A reliability testing system for a servo tool holder and a testing method using the system

A test system and servo tool post technology, applied in general control systems, control/adjustment systems, instruments, etc., can solve the problems of easy loss of precision, increase of research costs, and influence of research efficiency, so as to achieve true and reliable reliability values and improve Acquisition speed of faults and scientific effects of test methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

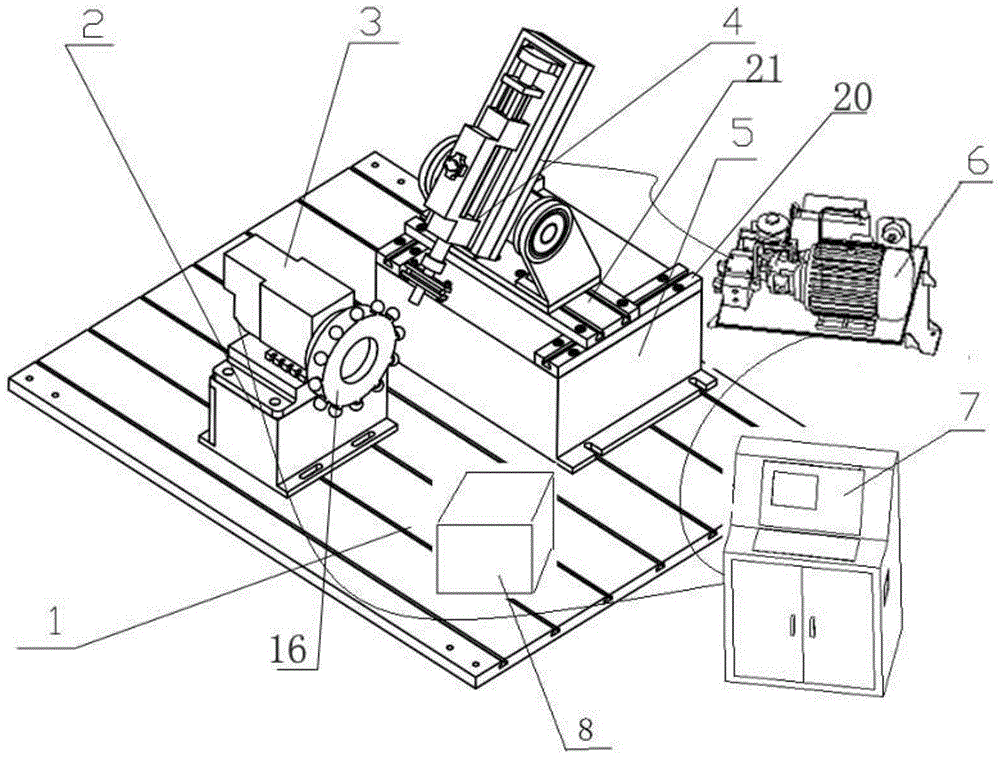

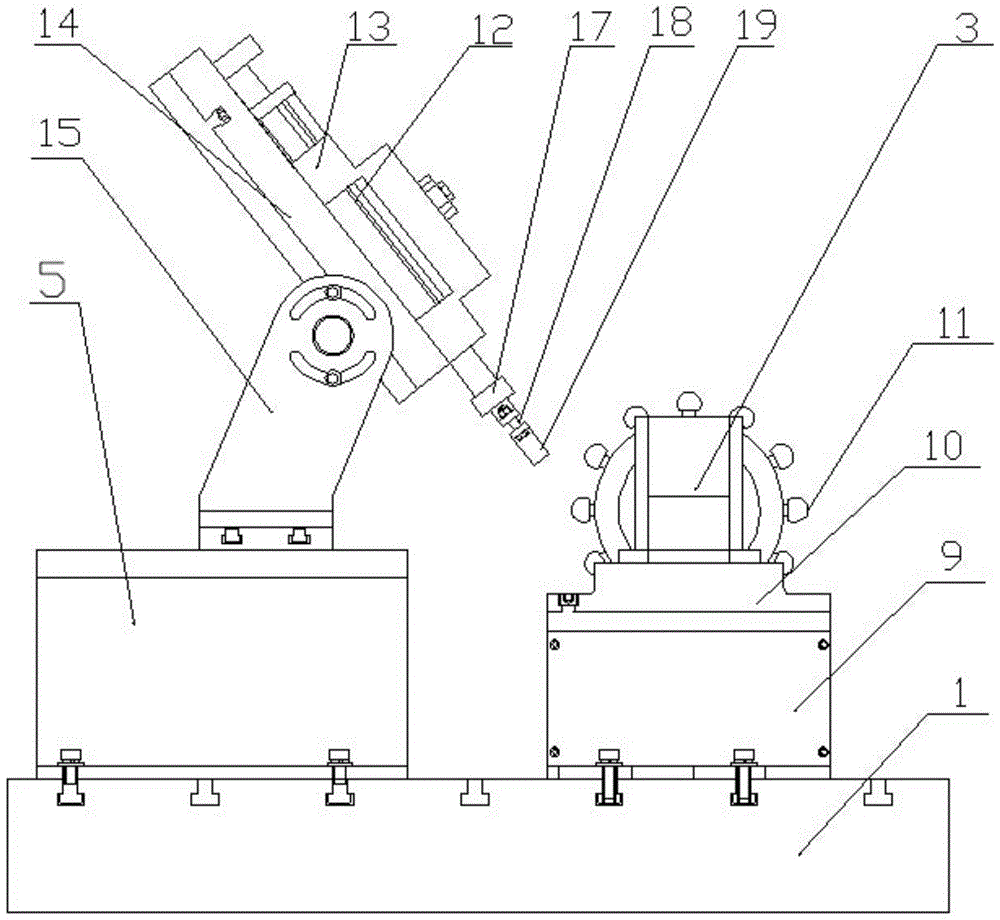

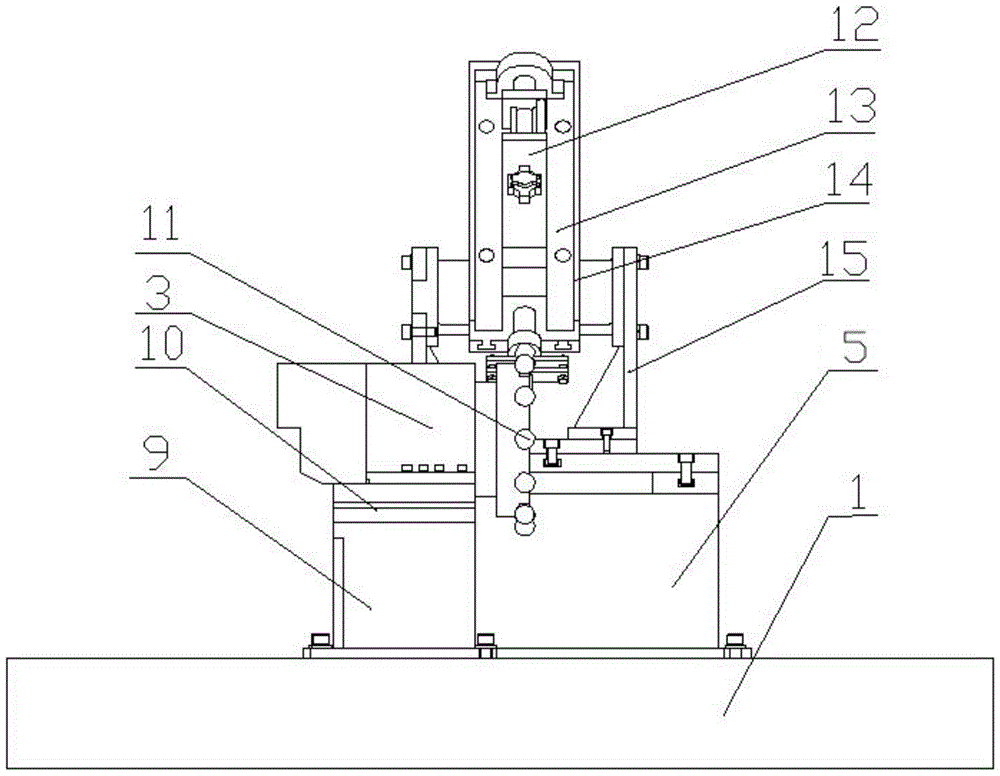

[0032] Embodiment 1 A reliability test system for servo tool post

[0033] Such as Figure 1-3 As shown, a servo tool rest reliability testing system includes a test bench body 1, a tested tool rest 3, an electro-hydraulic loading device 4, and a hydraulic drive system 6. Preferably, the test bench body 1 is a gray cast iron structure. Wherein the tool rest 3 under test is placed on the test bench body 1 through the tool rest support mechanism 2, and a backing plate 10 is provided between the tool rest 3 under test and the tool rest support mechanism 2, and the number or thickness of the backing plate 10 can be adjusted, Adjust the height of the tool rest 3 under test. The tool rest 3 has a cutter head 16 and a motor placed inside the tool rest 3 to drive the rotation of the cutter head 16. The simulated tool holder 11 is installed on the cutter head 16. 16 are evenly distributed with 12 connection positions for simulating the tool bar 11, the electro-hydraulic loading device...

Embodiment 2

[0037] Embodiment 2 A method of testing using a servo tool holder reliability testing system

[0038] The specific steps are:

[0039] 1) Adjust the position and height of the tool holder 3 under test, and place the simulated tool holder 11 on the cutter head 16;

[0040] 2) Carry out a 72-hour continuous dry run test on the tool holder 3 under test, stop the machine once every 24 hours, and test the indexing accuracy of the tool holder 3 under test;

[0041] 3) Control the motor of the tool holder 3 under test, so that the simulated tool bar 11 remains on the position to be tested;

[0042] 4) Adjust the position and angle of the electro-hydraulic loading device 4, so that the loading rod 19 acts on the simulated tool bar 11;

[0043] 5) Control the magnitude of the force applied by the electro-hydraulic loading device 4 to the simulated cutter bar 11 through the hydraulic drive system 6;

[0044]6) Carry out a 24h radial loading test on the tool holder 3 under test, each ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com