Method for measuring shaping effect of tobacco stem after stem pressing

A measuring method and technology for tobacco stems, which are applied in measurement devices, preparation of test samples, material analysis by optical means, etc., can solve the problem of weak "rebound" ability of tobacco stems, unfavorable blending of shredded leaves, and large test errors. and other problems, to achieve the effect of simple, practical and accurate measurement methods, improving the use value and scope of use, and avoiding large randomness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Example 1: Determination of the shaping effect of a certain brand of incoming tobacco stem A after pressing the stem. In the tobacco stem thread making section, the moisture content of the tobacco stem A before stalk pressing is 33.5%, the gap between the pressing rollers of the stalk pressing machine is 0.8 mm, and the process flow rate is 3000 kg / h. Proceed as follows:

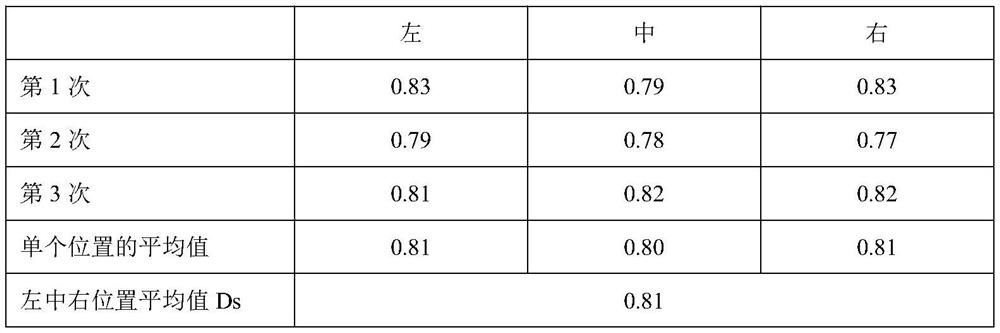

[0028] 1. Under normal production conditions, the left, middle and right positions of the tank are vibrated in front of the stem press machine, and nine tin bars with a diameter of 2.3 mm and a length of 25 mm are respectively put into the tobacco stems, and three tin bars are put into each position. Tin bar; pick out the tin bar after pressing the stem, measure the thickness of the tin bar with a micrometer, calculate the average value Ds of the thickness of nine tin bars, and keep two valid data, as shown in Table 1:

[0029] Table 1 Test results of tin bar thickness at different positions (unit: m...

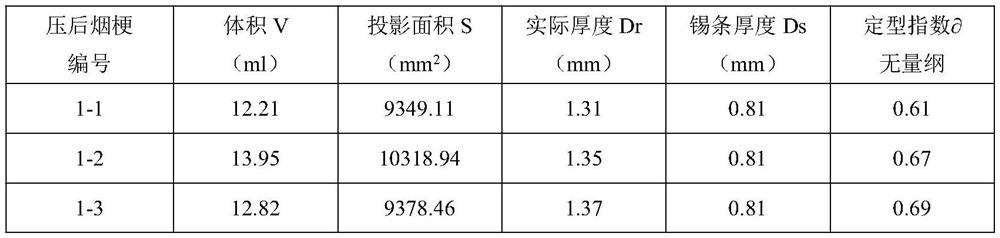

Embodiment 2

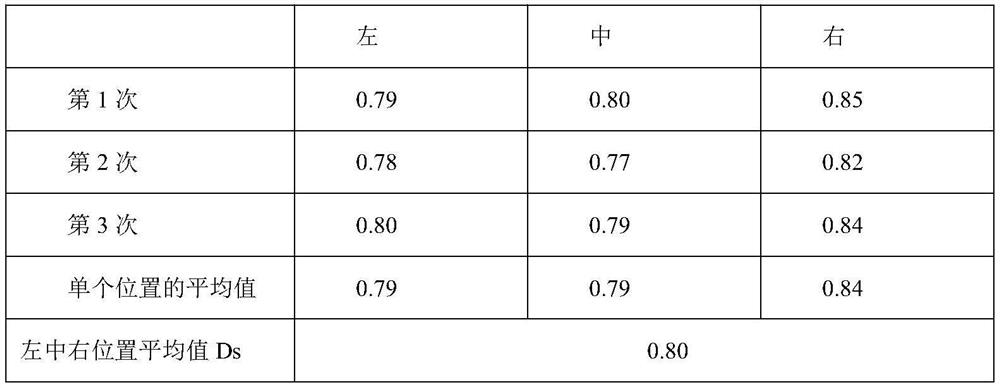

[0038] Example 2: Determination of the shaping effect of a certain brand of incoming tobacco stem B after being pressed. In the tobacco stem thread making section, the moisture content of the tobacco stem B before stalk pressing is 31.5%, the gap between the pressing rollers of the stalk press machine is 0.8 mm, and the process flow rate is 3000 kg / h. Step is with embodiment 1. The results are shown in Table 3 and Table 4.

[0039] Table 3 Test results of tin strip thickness at different positions (unit: mm)

[0040]

[0041] Table 4 The detection results of related indicators of tobacco stem stereotyping index

[0042]

[0043] stem shape index Belongs to small indicators, this indicator The closer it is to 0, the closer the tobacco stem is to the tin bar after pressing, that is, the better the setting effect of the tobacco stem.

[0044] The results of the above two examples show that although the varieties of tobacco stems are different, the shaping effects of ...

Embodiment 3

[0047] The same section of the cut stem production line as in Example 2, and the same incoming tobacco stem B, increased the moisture content of the tobacco stem, that is, the moisture content of the tobacco stem B before pressing was 33.5%, and the gap between the rollers of the pressing machine was also 0.8mm , The process flow rate is also 3000kg / h. Using the same detection method as in Example 2, the results are shown in Table 5.

[0048] Table 5 The detection results of related indicators of tobacco stem stereotyping index

[0049]

[0050] Comparing Example 2 and Example 3, it can be seen that by increasing the moisture content of tobacco stem B, the stereotyped effect of tobacco stem is obviously improved, that is, the stereotyped index Significantly reduced to close to 0. This shows that the moisture content of the tobacco stem is an important index affecting the setting effect of the tobacco stem, and there is a significant correlation between the two. By incre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com