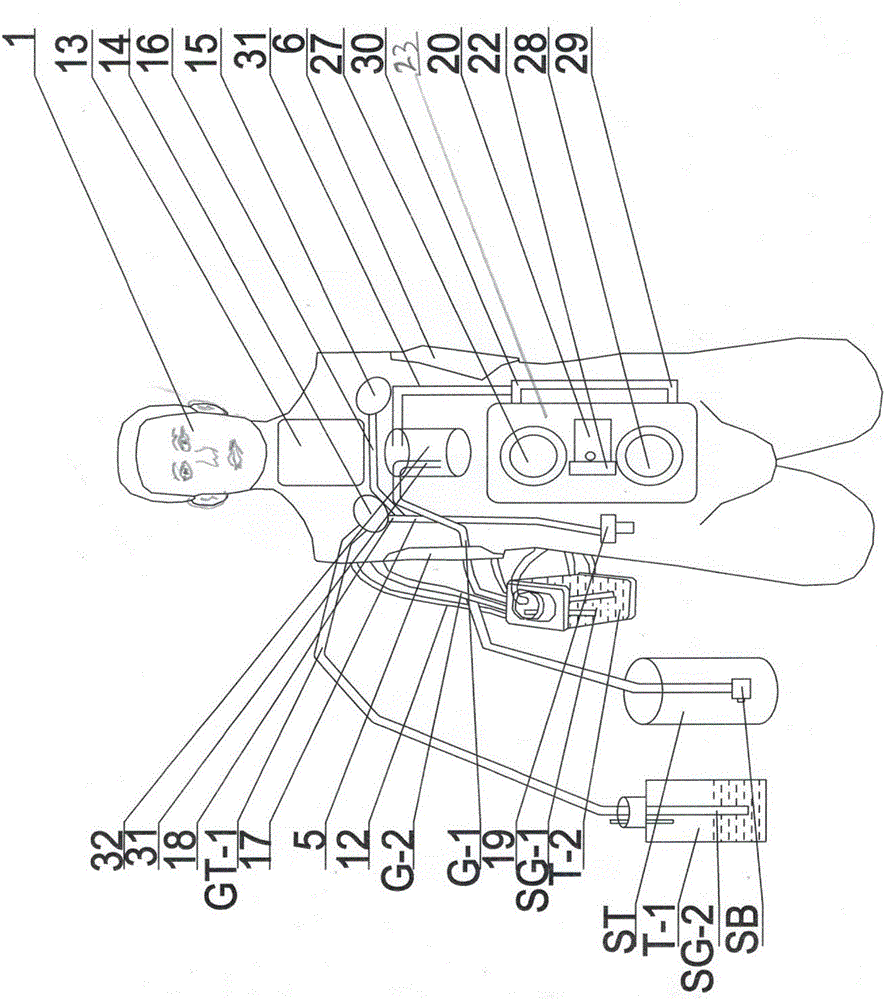

Highly-simulative fully-automatic thoracocentesis and closed drainage computer simulated human being

PendingCN106373472AAddress the degree of automationSolve the problem of poor simulation effectEducational modelsPipe waterPneumothorax

A highly-simulative fully-automatic thoracocentesis and closed drainage computer simulated standardized patient relates to the technical field of medical education equipment. The computer simulated standardized patient comprises a microcomputer controller, a simulated human body model, a simulated pneumothorax capsule, a simulated pleural effusion capsule, a breathing exercise simulator, a thorax closed drainage bottle transparent pipe water column fluctuation and fluctuation adjustment simulator, an automatic voice alarm device, a micro water pump, a water tank, a micro air pump, a half-lying bracket, and a fixed plate. The advantages are as follows: simulation is highly simulative and fully automatic; by operating the keyboard of the microcomputer controller, liquid and air can be injected into the thorax automatically, and simulated pleural effusion and simulated pneumothorax are formed automatically; breathing exercise is simulated automatically; the transparent pipe water column of the thorax closed drainage bottle can fluctuate up and down with the breathing rhythm, and the amplitude of fluctuation can be adjusted automatically; the alarm is raised by voice automatically when a thoracentesis needle is inserted at a wrong position; and the computer simulated standardized patient can be used to train and assess the thorax closed drainage and thoracocentesis skills of medical students and medical personnel, and can significantly improve the teaching effect.

Owner:营口市贵东医疗器械制造有限公司

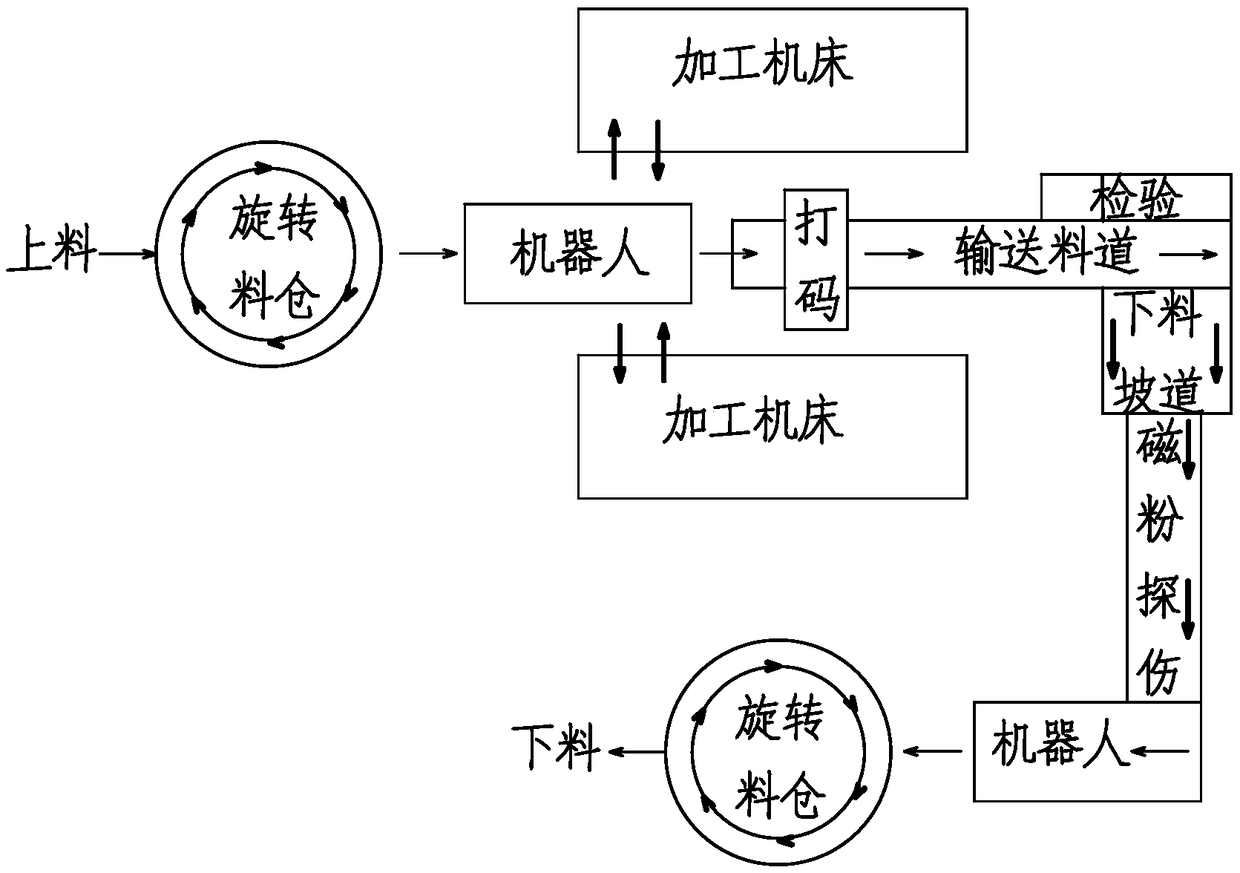

Production material circulation technology of oil casing coupling

The invention provides a production material circulation technology of an oil casing coupling, and belongs to the field of oil casing coupling machining production. The process comprises the followingsteps that a wool blank is fed from a rotary stock bin to a feeding position by utilizing a feeding robot; the wool blank is fed into a numerical control machining machine tool for automatic machining by using a material taking truss mechanical arm; and a machined product is grabbed by the truss mechanical arm to a discharging position; the feeding robot is used for conveying the machined productto a material conveying channel; the product sequentially passes through a code printing and a thread inspection procedure in the material conveying channel, and unqualified product which fails in geometric parameters is removed; the product is subjected to magnetic powder inspection; and the finished product subjected to magnetic powder flaw inspection is grabbed into a semi-finished product transfer basket of the rotary stock bin of the discharging position by utilizing a discharging robot; and a discharging forklift is used for conveying the finished product to the rotary stock bin of thedischarging position. The production material circulation technology of the oil casing coupling can solves the problems of high labor intensity, complex working procedures, low automation degree of anexisting coupling production technological process.

Owner:DALIPAL PIPE

Efficient board cutting machine convenient to cut

InactiveCN107363912AAvoid spillingSolve the problem of pollution affecting human healthCircular sawsTransmission beltEngineering

The invention discloses a high-efficiency wood cutting machine which is convenient for cutting. A blade is sleeved, the right side of the protective shell is connected with a first rotating shaft, the right side of the rotating shaft is connected with a motor, and a second rotating shaft is connected between the two baffles, and the second rotating shaft The outer side of the first rotating shaft is sleeved with a transmission belt, the outer side of the first rotating shaft is sleeved with a transmission belt, the bottom of the driving belt is connected to the second rotating shaft, the two sides of the top of the protective shell are connected with support rods, and the outer side of the support rod A spring is sheathed, and a bearing is connected to the bottom of the spring, and a third rotating shaft is connected through the two bearings. The new type has the advantages of multiple cuttings at the same time and a high degree of automation, and solves the problem of low cutting efficiency of traditional wood cutting machines.

Owner:扬州纭旭健康科技有限公司

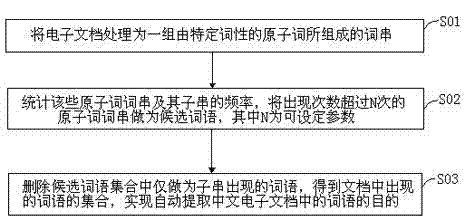

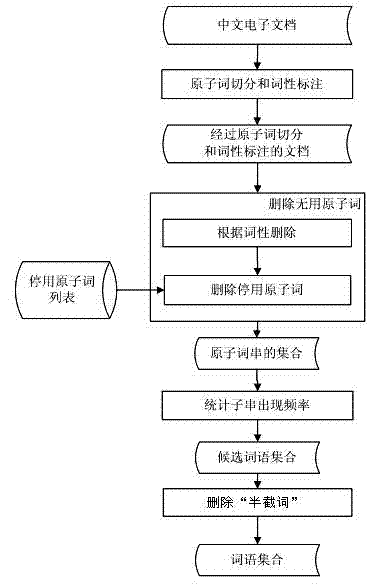

Method for automatically extracting terms from Chinese electronic document

InactiveCN103207921AImprove accuracyAvoid false promptsSpecial data processing applicationsElectronic documentDocument preparation

The invention relates to a method for automatically extracting terms from a Chinese electronic document. The method is characterized by comprising the following steps of: step S01: processing the electronic document into a group of word strings consisting of atomic words with a special property; step S02: counting the frequency of the atomic word strings and substrings, adopting the atomic word string with the appearance times being more than N times as a candidate term, wherein N is a settable parameter; and step S03: deleting the term which only appears as a substring in a candidate term set to obtain a term set appearing in the document, and realizing the purpose for automatically extracting the terms in the Chinese electronic document. The method has the effects and benefits that the real problem and difficulty that the performance for automatically extracting the term is not high and the automation degree is limited can be solved. The high-efficient automatic method for extracting the terms is a foundation for automatically processing a text and can powerfully guarantee the information search, text summarization, content management and the like. The good term extracting method can promote the automation degree and the performance of the work.

Owner:FUZHOU UNIV

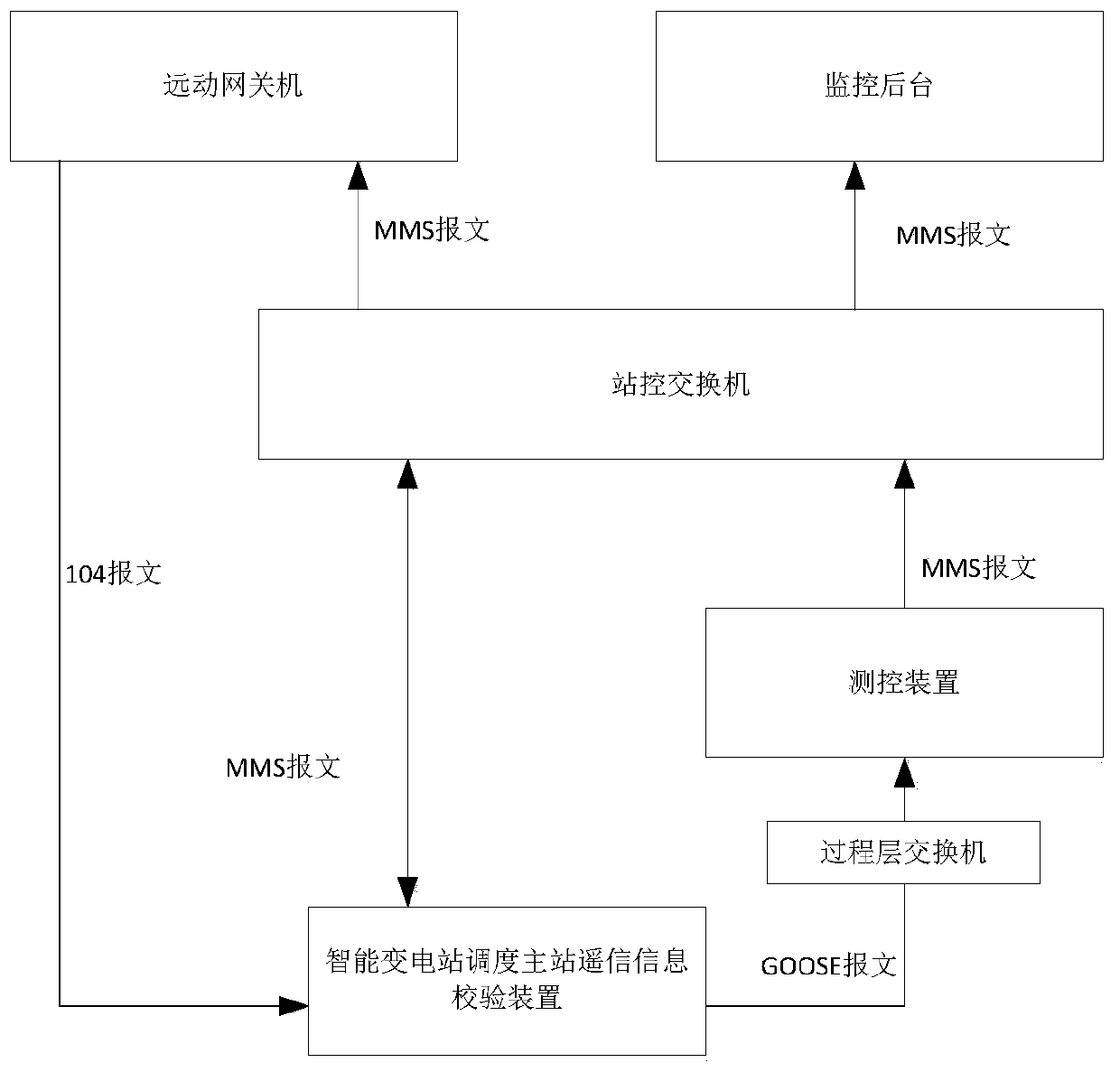

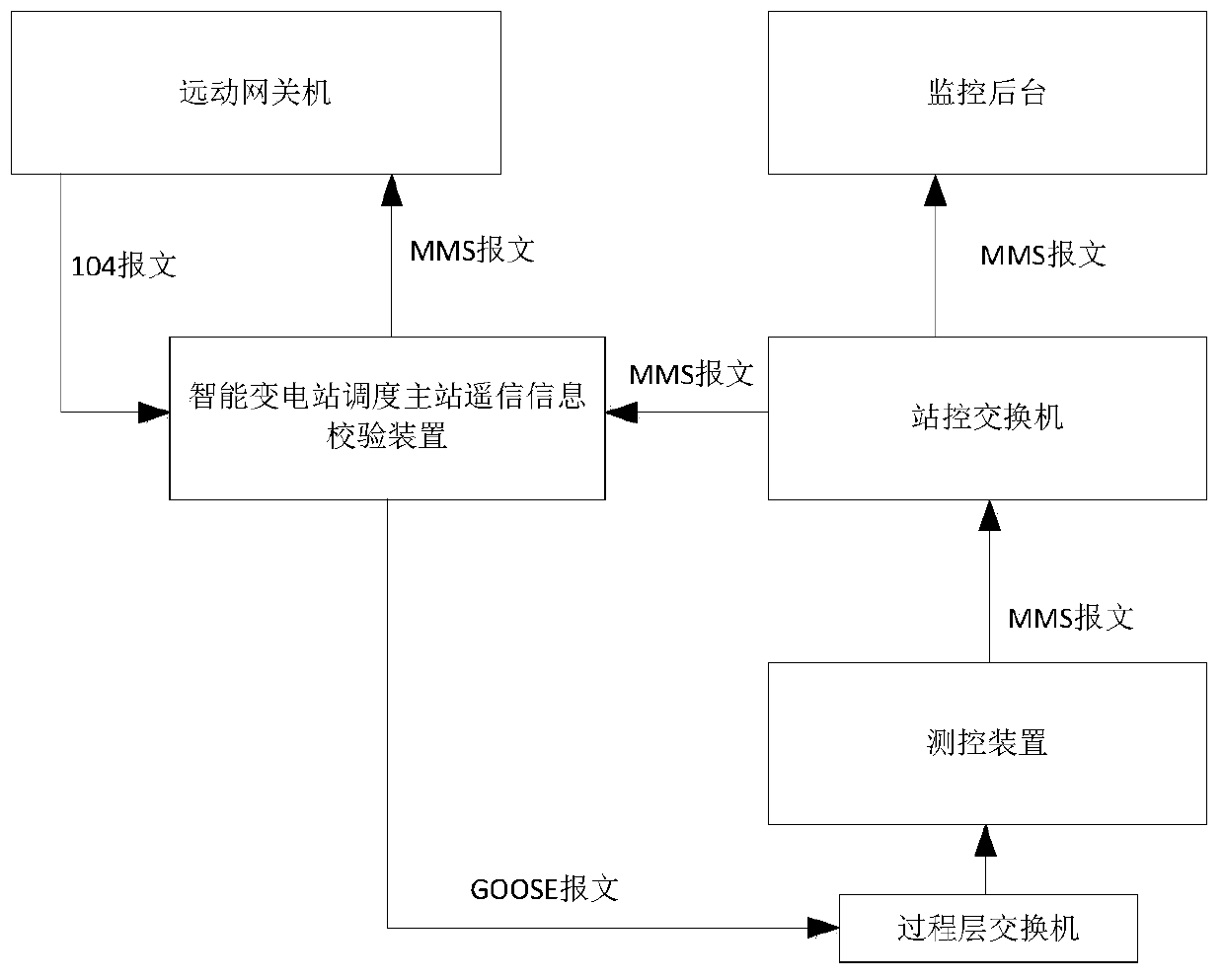

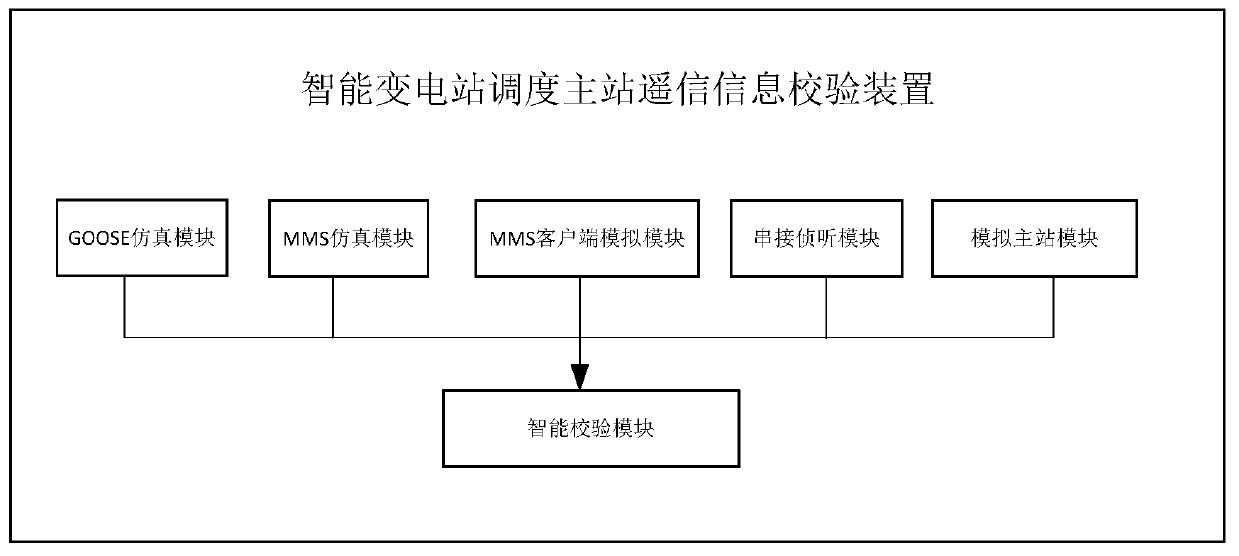

Remote signaling information verification method and device for dispatching master station of intelligent substation

ActiveCN110932406ASolve the workloadAddress the degree of automationCircuit arrangementsTransmissionSmart substationPower substation

The invention discloses a remote signaling information verification device for a dispatching master station of an intelligent substation, which comprises a GOOSE simulation module, an MMS simulation module, an MMS client module, an analog master station module, a serial listening module and an intelligent verification module, and is characterized in that the GOOSE simulation module is connected with a process layer switch through a first optical Ethernet port; the MMS simulation module and the MMS client module are connected with the station level switch through a first electric Ethernet port;the simulation main station module is connected with the motion gateway machine through a third electric Ethernet port; and the GOOSE simulation module, the MMS simulation module, the MMS client module and the simulation main station module are connected with the intelligent verification module. The invention further discloses a remote signaling information verification method for the dispatchingmaster station of the intelligent substation. Configuration-free automatic verification of the remote signaling information of the dispatching master station of the intelligent substation is realized, and the acceptance efficiency and the acceptance quality of the remote signaling information of the dispatching master station are greatly improved.

Owner:STATE GRID GANSU ELECTRIC POWER CORP +2

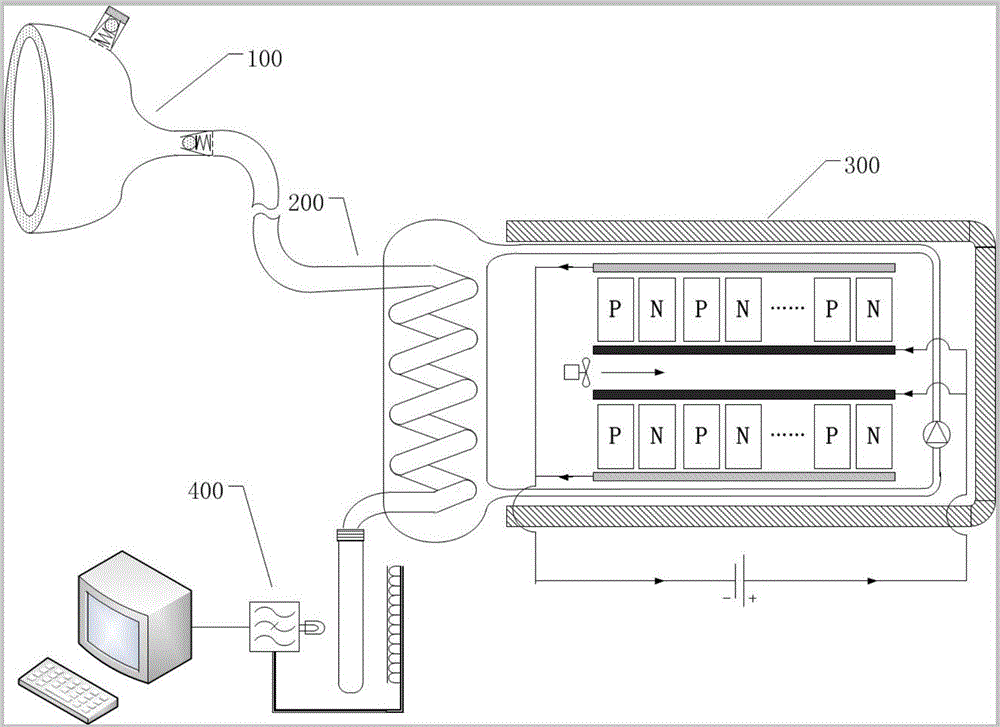

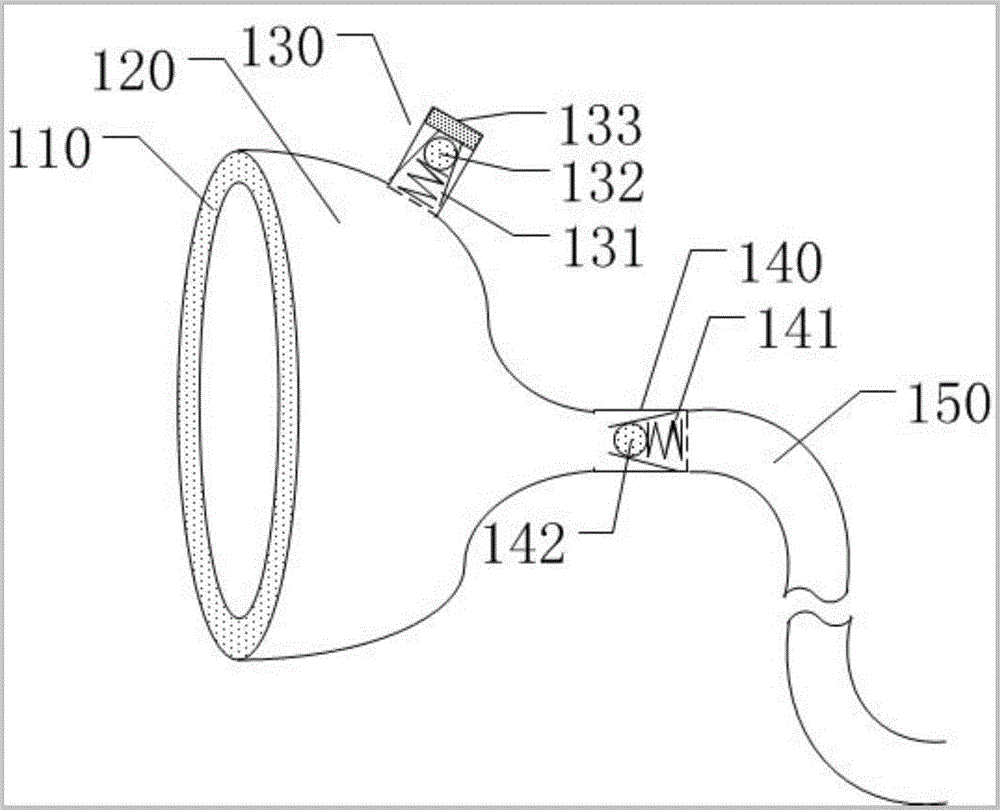

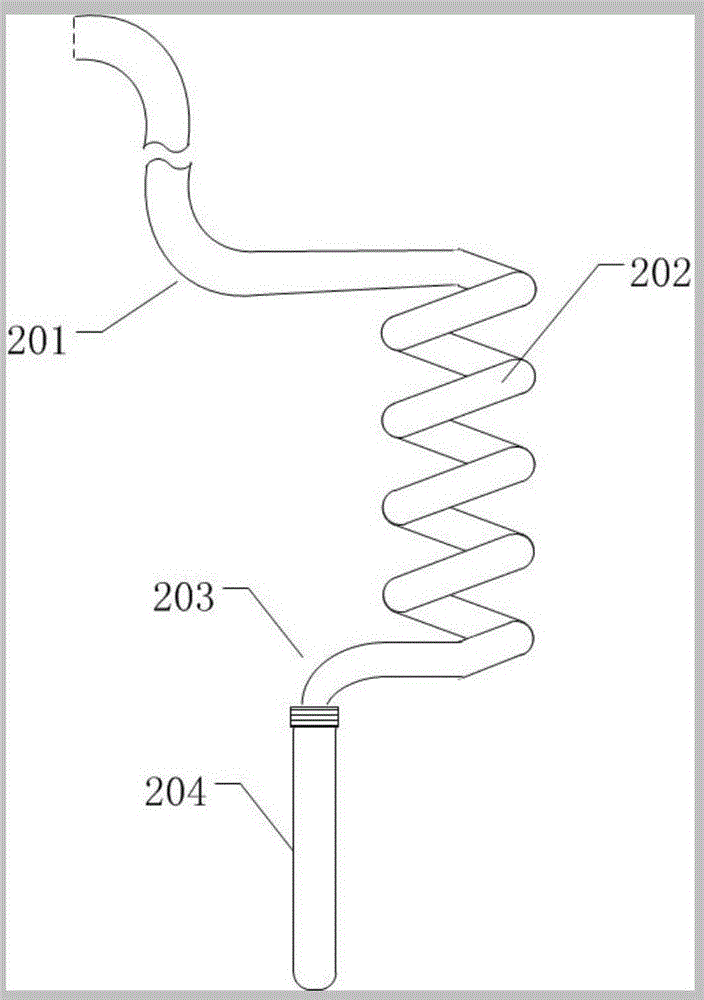

Collection device of expired air condensed liquid

PendingCN106644606ASolving inconsistent standardsFix stability issuesWithdrawing sample devicesPreparing sample for investigationArtificial ventilationEngineering

The invention provides a collection device of expired air condensed liquid. The collection device comprises an oral-nasal mask, a cooling pipeline and a refrigerating system, wherein the oral-nasal mask is used for collecting expired air of a person to be tested; one end of the cooling pipeline is connected with the oral-nasal mask and the other end of the cooling pipeline is connected with a sampling pipe; the refrigerating system acts on the cooling pipe and the expired air in the cooling pipeline is cooled to be lower than a dew point so that the expired air is converted into the condensed liquid; the condensed liquid falls into the sampling pipe due to gravity through setting an angle of the cooling pipeline; the collection device can further comprise a quantifying system; a liquid level height in the sampling pipe is monitored through a photoelectric induction manner; when the condensed liquid in the sampling pipe reaches a pre-set liquid level height, prompting information is sent out and specimen collection is stopped; the device can be used for collecting the expired air condensed liquid under the condition that normal breathing of the person to be tested is not disturbed or manual ventilation is utilized, and the problems of a current collection device of expired air condensed liquid that standards are not uniform, the effect is not stable and the automation degree is poor are solved.

Owner:XIAN PEIHUA UNIV

Quick air-drying device for camshaft

InactiveCN105403002AAddress the degree of automationSolve complexityDrying solid materialsDrying machines with local agitationGear wheelMotronic

The invention belongs to the technical field of camshaft equipment, and particularly relates to a quick air-drying device special for a camshaft. According to the technical purposes, the quick air-drying device special for the camshaft is high in automation degree and simple in structure. In order to achieve the technical purposes, the quick air-drying device special for the camshaft comprises a base, a storage rack, the camshaft, a top plate, a connecting rod I, a connecting rod II, an electric gear, a driven gear, a conveying belt, a fixing plate, an upper bearing pedestal, a lower bearing pedestal, a servo motor, a nut, a screw rod, a connecting rod III, a thumb cylinder, an air-drying unit, a cover plate, a telescopic cylinder, a heating unit, absorbent paper, a left cylinder, a right cylinder, a left fixing clamping ring and a right fixing clamping ring. The defects that an existing camshaft air-drying device is low in automation degree and complex in structure are overcome through the quick air-drying device special for the camshaft, and the quick air-drying device special for the camshaft achieves the effects of being high in automation degree and simple in structure.

Owner:CHONGQING BENCHUANG MACHINERY CO LTD

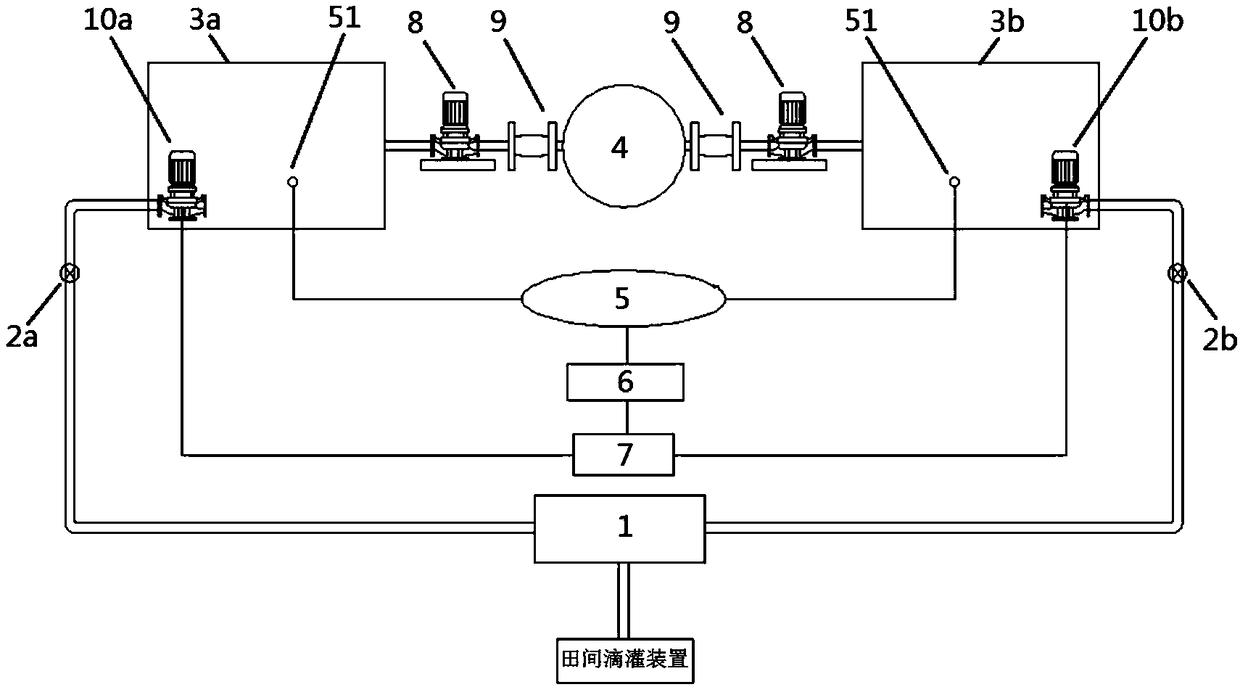

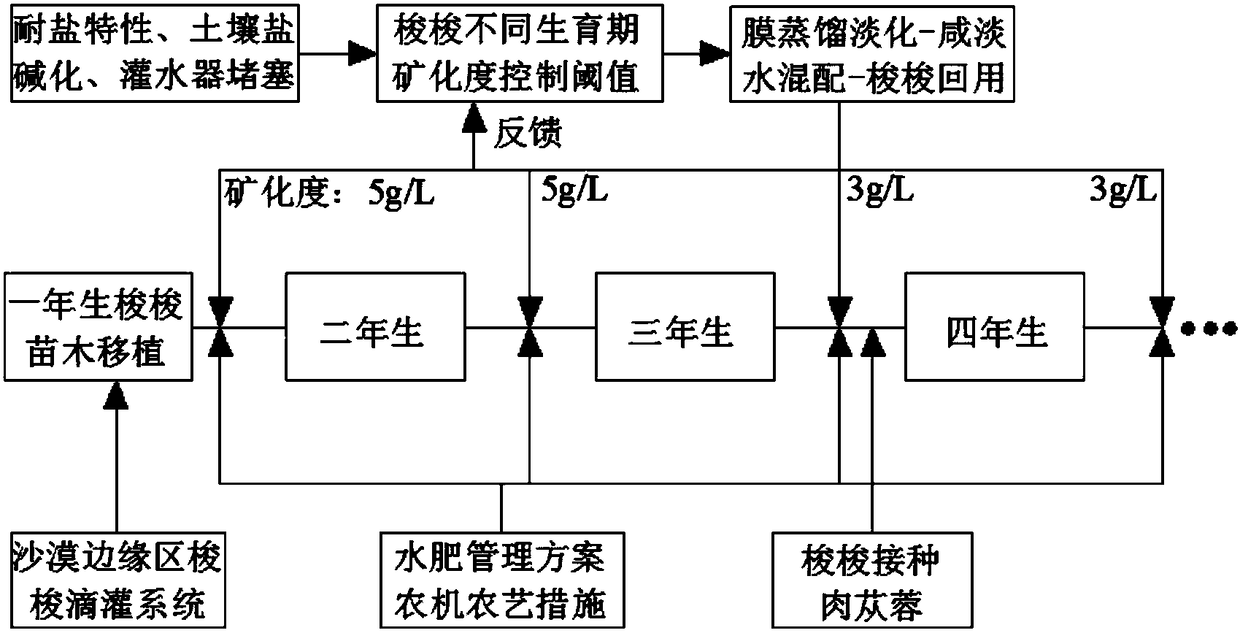

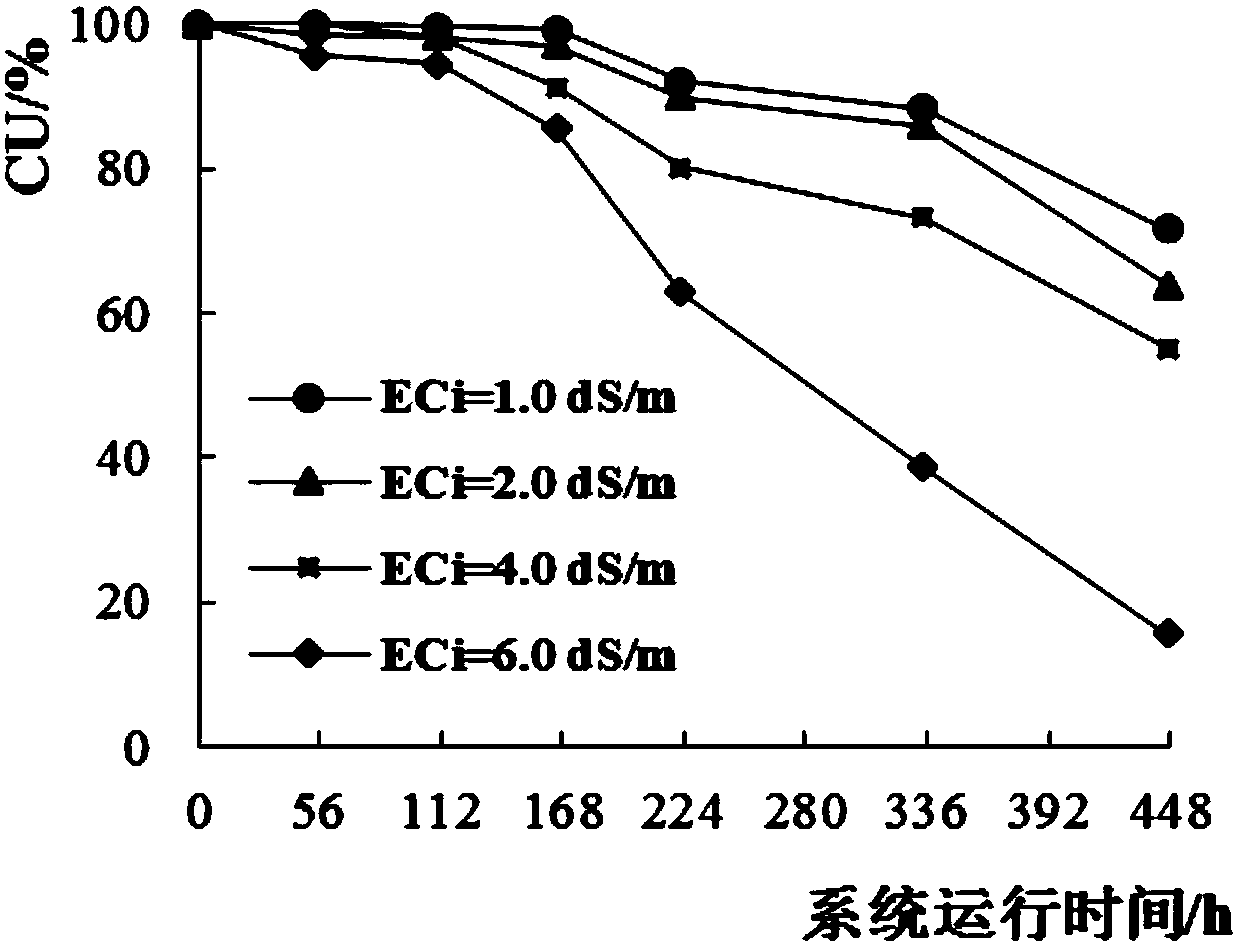

Drip-irrigation system for Haloxylon ammodendron in desert marginal area, and planting method and application for Haloxylon ammodendron

InactiveCN108464225ASolve the problem of energy consumptionSolve the costClimate change adaptationWatering devicesHaloxylon ammodendronWater source

The invention relates to a drip-irrigation system for Haloxylon ammodendron in a desert marginal area, and a planting method and an application for the Haloxylon ammodendron, belonging to the technical field of drip irrigation. The drip-irrigation system comprises a first reuse device and a field drip-irrigation device, wherein the first reuse device is connected with the field drip-irrigation device through a water delivery pipeline; through the first reuse device, an underground water source in the desert marginal area is distilled, and brackish water and fresh water obtained from distillation and separation are mixed into brackish-fresh mixed water in proportion; and the brackish-fresh mixed water is delivered to the field drip-irrigation device through the water delivery pipeline. Thedrip-irrigation system provided by the invention comprehensively considers salt tolerance of the Haloxylon ammodendron, clogging of an irrigation emitter and secondary salinization of soil under the condition of drip irrigation with brackish water, provides the control range of the salinity of irrigation water in different growth stages of the Haloxylon ammodendron, and solves the problems of over-high energy consumption and cost and low degree of automation for a conventional brackish-water desalination technology on the basis that the problems of root wilting of the Haloxylon ammodendron, clogging of the irrigation emitter and secondary salinization of the soil due to irrigation with high-salinity brackish water are solved.

Owner:CHINA AGRI UNIV

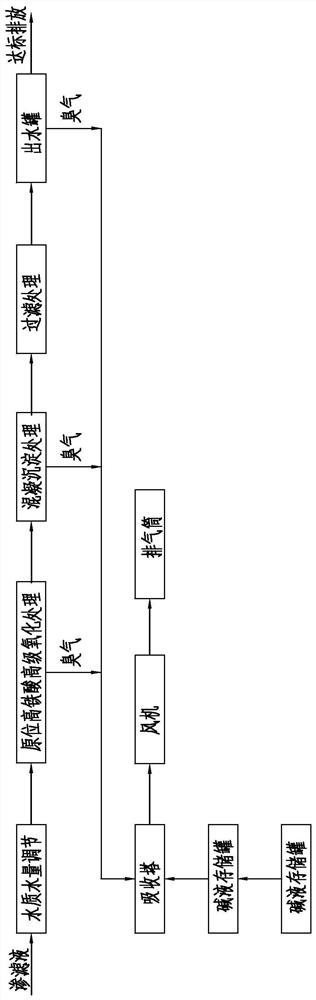

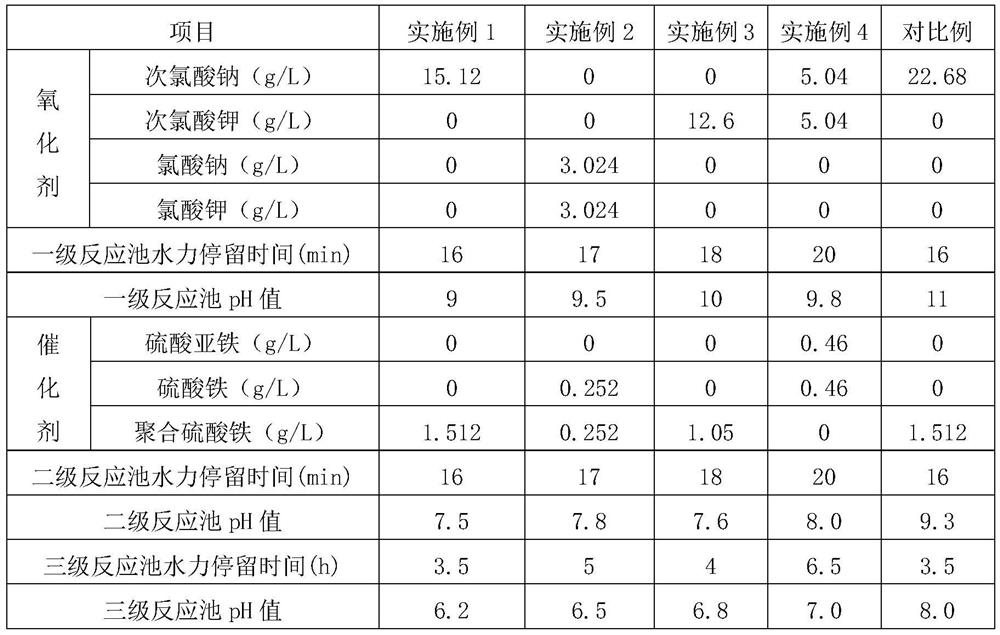

Treatment method of high-salt and high-hardness organic wastewater in fly ash landfill

PendingCN112624395AAvoid complexityAddress the degree of automationWater contaminantsDispersed particle separationPtru catalystActivated carbon filtration

The invention relates to a treatment method of high-salt and high-hardness organic wastewater in a fly ash landfill, which comprises the following steps of: sending percolate in different reservoir areas in a fly ash landfill into an adjusting tank, and stirring for homogenizing adjustment; pumping wastewater into a primary reaction tank to carry out primary oxidation on the wastewater by an oxidant, enabling the wastewater to flow into a secondary reaction tank for a transition reaction with a catalyst, enabling the wastewater in the secondary reaction tank to automatically flow into a tertiary reaction tank, fully stirring, carrying out advanced oxidation reaction to degrade organic matters in the wastewater, and carrying out complex breaking treatment on heavy metals; enabling the effluent to automatically flow into a coagulative precipitation tank, adding an alkali liquor metal recapturing agent and a flocculating agent and fully stirring, enabling supernatant obtained after solid-liquid separation to sequentially pass through a quartz sand filter, a multi-stage activated carbon filter and a heavy metal adsorption resin tank, and enabling the effluent to enter a water outlet tank to be discharged; and enabling odor to react with absorption liquid in an absorption tower and then discharging the odor. The method is simple in technological process, stable in operation, low in requirement for inflow water quality and higher in treatment efficiency, and the investment cost is greatly reduced.

Owner:WELLE ENVIRONMENTAL GRP CO LTD

Roller brush used for building decoration

InactiveCN110578394AAddress the degree of automationSolve the problem that it is inconvenient to replace the rollerBuilding constructionsAutomationArchitectural engineering

The invention discloses a roller brush used for building decoration. The roller brush used for building decoration comprises a handle, a first supporting rod, a paint spraying mechanism, a second supporting rod and a roller brush assembly, wherein the first supporting rod is fixedly connected to the top of the handle, and the paint spraying mechanism is fixedly connected to the top of the first supporting rod. According to the roller brush used for building decoration, through the cooperation of the handle, the first supporting rod, the paint spraying mechanism, a paint box, a feeding port, apaint pump, a discharging pipe, a paint spraying pipe, a spray head, a storage battery, the second supporting rod, the roller brush assembly, a concave block, a rolling bearing, a supporting rotary shaft, a baffle, a roller, a movable plate, a limiting rod, a limiting groove and a reset spring, the problems that a common roller brush used for building decoration is low in automation degree, and aroller cannot be replaced conveniently are solved; in the painting process, a user does not need to place a roller into a paint barrel to dip paint continuously, so that time and labor are saved, andthe working efficiency is greatly improved; and the roller can be disassembled easily, and convenience is brought to the user.

Owner:陕西锦瑞能源开发有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com