Belt wheel manual control device

A technology of belt pulley and disc rotation, which is applied in the direction of conveyor control devices, transportation and packaging, and conveyor objects, etc. It can solve problems such as shutdown failures, uneven feeding, overloading of motor loads, etc., and shorten the time to eliminate faults. Test method scientific effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0011] Embodiment 1 Composition of a manual control device for belt pulley rotation and the functions of its components:

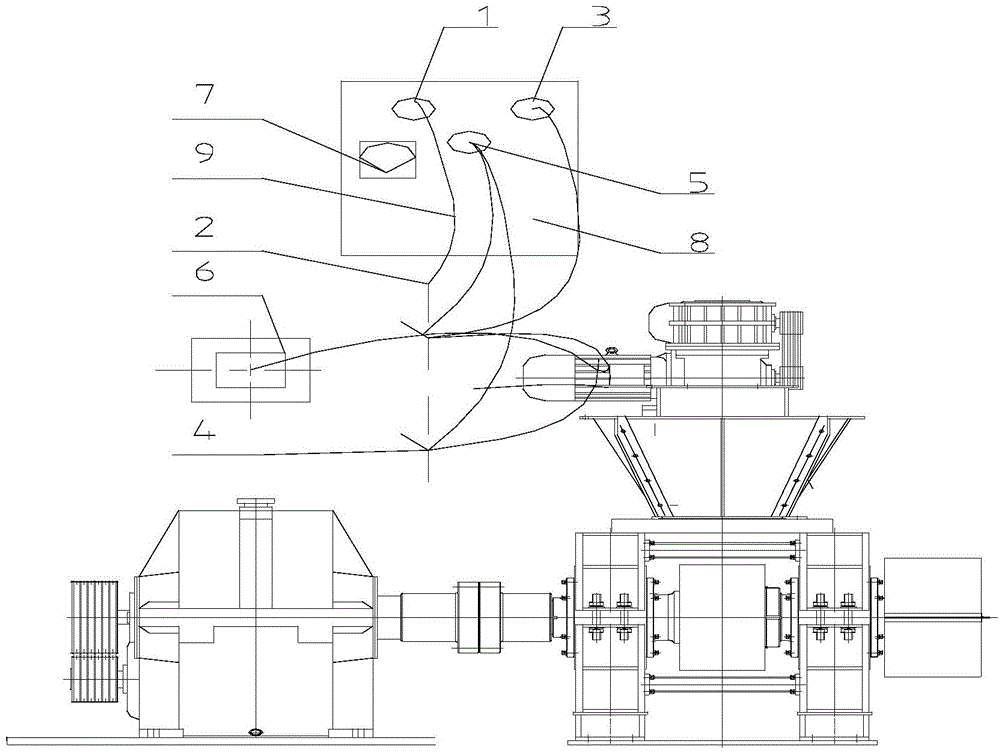

[0012] The device consists of a forward rotation button 1, a forward rotation contactor 2, a reverse rotation button 3, a reverse rotation contactor 4, a stop button 5, a current transformer 6, an ammeter 7, a control panel 8, and a signal control cable 9. A manual control device for the rotation of a pulley controls the forward and reverse rotation of a motor through a forward rotation contactor 2 and a reverse rotation contactor 4 to replace manual rotation of a pulley.

Embodiment 2

[0013] Embodiment 2 The working principle of a manual control device for the rotation of the pulley:

[0014] When the ball pressing equipment is blocked due to the uneven feeding of the upper material conveying link, causing the motor load to be overloaded and causing a shutdown failure, the current value detected by the current transformer 6 displayed by the ammeter 7 should be at a higher level. In the range interval, control the forward and reverse rotation of the motor through the forward rotation button 1 and the reverse rotation button 3 on the control panel 8 until the current display value on the ammeter 7 is normal, which means that the material blockage fault has been eliminated.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com