Method and device for testing the tightness of pressure-bearing components in low-temperature environments

A technology for tightness detection, low temperature environment, applied in measuring devices, liquid tightness measurement using liquid/vacuum degree, and detection of the appearance of fluid at the leak point, etc., can solve the slow control process, low temperature environment construction and maintenance costs Expensive, actual index data errors, etc., to achieve the effect of reliable working principle, low construction and maintenance costs, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

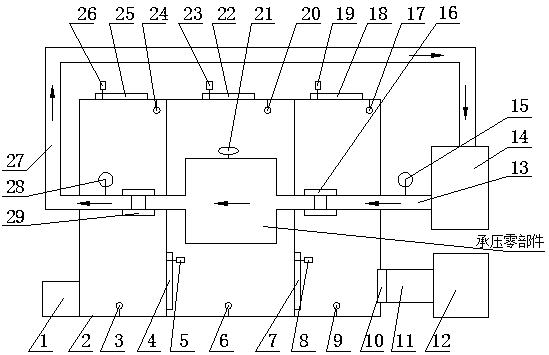

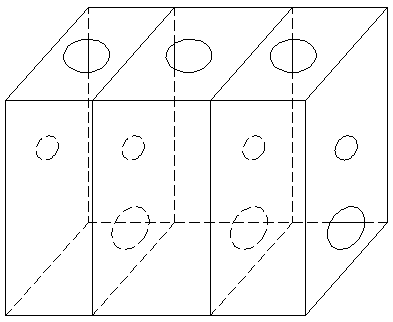

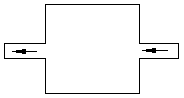

[0020] The shapes of pressure-bearing parts are various. By way of summary, it mainly includes the following: image 3 The single-input single-out type shown, Figure 4 The MIMO type shown, where Figure 4 The shown is actually two-input and three-out type, and the multi-input and multiple-out type is an example. Figure 5 The shown single-mouth container type, etc.; the present invention uses image 3 The structure of the single-input-single-out pressure-bearing parts shown is a case for detailed elaboration of the spatial structure, and the detection scheme of pressure-bearing parts of other structures is explained; the low temperature environment in the present invention refers to the temperature below 0° , the minimum temperature environment is determined by the pressure-enthalpy characteristics of the refrigerant selected by the refrigerator.

[0021] The detection methods that can be realized by the device for detecting the tightness of pressure-bearing parts in a lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com