Device and method for dynamically testing fabric quality

A technology for dynamic testing and fabrics, applied in measuring devices, testing material strength by applying repetitive force/pulsation force, testing wear resistance, etc., can solve the problems of no simultaneous testing and method evaluation, leakage of core yarn, affecting physical properties, etc. problems, to achieve the effect of overcoming methods and instrument tests, solving dynamic tests, and good detection results

Active Publication Date: 2018-11-20

江苏省纺织产品质量监督检验研究院

View PDF10 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0002] The quality of fabric and sewing is an important part of the quality of textile clothing. If the performance of fabric and sewing quality are not good, there are often appearance defects, which affect people's wearing and use, especially in the process of use due to elbow and knee joints. The parts such as the waist and buttocks are stretched and rubbed more, which will lead to loose yarn, core yarn leakage, partial breakage, and sewing slippage, cracks, damage and other quality conditions. On the one hand, it will affect the structure of the fabric, and then affect Its physical properties; on the other hand, the change of gloss will affect the appearance and color of the fabric; at present, the test method of the physical properties of textiles is mainly to simulate and test the physical indicators such as pilling performance, breaking strength and burs

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Login to View More

Abstract

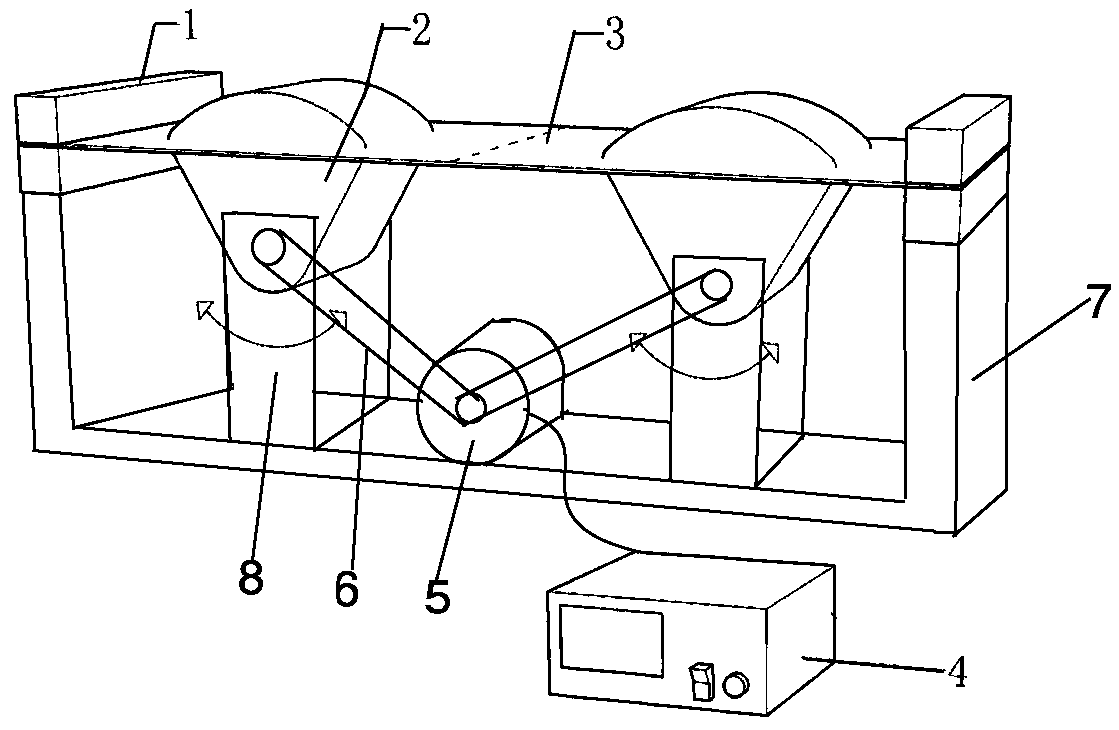

The invention discloses a device for dynamically testing fabric quality. The device comprises a frame, clamps are arranged on two sidewalls of the frame, two brackets are arranged between two sidewalls of the frame, and the top of each bracket is rotatably connected with a cam; the lower part of the cam is rotatably connected with the bracket through a wheel shaft, one end of the wheel shaft extends to outside of the bracket and bonded with a transmission wheel; a motor is arranged on the frame between two brackets, a driving wheel is bonded on the output shaft of the motor, and the driving wheel is in transmission connection with two transmission wheels through transmission belts; the motor drives two cams to synchronously swing by controlling the forward rotation and reverse rotation through a cam swing control device. By simulating the use on the fabric by the hip, the elbows and the knees when the human body wears the fabric, the fabric performance and the sewing quality conditionof the fabric and the sewed fabric under the tension, the torsion, the friction and like coupling dynamics effects are synchronously detected. The invention further discloses a method for dynamicallytesting the fabric quality by adopting the device.

Description

technical field [0001] The invention relates to a device and method for inspecting and testing the quality of fabrics and fabric sewing, in particular to a device and method for dynamically testing the quality of fabrics, belonging to the technical field of textile testing. Background technique [0002] The quality of fabric and sewing is an important part of the quality of textile clothing. If the performance of fabric and sewing quality are not good, there are often appearance defects, which affect people's wearing and use, especially in the process of use due to elbow and knee joints. The parts such as the waist and buttocks are stretched and rubbed more, which will lead to loose yarn, core yarn leakage, partial breakage, and sewing slippage, cracks, damage and other quality conditions. On the one hand, it will affect the structure of the fabric, and then affect Its physical properties; on the other hand, the change of gloss will affect the appearance and color of the fab...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): G01N3/02G01N3/04G01N3/38G01N3/56

CPCG01N3/02G01N3/04G01N3/38G01N3/56

Inventor 李杰张鸣

Owner 江苏省纺织产品质量监督检验研究院

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com