Test method for rapid evaluation of resistance to cracking of sheaths of flame retardant optical cables

A test method and technology for optical cables, applied in the direction of strength characteristics, weather resistance/light resistance/corrosion resistance, and the use of repetitive force/pulse force to test the strength of materials, etc. Scientific and easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Embodiment one: a kind of test method of rapid evaluation flame-retardant optical cable sheath anti-cracking performance, comprises the following steps:

[0032]1) Pretreatment: Take a 25-meter-long flame-retardant optical cable to be tested and bend it into a loop, which is 25 times the outer diameter (mm) of the flame-retardant optical cable; put the looped flame-retardant optical cable into a 79°C environmental simulation box In the middle, keep the temperature for 24 hours, observe it every 8 hours, and check whether the appearance is cracked;

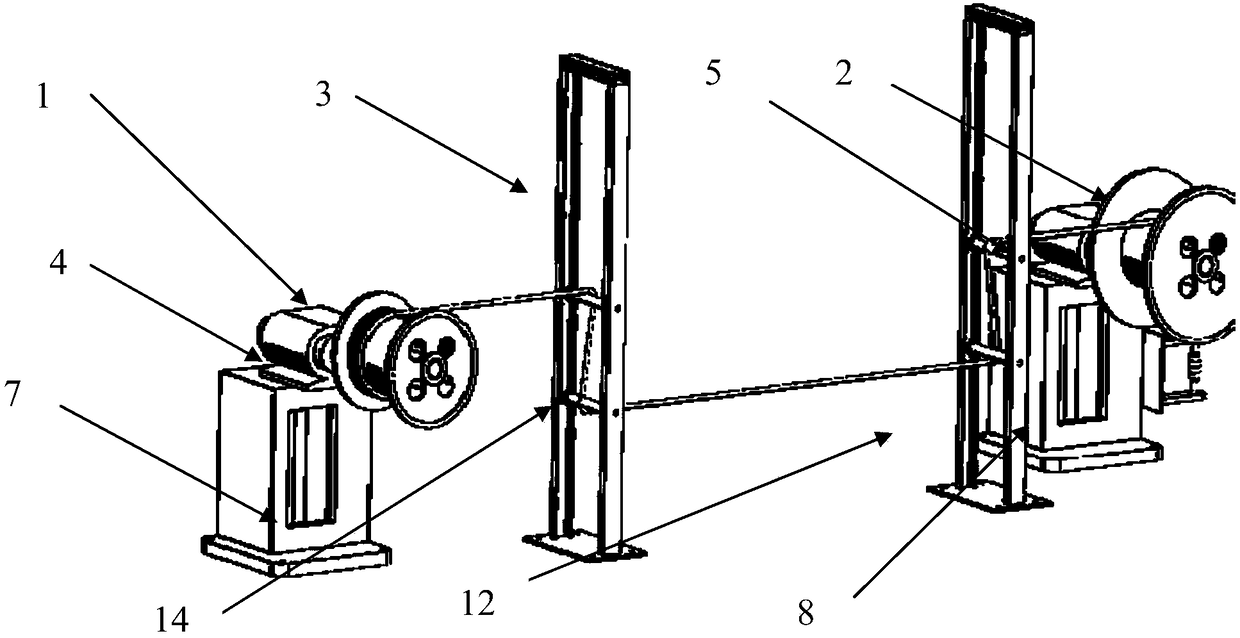

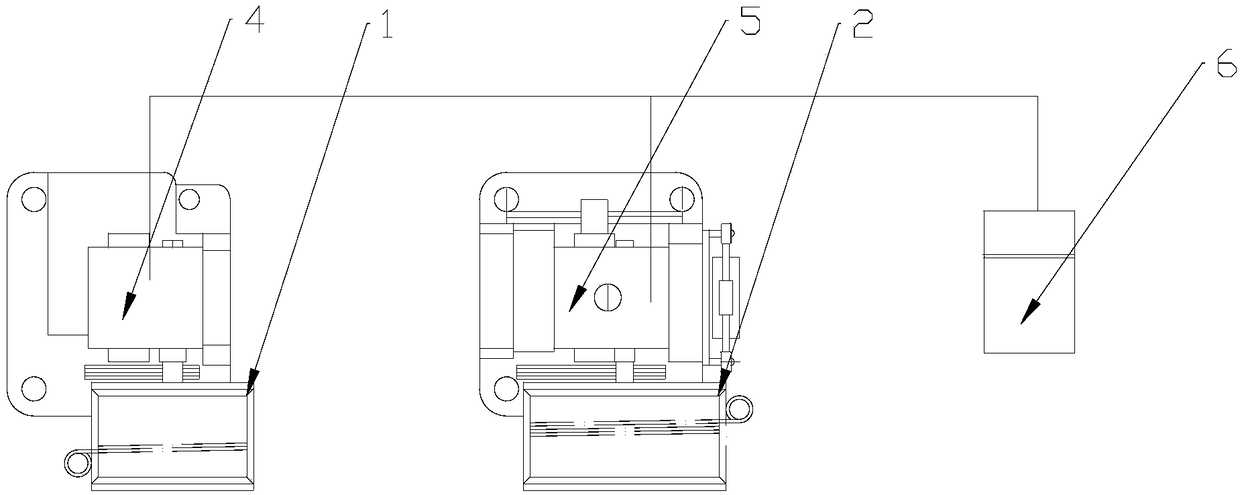

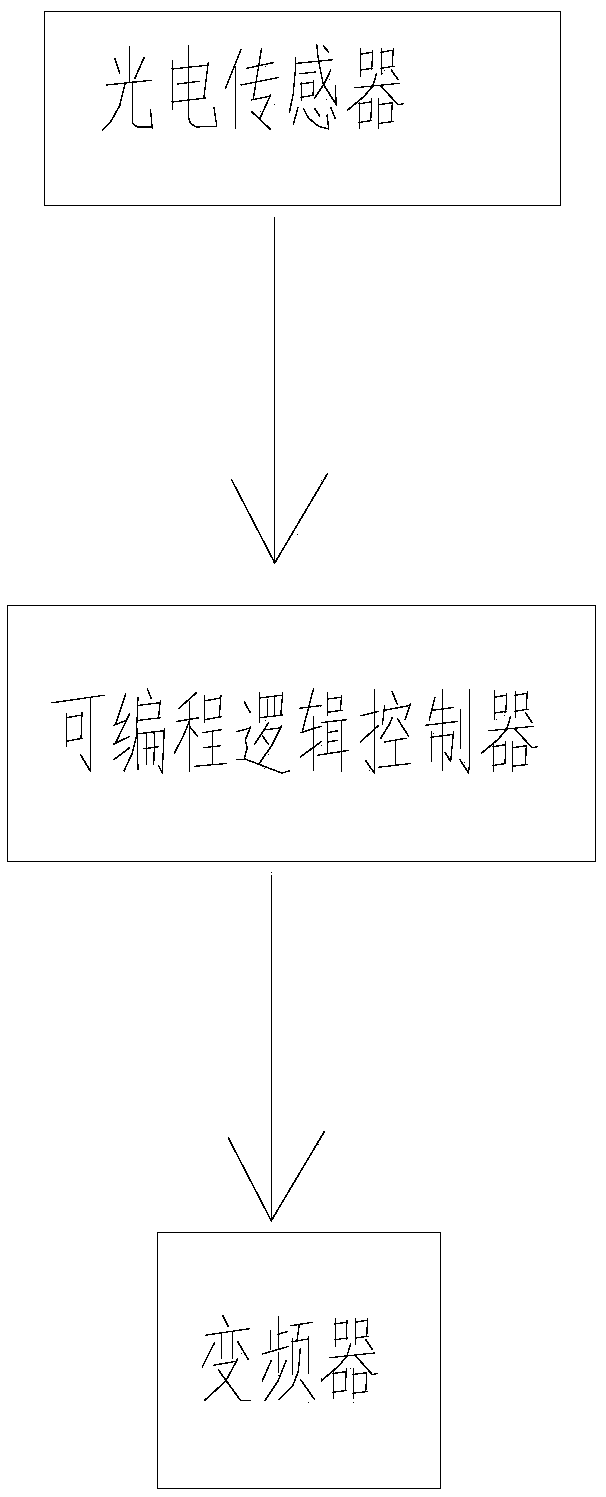

[0033] 2) Simulated construction test: Cool the pretreated flame retardant optical cable for at least 3 hours; install the pretreated flame retardant optical cable on the simulated construction test device, and the construction test device is used to drive the flame retardant optical cable at 5 times / per Rotate at a rotation rate of 1 minute; wind the flame-retardant optical cable in one direction and according to the set te...

Embodiment 2

[0036] Embodiment two: a kind of test method of rapid evaluation flame-retardant optical cable sheath anti-cracking performance, comprises the following steps:

[0037] 1) Pretreatment: Take a 30-meter-long flame-retardant optical cable to be tested and bend it into a loop, and the loop is not greater than 25 times the outer diameter (mm) of the flame-retardant optical cable; put the looped flame-retardant optical cable at 80±1°C In the environmental simulation box, keep the temperature constant for 24 hours, observe it every 8 hours, and check whether the appearance is cracked;

[0038] 2) Simulated construction test: cool the pretreated flame retardant optical cable for at least 3 hours; install the pretreated flame retardant optical cable on the simulated construction test device, and the construction test device is used to drive the flame retardant optical cable at 10 times / per Rotate at a rotation rate of 1 minute; wind the flame-retardant optical cable in one direction a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com