Back-to-back double-lens optical axis consistency test fixture and test method

A test fixture and dual-lens technology, which is applied in the direction of testing optical performance, etc., can solve the problems of complex test tool structure, large test result error, and cumbersome test process, so as to achieve scientific and rapid test methods, reduce test costs, and improve test results. effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

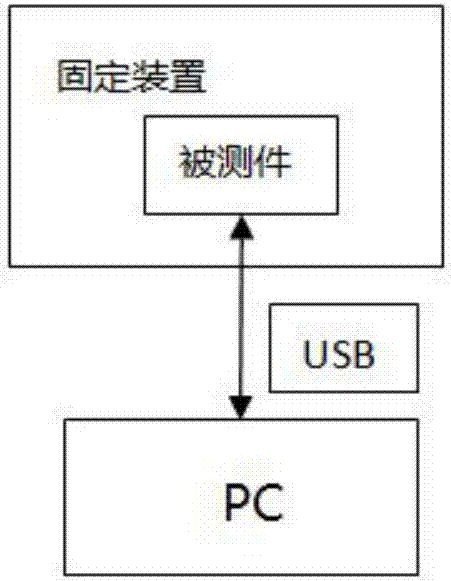

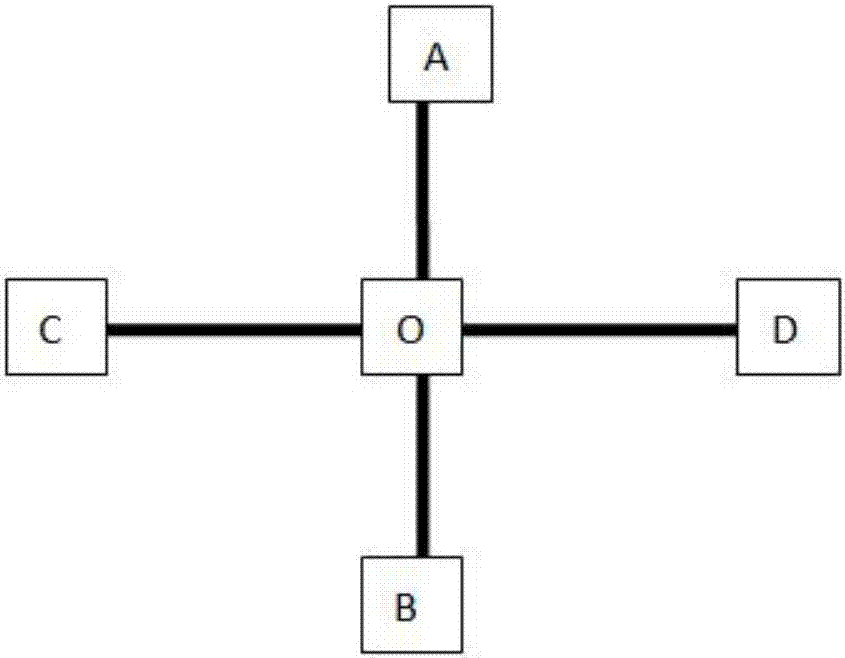

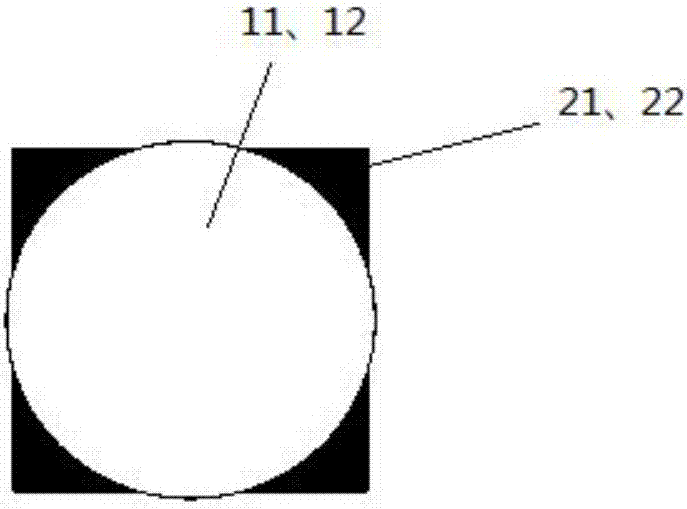

[0039] figure 1It is a schematic block diagram of the hardware connection between the camera and the PC of a back-to-back dual-lens optical axis consistency test fixture according to an embodiment of the present invention; figure 2 It is a schematic diagram of the center point mark and the four end point marks of the marked figure on the chart card according to an embodiment of the present invention; image 3 It is a structural schematic diagram of a camera lens and an optical receiver according to an embodiment of the present invention;

[0040] see figure 1 , the back-to-back double-lens optical axis consistency test fixture, the tested double-lens includes a first lens and a second lens set in a back-to-back structure; the first lens and the second lens are respectively arranged in the camera, and the camera is set There is a USB interface for communication connection with PC; figure 1 Among them, DUT is the device under test, Fixture is the fixture, USB is the universa...

Embodiment 2

[0047] This embodiment focuses on the description of a specific implementation of the back-to-back double-lens optical axis consistency test fixture. For other content, refer to other embodiments of the present invention. Figure 4 It is a structural schematic diagram of a double lens fixed on a 180° rotatable lens holder in an embodiment of the present invention; a specific implementation of the back-to-back double lens optical axis consistency test fixture is as follows:

[0048] see Figure 4 , the tested dual lens includes a first lens 11 and a second lens 12 arranged in a back-to-back structure; the first lens 11 and the second lens 12 are respectively arranged in the camera 3;

[0049] The double lens is fixed on the lens holder 4 which can rotate by 180°, and the lens holder 4 is installed on the jig table; the picture card is arranged at one end of the jig table.

[0050] In this way, after the camera takes pictures to obtain the image formed by the first lens 11 on t...

Embodiment 3

[0054] This embodiment focuses on the description of another specific implementation of the back-to-back dual-lens optical axis consistency test fixture. For other content, refer to other embodiments of the present invention. Figure 5 It is a front view of a back-to-back dual-lens optical axis consistency test fixture according to an embodiment of the present invention; Figure 6 It is a top view of a back-to-back double-lens optical axis consistency test fixture according to an embodiment of the present invention; a specific implementation of the back-to-back double-lens optical axis consistency test fixture is as follows:

[0055] see Figure 5 and Figure 6 , the tested dual lens includes a first lens 11 and a second lens 12 arranged in a back-to-back structure; the first lens 11 and the second lens 12 are respectively arranged in the camera 3;

[0056] The chart includes a first chart 61 and a second chart 62 respectively arranged at both ends of the jig stage 5, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com