Test device and method for characterizing coagulation characteristics of foam fluid by lost flow time

A foam fluid and testing device technology, applied in flow characteristics, measuring devices, instruments, etc., can solve the problems of very little research on the determination of coagulation time, no determination of coagulation time, and errors in the measurement data, etc., to achieve the test method Convenience, simple structure and high accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

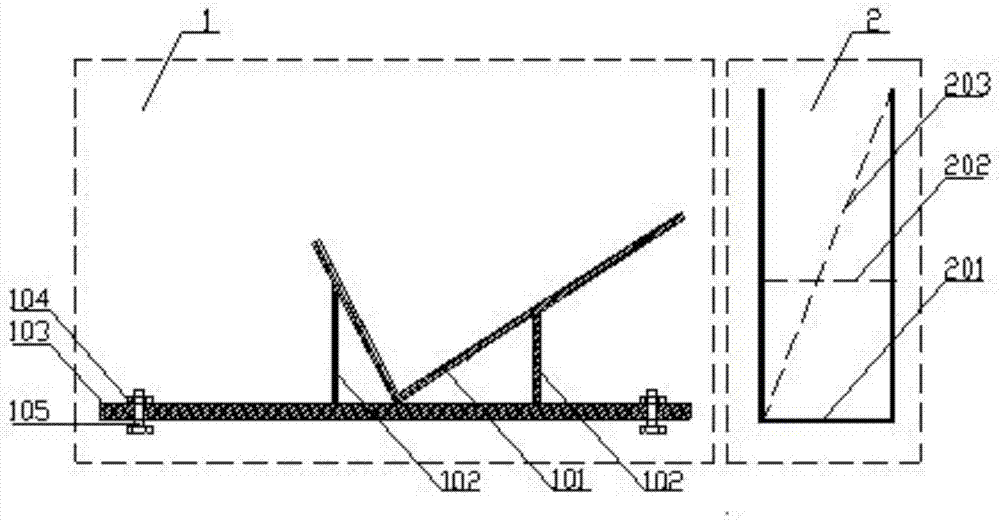

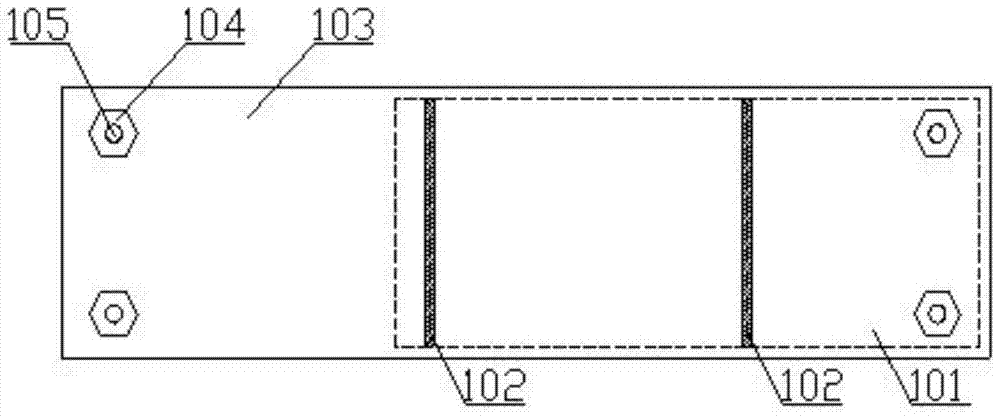

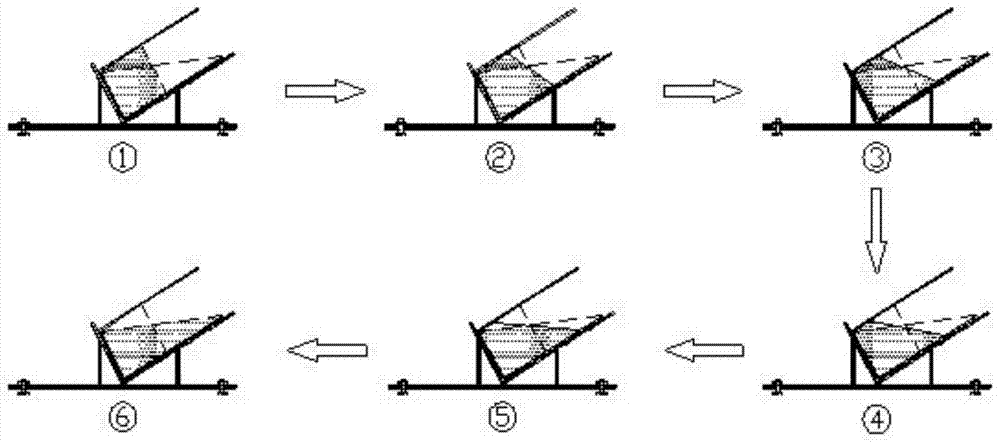

[0019] see figure 1 , figure 2 , the device of this embodiment includes a test rack 1 and a measuring container 2 . The test frame 1 includes a base plate 103, on which two support plates 102 are vertically fixed, and the two support plates 101 are fixed on the base plate 103 through the two support plates 102 at an angle of 90 degrees to each other, and the left and right support plates 101 forms an included angle of 60 degrees and 30 degrees with the bottom plate, so that the foam fluid to be measured in the measuring container 2 containing the foam fluid to be measured can flow to the horizontal line 203 in this embodiment. A leveling screw 105 and a leveling nut 104 are respectively arranged on the four corners of the bottom plate 103, and four pairs of leveling nuts 104 and leveling screws 105 cooperate with each other to make the whol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com