Patents

Literature

30results about How to "Test method science" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

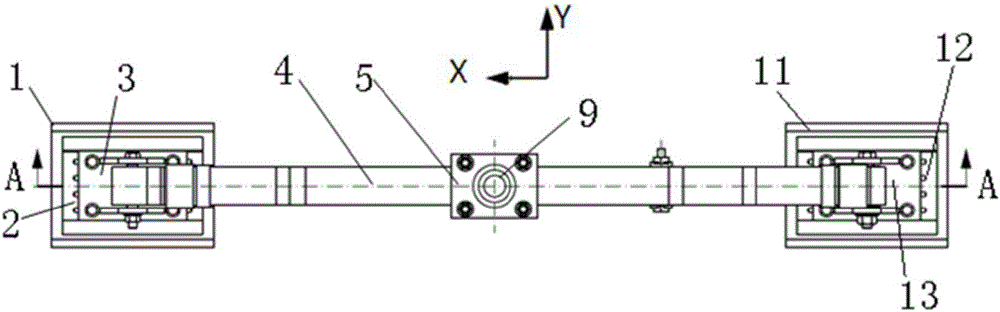

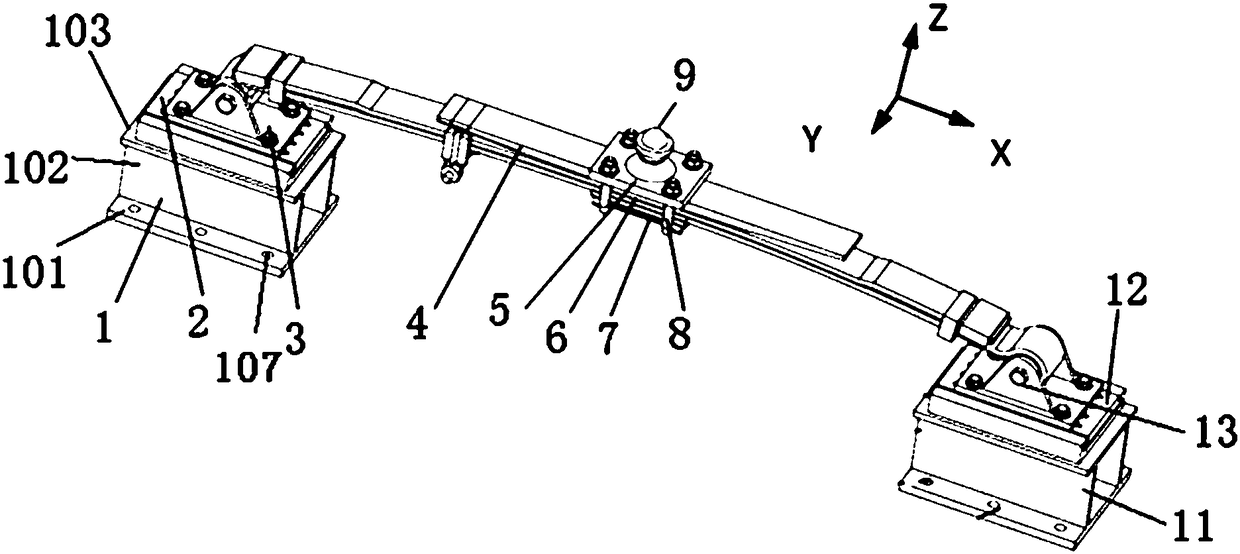

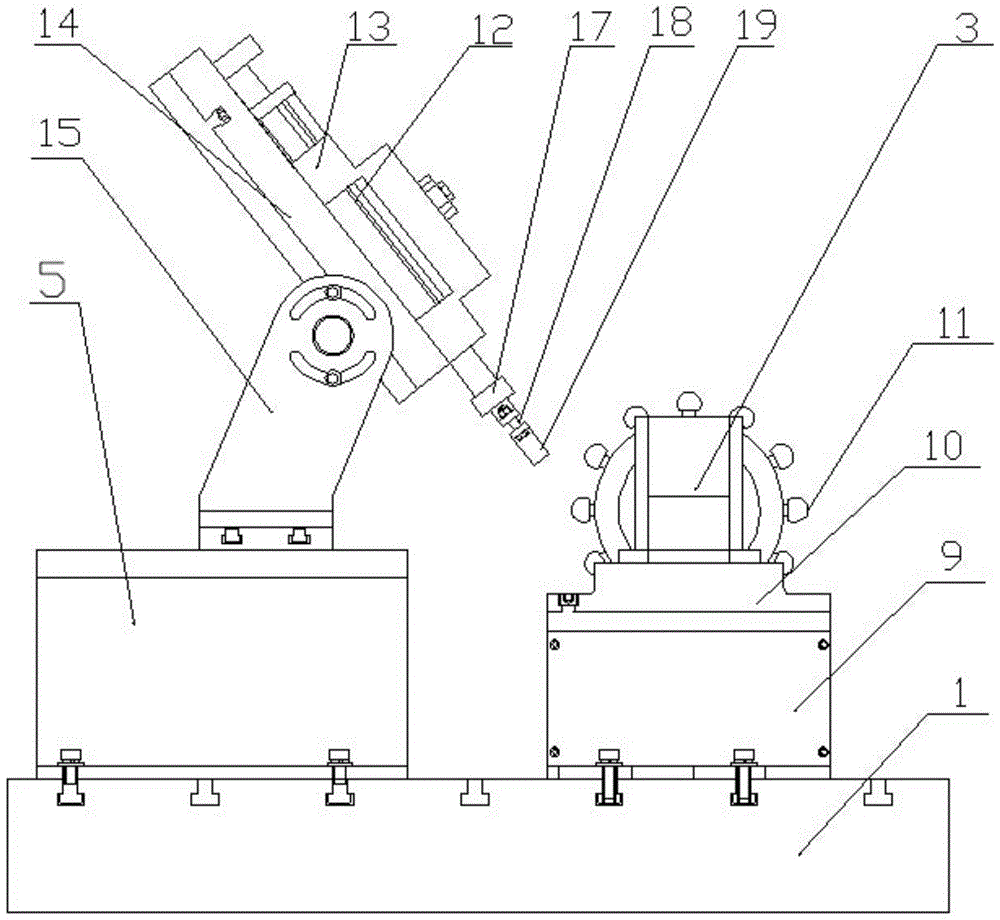

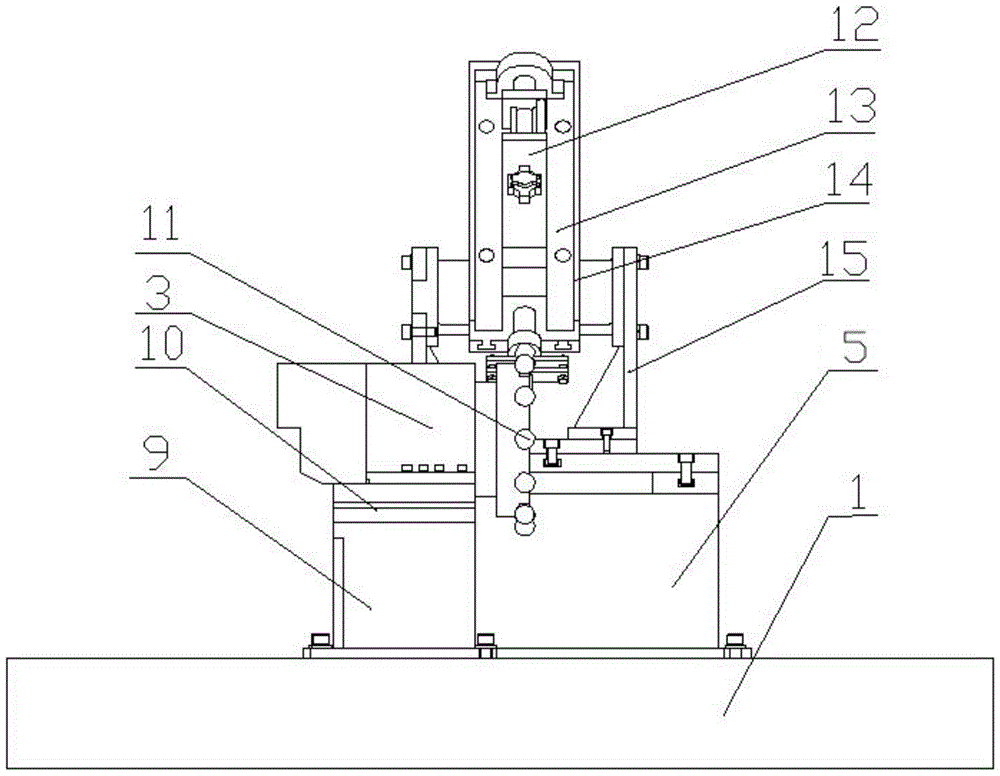

Back-to-back double-lens optical axis consistency test fixture and test method

ActiveCN107063640AAddressing Structural ComplexitySolve the cumbersome testingTesting optical propertiesCamera lensGraphics

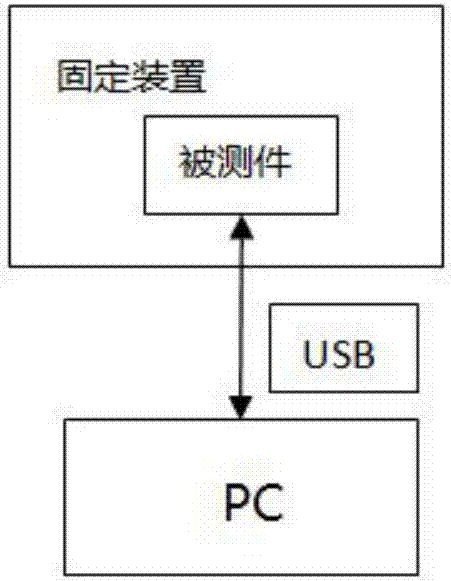

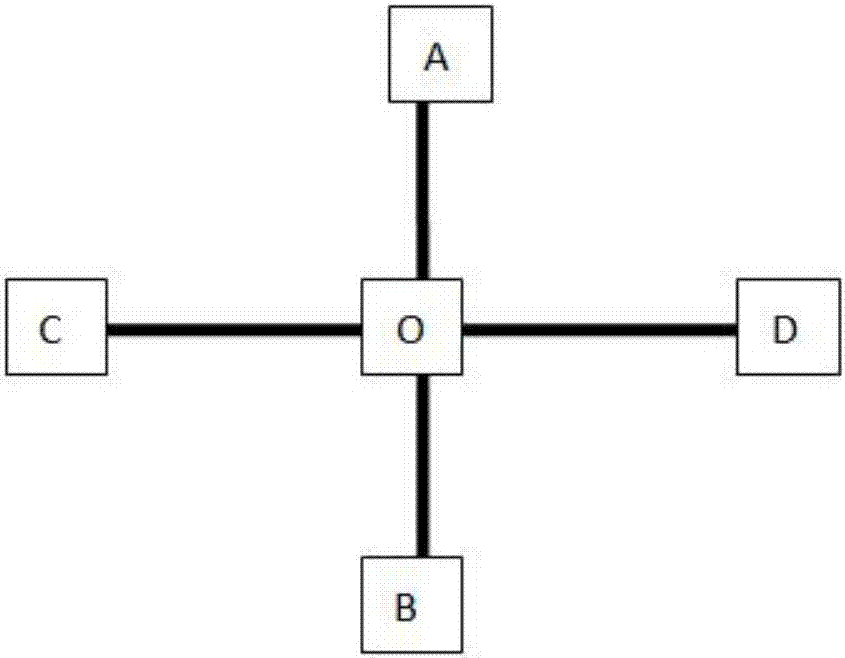

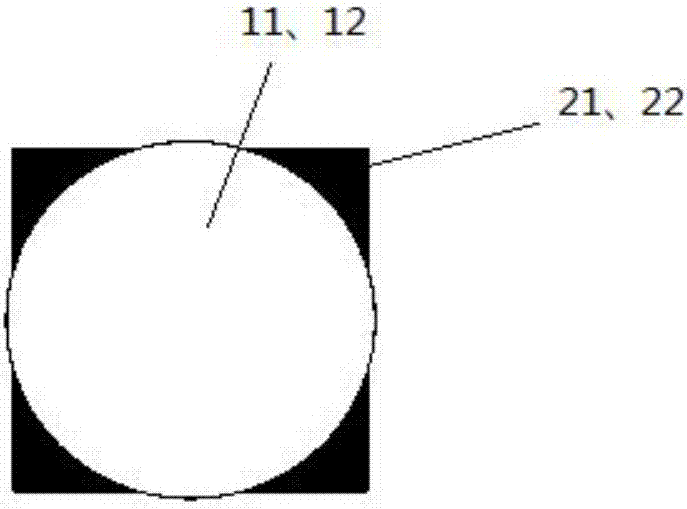

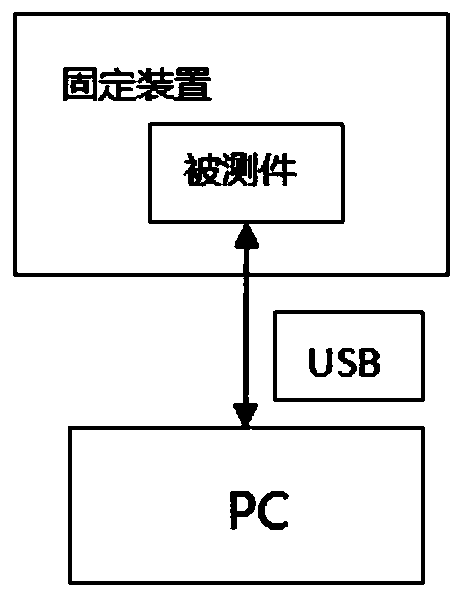

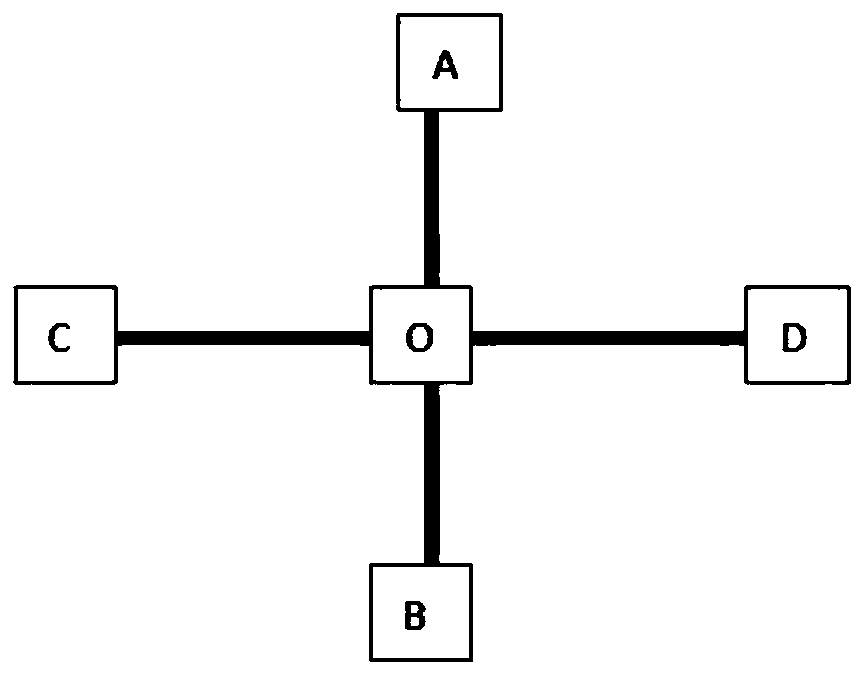

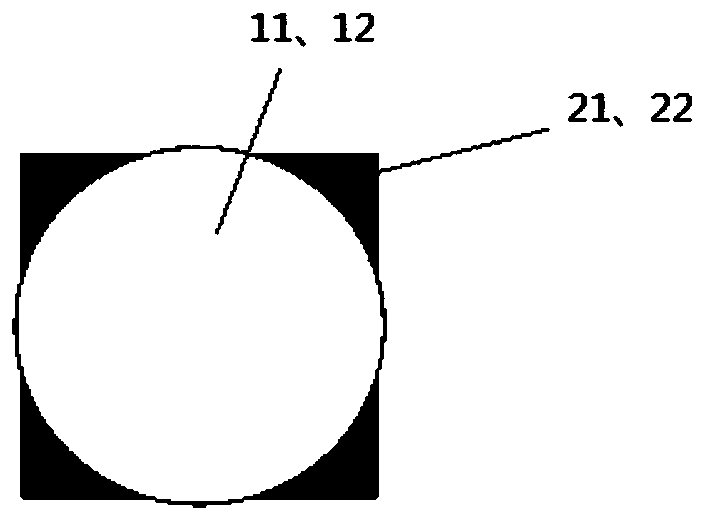

The invention discloses a back-to-back double-lens optical axis consistency test fixture and test method. The test fixture comprises a fixture stage and graph cards; the graph cards and two lenses are arranged on the fixture stage; the graph cards are located at the object sides of the two lenses; each of the graph cards is provided with a rotary variable mark graph; the mark graph includes a center point mark and four end point marks; connecting lines between the non-adjacent end point marks of the mark graph are perpendicular to and equally divided by each other, and the center point mark of the mark graph is overlapped with perpendicular equal-division points; the lens surfaces of the two lenses are parallel with the graph card surfaces of the corresponding graph cards; connecting lines between the center point marks of the graph cards and the centers of the two lenses are perpendicular to the lens surfaces of the two lenses; the tested two lenses include a first lens and a second lens which are arranged in a back-to-back manner; the first lens and the second lens are arranged in a camera; and the camera is provided with a USB interface for communicating with a PC. With the back-to-back double-lens optical axis consistency test fixture and test method provided by the technical schemes of the invention adopted, the problem of judging the consistency of optical axes can be judged. The accuracy of test results of the test fixture and test method is highly.

Owner:GOERTEK OPTICAL TECH CO LTD

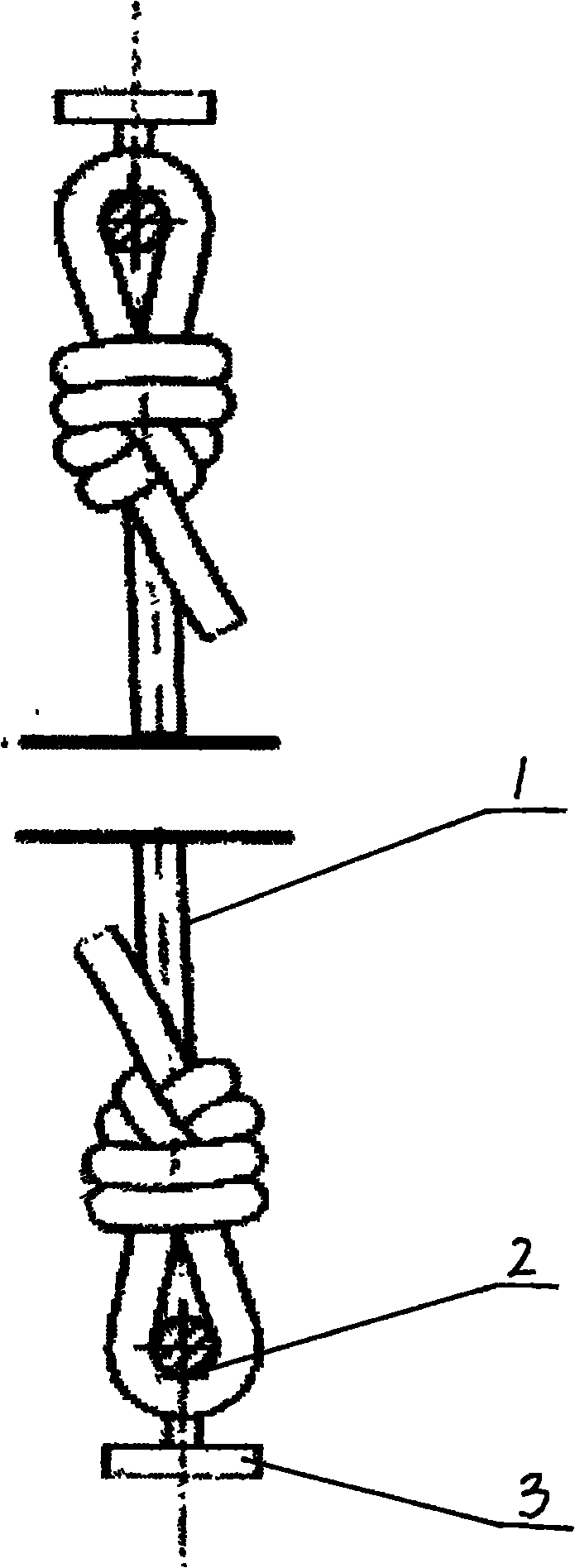

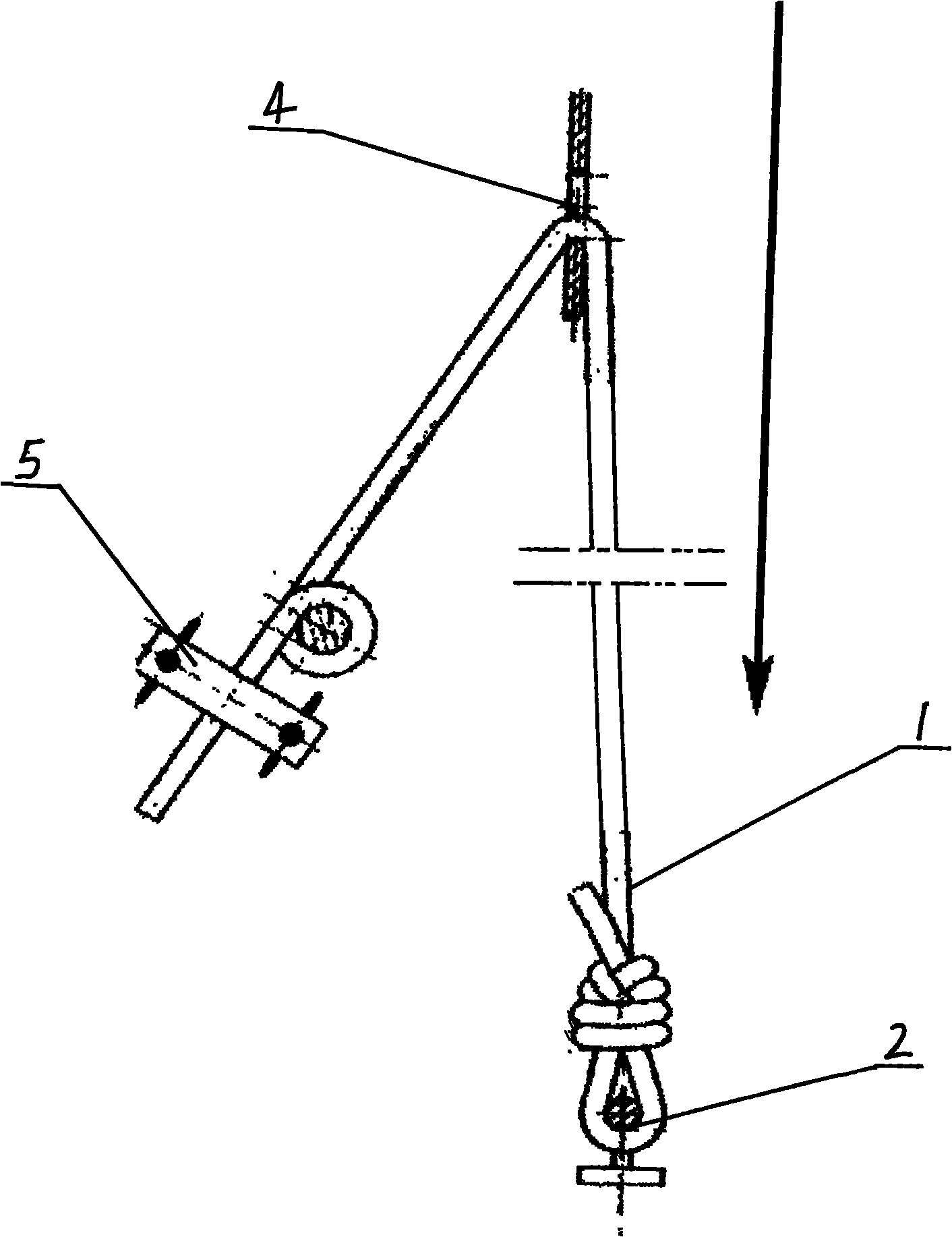

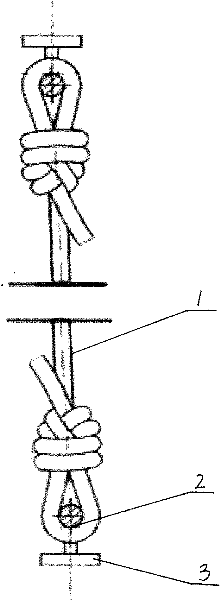

Testing method for safe performance of power climbing rope

ActiveCN101865788ATest method specificationThe test data is accurateStructural/machines measurementStrength propertiesStatic forceReliability engineering

The invention discloses a testing method for safe performance of a power climbing rope, comprising a structure and quality test, a rope leather sliding test, a static force elongation ratio test and a dynamic performance test. The dynamic performance test comprises power elongation ratio, first falling impact force and falling times. Because the testing method is standard and scientific, and the testing data are correct and reliable, the security and the reliability of the power climbing rope are improved.

Owner:TAIAN ROPE NET PLASTIC

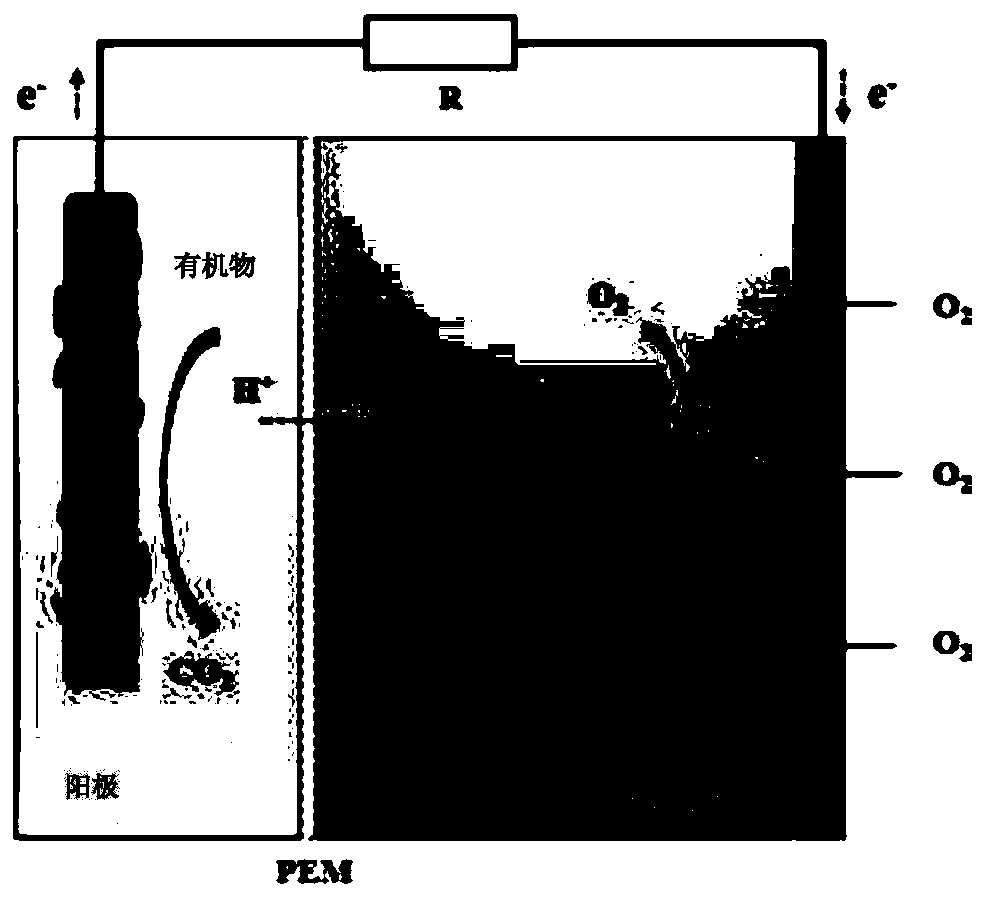

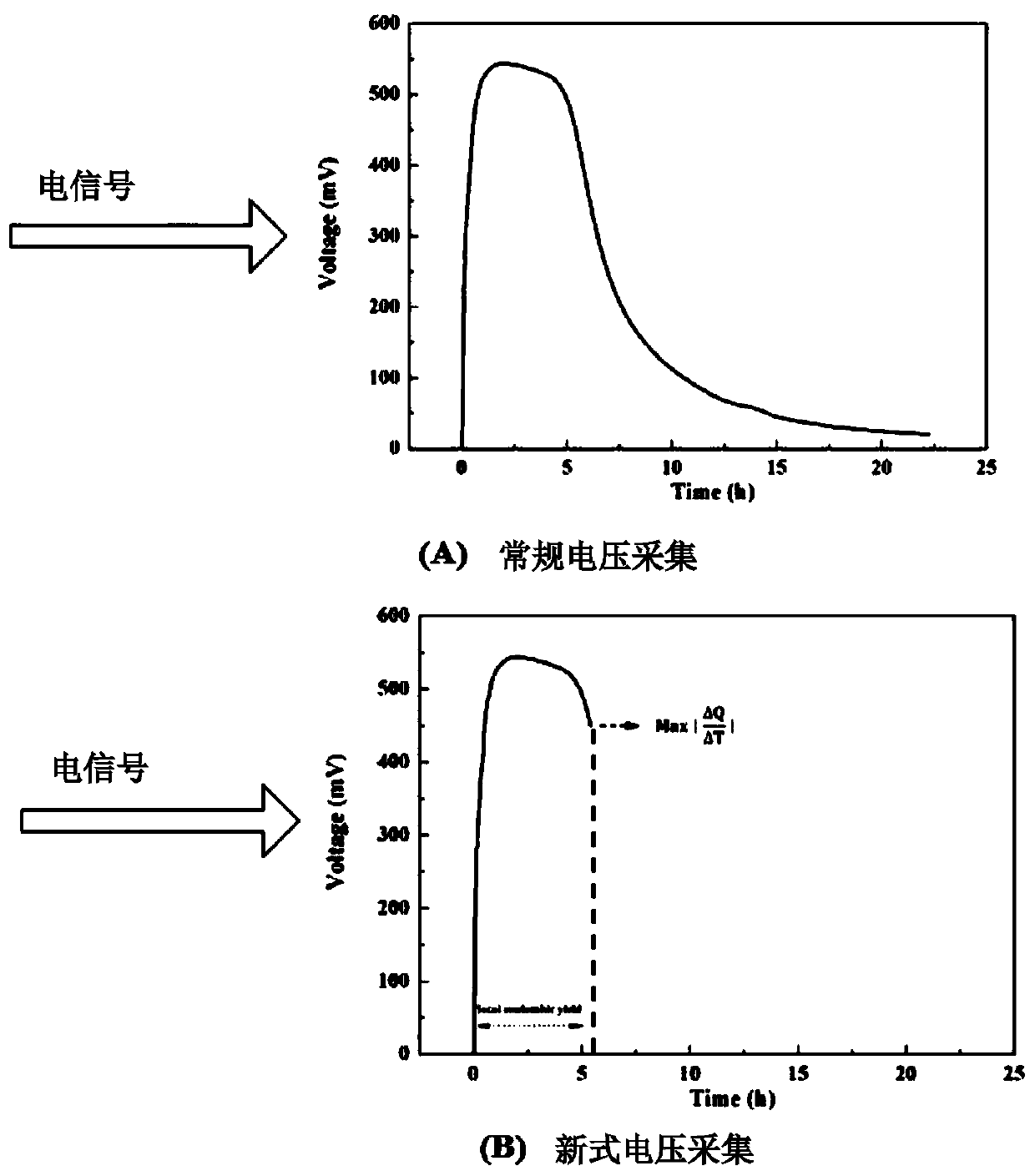

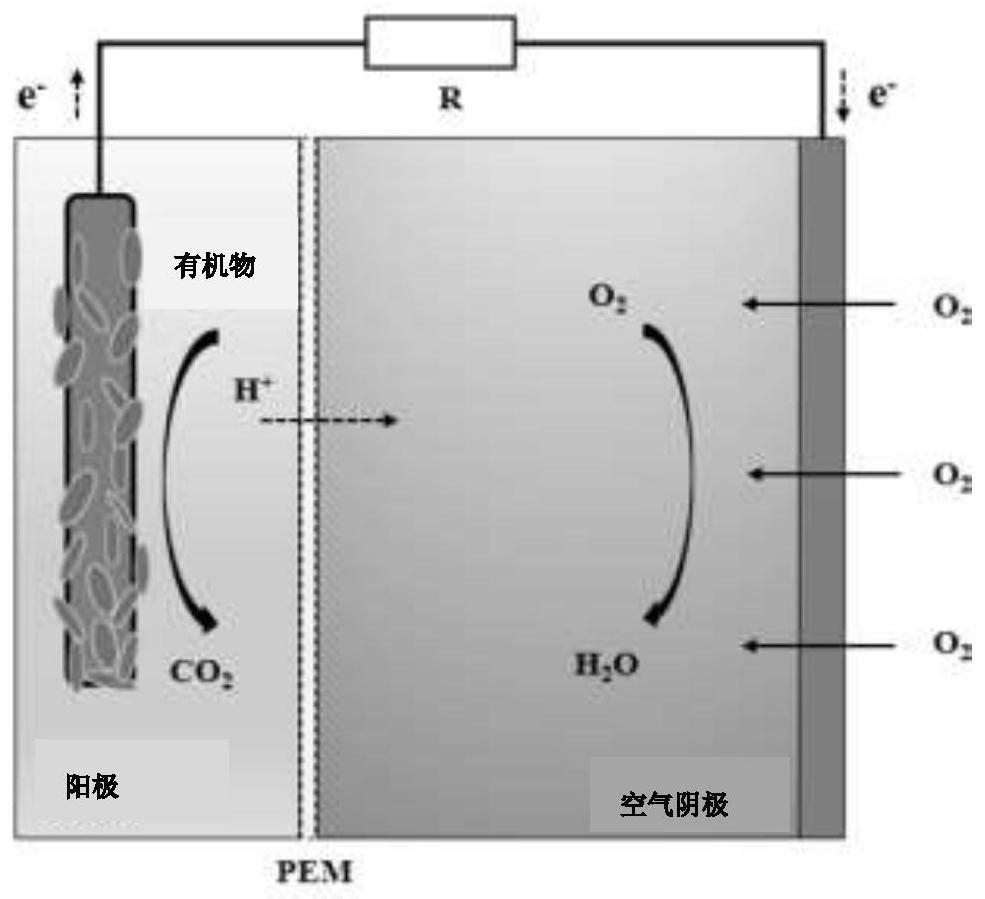

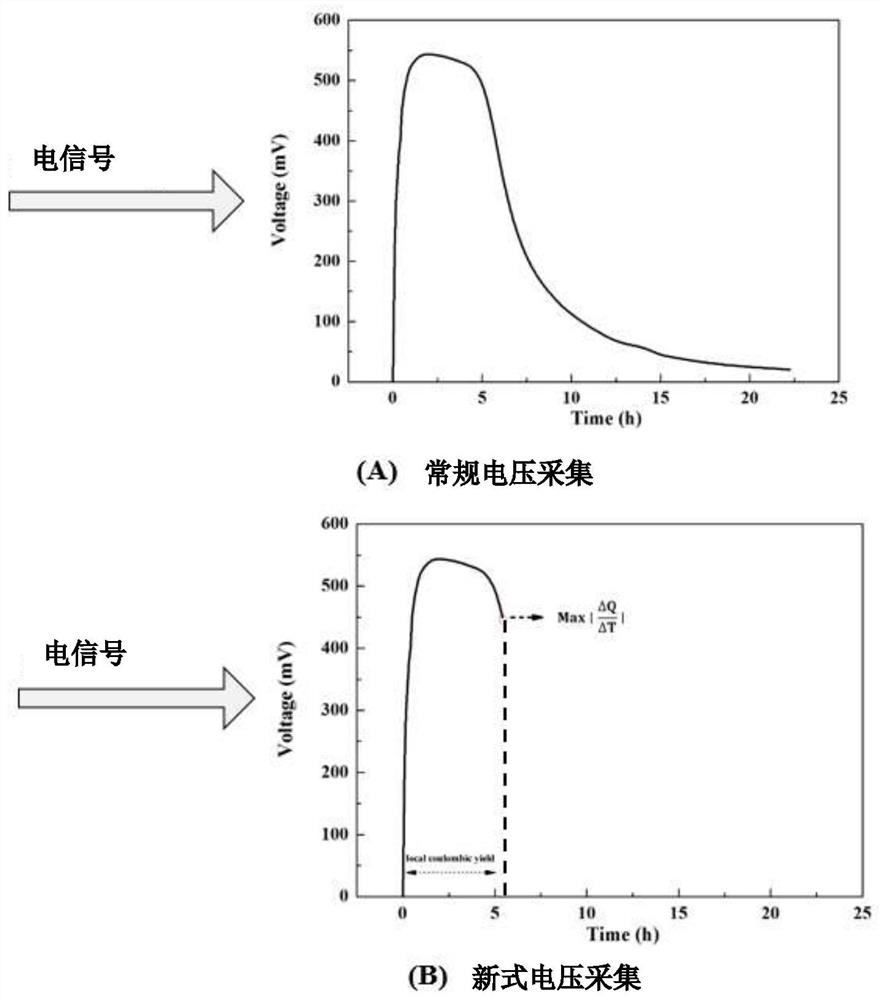

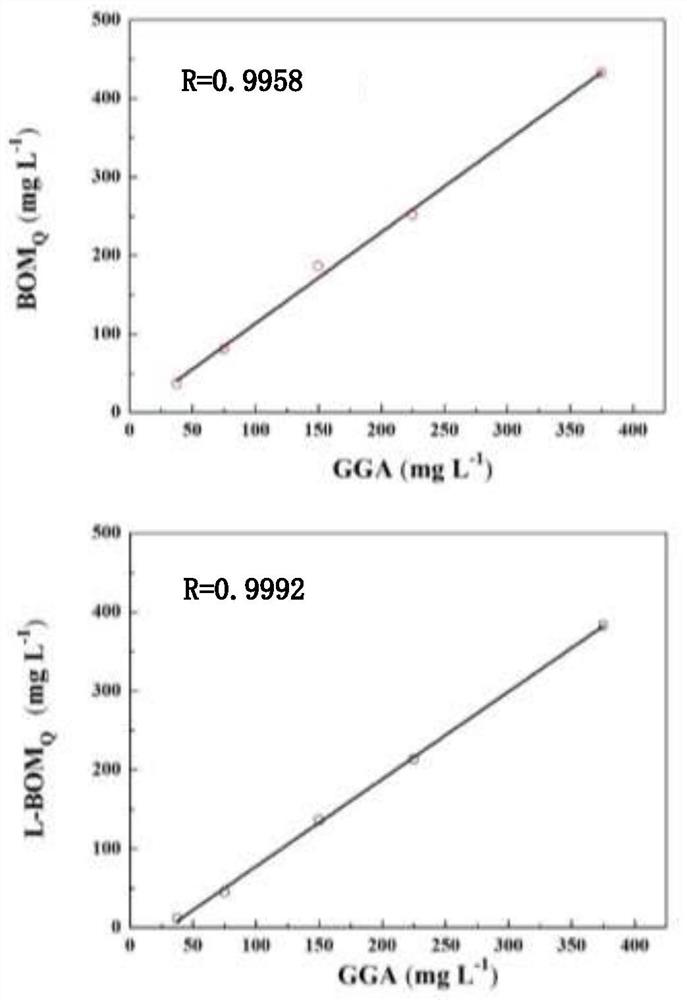

Local coulomb method for measuring biochemically degradable organic matters in water body

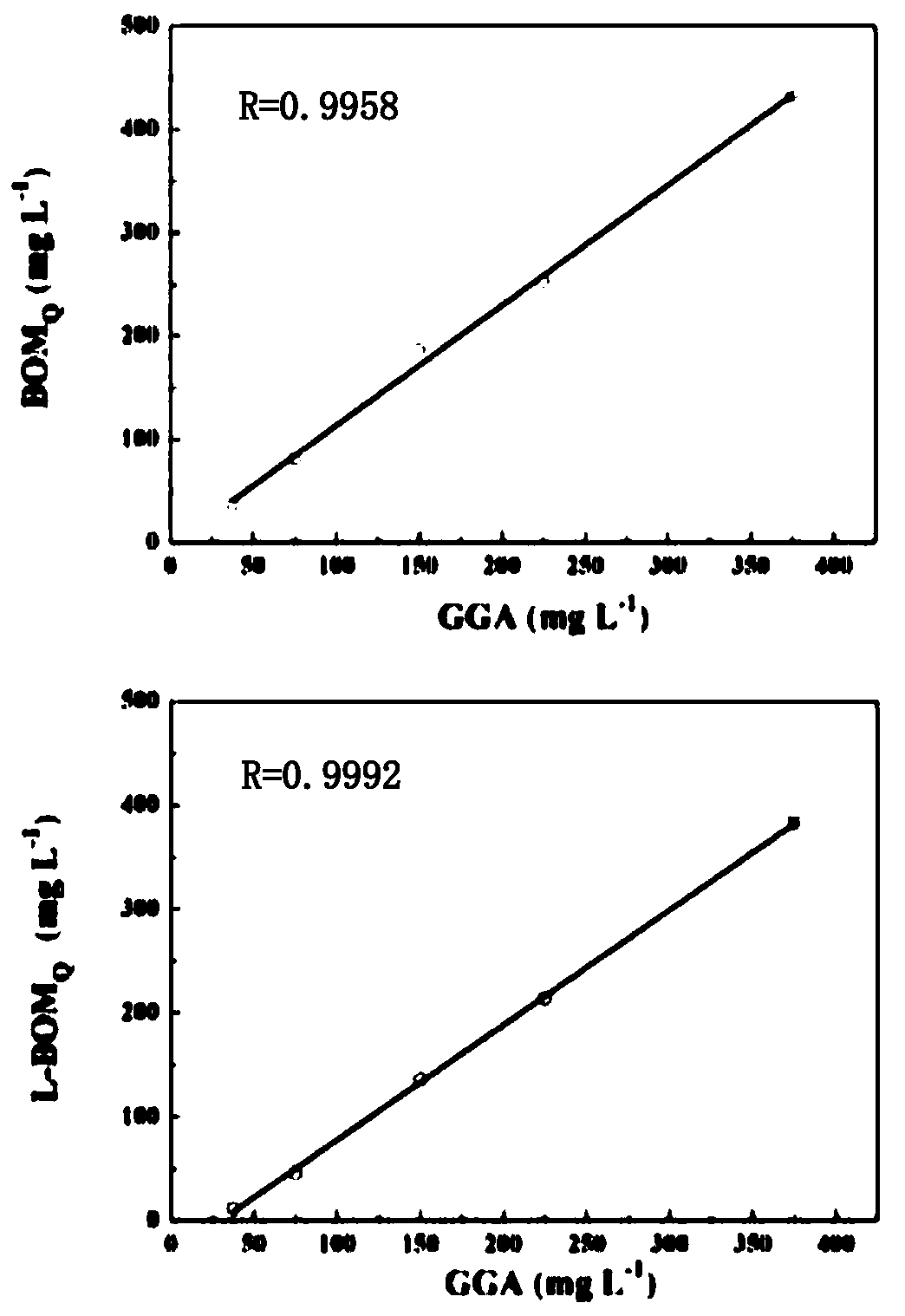

ActiveCN110530956AEasy to findGood linear correlationMaterial electrochemical variablesLinear correlationEngineering

The invention belongs to the technical field of water environment chemical analysis, and particularly relates to a local coulomb method for measuring biochemically degradable organic matters in a water body. According to the method, uniquely a fastest voltage reduction point is selected as a cut-off point for collecting a voltage; the cut-off point is easy to find, and the measurement time can begreatly shortened, so that the operation efficiency is improved; by means of the local coulomb method of the cut-off point selection method, the linear correlation between the value of oxygen consumption BOMQ1 in a measurement result and the concentration of a GGA standard solution for culture of electricigens is better, the more scientific, reasonable and accurate test method is provided for measuring the biochemically degradable organic matters in the water body by utilizing a microbial fuel cell, and new idea and direction are provided for scientific control of water environment pollution;and the method has great popularization values and wide application prospects.

Owner:CHONGQING INST OF GREEN & INTELLIGENT TECH CHINESE ACADEMY OF SCI

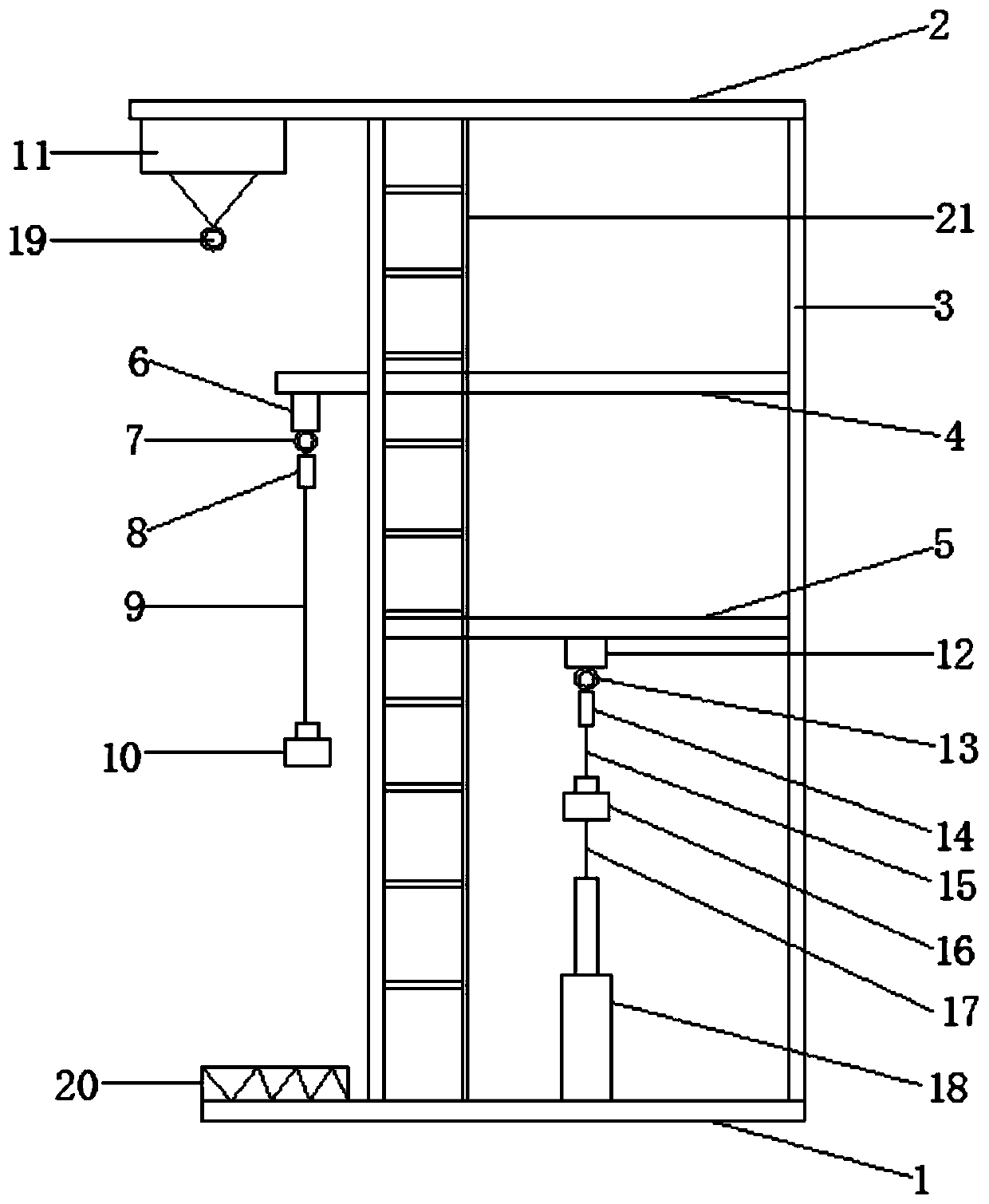

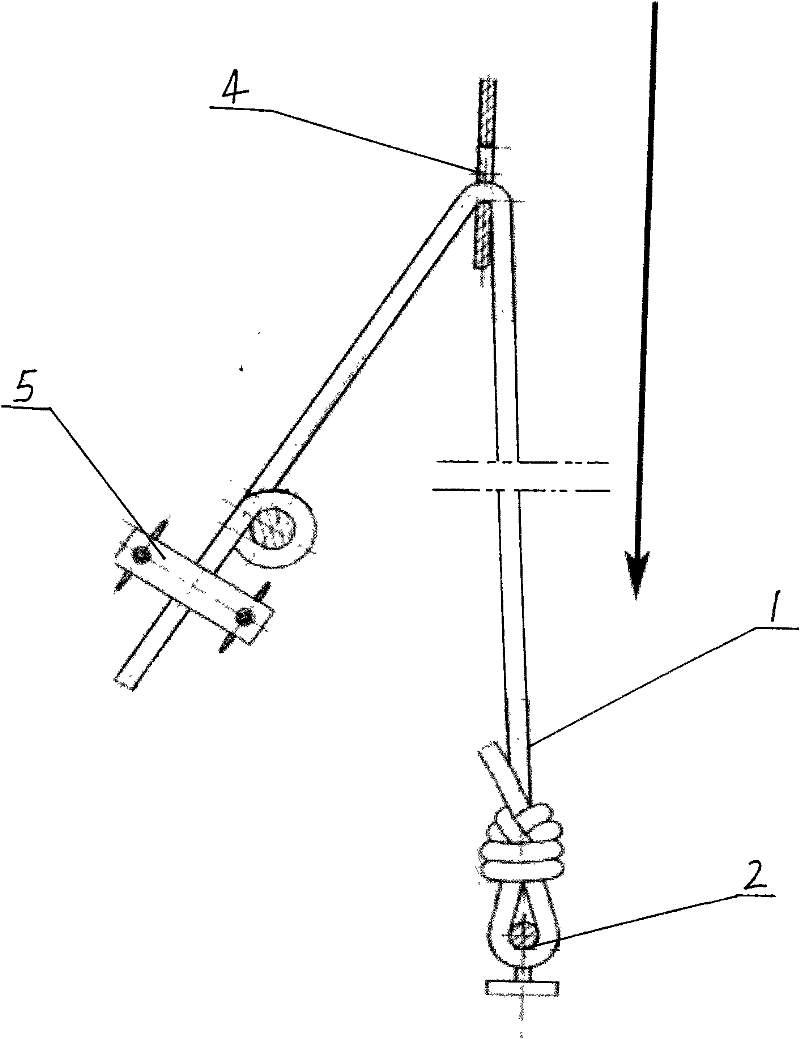

Falling safety protection system comprehensive performance tester and testing method thereof

The invention provides a comprehensive performance tester for a falling safety protection system. The tester includes a bottom plate and a top plate, and four stand columns are fixedly connected between the bottom plate and the top plate; a first installation platform and a second installation platform which are fixedly connected with the four stand columns are sequentially arranged below the topplate, the bottom of the end, extending out of the four stand columns, of the first installation platform is fixedly connected with an impact sensor, a first hanging ring of the impact sensor is connected with a first buffer bag, the first buffer bag is connected with a first safety rope, and the first safety rope is connected with a safety belt worn on a first test dummy; and a tension sensor isfixedly connected to the middle of the bottom of the second installation platform, a second hanging ring of the tension sensor is connected with a second buffer bag, the second buffer bag is connectedwith a second safety rope, the second safety rope is connected with a safety belt worn on a second test dummy, and the second test dummy is connected with an oil cylinder through a third safety rope.The tester is convenient to operate, high in test efficiency, accurate and reliable in test data and capable of testing the static performance of the falling safety protection system.

Owner:TAIAN ROPE NET PLASTIC

Testing device for analyzing moving function of animal limb and footmark

The invention relates to the research field of animal limb movement function and footprint analysis, and discloses a test device for analyzing the animal limb movement function and the footprint. The test device comprises tracks and soft ceramic layers applied on the bottom plates of the tracks, wherein the tracks consist of a straight flat segment, a turning segment, an upslope segment, a downslope segment and an upper step or lower step segment; lateral plates are arranged on both sides of the tracks; the lateral plates and the bottom plates are detachable; and particularly, the lateral plates can be made of one-way transparent glass to facilitate observation or photographing.

Owner:许汉鹏

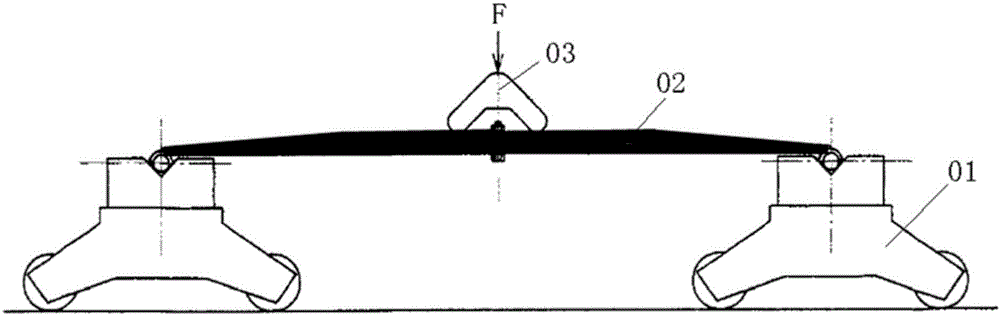

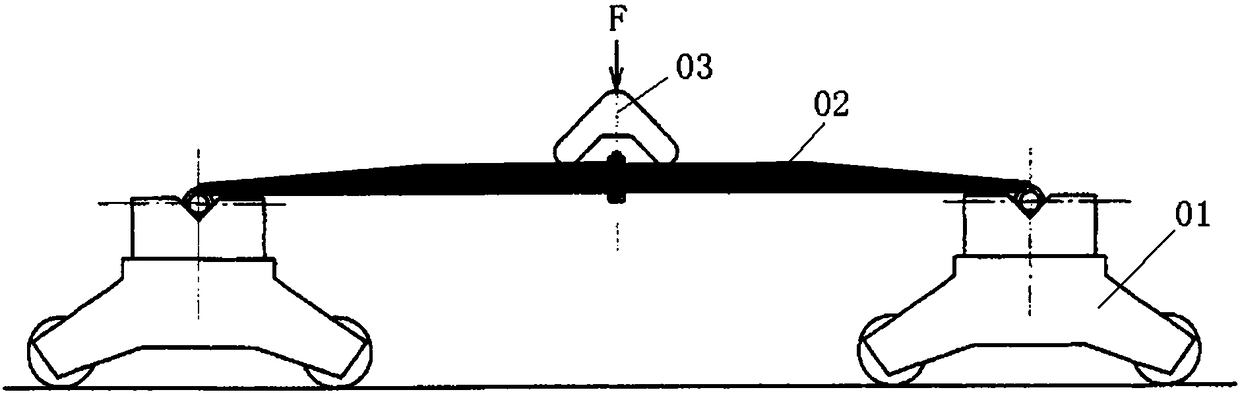

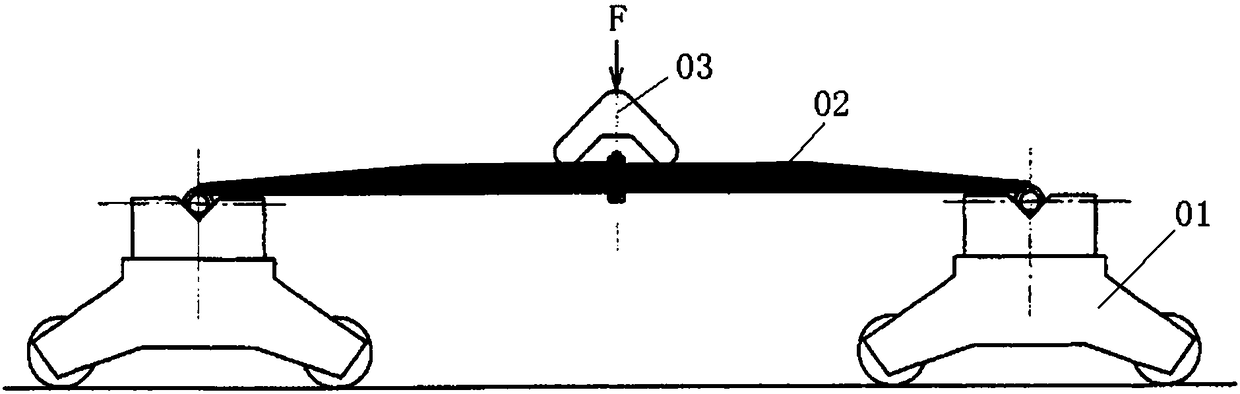

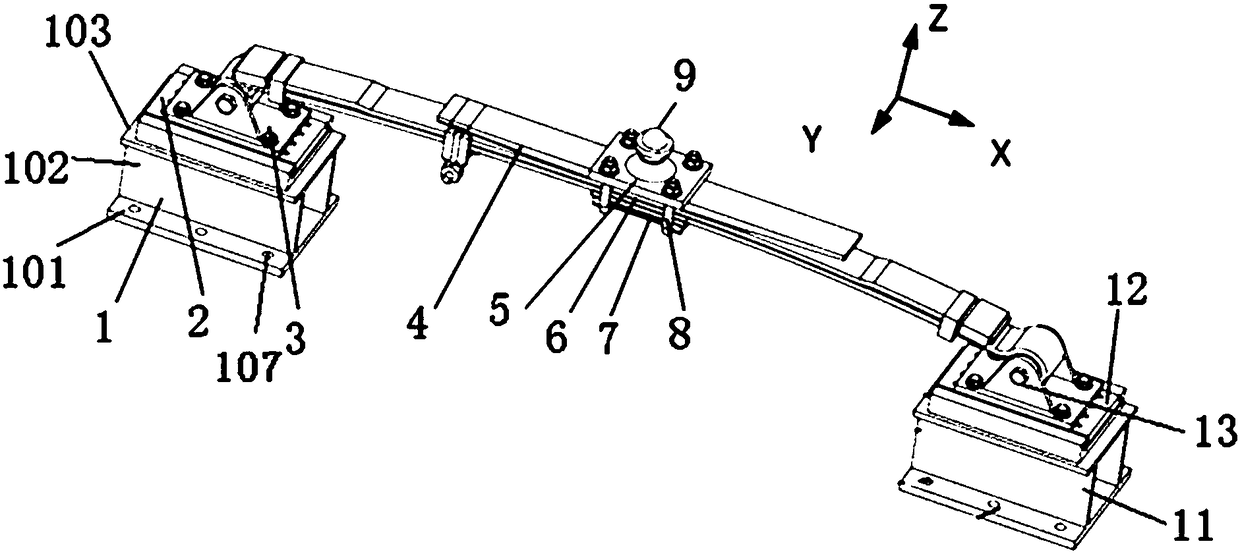

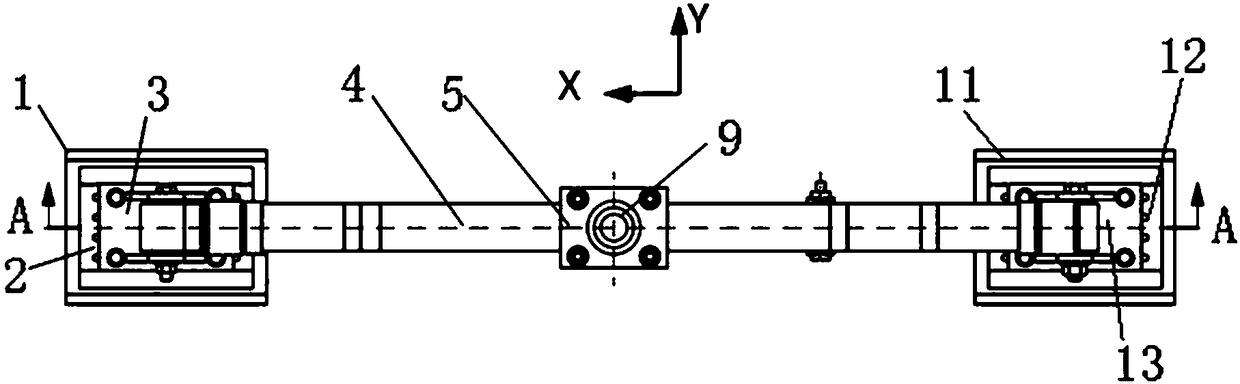

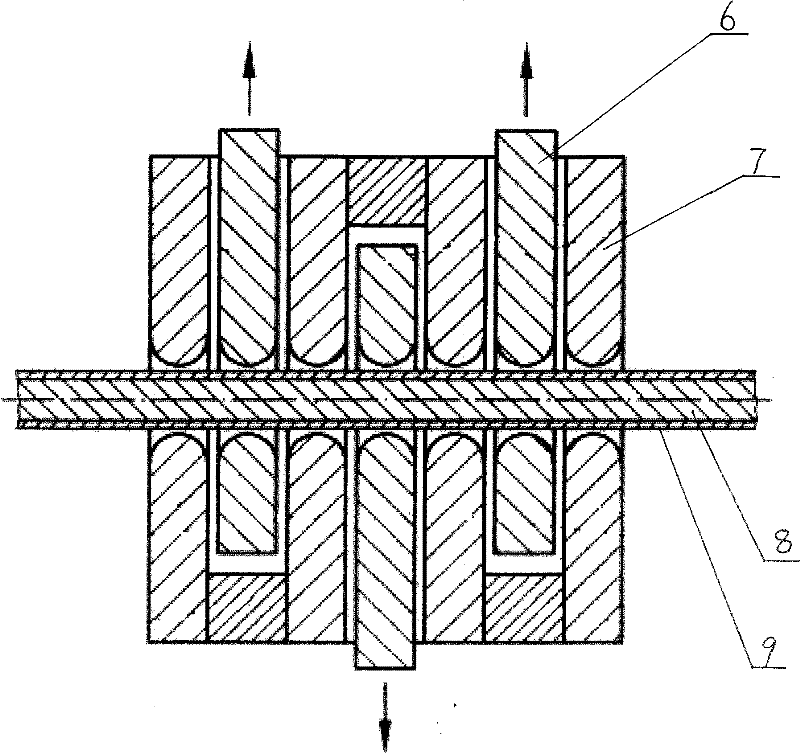

Vertical force-bearing bench testing method for plate spring

ActiveCN106323612AMeet the needs of exerciseEliminate the effects ofMachine part testingElasticity measurementEngineeringVertical force

The invention provides a vertical force-bearing bench testing method for a plate spring. The vertical force-bearing bench testing method comprises a rigidity characteristic test, a dynamic rigidity characteristic test and a vertical-direction fatigue test. The testing method of the invention realizes sufficient simulation of vertical force bearing and motion of a plate spring assembly on a vehicle so that performance of the plate spring assembly sufficiently satisfies a requirement for whole-vehicle motion. In the rigidity characteristic test, the dynamic rigidity characteristic test and the vertical-direction fatigue test, scientific performance and high accuracy are realized; and furthermore through a vertical force-bearing bench structure for the plate spring, influence of a torque which is generated after inclination of the plate spring assembly to the bench is prevented, and high safety in the testing process is ensured.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

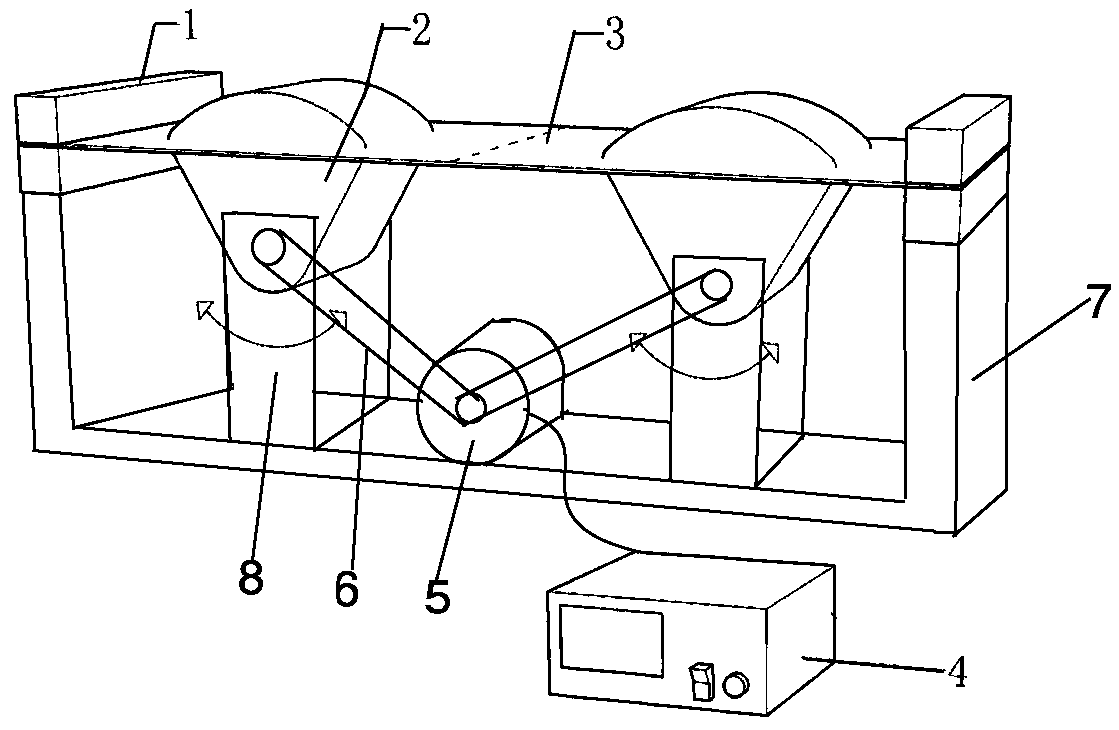

Device and method for dynamically testing fabric quality

ActiveCN108844808AGood detection effectImprove efficiencyMaterial strength using repeated/pulsating forcesInvestigating abrasion/wear resistanceThrough transmissionCam

Owner:江苏省纺织产品质量监督检验研究院

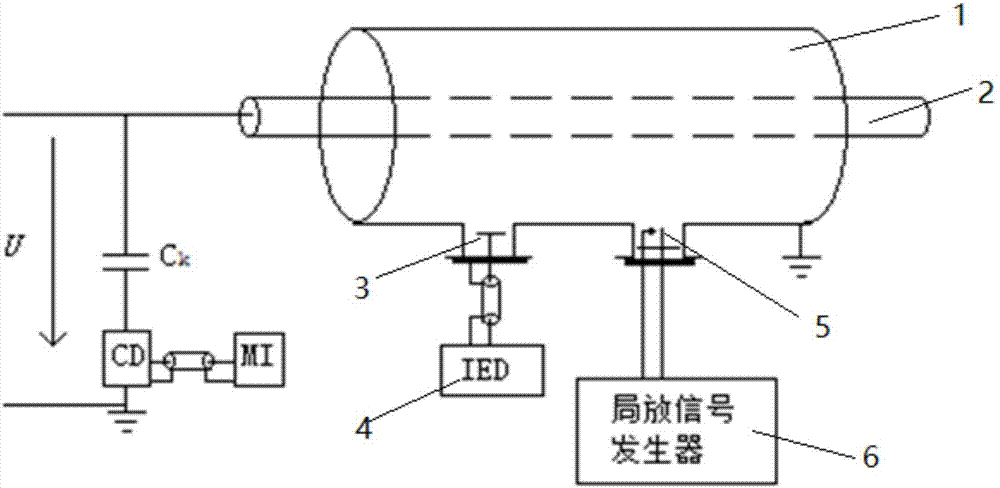

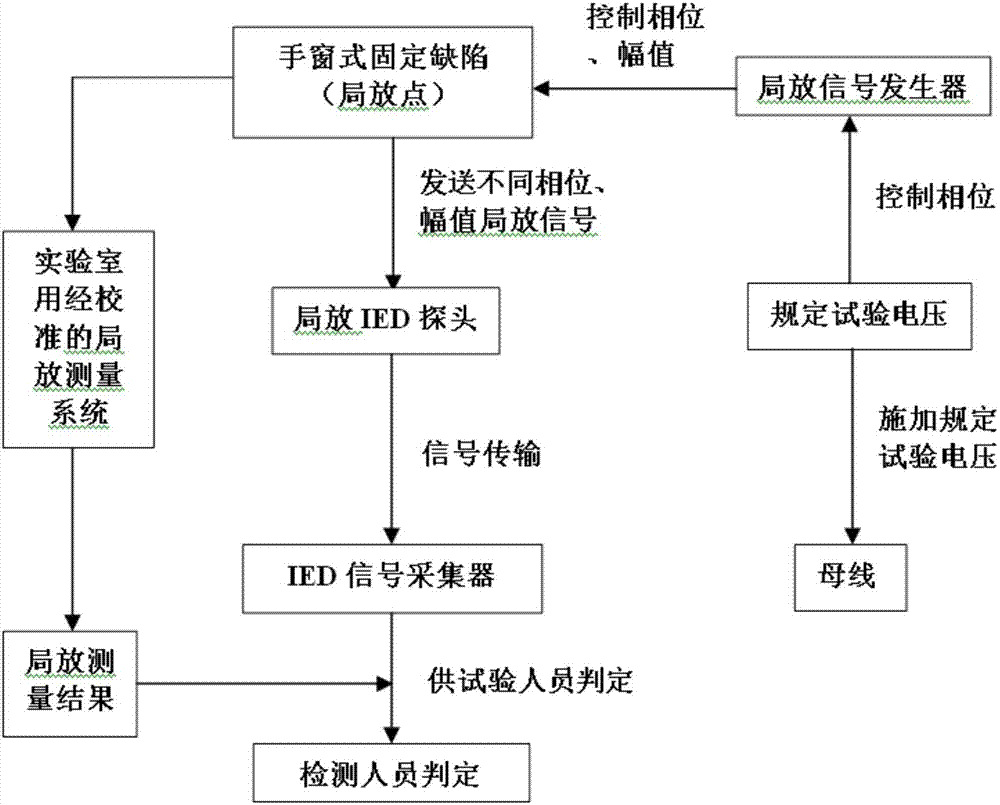

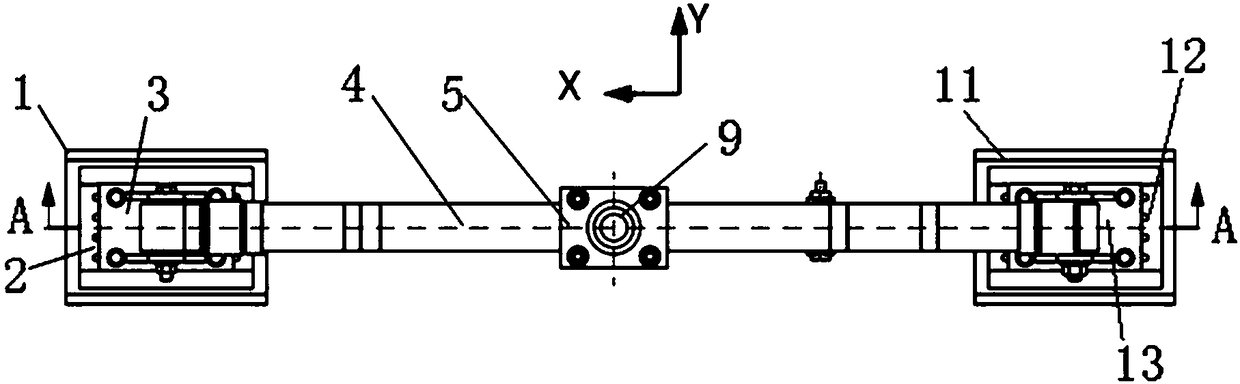

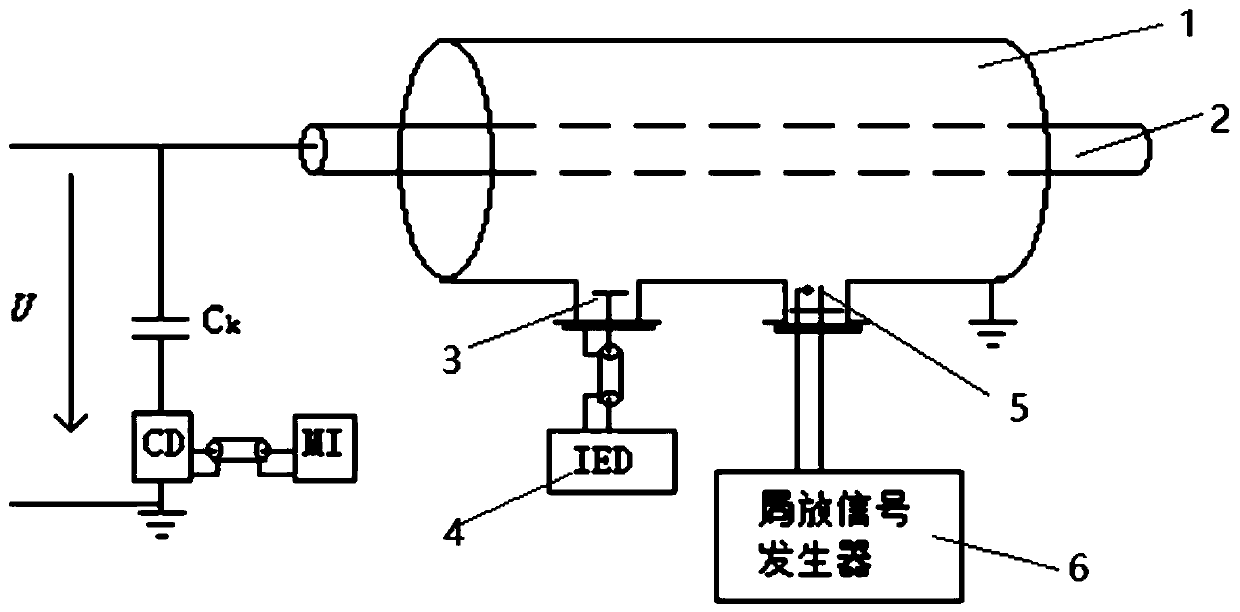

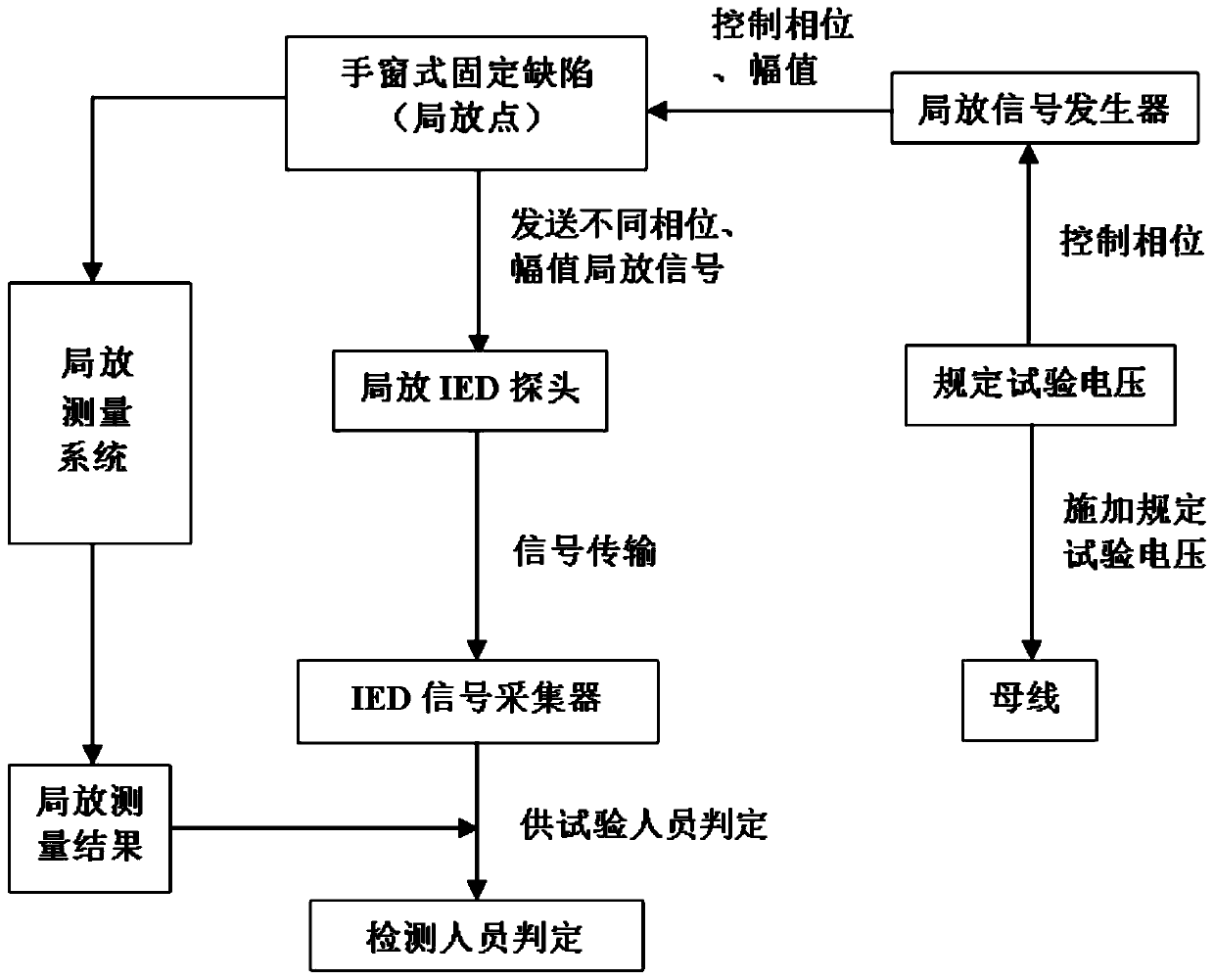

Intelligent GIS partial discharge IED test loop and method

ActiveCN107167715ASimple test circuitIncrease the partial discharge test voltageTesting dielectric strengthCapacitancePartial discharge

The invention discloses an intelligent GIS partial discharge IED test loop and method, and the test loop comprises a partial discharge signal generator, a partial discharge IED probe, a coupling capacitor Ck, a coupling device CD, a partial discharge measurement system MI, and a test power supply U. The high-voltage end of the test power supply U is connected with the coupling capacitor Ck and the coupling device CD, and the other end of the coupling device CD is connected with the lower end of the test power supply U and is also grounded. The partial discharge measurement system MI is connected with the coupling device CD. The high-voltage end of the test power supply U is connected with one end of a bus passing through a GIS housing, and the GIS hosing is grounded. The partial discharge IED probe stretches into the GIS housing, and a signal transmitting end of the partial discharge signal generator stretches into the GIS housing, and is used for generating a partial discharge signal. The test loop is simple. Only if a hand-window type discharge gap is made on an intelligent GIS housing, can the test loop achieve the purposes of improving the partial discharge voltage, improving the testing efficiency and protecting the environment.

Owner:XIAN HIGH VOLTAGE APP RES INST CO LTD

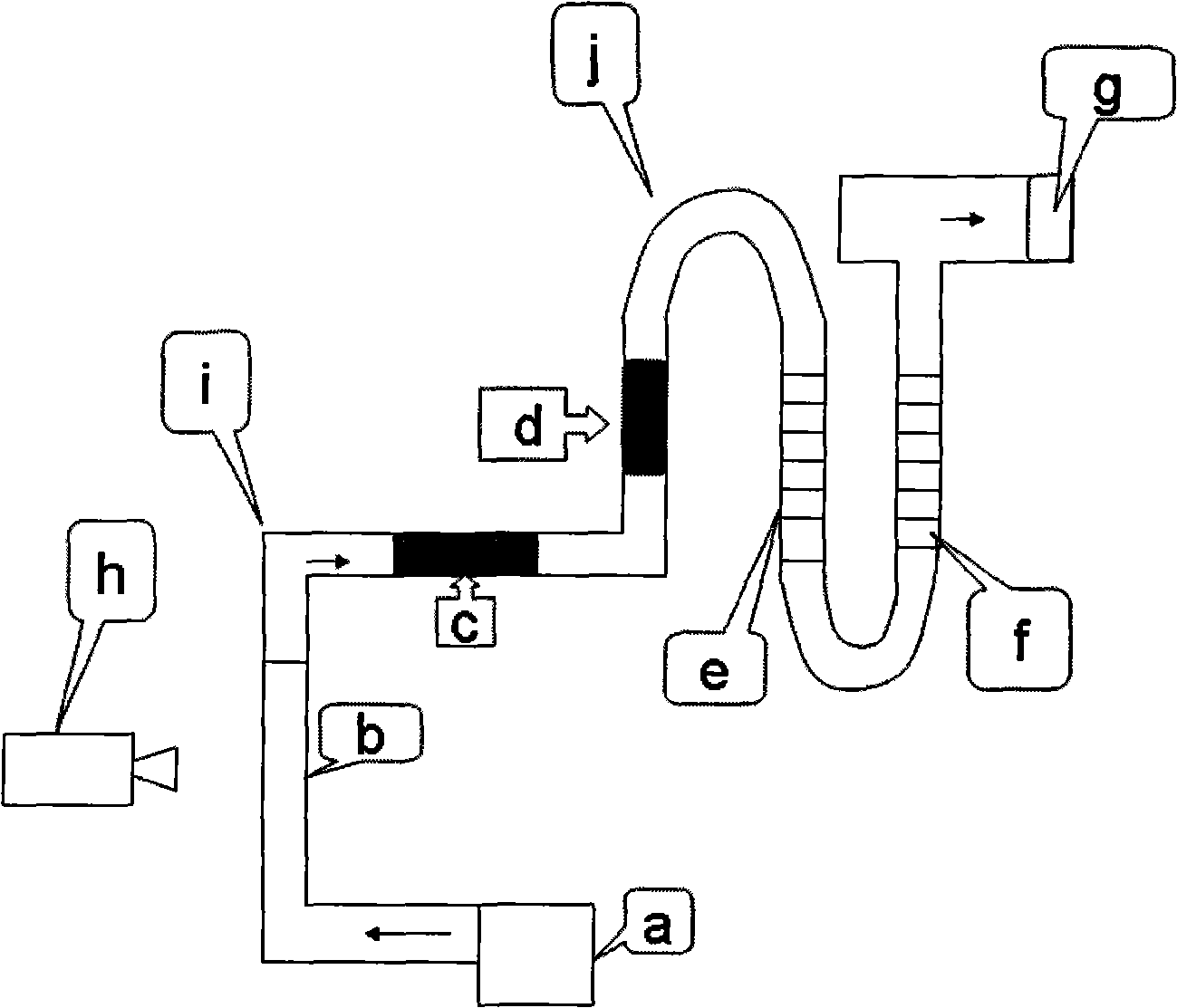

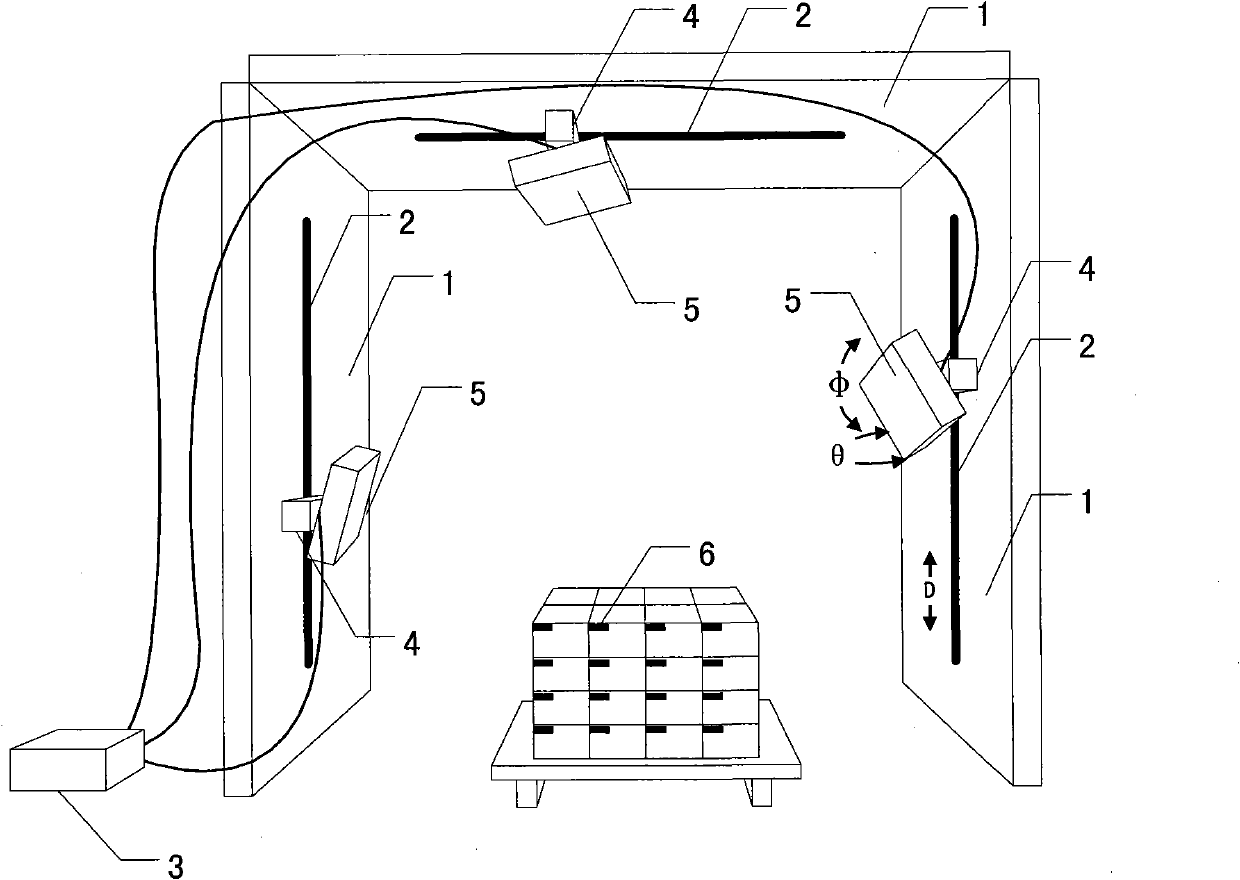

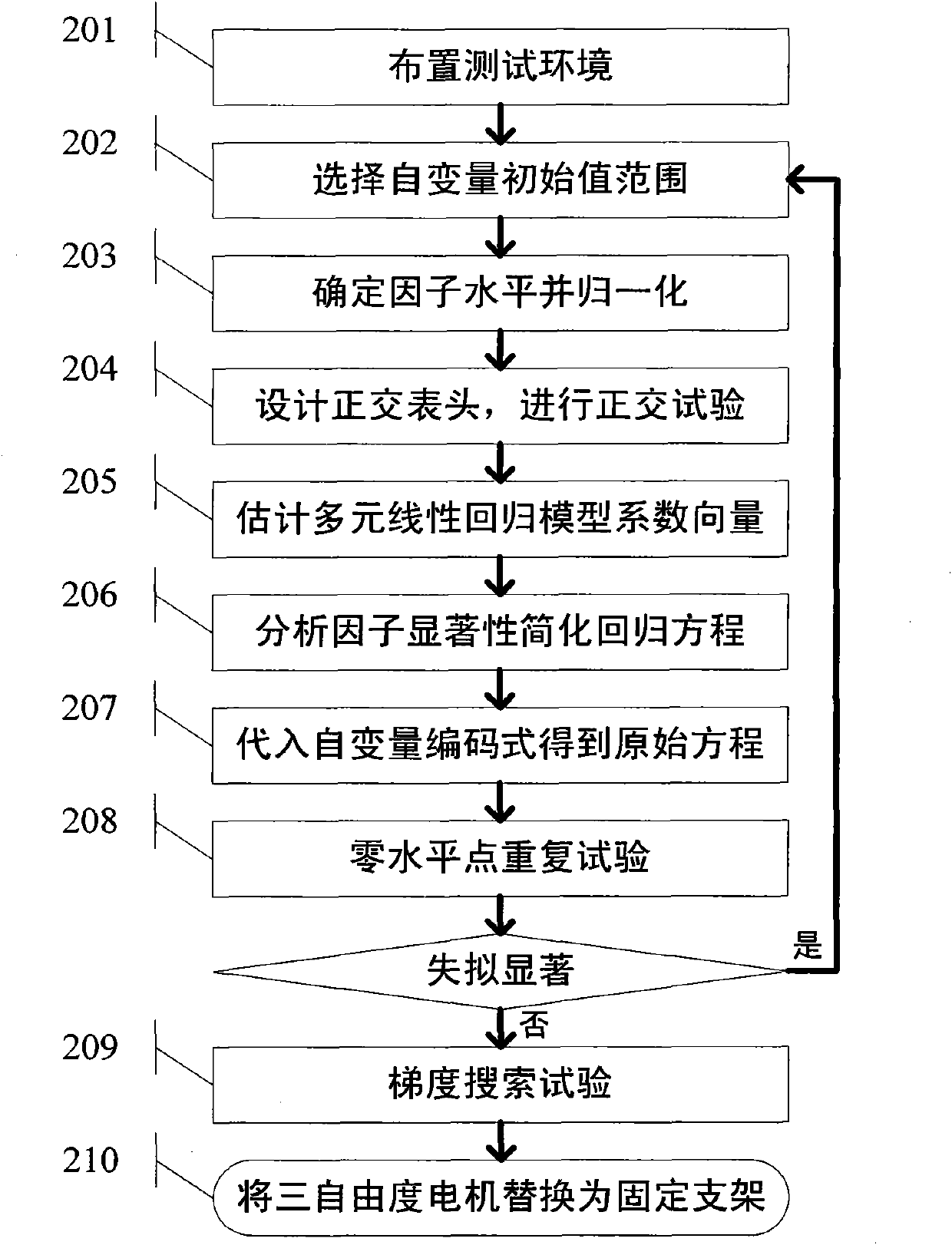

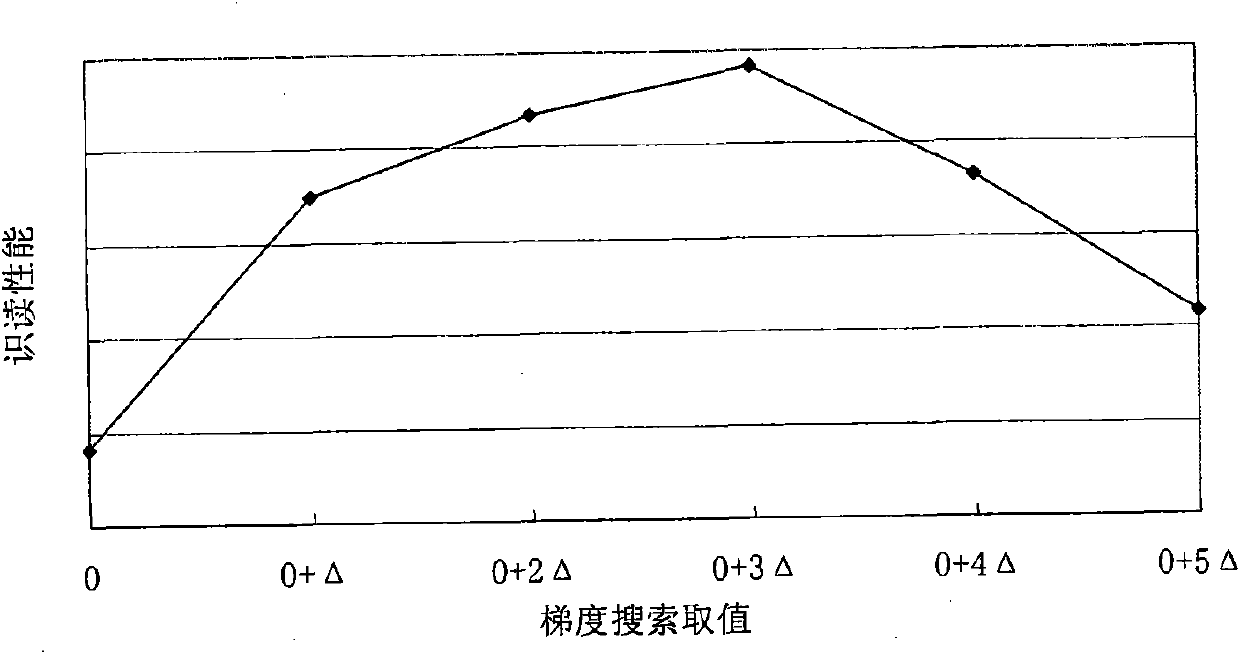

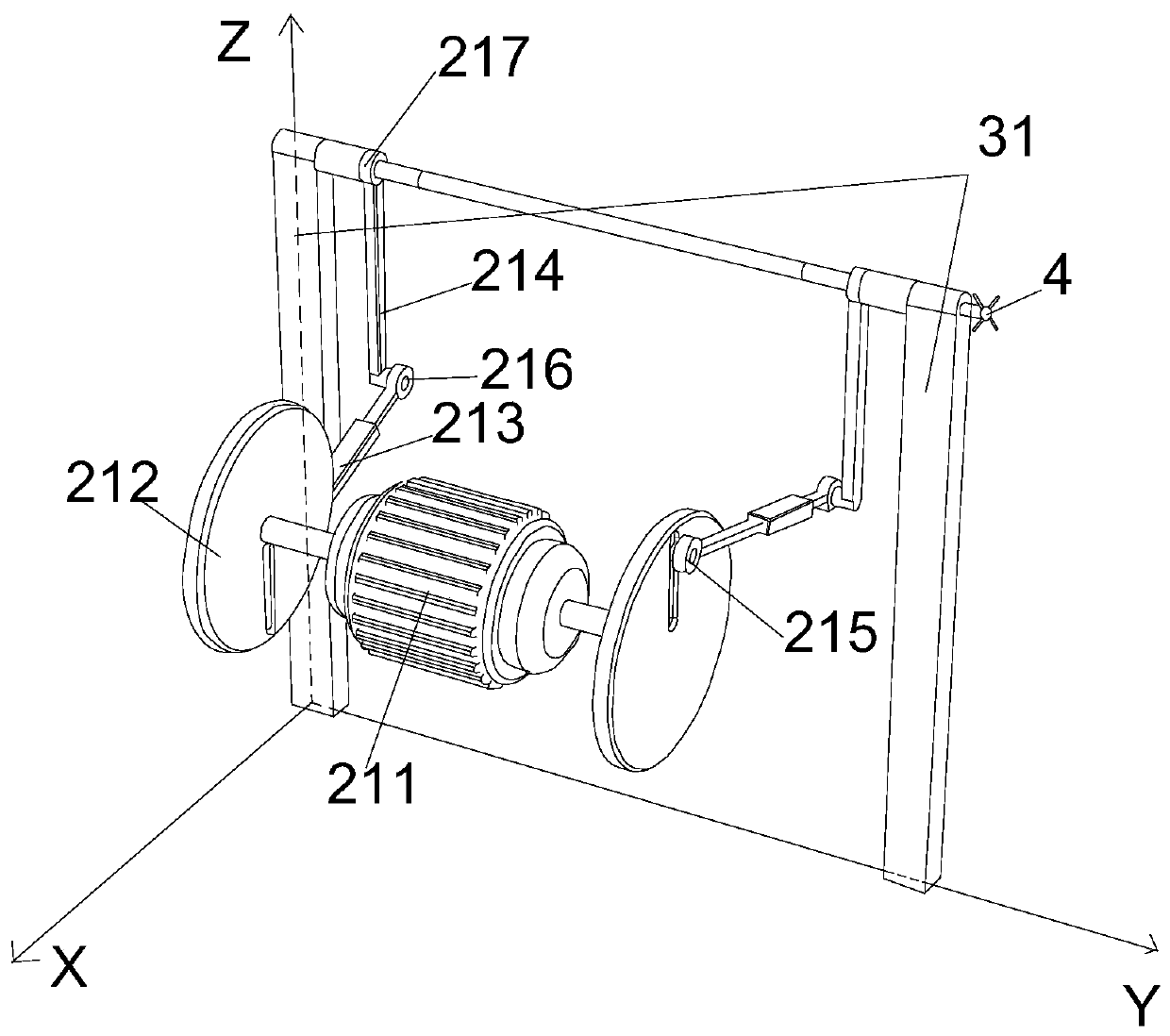

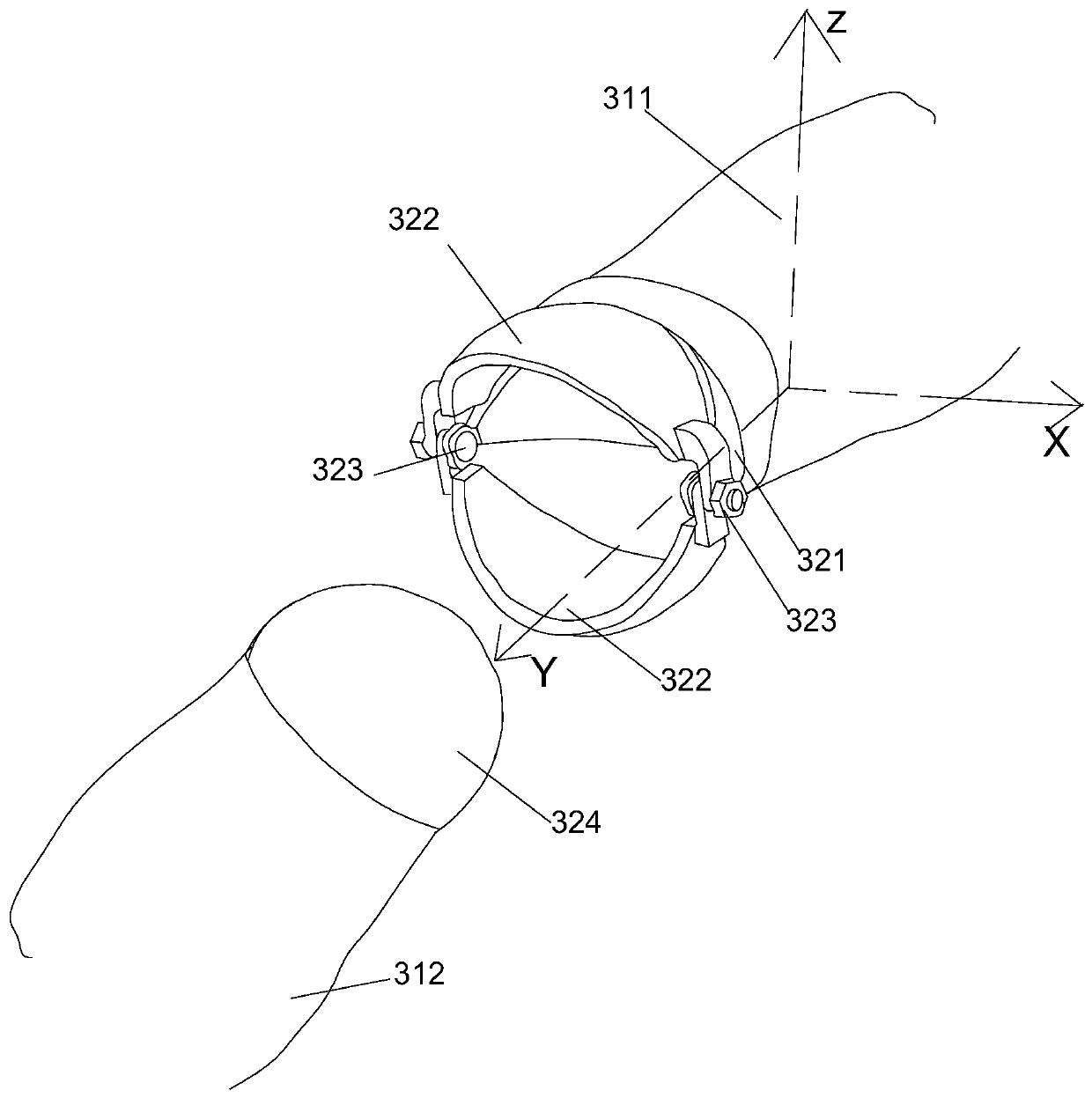

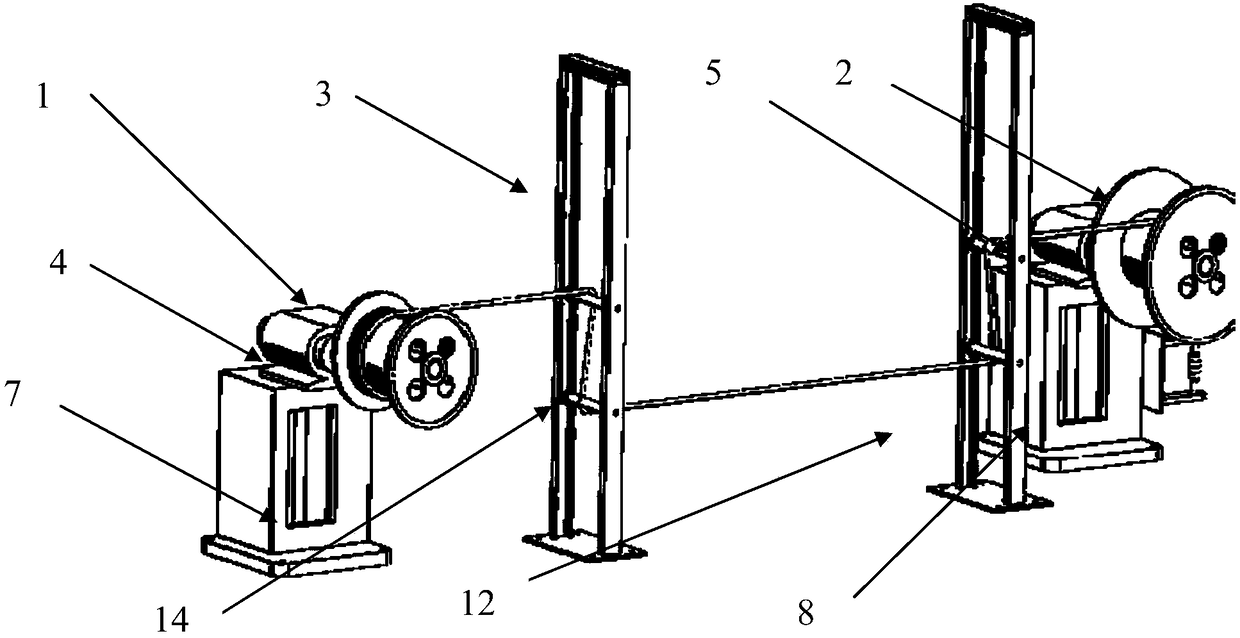

Rapid deploying system and method for a RFID (radio frequency identification devices) antenna

ActiveCN101872885BReduce the influence of electromagnetic signalsMeet the needs of deploymentAntenna supports/mountingsCo-operative working arrangementsThree degrees of freedomEngineering

The invention discloses a rapid deploying system and a method for a RFID antenna. In the invention, the RFID antenna is deployed by arranging a portal frame structure in an in and out storage environment and utilizing different space positions and angles in the portal frame structure, and the reading performances of the parameter combinations of one or more than one RFID antenna on RFID labels stuck to commodities in the application site environment are compared. In order to optimize the test process and shorten the test time, firstly, the method selects a representative test point through anorthogonal test to conduct a test, secondly, inspects fitting relation between an independent variable and a dependent variable through a zero-level repeated test, subsequently determines the best deploying position of the RFID antenna through a gradient search test and finally replaces a three degree of freedom motor in the test with a fixed support to complete RFID antenna deployment in the environment. The invention provides reliable guarantee for improving the RFID system performance, predicting the deploying effect and optimizing the deploying conditions under complex environmental conditions.

Owner:INST OF AUTOMATION CHINESE ACAD OF SCI

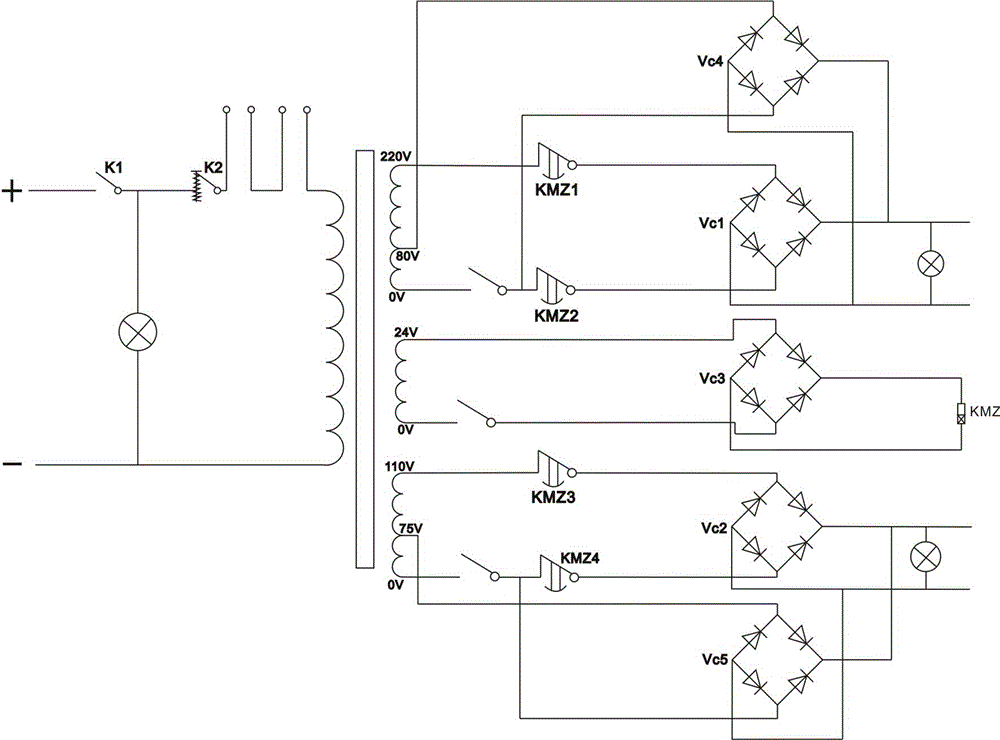

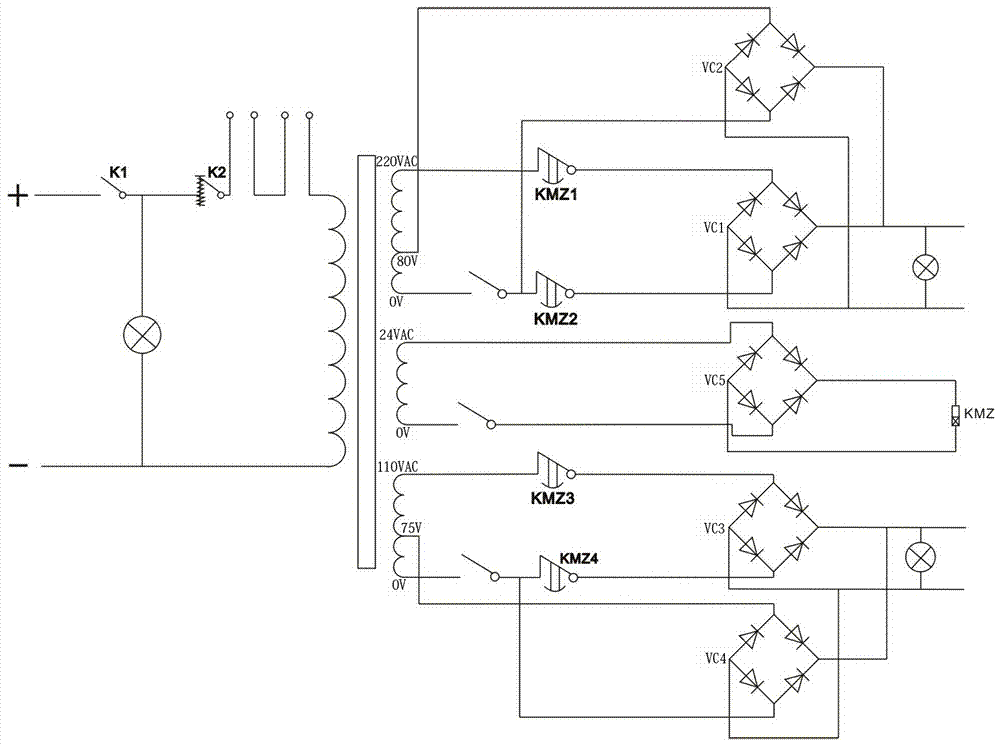

Portable uplink overspeed protection tester for permanent magnet synchronous tractor elevator

A portable uplink overspeed protection tester for a permanent magnet synchronous tractor elevator comprises a safety transformer with a tap. A primary coil of the transformer is connected with an electric supply 220 VAC power source. The number of secondary coils of the transformer is three, the first secondary coil outputs the 220 VAC voltage, the second secondary coil outputs the 110 VAC voltage, and the third secondary coil outputs the 24 VAC voltage. The portable uplink overspeed protection tester can be placed in a tool box, and field inspecting and carrying are convenient. Operation is easy, the tester only has one path of mains input, two paths of output and two signal lines, a bolt mode is adopted in power input line connection, a line clip mode is adopted in connection of all output lines and the signal lines, and during using, line connecting is easy and quick. An operation panel only has one main power switch, one starting / stopping button and the like, and operation is easy.

Owner:河南省特种设备安全检测研究院商丘分院

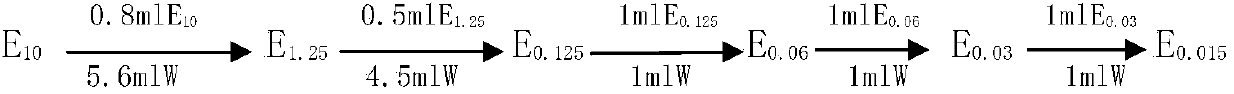

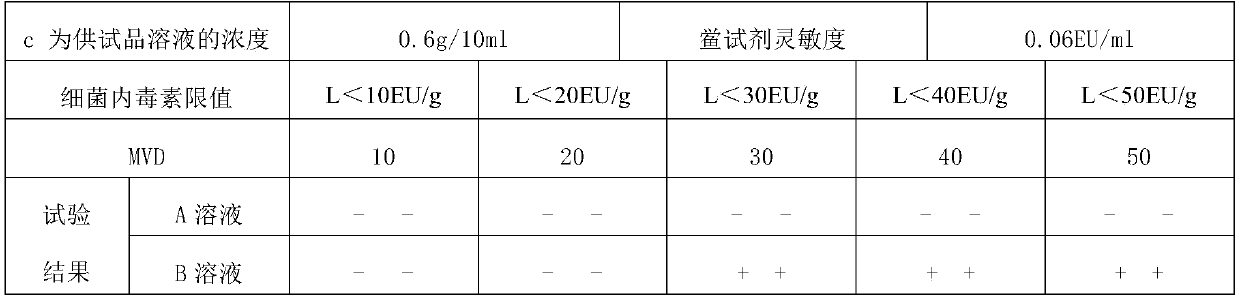

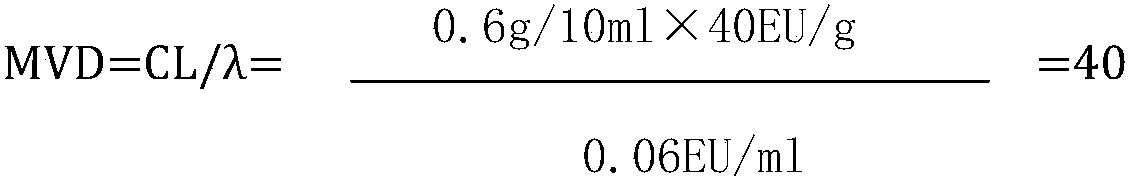

Method for testing bacterial endotoxin of ferric citrate pyrophosphate raw material

InactiveCN109613250ASolve the problem of difficult limit settingTest method scienceMaterial analysisFerric citratePyrophosphate

The invention discloses a method for testing bacterial endotoxin of a ferric citrate pyrophosphate raw material, comprising the following steps of: preparing the ferric citrate pyrophosphate raw material into a sample solution S having a concentration of 0.6 g / 10 ml by using bacterial endotoxin test water; diluting the sample solution S 40 times with the bacterial endotoxin test water, that is, solution A (S40); performing a bacterial endotoxin test with a TAL (Tachypleus Amebocyte Lysate) having sensitivity of 0.06 EU / ml; keeping warm for 60+ / -2 minutes in a 37+ / -1 DEG C tube thermostat; andgently removing a test tube from the thermostat and slowly reversing by 180 degree. If an in-tube gel does not deform and slip off a tube wall, it is positive. If the in-tube gel does not remain intact and slips off the wall, it is negative. The test method of the invention is scientific, has an accurate test result, fills the blank of the method for testing bacterial endotoxin of the ferric citrate pyrophosphate raw material, and has broad application prospect.

Owner:CHINA OTSUKA PHARM CO LTD

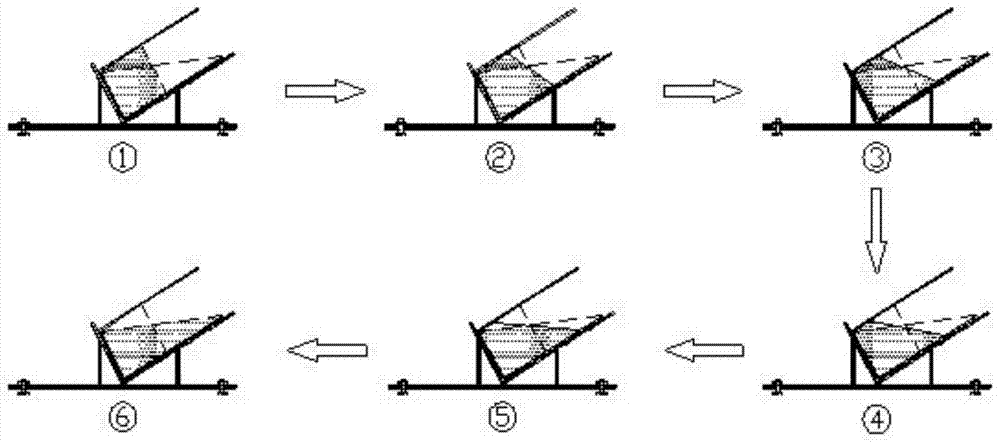

Up-down stress bench test method for plate spring

InactiveCN108444691AMeet the needs of exerciseEliminate the effects ofMachine part testingElasticity measurementDynamic stiffnessBench test

The invention provides an up-down stress bench test method for a plate spring. The bench test method comprises a stiffness characteristic test, a dynamic stiffness characteristic test and an up-down fatigue test. According to the test method provided by the invention, the up-down stress and the movement of a plate spring assembly on a vehicle are fully simulated, so that the performance of the plate spring assembly can fully meet the needs of the movement of the whole vehicle. The test method, including the stiffness characteristic test, the dynamic stiffness characteristic test and the up-down stress fatigue test, is scientific and precise, and the influence of torque generated by the tilting of the plate spring assembly on a bench is eliminated by the up-down stress bench structure of the plate spring, thereby ensuring the safety of the test process.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

An intelligent gis partial discharge ied test circuit and method

ActiveCN107167715BSimple test circuitIncrease the partial discharge test voltageTesting dielectric strengthCapacitanceTest power

The invention discloses an intelligent GIS partial discharge IED test loop and method, and the test loop comprises a partial discharge signal generator, a partial discharge IED probe, a coupling capacitor Ck, a coupling device CD, a partial discharge measurement system MI, and a test power supply U. The high-voltage end of the test power supply U is connected with the coupling capacitor Ck and the coupling device CD, and the other end of the coupling device CD is connected with the lower end of the test power supply U and is also grounded. The partial discharge measurement system MI is connected with the coupling device CD. The high-voltage end of the test power supply U is connected with one end of a bus passing through a GIS housing, and the GIS hosing is grounded. The partial discharge IED probe stretches into the GIS housing, and a signal transmitting end of the partial discharge signal generator stretches into the GIS housing, and is used for generating a partial discharge signal. The test loop is simple. Only if a hand-window type discharge gap is made on an intelligent GIS housing, can the test loop achieve the purposes of improving the partial discharge voltage, improving the testing efficiency and protecting the environment.

Owner:XIAN HIGH VOLTAGE APP RES INST CO LTD

A Partial Coulometric Method for Determination of Biodegradable Organic Matter in Water

ActiveCN110530956BEasy to findGood linear correlationMaterial electrochemical variablesLinear correlationPollution

The invention belongs to the technical field of water environment chemical analysis, and in particular relates to a local coulometric method for measuring biochemically degradable organic matter in water bodies. The present invention finds a unique way to select the fastest point of voltage drop as the cut-off point of voltage collection. The cut-off point is easy to find and can greatly shorten the measurement time and improve the work efficiency. Moreover, the local Coulomb method of the cut-off point selection method is used. Oxygen BOM Q1 The linear correlation between the value and the concentration of GGA standard solution for cultivating electrogenic microorganisms is better, which provides a more scientific, reasonable and accurate test method for the determination of biodegradable organic matter in water by microbial fuel cells, and provides a new method for scientific control of water environmental pollution. The idea and direction of this paper have great promotion value and broad application prospects.

Owner:CHONGQING INST OF GREEN & INTELLIGENT TECH CHINESE ACADEMY OF SCI

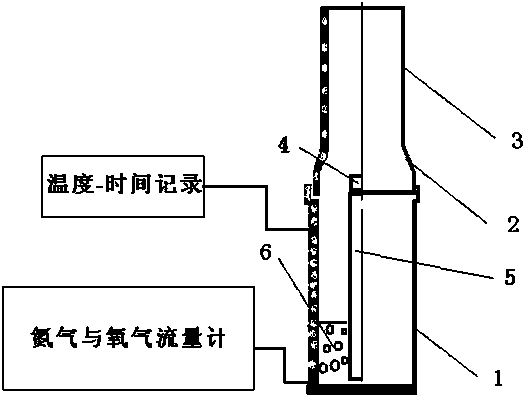

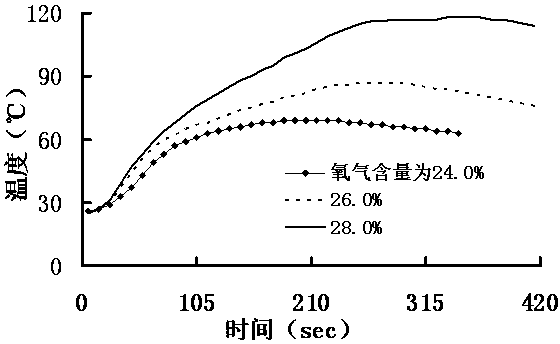

Oxygen index detection method and device

InactiveCN102608256BEasy to measureSimple structureChemical analysis using combustionCombustorNitrogen

The invention discloses an oxygen index detection method and device. The detection method comprises an oxygen and nitrogen inputting and measuring device and a combustor, and is characterized by further comprising a temperature sensor and a temperature-time recording device, wherein the combustor is in a cylindrical combined structure and is divided into a lower cylinder, a transition area cylinder and an upper cylinder; the inner diameter of the lower cylinder is 110-120 mm and the inner diameter of the upper cylinder is 100-110 mm; the inner diameter of the transition area cylinder is gradually changed so that the transition area cylinder is connected with the upper cylinder and the lower cylinder in a transitional manner; a sample tank is fixedly arranged at the center of the transition area cylinder by a bracket; the temperature sensor is placed at the bottom of the outer wall of the sample tank; and an output end of the temperature sensor is connected with the temperature-time recording device. An oxygen index is detected by obtaining a combustion temperature-time relation curve. By the oxygen index detection method and device, disclosed by the invention, a sample to be detected without a fixed shape is conveniently detected and bases are supplied for researching and developing a new material.

Owner:SUZHOU UNIV

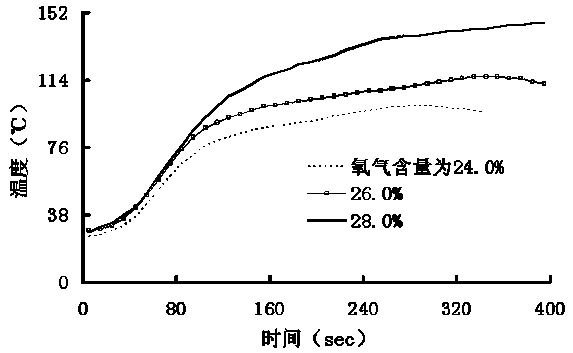

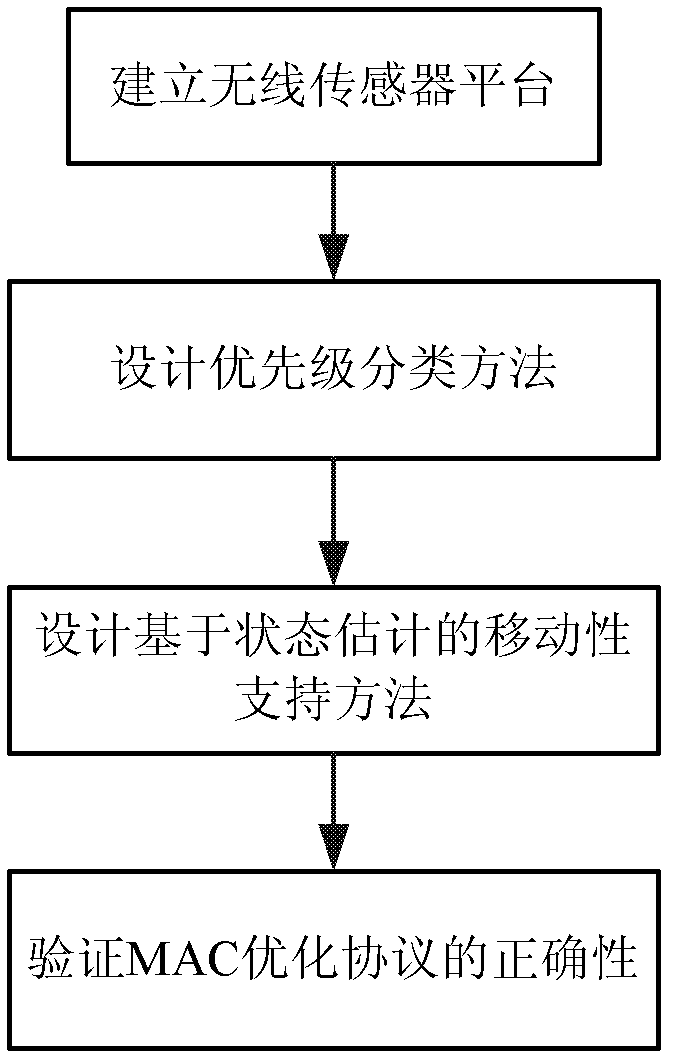

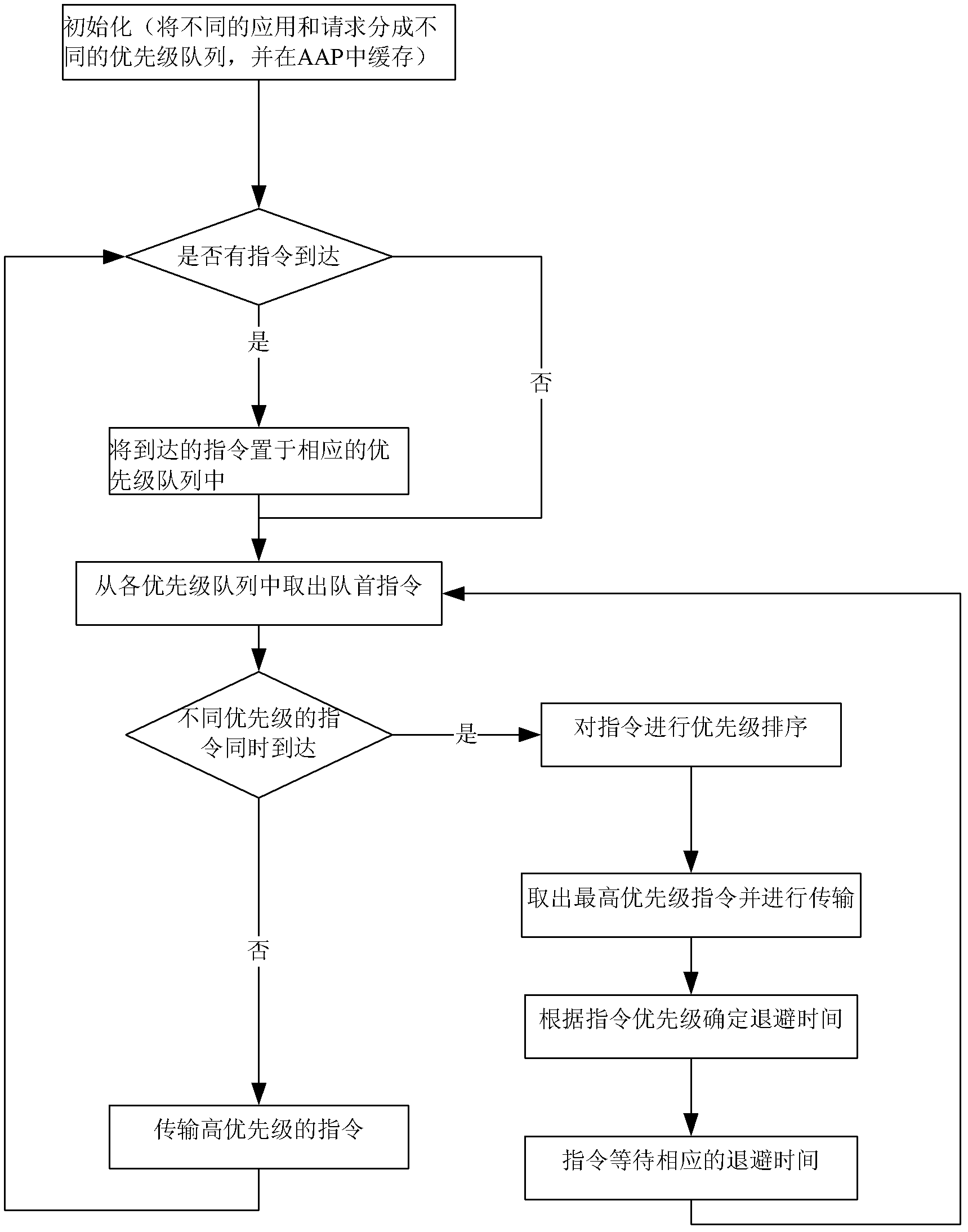

Method for realizing digital home network control technology

ActiveCN102263682BVerify correctnessComprehensive testing methodsData switching by path configurationWireless sensor networkingNetwork control

The invention discloses a method for realizing a digital home network control technology. The method comprises the following steps: firstly, establishing a wireless sensor network experimental platform with equipment control capacity; then designing a priority classification optimization method according to the requirement of service classification; then designing a mobility support method based on state estimation aiming at the requirement on mobility; and finally, verifying the correctness of the optimized MAC (medium access control) protocol on a test bed. The invention provides a comprehensive and scientific test method for the digital home network test; and by using the test platform, the verification on the accuracy of the newly developed MAC optimization protocol can be well finished. The consistency and widespread adaptability of the platform provide a good practice platform for theoretical research.

Owner:SUN YAT SEN UNIV

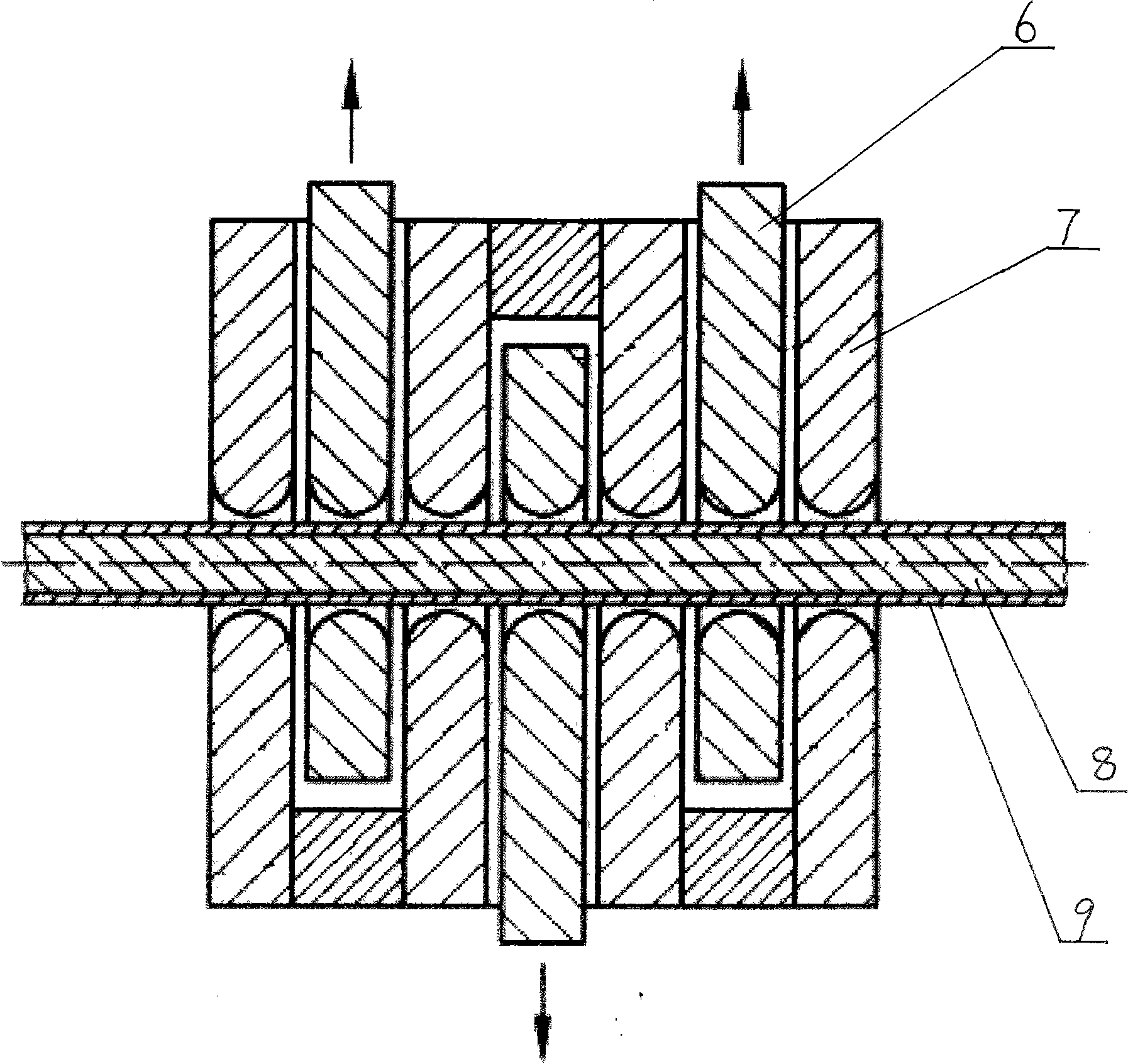

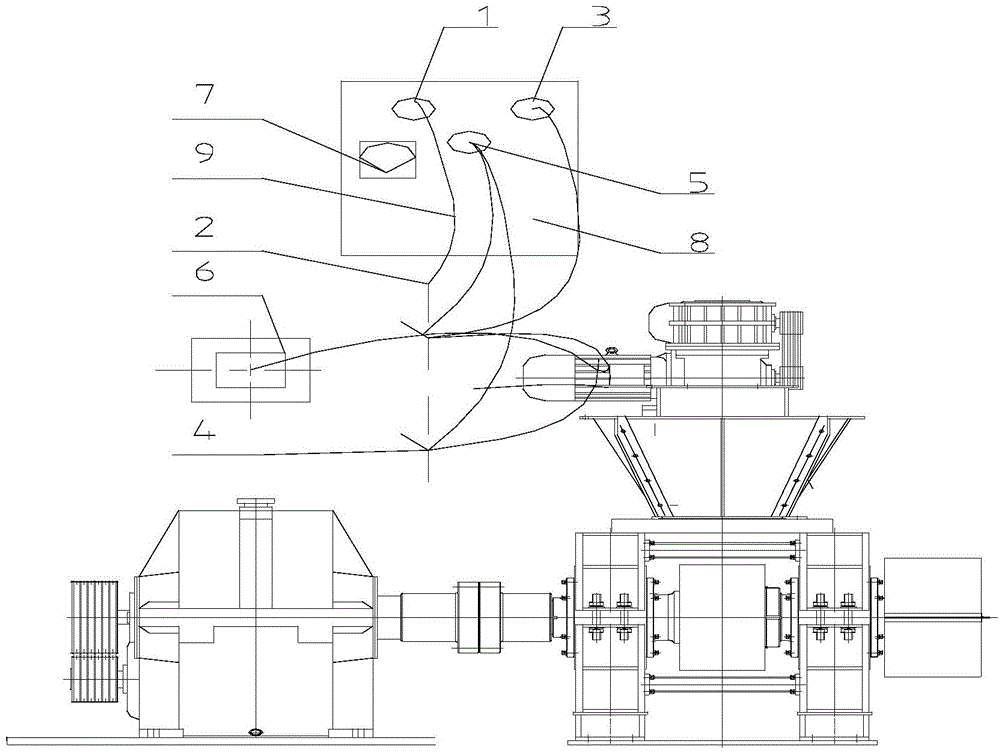

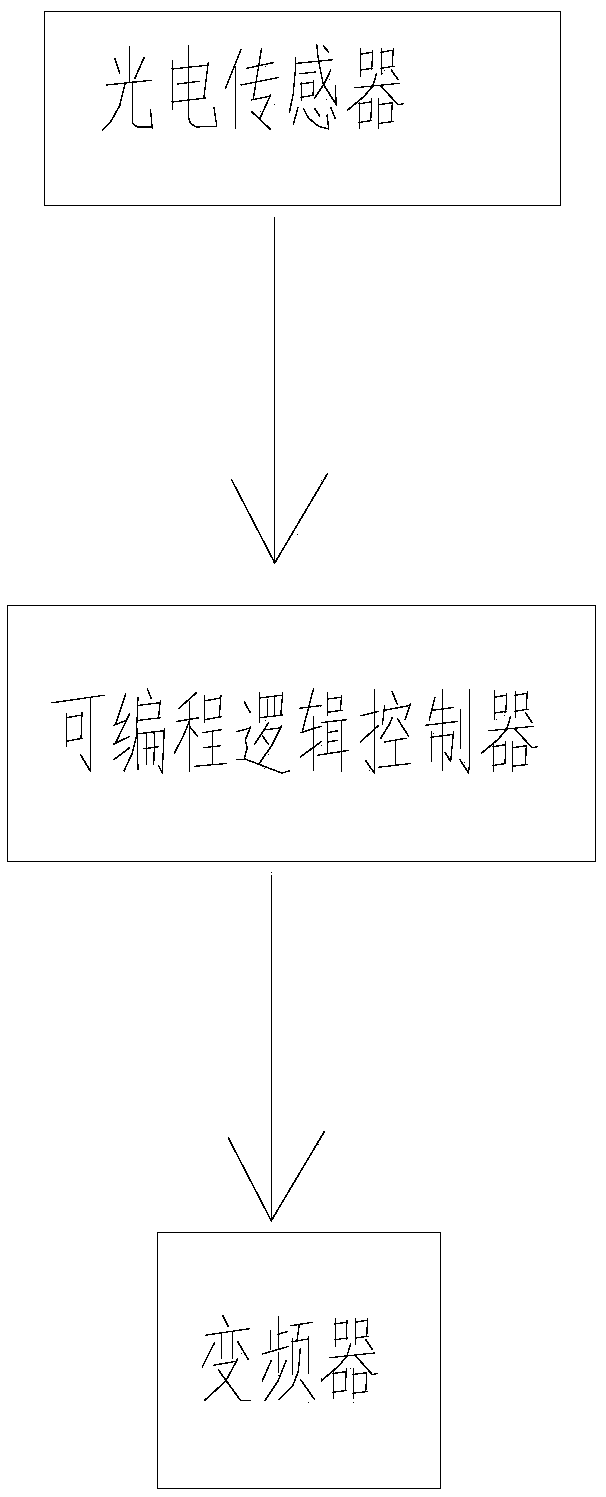

Belt wheel manual control device

InactiveCN104418039ATest method scienceThe test method is accurateControl devices for conveyorsElectric machineControl engineering

The invention relates to a belt wheel rotation manual control device. The device consists of a forward button 1, a forward contactor 2, a reverse button 3, a reverse contactor 4, a stop button 5, a current transformer 6, an ammeter 7, a control panel 8, and a signal control cable 9, wherein the forward contactor 2 and the reverse contactor 4 are used for controlling the forward and reverse rotation of a motor, and manual rotation of a belt wheel is replaced.; the current transformer 6 is used for detecting a current value of the motor; and the ammeter 7 is used for displaying the current value of the motor. The belt wheel rotation manual control device has main advantages that a test method is scientific and accurate; and manual rotation of the belt wheel is replaced, so that the failure eliminating time is reduced.

Owner:宁夏鹏程致远自动化技术有限公司

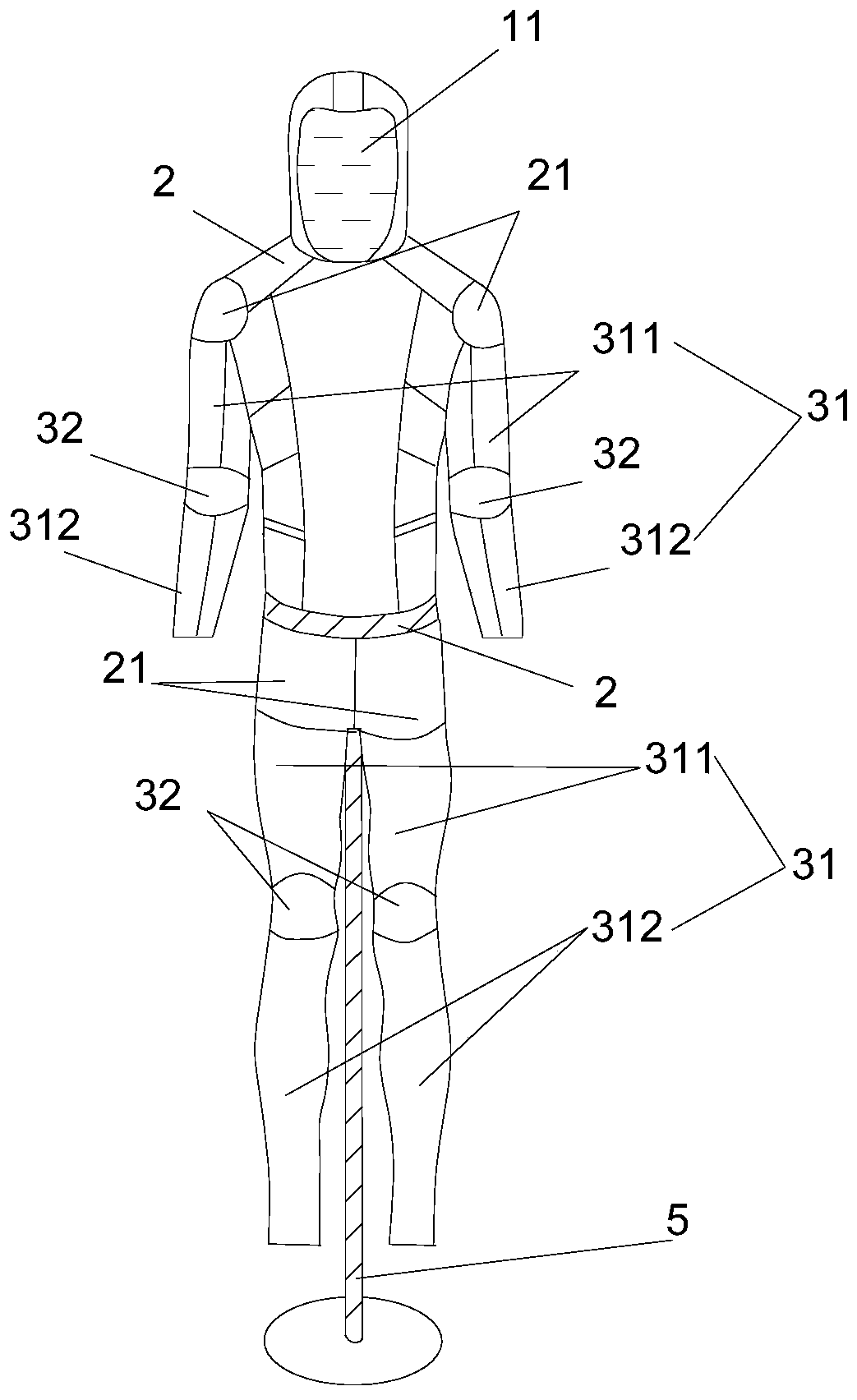

Clothes performance simulation tester and test method

PendingCN110082243ATo meet the needs of takingIntuitive test resultsMaterial strength using tensile/compressive forcesInvestigating abrasion/wear resistanceTester deviceEngineering

The invention provides a clothes performance simulation tester and test method. The clothes performance simulation tester comprises a control module, a trunk body, a swinging device and a friction adjusting device. The control module is in signal connection with the trunk body, the swinging device and the friction adjusting device. Therefore, the clothes friction or stretching states in a state ofwalking, moving, sitting or standing of the user wearing the textile actually can be simulated to the greatest extent; and thus the actual fitting behavior of the personnel for the risk-fabric ready-made clothes in the clothes enterprise or the fabric enterprise is replaced. After simulation of the walking motion of the consumer, various performances like fluffing resistance and pilling resistance of the fabric are tested for the ready-made clothes; and the friction process of clothes wearing by the consumer is restored truly in the testing process.

Owner:LILANG CHINA

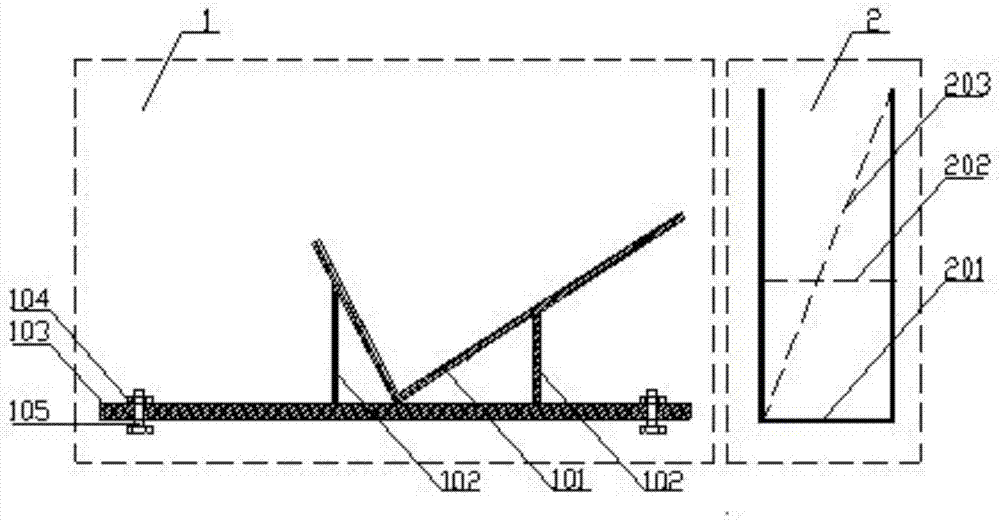

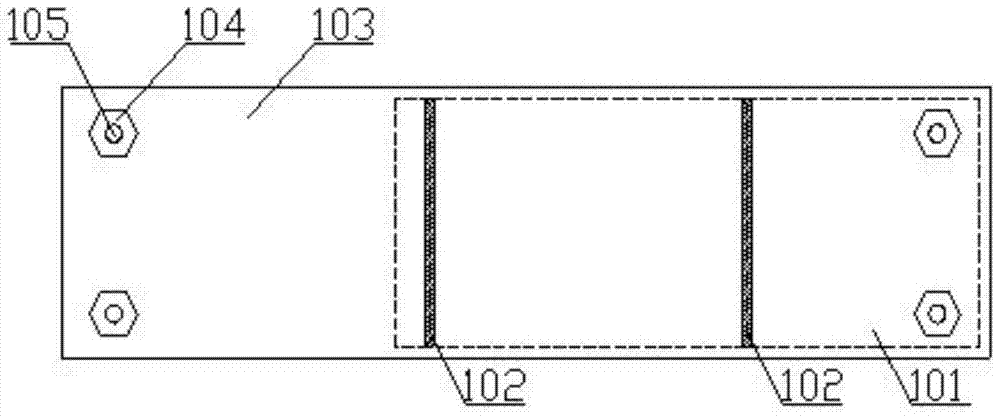

Test device and method for characterizing coagulation characteristics of foam fluid by lost flow time

ActiveCN105388088BSimple structureIngenious ideaFlow propertiesMaterial testing goodsVertical edgeEngineering

The invention discloses a test apparatus for characterizing the condensation characteristic of a foam fluid by a loss flow time, and a method thereof. The apparatus comprises a test rack and a measurement container; the test rack comprises a baseboard, the baseboard is vertically fixedly provided with two supporting plates, two support plates are vertical to each other and are fixedly arranged on the baseboard through the two supporting plates, and four corners of the baseboard are respectively provided with a leveling screw and a leveling nut; and the measurement container is a cuboid, the upper end of the measurement container is opened, the middle portion of the wall of the measurement container is engraved with an initial line, and a connecting line from the bottom end of one vertical edge of one side surface of the measurement container to the upper portion of another vertical edge is adopted as a horizontal line. The invention also provides a method using the apparatus to test the loss flow time of a foam fluid to be tested, and steps thereof. The condensation time of the tested foam fluid, which is the loss flow time, can be obtained by adopting the apparatus and the method. The test apparatus has the advantages of simple structure and ingenious conception, and the test method has the advantages of simple operation and result accuracy.

Owner:HUNAN UNIV OF SCI & TECH

A back-to-back double-lens optical axis consistency test fixture and test method thereof

ActiveCN107063640BTest method scienceReduce testing costsTesting optical propertiesGraphicsConsistency test

The invention discloses a back-to-back double-lens optical axis consistency test fixture and test method. The test fixture comprises a fixture stage and graph cards; the graph cards and two lenses are arranged on the fixture stage; the graph cards are located at the object sides of the two lenses; each of the graph cards is provided with a rotary variable mark graph; the mark graph includes a center point mark and four end point marks; connecting lines between the non-adjacent end point marks of the mark graph are perpendicular to and equally divided by each other, and the center point mark of the mark graph is overlapped with perpendicular equal-division points; the lens surfaces of the two lenses are parallel with the graph card surfaces of the corresponding graph cards; connecting lines between the center point marks of the graph cards and the centers of the two lenses are perpendicular to the lens surfaces of the two lenses; the tested two lenses include a first lens and a second lens which are arranged in a back-to-back manner; the first lens and the second lens are arranged in a camera; and the camera is provided with a USB interface for communicating with a PC. With the back-to-back double-lens optical axis consistency test fixture and test method provided by the technical schemes of the invention adopted, the problem of judging the consistency of optical axes can be judged. The accuracy of test results of the test fixture and test method is highly.

Owner:GOERTEK OPTICAL TECH CO LTD

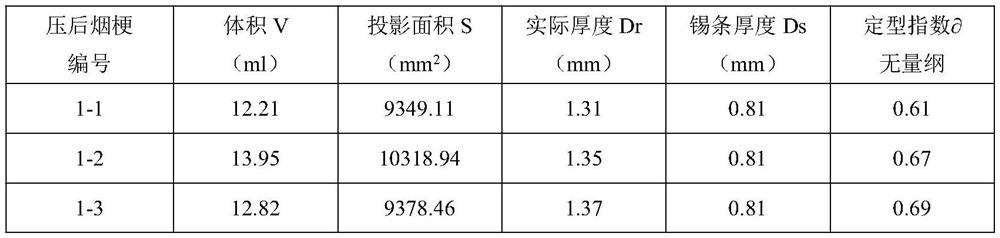

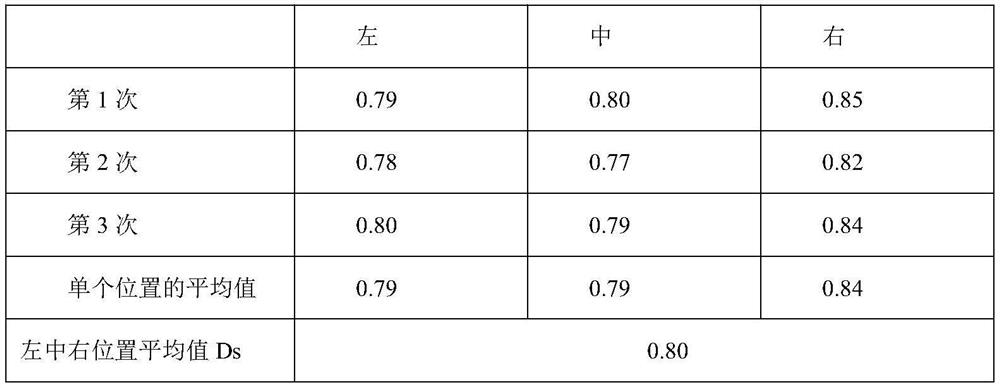

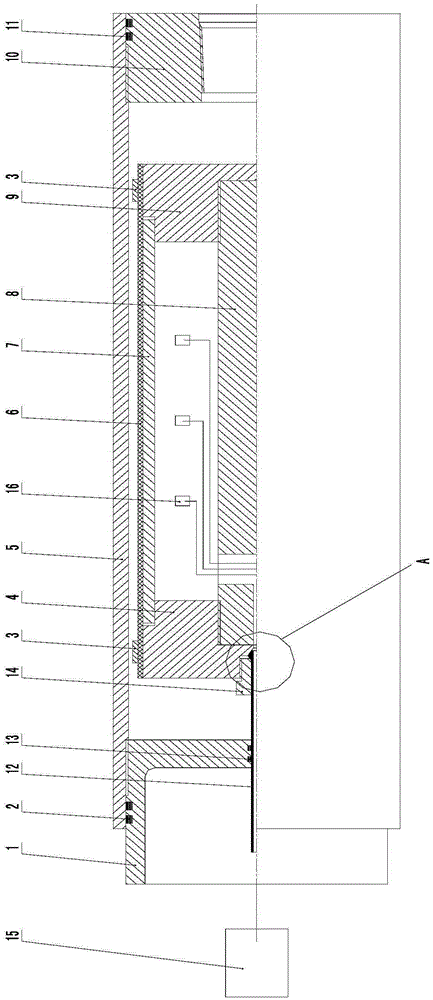

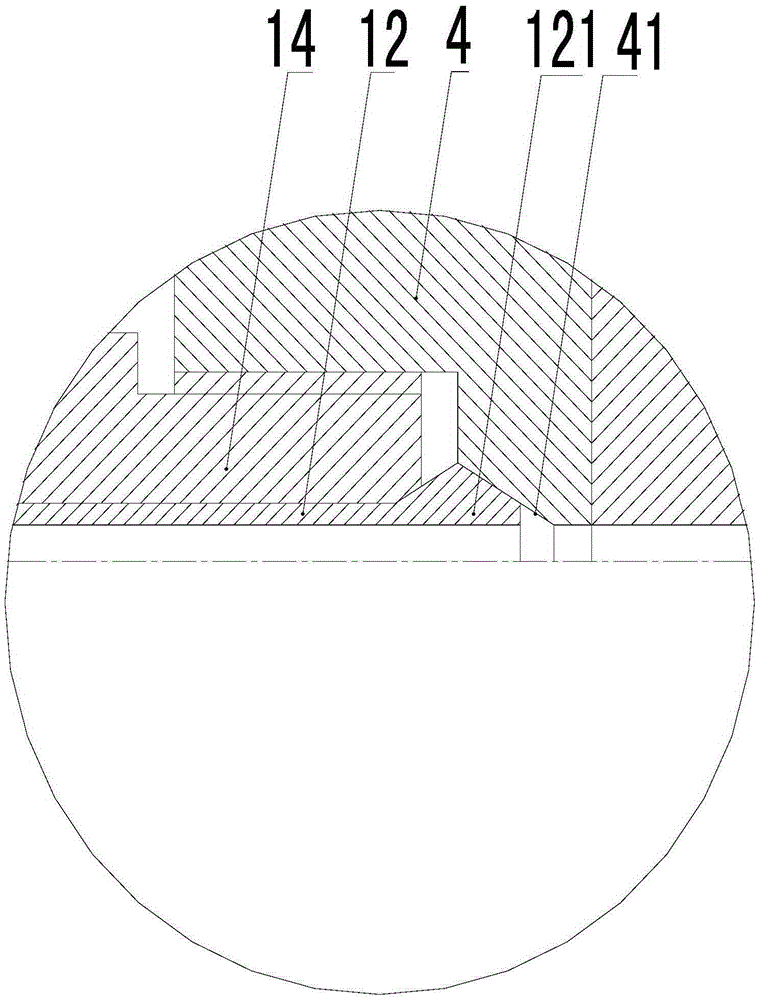

Method for measuring shaping effect of tobacco stem after stem pressing

PendingCN114062363AData representativeness is strongTest method sciencePreparing sample for investigationMaterial analysis by optical meansEngineeringMechanical engineering

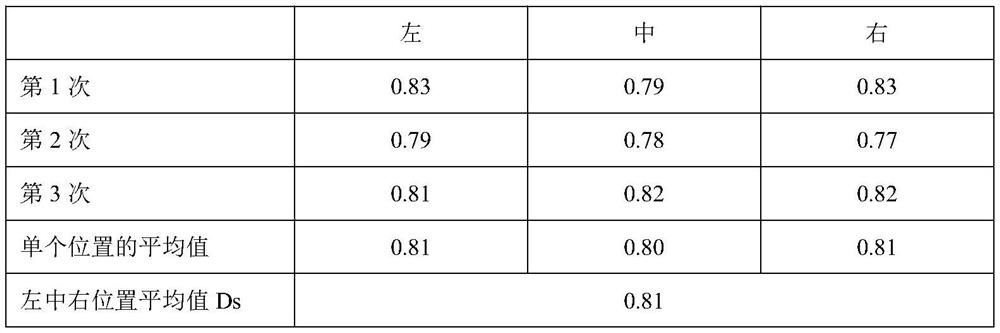

The invention discloses a method for measuring the shaping effect of a tobacco stem after stem pressing. The method comprises the following steps: (1) measuring the average value of the thickness of a tin bar after stem pressing, namely Ds; (2) collecting the image of the pressed tobacco stem to obtain the area S of the pressed tobacco stem; (3) measuring the volume V of the pressed tobacco stem by adopting a liquid replacement method; (4) calculating the actual thickness Dr of the tobacco stem, wherein the formula is Dr = V / S; (5) calculating a tobacco stem shaping index formula; and (6) judging the tobacco stem shaping effect after stem pressing according to the value. The measuring method is simple, practical and accurate.

Owner:CHINA TOBACCO YUNNAN IND

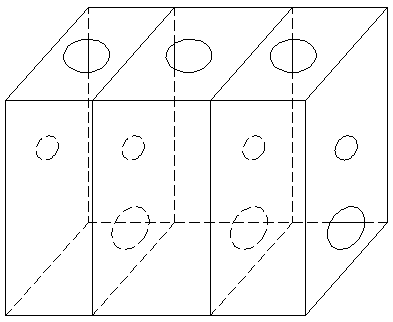

Sand prevention screen tube hydraulic test apparatus

InactiveCN105388070AUniform radial forceTest method scienceMaterial strength using tensile/compressive forcesHydraulic testStrain sensor

The invention provides a sand prevention screen tube hydraulic test apparatus. The apparatus is used for testing the outer pressure resistance of a sand prevention screen tube, and the sand prevention screen tube hydraulic test apparatus comprises: a test cylinder having a closed cavity for accommodating the sand prevention screen tube; a bearing assembly comprising an elastic sealing sleeve surrounding the side direction of the sand prevention screen tube, and screen tube plugs sealing two ends of the sand prevention screen tube; and a strain test assembly comprising a strain sensor arranged on the inner side surface of the sand prevention screen tube. The sand prevention screen tube hydraulic test apparatus allows the uniform radial force to be applied to the whole sand prevention screen tube and a test method to be highly scientific; and a hydraulic value obtained in the invention is the practical outer pressure resistance of the screen tube, and does not need conversion. The sand prevention screen tube hydraulic test apparatus has the advantages of simple, scientific and reasonable structure, and effective measurement of the outer pressure resistance of the sand prevention screen tube.

Owner:PETROCHINA CO LTD

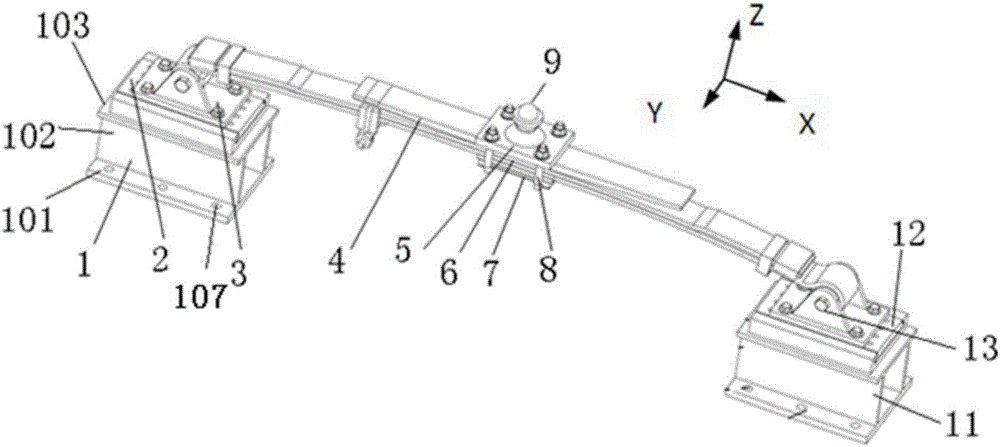

A test device for the upper and lower force bench of the leaf spring

ActiveCN106197984BDoes not cause test distortionEliminate the effects of trialsMachine part testingDynamic stiffnessBench test

The invention relates to a bench test device for vertical stress on a plate spring. The bench test device comprises supports, sliding plates, spring eye brackets, a plate spring assembly to be tested, a stress base plate, a base plate, a lower base plate, U-shaped bolts and a steel ball. By means of the bench test device for the vertical stress on the plate spring, the safety in the bench test process is guaranteed, and a stiffness characteristic test, a dynamic stiffness characteristic test and a fatigue test can be carried out; the influence of torque generated after inclination of the plate spring on the bench test is eliminated, distortion of the bench test is avoided, and the test method is scientific and precise; the vertical stress and movement of the plate spring are fully simulated, and the performance of the plate spring fully meets the demand of whole vehicle movement.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

A portable uplink overspeed protection tester for permanent magnet synchronous traction machine elevators

A portable uplink overspeed protection tester for a permanent magnet synchronous tractor elevator comprises a safety transformer with a tap. A primary coil of the transformer is connected with an electric supply 220 VAC power source. The number of secondary coils of the transformer is three, the first secondary coil outputs the 220 VAC voltage, the second secondary coil outputs the 110 VAC voltage, and the third secondary coil outputs the 24 VAC voltage. The portable uplink overspeed protection tester can be placed in a tool box, and field inspecting and carrying are convenient. Operation is easy, the tester only has one path of mains input, two paths of output and two signal lines, a bolt mode is adopted in power input line connection, a line clip mode is adopted in connection of all output lines and the signal lines, and during using, line connecting is easy and quick. An operation panel only has one main power switch, one starting / stopping button and the like, and operation is easy.

Owner:河南省特种设备安全检测研究院商丘分院

Testing method for safe performance of power climbing rope

ActiveCN101865788BImprove securityImprove reliabilityStructural/machines measurementStrength propertiesDependabilityStatic force

The invention discloses a testing method for safe performance of a power climbing rope, comprising a structure and quality test, a rope leather sliding test, a static force elongation ratio test and a dynamic performance test. The dynamic performance test comprises power elongation ratio, first falling impact force and falling times. Because the testing method is standard and scientific, and the testing data are correct and reliable, the security and the reliability of the power climbing rope are improved.

Owner:TAIAN ROPE NET PLASTIC

Method for detecting color fastness of fabric products to water

ActiveCN102236008BEasy to identifySimplify testing proceduresTextile testingProcess engineeringEnvironmental engineering

The invention relates to a method for detecting color fastness of fabric products to water. The method comprises the following steps of: respectively cutting to-be-detected fabric samples with the same specification and a standard adjacent fabric subjected to bleaching, dyeing and splashing processes and preparing a liquid soap reagent with concentration of 10g / L; fixing and overlapping the standard adjacent fabric on the to-be-detected fabric samples to obtain combined samples; immersing the combined samples in the liquid soap reagent with proper temperature and standing still for detecting; taking the combined samples out, cleaning and disassembling; drying the standard adjacent fabric and the to-be-detected samples; and grading and comparing the standard adjacent fabric and the to-be-detected fabric samples with a grey standard sample card to obtain color fastness to water. The detection process is simple and feasible, the detection method is scientific and the detection results are accurate; by comparison with the grey standard sample card, the discoloration and staining grades of the to-be-detected fabric samples can be determined accurately. The unification of the detection method of color fastness of fabric products to water is beneficial to the quality detection of fabric products according to the grades of color fastness to water detected by using a unified method.

Owner:JINJIANG LONGXINGLONG DYEING & WEAVING INDALCO

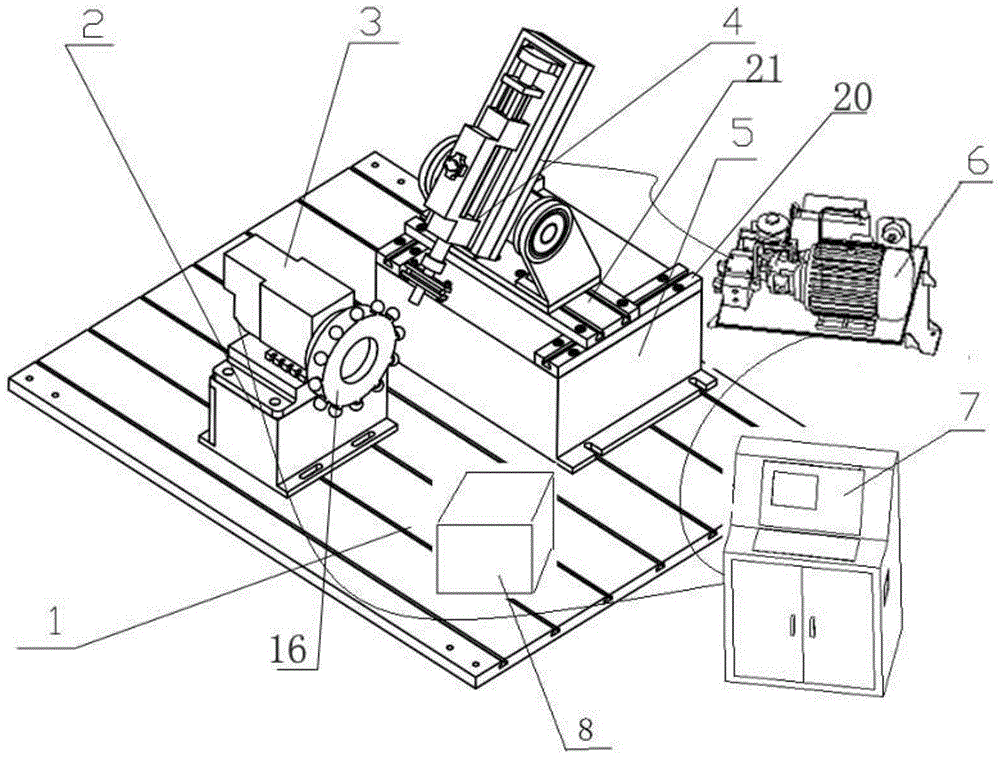

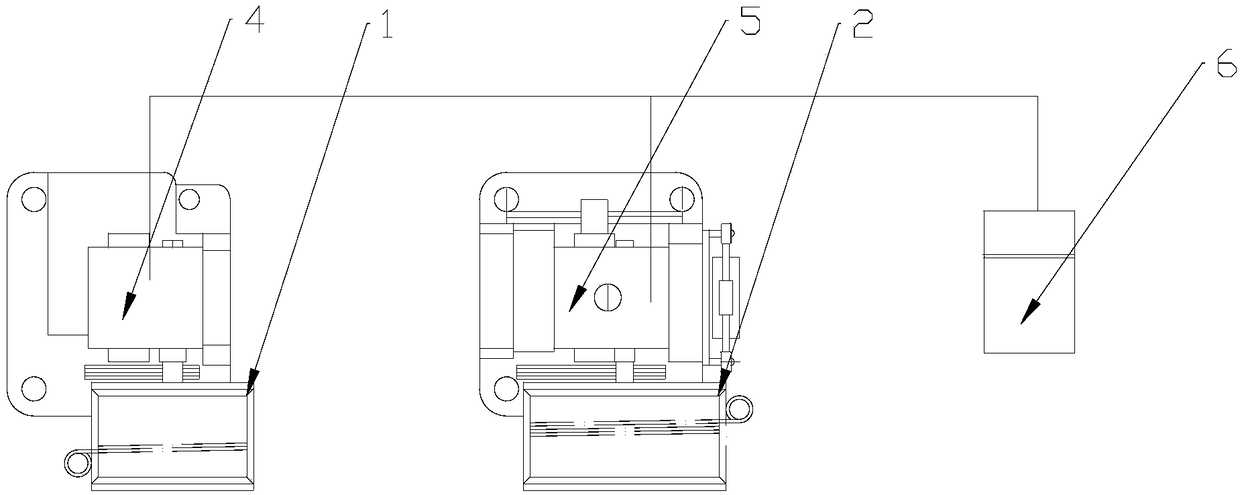

A reliability testing system for a servo tool holder and a testing method using the system

ActiveCN104076741BRestore the real working stateThe reliability value is true and reliableProgramme controlComputer controlRegression testingHydraulic cylinder

The invention discloses a servo tool rest reliability testing system and a testing method using the system. The testing system includes a test bench body, a tested tool rest, an electro-hydraulic loading device, a hydraulic drive system, and the tested knife The frame is placed on the test bench body through the tool holder support mechanism. The tool holder under test has a cutter head and a motor placed inside the tool holder to drive the rotation of the cutter head. The simulated tool holder is installed on the cutter head. The electro-hydraulic loading device can The adjustable bracket is set on the base, and the base is fixed on the test bench body. The electro-hydraulic loading device includes a fixed plate placed on the adjustable bracket, and a hydraulic cylinder fixed on the fixed plate through the cage. One end of the hydraulic cylinder passes through the pipeline. It is connected with the hydraulic drive system, and the other end is connected with a pressure sensor and connected with the loading rod through an elastic mechanism. The system and method realize the reliability test and the precision decline test of the tool holder, expose the early failure of the tool holder and grasp the law of its precision decline.

Owner:通用技术集团沈阳机床有限责任公司

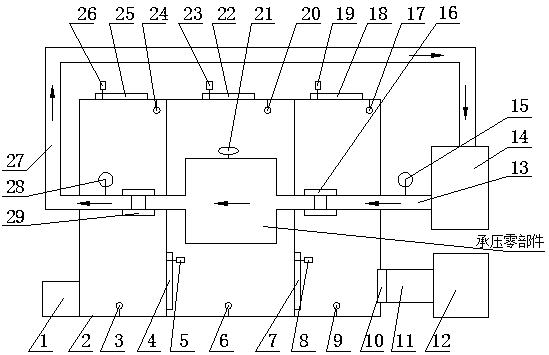

Method and device for testing the tightness of pressure-bearing components in low-temperature environments

InactiveCN106323557BAccurate statistics of rated working life indicatorsReduce buildDetection of fluid at leakage pointWeather/light/corrosion resistanceAutomatic controlWorking environment

The invention discloses a device and a method for airtightness detection of pressure bearing parts in a low-temperature environment. Since the low-temperature environment is directly established in a tested part, low establishment and maintenance cost of the low-temperature environment is realized; internal temperature and pressure of the tested part can be controlled to change quickly according to requirements, a practical operating environment of the tested pressure bearing part can be simulated, and limit indexes of low temperature resistance and pressure resistance of the tested pressure bearing part can be tested; airtightness detection is realized by detecting whether a refrigerating agent leaks or not. An automatic data acquisition module and an automatic control module of the device are capable of fully automatically operating for a long time under an unattended condition to acquire detection data in a long period, and rated service life indexes of the tested pressure bearing part can be accurately calculated out through long-period data analysis.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

Testing device for analyzing moving function of animal limb and footmark

InactiveCN100594000CLow costEasy to storeDiagnostic recording/measuringSensorsComputer scienceRunway

The invention relates to the research field of animal limb movement function and footprint analysis, and discloses a test device for analyzing the animal limb movement function and the footprint. Thetest device comprises tracks and soft ceramic layers applied on the bottom plates of the tracks, wherein the tracks consist of a straight flat segment, a turning segment, an upslope segment, a downslope segment and an upper step or lower step segment; lateral plates are arranged on both sides of the tracks; the lateral plates and the bottom plates are detachable; and particularly, the lateral plates can be made of one-way transparent glass to facilitate observation or photographing.

Owner:许汉鹏

Test method for rapid evaluation of resistance to cracking of sheaths of flame retardant optical cables

ActiveCN106769568BSimple structureEasy to operateWeather/light/corrosion resistanceMaterial strength using repeated/pulsating forcesCrack resistanceEnvironmental tests

Owner:HANGZHOU FUTONG COMM TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com