Clothes performance simulation tester and test method

A tester and performance technology, applied in the direction of testing wear resistance, applying stable tension/pressure to test material strength, instruments, etc., can solve problems such as unsatisfactory and labor-intensive efficiency, achieve good detection effect, and solve dynamic testing problems, high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

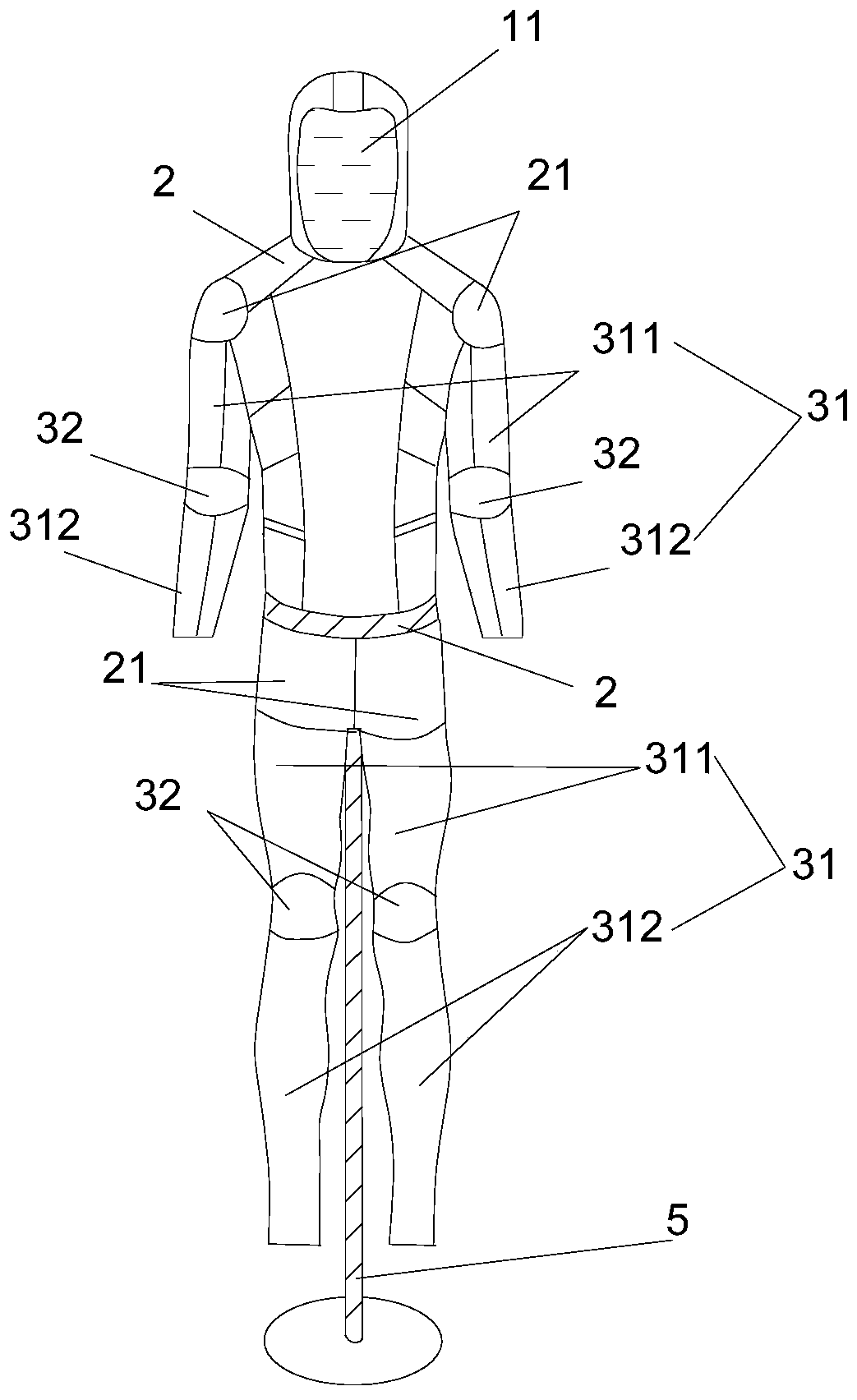

[0036] A clothing performance simulation tester, such as figure 1 As shown, it includes a control module, a trunk body 2, a swing device, a friction adjustment device 4, a buffer support device 5, and a temperature control device;

[0037] The control module is in signal connection with the trunk body 2, the swing device, the friction adjustment device 4, and the temperature control device; the control module includes a control panel 11 for setting and / or viewing the clothing performance simulation tester Working parameters

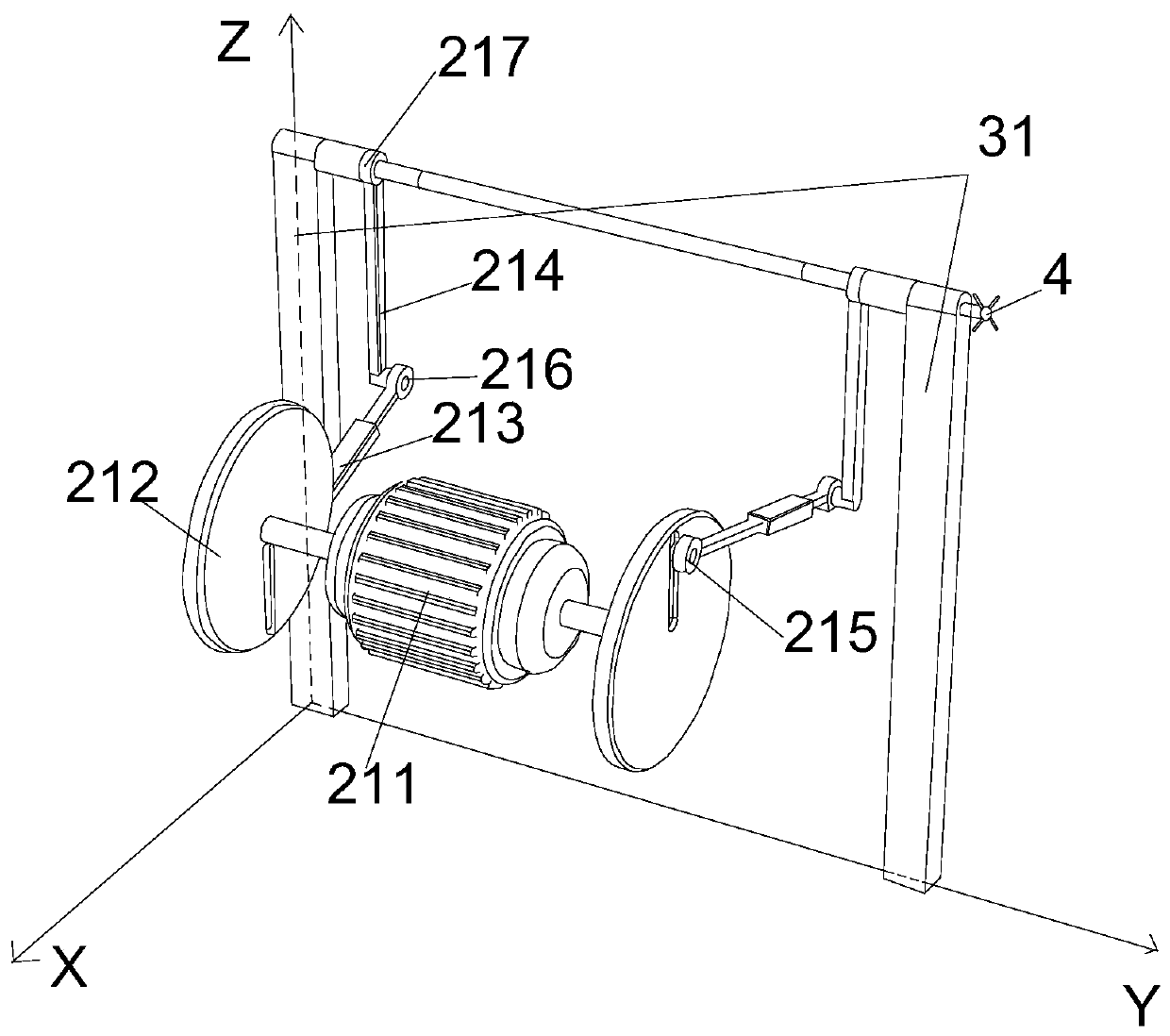

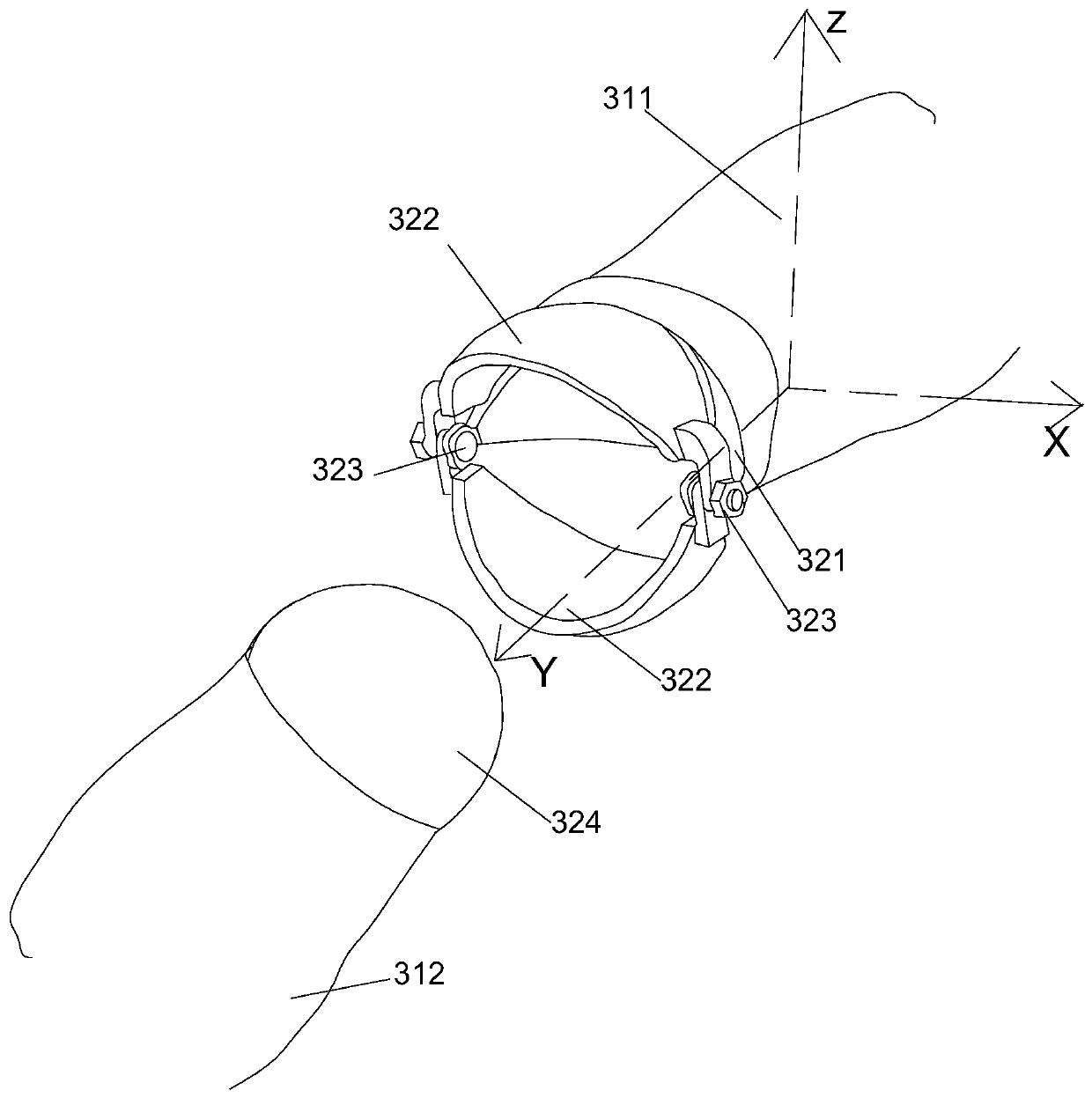

[0038] Such as figure 1 The torso body 2 further includes a first connecting mechanism 21, the torso body 2 and the swinging device are movably connected by the first connecting mechanism 21, and the torso body 2 and the swinging device can be connected by the first connecting mechanism 21. A connecting mechanism 21 realizes swing for the rotating shaft; such as figure 2 As shown, the first connecting mechanism 21 includes a connecting motor 211, a disc 212, ...

specific Embodiment 2

[0045] A clothing performance simulation tester, such as Figure 4 As shown, the clothing performance simulation tester adds a humidity adjustment device on the basis of the foregoing specific embodiment 1, and can realize all the details of the foregoing specific embodiment;

[0046] The humidity adjustment device is signally connected to the control module, and the humidity adjustment device includes a liquid storage tank and one or more drain holes 61 provided on the surface of the trunk body 2 and / or the swing device. The liquid storage tank is connected with the liquid drain hole 61 through a pipe; the liquid storage tank can be arranged outside the clothing performance simulation tester to facilitate adding liquid, and the liquid in the liquid storage tank can simulate human sweat; The target humidity is set by the control module. After receiving the signal, the humidity adjusting device discharges the solution through the drain hole 61 provided on the surface of the trunk b...

specific Embodiment 3

[0048] A clothing performance simulation tester, such as Figure 4 and Figure 5 As shown, the clothing performance simulation tester adds a girth adjustment mechanism 7 on the basis of the above-mentioned specific embodiment 2, and can realize all the details of the above-mentioned specific embodiment;

[0049] The trunk body 2 and / or the swing device is provided with a circumference adjustment mechanism 7 for adjusting the circumference of the trunk body 2 and / or the swing device; preferably, the trunk body 2 and / or Or the swing device includes a first blade 8 and a second blade 9, and the first blade 8 and the second blade 9 are connected by the circumference adjustment mechanism 7, and the circumference adjustment mechanism 7 includes an adjustment nail 71 and a device. There are a plurality of adjusting holes 72 with different pitches. The adjusting nails 71 can be inserted into the adjusting holes 72, and the torso body 2 and / or the swing can be adjusted by adjusting the dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com